Spontaneous heating floor

A technology of self-heating and self-heating components, applied in the field of architectural decoration, can solve problems such as difficult processing, easy to damage the insulating skin of the wire, and complicated manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] (Example 1, self-heating floor)

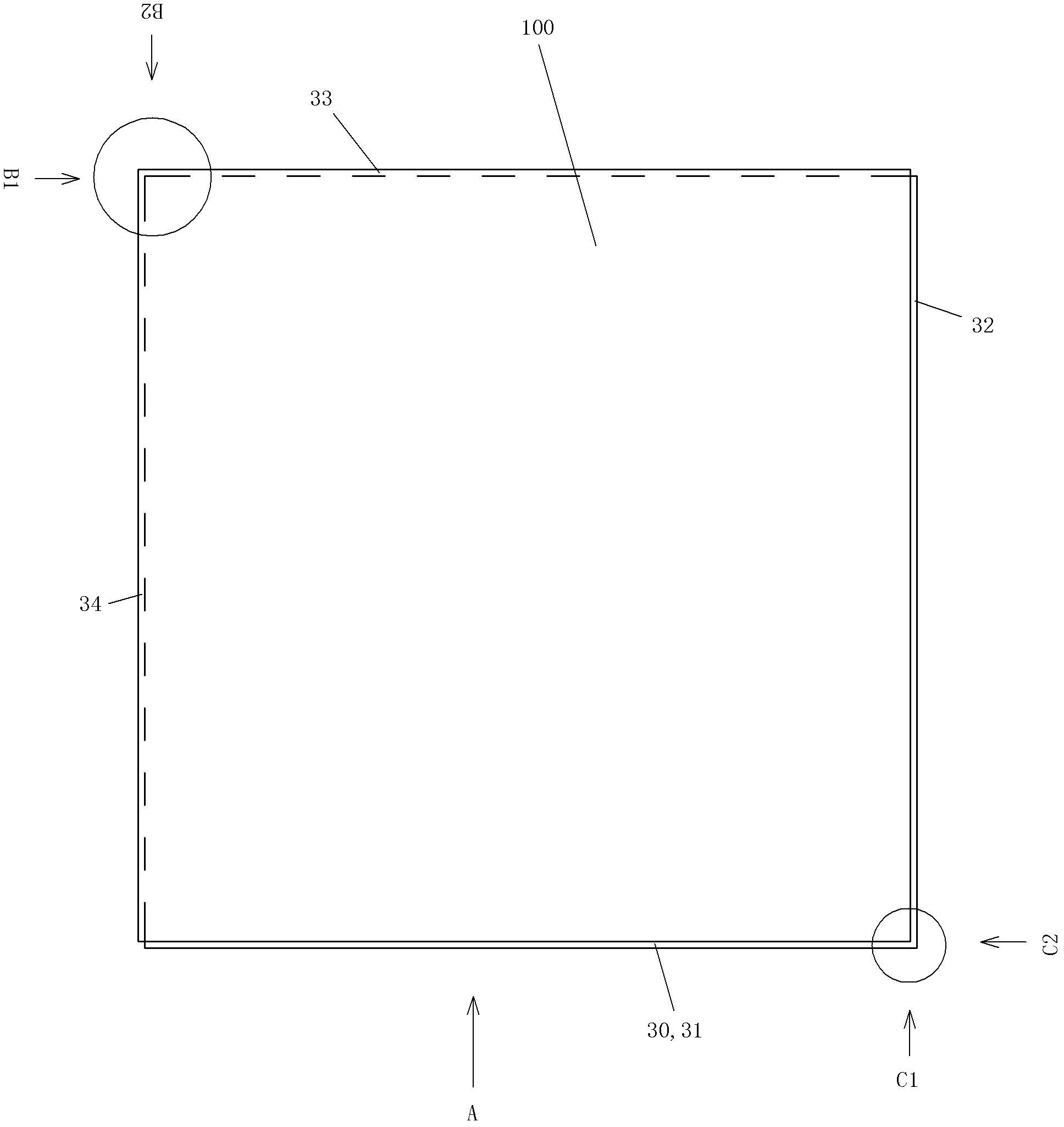

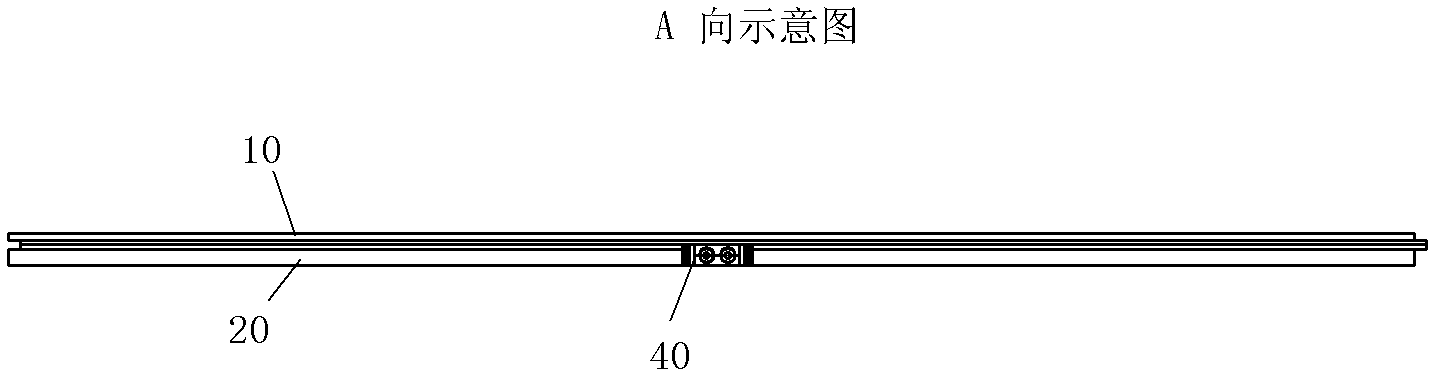

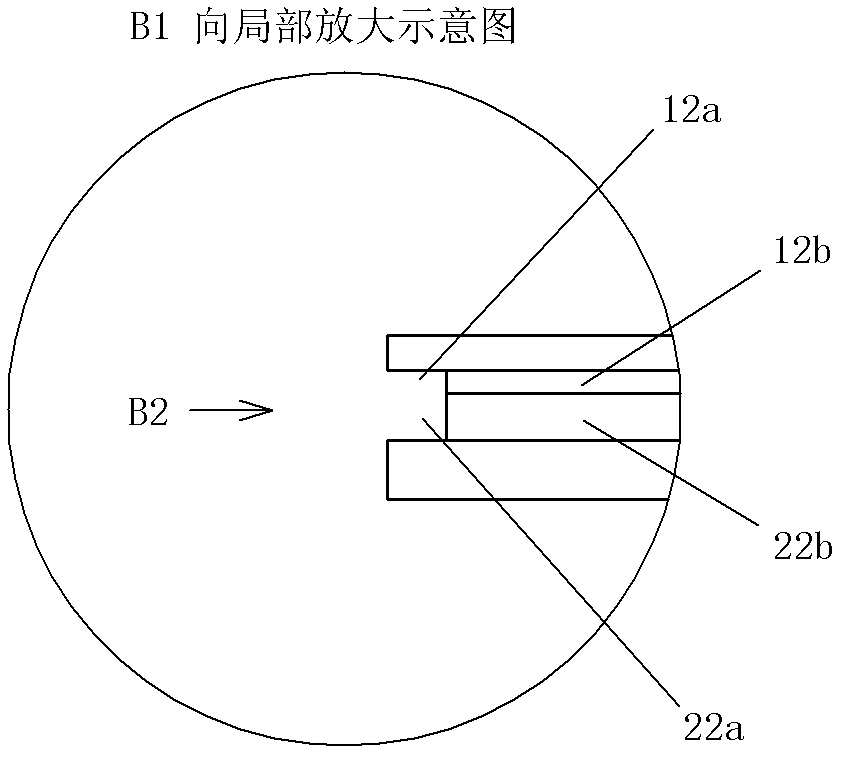

[0128] See figure 1 and figure 2 , the self-heating floor 100 of the present invention includes a panel 10 , a bottom plate 20 and a self-heating component 40 . The panel 10 is glued and fixed on the bottom plate 20 from above to form a floor body with an internal cavity. The peripheral ends of the floor main body are plug-in parts 30 . The front side end of the floor main body is the front side insertion tenon 31 of the insertion part 30, the right side end of the floor main body is the right side insertion tenon 32 of the insertion part 30, and the rear side end of the floor main body is the insertion joint. The rear insertion slot 33 of the part 30 and the left end of the floor main body is the left insertion slot 34 of the insertion part 30 . The front side joint tenon 31 is the position where the rear side joint grooves of the self-heating floor adjacent to the front side are connected and matched with each other during use, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com