Production process of warp-knitting automobile interior trim composite material for film bonding

A technology for automobile interior and composite materials, applied in the field of automobile interior parts materials, can solve the problems of excess around the profile structure, the separation of the fabric and the base material, affecting the appearance, etc., to achieve full adhesion fastness and full style. , the effect of strong layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: GM LaCrosse crown composite material production process.

[0028] (1) Choose PET low-elastic yarn 85dtex / 36f and PET filament 44dtex / 24f with crimp shrinkage rate of 20%, crimp shrinkage coefficient of variation ≤7%, and crimp stability ≥78% as raw materials.

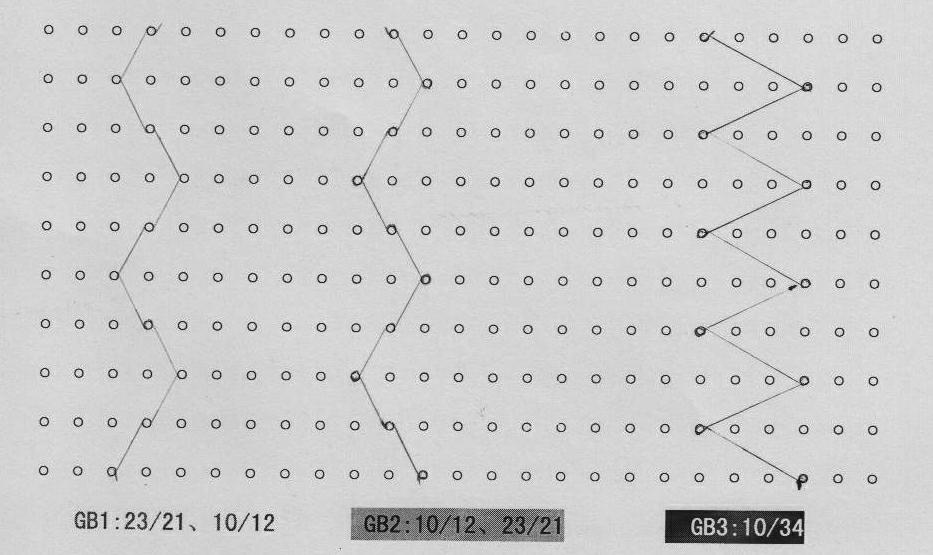

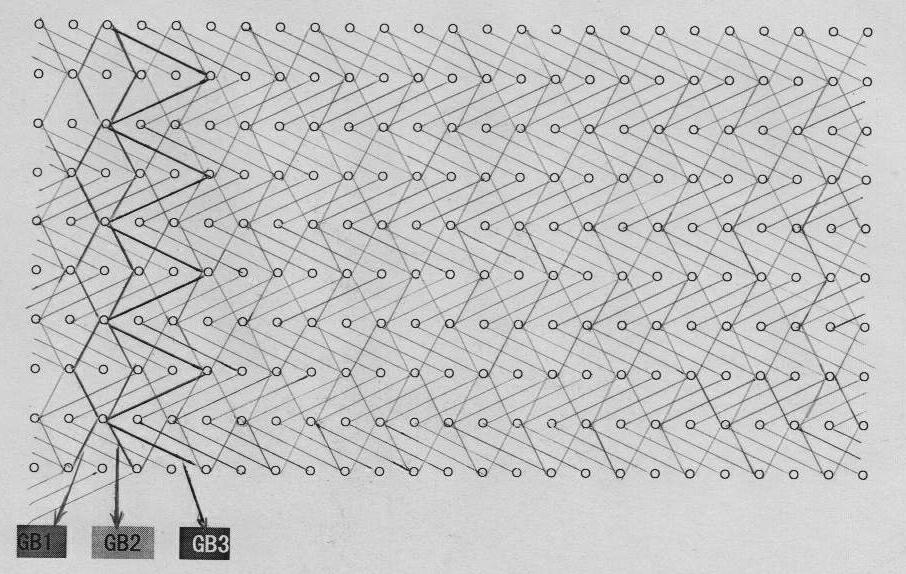

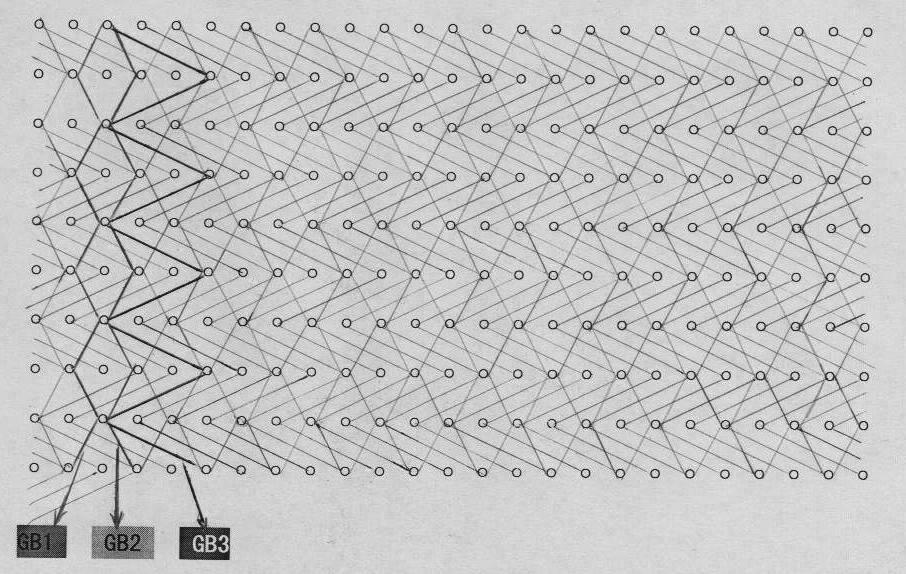

[0029] ⑵Adopt the high-speed warping machine to arrange the raw material yarn into a pan head, the number of yarns GB1: 275 × 4 (1100), using PET filament 44dtex / 24f; GB2: 275 × 4 (1100), Use PET filament 44dtex / 24f; GB3: 550 pieces x 4 pieces (2200 pieces), use PET low-elasticity yarn 85dtex / 36f; the line speed is controlled at 430 m / min during finishing, and the tension of each yarn is controlled at 18g / piece , Strictly control the tension deviation between silk and silk to ensure uniform warping tension.

[0030] ⑶ Install the prepared pan heads on the warp beam, each warp beam covers 4 pan heads, and then install it on the Tricot warp knitting machine for three-comb composite weaving. By adjusti...

Embodiment 2

[0036] Example 2: The invention discloses a production process of a general top decoration composite material.

[0037] (1) Choose PET low elastic yarn 85dtex / 36f and PET filament 44dtex / 24f with crimp shrinkage rate of 18%, crimp shrinkage coefficient of variation ≤7%, and crimp stability ≥78% as raw materials.

[0038] ⑵Adopt the high-speed warping machine to arrange the raw yarn into a pan head, the number of yarns GB1: 262 × 4 (1048), using PET filament 44dtex / 24f; GB2: 262 × 4 (1048), Use PET filament 44dtex / 24f; GB3: 525 pieces x 4 pieces (2100 pieces), use PET low-elasticity yarn 85dtex / 36f; the line speed is controlled at 410m / min during finishing, and the tension of each thread is controlled at 15g / piece. Strictly control the tension deviation between silk and silk to ensure uniform warping tension.

[0039] ⑶ Install the finished warp heads on the warp beam, each warp beam covers 4 pan heads, and then install it on the Tricot warp knitting machine for three-comb c...

Embodiment 3

[0045] Example 3: Another production process for general purpose crown composites.

[0046] (1) Choose PET low-elastic yarn 85dtex / 36f and PET filament 44dtex / 24f with crimp shrinkage rate of 21%, crimp shrinkage coefficient of variation ≤7%, and crimp stability ≥78% as raw materials.

[0047] ⑵Adopt the high-speed warping machine to arrange the raw material yarn into a pan head, the number of yarns GB1: 287 × 4 (1148), using PET filament 44dtex / 24f; GB2: 287 × 4 (1148), PET filament 44dtex / 24f is used; GB3: 575 pieces × 4 pieces (2300 pieces), PET filament 85dtex / 36f is used; the line speed is controlled at 450m / min during finishing, and the tension of each filament is controlled at 20g / piece, strictly Control the tension deviation between yarns to ensure uniform warping tension.

[0048] ⑶ Install the finished warp heads on the warp beam, each warp beam covers 4 pan heads, and then install it on the Tricot warp knitting machine for three-comb composite weaving, adjust the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com