Composite cloth for curtain roller shutter and preparation method of composite cloth

A technology for roller blinds and fabrics, applied in the field of composite fabrics for roller blinds and their preparation, can solve the problems of high fabric weight and high raw material cost, and achieve strong bonding fastness, excellent light resistance, aging resistance and mildew resistance. , the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

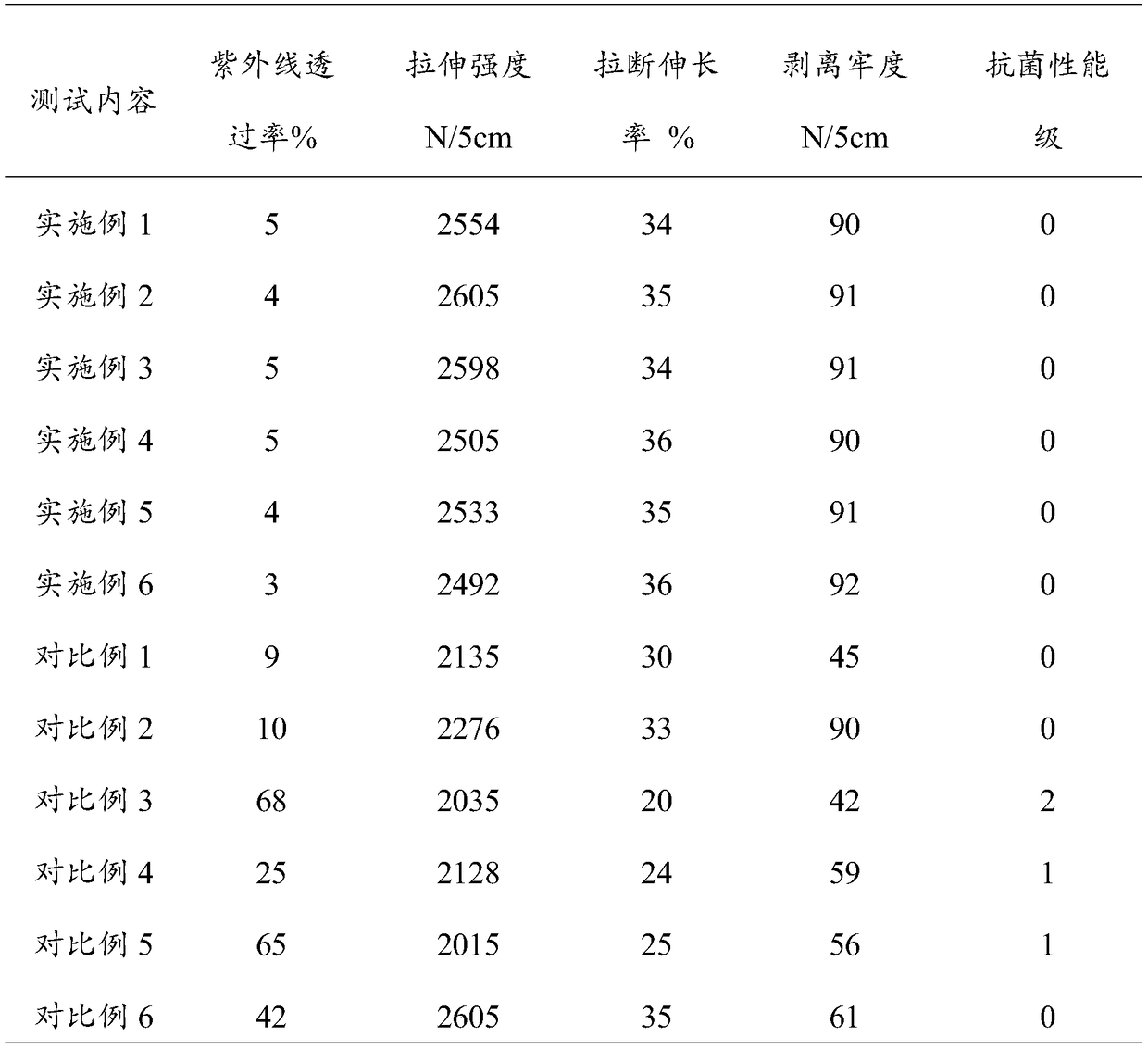

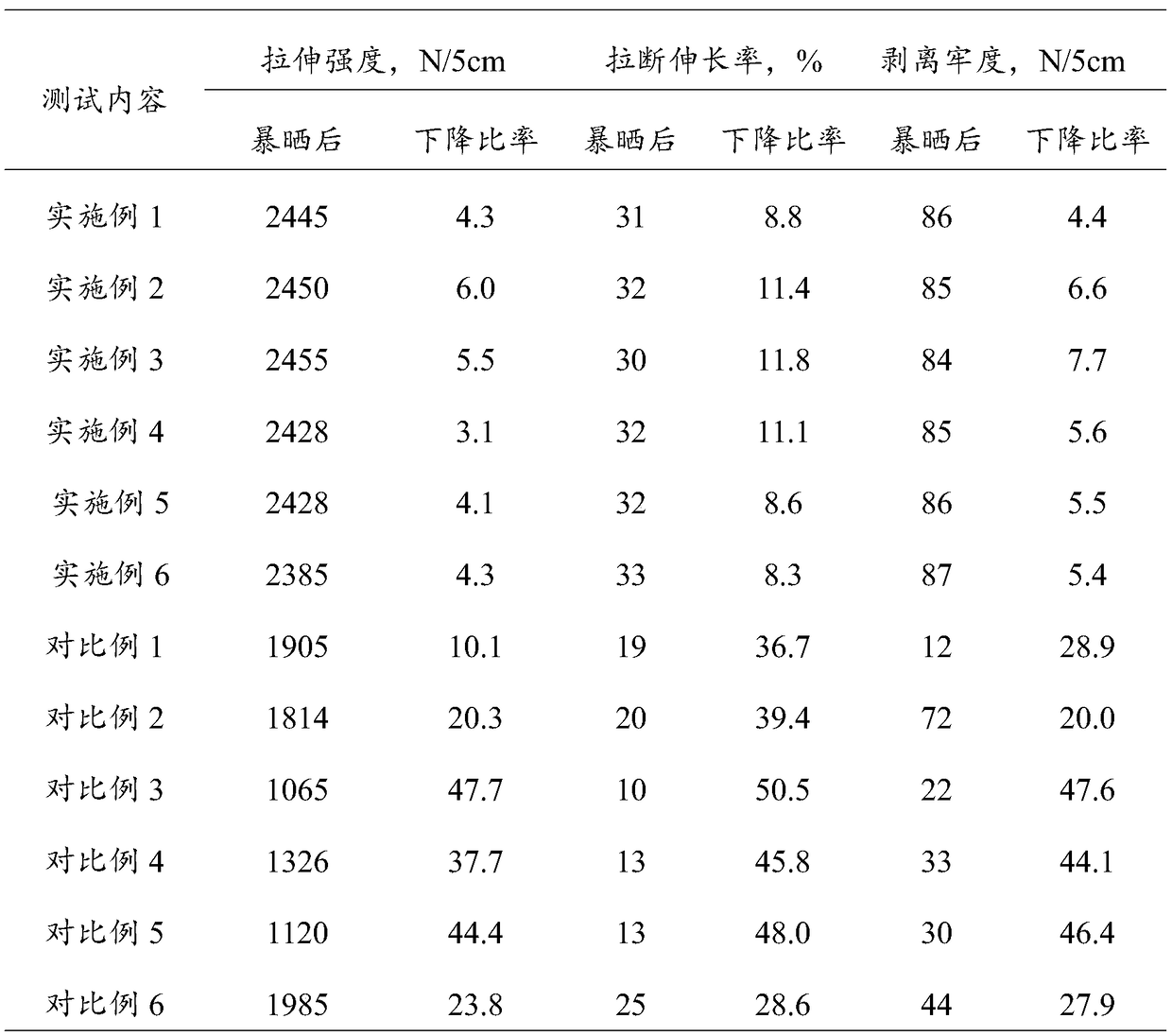

Examples

Embodiment 1

[0028] A composite fabric for curtain roller blinds comprises a plasma-treated base cloth and a modified polyurethane TPU film pasted on the base cloth.

[0029] Among them, the polyurethane TPU film is prepared by the following method: use a high-speed mixer to mix 75 parts by mass of non-porous polyurethane TPU, 5 parts of low-density polyethylene LDPE, and 5 parts of carbon black (particle size is 20-30nm, fluidity 26-28mm), 5 parts of titanium dioxide (particle size 10-50nm), 5 parts of nano-glass beads, 5 parts of phenyl salicylate, mixed evenly, the speed of high-speed stirring is 1500r / min, and the time is 6min Then use the casting machine to squeeze and cast to form a film. The temperatures in each zone of the casting machine are: cylinder temperature 180°C, filter screen temperature 190°C, elbow temperature 190°C, connection temperature 190°C, die head temperature 190°C.

[0030] The preparation method of the above-mentioned composite cloth for roller blinds comprises...

Embodiment 2

[0035] A composite fabric for curtain roller blinds comprises a plasma-treated base cloth and a modified polyurethane TPU film pasted on the base cloth.

[0036] Wherein, the modified polyurethane TPU film is prepared by the following method: use a high-speed mixer to mix 70 parts by mass of non-porous polyurethane TPU, 6 parts of low-density polyethylene LDPE, and 6 parts of carbon black (with a particle size of 20 to 30 nm, Fluidity is 26-28mm), 6 parts of titanium dioxide (particle size is 10-50nm), 6 parts of nano-glass beads, 6 parts of phenyl salicylate are mixed evenly, the speed of high-speed stirring is 1000r / min, time 10 minutes; then use the casting machine to extrude and cast to form a film. The temperature of each area of the casting machine is: cylinder temperature 200 ° C, filter temperature 205 ° C, elbow temperature 205 ° C, connection temperature 205 ° C, die temperature 200 ° C .

[0037] The preparation method of the above-mentioned composite cloth for r...

Embodiment 3

[0042] A composite fabric for curtain roller blinds comprises a plasma-treated base cloth and a modified polyurethane TPU film pasted on the base cloth.

[0043]Wherein, the modified polyurethane TPU film is prepared by the following method: use a high-speed mixer to mix 80 parts by mass of non-porous polyurethane TPU, 4 parts of low-density polyethylene LDPE, and 4 parts of carbon black (with a particle size of 20 to 30 nm, Fluidity is 26-28mm), 4 parts of titanium dioxide (particle size is 10-50nm), 4 parts of nano-glass beads, 4 parts of phenyl salicylate are mixed evenly, the speed of high-speed stirring is 1500r / min, time 8 minutes; then use the casting machine to squeeze and cast the film, the temperature of each area of the casting machine is: barrel temperature 180 °C, filter temperature 190 °C, elbow temperature 190 °C, connection temperature 190 °C, die temperature 190 °C .

[0044] The preparation method of the above-mentioned composite cloth for roller blinds co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com