Reactive dye cold pad-batch printing method

A technology of reactive dyes and printing methods, applied in the field of textile printing and dyeing, can solve problems such as pattern infiltration when padding alkali solution, and achieve the effects of reducing white ground staining, saving the use cost of auxiliaries, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

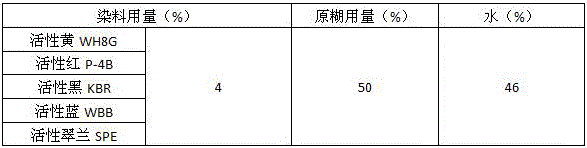

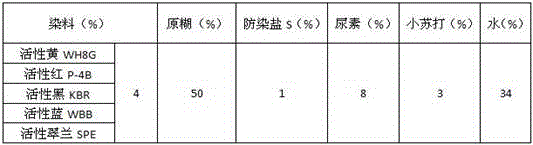

Embodiment 1

[0053] A reactive dye cold pad-batch printing method, the application process includes: (1) use pure sodium alginate and reactive dyes to prepare color paste for printing and drying; (2) directly pad the dried fabric with a color-fixing alkali agent and Carry out coiling, with a rolling surplus rate of 45%. During the coiling process, a plastic film is used for isolation. After coiling, it is stacked at 35°C for 4 hours; (3) After stacking, it is washed in cold water for 2 times at a temperature of 30-40°C. Then carry out hot water washing→soap washing→hot water washing, the temperature is 85-95 ℃, and dry the cloth. Its color-fixing alkali agent components and weight percentages are as follows: alkali supply agent is sodium hydroxide 5%, sodium carbonate 10%, buffering agent is sodium citrate 15%, chelating agent is sodium ethylenediamine tetramethylene phosphate 5% %, the dispersing detergent is fatty alcohol sulfate 5%, alkali-resistant penetrating agent fatty alcohol polyo...

Embodiment 2

[0055] A reactive dye cold pad-batch printing method, the application process includes: (1) use pure sodium alginate and reactive dyes to prepare color paste for printing and drying; (2) directly pad the dried fabric with a color-fixing alkali agent and Carry out coiling, with a rolling surplus rate of 51%. During the coiling process, plastic film is used for isolation. After coiling, it is stacked at 35°C for 3 hours; (3) After stacking, it is washed in cold water for 2 times at a temperature of 30-40°C. Then carry out hot water washing→soap washing→hot water washing, the temperature is 85-95 ℃, and dry the cloth. The components and weight percentages of the color-fixing alkali agent are as follows: the alkali supply agent is 10% sodium hydroxide, 7% potassium carbonate, the buffering agent is 15% sodium silicate, and the chelating agent is diethylenetriaminepentamethylene phosphate 5%, the dispersing detergent is fatty alcohol sulfate 3%, alkali-resistant penetrating agent f...

Embodiment 3

[0057] A reactive dye cold pad-batch printing method, the application process includes: (1) use pure sodium alginate and reactive dyes to prepare color paste for printing and drying; (2) directly pad the dried fabric with a color-fixing alkali agent and Carry out coiling, with a rolling surplus rate of 59%. During the coiling process, plastic film is used for isolation. After coiling, it is stacked at 40°C for 2.5 hours; (3) After stacking, it is washed in cold water for 2 times at a temperature of 30-40°C , and then hot water washing→soap washing→hot water washing, the temperature is 85-95 ℃, and the cloth is dried. Its color-fixing alkali agent components and weight percentages are as follows: alkali supply agent is potassium hydroxide 6%, potassium carbonate 9%, buffering agent is sodium acetate 12%, chelating agent is amine trimethylene phosphate 5%, disperse washing The agent is 8% sodium naphthalenesulfonic acid formaldehyde condensate, 2% alkali-resistant penetrating ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com