Water-borne matte water-proof ink jet canvas and preparation method thereof

A production method and technology of oil canvas, applied in painting tools, decorative arts, coatings, etc., can solve the problems of hard ink-absorbing layer, slow drying speed, poor water resistance, etc., and achieve high color vividness and strong ink-absorbing ability , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0026] A method for making a water-based matt waterproof inkjet oil canvas, which is composed of a base material, a primer layer, an ink-absorbing layer and a color-fixing layer, and the method of making is as follows:

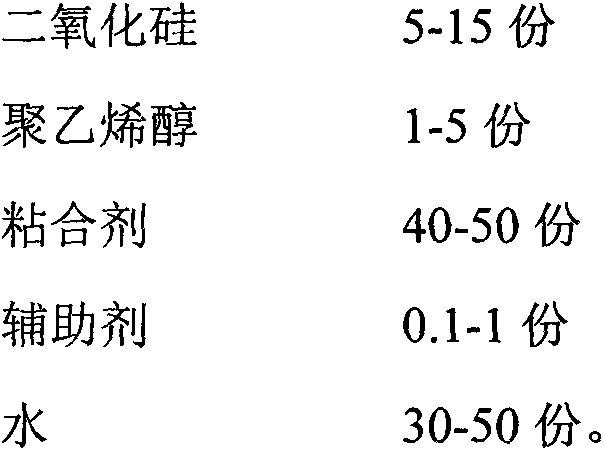

[0027] The pure cotton cloth base material is dried and shaped, then coated with a primer, dried, and repeatedly coated 3 times, and then dried. The composition of the primer is: 5 parts of silicon dioxide, 2 parts of domestic 1788 polyvinyl alcohol 50 parts of pure acrylic emulsion, 0.5 parts of defoamer, 42.5 parts of water;

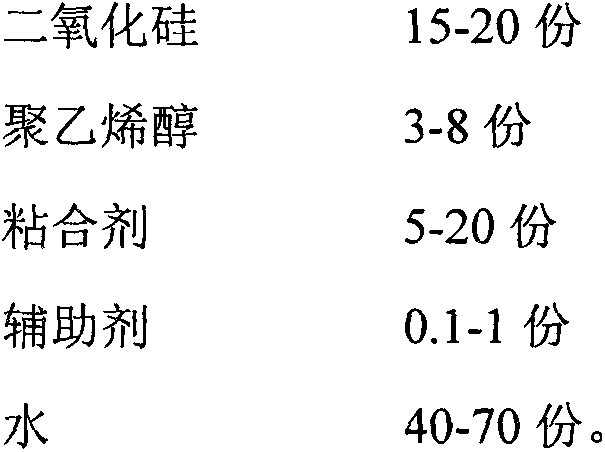

[0028] Then apply the ink-absorbing layer coating, dry and repeat the coating once, wherein the composition of the ink-absorbing layer coating is: 20 parts of silicon dioxide, 3 parts of domestic 1799 polyvinyl alcohol, 15 parts of vinegar-acrylic emulsion, leveling agent 0.1 parts, 0.4 parts of defoamer, 61.5 parts of water;

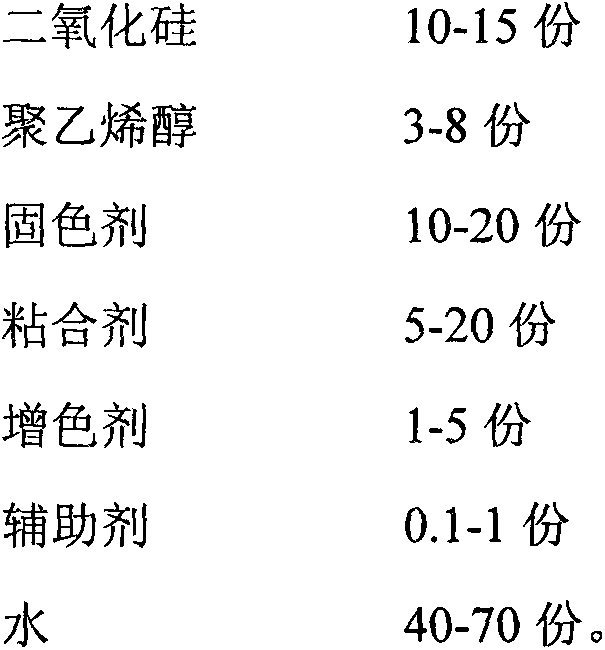

[0029] Finally, the color-fixing layer coating is applied and dried and rolled, wherein the color-fixing coa...

specific Embodiment 2

[0033] A method for making a water-based matt waterproof inkjet oil canvas, which is composed of a base material, a primer layer, an ink-absorbing layer and a color-fixing layer, and the method of making is as follows:

[0034] After the pure cotton cloth substrate is dried and shaped, it is coated with a primer, dried, and re-coated twice. The composition of the primer is: 10 parts of silicon dioxide, 5 parts of imported 117 polyvinyl alcohol, vinegar 30 parts of acrylic emulsion, 10 parts of styrene-acrylic emulsion, 1 part of defoamer, 44 parts of water;

[0035] Then apply the ink-absorbing layer paint, dry and repeat the coating once. The composition of the ink-absorbing layer paint is: 15 parts of silicon dioxide, 3 parts of imported 217 polyvinyl alcohol, 10 parts of vinegar-acrylic emulsion, pure acrylic emulsion 5 parts, 0.5 parts of leveling agent, 0.5 parts of defoamer, 66 parts of water;

[0036] Finally, the color-fixing coating is applied, dried and rolled, wher...

Embodiment 3

[0042] A kind of preparation method of water-based matte waterproof ink-jet oil canvas, is made of base material, primer layer and color-fixing layer, and preparation method is the same as embodiment 1, just has removed ink-absorbing layer, specifically as follows:

[0043] The pure cotton cloth base material is dried and shaped, then coated with a primer, dried, and repeatedly coated 3 times, and then dried. The composition of the primer is: 5 parts of silicon dioxide, 2 parts of domestic 1788 polyvinyl alcohol 50 parts of pure acrylic emulsion, 0.5 parts of defoamer, 42.5 parts of water;

[0044]Then coat the color-fixing layer coating and dry it for winding, wherein the color-fixing coating coating composition is: 10 parts of silicon dioxide, 5 parts of domestic 1799 polyvinyl alcohol, 15 parts of cationic polyamine polymer, 10 parts of vinegar-acrylic emulsion 5 parts of styrene-acrylic emulsion, 1 part of environmentally friendly whitening agent, 2 parts of PEG, 2 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com