Patents

Literature

486results about How to "Reduce drying energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

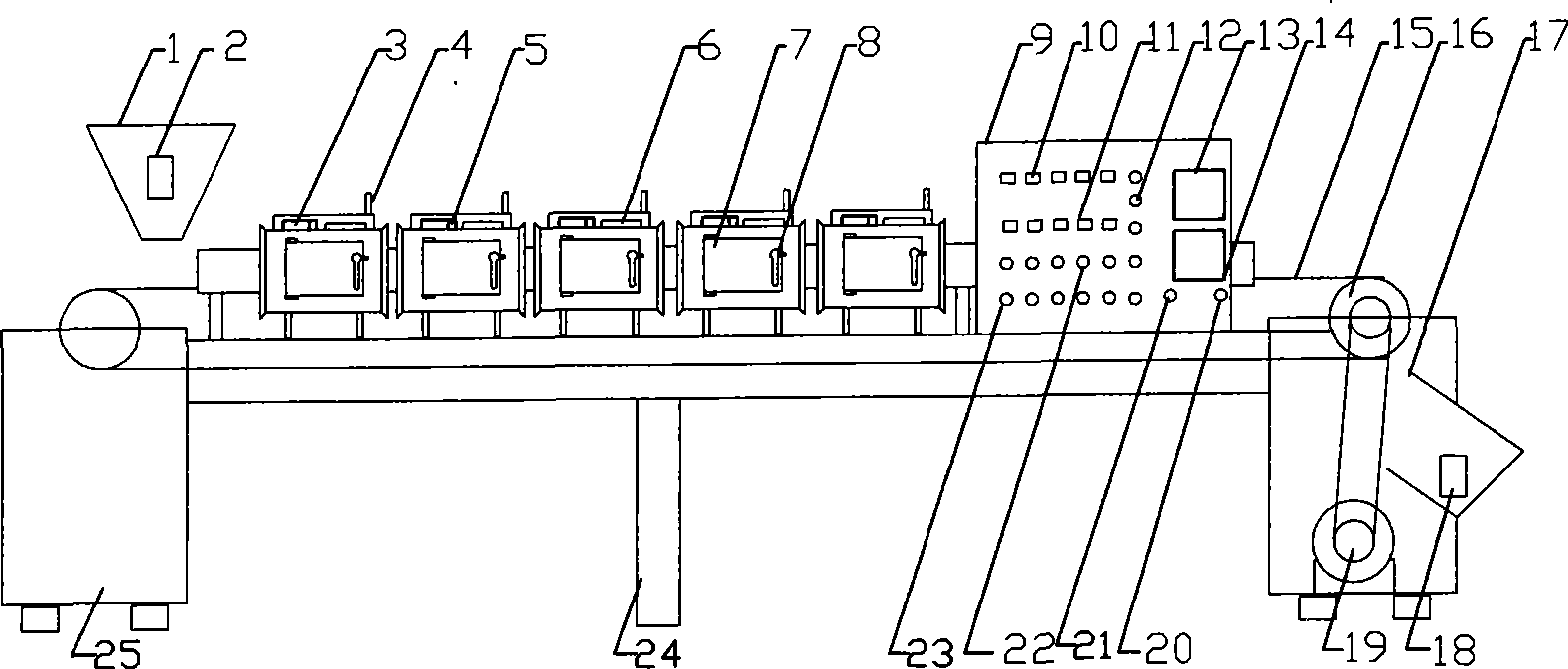

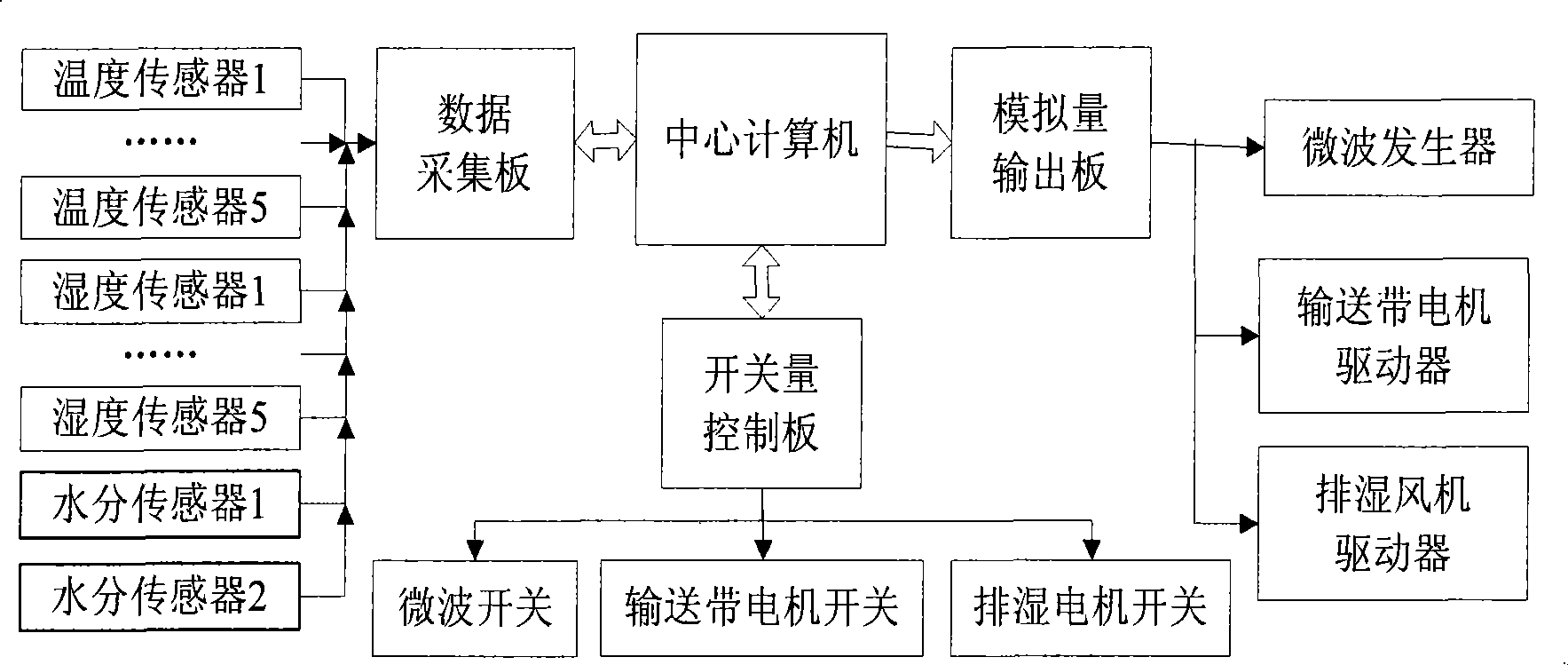

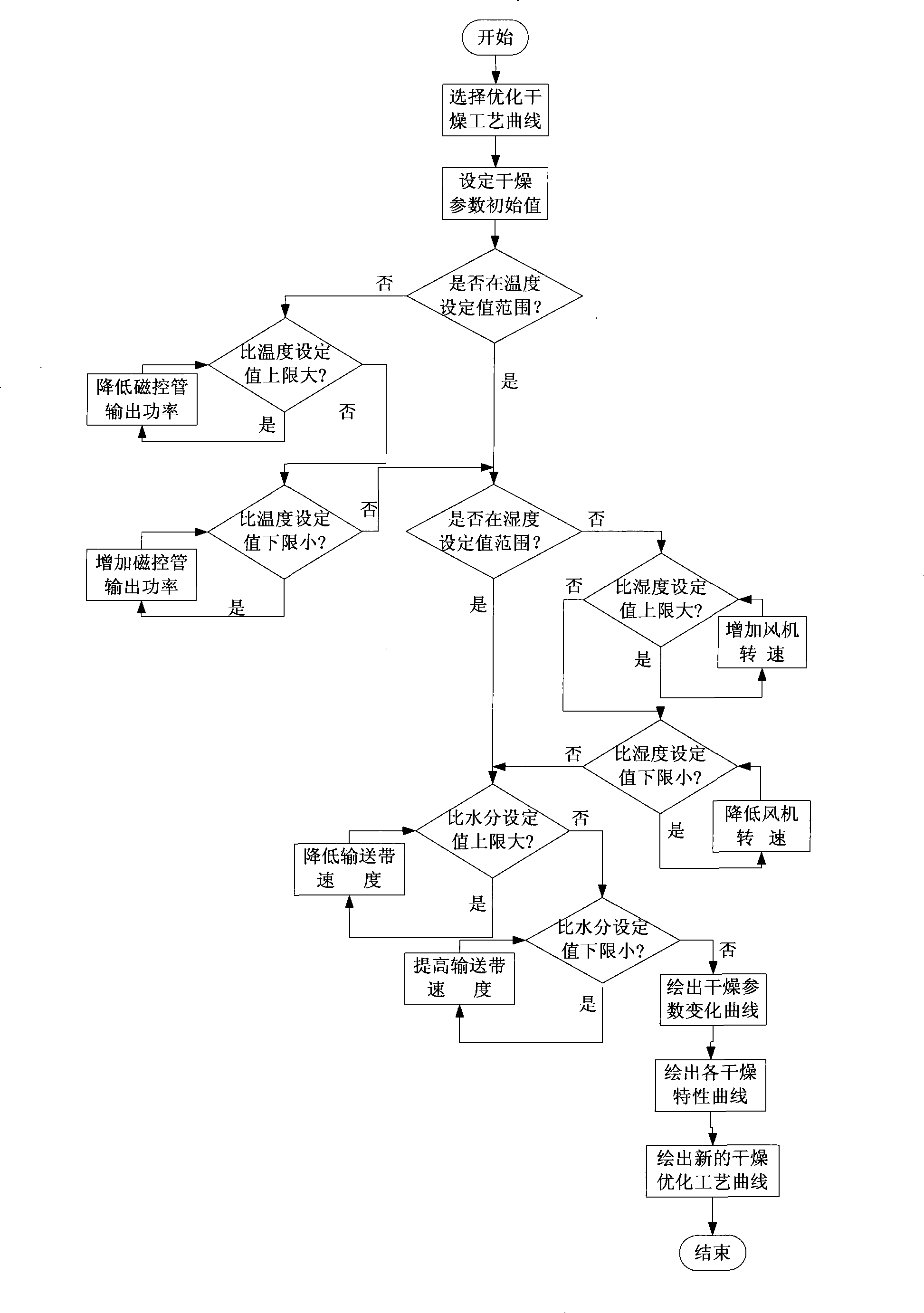

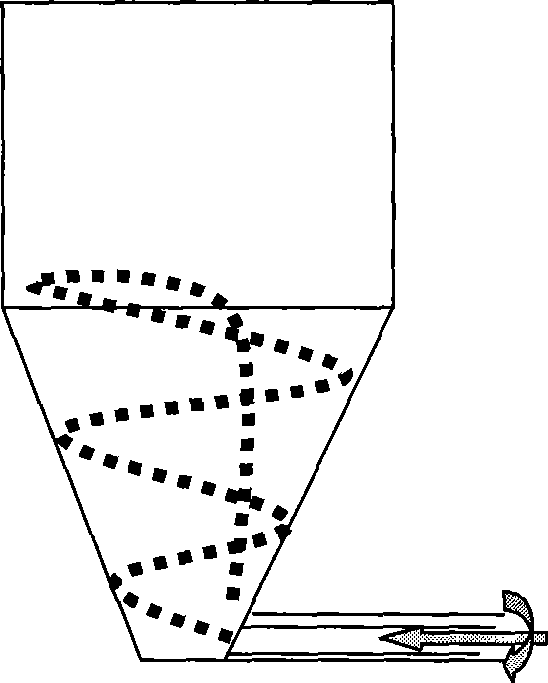

Intelligent microwave continuous drier and control method thereof

InactiveCN101382379AImprove drying qualityEasy to operateDrying solid materials with heatDrying machines with progressive movementsFrequency changerDrive motor

The invention discloses an intellectualized microwave continuous drier and a control method thereof; the drier comprises a rack, a conveying belt, a conveying belt wheel, a driving motor, an instrument control box and a computer; two ends of the conveying belt are respectively provided with a feed hopper and a discharge hopper and the conveying belt runs through a plurality of microwave drying cavities with doors; each microwave drying cavity is internally provided with a microwave magnetron, a temperature sensor, a humidity sensor and a speed-regulating fan; the feed hopper and the discharge hopper are respectively provided with a moisture sensor, and the conveying belt is driven by a speed-regulating motor controlled by a frequency converter. A control system can automatically draw variation curves of the temperature and the humidity of the materials in each drying cavity and the water content ratio of the discharged materials in the drying process of the materials in shorter time according to the collected data of the temperature, the humidity and the water content ratio of the materials in the drying process of the materials, can optimize control parameters continuously according to the change of the temperature, the humidity and the water content ratio in the drying process of the materials, and can regulate the system parameters automatically and realize the dynamic optimization of the drying technique parameters.

Owner:ANHUI AGRICULTURAL UNIVERSITY

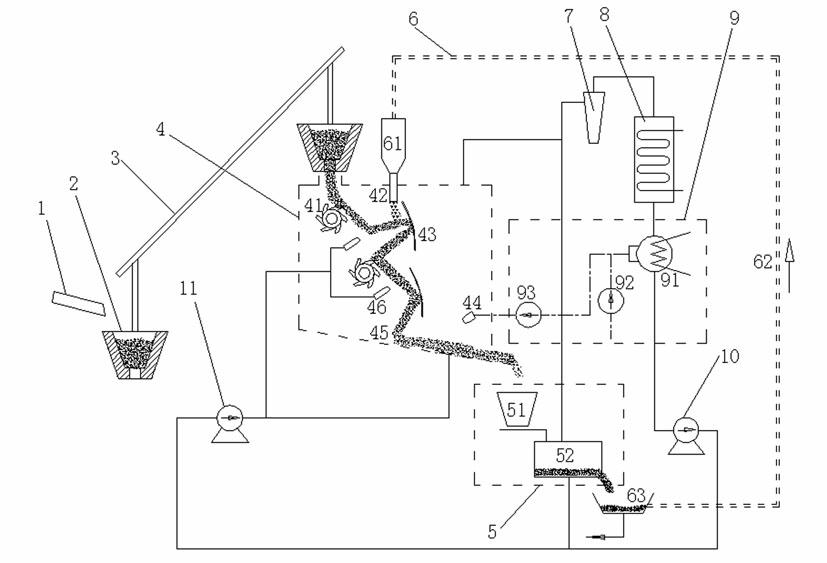

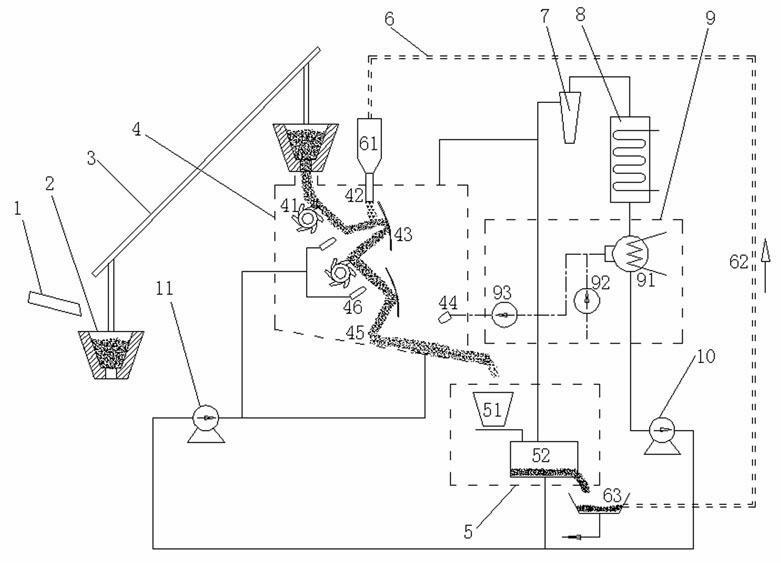

Method and system for recovering high-temperature sensible heat of molten blast furnace slag

ActiveCN102162016ADoes not affect activityImprove waste heat qualityIncreasing energy efficiencyDischarge devicesSlagSlow cooling

The invention discloses a method and a system for recovering high-temperature sensible heat of molten blast furnace slag. The system comprises a blast furnace slag runner, a slag hopper, a slag hopper lifting mechanism, a quenching unit, a slow cooling unit, a cold slag particle circulation unit, a cyclone dust collector, a waste heat boiler, a condensing unit, a circulating fan, and a booster fan. The method for recovering waste heat comprises the following steps of: crushing and quickly cooling the molten blast furnace slag in the quenching unit in a composite way of a rotary crushing wheel, high-pressure cold air, a slag trap, cold slag particles and cooling water, and fully exchanging heat with solidified blast furnace slag in the slow cooling unit by using cooling air; and allowing high-temperature air which comes out of the quenching unit and the slow cooling unit to enter the waste heat boiler and performing heat exchange, transforming into steam or electric power and then outputting. The subsequent utilization of blast furnace slag and the waste heat recovery efficiency are synchronously considered, condensed water is recycled, finished slag does not contain water or only contains a small amount of water, the granulation effect of the slag is better, and the contradiction between intermittent slagging and continuous heat production of blast-furnace ironmaking is resolved.

Owner:HANGZHOU BOILER GRP CO LTD

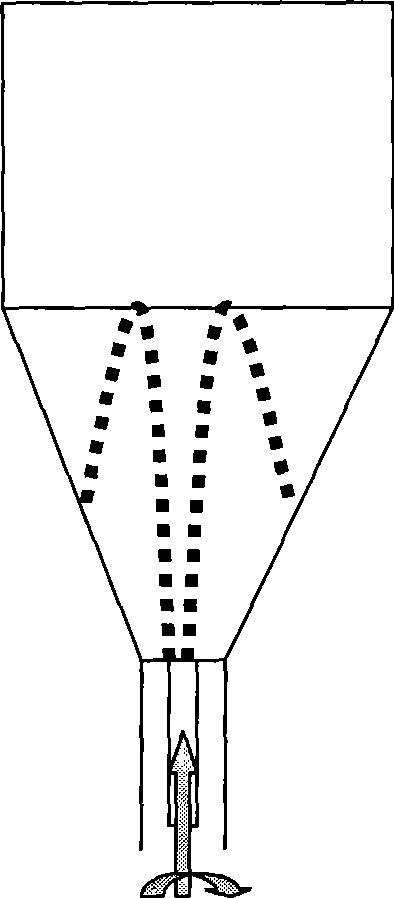

Sprouted auxiliary means for improving microwave desiccation homogeneity of granular garden stuff

InactiveCN101433233ASpray evenlyImprove uniformityFruits/vegetable preservation by dehydrationFood treatmentAir volumeAgricultural engineering

The invention discloses an auxiliary spouting method for improving the uniformity of microwave drying of granular fruits and vegetables, which belongs to the technical field of the processing of fruit and vegetable food. Pretreated fruits and vegetables are placed into a microwave spouting drying bed, the microwave power and the air intake heating temperature are preset, then the central air intake volume and the air intake angle of the spouting bed are adjusted to ensure that a dried material spouts in the spouting bed in different forms, the air intake pressure and the air intake angle are adjusted according to different drying stages of the material at the same time, and the microwave energy received by the material is more uniform than that of the prior fixation or fluidization mode; and the microwave adopts internal heating, so the moisture of the dried fruits and vegetables is effectively and quickly evaporated to achieve the aim of uniform drying. Through the auxiliary spouting method, the material is uniformly heated in a microwave field, the moisture is evaporated quickly, the drying time is greatly shortened, the prior color and luster, shape and nutrient substances of the dried fruits and vegetables can be furthest retained, and the dried fruits and vegetables have porous structures and good rehydration property, thereby obtaining a high-quality dehydrated fruit and vegetable product.

Owner:JIANGNAN UNIV +1

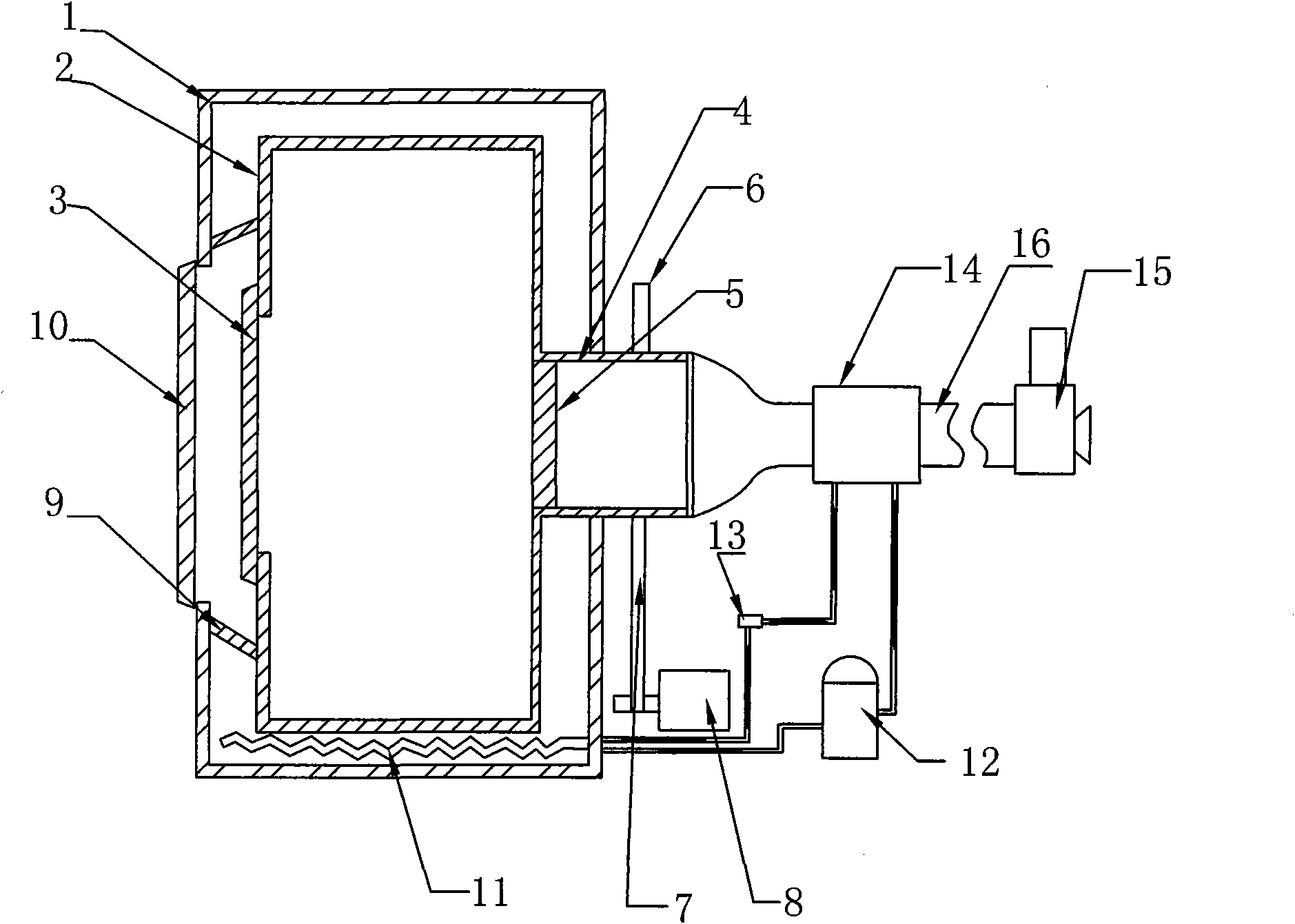

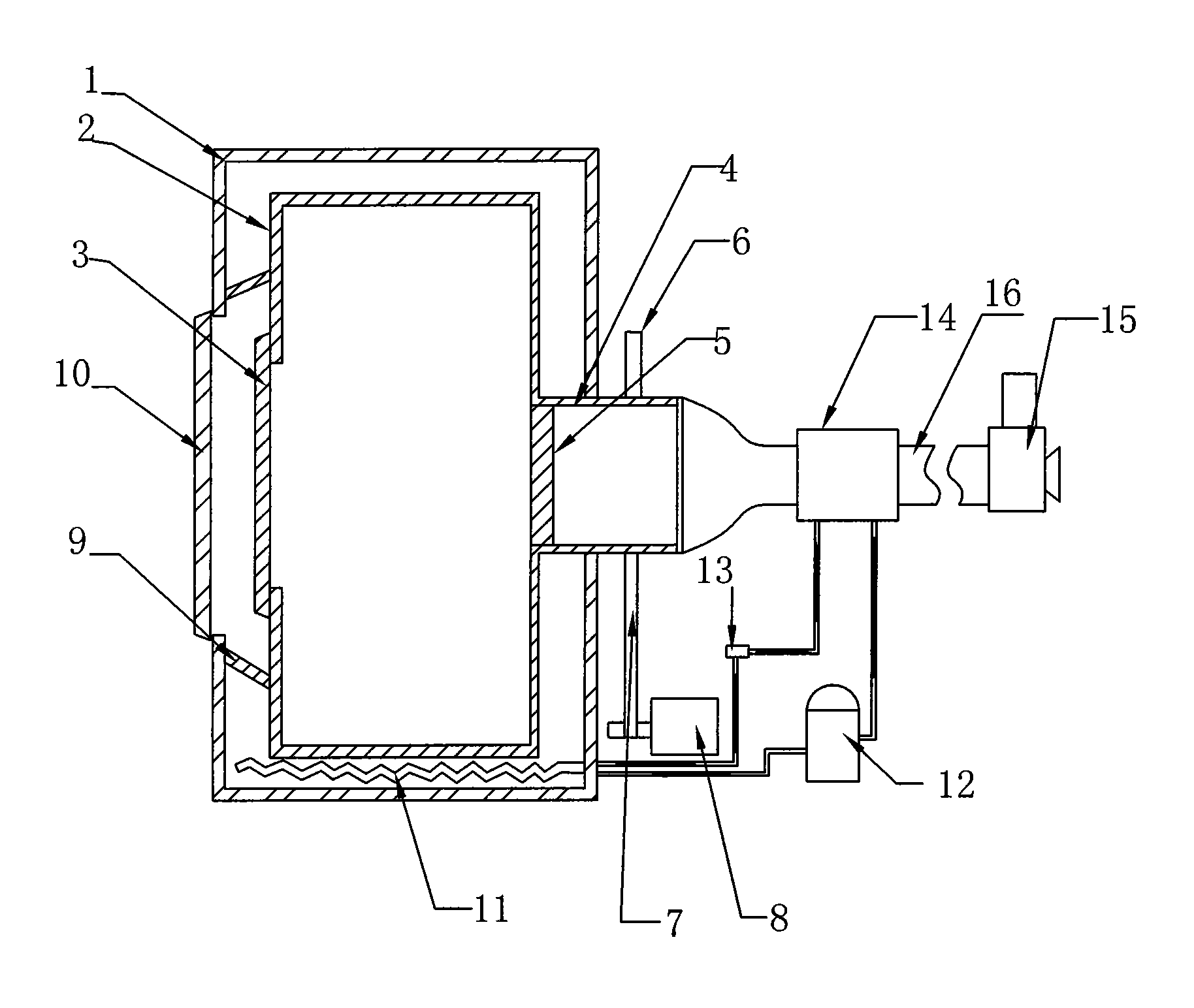

High-voltage electric field and hot air combined drying device

ActiveCN103983091AImprove retentionGood appearanceDrying gas arrangementsDrying chambers/containersThermal instabilityOperability

The invention discloses a high-voltage electric field and hot air combined drying device. The high-voltage electric field and hot air combined drying device comprises a box body, a high-voltage electric field drying system, a hot air circulation drying system and a monitoring control system, wherein the high-voltage electric field drying system, the hot air circulation drying system and the monitoring control system are arranged on the box body. According to the high-voltage electric field and hot air combined drying device provided by the invention, the structural design is reasonable, the operability is strong, and the use is convenient; compared with traditional hot air drying, the drying efficiency is high, the drying temperature is low, the drying time can be shortened by 50% than the drying time of drying by pure hot air under the same temperature, the drying energy consumption can be reduced by 51.9%, the high-voltage electric field and hot air combined drying device is particularly suitable for drying materials containing thermal-instability active components, for example, drying the materials of traditional Chinese medicine, medicinal slices, drug, agricultural products, food, biological products and the like, the appearance quality after the drying is good, the reservation degree of the active components is high, and the application range is very wide.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

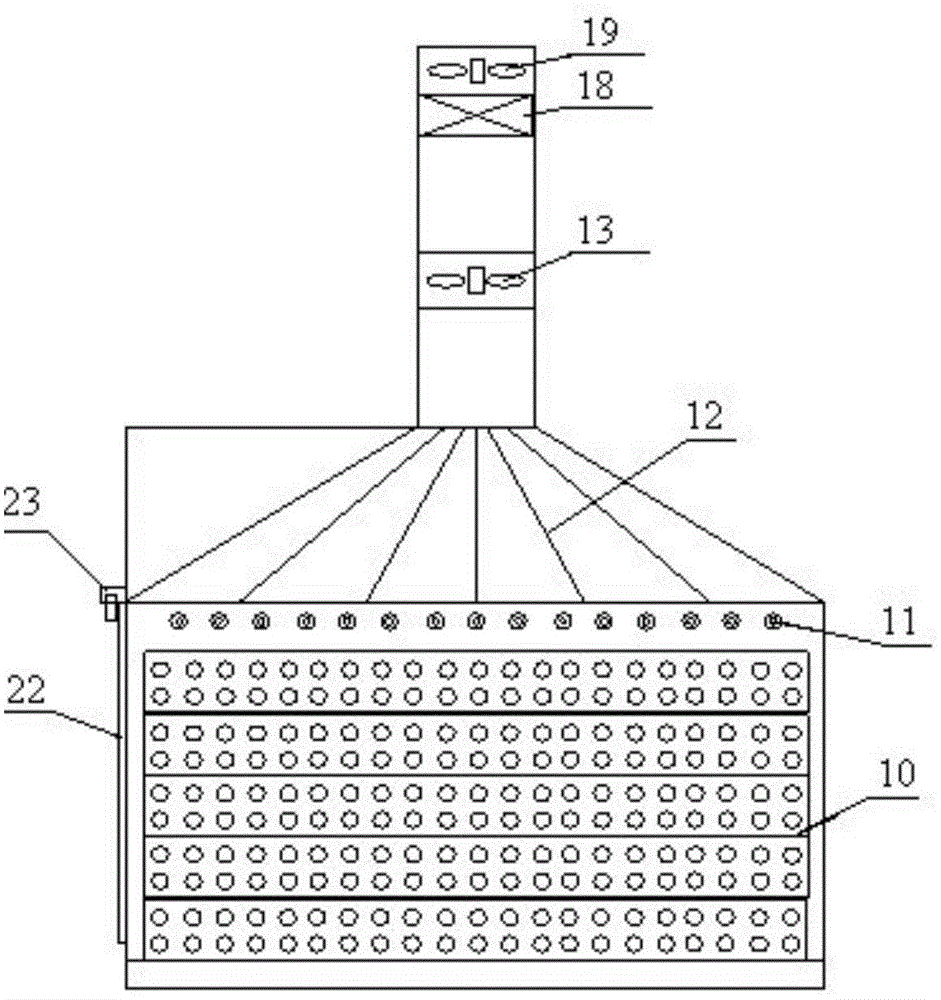

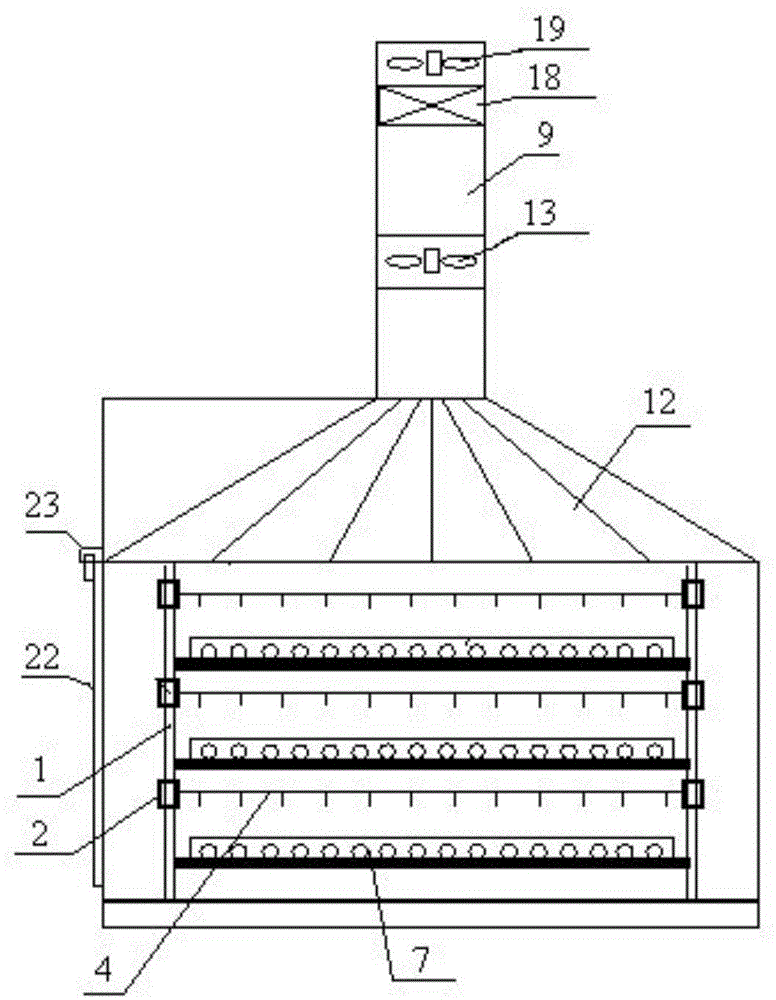

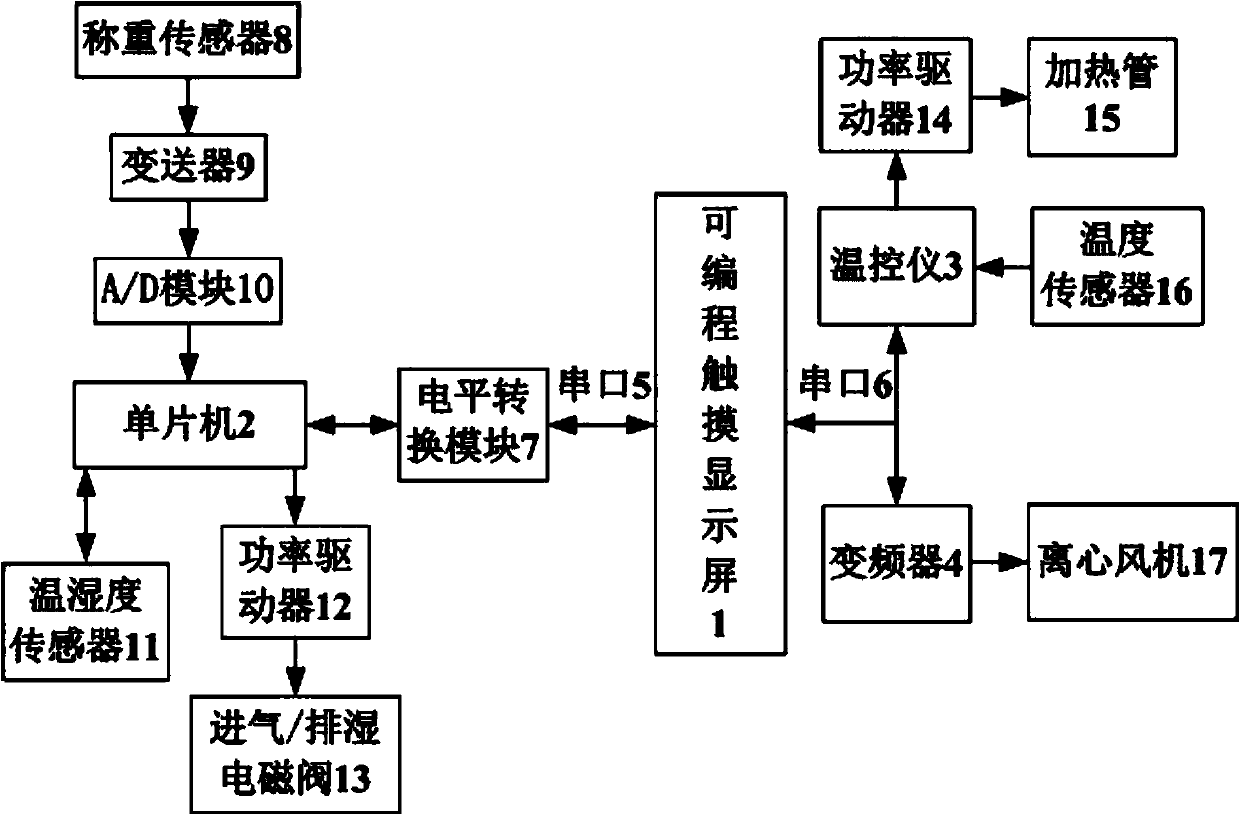

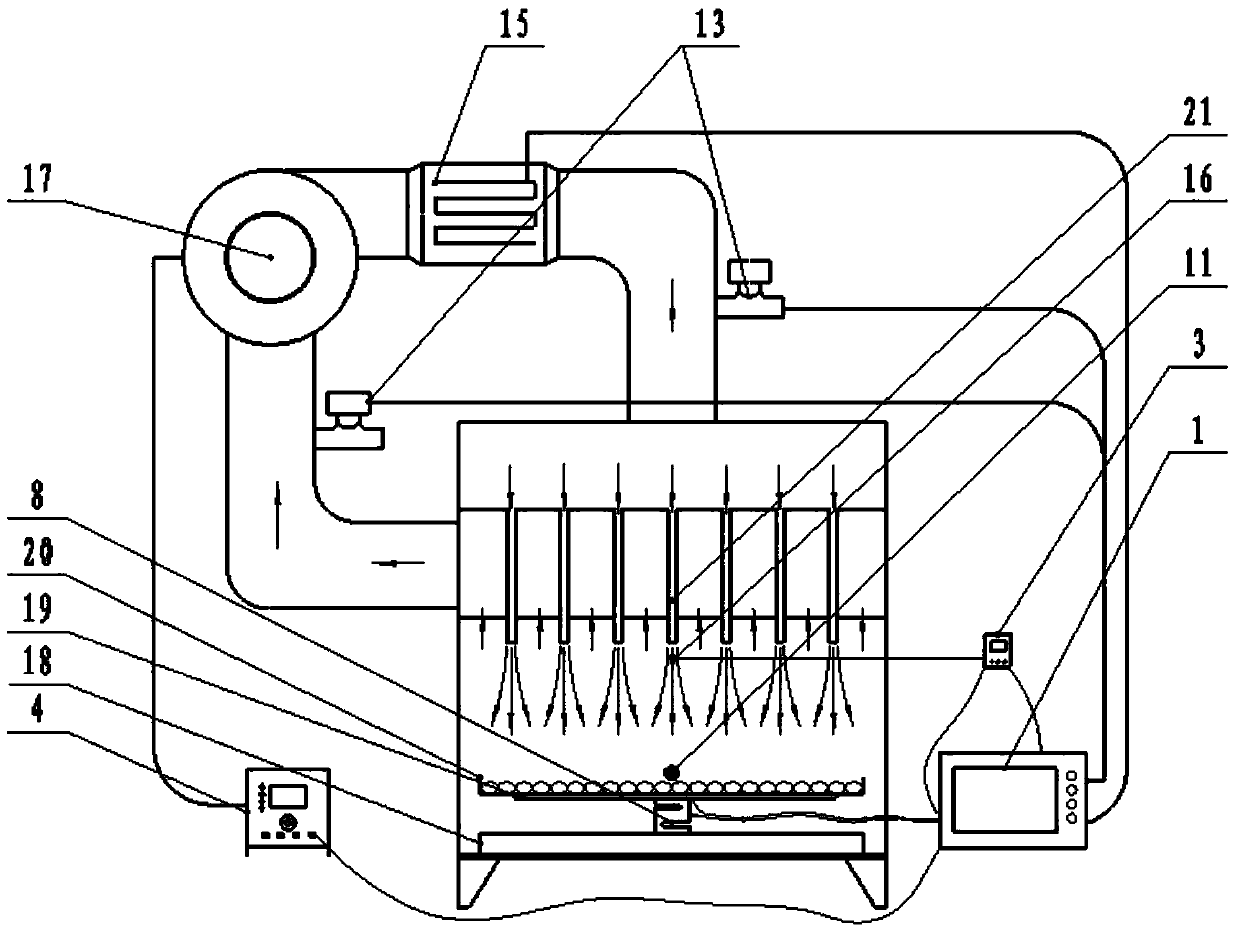

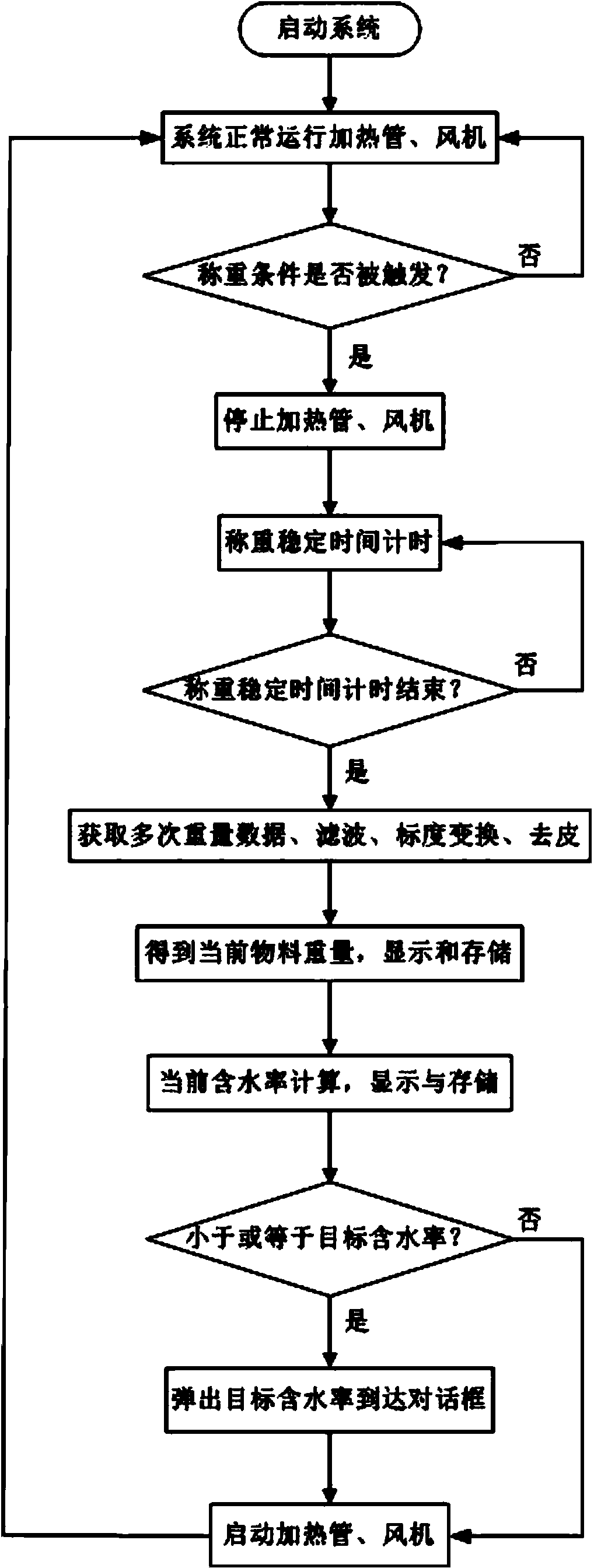

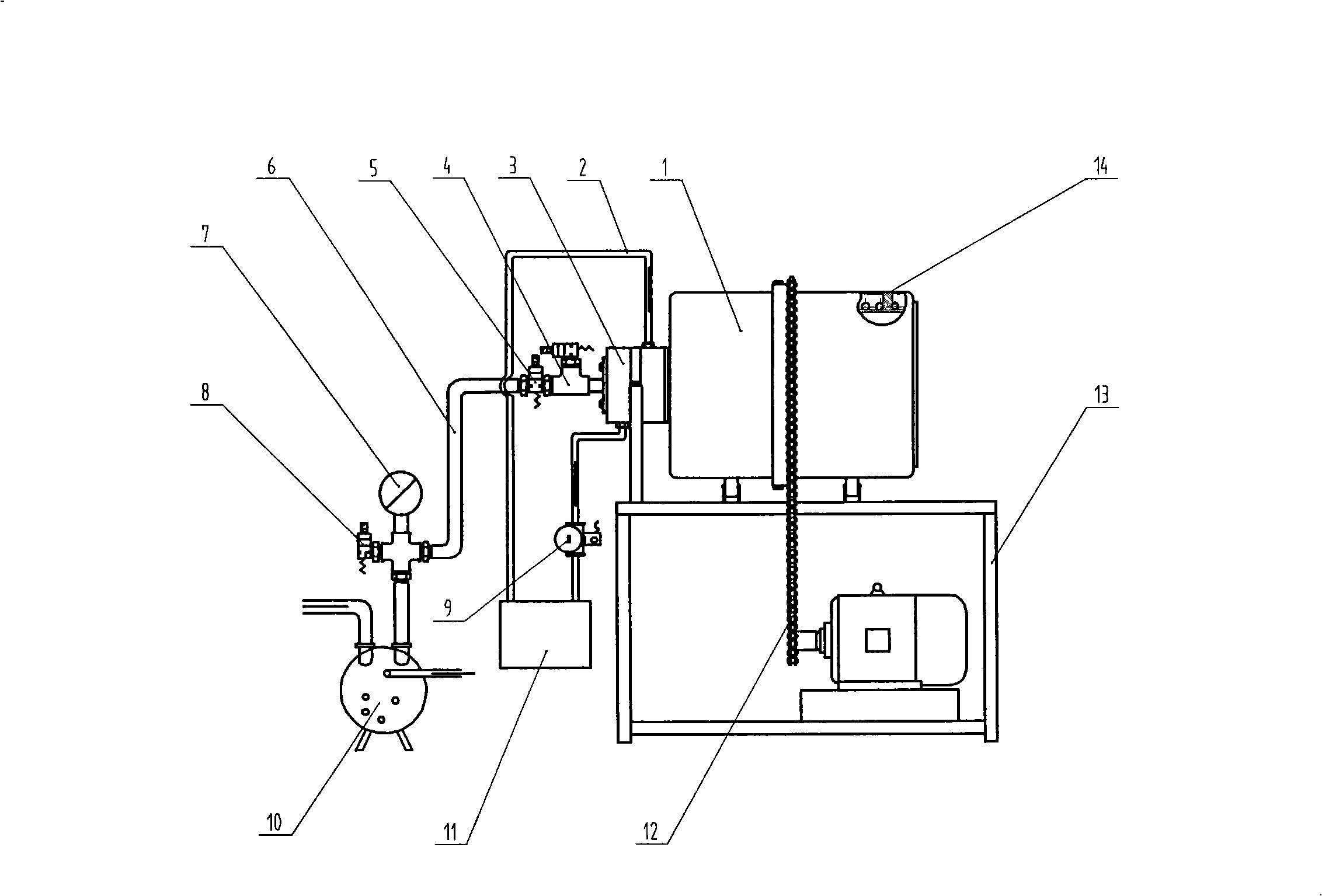

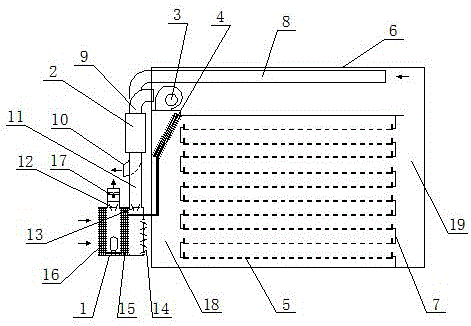

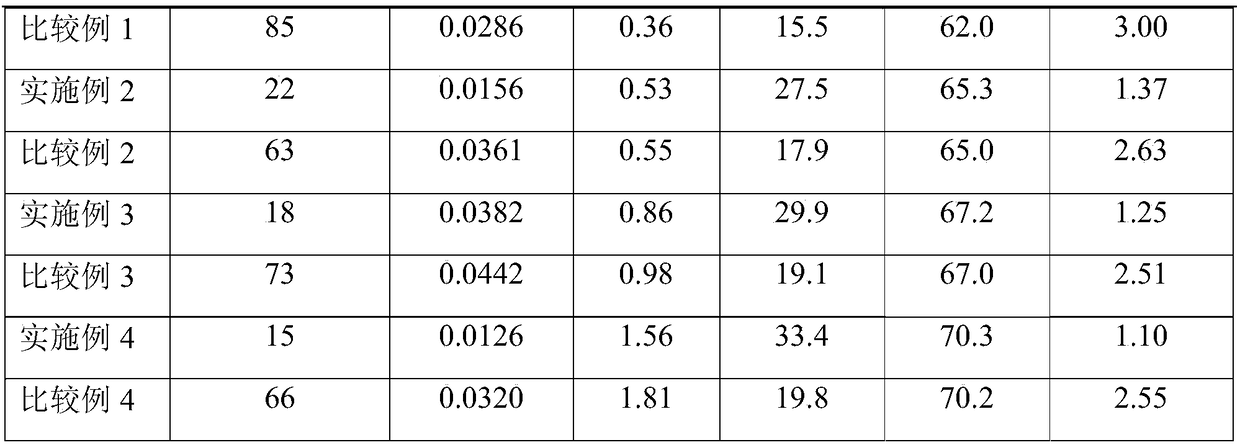

Automatic control system of gas jet impact drying machine

InactiveCN103438693AReduced impact on weighing accuracyElimination of influence on weighing accuracyDrying solid materialsAutomatic controlEngineering

The invention discloses an automatic control system of a gas jet impact drying machine, and belongs to the technical field of drying machines. The system comprises a programmable touch display screen (1), a single chip microcomputer (2), a weighing sensor (8), a temperature and humidity sensor (11), an air inflow / moisture discharging electromagnetic valve (13), a temperature controller (3), a heating pipe (15), a temperature sensor (16), a frequency converter (4) and a centrifugal fan (17). According to the automatic control system, in a drying process, the functions of automatic weighing of materials, moisture content detection, drying temperature precise controlling, drying temperature automatic regulation, drying air speed automatic conversion and the like can be achieved, the problem that the materials need to be weighed relying on manual work when the moisture content in a product is obtained in the drying process is solved, labor intensity of operating staff is reduced, meanwhile the quality of drying products can be effectively guaranteed, and automatic and intelligent level of gas jet impact drying equipment is improved.

Owner:CHINA AGRI UNIV

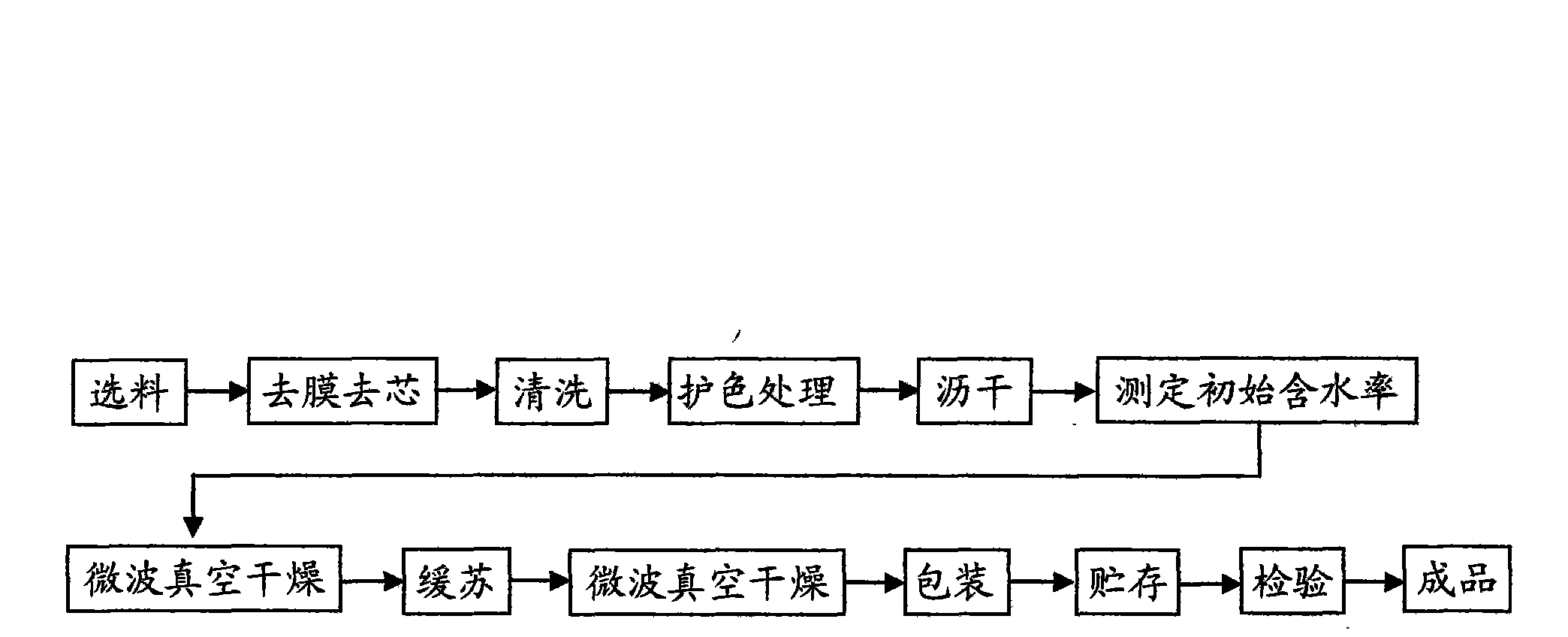

Microwave vacuum drying process for lotus seed

The invention provides a microwave vacuum drying process for lotus seeds, comprising the following steps of: selecting materials, removing films and cores, protecting color, dewatering, vacuum drying by microwave, packaging and storing, thus preparing the dry lotus seed product. The process aims at improving the quality research of the dry lotus seed and reducing the energy consumption, dries the fresh lotus seeds by microwave vacuum drying technology, improves the quality of the lotus seeds, and prolongs the shelf life of the product; the application of the high combination drying technology inaugurates another dry preparation way for drying preparation of fresh lotus seeds; the process is easy for instant control and the production is environment-protective; and the real continuous automatic clean production can be realized.

Owner:FUJIAN AGRI & FORESTRY UNIV

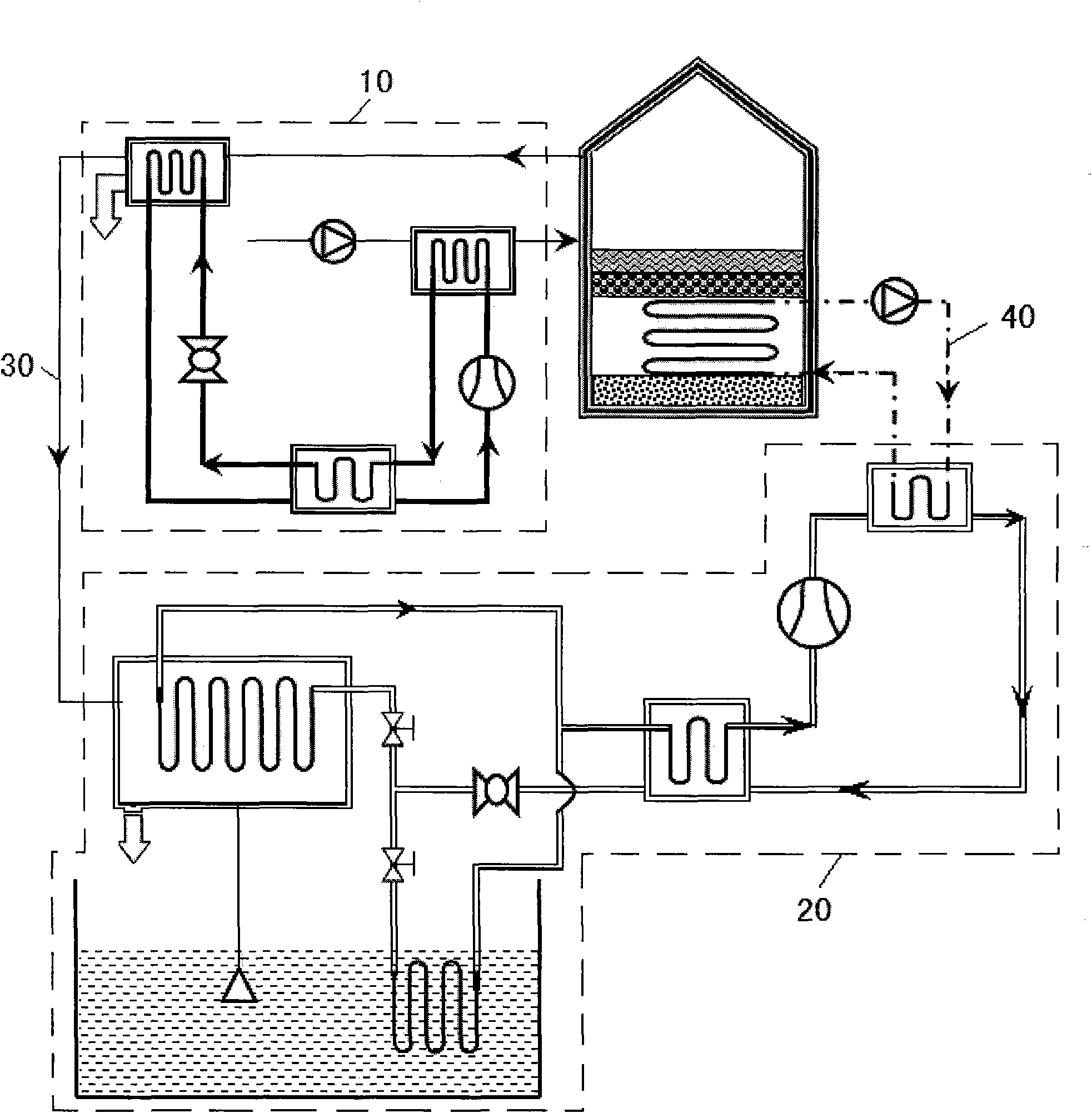

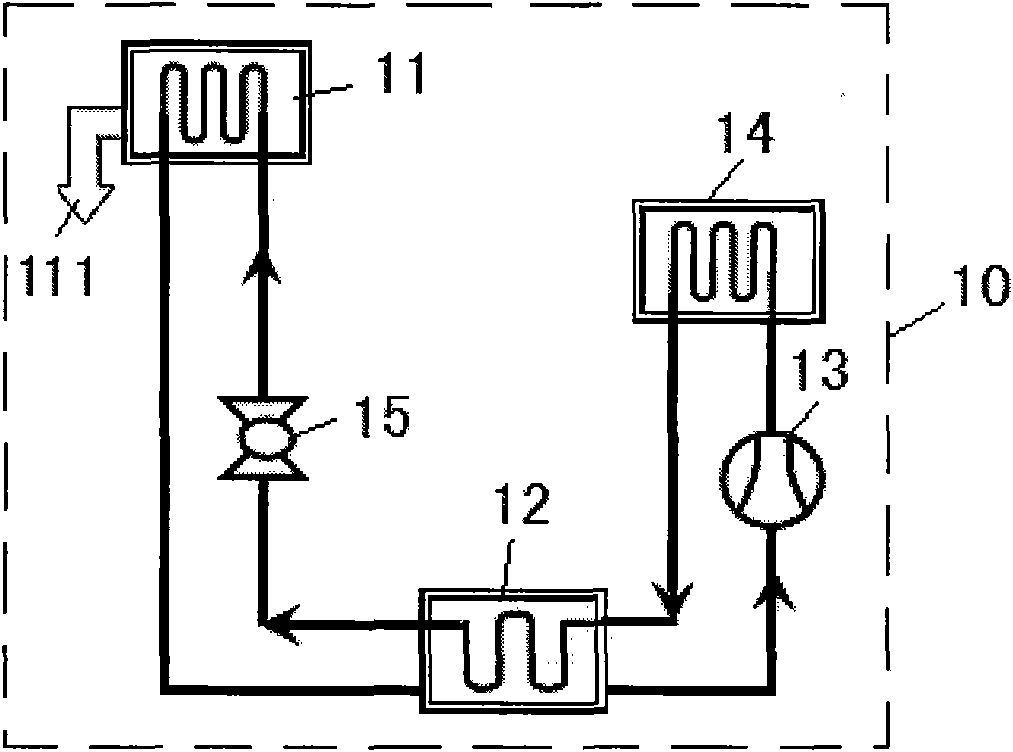

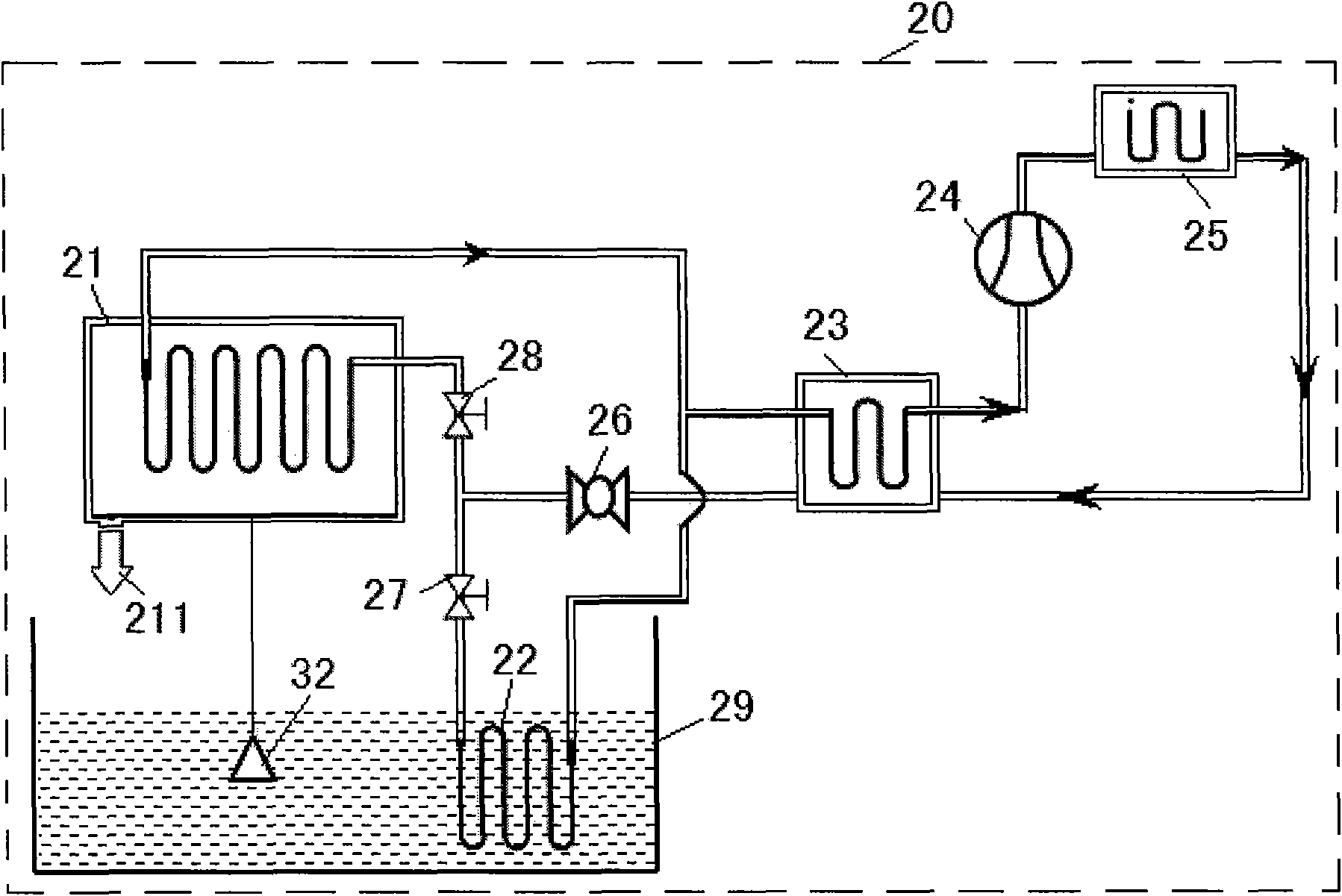

Mud drying system and use method thereof

ActiveCN101618930AHigh drying yieldReduce drying energy consumptionSludge treatment by de-watering/drying/thickeningHeat pumpsSludgeWater circulation

The invention relates to a mud drying system and a use method thereof. The mud drying system comprises a transcritical heat pump auxiliary heat supplying loop, a heat pump auxiliary heat supplying loop, an air heating and waste heat recovering loop and a hot water circulation loop; the transcritical heat pump auxiliary heat supplying loop comprises an evaporator, an internal heat exchanger, a compressor, a gas cooler and a throttle valve; the heat pump auxiliary heat supplying loop comprises an evaporator, a wastewater and waste heat recovering evaporator, an internal heat exchanger, a compressor, a condenser, a throttle valve, two stop valves and a wastewater tank; the air heating and waste heat recovering loop comprises a hothouse, an air compressor, a gas discharging and carrying port, a first evaporator, the other evaporator and a condenser; and the hot water circulation loop comprises a pump, a hothouse and the condenser in the heat pump auxiliary heat supplying loop. The invention adopts the hothouses to obtain solar energy to heat mud and utilizes the transcritical heat pump auxiliary heat supplying loop and the heat pump auxiliary heat supplying loop to recover the sensible heat and the latent heat in humid air to heat mud, thereby lowering the energy consumption for drying the mud. The invention can be widely applied to various mud processing fields.

Owner:TSINGHUA UNIV +3

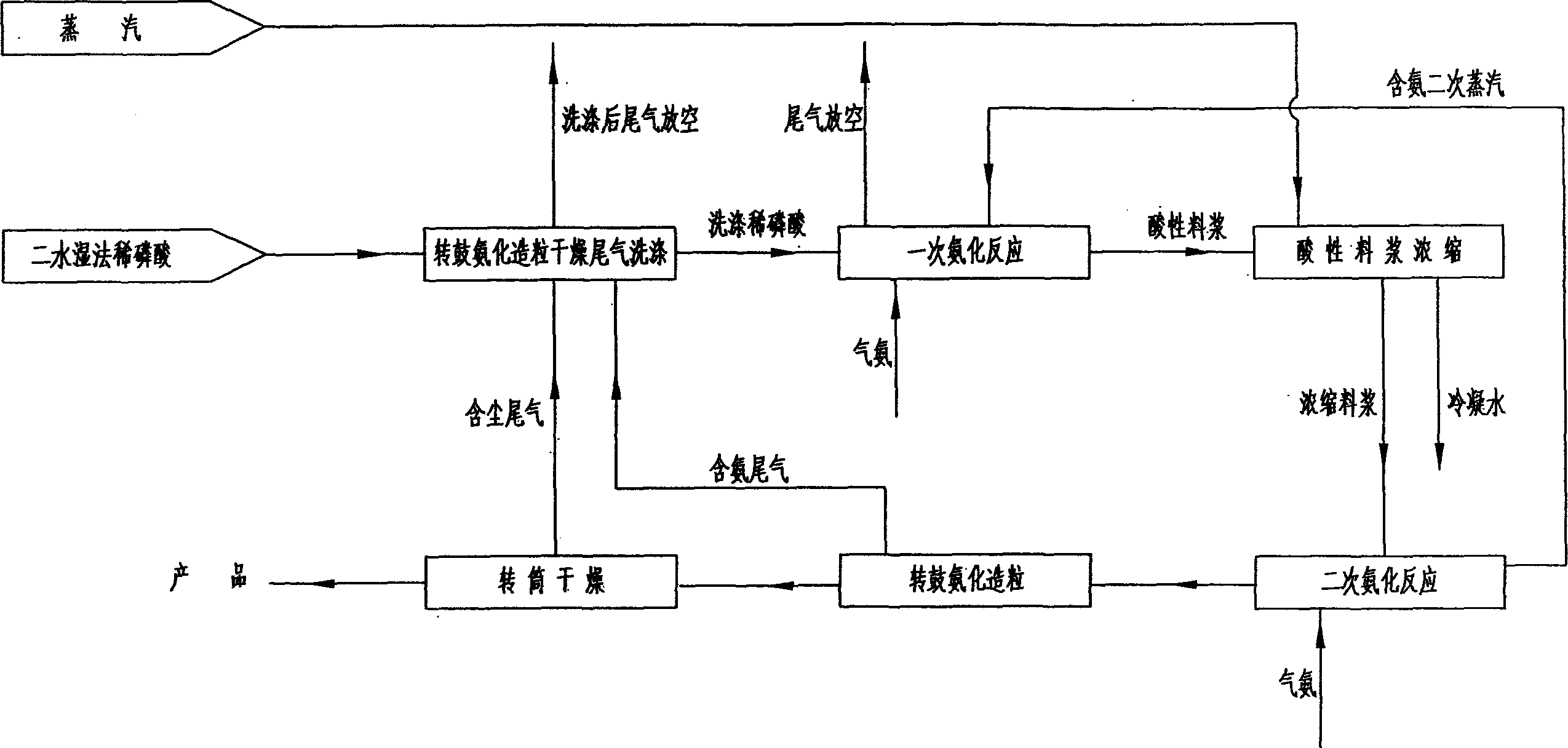

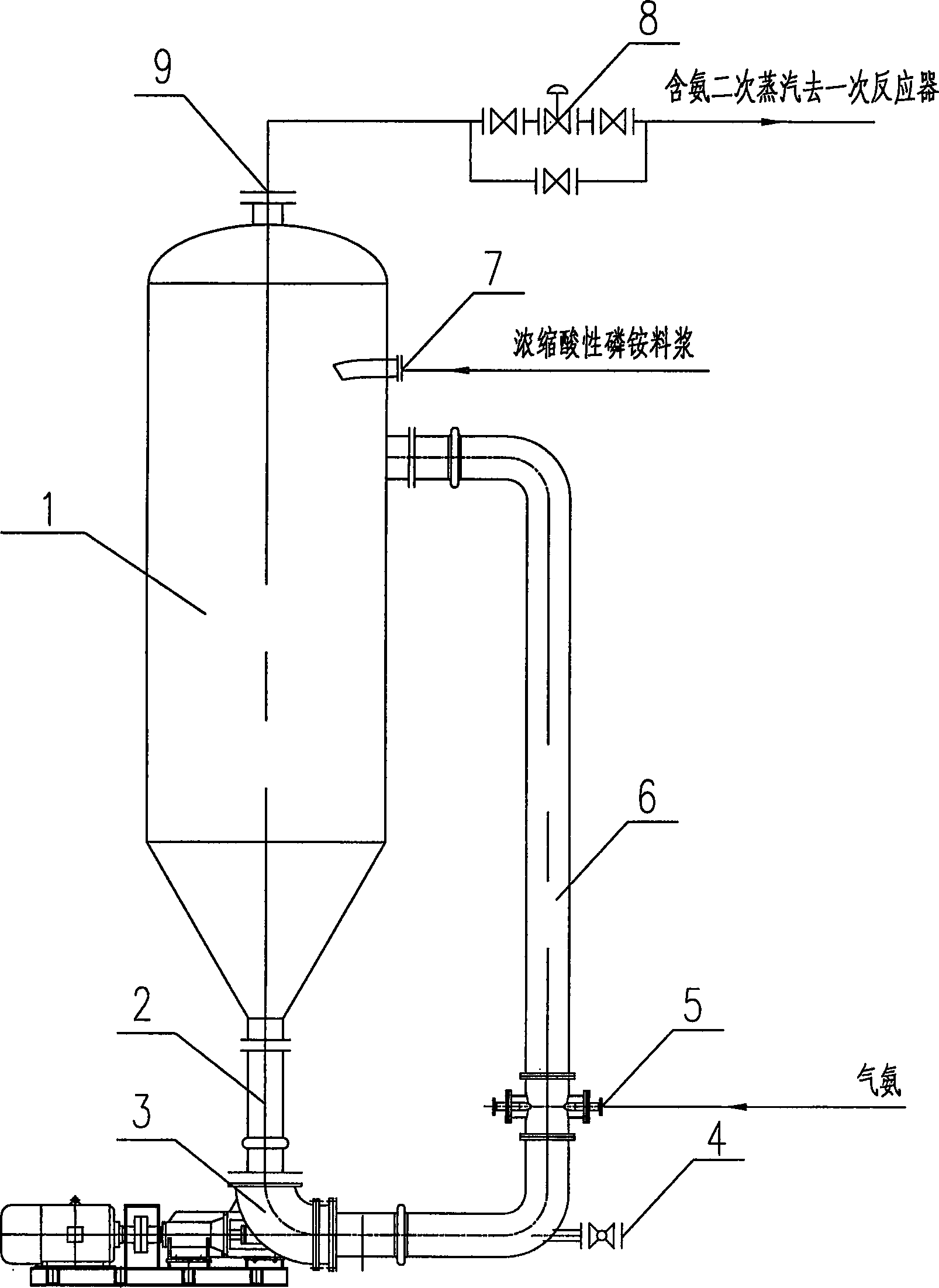

Method for producing diammonium phosphate by concentrating acid slime, and secondary ammoniation reactor

InactiveCN1872669AGood characterIncrease concentrationPhosphatesAlkali orthophosphate fertiliserDiammonium phosphatePhosphoric acid

This invention discloses a method for producing di-ammonium phosphate by concentration of acidic slurry. The method comprises: (1) performing a first ammonification on diluted phosphoric acid to obtain an acidic slurry of ammonium dihydrogen phosphate; (2) concentrating so that the water content is 13-20%; (3) performing a second ammonification so that the neutralization degree is increased to 1.30-1.50; (4) performing further ammonification so that the neutralization degree reaches 1.60-1.90; (5) granulating and controlling the water content at 2-4%. The mol. ratio of P to N in ammonium dihydrogen phosphate is 0.32-0.40.

Owner:四川川大中德环保技术有限公司

Drum-type vacuum pulsing temperature-variable drying method and apparatus

InactiveCN101261073AKeep drySolve delivery difficultiesDrying using combination processesDrying solid materials with heatControl systemChemical products

The invention discloses a drum-type vacuum pulsing transformation temperature drying method and a device, comprising a sealed circular roller, a heating circulating system, a pulsing vacuum system connected with the roller and a control system, wherein, the vacuum degree of the pulsing vacuum system connected with the roller varies with the material arranging from 0.097 MPa to 0 MPa, the heating temperature of the heating circulating system varies with the state of the material. The device has good heat transmitting performance, preserves the nutrient content and the active material of the material as well as the color and luster of the material well, greatly raises the drying speed, shortens the drying time, reduces the drying energy consumption and lowers the drying cost. The drum-type vacuum pulsing transformation temperature drying method and the device are suitable for drying the foods, the biological products, the drugs and the chemical products with good fluidness, particularly for drying the products thermally sensitive; especially, the effect for drying the foods and the biotechnology products with high added value is better.

Owner:CHINA AGRI UNIV

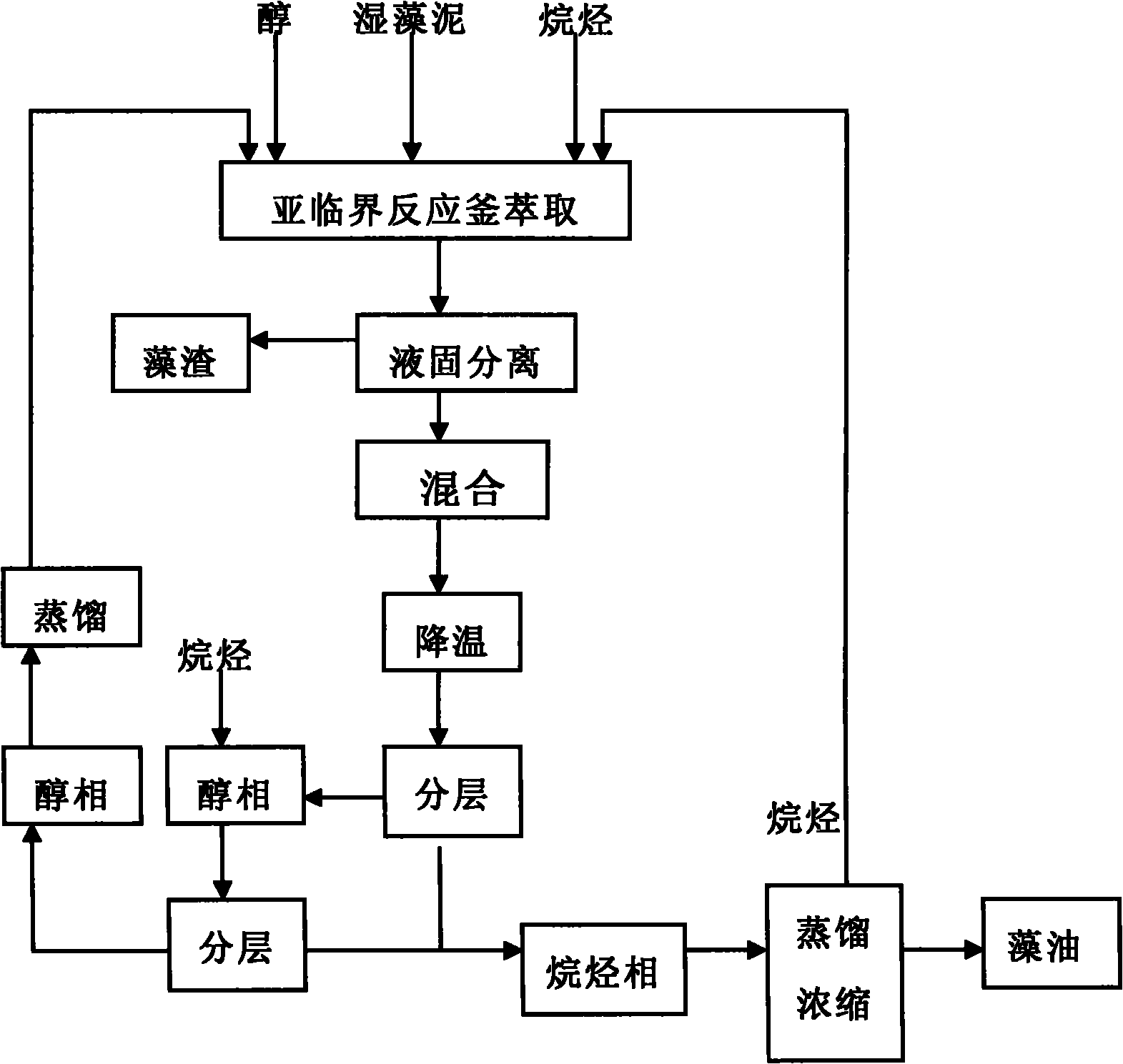

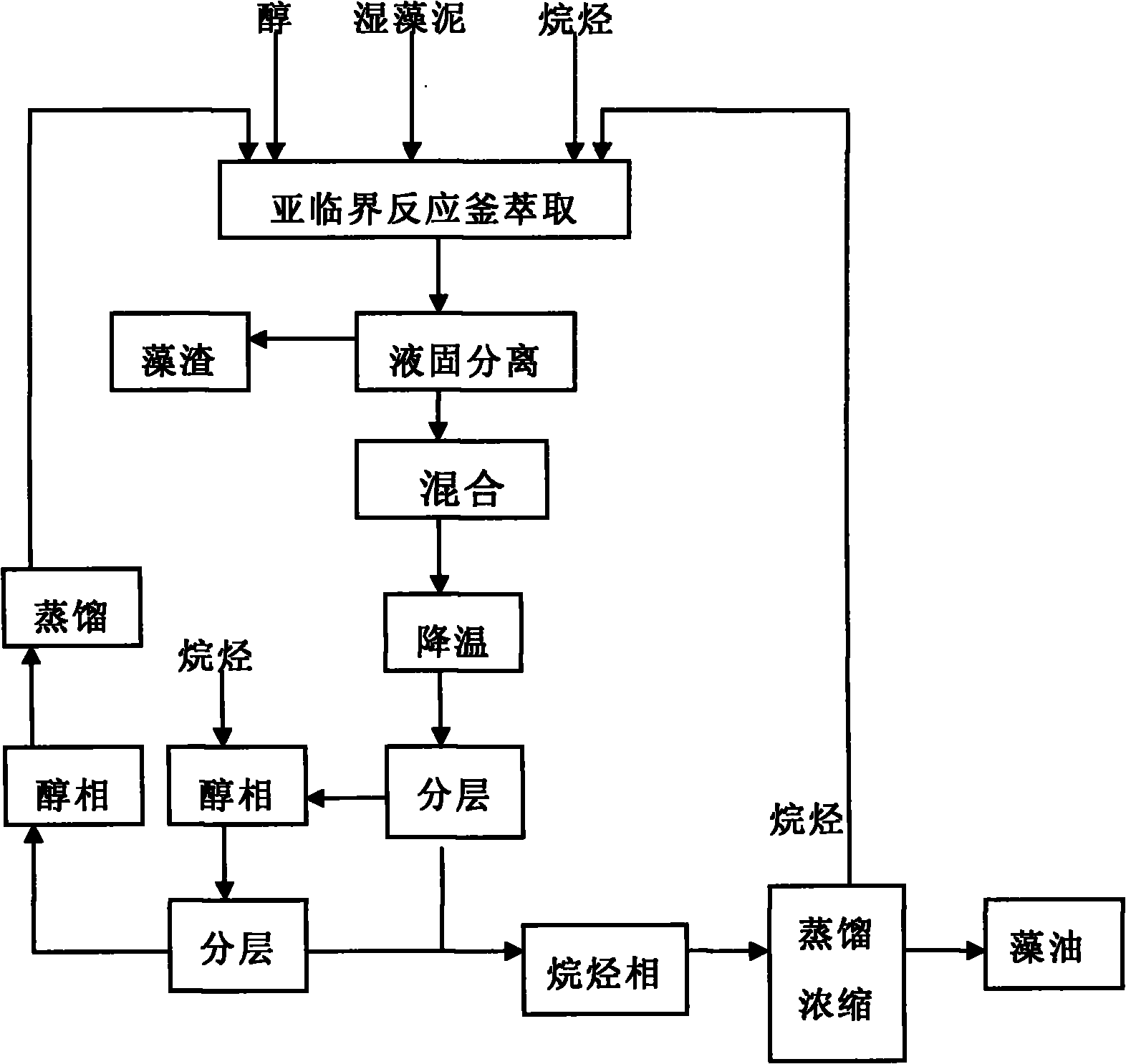

Method for extracting grease from wet alga mud by using mixed organic solvent

InactiveCN102071100AReduce drying energy consumptionReduce dosageFatty-oils/fats productionSolventPARAFFIN HYDROCARBONS

The invention discloses a method for extracting grease from wet alga mud by using a mixed organic solvent. The method mainly comprises the following steps of: adding wet alga mud of microalgae which produce oil into a mixed solvent of a lower alcohol solvent and a lower paraffin hydrocarbon, heating in a reactor and introducing nitrogen, keeping the pressure and temperature of the reactor at a subcritical state and reacting; and performing liquid-solid separation and then cooling the obtained mixed liquid, collecting an upper-layer paraffin hydrocarbon phase, performing washing, extracting and phase splitting on a lower-layer alcohol-water phase by using lower paraffin hydrocarbon to obtain a paraffin hydrocarbon extraction phase, mixing the paraffin hydrocarbon extraction phase and the upper-layer paraffin hydrocarbon phase, performing evaporation concentration to obtain microalgae grease, and recovering paraffin hydrocarbon. Microalgae cells with high water content can be directly used, alga cells are not required to be dried and dehydrated, drying energy consumption is saved, the using amount of the extraction solvent is small, the extraction efficiency of the grease is high, the separation can be performed easily and the process is easy to amplify. The method has significance to the high-efficiency microalgae grease extraction with low energy consumption and the industrialization of microalgae bioenergy.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

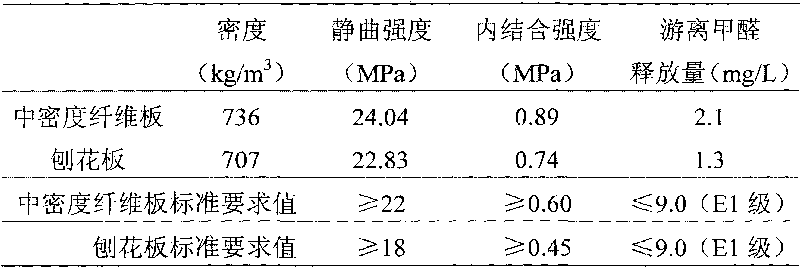

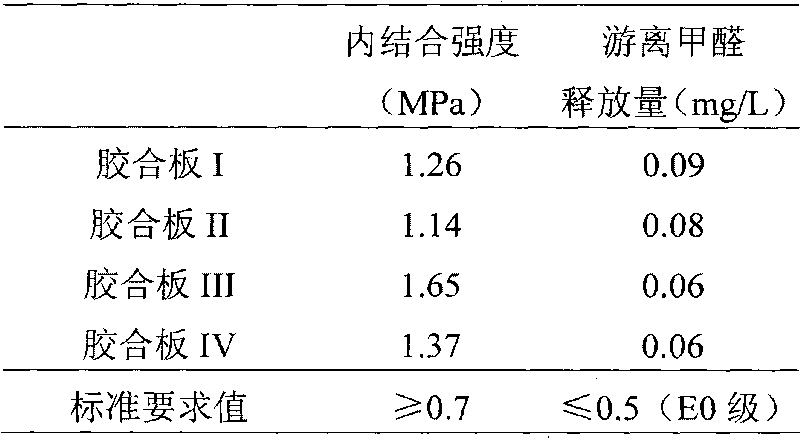

Wood adhesive prepared by degrading soybean protein by utilizing strong basicity and preparation method thereof

InactiveCN101724376AHigh viscosityImprove adsorption capacityProtein adhesivesGlue/gelatin preparationMedium densityAdhesive

The invention discloses a wood adhesive prepared by degrading soybean protein by utilizing strong basicity and a preparation method thereof, and relates to a soybean protein-based wood adhesive and a preparation method thereof. The invention solves the problems of low content of the soybean protein, high moisture content and large viscosity existing in conventional soybean adhesives or soybean protein adhesives. The product is prepared by performing a degradation reaction of defatted soybean protein powder or soybean protein isolate, strong base and water, then using strong phosphoric acid to adjust the pH value of the obtained solution, and then adding dialdehyde into the obtained solution to mix the solution evenly. The method comprises the steps of: 1, weighing; 2, preparing strong base solution, heating the strong base solution, adding the defatted soybean protein powder or the soybean protein isolate into the strong base solution under stirring, and then cooling the strong base solution to a room temperature after heating reflux; and 3, using the strong phosphoric acid to adjust the pH value, adding the dialdehyde into the solution, and stirring the solution evenly. The adhesive has the advantages of high content of the soybean protein, low moisture content and low viscosity, and can be used for preparing plywood, flakeboards and medium-density fiberboards.

Owner:NORTHEAST FORESTRY UNIVERSITY

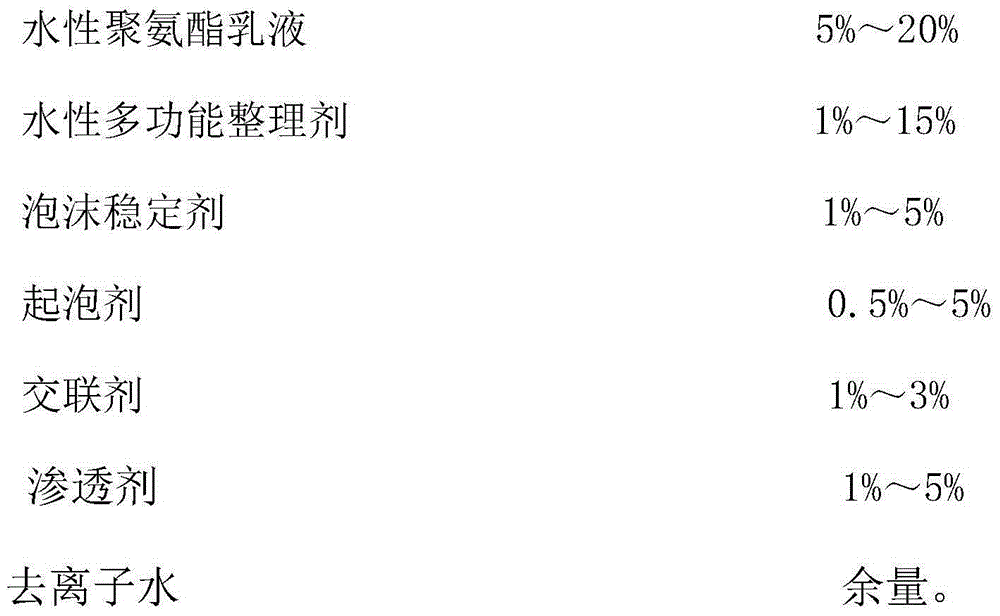

Multifunctional finishing liquor formula for foam finishing and application process

The invention discloses a multifunctional finishing liquor formula for foam finishing. The multifunctional finishing liquor formula comprises 5-20% of water-based polyurethane emulsion, 1-15% of water-based multifunctional finishing agents, 1-5% of foam stabilizer, 0.5-5% of foaming agents, 1-3% of cross-linking agents, 1-5% of penetrant and the balance deionized water. An application process includes the steps that foam multifunctional finishing liquid is prepared; a finishing foam body is obtained, and the finishing foam body is evenly applied to fabric or synthetic leather in need of finishing; drying is conducted through a drying oven, and multifunctional ecological textiles generated after foam finishing are obtained. According to the multifunctional finishing liquor formula for foam finishing and the application process, a computer controls the liquor rate for conducting accurate liquor feeding, water resources and drying energy consumption are saved through the low liquor rate, multifunctionality can be provided for the fabric, the value and level of the fabric are improved, no waste gas and waste water are discharged in the whole production process, and the application process is a real environmentally friendly clean production process.

Owner:宋婷婷

Graphene dispersion liquid and method for preparing graphene material power

The invention provides a graphene dispersion liquid which comprises an organic solvent and a graphene material dispersed in the organic solvent, wherein the graphene dispersion liquid is prepared by virtue of the following steps: S1, providing a graphene water-based slurry which comprises the graphene material and water; S2, adding the organic solvent once or multiple times into the graphene water-based slurry in an accumulated manner to obtain a mixed slurry, wherein the organic solvent and the water can form an azeotropic system; S3, heating the mixed slurry till all moistures in the mixed slurry are removed, so as to obtain the graphene dispersion liquid. The invention further provides a method for preparing graphene material power by using the graphene dispersion liquid.

Owner:NINGBO MORSH TECH +1

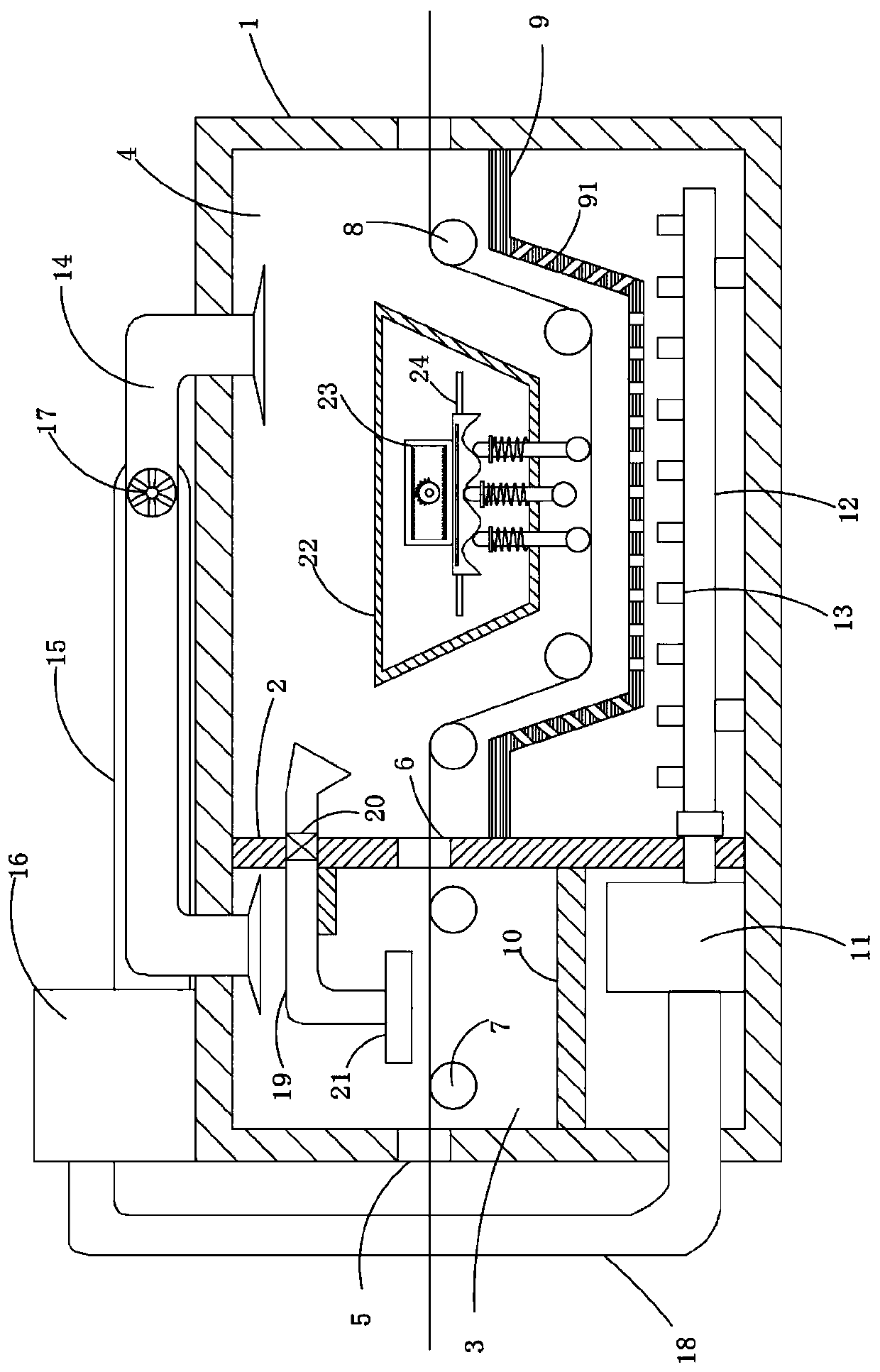

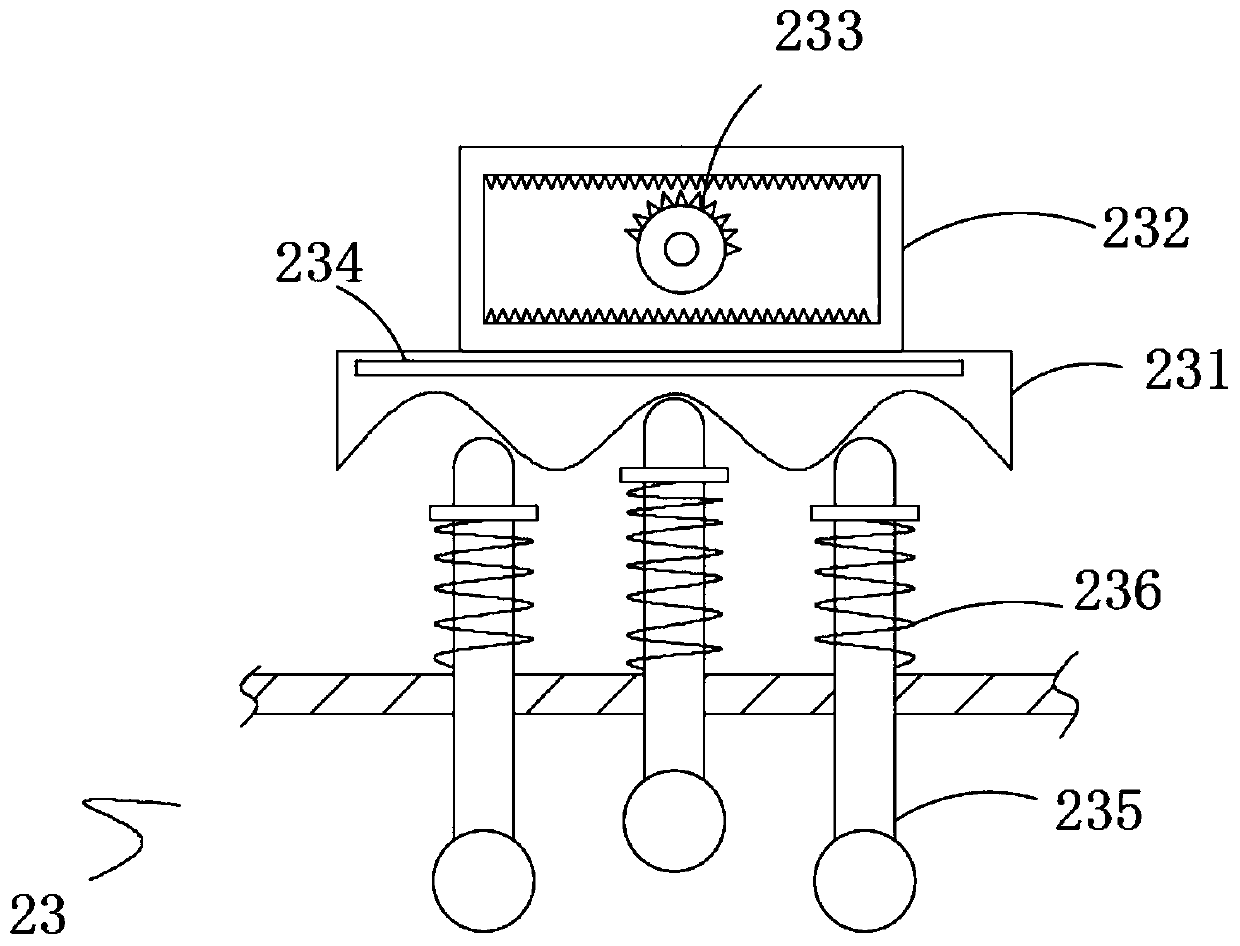

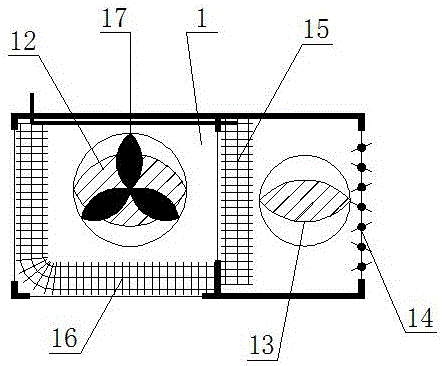

Oscillation type drying system used for non-woven fabric production

InactiveCN110736324AImprove drying effectReduce lossDrying gas arrangementsDrying machines with progressive movementsNonwoven fabricMaterial distribution

The invention relates to an oscillation type drying system used for non-woven fabric production. The oscillation type drying system comprises a box body. A vertical partition plate is arranged in an inner cavity of the box body. The inner cavity of the box body is divided into a preheating cavity and a drying cavity through the vertical partition plate. Inlets and outlets are symmetrically formedin the middle portions of the left side wall and the right side wall of the box body. A communicating opening is formed in the portion, corresponding to the inlets and outlets, of the middle portion of the vertical partition plate. A first guide roller set is arranged in the preheating cavity. A second guide roller set is arranged in the drying cavity. A U-shaped plate is arranged on the lower portion of the drying cavity. The second guide roller set is distributed along the U-shaped face of the U-shaped plate. A transverse partition plate is arranged on the lower portion of the preheating cavity. An air heater is arranged in a lower side cavity of the transverse partition plate. A hot air pipe is arranged on the lower side of the U-shaped plate. According to the oscillation type drying system, by means of the technological means such as an arranged hot air circulation pipeline, an arranged material distribution vibration mechanism and an arranged preheating structure, the technical problems that in the prior art, the non-woven fabric drying efficiency is low, the drying effect is poor and the drying energy consumption is large are solved.

Owner:长兴燕莎纺织有限公司

Air energy heat pump agricultural product drying device

ActiveCN106369959AImprove drying uniformityReduce drying energy consumptionHeat pumpsDrying gas arrangementsProcess engineeringRefrigeration

The invention relates to an air energy heat pump agricultural product drying device. The air energy heat pump agricultural product drying device is formed by an air energy heat pump outdoor main engine, a total heat exchanger, a first draught fan, a condenser, a material disc, a drying box shell, barge boards, an air exhaust pipe, an air supply pipe, an air supply static pressure chamber and an air return static pressure chamber. The air energy heat pump outdoor main engine comprises three air quantity adjusting valves and two evaporators, the two evaporators are connected in parallel, and are connected with the condenser in series through a refrigeration agent pipe to form a part of refrigerating cycle; outdoor fresh air treated through the air energy heat pump outdoor main engine exchanges heat with exhausted air in the total heat exchanger to be supplied into the drying box shell; the first draught fan provides power for circular flow of air in the drying box shell; and the barge boards are installed at appropriate positions of the front and the back of the material disc, and needled airflow paths in the material disc are obtained. By means of the air energy heat pump agricultural product drying device, three drying working conditions including single heating, low temperature dehumidification and dehumidification while heating of agricultural products can be achieved, the uniform air supply speed of the material disc can be achieved, and the energy using efficiency and the agricultural product drying uniformity can be improved.

Owner:福建古田康亿达生物科技有限公司

Microwave processing method for chrysanthemum tea

The invention relates to a microwave processing method for chrysanthemum tea. The method comprises the following steps of: firstly, picking out satisfactory fresh chrysanthemums, and spreading the chrysanthemums at room temperature to air; performing microwave green removing, quickly reducing the temperature after green removing, and repeatedly kneading the chrysanthemums; and drying, screening, inspecting and packing the chrysanthemums to obtain the finished product of chrysanthemum tea. Compared with the traditional common green removing method through heating, distilling and drying, the method can effectively reserve important drugs and nutrition constituents such as volatile oil, flavone, chlorogenic acid, stevia, choline, amino acids, vitamins, abundant mineral elements and the like contained in the chrysanthemums, and the disinfection effect is improved.

Owner:程雪翔

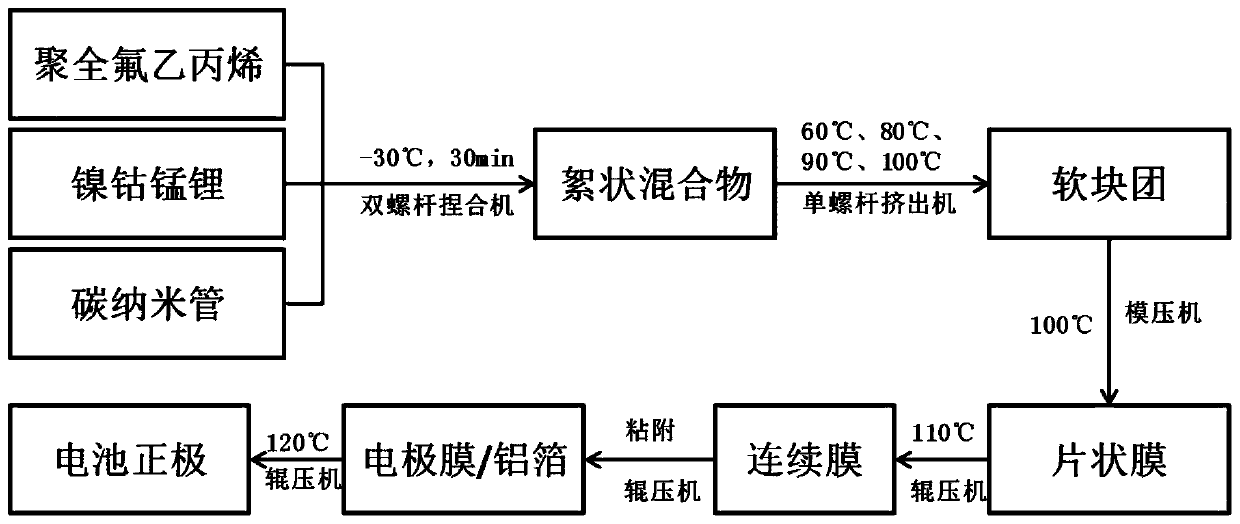

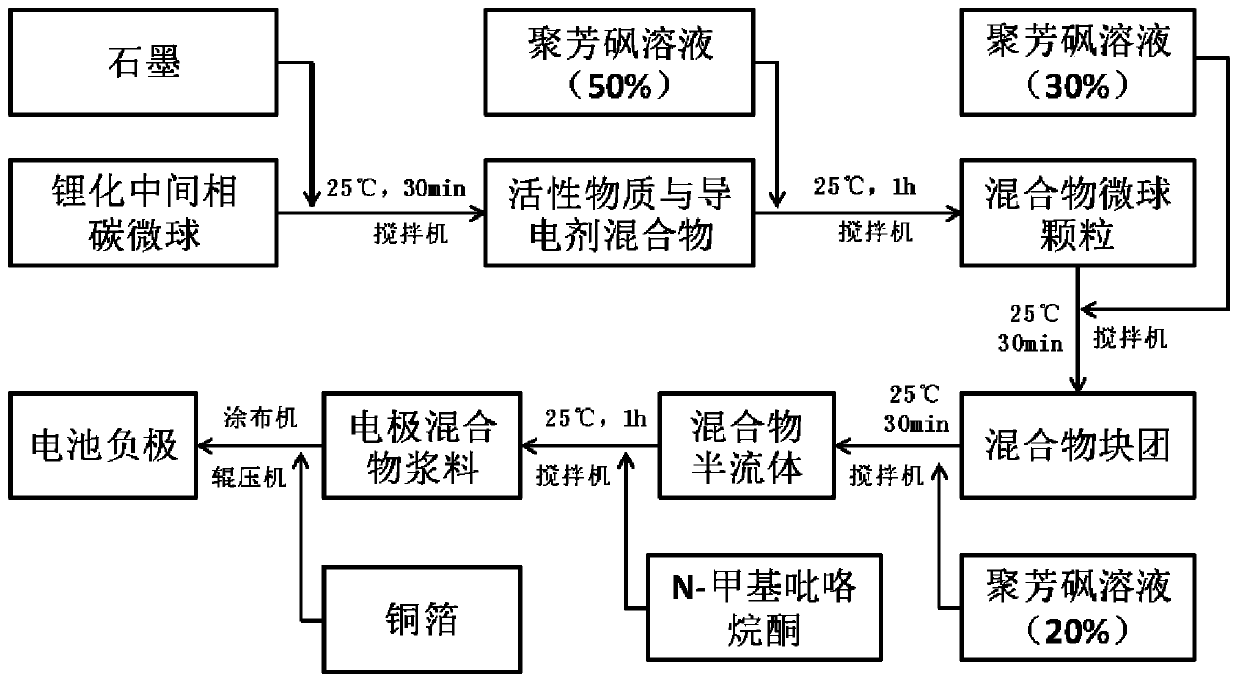

Electrode preparation method and battery

ActiveCN109841796AIncrease areal densityImprove structural stabilityElectrode manufacturing processesSecondary cellsLamellar crystalsInternal resistance

The invention discloses an electrode preparation method and a battery. The battery anode is prepared by pasting an electrode film prepared from an active substrate, a conductive agent and a binder toa current collector, the surface density of a pole piece is improved, the electrode capacity and the pole piece stability are improved, and the internal resistance is reduced. In the preparation process of the electrode film, lamellar crystals of the binder are stretched to paste the active substance and conductive agent, influence of expansion and contraction of the active substance caused by ionembedding and separating is reduced. The battery cathode is prepared by coating a slurry prepared from a pre-lithium active substance, a binder and a conductive agent on the current collector, the active substrate and conductive agent of the cathode are wetted rapidly, dispersed ultra-finely and homogeneous in a binder solution, the amount of the solvent for slurry dispersion is reduced, energy consumption for drying is reduced, the electrode process is shortened, and the load capacity of the cathode active substance is improved. The anode and cathode of the battery can be designed in an integrated way, and energy storage of the battery is improved. The electrode preparation method is simple, production and manufacture are realized by means of existing equipment, and the method is easy topopularize.

Owner:CHINA FIRST AUTOMOBILE

Method for drying apple pieces by nitrogen source low-oxygen heat pump

InactiveCN103444857AExtended storage timeLess nutrient lossFruits/vegetable preservation by irradiation/electric treatmentFood processingQuinoneVitamin C

The invention belongs to the field of drying of agricultural products, and particularly relates to a method for drying apple pieces by a nitrogen source low-oxygen heat pump. The method comprises the following steps of cutting applies into pieces after the apples are selected, peeled and seeded, performing color protection, shape fixation, blanching and draining, drying the apple pieces in a nitrogen source heat pump dryer, drying the apple pieces in a vacuum drying box, and sealing and storing the apple pieces. According to the method, the drying energy consumption is reduced, the drying efficiency is improved, and the shortcomings of low drying efficiency and long drying time in the later drying period of heat pump drying are overcome; the apple pieces are subjected to heat pump drying and vacuum low-temperature drying after the color protection and blanching treatment, so that the problems of reduction of the gloss of the apple pieces and changes in colors are effectively solved; phenolic substances in the apples can be prevented from being oxidized to generate quinone, the oxidation loss of vitamin C can be reduced, the color and the texture of the apple pieces can be prevented from being damaged by an oxidation effect in a drying process, and dry products with natural colors can be obtained.

Owner:HENAN UNIV OF SCI & TECH

Negative pressure type heat pump clothes dryer

ActiveCN102011294AAvoid damageAchieve low temperature dryingTextiles and paperLaundry driersMotor drivePulp and paper industry

The invention discloses a negative pressure type heat pump clothes dryer comprising a housing, a motor driving device and a control device. The clothes dryer further comprises a clothes drying roller, a heating device and a negative pressure device. The clothes drying roller comprises two parts of an outer cylinder, and an inner cylinder which is rotatably arranged in the outer cylinder; the opening of the front end of the inner cylinder is provided with a sealable door body; the negative pressure device is communicated with the interior of the inner cylinder to form the negative pressure in the inner cylinder; and the heating device is arranged between the outer cylinder and the inner cylinder to supply heat to the inner cylinder. The opening of the front end of the outer cylinder is provided with an outer cylinder door body; a protective ring is arranged at the periphery of a passage between the opening of the front end of the inner cylinder and the opening of the front end of the outer cylinder; and the negative pressure device is communicated with the inner cylinder through a hollow rotating shaft on the back end of the inner cylinder. The negative pressure type heat pump clothes dryer accelerates the clothes drying speed and reduces energy consumption.

Owner:HAIER GRP CORP +2

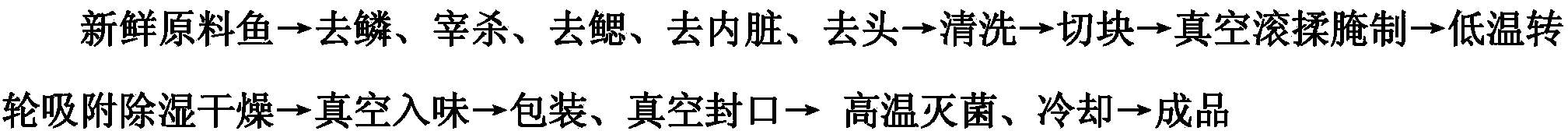

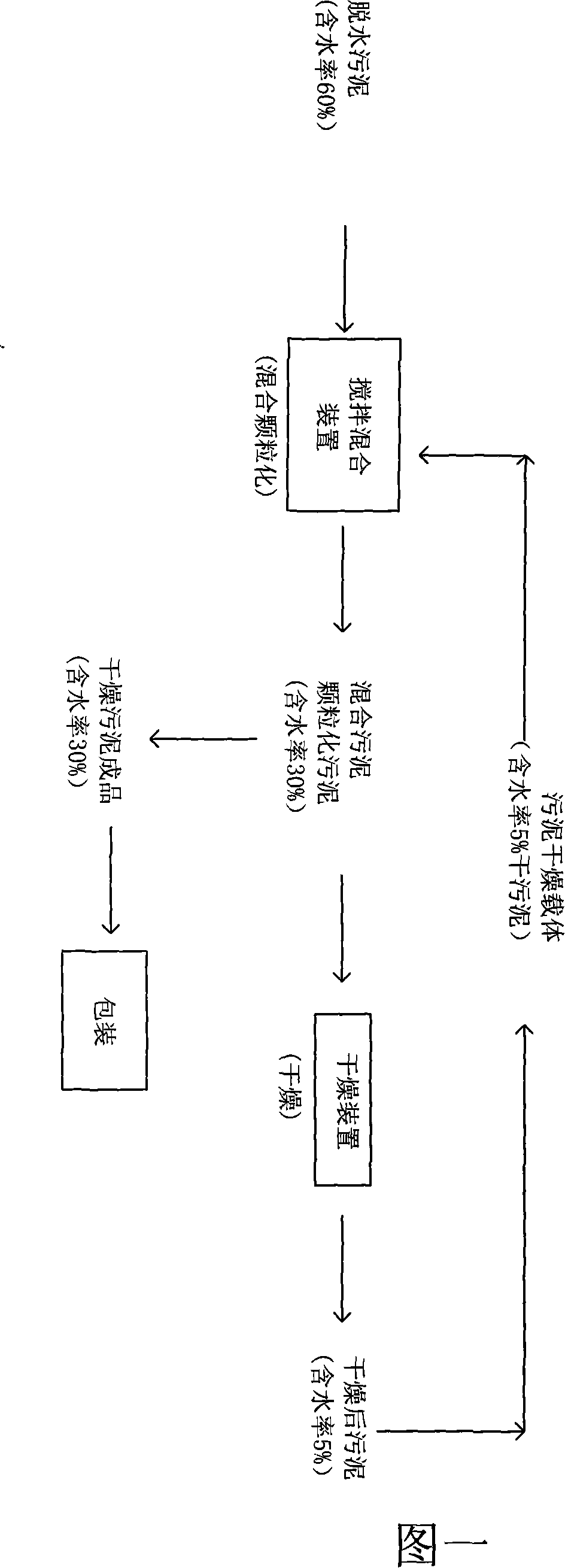

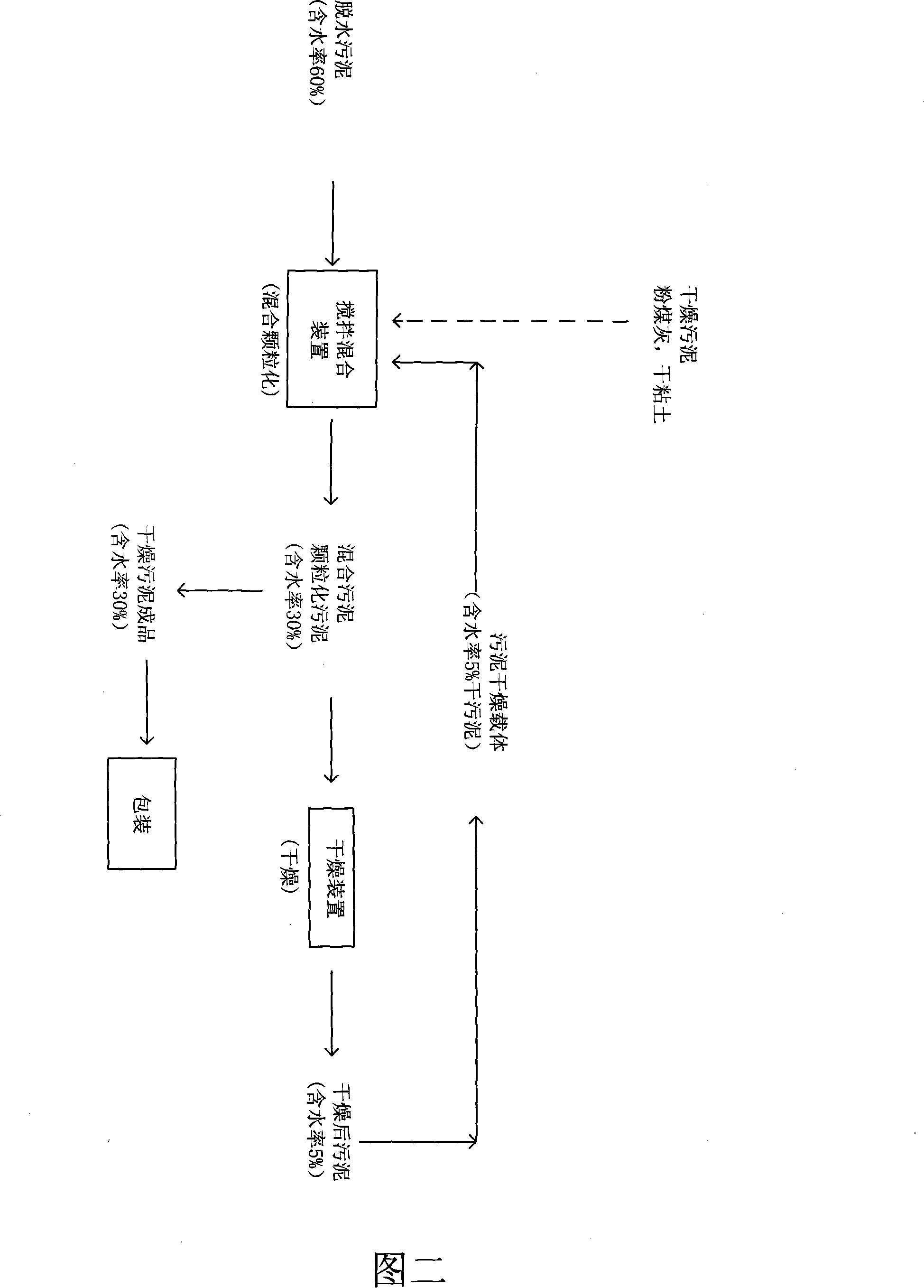

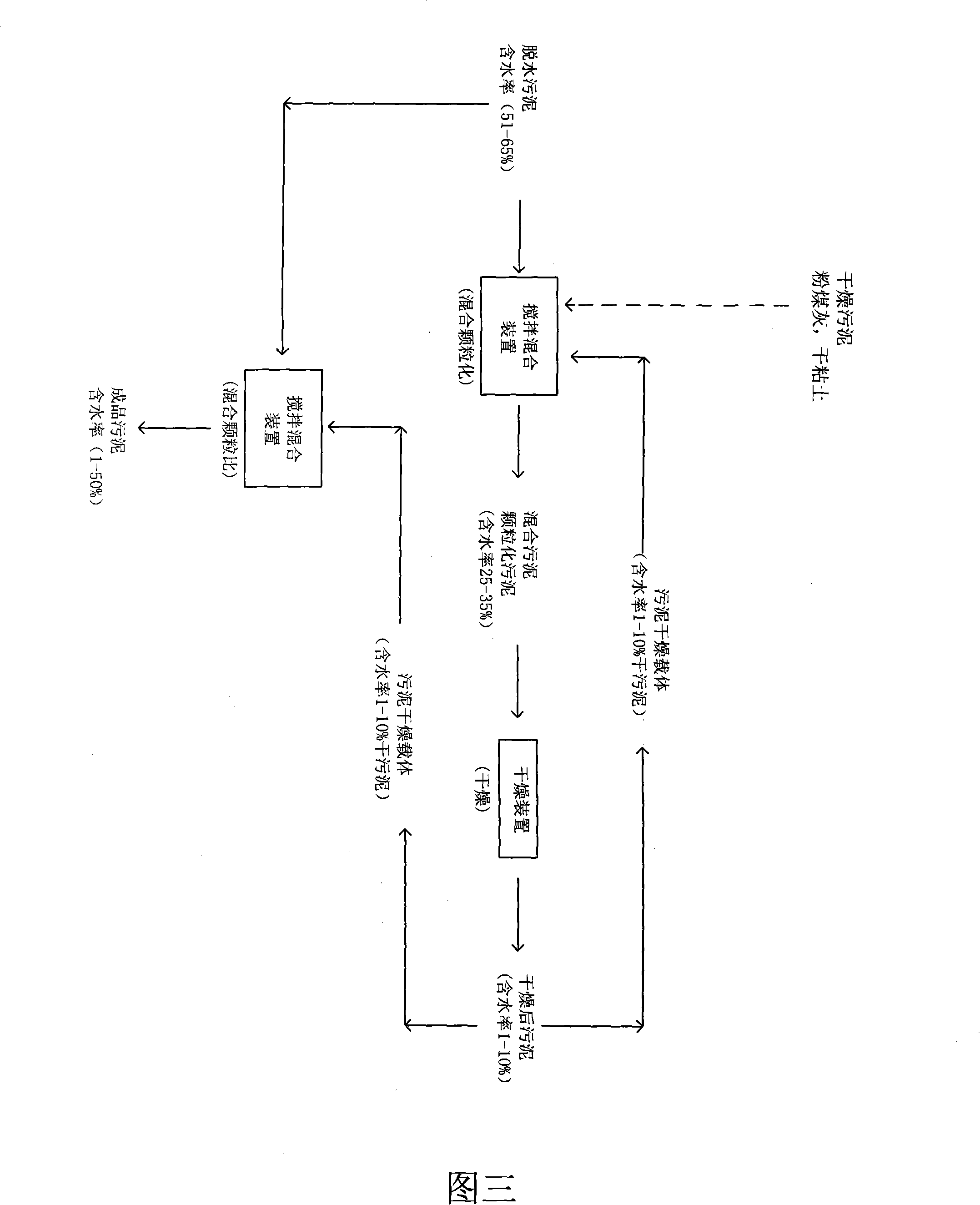

Ready-to-eat special flavor fish product subjected to cold smoking, and production process thereof

The invention belongs to the field of processing of aquatic products, and particularly relates to a ready-to-eat special flavor fish product subjected to cold smoking, and a production process thereof. The production process of the special flavor fish product comprises the following steps: using freshwater fish, a composite curing agent and a compound seasoning as raw materials, cutting the freshwater fish into square blocks after scaling, killing, gill removing, gutting removing, head removing and washing, then performing vacuum rolling and curing on the blocks, using a runner to absorb moisture of the blocks to realize drying at a low temperature, performing vacuum rolling for seasoning, and performing high-temperature sterilization and other processes to obtain the ready-to-eat special flavor fish product subjected to cold smoking. According to the invention, the curing process combines the curing agent with the vacuum rolling and curing, the drying manner that the runner is used to absorb moisture to realize drying at the low temperature is combined with a way that a surface air cooler is used to cool, and the compound seasoning is combined with the vacuum rolling technology, so that not only can the curing agent, the compound seasoning and a fish body be uniformly fixed, but also the curing time, the seasoning time and the drying time are remarkably reduced, the production cost is reduced, the fish tissue is promoted to be tighter, the texture and the taste are improved, the oxidation of highly unsaturated fatty acids in the fish body can be avoided, benzopyrene can not be produced, and the quality and safety of the product can be remarkably improved.

Owner:HUAZHONG AGRI UNIV +1

Color protection and combined drying method of apple chips

InactiveCN101991070AKeep the original color and tasteLess nutrient lossFood preparationSulfurEngineering

The invention relates to a color protection and a combined drying method of apple chips, which comprises the following steps of: peeling, denucleating and slicing apples; immediately placing the sliced apples into sulfur-free color protection liquid; cleaning the apple slices after being subject to the color protection fixing by clean water; paving and placing the apple slices into a disc to be sent into a hot air drying box for being dried; carrying out vacuum low-temperature drying after the hot air drying is completed; and encapsulating the dried and checked apple chips to complete the production of the apple chips. The invention belongs to the combined drying process of the apple chips, which prepares the sulfur-free color protection liquid of the apple chips according to the browning prevention mechanism of the apple chips and the characteristics of the water losing process of the apple slices, and combines the hot air drying with the vacuum low-temperature drying technology. The sulfur-free color protection liquid of the invention effectively prevents the browning of the apple slices and the shrinkage strain in the drying process, greatly reserves the original color and original taste of the apples, and realizes the sulfur-free color protection. The invention combines the hot air drying and the vacuum low-temperature drying, reduces the drying energy consumption and improves the drying efficiency, the produced apple chips have low nutrient loss, and the invention has the advantages of health and environment protection.

Owner:SHAANXI UNIV OF SCI & TECH

Method for drying sludge

ActiveCN101224912AReduce energy consumptionImprove mass transfer efficiencySludge treatment by de-watering/drying/thickeningWater/sewage treatmentDrying timeDewatered sludge

The invention discloses a sludge drying method for treating sludge with different water content, which includes the following steps: (1) dry the dewatered sludge to be used as a dry support of the sludge; (2) transfer the dry support of the sludge and the dewatered sludge to be dried to a stirring and mixing device respectively for carrying out stirring and mixing to obtain mixed sludge; (3) transfer the mixed sludge to a drying device to be dried; (4) repeat step (2) and step (3); the invention is characterized in that the mixed sludge output from the stirring and mixing device in step (4) is taken out and transferred to the drying device to be dried according to the needed amount of sludge carrier when drying is carried out and becomes the dry support of the sludge; the residual part becomes the finished product. The invention provides a sludge drying method that is high in drying efficiency, low in energy consumption, short in drying time and low in investment and operation cost.

Owner:SWISON CREATIVE ENVIRONMENTAL SOLUTIONS CO LTD

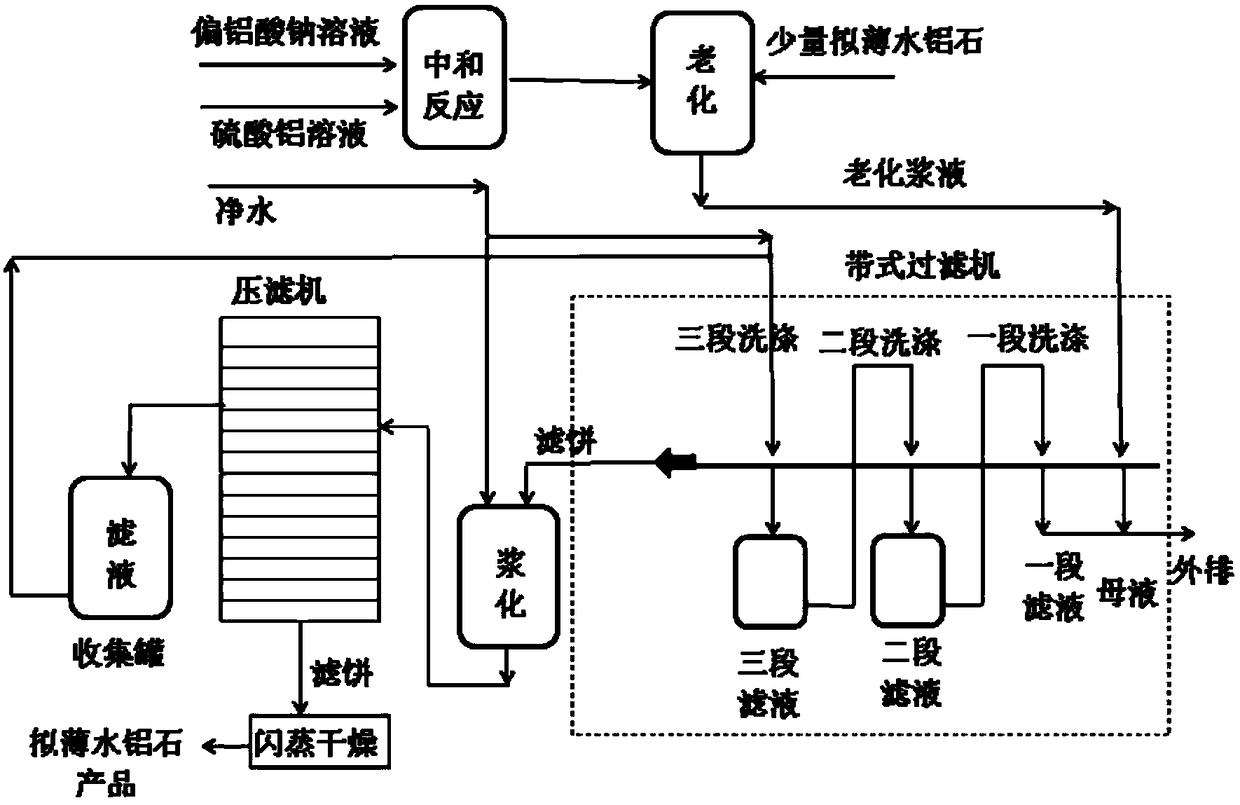

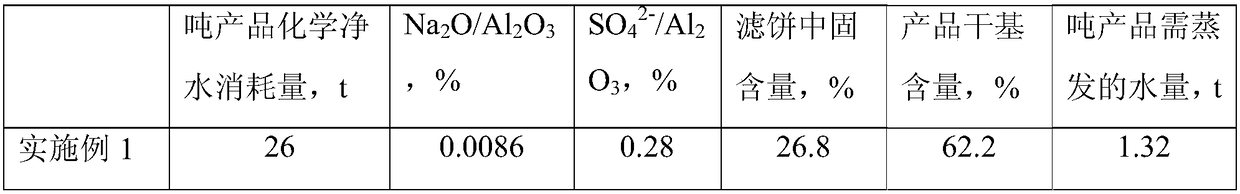

Preparation method of pseudoboehmite

ActiveCN108910925AGood water permeabilityReduce dosageAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPseudoboehmiteEvaporation

The invention discloses a preparation method of pseudoboehmite. The whole process consists of neutralization, aging, washing and drying steps. The process is characterized in that: 0.5%-5% of dried pseudoboehmite is added at the end of aging, the washing process adopts a continuous belt filter and intermittent filter press two-stage combination process, the washing water amount is 10-30 times thatof the pseudoboehmite product, the solid content of a pseudoboehmite filter cake is in the range of 26.0%-35.0%, the washing water amount is reduced by 50% or more, the amount of water needing evaporation for unit product is reduced by 40% or more, and the energy consumption for drying is reduced by 40% or more. The process saves the washing water amount, reduces the energy consumption for dryingand makes the product quality more stable.

Owner:ZIBO QIMAO CATALYST

Method for preparing powdery Alpha-olefin sulfonate and preparation device

ActiveCN103012220ALower starting moisture contentReduce consumptionOrganic compound preparationSulfonic acids salts preparationSulfonatePulp and paper industry

The invention relates to a method for preparing powdery Alpha-olefin sulfonate and a preparation device and aims to achieve the purposes that the energy consumption is low, the device is compact in structure, the investment can be saved, and the operation is stable. The technical scheme is as follows: the method for preparing the powdery Alpha-olefin sulfonate comprises the following steps: 1), stirring, mixing and heating; and introducing dry air; 2), performing atomization; 3), performing primary separation, so that a powdery material enters a power bin; and 4), performing secondary separation, so that the powdery material enters the power bin, the secondary mixed gas flow is evacuated through an induced draft fan; and the heated dry air comes from evacuated tail gas of an air drying system or a nearby sulphuric acid plant. The device for preparing the powdery AOS (Alpha-olefin sulfonate) comprises a feeding device, a spray drying tower, a cyclone separation device and a de-dusting device and is characterized in that a feeding port and a dry air inlet are arranged at the top end of the spray drying tower, a mixed gas flow outlet is arranged on one side of the spray drying tower, and a washing outlet is arranged at the bottom of the spray drying tower.

Owner:JIAXING ZANYU TECH DEV CO LTD +1

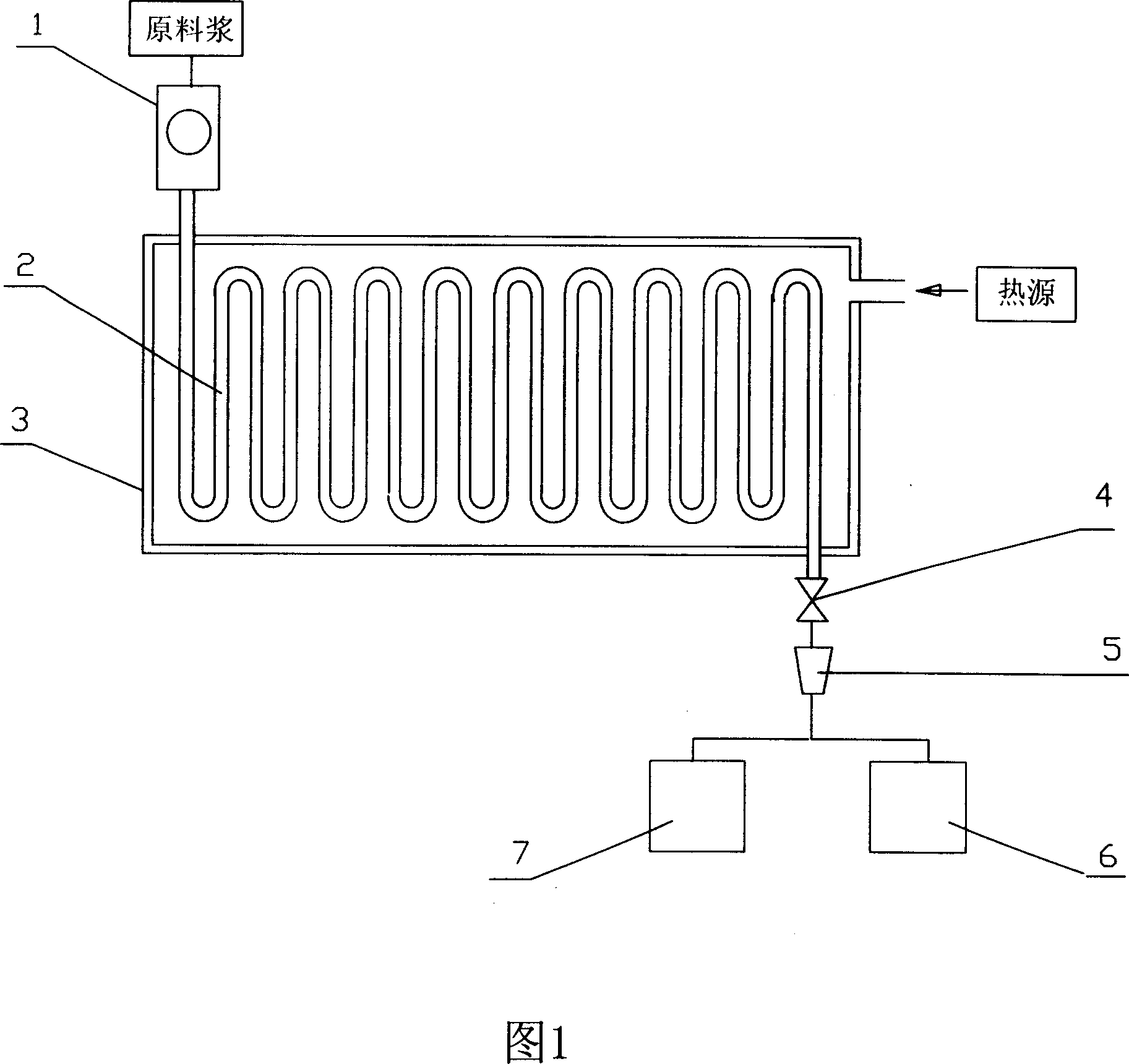

Continuous production method and apparatus for alpha semi-water gypsum

The invention discloses an alpha-semi-hydrated gypsum continuous producing method and device. And the traditional 'liquid phase process' has disadvantages of high equipment investment, wide occupied land, complex to operate and high labor strenghth. But the invention changes the traditional reaction kettle into a reaction pipe with a certain length, which is coilded in a heating box, one end of the reaction pipe connected with raw material pulp high pressure pump and the other end connected with a drying separation tower or gypsum blend-mouding device, thus implemnting continuous production of alpha-semi-hydrated gypsum. Therefore, the invention has advantages of saving reaction equipment investment and reducing production energy consumption.

Owner:SHANXI BEIFANG GYPSUM IND

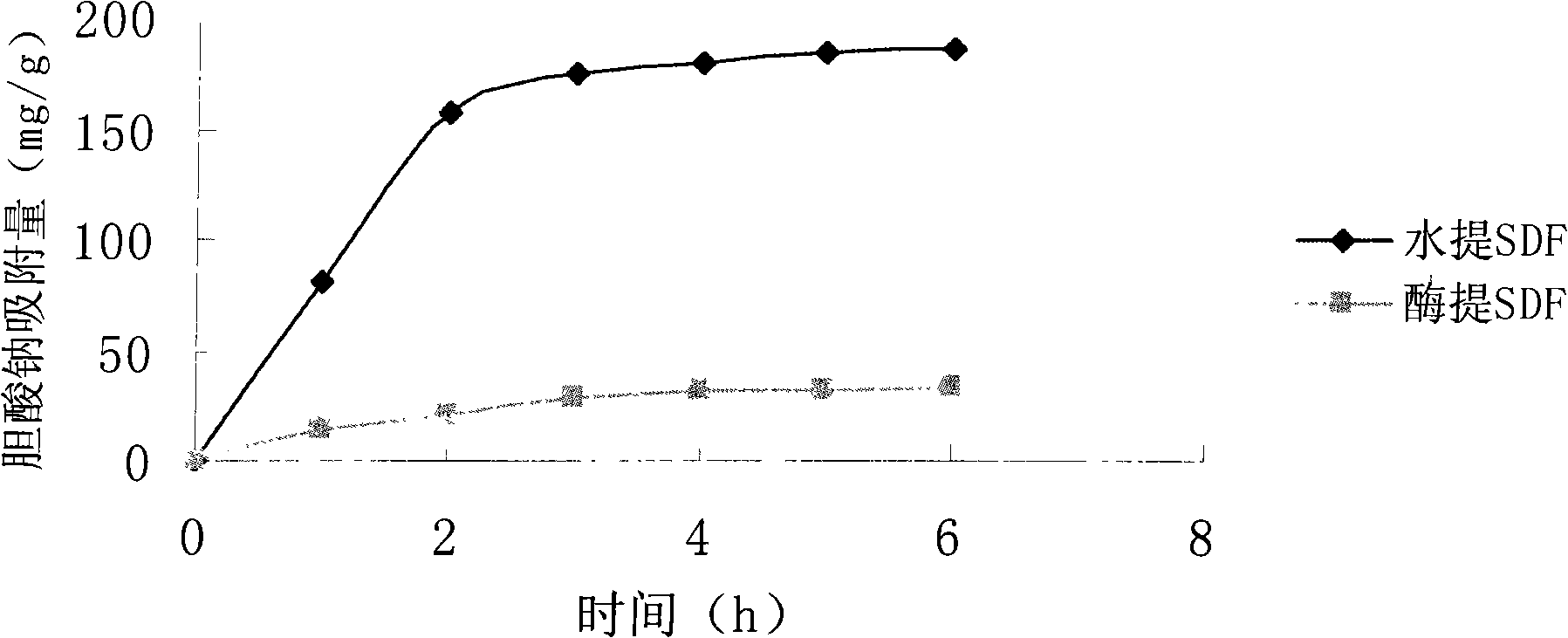

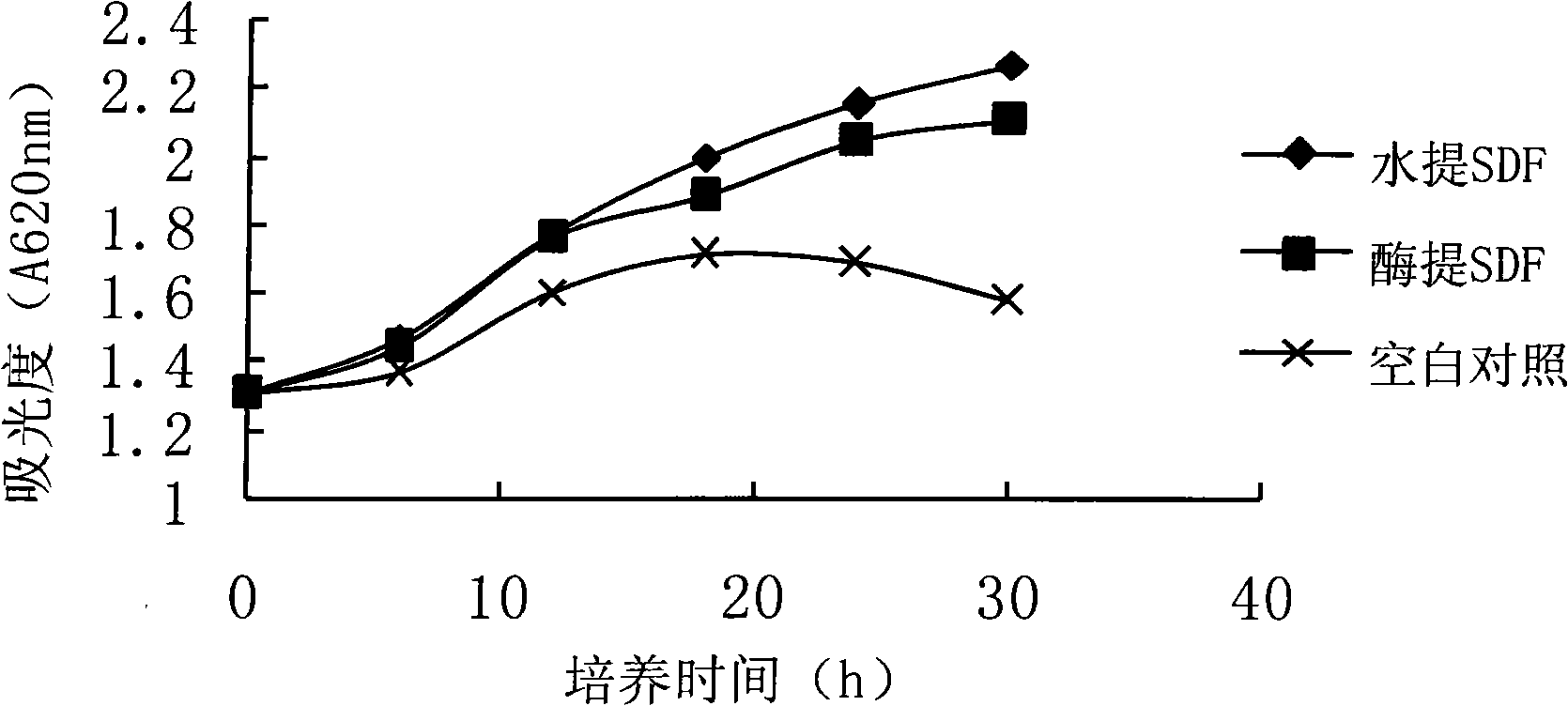

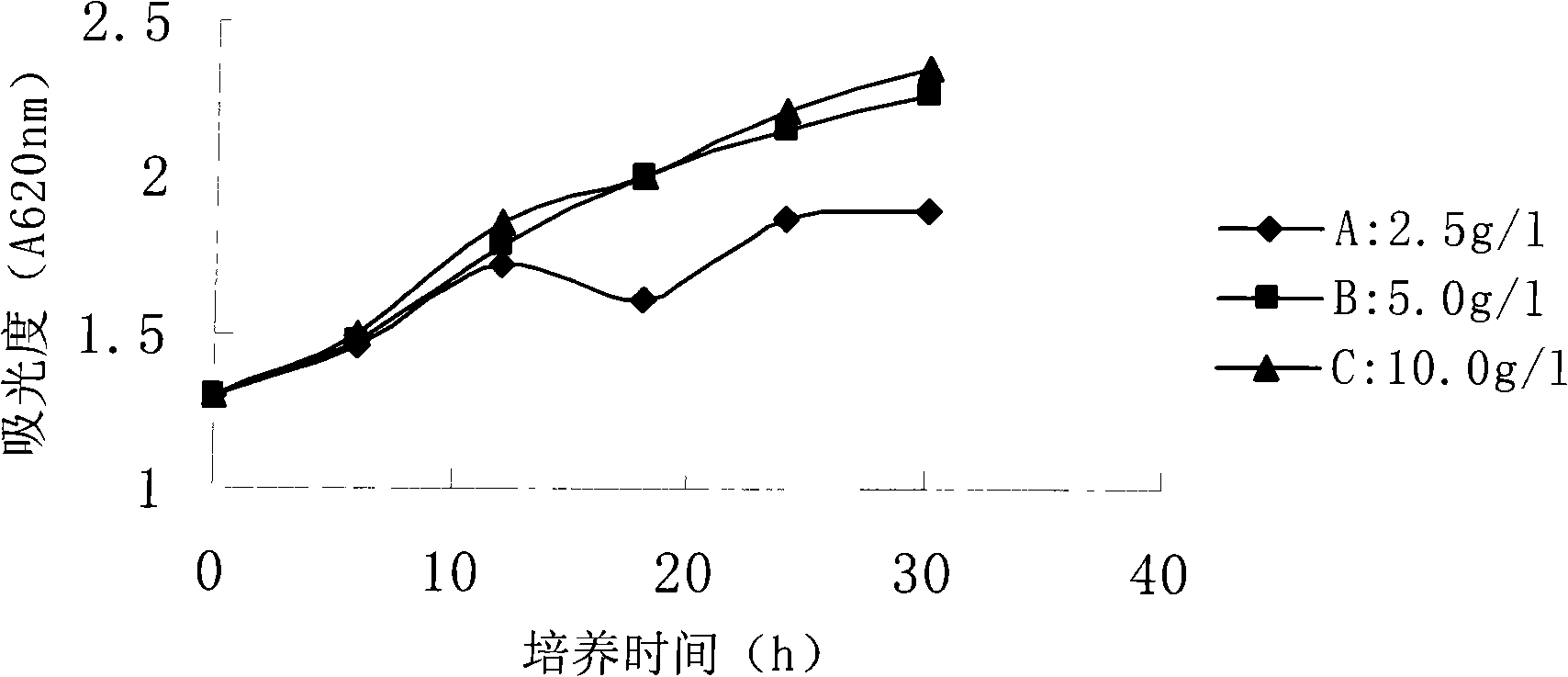

A method for extracting and preparing meal fibre from the peach dregs

InactiveCN101283760AReduce drying energy consumptionShorten the preparation processFood preparationStrong acidsFilter cake

The invention discloses a method for extracting dietary fibers from peach residue. The method comprises the following steps: (1) impurity removal and sterilization: dispersing peach residue iin water, removing crushed peach stones and sterilizing; (2) lixiviation under heat insulation; (3) solid-liquid separation to obtain filtrate and filter cake; (4) concentration and ethanol precipitation of filtrate and drying of precipitates, to obtain soluble dietary fibers; and (5) mixing filter cake and warter, adjusting pH to 4-5, digesting with compound enzymes at 40-50 DEG C for 10-20 hours, filtering, collecting filtrate and filter cake after enzymolysis, concentrating filtrate after enzymolysis, precipitating with ethanol, drying the precipitates to obtain soluble dietary fibers, drying the filter cake after enzymolysis to obtain insoluble dietary fibers. The invention increases the yield of soluble dietary fibers, reduces the energy consumption, production cycle and production cost, simplifies the operation, doesn't need strict working conditions such as high temperature and pressure and strong acid and base, has no strict requirement for equipment, and is environment-friendly.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

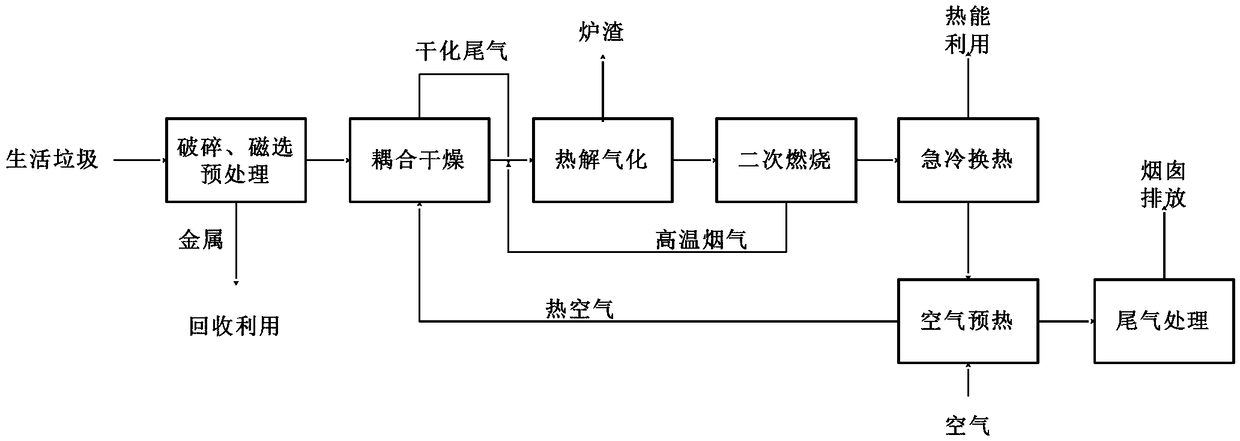

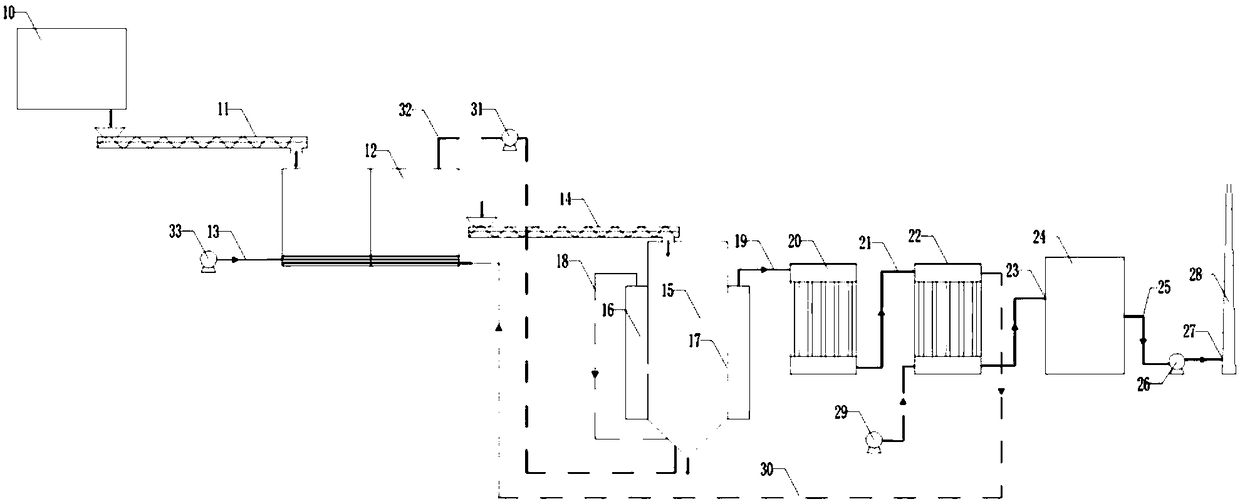

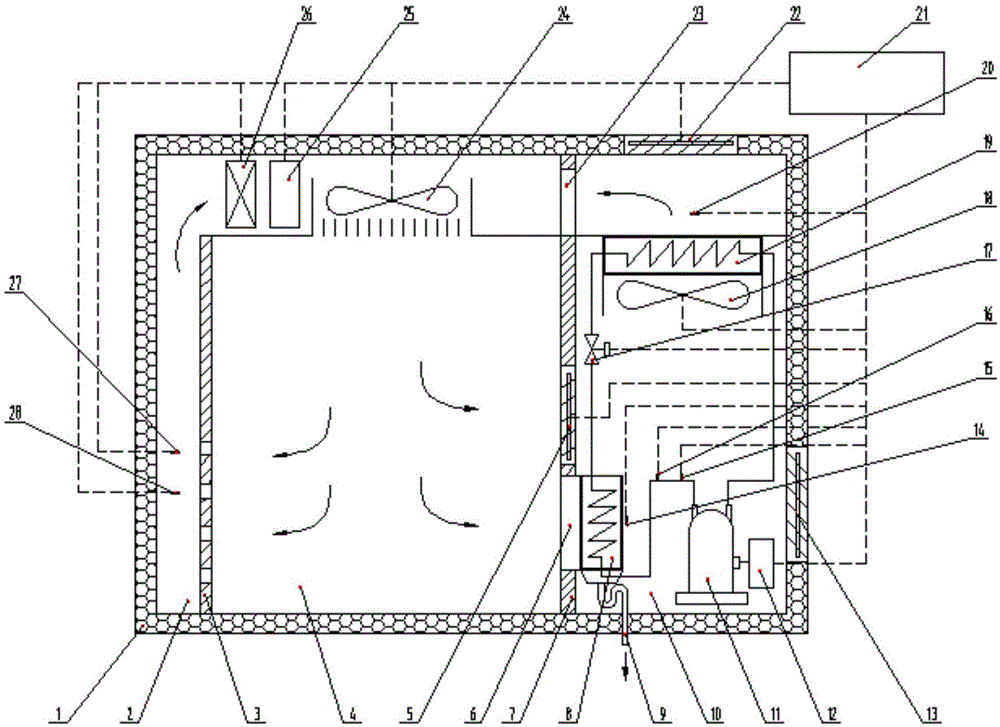

Treatment process and system for coupling, drying and pyrolyzing household garbage

InactiveCN109185887AControl moisture contentImprove pyrolysis efficiencyIncinerator apparatusCombined combustion mitigationAir preheaterCombustion chamber

The invention discloses a treatment process and system for coupling, drying and pyrolyzing household garbage. The treatment process includes the steps that (1) the household garbage is subjected to crushing and magnetic separation pretreatment; (2) the household garbage is subjected to biothermal air coupling and drying treatment; (3) the household garbage is subjected to pyrolysis gasification through a pyrolysis gasification furnace; (4) pyrolysis produces combustible gas into a secondary combustion chamber for secondary combustion; (5) secondary combustion produces high temperature flue gasto pass through a quenching heat exchanger; (6) after the heat exchange, the flue gas is exchanged with the air through an air preheater; and (7) the flue gas is finally discharged through an exhaustgas treatment system. The treatment system includes a crushing magnetic separation device, a biothermal air coupling and drying treatment device, the pyrolysis gasification furnace, the secondary combustion chamber, the quenching heat exchanger, the air preheater, the exhaust gas treatment system, and a chimney. The system has the advantages of high pyrolysis treatment efficiency of the householdgarbage, high stability of garbage pyrolysis and gasification, high controllability of the process, and low difficulty in treatment of exhaust gas, and can be widely applied to the technical field ofhousehold garbage pyrolysis treatment.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Drying wardrobe for ship

InactiveCN103603175AReduce drying energy consumptionImprove working environmentTextiles and paperLaundry driersOzone generatorEngineering

The invention discloses a drying wardrobe for a ship. A wardrobe body is fixed on a ship body and is internally divided into a clothes hanging chamber and a cabin, a convection fan is installed at the top of the clothes hanging chamber, and a heater and an ozone generator are installed in an induced draft channel of the convection fan. A compressor, a frequency converter, an evaporator, an electronic expansion valve, a drain pipe, a circulating fan and a condenser are installed in the cabin, an air inlet door is installed on an opening on the outer side of the lower portion of the cabin, and an air outlet door is installed on an opening on the upper portion of the cabin. A controller collects signals of humid wind temperature, air suction pressure, air suction temperature, hot air temperature, the temperature of the clothes hanging chamber and humidity and the like to be used for controlling a circulating air door, the frequency converter, the air inlet door, the electronic expansion valve, the circulating fan, the air outlet door, the convection fan, the ozone generator and the heater to work. The drying wardrobe is low in clothes drying energy consumption, clothes are clean and do not deform, hot and humidity gas is not discharging into the cabin in the drying process, automatic preheating can be performed when the ship sails in a cold region, normal starting is guaranteed, forced heat removal can be performed when the ship sails in a hot region, and the drying wardrobe can work normally.

Owner:JIANGSU UNIV OF SCI & TECH

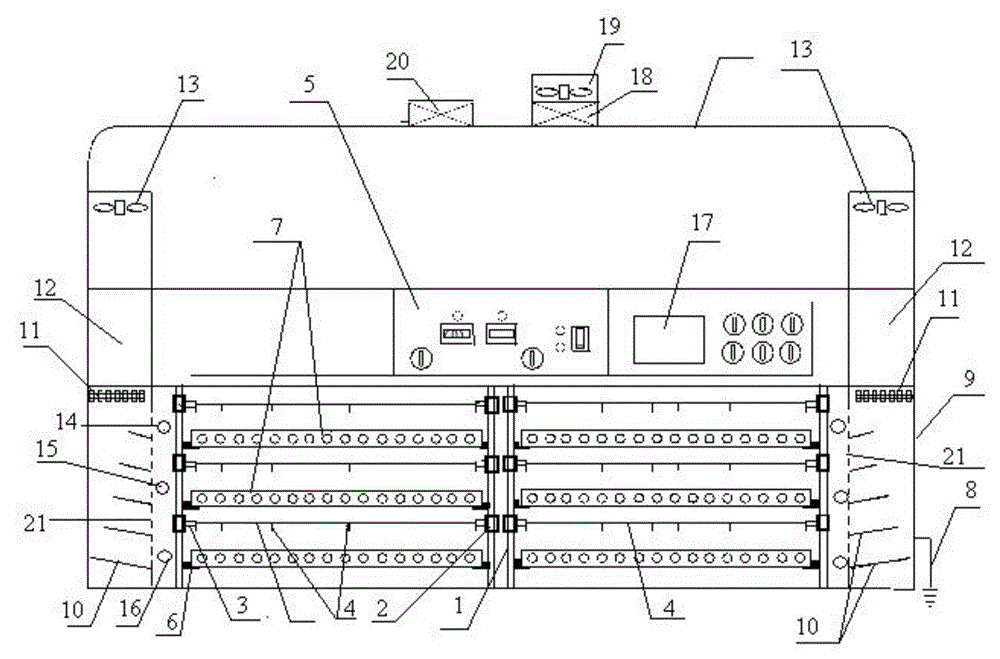

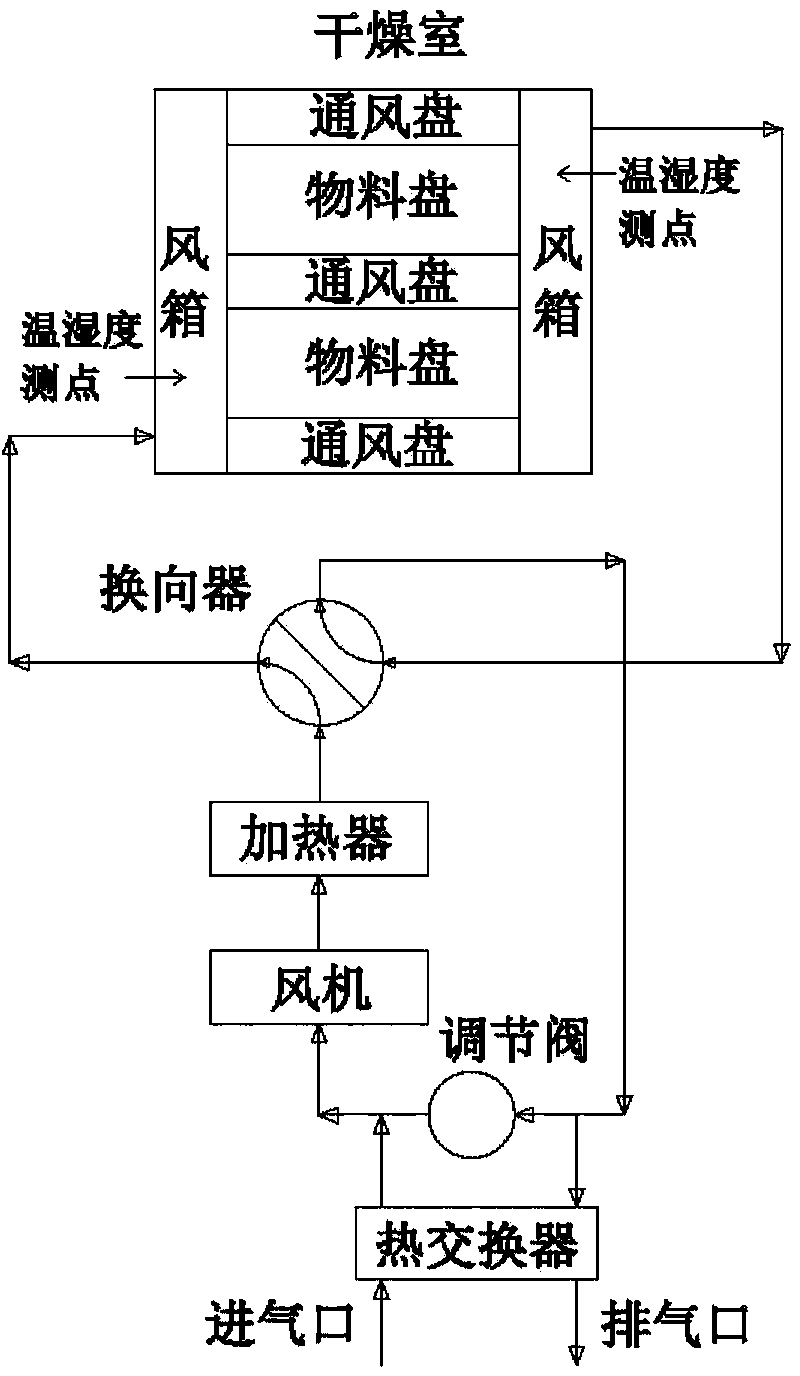

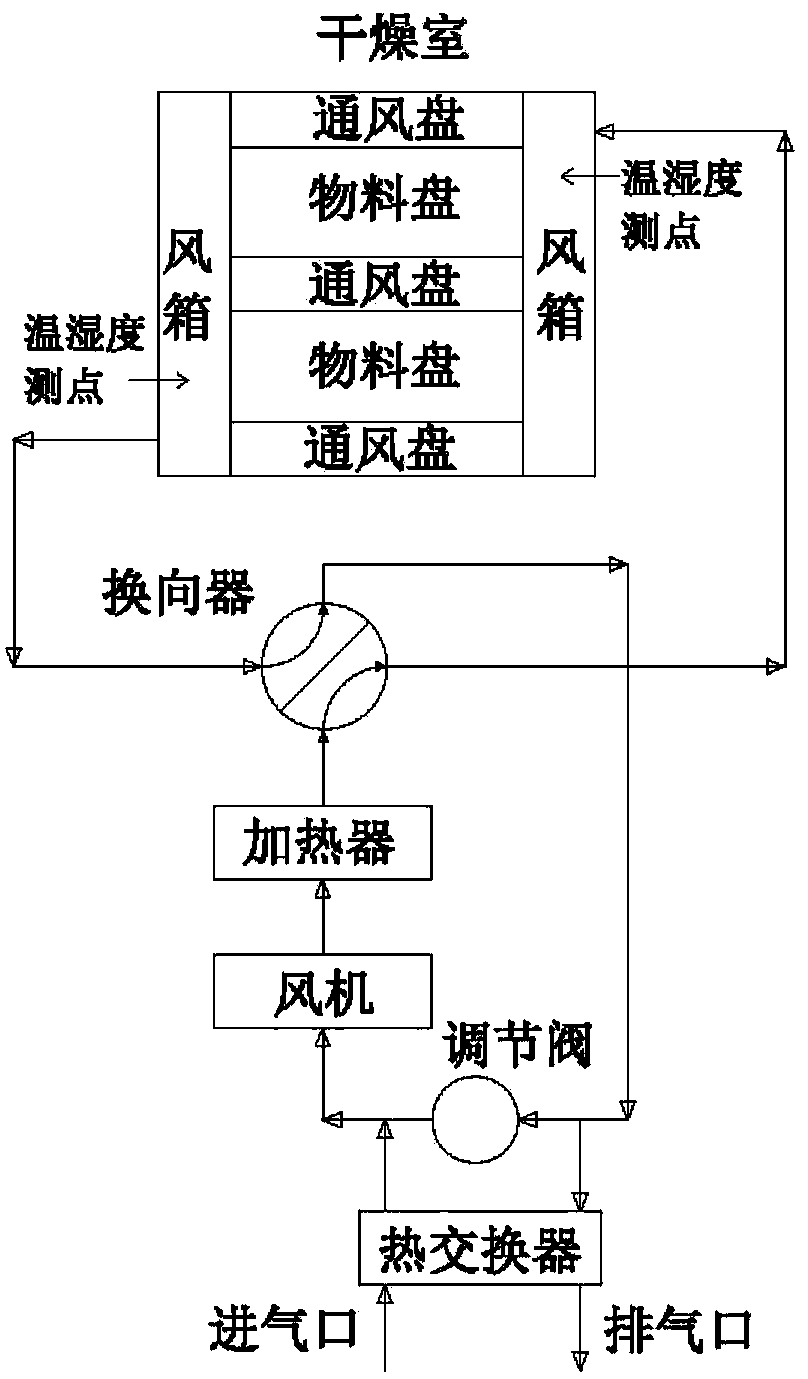

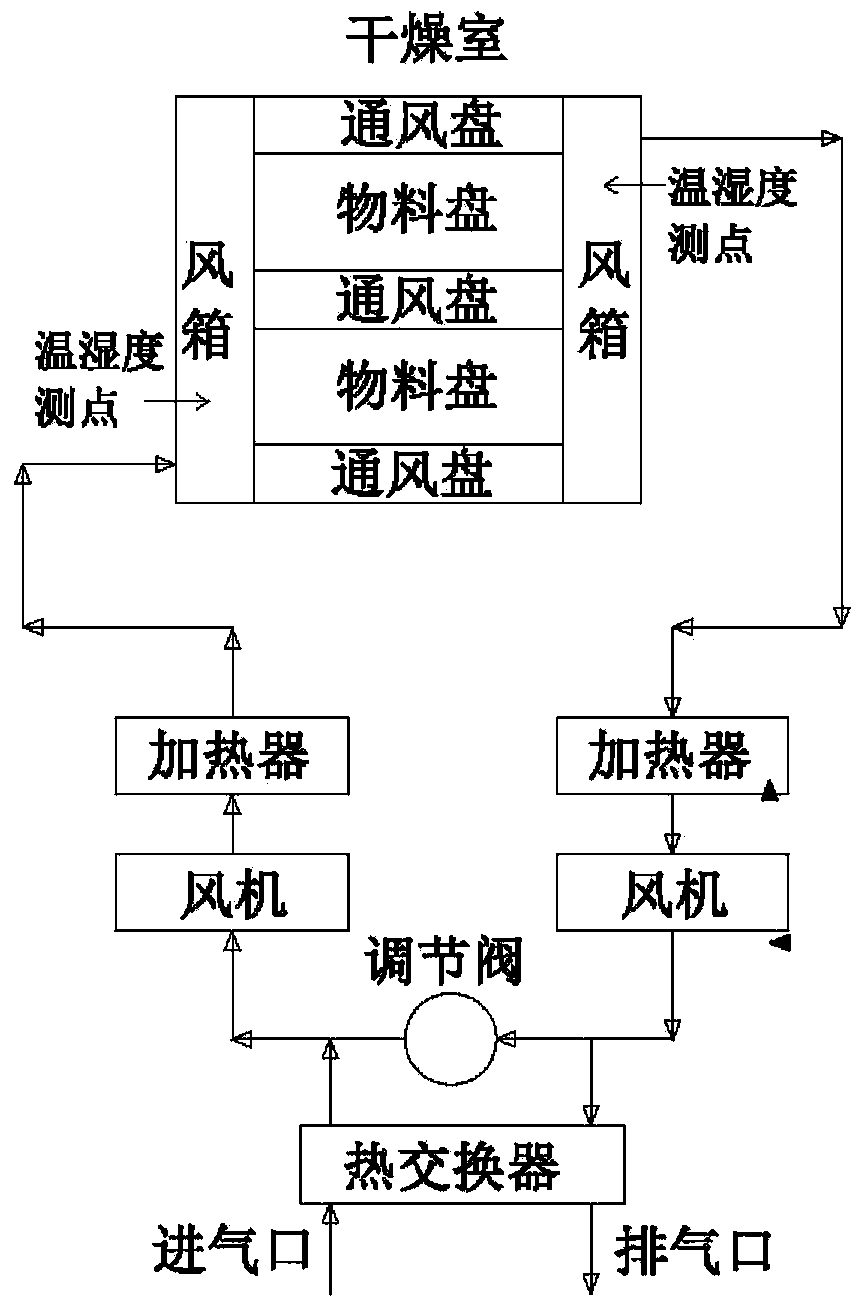

System and method for drying thick-layer traditional Chinese medicine by aid of variable-temperature alternate airflow

ActiveCN104180635AIncrease productionReduce energy consumptionDrying gas arrangementsDrying solid materialsTemperature controlEngineering

The invention provides a system and a method for drying thick-layer traditional Chinese medicine by the aid of variable-temperature alternate airflow, and relates to the technical field of traditional Chinese medicine drying and storing. The system for drying the thick-layer traditional Chinese medicine by the aid of the variable-temperature alternate airflow comprises a drying chamber, an air supply system and a temperature and humidity detecting system. A left air supply hole and a right air supply hole are respectively formed in the left side and the right side of the drying chamber, and the drying chamber further comprises a left air box, a right air box, a ventilating disc and a material disc; the air supply system comprises an air supply fan, a heater, a temperature control module and an air supply control module. The method for drying the thick-layer traditional Chinese medicine by the aid of the variable-temperature alternate airflow includes forwardly drying the thick-layer traditional Chinese medicine at moderate temperatures; reversely drying the thick-layer traditional Chinese medicine at moderate temperatures; forwardly drying the thick-layer traditional Chinese medicine at high temperatures; reversely drying the thick-layer traditional Chinese medicine at high temperatures, and repeatedly carrying out high-temperature forward drying and high-temperature reverse drying procedures until moisture contents of traditional Chinese medicine materials reach preset moisture contents. The system and the method have the advantage that problems of poor traditional Chinese medicine drying effect and low traditional Chinese medicine drying efficiency at present can be solved by the aid of the system and the method.

Owner:汉广中药科技(天津)有限公司

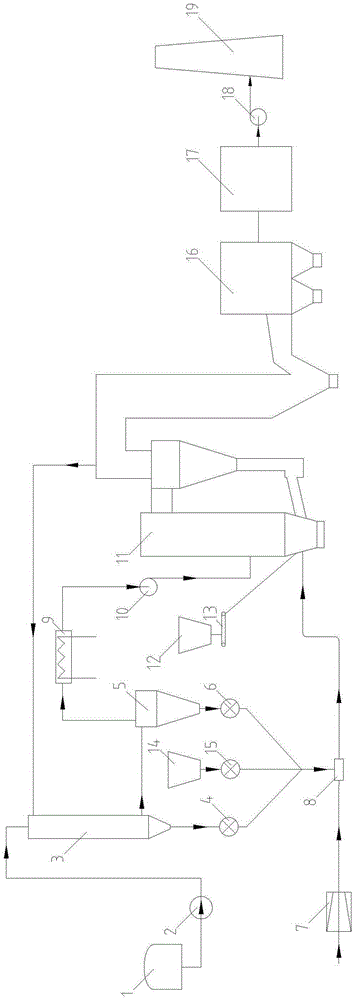

Coal-sludge co-combustion system based on high-temperature smoke drying and pneumatic conveying

ActiveCN105276603AIncrease speedEasy to handleSludge treatment by de-watering/drying/thickeningDispersed particle separationSludgeRotary feeder

The invention relates to a coal-sludge co-combustion system based on high-temperature smoke drying and pneumatic conveying. A sludge storage bin is connected with a spray drying pipe through a screw pump. An air inlet of the spray drying pipe is connected with a cyclone separator outlet flue of a circulating fluidized bed boiler. A first outlet of the spray drying pipe is connected with a first rotary feeder, and a second outlet of the spray drying pipe is connected with a cyclone separator. An exhaust opening of the cyclone separator is connected with the circulating fluidized bed boiler through a cooling condenser and an exhaust gas fan, and a discharging opening of the cyclone separator is connected with a second rotary feeder. A limestone bin is connected with a third rotary feeder. An outlet of the first rotary feeder, an outlet of the second rotary feeder and an outlet of the third rotary feeder are connected with a feeding opening of a jet feeding device, an air inlet of the jet feeding device is connected with a Roots fan, and an outlet of the jet feeding device is connected with the circulating fluidized bed boiler. The functions of sludge drying and conveying, dry tail gas waste heat utilization, sludge and coal co-combustion, pollutant control and the like can be achieved, bad smell and dust diffusion can be avoided, and the coal-sludge co-combustion system has the beneficial effects of being simple, environment-friendly and efficient.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com