Method for drying sludge

A technology of sludge drying and sludge, which is applied in the direction of sludge drying, preliminary treatment of promoting the drying of solid materials, drying of solid materials, etc., can solve problems such as large sites, and achieve energy saving, water reduction, and The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

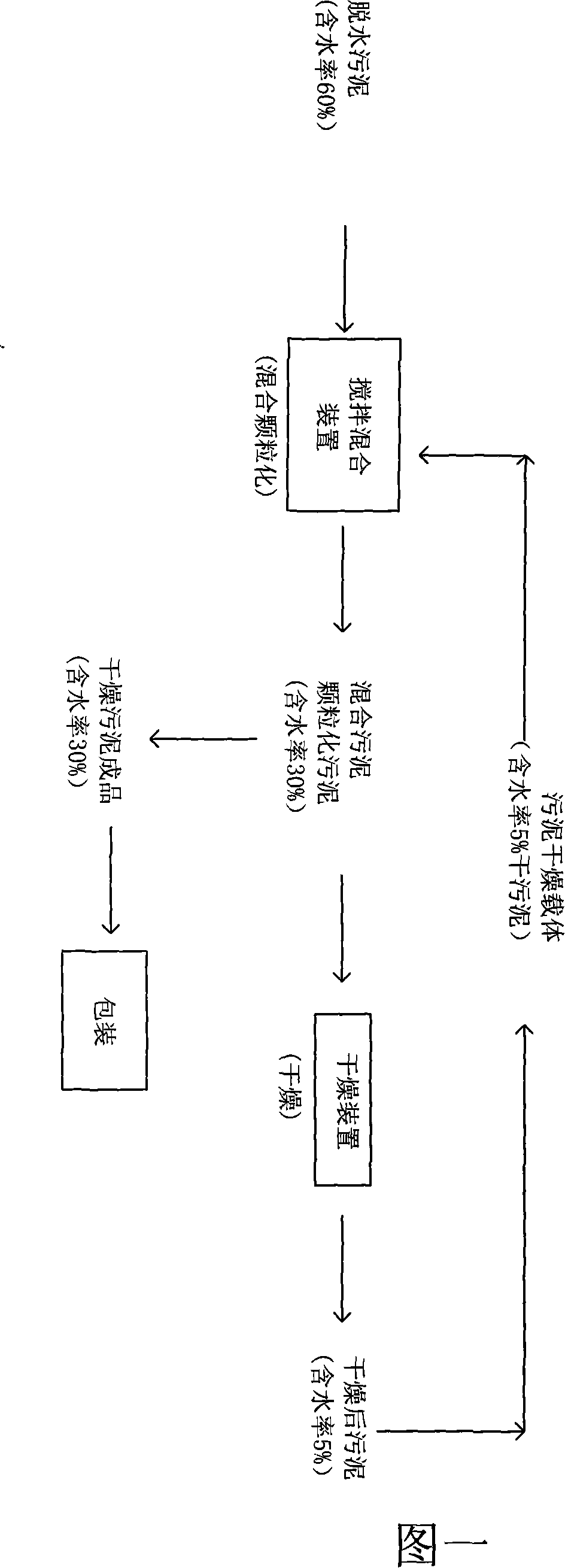

Embodiment 1

[0056] The sludge filter cake unloaded from the plate-and-frame filter press (sludge after press filter dehydration), with a water content of 65%, is transported to the stirring and mixing device by a screw conveyor, and is transported from the dry material bin to the stirring and mixing device. Dry sludge with a moisture content of 1.8% was mixed. The conveying speed of dry sludge is 14kg / min, the dry-wet ratio is set to 1.15:1, the conveying speed of wet (after dehydration) sludge is 12kg / min, and the water content of the mixed sludge discharged from the mixing device after mixing is 31%. . Part of the mixed sludge is used as a carrier for sludge drying to continue drying; the other part is used as a finished product package after drying, and the moisture content of the finished sludge after drying is 31%.

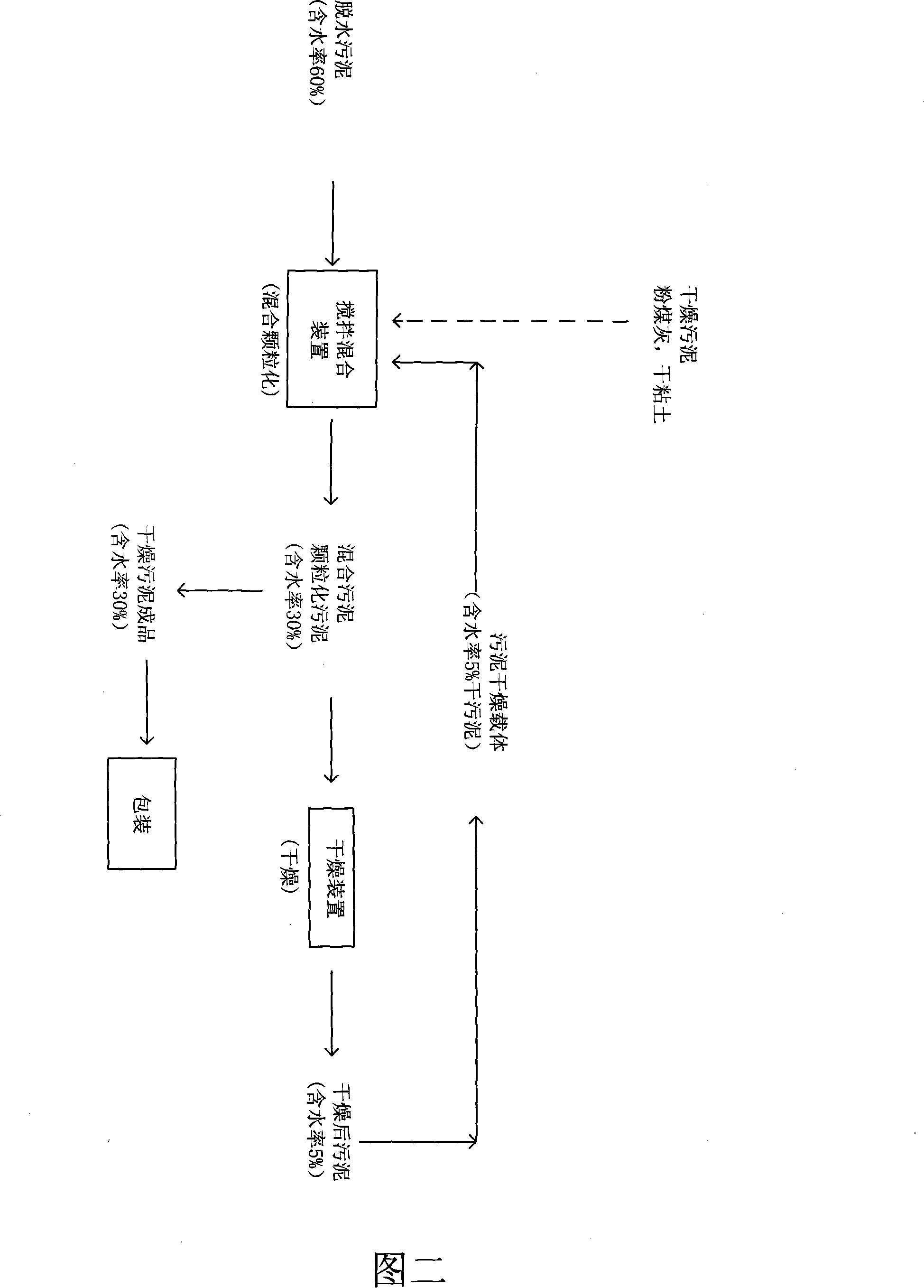

Embodiment 2

[0058] The sludge filter cake unloaded from the plate-and-frame filter press (sludge after press filter dehydration), with a moisture content of 51%, is transported to the mixing device by a screw conveyor, and is transported from the dry material bin to the mixing device. The dried sludge with a moisture content of 2.1% was mixed. The conveying speed of the dry sludge is 14kg / min, the dry-wet ratio is set to 0.8:1, the conveying speed of the wet sludge is about 17.5kg / min, and the moisture content of the mixed sludge discharged from the stirring and mixing device is 29%. Part of the mixed sludge is used as a carrier for sludge drying to continue drying; the other part is used as a finished product package after drying, and the moisture content of the finished sludge after drying is 29%.

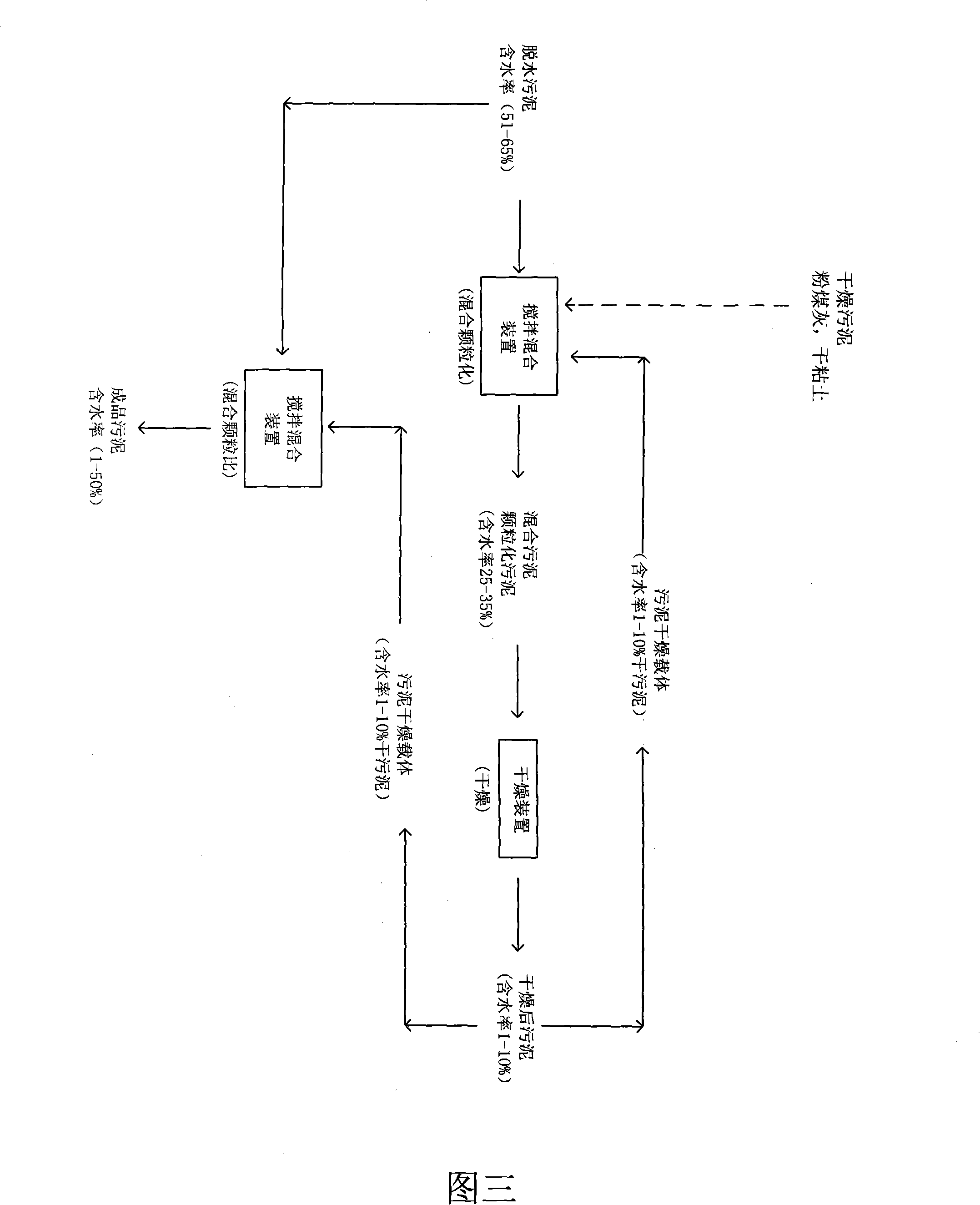

Embodiment 3

[0060] The sludge filter cake unloaded from the plate-and-frame filter press (sludge after press filtration and dehydration), with a moisture content of 58%, is transported to the stirring and mixing device by a screw conveyor, and is transported from the dry material bin to the stirring and mixing device. The dried sludge with a moisture content of 2.5% was mixed. The conveying speed of dry sludge is 12kg / min, the dry-wet ratio is set to 0.9:1, the conveying speed of wet sludge is about 13.3kg / min, and the moisture content of the mixed sludge discharged from the stirring and mixing device is 32%. Part of the mixed sludge is used as a carrier for sludge drying to continue drying; the other part is used as a finished product package after drying, and the moisture content of the finished sludge after drying is 32%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com