Oscillation type drying system used for non-woven fabric production

A drying system, non-woven technology, applied in drying, dryer, progressive dryer and other directions, can solve the problems of low drying efficiency of non-woven fabrics, increased heating time, poor drying effect, etc. To achieve the effect of reducing drying energy consumption, reducing energy consumption, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

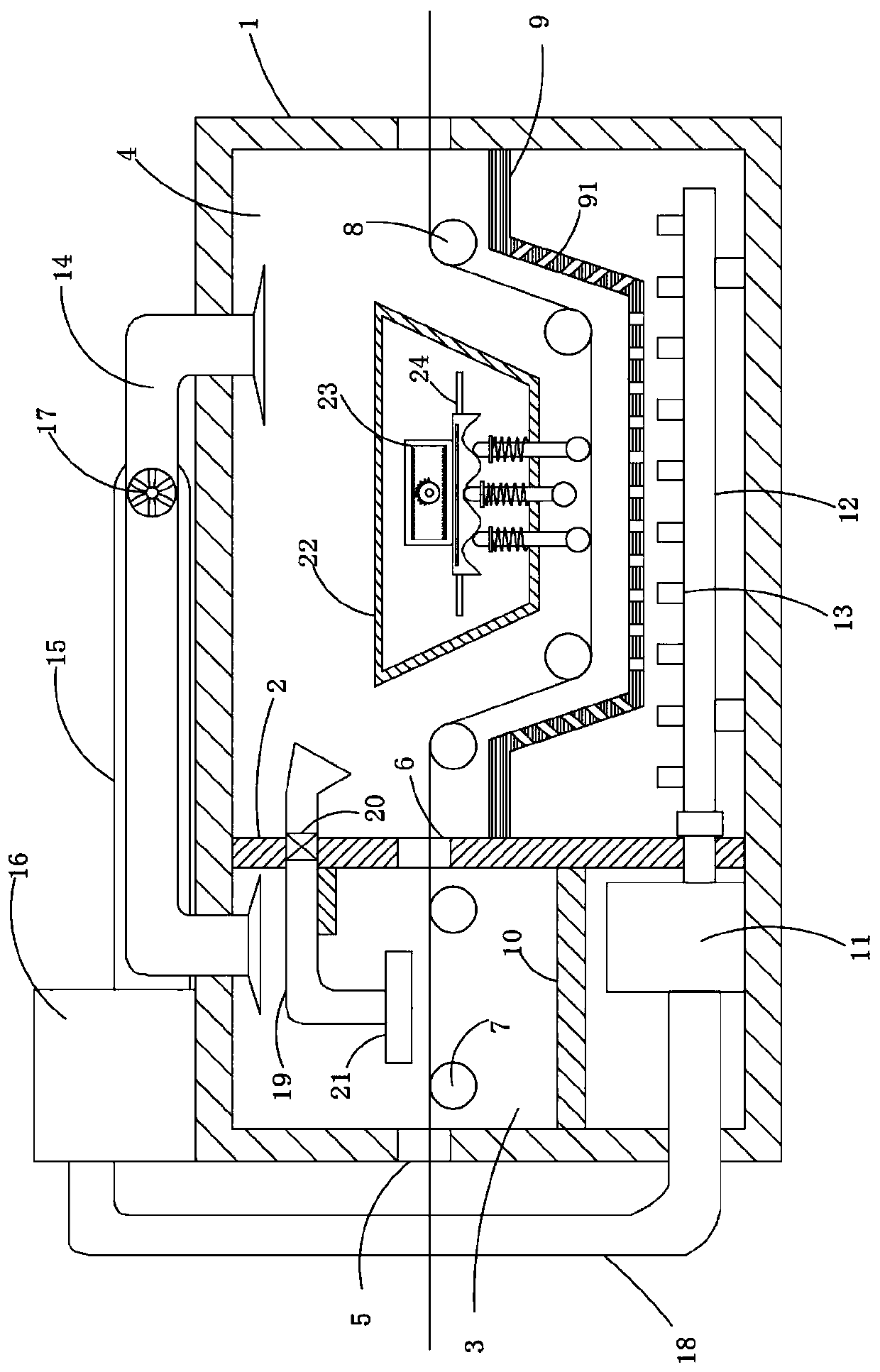

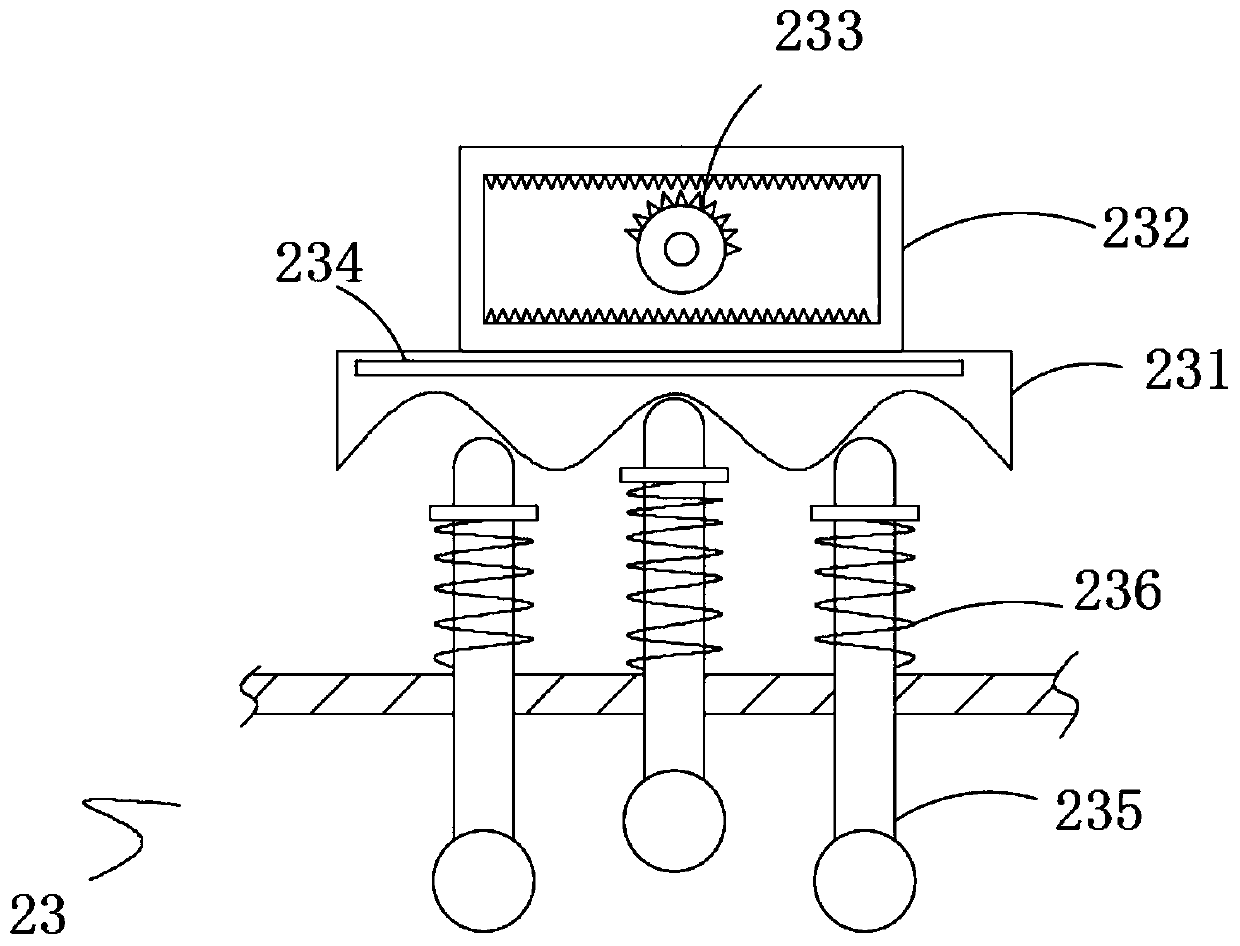

[0031] like Figure 1 to Figure 7 As shown, the present invention provides an oscillating drying system for the production of non-woven fabrics, comprising a box 1, the inner cavity of the box 1 is provided with a vertical partition 2, and the vertical partition 2 divides the inner cavity of the box 1 into The preheating chamber 3 and the drying chamber 4, the middle part of the left and right side walls of the box body 1 are symmetrically provided with an inlet and outlet 5, the middle part of the vertical partition 2 is provided with a communication port 6 corresponding to the inlet and outlet 5, and the first guide roller is arranged in the preheating chamber 3 Group 7, the drying chamber 4 is provided with a second guide roller group 8, the lower part of the drying chamber 2 is provided with a concave plate 9, the second guide roller group 8 is distributed along the concave surface of the concave plate 9, and the lower part of the preheating chamber 3 is provided with a hor...

Embodiment 2

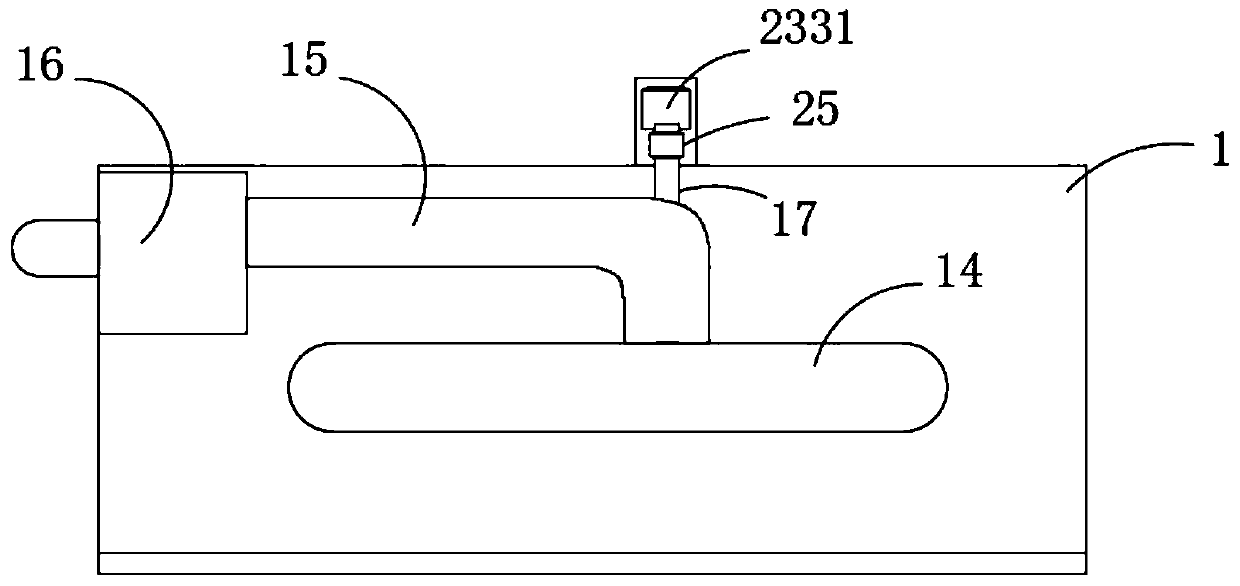

[0041] like Figure 1 to Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is: as Image 6 As shown, the fan blade mechanism 17 includes a rotating rod 171, which is rotatably arranged in the first pipe 15, and the rotating rod 171 is provided with a fan blade 172, which is located inside the first pipe 15, and the inner end of the rotating rod 171 A transmission belt 25 is connected through the first pipeline 15, and the other side of the transmission belt 25 is connected with the output shaft of the driving motor 2331;

[0042] By means of the blade mechanism 17, a negative pressure can be formed to guide the hot air into the hot air circulation pipe, reducing the direct discharge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com