Preparation method of pseudoboehmite

A technique for pseudo-boehmite and water purification, which is applied in the field of pseudo-boehmite preparation, can solve the problems of affecting the washing effect, poor dense water permeability of the filter cake, uneven thickness distribution of the filter cake, etc. The effect of improving the stability of production quality and reducing the energy consumption of drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

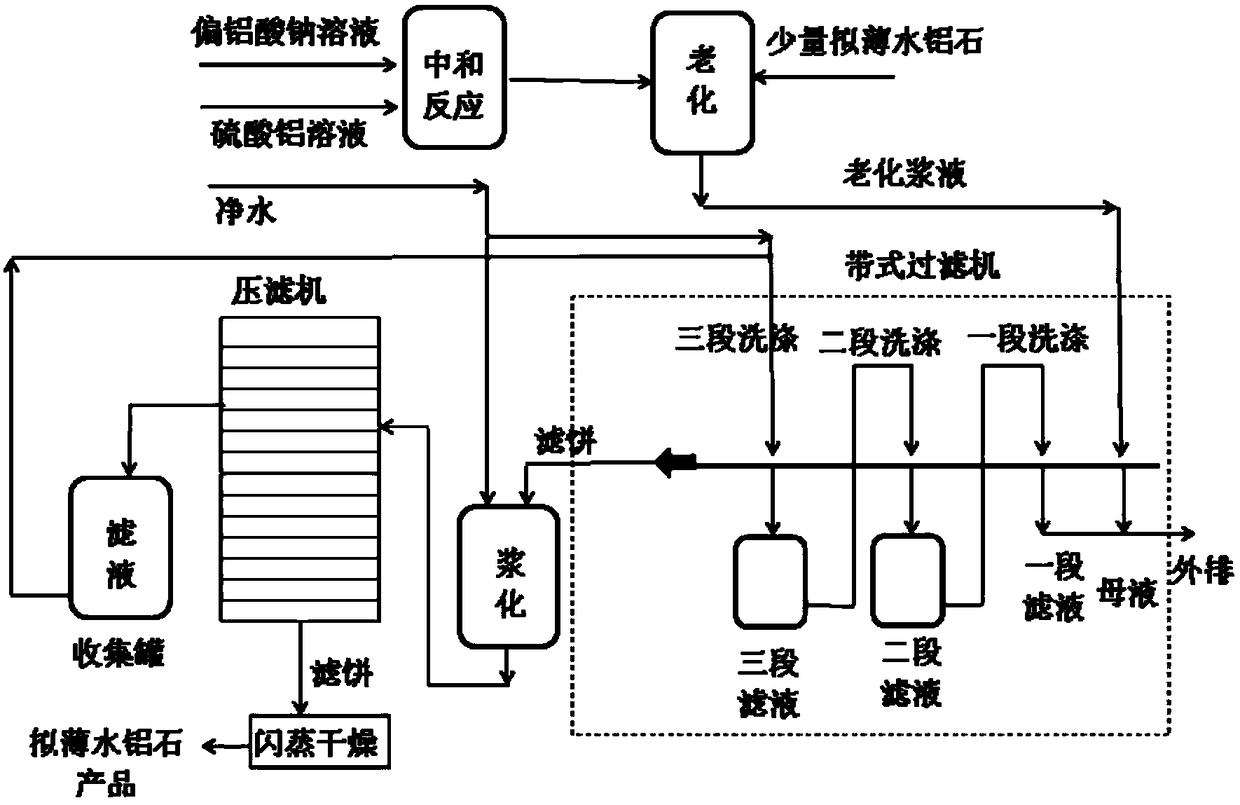

[0035] A preparation method of pseudo-boehmite, comprising the following steps:

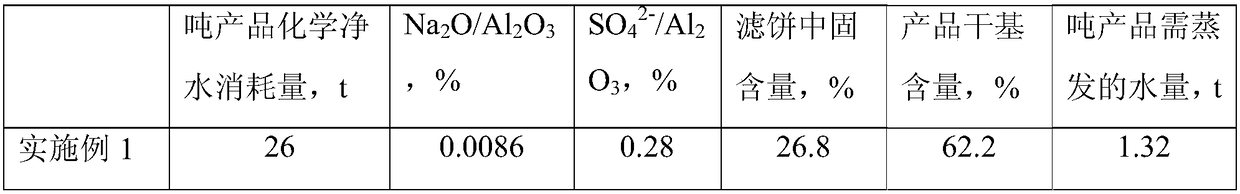

[0036] Continuous co-flow feeding of NaAlO in the neutralization reactor 2 solution and Al 2 (SO 4 ) 3 solution for neutralization reaction, NaAlO 2 The concentration of the solution as alumina is 200g / L, the concentration of aluminum sulfate solution as alumina is 50g / L, the temperature of the neutralization reaction is 70°C, the pH of the neutralization slurry is 8.0, and the neutralization residence time is 15 minutes. The neutralized slurry is collected in an aging tank, and the stirring is continued, and the temperature is raised to 80° C. with steam, and the aging temperature is kept constant, and the aging time is 180 minutes. After the aging process, 0.6% of dried pseudo-boehmite was added and stirred for 25 minutes. The aged slurry is pumped into the belt filter, filtered to remove the mother liquor, and washed in a three-stage recycling cycle of washing water. The temperature of th...

Embodiment 2

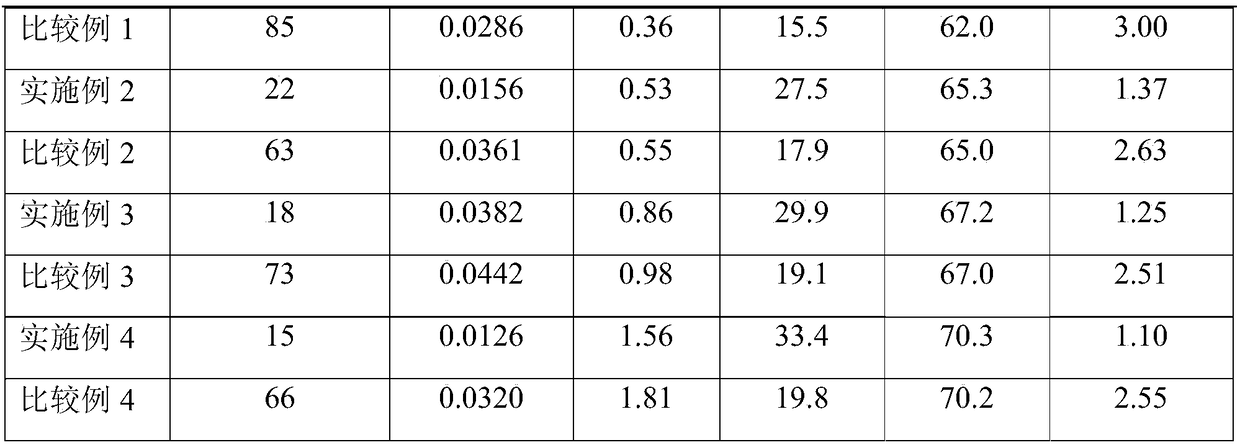

[0041] Continuous co-flow feeding of NaAlO in the neutralization reactor 2 solution and Al 2 (SO 4 ) 3 solution for neutralization reaction, NaAlO 2 The concentration of the solution in terms of alumina is 200g / L, the concentration of the aluminum sulfate solution in terms of alumina is 60g / L, the temperature of the neutralization reaction is 75°C, the pH value of the neutralization slurry is 7.5, and the neutralization residence time is 20 minutes. The neutralized slurry is collected in an aging tank, and the stirring is continued, and the temperature is raised to 85° C. with steam, and the aging temperature is kept constant, and the aging time is 240 minutes. After the aging process, 1.5% of dried pseudo-boehmite was added and stirred for 20 minutes. The aged slurry is pumped into a belt filter, filtered to remove the mother liquor, and washed in a three-stage recycling cycle. The temperature of the washing water is 85°C, and the total washing time is 20 minutes: the thi...

Embodiment 3

[0045] Continuous co-flow feeding of NaAlO in the neutralization reactor 2 solution and Al 2 (SO 4 ) 3 solution for neutralization reaction, NaAlO 2The concentration of the solution in terms of alumina is 210g / L, the concentration of the aluminum sulfate solution in terms of alumina is 80g / L, the temperature of the neutralization reaction is 60°C, the pH of the neutralization slurry is 7.0, and the neutralization residence time is 25 minutes. The neutralized slurry is collected in an aging tank, and the stirring is continued, and the temperature is raised to 90° C. with steam, and the aging temperature is kept constant, and the aging time is 120 minutes. After the aging process, 2.5% of dried pseudo-boehmite was added and stirred for 20 minutes. The aged slurry is pumped into the belt filter, filtered to remove the mother liquor, and washed in a three-stage recycling cycle. The temperature of the washing water is 90°C, and the total washing time is 25 minutes: the third st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com