Intelligent microwave continuous drier and control method thereof

A dryer and microwave technology, applied in progressive dryers, dryers, drying of solid materials, etc., can solve the problems of affecting storage and normal use, cumbersome statistical analysis of data, and low degree of automation, so as to avoid excessive drying temperature. High, ensure drying efficiency, reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

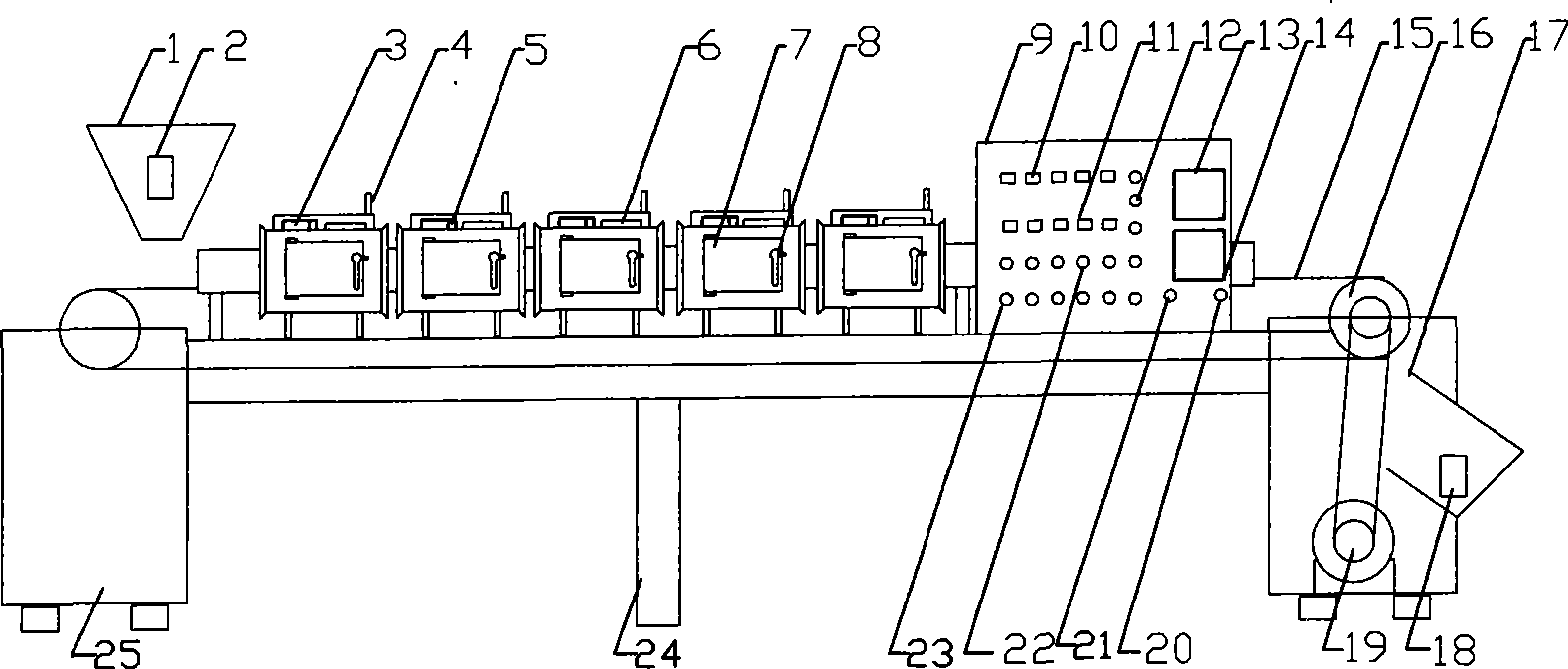

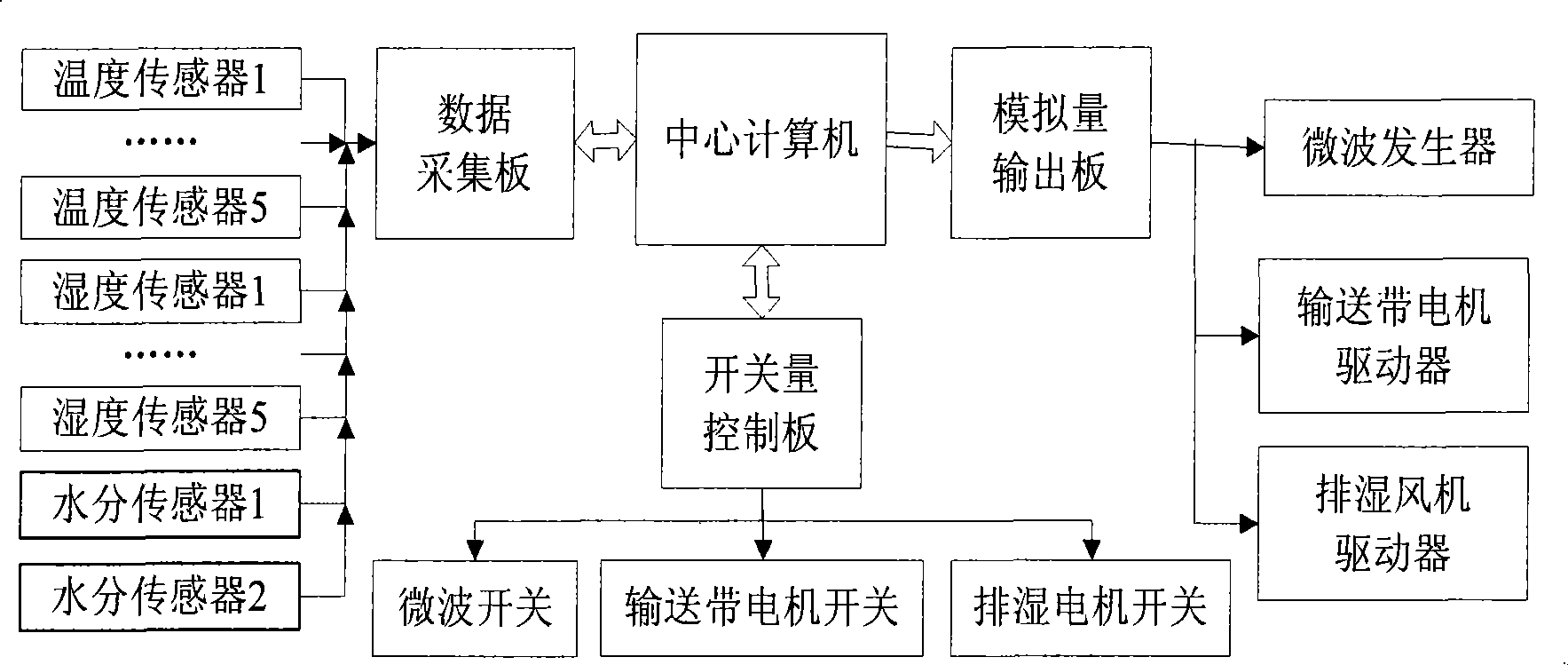

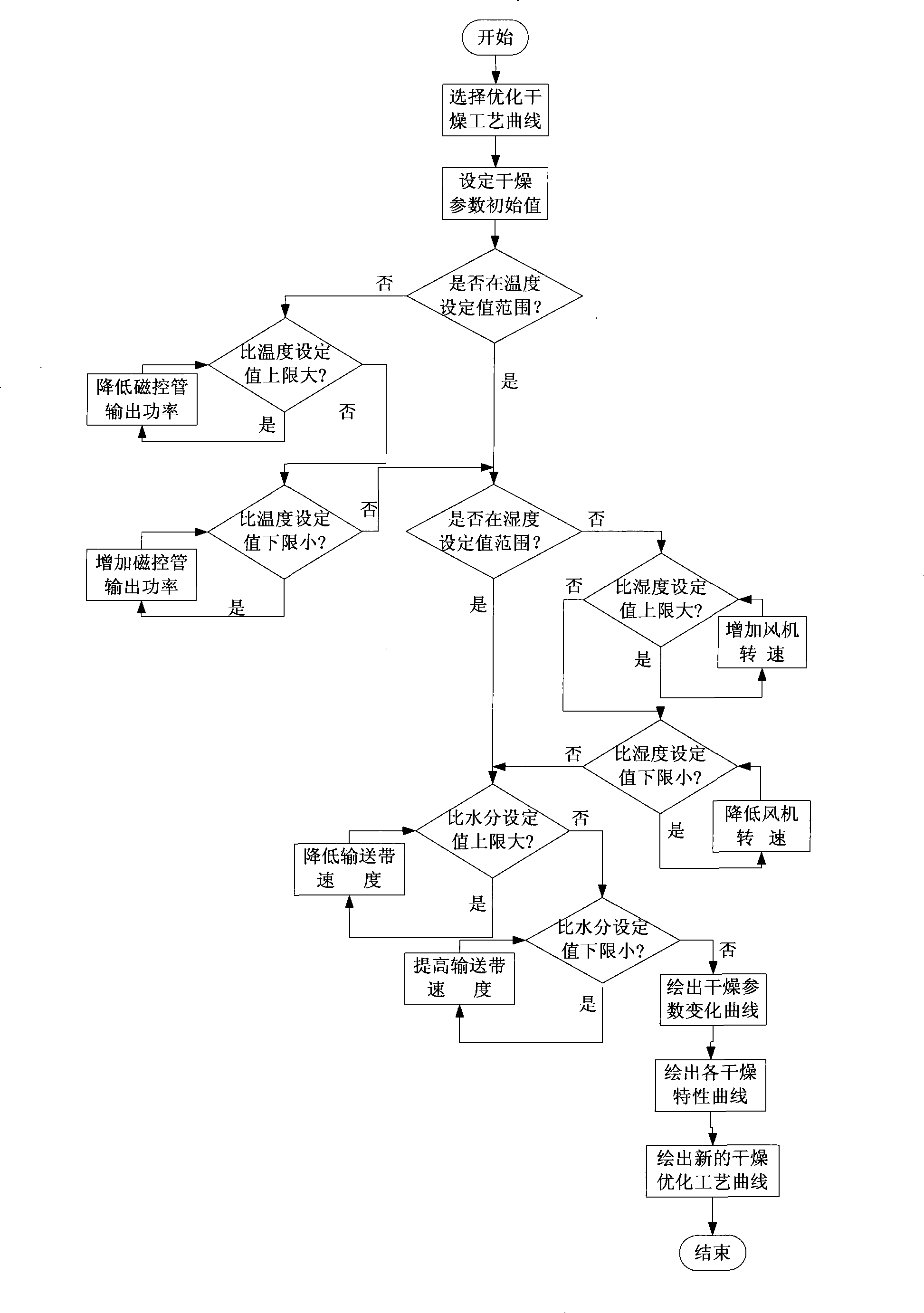

[0027] An intelligent microwave continuous dryer, comprising a frame 24, a feed hopper 1 and a guard plate 25 are installed above the left end of the frame 24, a moisture sensor 2 is installed on the feed hopper 1, and a conveyor belt 15 is mounted on the frame, The left and right ends of the conveyor belt 15 are sleeved on the conveyor pulley 16, and the conveyor pulley 16 is driven by an adjustable reduction motor 19 on the installation frame 24. There is a discharge hopper 17 under the right end of the conveyor belt, and a moisture sensor 18 is installed in the discharge hopper 17. , the conveyor belt 15 passes through five microwave drying chambers connected in series, and each microwave drying chamber is equipped with three microwave magnetrons 6, a far-infrared temperature sensor 4, a humidity sensor 5 and a speed-regulating fan 3; A microwave magnetron is 0.7KW. A box door 7 is arranged on the microwave drying cavity, a handle 8 is arranged on the box door 7, an instrum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com