Strip steel drying device

A technology of drying device and strip steel, applied in drying, dryer, drying gas arrangement and other directions, to achieve the effects of large power consumption, improved efficiency and reduced quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

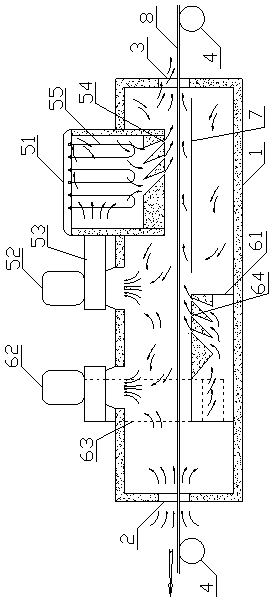

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] see figure 1, the embodiment of the present invention provides a strip steel drying device, the strip steel drying device includes a box body 1, at least one set of heating structures in the box body 1, and openings on the front and rear side walls of the box body 1 for the strip steel 8 to enter and exit The strip outlet 2 (also serves as the air inlet) and the strip inlet 3 (also serves as the water vapor outlet). Wherein, the heating structure includes a first guide box 51 , a second guide box 61 , a first circulation fan 52 , a second circulation fan 62 , a first air duct 53 , a second air duct 63 , a heater 55 and the like. The first diversion box 51, the first circulating fan 52, the first air channel 53 and the heater 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com