Radix puerariae particle crushing unit

A pulverizer and particle technology, which is applied in the direction of grain processing, etc., can solve the problems of inconvenient switching of conveyors, powder loss, large grinding particle size, etc., and achieve the effect of reducing powder efflux loss, less powder loss, and small crushing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

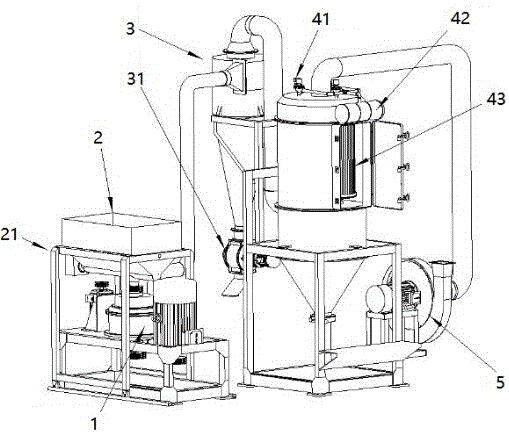

[0025] Embodiment one (such as figure 1 shown)

[0026] A kudzu root particle pulverization unit, comprising a pulverizer 1, a feed bin 2 and a cyclone collector 3, the feed port of the pulverizer 1 is connected to the feed bin 2 through a feed pipe, and the discharge port of the pulverizer 1 is passed through a discharge pipe Unicom cyclone collector 3, the silo 2 is movably installed above the pulverizer 1, the silo 2 is movable relative to the pulverizer, and the silo 2 is installed on the frame of the pulverizer 1 through a sliding bracket 21; the cyclone collector 3 The exhaust port of the exhaust port is connected to the dust collector 4, and the dust collector 4 is connected to the induced draft fan 5; the pulverizer 1 is a type 30 pulverizer; the silo 2 is a 600L large-capacity bin.

[0027] As a further specific description, a discharge shut-off fan 31 is installed at the discharge port of the cyclone collector 3 .

[0028] As a further specific illustration, the du...

Embodiment 2

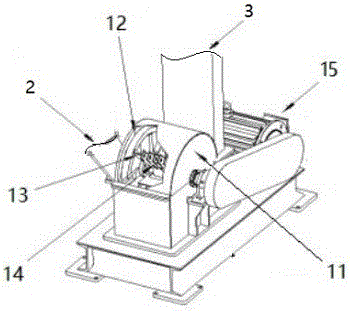

[0029] Embodiment two (such as figure 2 shown)

[0030] The difference from Embodiment 1 is that the pulverizer 1 includes a cylindrical shell 11, a planing cutterhead 12, a centrifugal wind wheel 13, a hammer knife set 14 and a motor 15, and the axial direction of the cylindrical shell 11 is installed sequentially. The planing cutter head 12, the centrifugal wind wheel 13 and the hammer blade group 14, the near planing cutter head 12 side of the cylindrical shell 11 is connected to the discharge port of the material bin 2, and the near hammer blade group 14 of the cylindrical shell 11 is a The side communicates with the cyclone collector 3, and the planing cutter head 12, the centrifugal wind wheel 13 and the hammer blade group 14 are jointly driven by the motor 15.

[0031] As a further specific illustration, the discharge port of the cyclone collector 3 is also connected with a centrifugal classifier.

[0032] As a further specific description, the pulverizer 1 adjusts t...

Embodiment 3

[0034] The difference from the first embodiment is that the silo 2 adopts a 500L large-capacity silo body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com