Multi-stage composite steam dehydration structure and heat accumulator

A dehydration structure and steam technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as "water hammer" and steam with water, so as to improve steam dryness, reduce effluent loss, and reduce The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

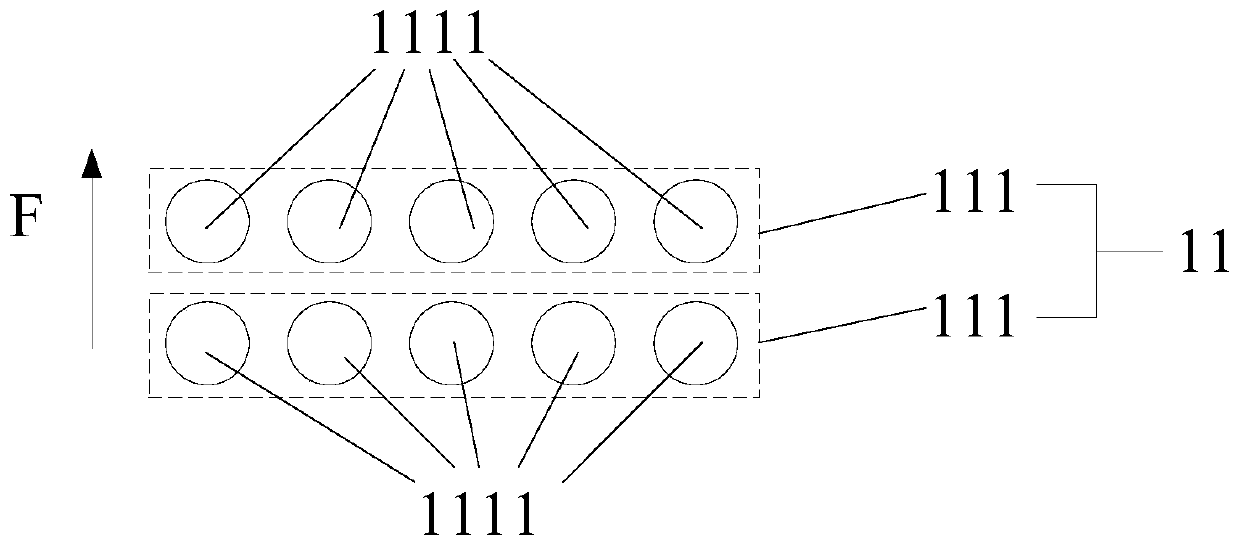

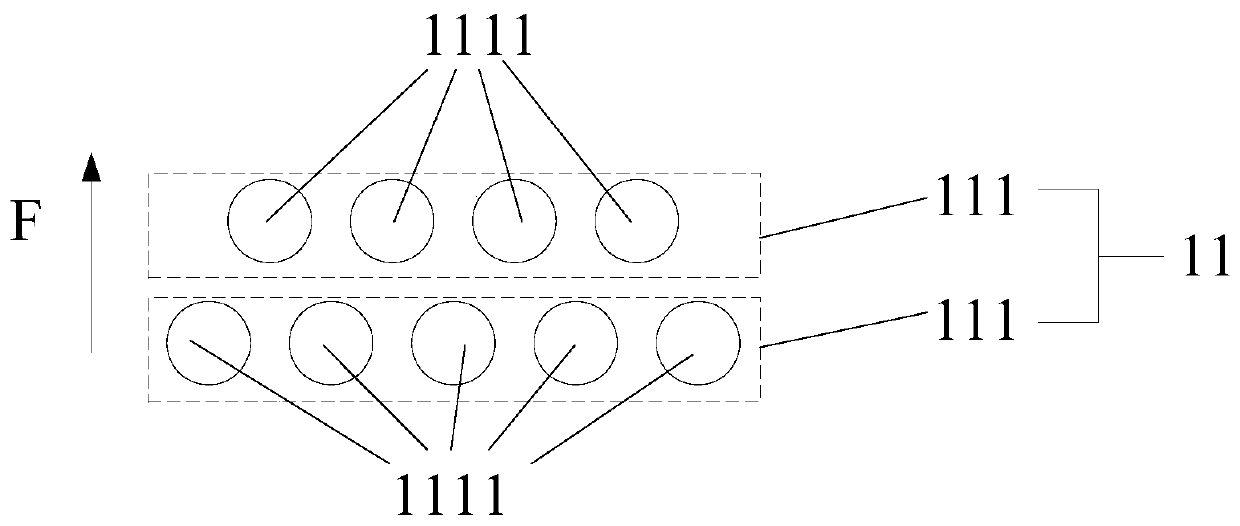

[0033] The present invention provides a multi-stage composite steam dehydration structure 1, please refer to Figure 1 to Figure 8 , The multi-stage composite steam dehydration structure 1 includes a primary dehydration element 11 , a secondary dehydration element 12 and a tertiary dehydration element 13 .

[0034] Specifically, the primary dewatering element 11 has multi-layer close-packed tube bundles 111 arranged at intervals along the first direction F, and each layer of close-packed tube bundles 111 has a plurality of tube bodies 1111 arranged side by side; 11, the secondary dewatering part 12 has a plurality of corrugated plates 121 arranged at intervals along the horizontal direction; the tertiary dewatering part 13 is located above the secondary dewatering part 12, and the tertiary dewatering part 13 is connected by a plurality of bending holes The plate 131 is formed, and the bent orifice plate 131 is provided with a perforation 1313 .

[0035] The multi-stage compos...

Embodiment approach 2

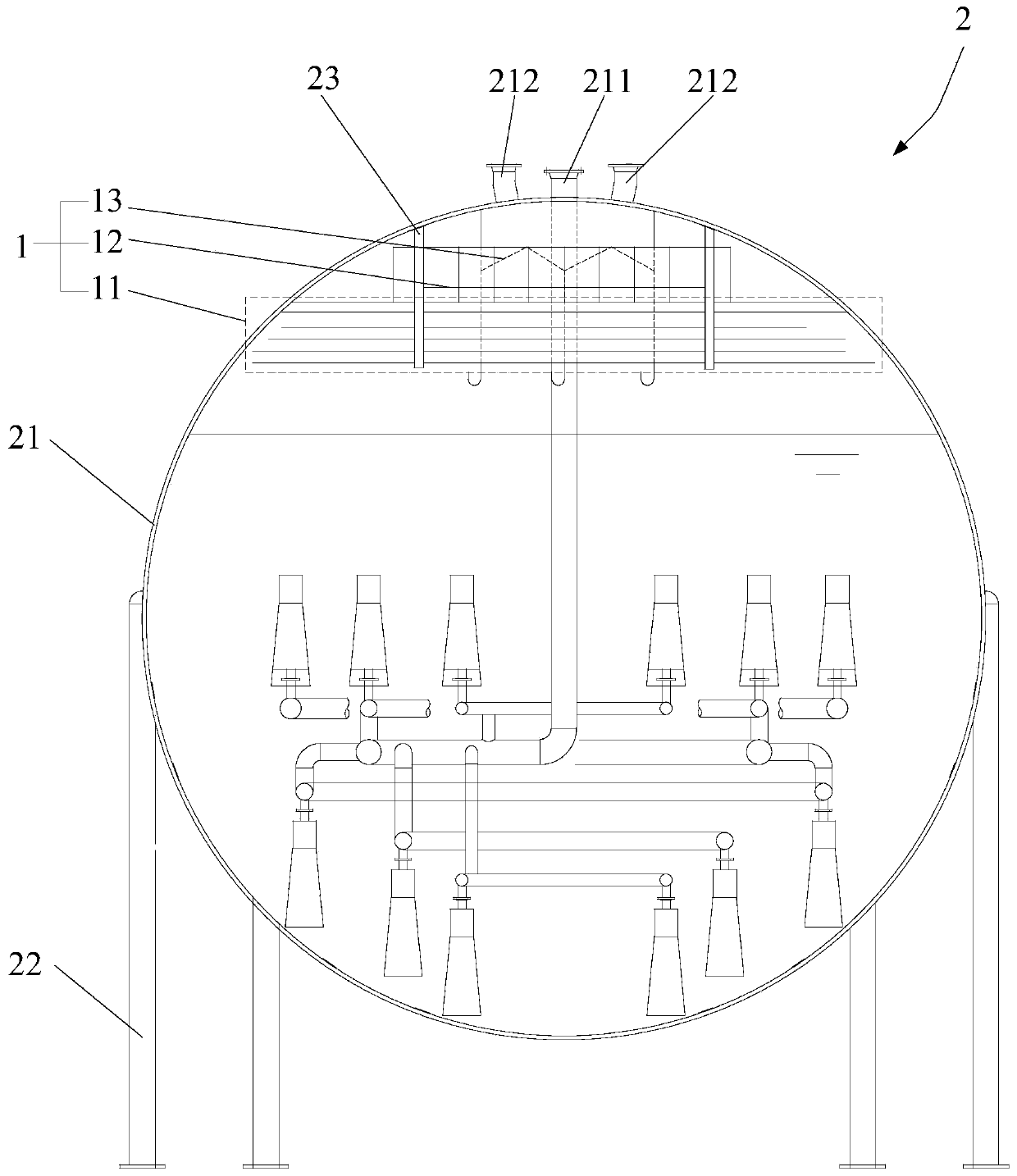

[0059] The present invention provides a heat accumulator 2, please refer to figure 1 , the heat accumulator 2 includes a tank body 21 and a multi-stage composite steam dehydration structure 1 . Wherein, the top of the tank body 21 is provided with a steam inlet pipe 211 and at least one steam outlet pipe 212, and the steam inlet pipe 211 can extend into the lower inner cavity of the tank body 21; In the upper inner cavity, and located below at least one steam outlet pipe 212. The specific structure, working principle and beneficial effects of the multi-stage composite steam dehydration structure 1 in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0060] The regenerator 2 is equipped with a multi-stage composite steam dehydration structure 1 inside, and the water droplets carried by the wet saturated steam are filtered out in the inner cavity of the tank body 21 through multi-stage filtration, thereby increasing the dryness of the steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com