Device for preparing water by utilizing evaporated secondary condensate in aluminum oxide production

A water production device and alumina technology, which is applied in general water supply conservation, chemical industry, natural water treatment, etc., can solve the problems of waste of water resources and high cost of water production, reduce water production costs, reduce raw water consumption, and improve The effect of water production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

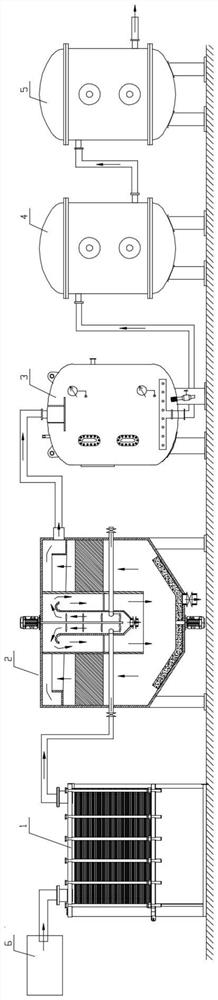

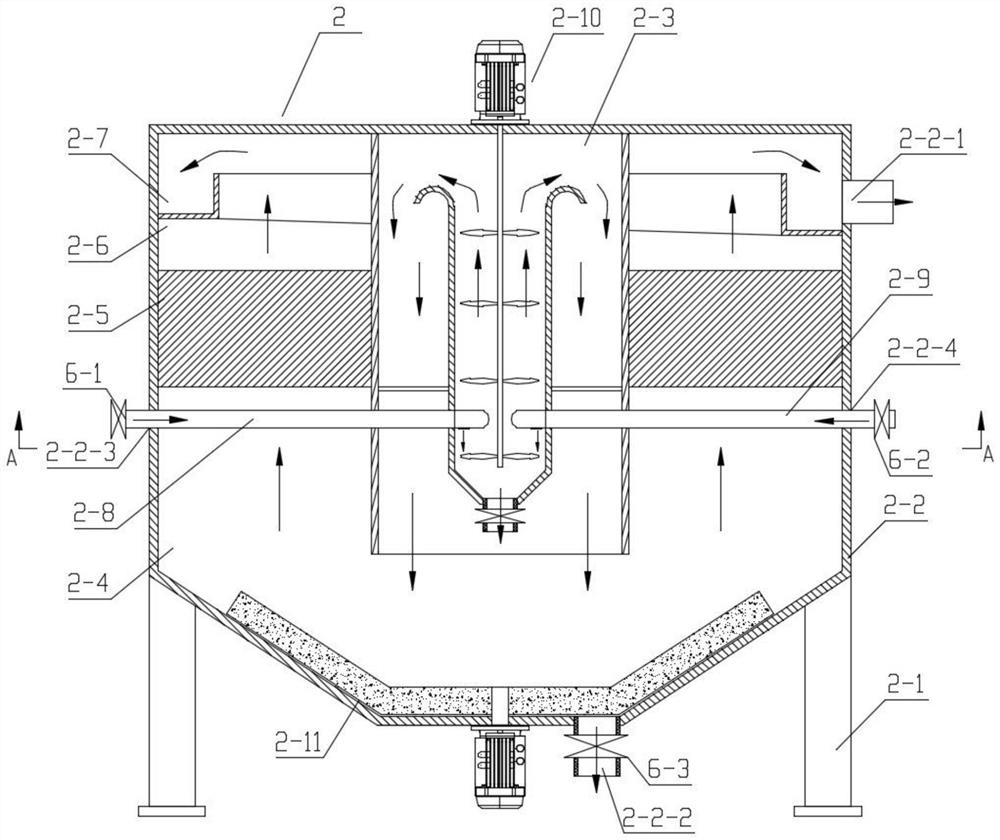

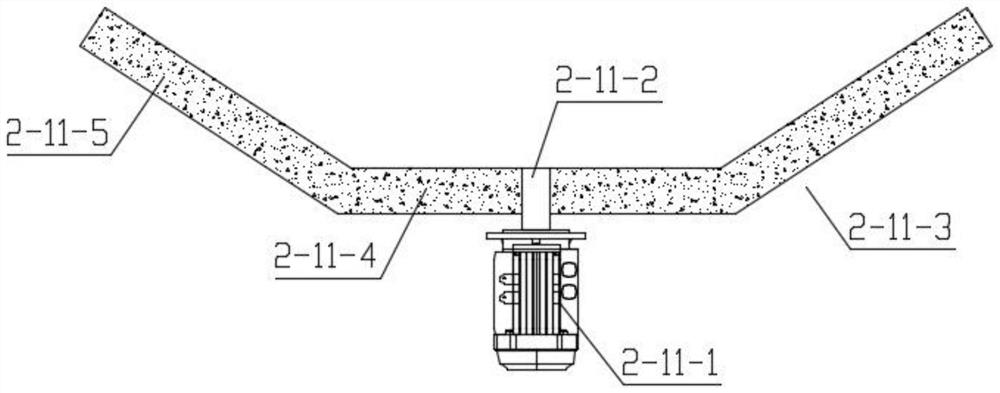

[0036] like Figures 1 to 7 A water-making device for evaporating secondary condensate in the production of alumina is shown, wherein: comprising a heat exchange device 1, a mechanical stirring clarifier 2, a quartz sand filter 3, an anion and anion bed ion exchanger 4 and a mixed bed ion Exchanger 5; Evaporated secondary condensate 6 is first cooled by heat exchange device 1, then flocculated and removed in mechanical stirring clarifier 2, and then filtered through quartz sand filter 3, and then enters anion-and-yang bed ion exchanger 4 for chemical treatment. Desalination, and then enter the mixed bed ion exchanger 5 for chemical demineralization again, and the demineralized water that reaches the qualified index is supplied to each water point.

[0037] The evaporative secondary condensate 6 is connected with the heat exchange device 1 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com