Two-stage ammonia leaching-flow distributing extraction method for copper oxide ore

A copper oxide ore and extraction technology is applied in the field of two-stage ammonia leaching-split extraction and refractory copper oxide ore, which can solve the problems of aggravating ammonia volatilization, worsening industrial hygiene conditions in production workshops, and ammonia volatilization loss, and reducing volatilization. loss, the effect of improving industrial hygiene conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

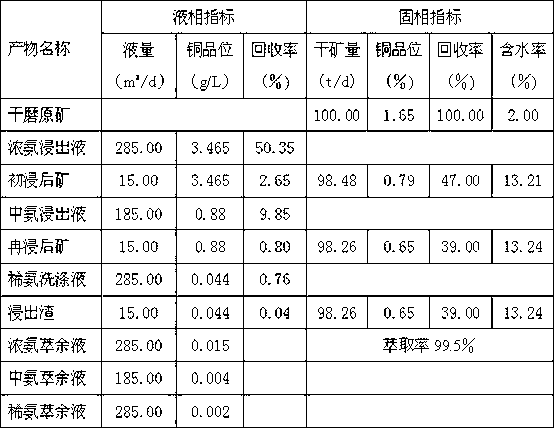

[0034] Copper oxide ore: copper 1.65%, free copper oxide distribution rate 70.30%, combined copper distribution rate 28.48%, copper sulfide distribution rate 1.22%, CaO: 28.12%, Fe 2 o 3 : 11.40%, MgO: 2.80%, Al 2 o 3 : 0.90%, SiO 2 : 9.28%, (both are mass percentages, test results after drying, the same below), the water content of ore before drying is 4.0%.

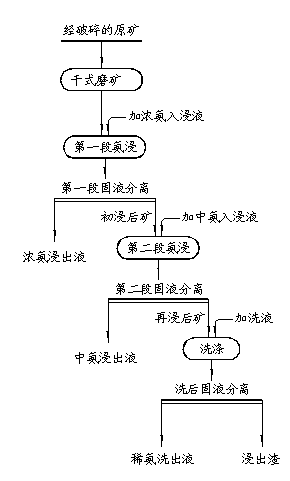

[0035] Above-mentioned raw ore is processed according to following process steps:

[0036] (1) Dry grinding: dry-grind the copper oxide ore, and control the mass of powder particles smaller than 74 μm to account for 85%;

[0037] (2) The first stage of ammonia leaching: the material treated in step (1) is mixed with concentrated ammonia into the immersion solution under normal temperature and pressure airtight conditions, and the first stage of stirring ammonia immersion is carried out. The liquid-solid mass ratio is 3: 1. The ammonia leaching time is 2 hours, and then the concentrated ammonia leaching solution and...

Embodiment 2

[0049] Copper oxide ore: copper content 1.54%, free copper oxide distribution rate 72.93%, copper binding rate 15.47%, copper sulfide distribution rate 11.60%, CaO: 27.88%, MgO: 3.79%, Al 2 o 3 : 1.36%, SiO 2 : 29.87%, Fe 2 o 3 : 2.96%, the ore contains 4.0% water before drying.

[0050] Above-mentioned raw ore is processed according to following process step:

[0051] (1) Dry grinding: dry-grind the copper oxide ore, and control the mass of powder particles smaller than 74μm to account for 80%;

[0052] (2) The first stage of ammonia leaching: the material treated in step (1) is mixed with concentrated ammonia into the immersion solution under normal temperature and pressure airtight conditions, and the first stage of stirring ammonia immersion is carried out. The liquid-solid mass ratio is 3: 1. The ammonia leaching time is 2 hours, and then the concentrated ammonia leaching solution and the ore after primary leaching are obtained through solid-liquid separation under a...

Embodiment 3

[0060] Copper oxide ore: copper 0.78%, free copper oxide distribution rate 79.82%, copper binding rate 8.27%, copper sulfide distribution rate 11.91%, CaO: 16.42%, MgO: 7.74%, Al 2 o 3 : 6.87%, SiO 2 : 18.37%, Fe 2 o 3 : 5.33%, the ore contains 4.0% water before drying.

[0061] Above-mentioned raw ore is processed according to following process step:

[0062] (1) Dry grinding: dry-grind the copper oxide ore, and control the mass of powder particles smaller than 74μm to account for 75%;

[0063] (2) The first stage of ammonia leaching: the material treated in step (1) is mixed with concentrated ammonia into the immersion solution under normal temperature and pressure airtight conditions, and the first stage of stirring ammonia immersion is carried out. The liquid-solid mass ratio is 2: 1. The ammonia leaching time is 1.5h, and then the concentrated ammonia leaching solution and the ore after initial leaching are obtained through solid-liquid separation under airtight cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com