Acrylonitrile quenching device and process

An acrylonitrile and process technology, which is applied in the field of acrylonitrile synthesis, can solve the problems such as the inability to effectively solve the uneven flow field, reduce the ammonia absorption efficiency, increase the loss of acrylonitrile, etc., so as to reduce the amount of discharged wastewater and increase the gas-liquid contact area. , the effect of reducing efflux loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

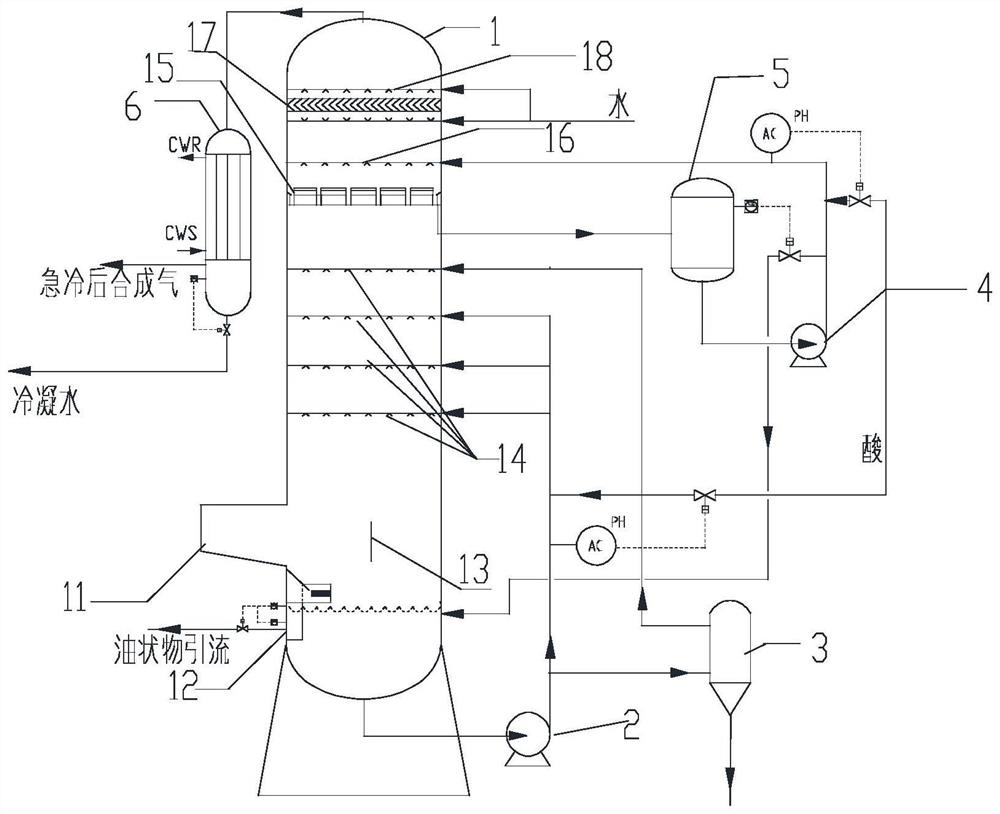

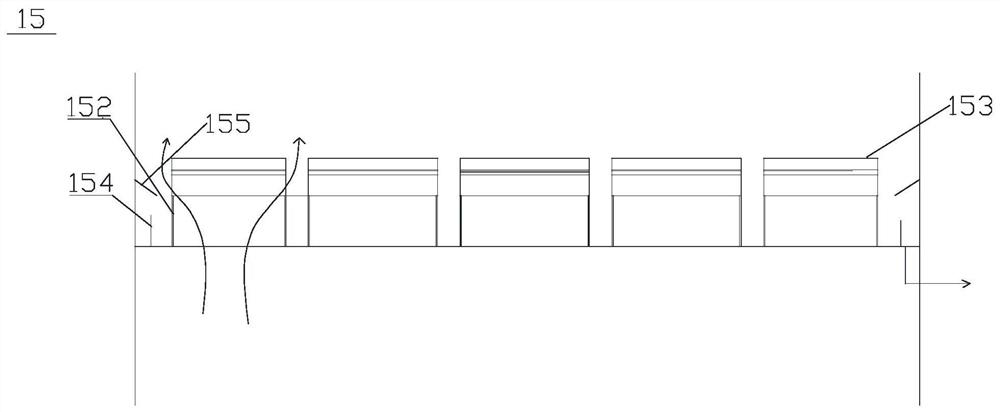

Embodiment 1

[0077] The composition of the reactor off-gas, the dust content, and the acid absorbent were the same as those of Comparative Example 1. The feed temperature is 220°C, and the quenching technology of the present invention is adopted. The structure of the quenching tower is as follows: the upper and lower sections are empty towers, the first-level spraying of the lower section is provided with 5 layers of sprays, the distance between the spray layers is 1 meter, and the upper section is provided with 2 layers of sprays, The spacing between the spray layers is 1 meter. The spray density and spray particle size of the first-level spray from bottom to top are: (1) the spray density is 500%, the spray particle size is 200μm, (2) the spray density is 400%, and the spray particle size is 300μm , (3) spray density 300%, spray particle size is 500μm, (4) spray density 300%, spray particle size is 500μm, (5) spray density 300%, spray particle size is 800μm. The solid content of the pri...

Embodiment 2

[0079] Reactor tail gas composition and dust content, and acid absorbent are the same as in Example 1. The feed temperature is 210°C, and the quenching technology of the present invention is adopted. The structure of the quenching tower is as follows: the upper and lower sections are empty towers, the first-level spray in the lower section is provided with 4 layers of sprays, the distance between the spray layers is 1 meter, and the upper section is provided with 2 layers of sprays. The spacing between the spray layers is 1 meter. The spray density and spray particle size of the first-level spray from bottom to top are: (1) the spray density is 600%, the spray particle size is 200μm, (2) the spray density is 500%, and the spray particle size is 300μm , (3) the spray density is 400%, the spray particle size is 500 μm, (4) the spray density is 400%, and the spray particle size is 800 μm. The solid content of the primary spray circulating fluid is reduced by 15% bypass desolidif...

Embodiment 3

[0081] Reactor tail gas composition and dust content, and acid absorbent are the same as in Example 1. The feed temperature is 210°C, and the quenching technology of the present invention is adopted. The structure of the quenching tower is as follows: the upper and lower sections are empty towers, the first-level spray in the lower section is provided with 5 layers of sprays, the distance between the spray layers is 1 meter, and the upper section is provided with 2 layers of sprays. The spacing between the spray layers is 1 meter. The spray density and spray particle size of the first-level spray from bottom to top are: (1) the spray density is 600%, the spray particle size is 200μm, (2) the spray density is 400%, and the spray particle size is 500μm , (3) spray density of 400%, spray particle size of 500μm, (4) spray density of 400%, spray particle size of 500μm, (5) spray density of 300%, spray particle size of 1000μm. The solid content of the primary spray circulating flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com