Patents

Literature

311results about How to "Guaranteed drying efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

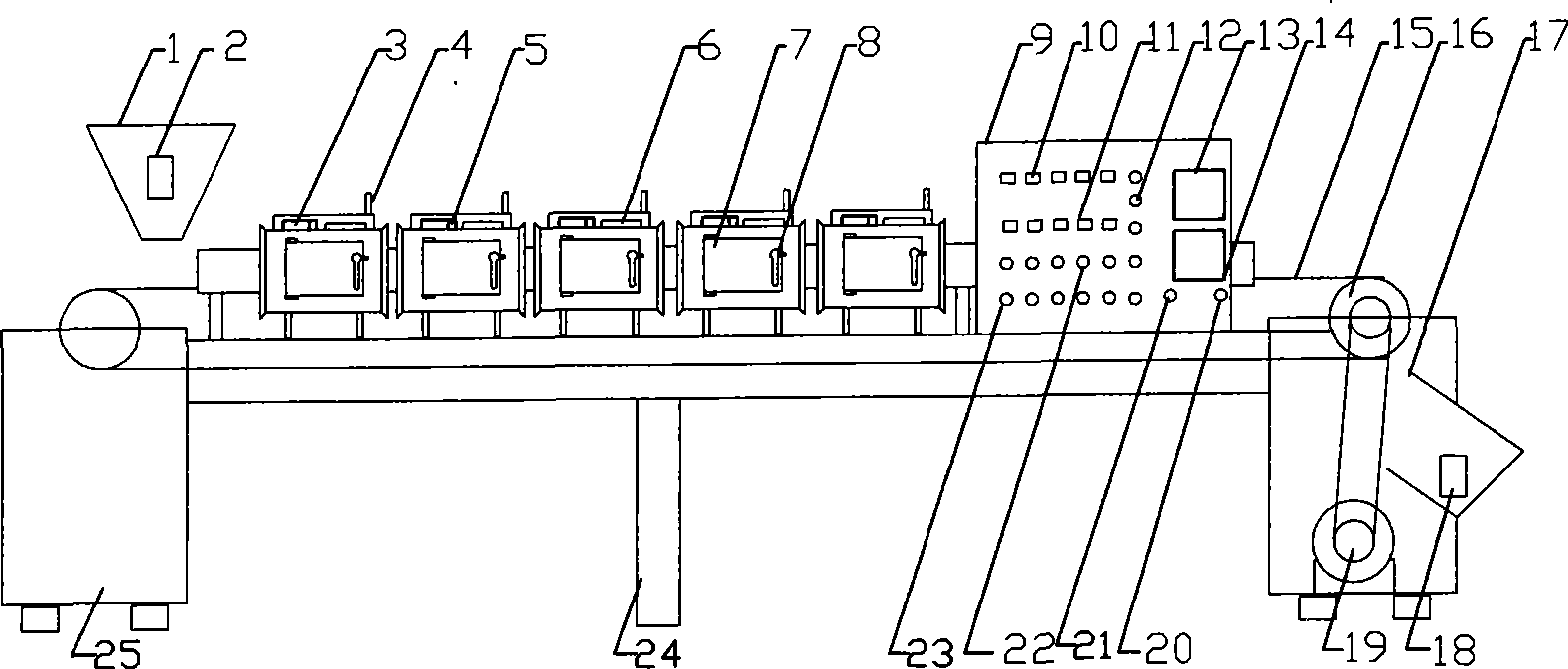

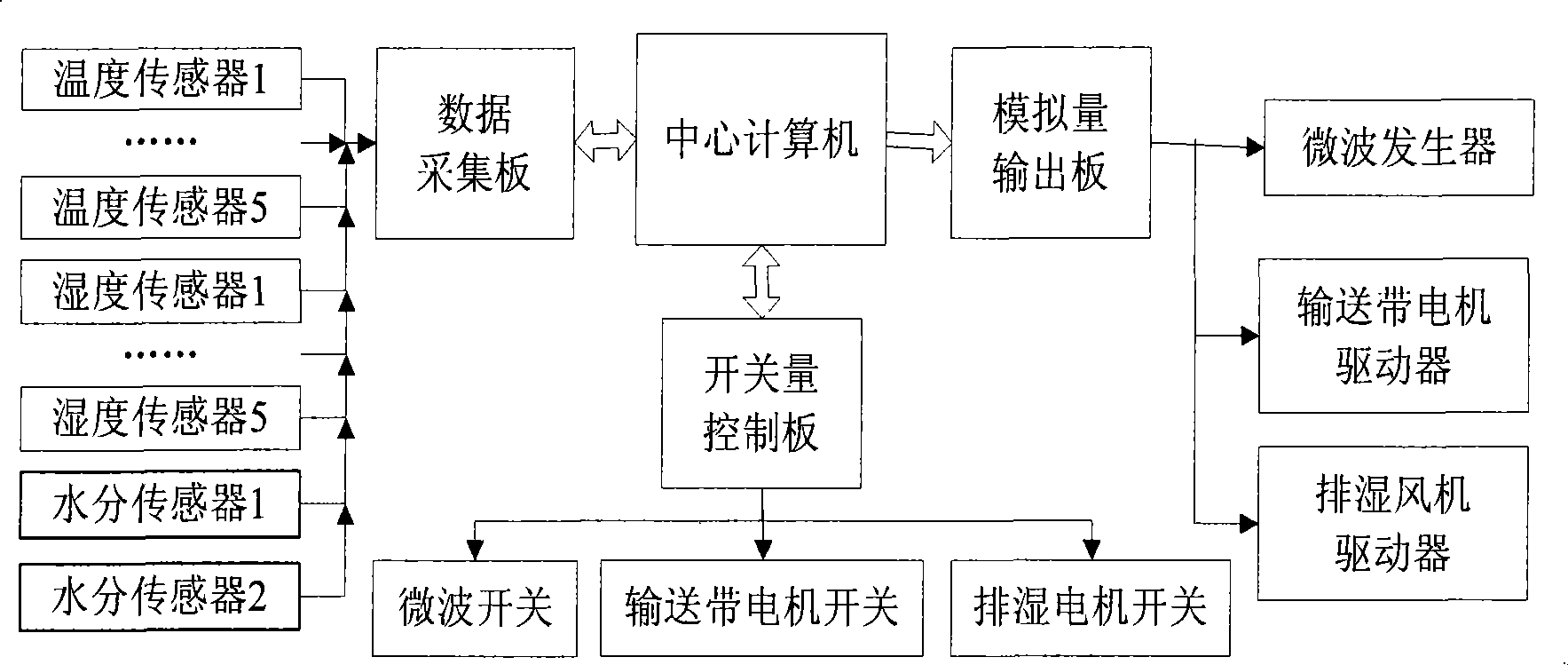

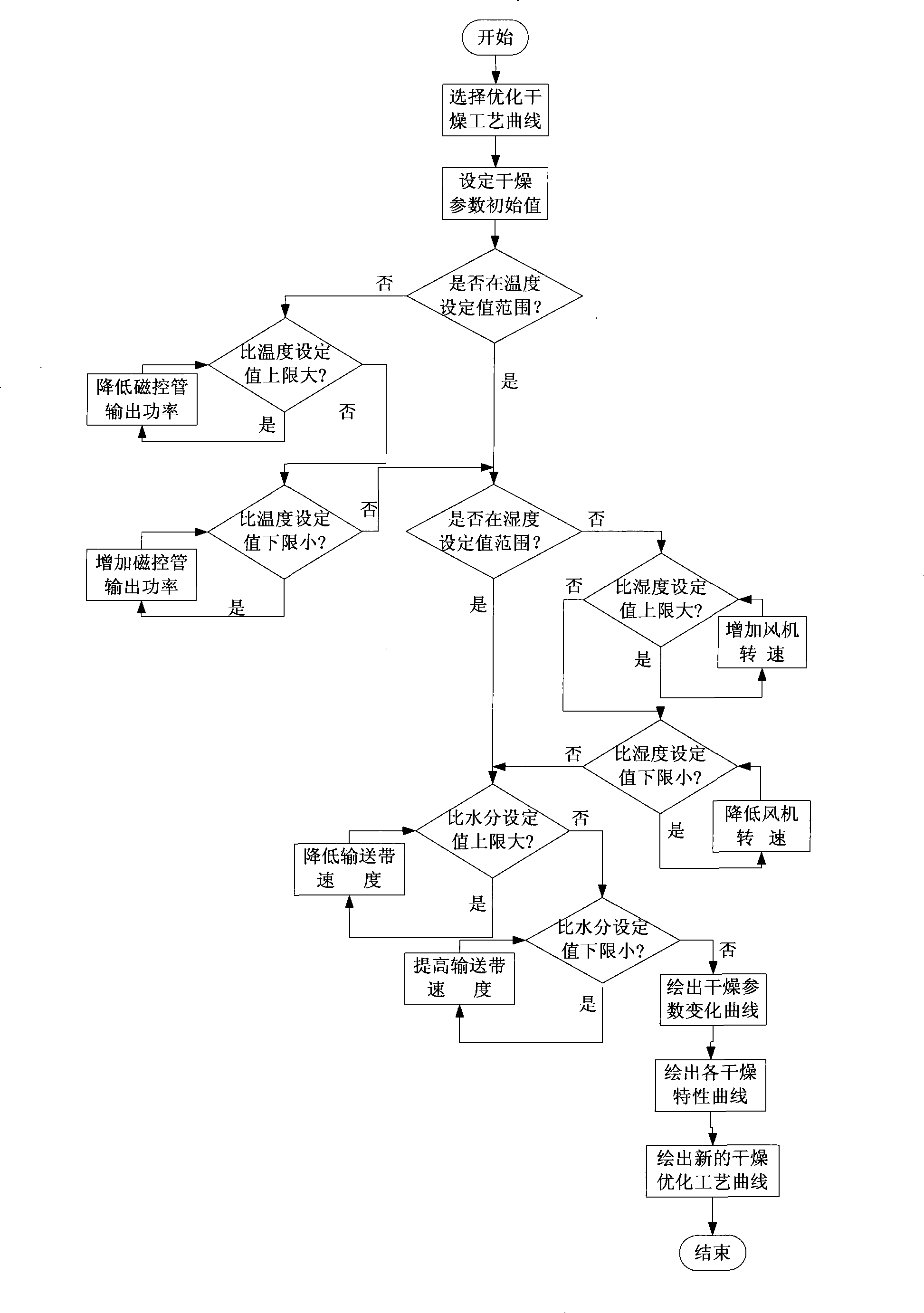

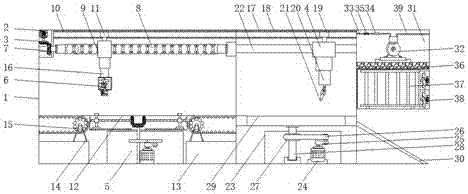

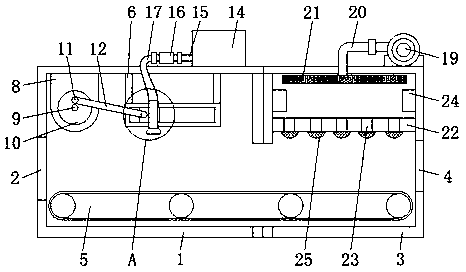

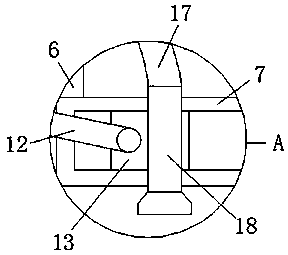

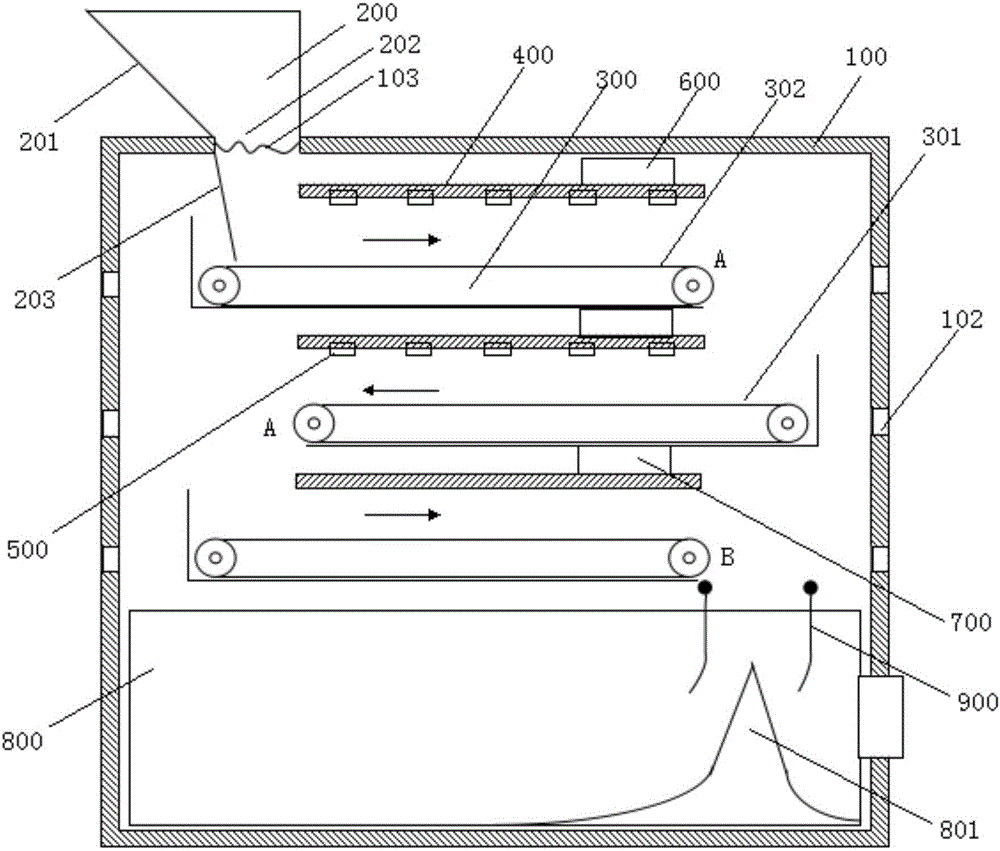

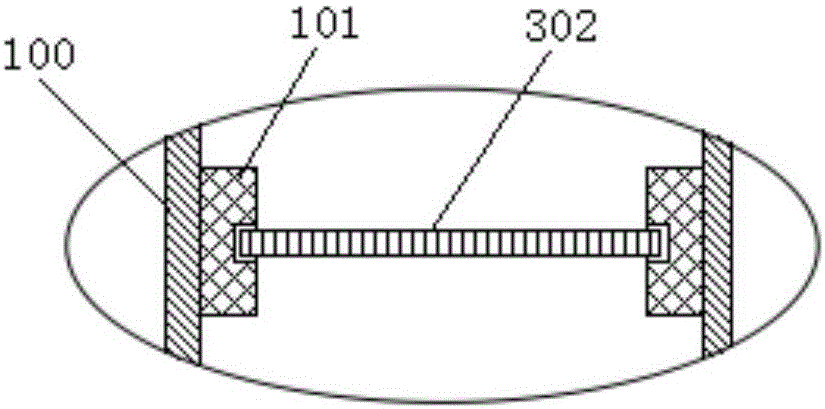

Intelligent microwave continuous drier and control method thereof

InactiveCN101382379AImprove drying qualityEasy to operateDrying solid materials with heatDrying machines with progressive movementsFrequency changerDrive motor

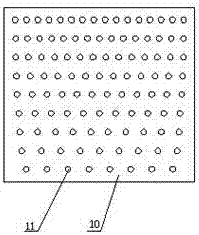

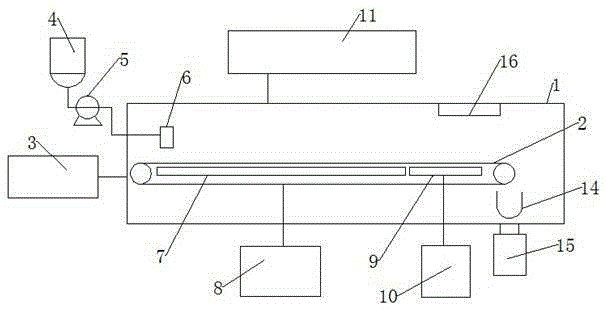

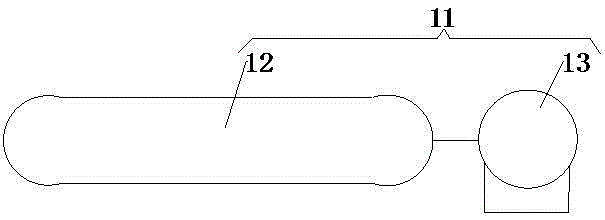

The invention discloses an intellectualized microwave continuous drier and a control method thereof; the drier comprises a rack, a conveying belt, a conveying belt wheel, a driving motor, an instrument control box and a computer; two ends of the conveying belt are respectively provided with a feed hopper and a discharge hopper and the conveying belt runs through a plurality of microwave drying cavities with doors; each microwave drying cavity is internally provided with a microwave magnetron, a temperature sensor, a humidity sensor and a speed-regulating fan; the feed hopper and the discharge hopper are respectively provided with a moisture sensor, and the conveying belt is driven by a speed-regulating motor controlled by a frequency converter. A control system can automatically draw variation curves of the temperature and the humidity of the materials in each drying cavity and the water content ratio of the discharged materials in the drying process of the materials in shorter time according to the collected data of the temperature, the humidity and the water content ratio of the materials in the drying process of the materials, can optimize control parameters continuously according to the change of the temperature, the humidity and the water content ratio in the drying process of the materials, and can regulate the system parameters automatically and realize the dynamic optimization of the drying technique parameters.

Owner:ANHUI AGRICULTURAL UNIVERSITY

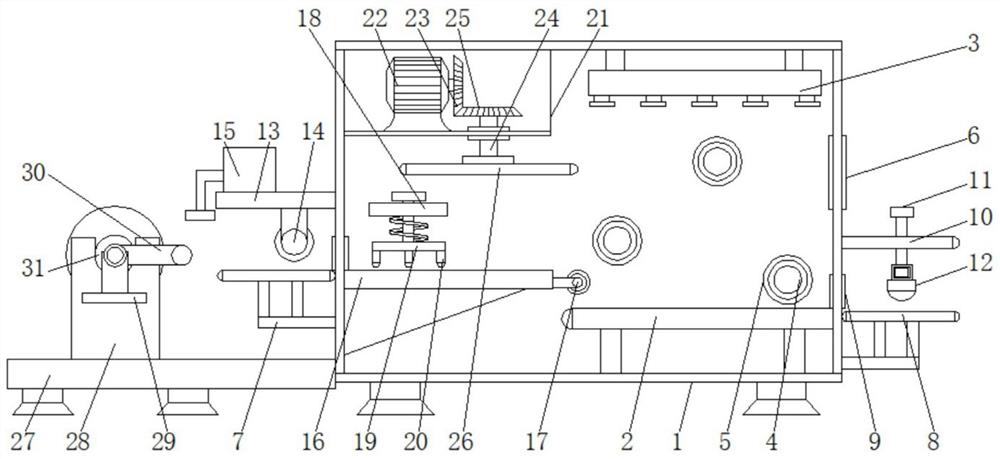

Grinding and painting equipment of locks for metal doors and windows

InactiveCN107497629AGuaranteed position changeReach spray paintLiquid surface applicatorsGrinding machinesWorking environmentArchitectural engineering

The invention discloses a polishing and painting equipment for metal door and window locks, which includes a frame, a first motor is fixedly connected to the top of the inner wall of the frame, and a first cone wheel is fixedly connected to the output shaft of the first motor through a flat key. , the bottom of the first conical wheel is fixedly connected with a second conical wheel, the second conical wheel is fixedly connected with a threaded rod through a flat key, and the top of the inner wall of the frame is fixedly connected with an auxiliary sliding track, the auxiliary An auxiliary slider is slidably connected to the inner wall of the sliding track, and the bottom of the auxiliary slider is fixedly connected to the slider through a connecting rod. The invention relates to the technical field of metal door and window lock processing. The grinding and painting equipment for metal doors and windows locks solves the problem of clamping and grinding workpieces, and can be positioned in different positions. The grinding device can change positions, ensuring the quality and accuracy of grinding and the adaptability to multiple working environments. After grinding The problem of painting and drying the workpiece.

Owner:ZHEJIANG DEQING DETAI DOOR IND

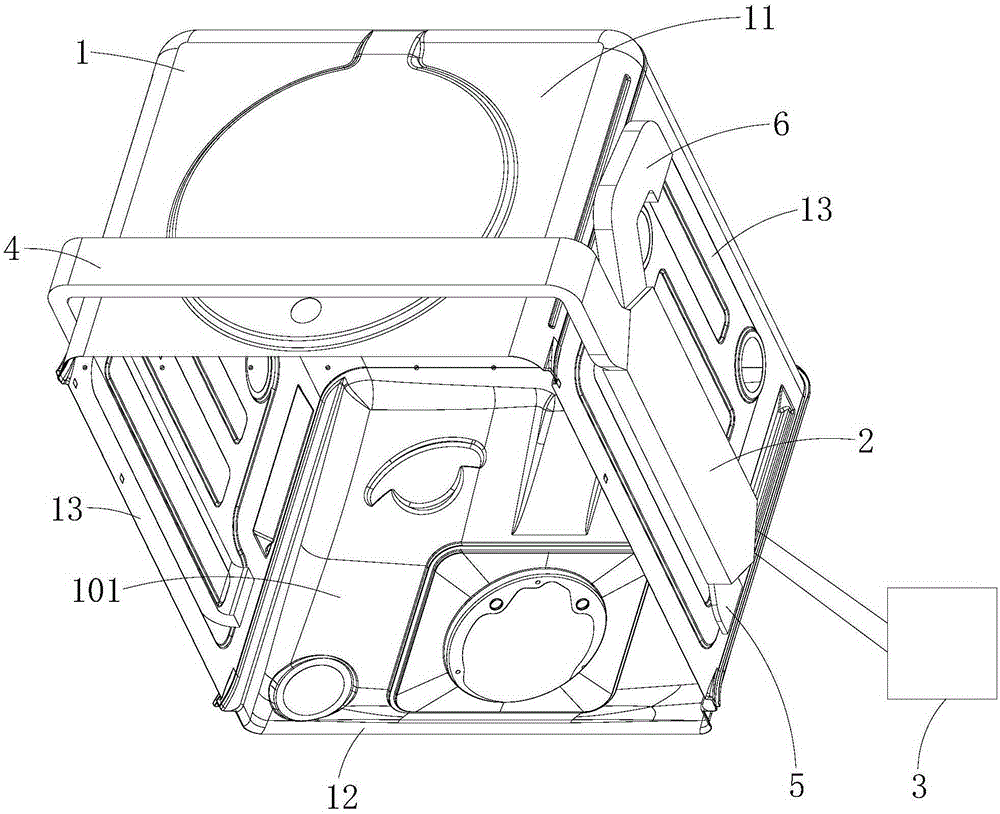

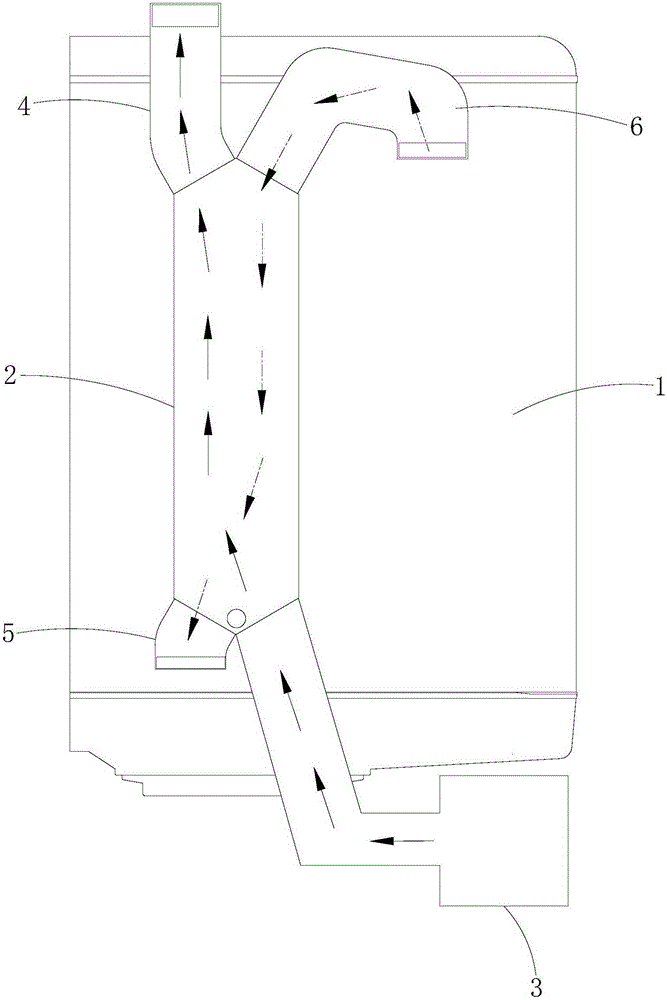

Draught fan drying system of dish-washing machine

ActiveCN105147219AImprove drying efficiencyReduce drynessTableware washing/rinsing machine detailsCold airEngineering

The invention is suitable for the field of dish-washing machines, and discloses a draught fan drying system of a dish-washing machine. The draught fan drying system comprises an inner container with an inner cavity, a heat exchanger installed outside the inner container and a first draught fan installed outside the inner container. The heat exchanger is provided with at least one cold air flow passage and at least two hot air flow passages. The cold air flow passages and the hot air flow passages are alternately arranged in the heat exchanger at intervals. Inlets of the cold air flow passages are communicated with an air outlet of the first draught fan, outlets of the cold air flow passages and inlets of the hot air flow passages are communicated with the inner cavity, an outlet of at least one hot air flow passage is communicated with the inner cavity, and an outlet of at least one hot air flow passage is communicated with external air. According to the draught fan drying system, air obtained after heat exchanging is carried out through the hot air flow passages is divided into two parts to be exhausted out of the heat exchanger, one part of the air is directly exhausted out of the dish-washing machine, and the other part of the air flows back to the inner cavity again; in this way, bad influences on objects around the dish-washing machine can be avoided, cost is low, and the drying effect and the drying efficiency are also high.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

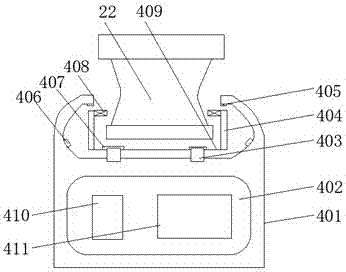

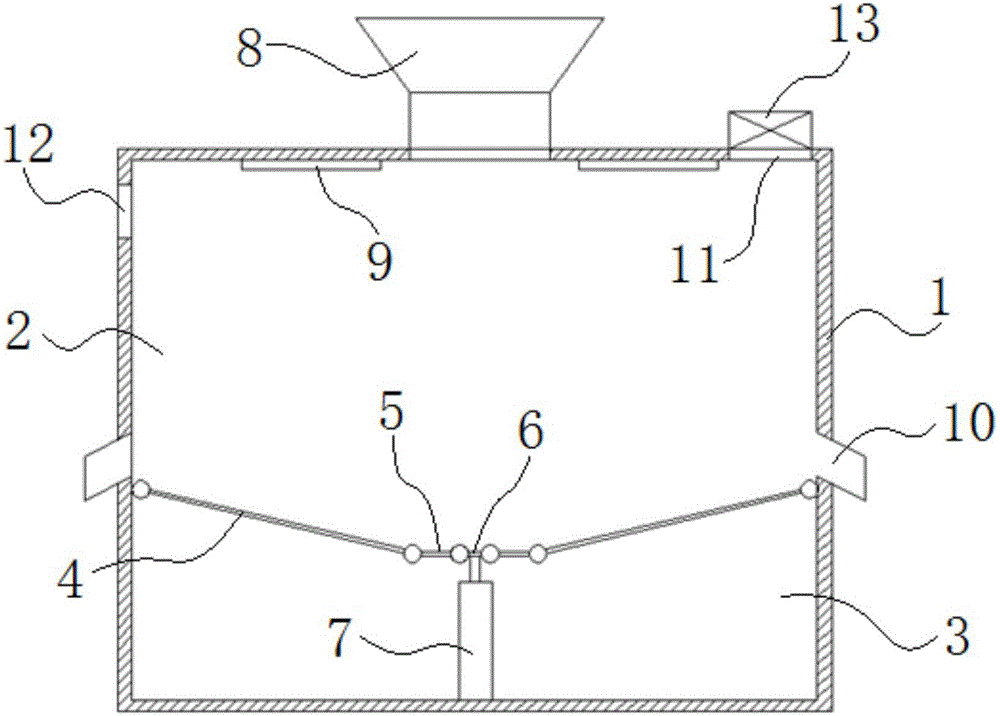

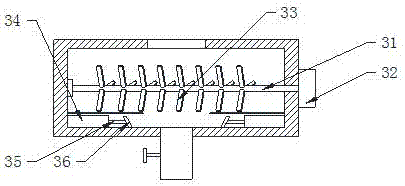

Fodder drying device

InactiveCN106568301ASimple structureReduce volumeDrying gas arrangementsDrying solid materialsEngineeringFodder

The invention discloses a fodder drying device. The fodder drying device comprises a machine shell, a swing plate, two connection plates, a lifting plate, a lifting drive mechanism, a feeding hopper, heating devices and discharge chutes, wherein the swing plate separates an inner cavity of the machine shell into an upper chamber and a lower chamber, and the upper cavity serves as a driving chamber; the swing plate comprises two side plates, and one end of each of the two side plates is hinged to the inner wall; one end of each of the two connection plates is hinged to the other end of the corresponding side plate; the two ends of the lifting plate are hinged to the other end of the corresponding connection plate; the lifting drive mechanism is used for driving the lifting plate to ascend and descend; the feeding hopper is arranged at the top of the machine shell; the heating devices are arranged in the drying chamber; the left side and the right side of the drying chamber are provided with the discharge chutes respectively, and each discharge chute is higher than or equal to the hinge position of the side plate on the same side and the inner wall of the machine shell. According to the fodder drying device, fodder is turned through vertical swing of the swing plate so that the fodder can be dried uniformly; the fodder can also be discharged out of the two discharge chutes by lifting the swing plate; and the fodder drying device is simple in structure, small in size and low in weight.

Owner:南宁市美嘉农饲料有限责任公司

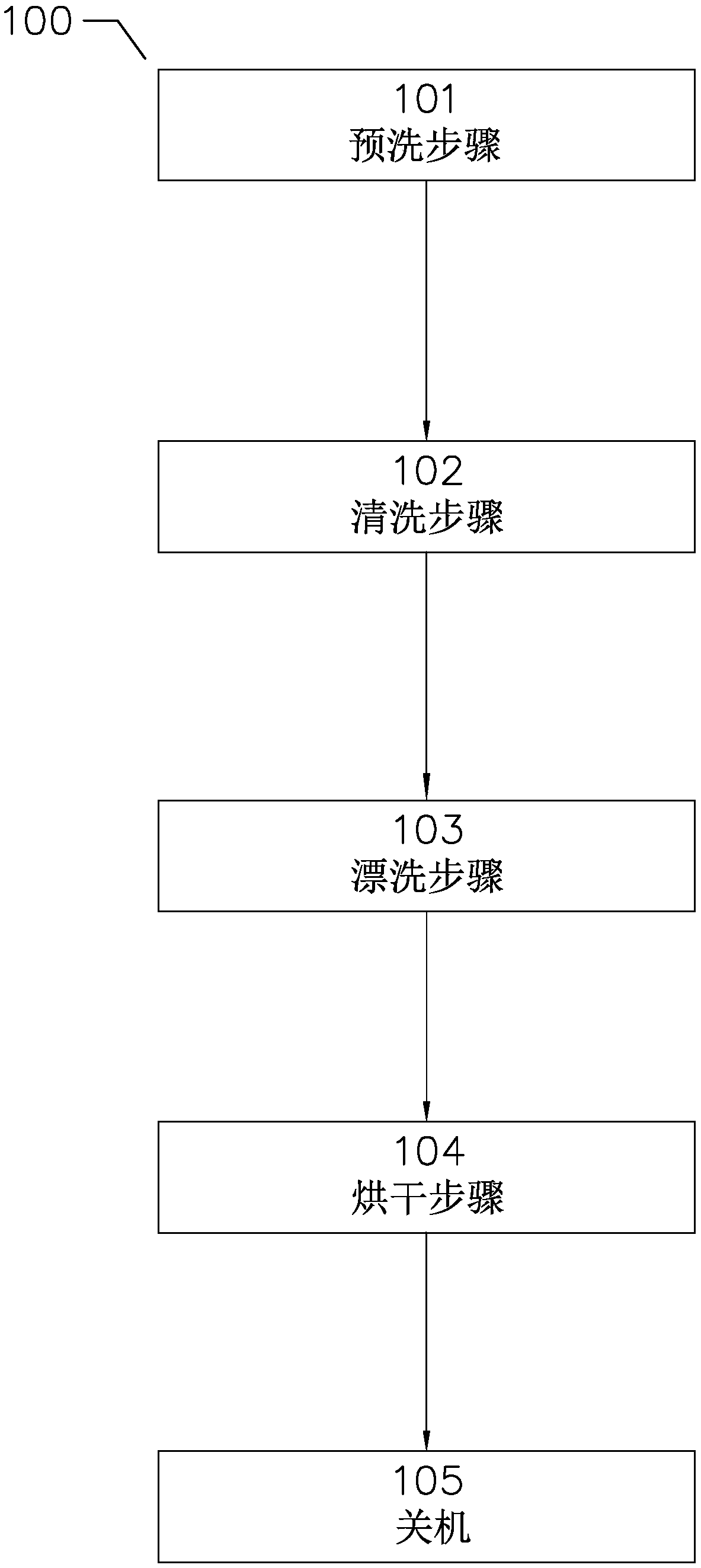

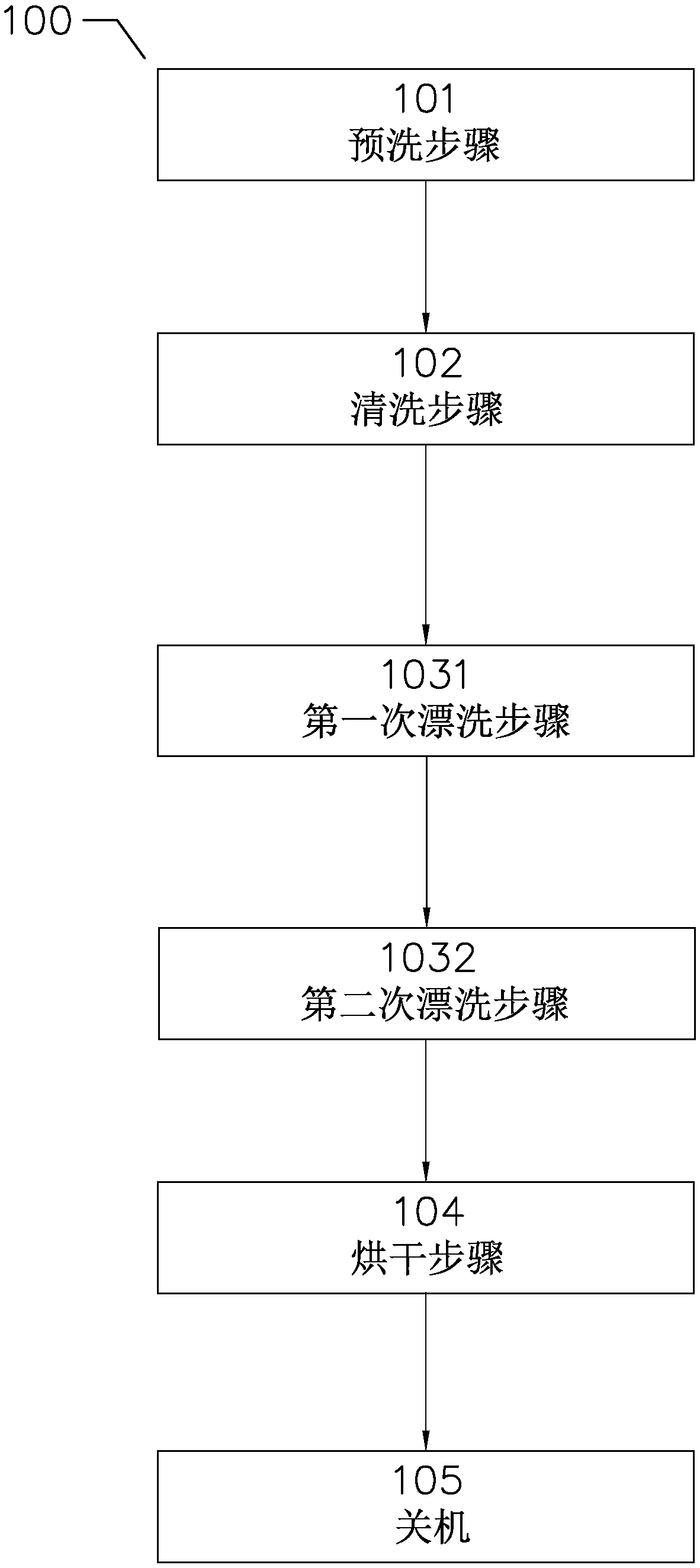

A Dishwasher Washing Method and a Dishwasher

InactiveCN108968861AImprove intelligenceGuaranteed washing effectWashing processesTurbidityProcess engineering

The invention provides a dishwasher washing method and a dishwasher, comprising a washing step, a rinsing step and a drying step. The dishwasher sets a pre-washing step before the washing step by adding water of capacity C1 to the sink and heating the water until the temperature reaches temperature T1. The washing pump works for time t1 and then suspends for time t2; the dishwasher determines thewashing mode according to the turbidity of the water detected by the turbidity sensor. The dishwasher determines the washing mode by adding a certain capacity of water, heating the water to a certaintemperature, washing for a period of time and then suspending for a period of time, and finally detecting the turbidity of the water through the turbidity sensor. This method adds a fast, accurate andefficient pre-washing process, and then determines the washing mode according to the detection of the turbidity sensor. Compared with the existing method of continuously detecting the turbidity of the water during the cleaning process, the method is more efficient for ensuring the washing effect by prolonging the cleaning time.

Owner:杭州小月亮科技有限公司

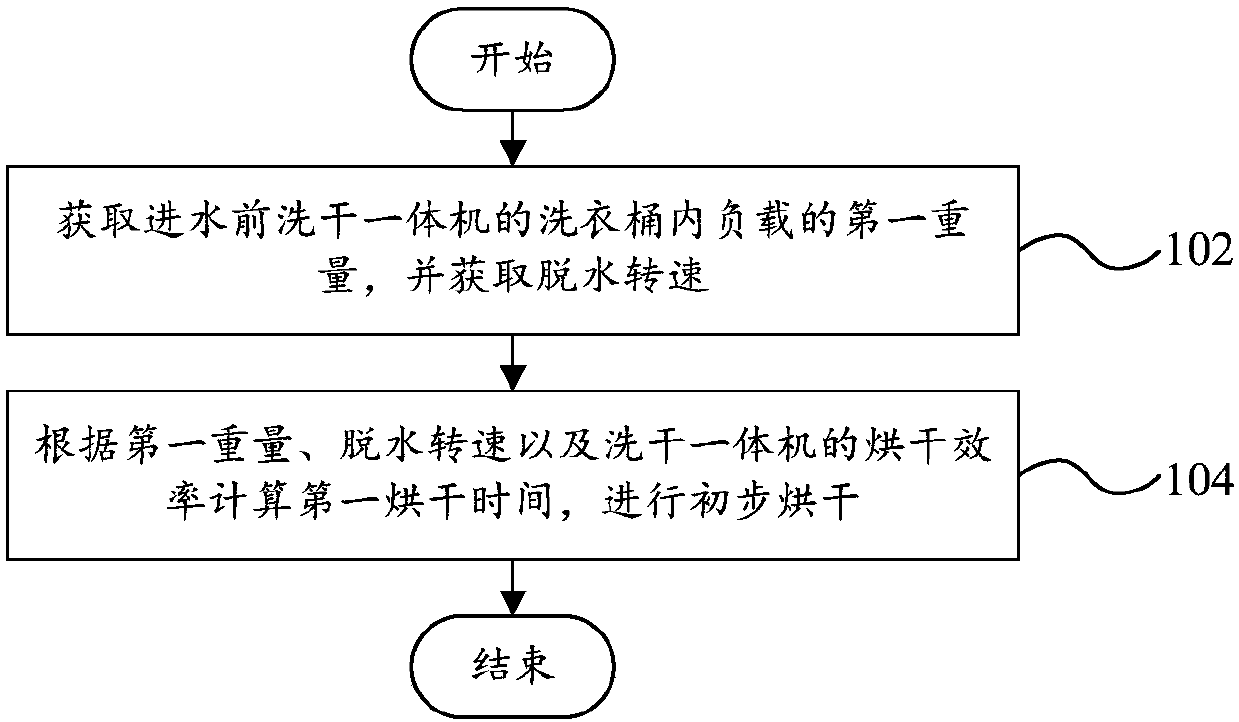

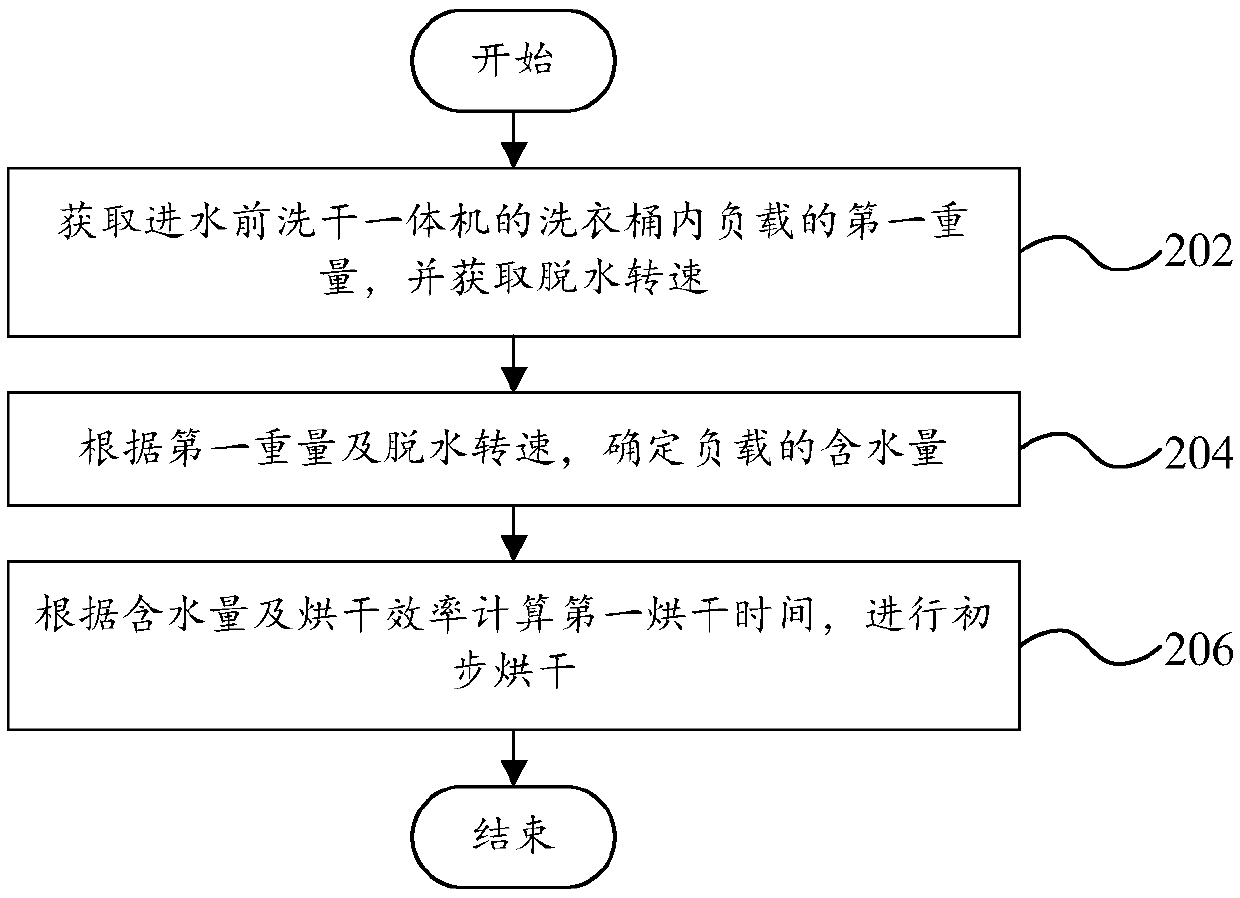

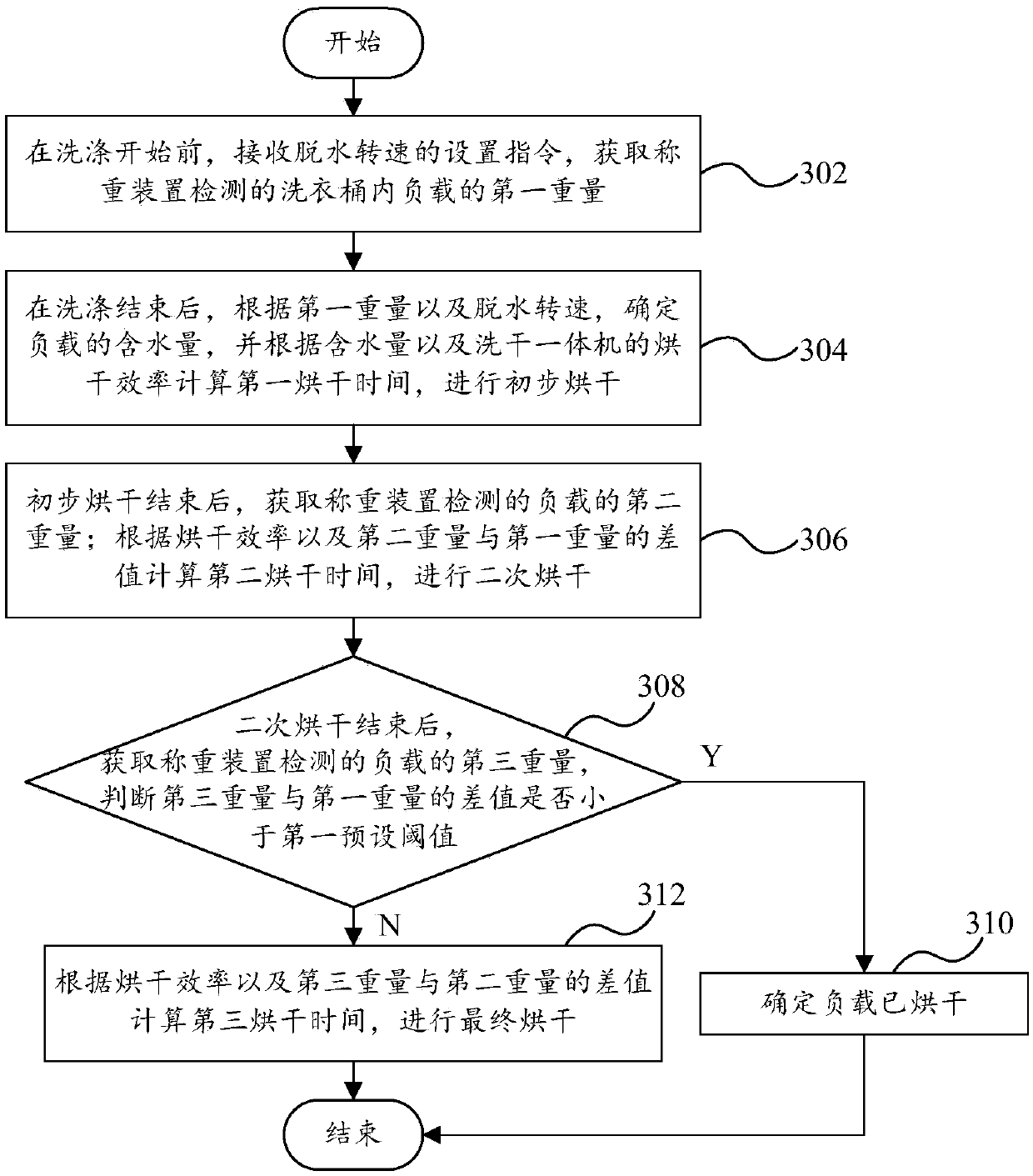

Control method of washing and drying all-in-one machine, control device for washing and drying all-in-one machine, and washing and drying all-in-one machine

ActiveCN109957955ASolve the problem that it is impossible to distinguish the difference in weighing of small loads before and after washingAvoid overbakingControl devices for washing apparatusTextiles and paperWater savingPulp and paper industry

The invention provides a control method of a washing and drying all-in-one machine, a control device for the washing and drying all-in-one machine, and the washing and drying all-in-one machine. The control method comprises the following steps: acquiring a first weight of a load in a washing drum of the washing and drying all-in-one machine before water enters the washing and drying all-in-one machine, and acquiring a spinning speed; calculating first drying time according to the first weight, the spinning speed and the drying efficiency of the washing and drying all-in-one machine, and carrying out preliminary drying. By adopting the technical scheme provided by invention, the water content of clothing can be accurately known, and the drying time can be initially determined, so that the problem that a motor can not discriminate the weighing difference before and after washing of the micro load is solved, and the problem that when a user puts wet clothes into the machine, the drying program is not performed due to a small weighing difference value before and after washing is also solved; therefore, the situation of over-baking or not baking to dryness is avoided, and the drying effect is effectively improved. Compared with related washing and drying all-in-one machines, the washing and drying all-in-one machine provided by the invention is more intelligent, water-saving and power-saving.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

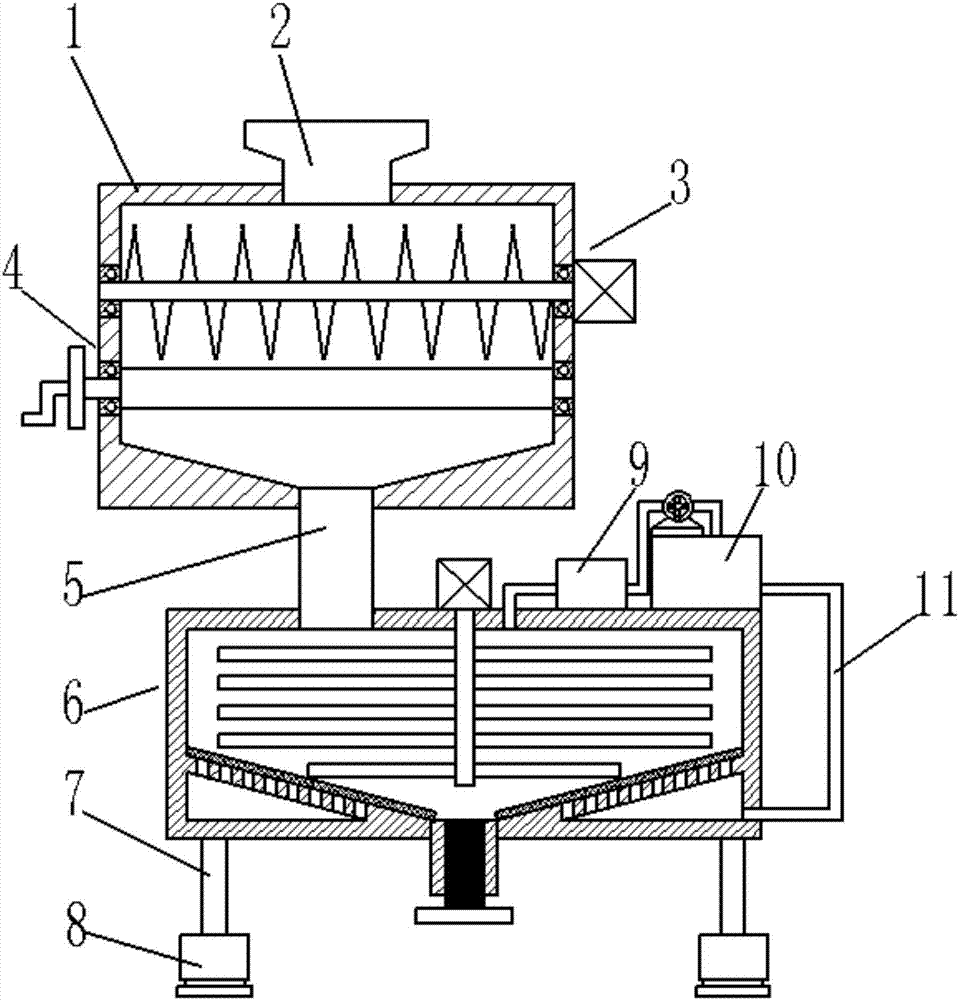

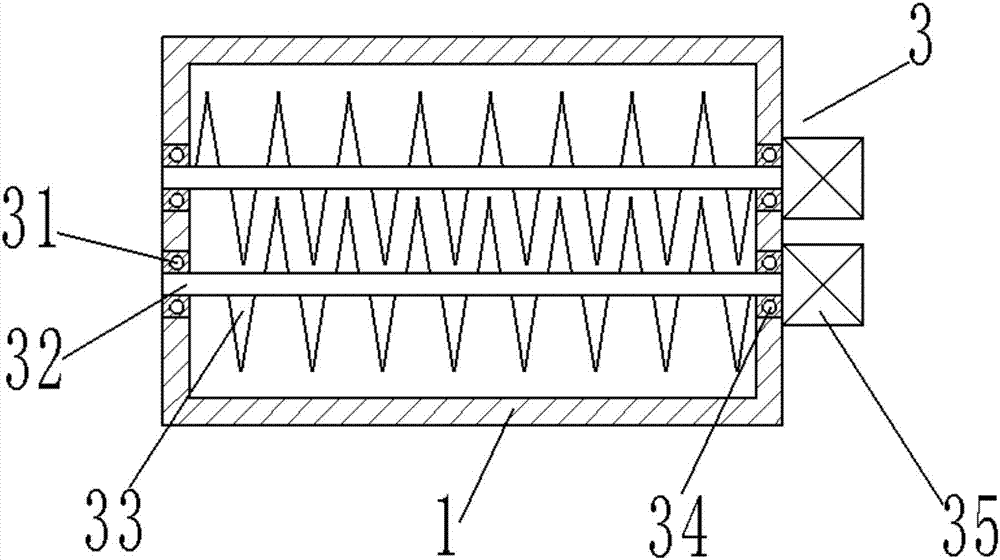

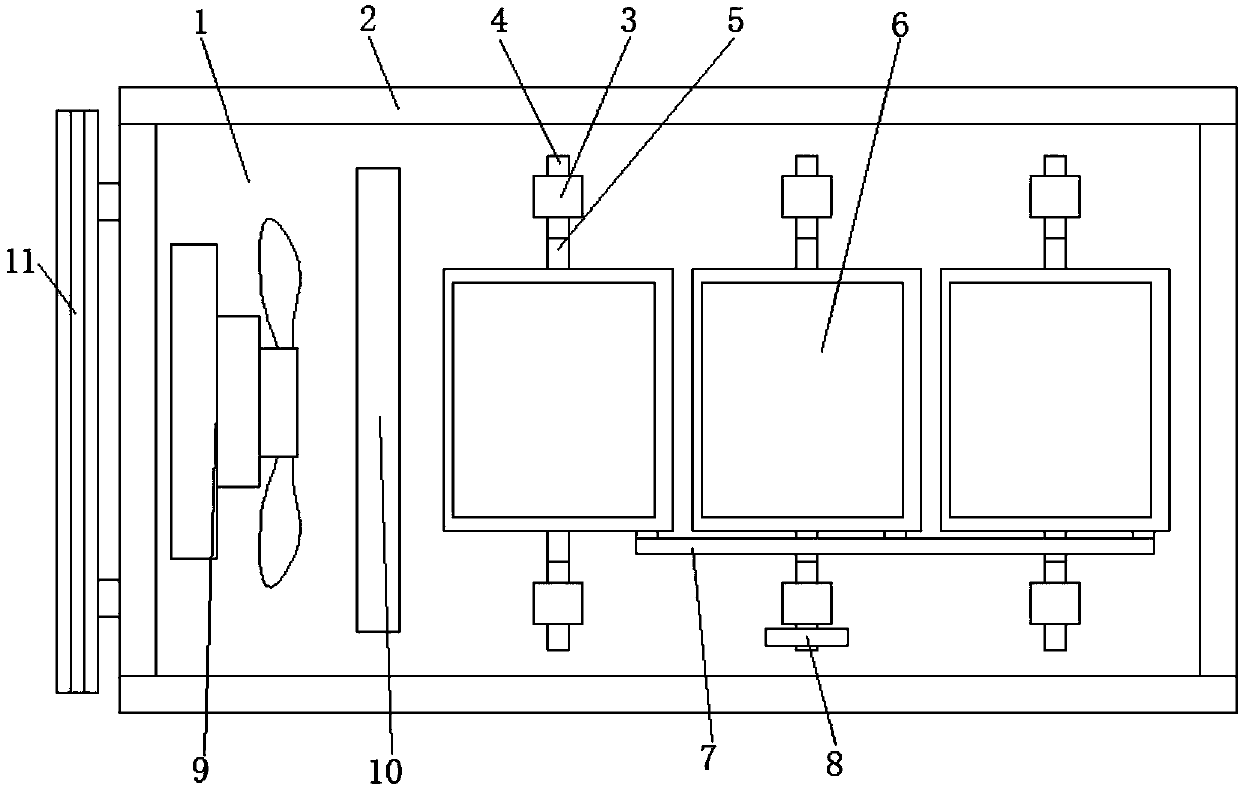

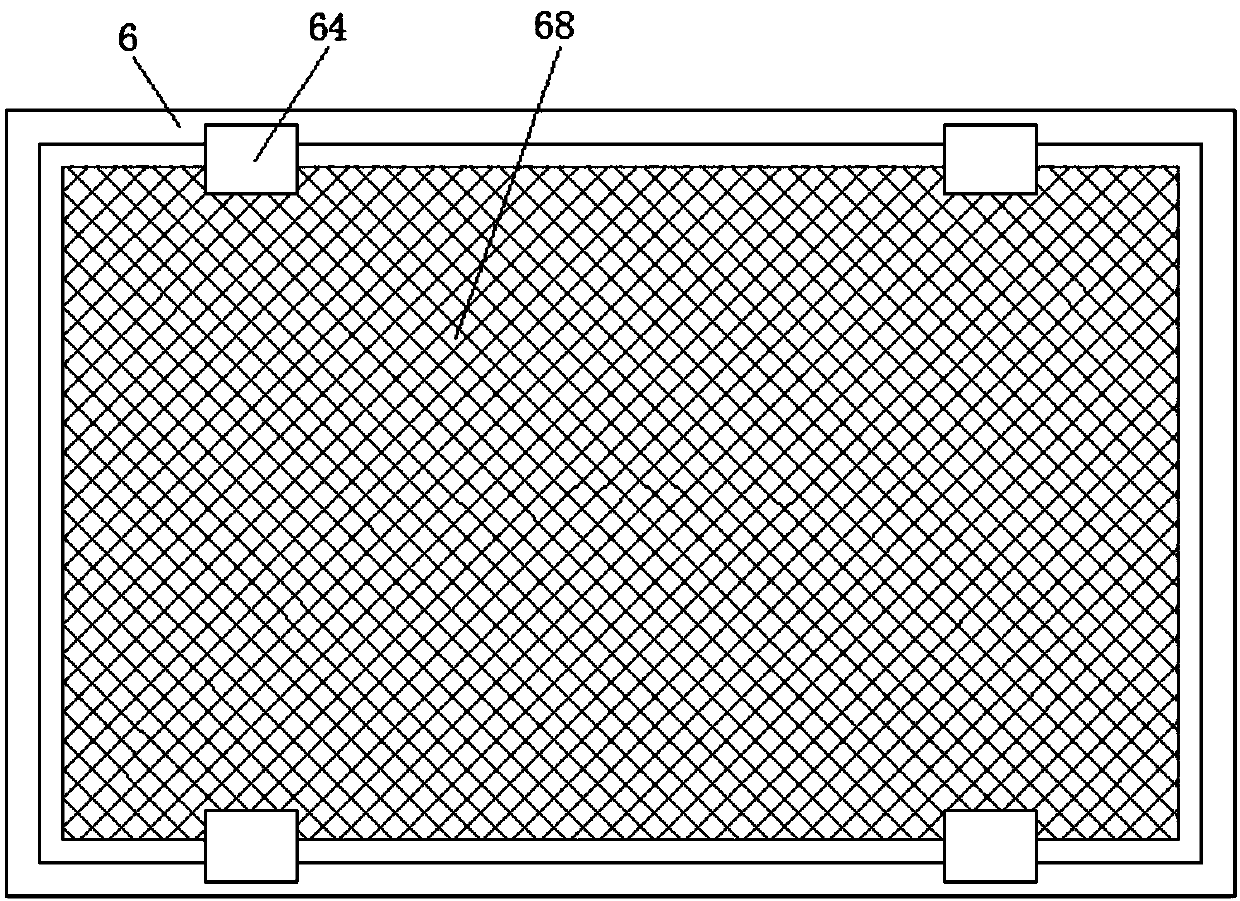

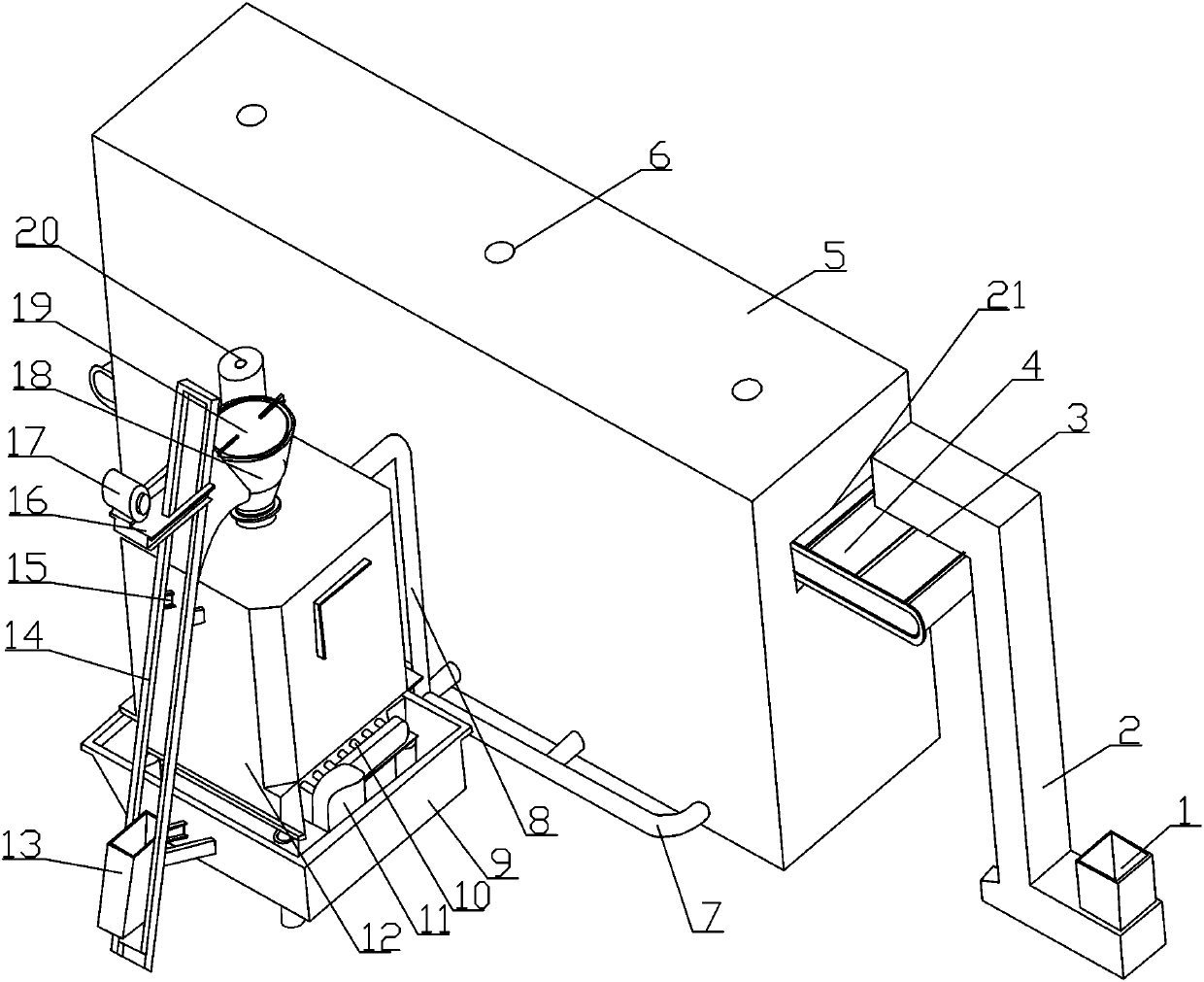

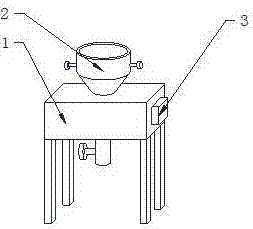

Straw grinding stirring drying device

InactiveCN107211666ACrushed fullyImprove crushing qualityDrying gas arrangementsCuttersPulp and paper industryComminution

The invention provides a novel straw crushing, stirring and drying device, which belongs to the technical field of mechanical equipment. It includes a crushing device (3), a stirring and drying device (6), a dehumidification device (9) and an air heating device (10); the crushing device (3) is fixed above the inside of the crushing box (1); the stirring and drying device (6) Welded on the four supporting columns (7); the dehumidification device (9) is fixedly installed on the right side of the upper end of the stirring drying box (61) in the stirring drying device (6); the air heating device ( 10) Fixedly installed on the right side of the upper end of the stirring drying box (61) in the stirring drying device (6), on the right side of the dehumidification device (9). The novel device of the invention has high crushing quality of straw, and after crushing, the straw is stirred and dried, and the air in the stirring drying box is extracted to carry out circulating hot air drying, thereby ensuring the drying efficiency of the straw, and the dried straw is convenient for storage.

Owner:合肥多智科技开发有限公司

Spraying device for transformer production

InactiveCN107774483ASpray evenlyGuaranteed spraying efficiencyPretreated surfacesCoatingsTransformerPulp and paper industry

The invention relates to the technical field of transformer production, and discloses a spraying device for transformer production, including a spraying box, a material inlet is opened on the left side of the spraying box, and a drying box is fixedly connected to the right side of the spraying box. The lower end of the right side of the drying box is provided with a discharge port, and the lower end of the right side of the spraying box and the lower end of the left side of the drying box are provided with through holes. The spraying device used for the production of transformers can drive the left and right movement of the spray head through the set slide plate, driven by the electric turntable, and through the cooperation with the slide plate, it can evenly spray the shell of the transformer, ensuring the spraying efficiency. Through the air outlet pipe, under the action of the fan, the wind can be blown into the upper end of the drying box, the heating plate can be used to heat the wind, and the air can be blown on the shell through the air outlet, and the air can be blown through the air collecting hood. The hot air is effectively gathered to ensure the uniform drying of the shell and the drying efficiency.

Owner:无锡匡威变压器有限公司

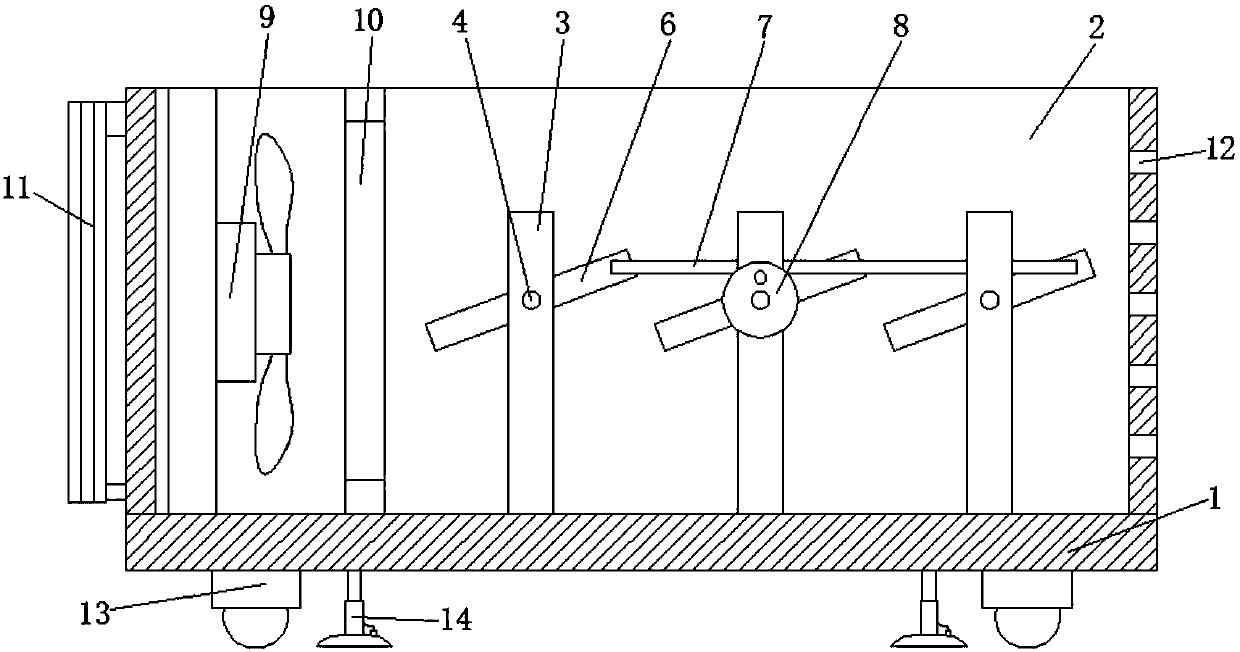

Agricultural product airing device

InactiveCN107796193AReduce the impactFlipDrying gas arrangementsDrying chambers/containersAgricultural engineeringElectric network

The invention relates to the technical field of agricultural devices, in particular to a drying device for agricultural products, which includes a base and a drying box. There are multiple sets of columns arranged side by side on the base, and each set of columns has two columns. Each column is rotatably connected with a rotating shaft for drying A central shaft is installed on both sides of the box, and the rotating shaft is coaxial with the central shaft. The drying box includes a frame and a second steel wire mesh. The bottom of the frame is equipped with a first steel wire mesh. There are four card slots in the frame. There is a block, a connecting column is inserted at the bottom of the block, a baffle is installed at the bottom of the connecting column, a spring is arranged between the baffle and the block, the second steel wire mesh is set at the bottom of the baffle, and the outside of the frame is rotatably connected with a connecting rod . The device can realize the flipping of the drying box, and at the same time, the drying box can ensure that the agricultural products placed in it will not be piled up due to inclination. In rainy weather, the agricultural products are dried by fans and electric heating nets to ensure drying efficiency and reduce weather damage. impact on agricultural products.

Owner:WUWEI XIAOLIN COMML & TRADE LTD

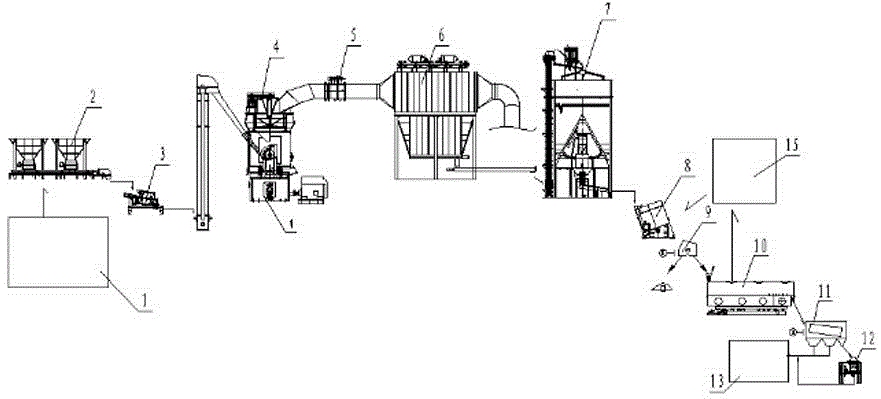

Ceramic raw material dry method granulation production line and production technology

InactiveCN105478056AImprove uniformityImprove pass rateSievingScreeningProduction lineFluidized bed drying

The invention relates to a ceramic raw material dry method granulation production line and a production technology. The production line orderly comprises a raw material field, a raw material bin, a grinding mechanism, a granulation mechanism, a drying mechanism and a screening mechanism. A mixer is arranged between a discharge outlet of the raw material bin and a feeding inlet of the grinding mechanism. A discharge outlet of the grinding mechanism is connected to a dust collector through a powder iron separator. An output end of the dust collector is connected to a powder homogenization mechanism. The powder iron separator is an iron separator with at least two rotary iron separation channels. A feeding end of a reciprocating type fluidized bed dryer is provided with a distributing device. The lower end of the distributing device is provided with an airlock. A ventilation partition plate is arranged in a blast chamber. The blast chamber is divided into a drying zone and a cooling zone through the ventilation partition plate. The screening mechanism is a rotary screen with a demountable screen. The production technology has a high one-step granulation qualified rate, a low production cost and good drying effects.

Owner:SHANDONG ECON ENERGY SAVING TECH

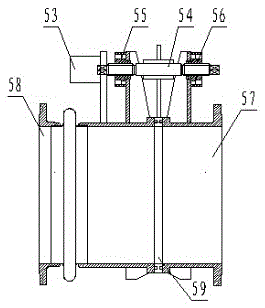

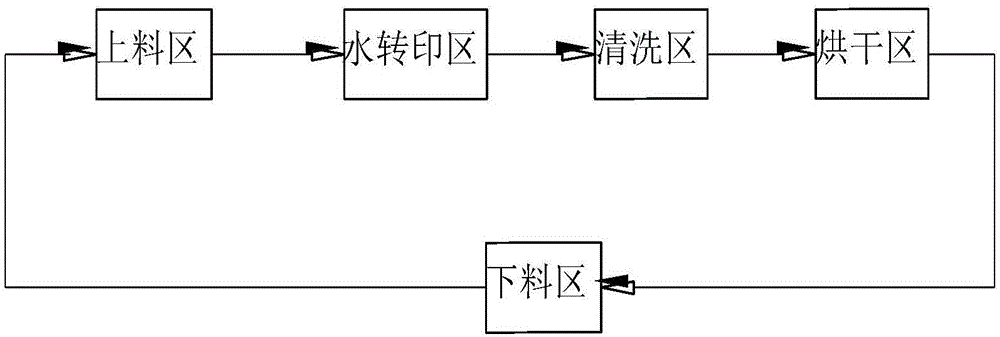

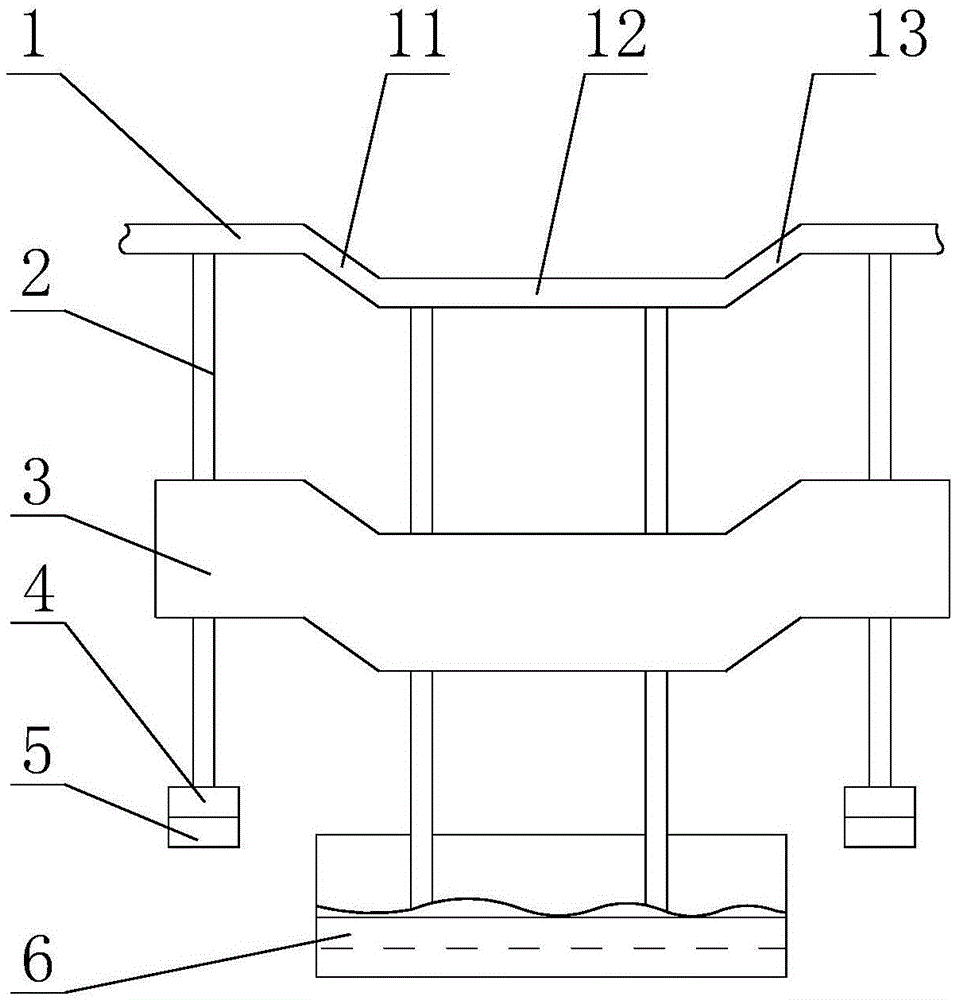

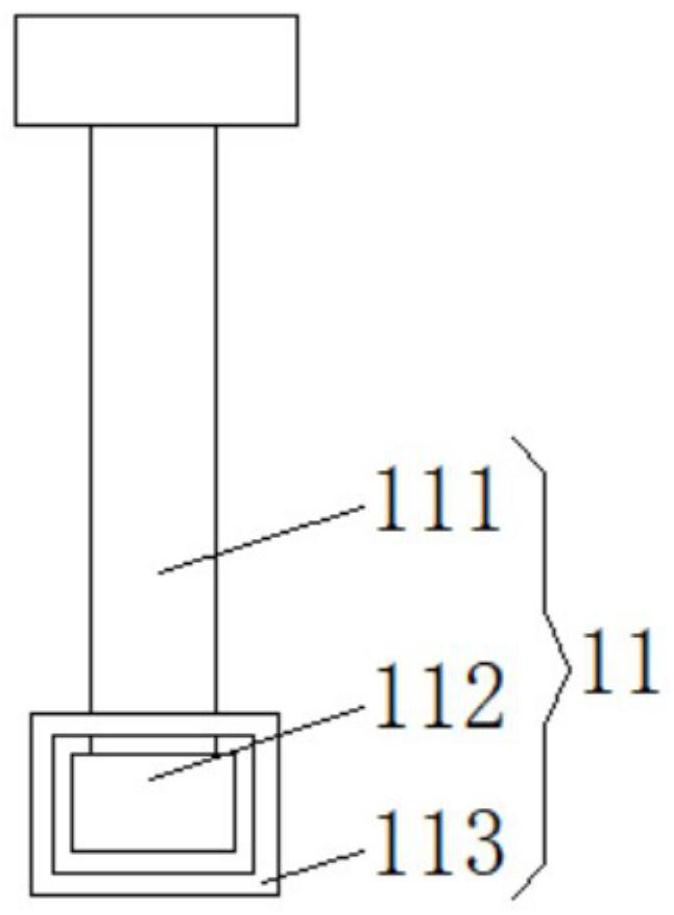

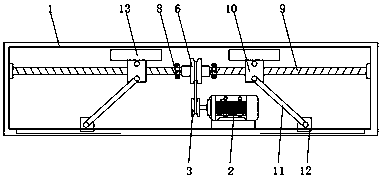

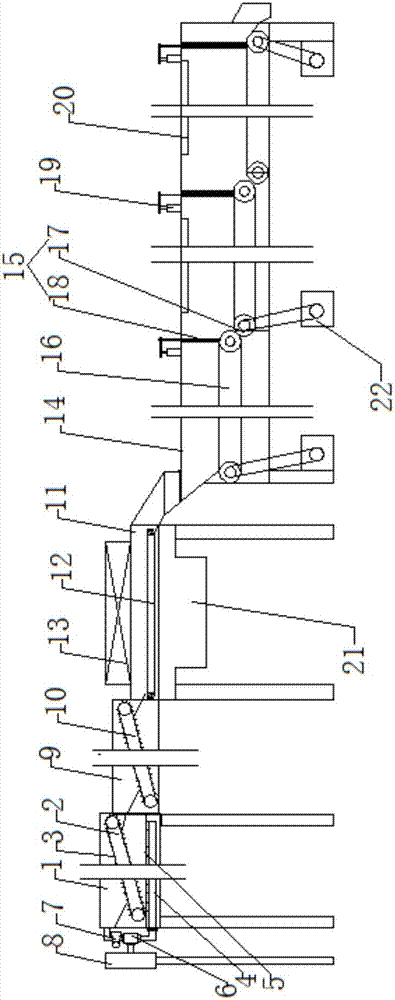

Water transfer printing production line

ActiveCN105129426AReduce labor intensityIncrease productivityTransfer printingCharge manipulationProduction lineEngineering

The invention discloses a water transfer printing production line. The water transfer printing production line comprises a hanging system, a feeding area, a water transfer printing area, a cleaning area, a drying area and a discharging area, wherein the hanging system is used for conveying workpieces, and the feeding area, the water transfer printing area, the cleaning area, the drying area and the discharging area are sequentially arranged below the hanging system. The hanging system comprises a guide rail which is used for conveying the workpieces automatically, hanging rods which are arranged on the guide rail and move along the guide rail, and clamps which are arranged at the lower ends of the hanging rods and used for clamping the workpieces. The trajectory of the guide rail constitutes a closed curve. According to the water transfer printing production line, the guide rail, the hanging rods and the clamps are used so that the workpieces can be conveyed automatically, the labor intensity of operators is relieved, and production efficiency is improved.

Owner:重庆市魏来雄鑫橡塑制品有限责任公司

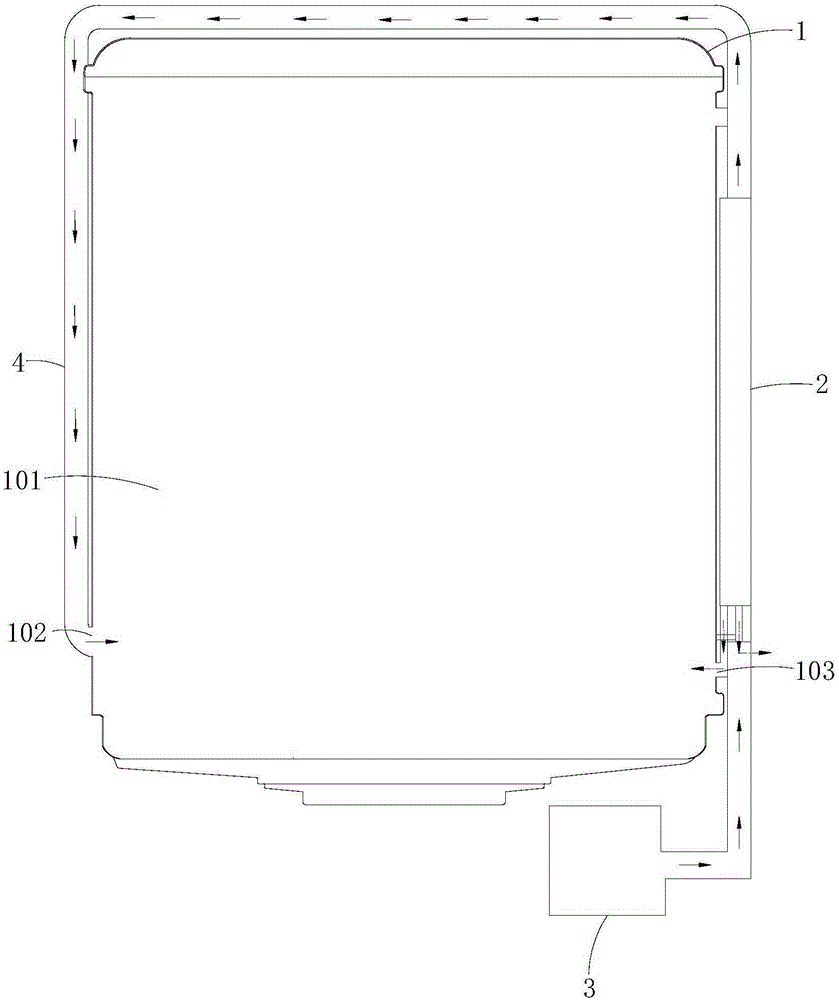

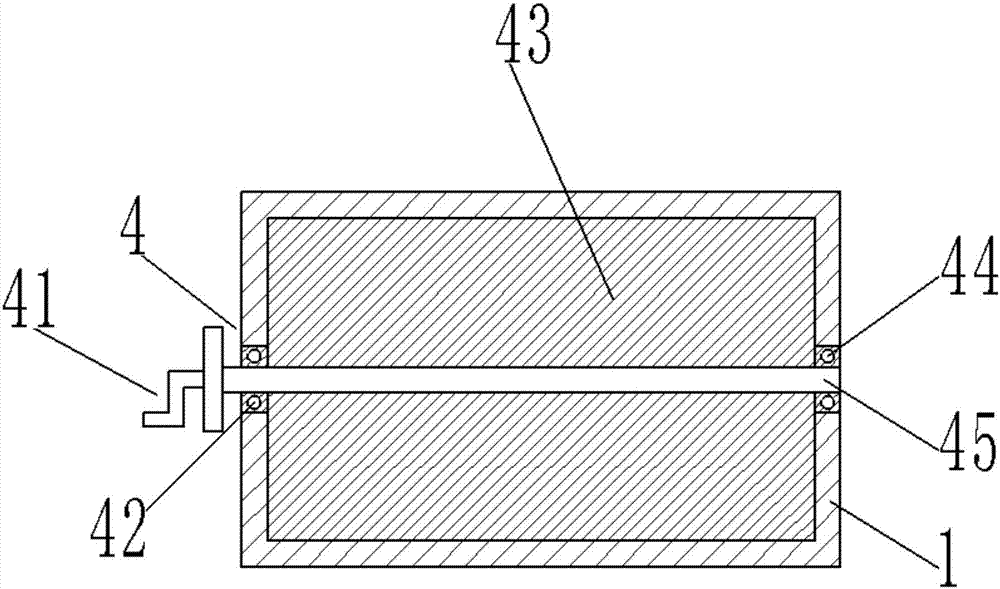

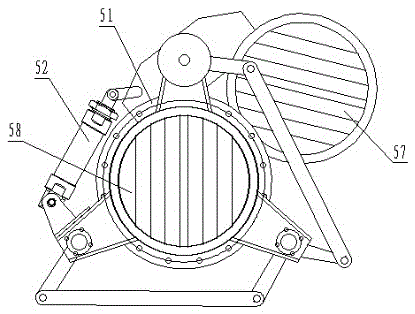

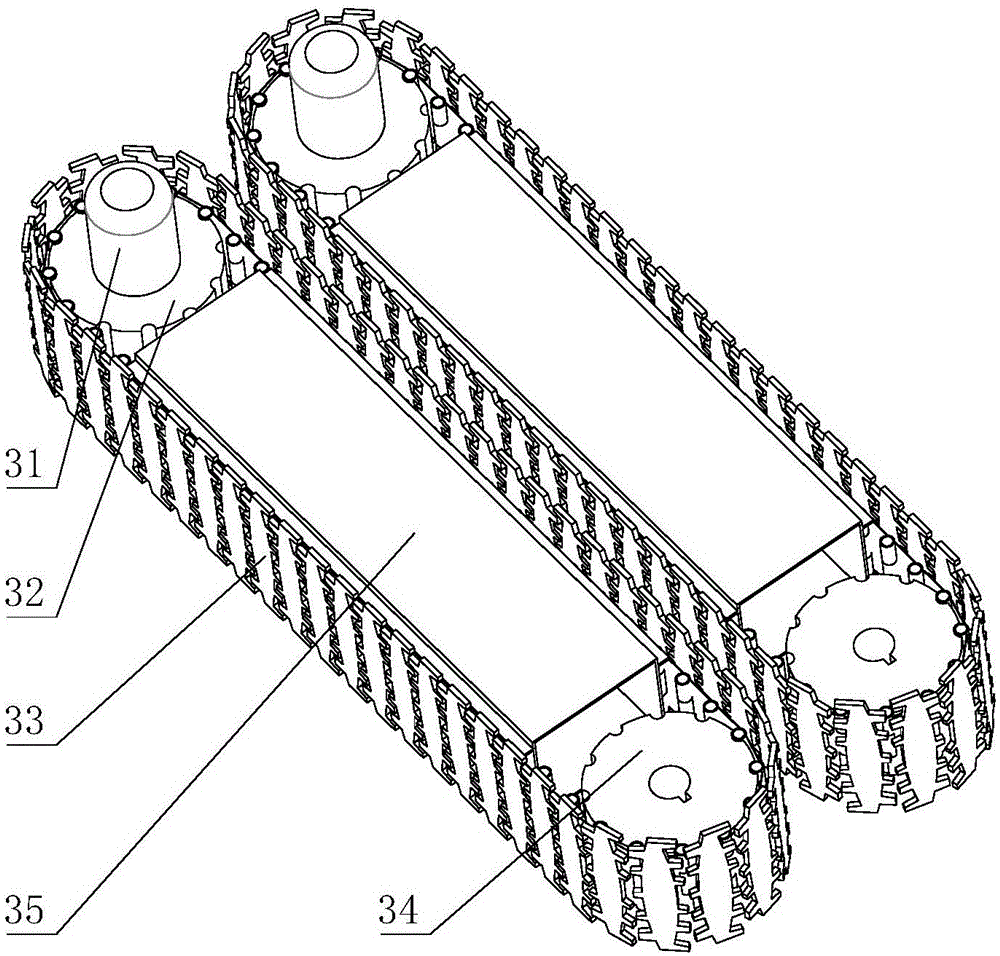

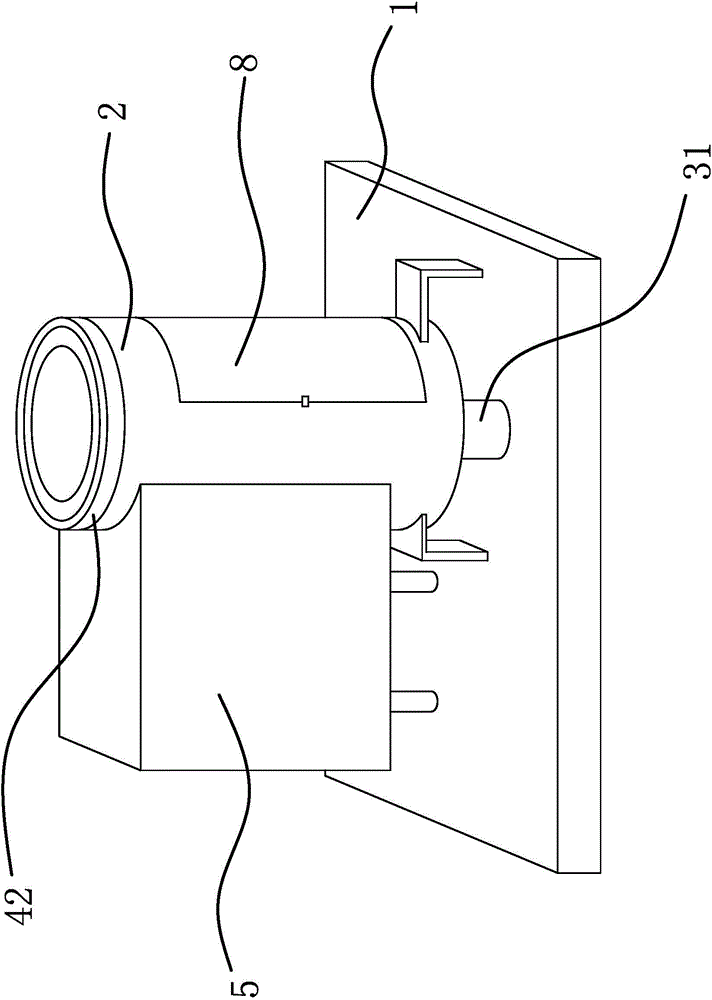

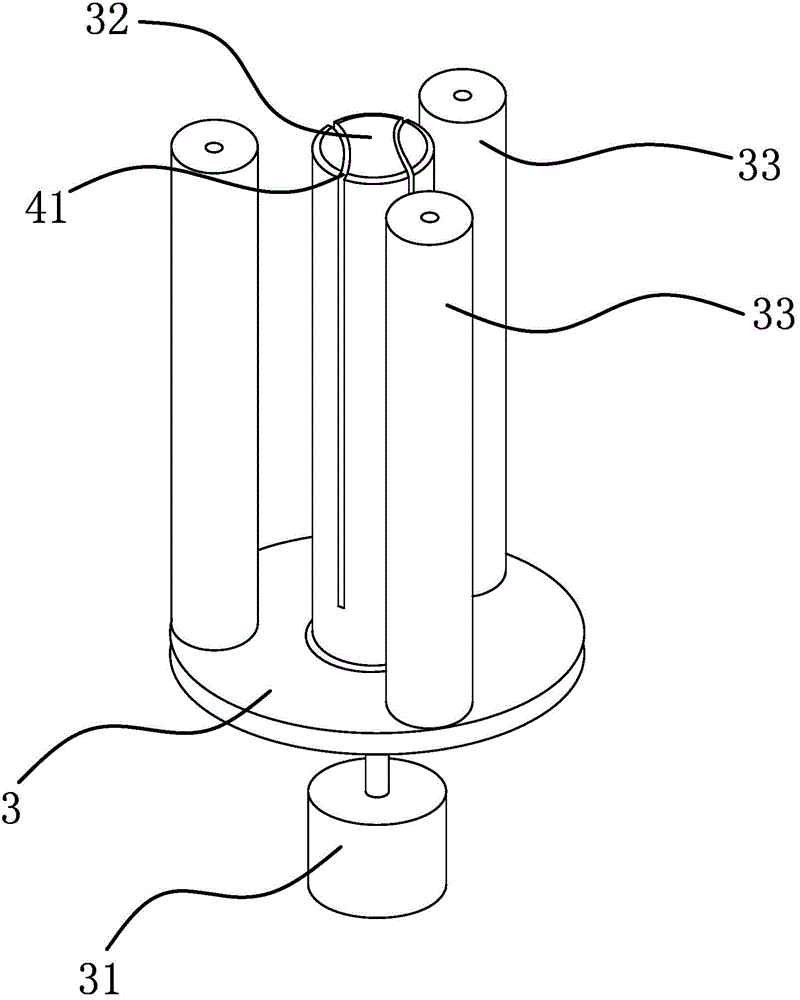

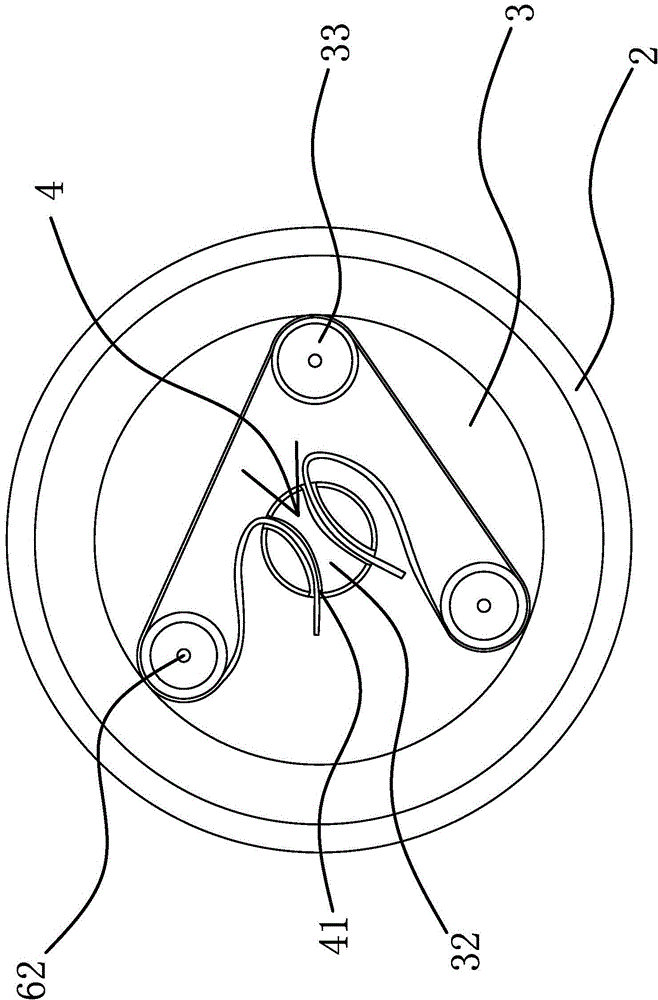

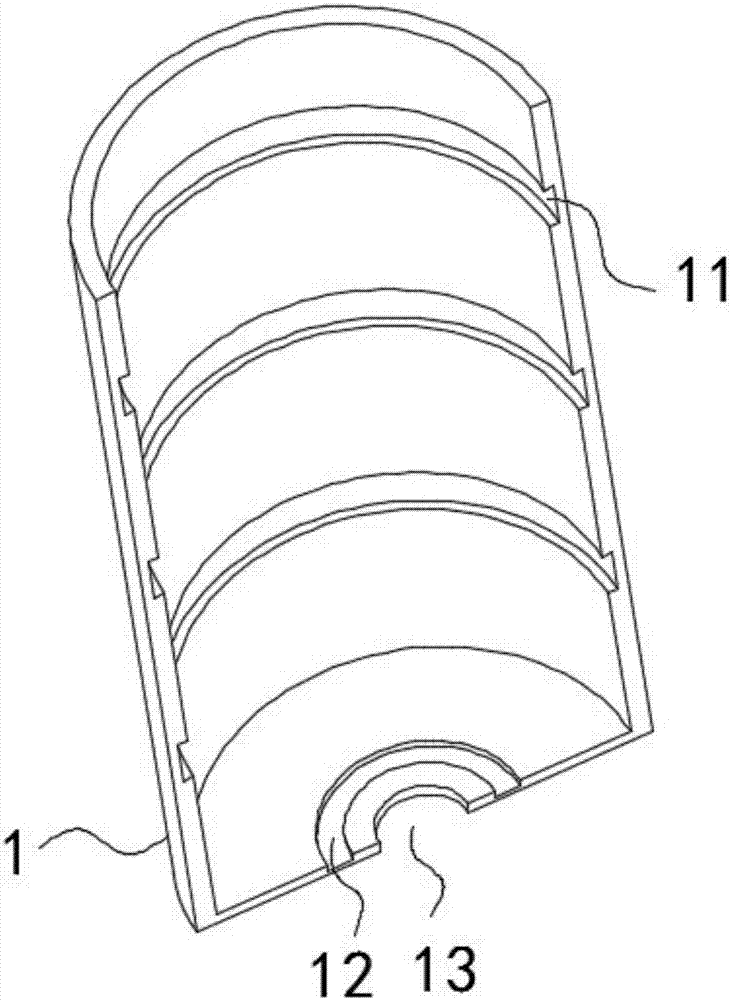

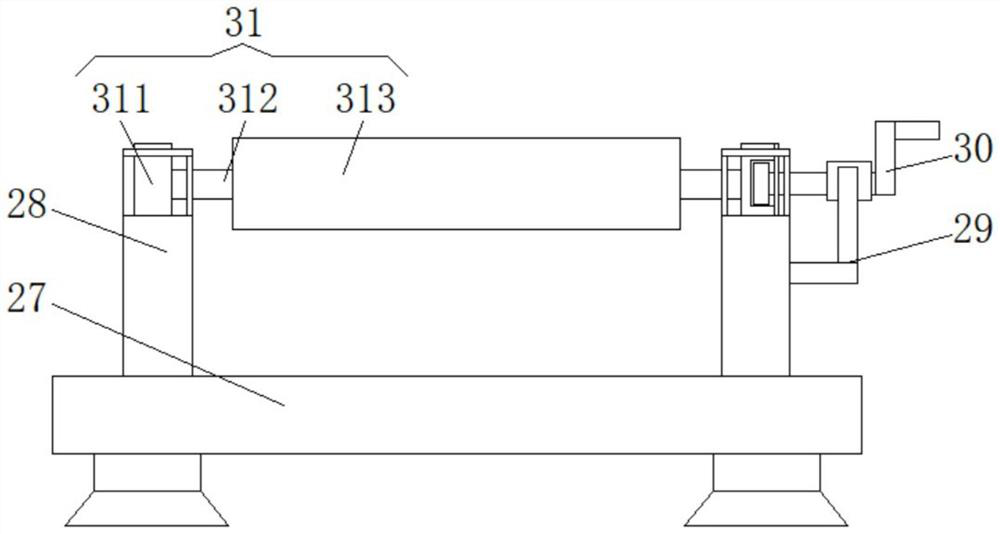

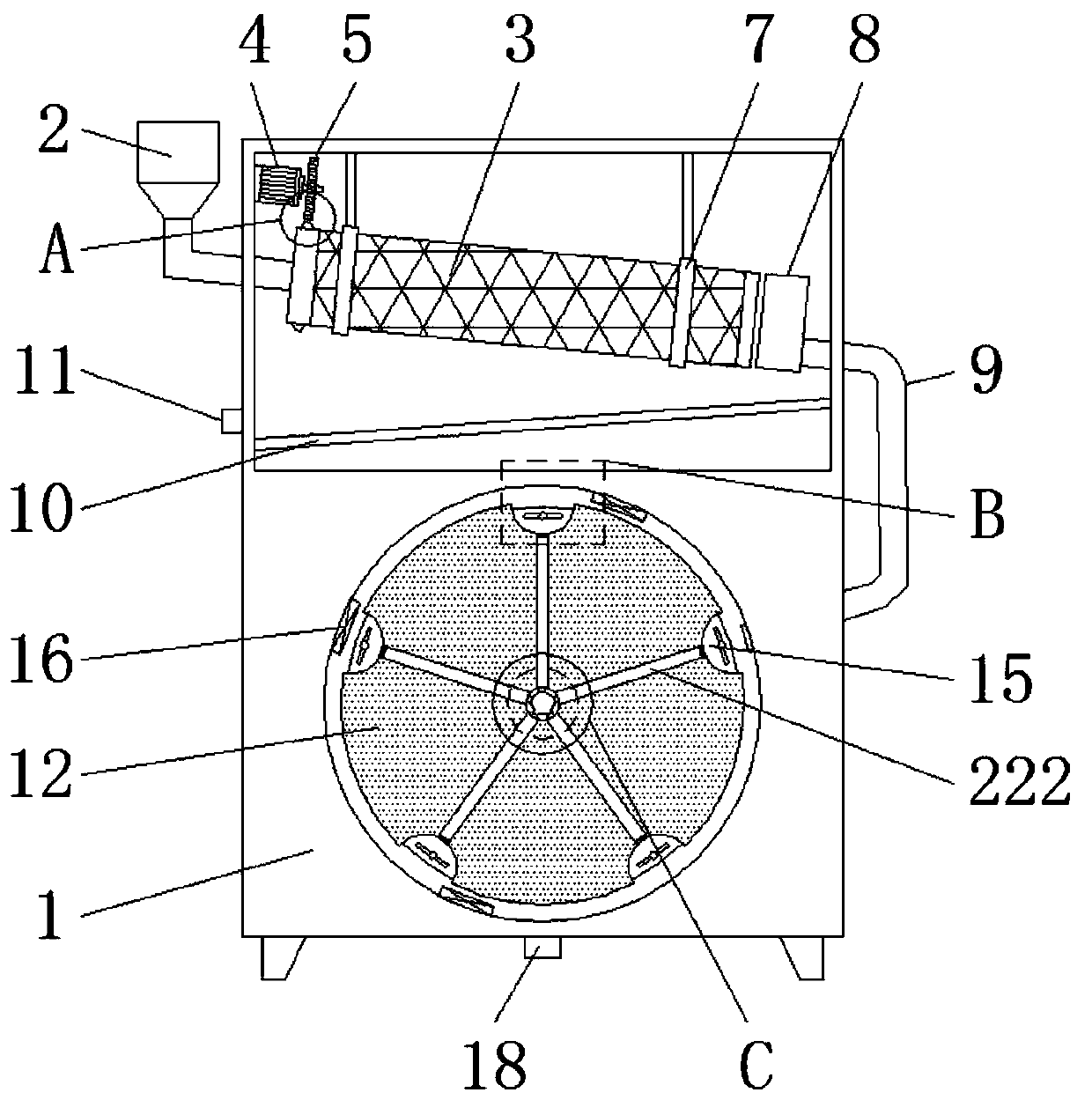

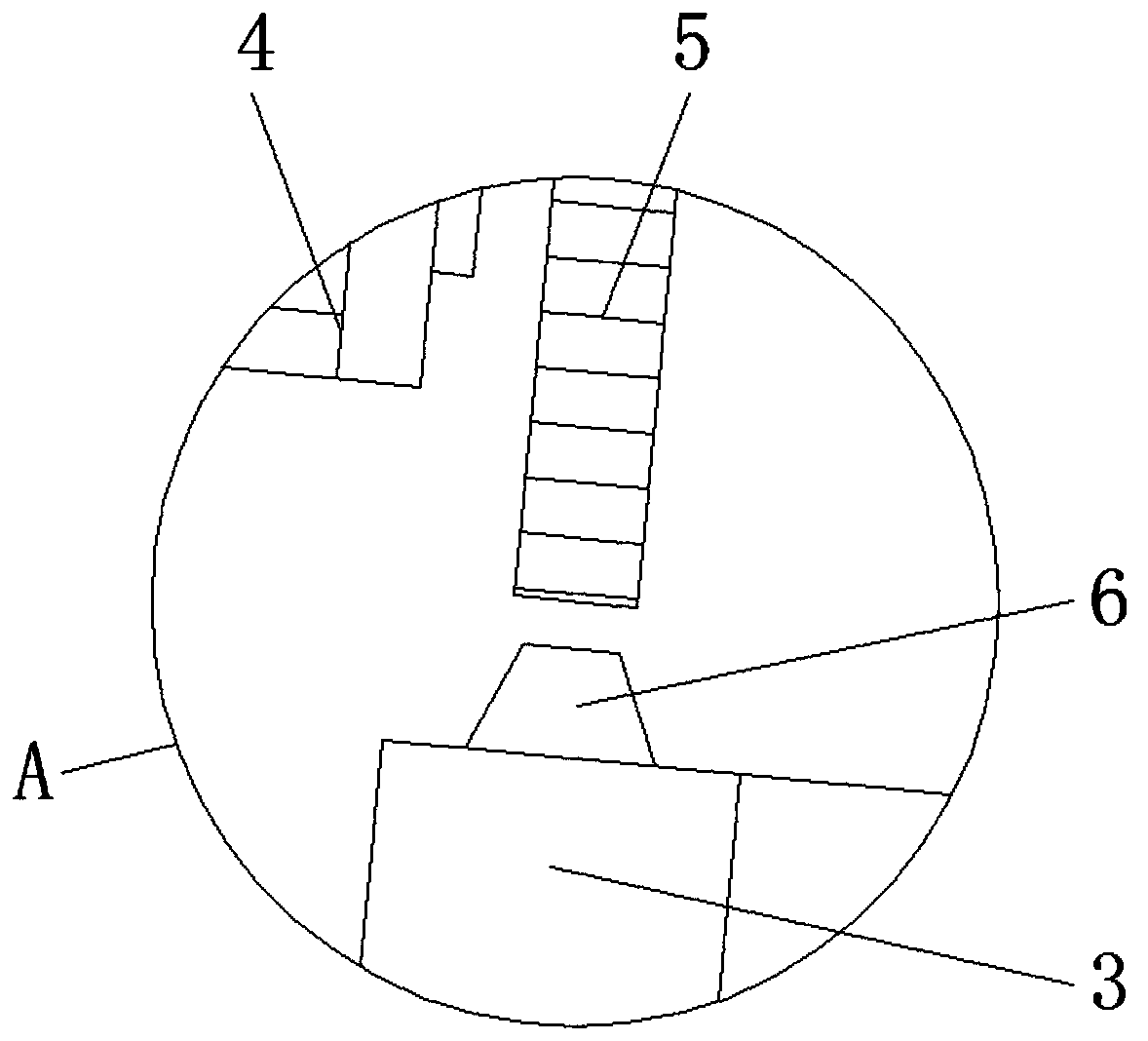

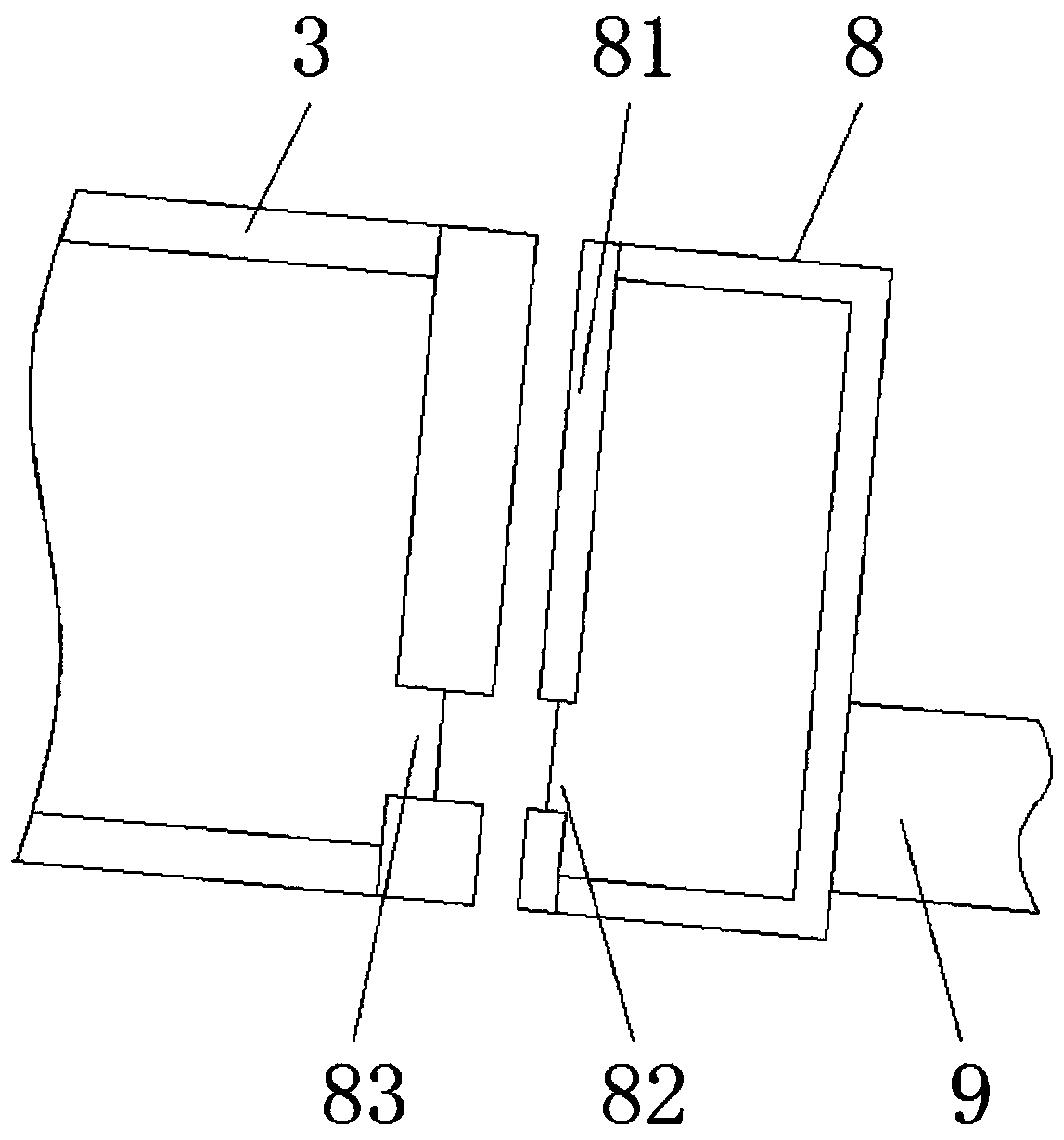

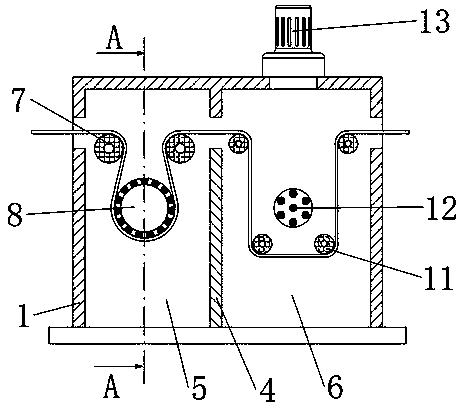

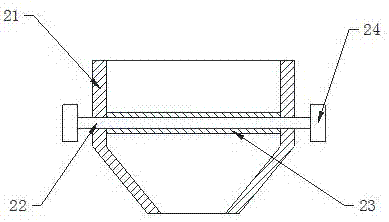

Leather drier with clamping device

InactiveCN104313198AGuaranteed drying effectGuaranteed drying efficiencySkins/hides/leather/fur manufacturing apparatusLeather dryingDrive motorPulp and paper industry

The invention provides a leather drier with a clamping device, belongs to the technical field of leather production equipment, and solves the technical problems of poor drying effect and the like of existing leather drying equipment. The leather drier with the clamping device comprises a base, the base is fixedly provided with a drying cylinder with an upper opening, a drive motor is arranged at the bottom of the drying cylinder, an output shaft of the drive motor is connected with a rotating disk, a central position of the rotating disk is provided with a positioning shaft, the clamping device capable of fixing two edges of leather onto the positioning shaft is arranged on the positioning shaft, the rotating disk is uniformly provided with three tensioning cylinders abutting the leather and tensioning the leather, the outer side of the drying cylinder is provided with an air cylinder, the air cylinder is provided with a fan, the air cylinder and the drying cylinder are communicated, a sponge water absorption plate for covering the opening is arranged on the upper end of the drying cylinder, and the the tensioning cylinder is provided with an electric heating wire. The leather drier has the advantages of good drying effect and the like.

Owner:江苏东方金狐狸服饰有限公司

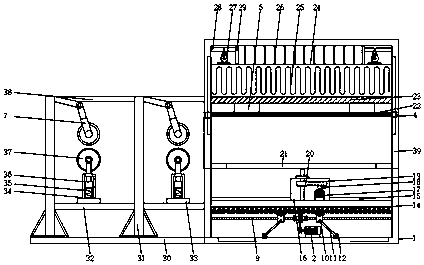

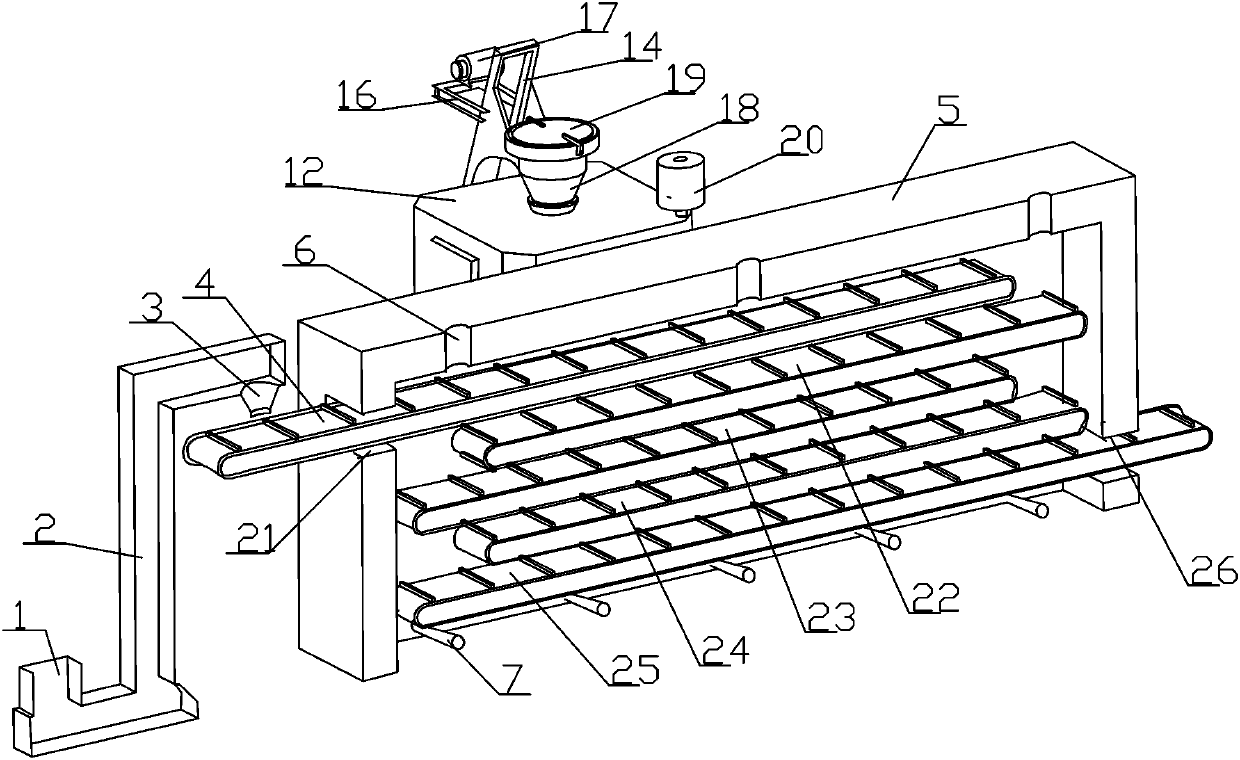

Efficient rice drying machine

ActiveCN104990388AWith drying functionWith cooling functionDrying gas arrangementsSeed preservation by dryingProcess engineeringAir blower

The invention discloses an efficient rice drying machine. The efficient rice drying machine comprises a machine shell, multiple rice conveyer belts and a rice storing box. The machine shell is provided with a feeding hopper. The multiple rice conveying belts are arranged in the machine shell from top to bottom in a staggered mode in sequence. The conveying directions of every two adjacent rice conveying belts are opposite so that rice can be conveyed layer by layer from top to bottom. The machine shell is provided with multiple partition plates, wherein each partition plate is located above the corresponding rice conveying belt. The partition plates are divided into an upper group and a lower group. Electric heating devices are arranged on the upper group of partition plates. The electric heating devices are further connected with first air blowers. Second air blowers are arranged on the lower group of partition plates. The rice storing box is arranged in the machine shell and located below the lowest rice conveying belt. The rice output portion, opposite to the lowest rice conveying belt, of the rice storing box is provided with a point portion enabling the dried rice to be distributed to the two sides. The rice drying machine has the drying and cooling functions, and the rice can be rapidly dried and is high in efficiency.

Owner:YANCHENG MAICRETE MACHINERY

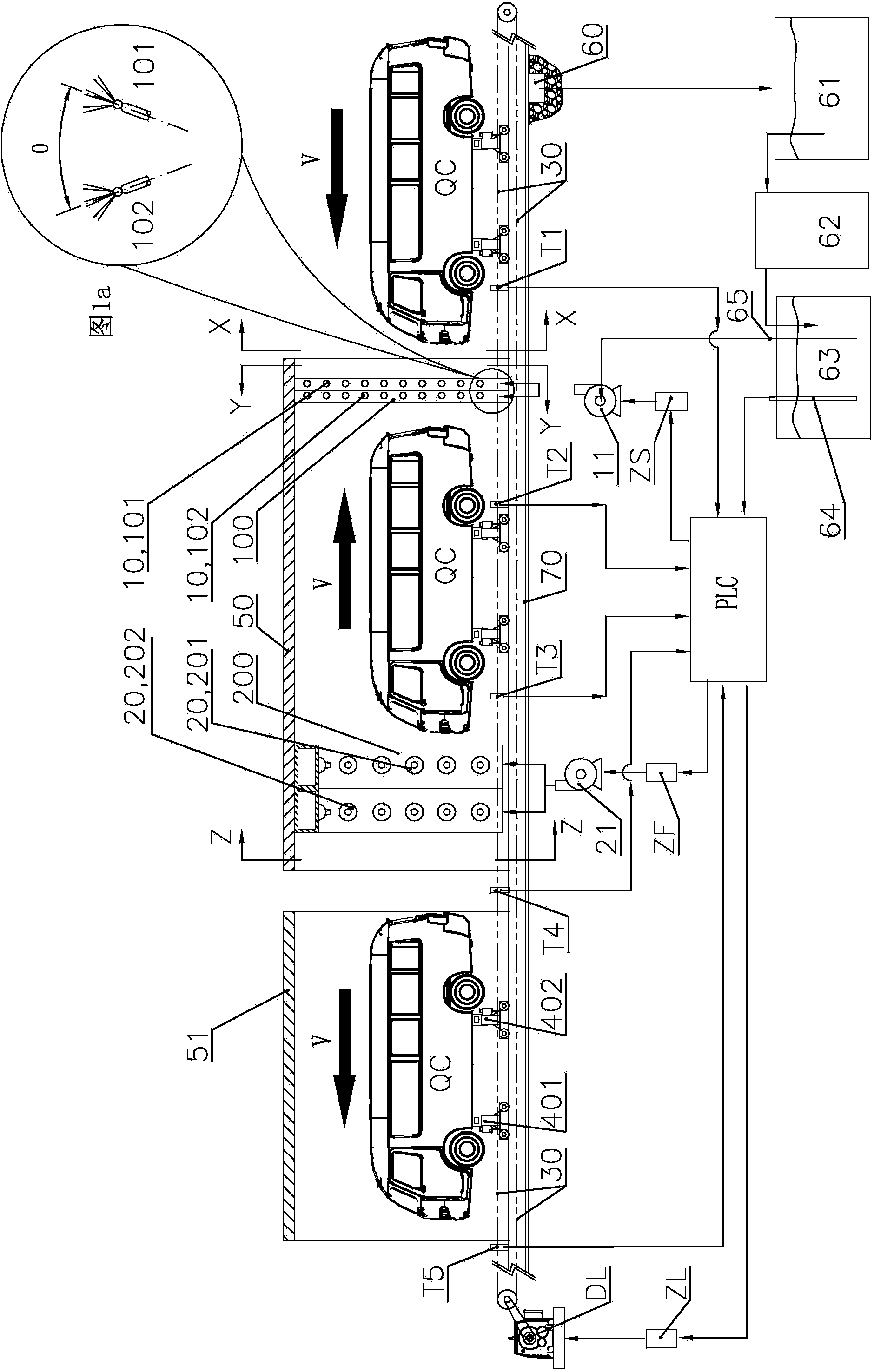

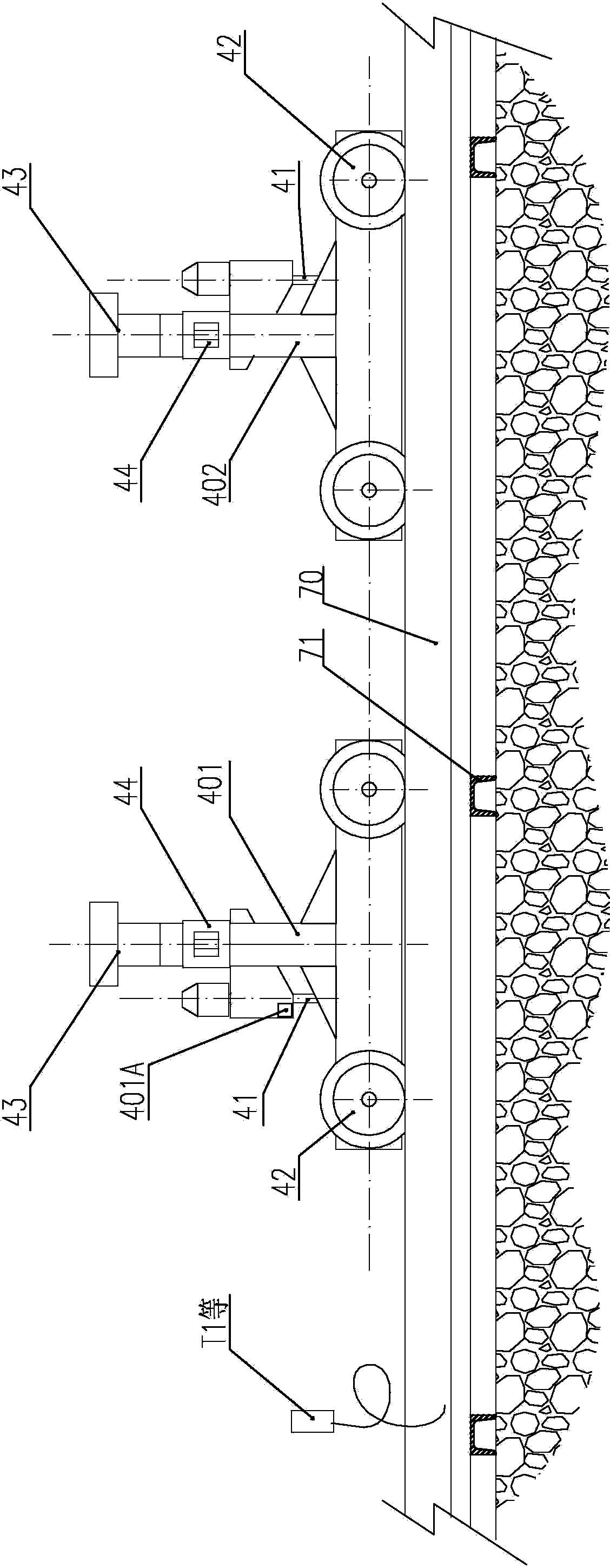

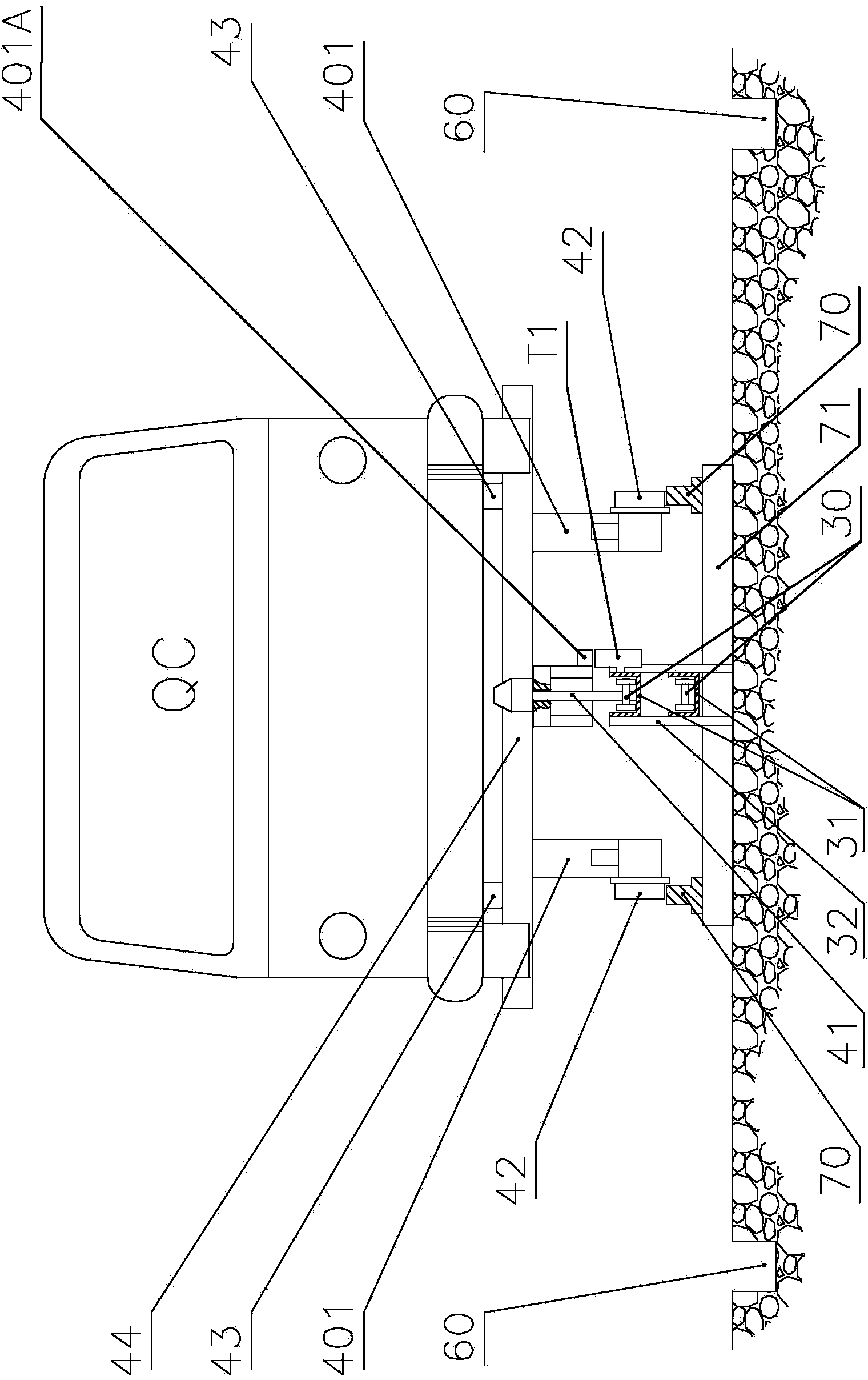

Automatic cleaning method and automatic cleaning device of scraped car

ActiveCN104029659AGuaranteed cleaning efficiencyReduce cleaning efficiencyCleaning apparatus for vehicle exteriorsWash waterBackup

The invention relates to an automatic cleaning method and automatic cleaning device of a scraped car. The method comprises the steps that a front sensor T1 and a rear sensor T2 are arranged in front of and behind a wash water spray head respectively to monitor a passing car body, a processor is adopted to receive the signals of the sensors and outputting instructions after processing to control the operation of wash water, a rail carrier dragged by a ground chain mechanism is adopted to transfer the washed scraped car in the automatic cleaning method, and the processor is adopted to monitor the traction direction of a ground chain and add up the number of backups of the carrier between the sensor T1 and the sensor T2; the rear end signals of the carrier are responded to, whether the number of backups of the ground chain exceeds a set number S1 or not is verified by the processor, the carrier is dragged to move backwards if the number of backups is smaller than or equal to S1, and if the number of backups is larger than S1, the ground chain is controlled to continue to drag the carrier to move forwards, and the wash water is closed. The cleaning work efficiency of the scraped car can be guaranteed on the premise of reducing or saving the occupied area of the automatic cleaning device and facilitating wash water recycling, and implementation is easy.

Owner:WUHAN GEM URBAN MINE EQUIP +3

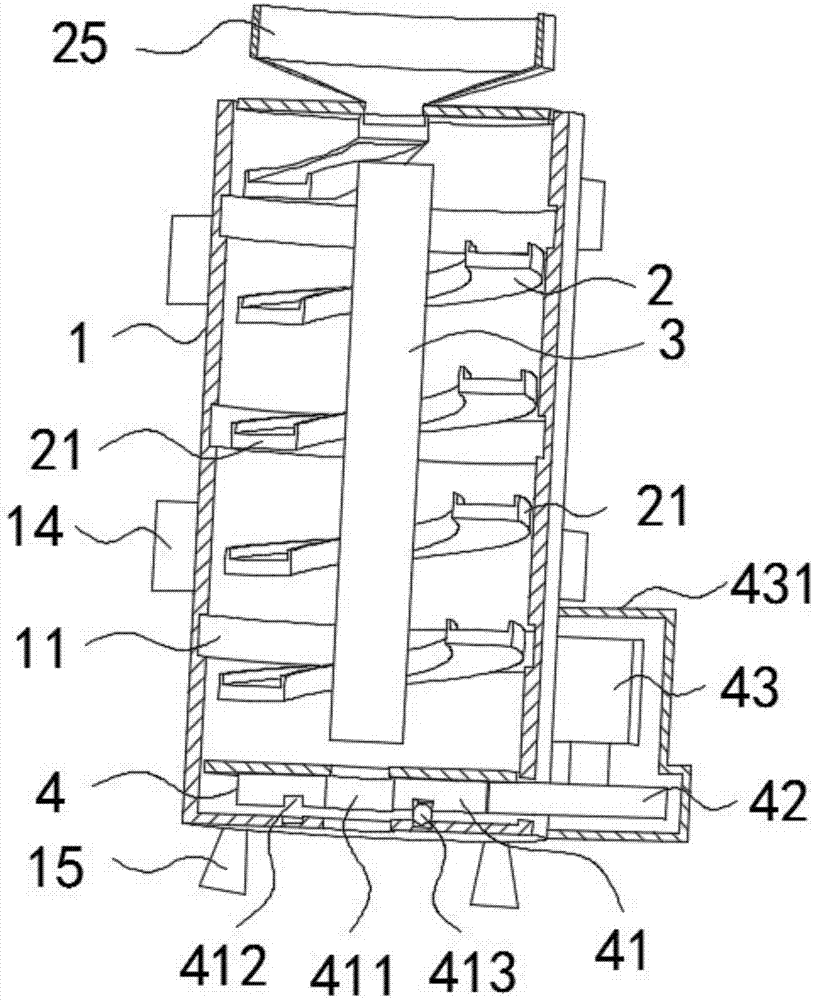

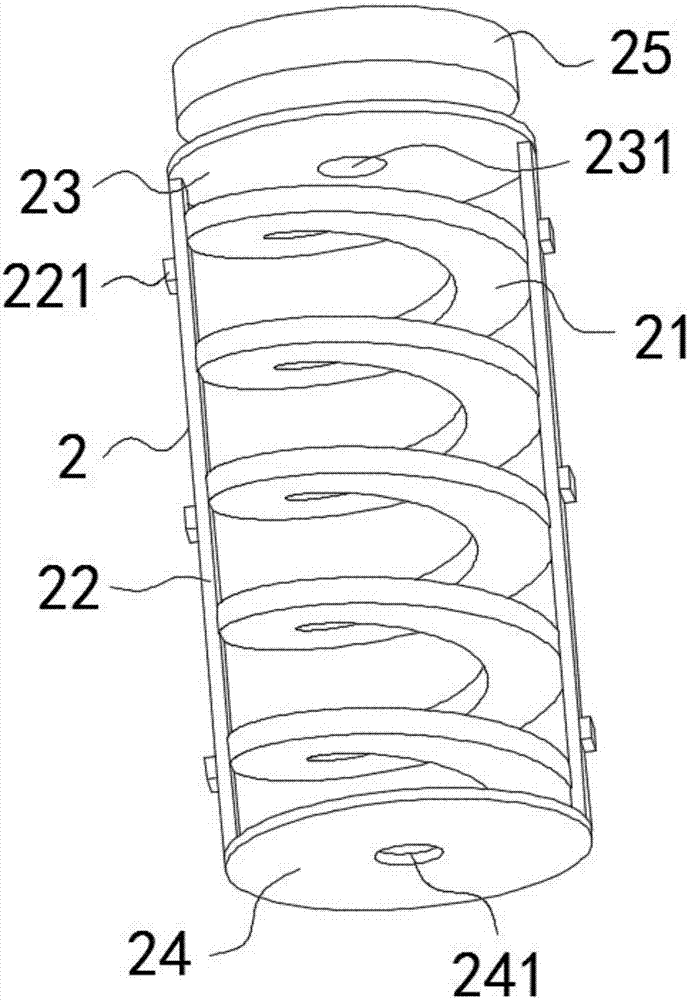

Spiral type traditional Chinese medicine drying device and using method thereof

InactiveCN107883731AGuaranteed drying efficiencyEvenly heatedDrying machines with progressive movementsDrying solid materialsEngineeringChinese herbology

The invention discloses a spiral type traditional Chinese medicine drying device and a using method thereof and relates to the technical field of traditional Chinese medicine processing equipment. Thespiral type traditional Chinese medicine drying device comprises a barrel and a rotating mechanism. The barrel comprises a plurality of barrel body sliding grooves, a barrel bottom sliding groove anda collecting opening, wherein the barrel body sliding grooves are evenly formed in the inner surface of the barrel, the round barrel bottom sliding groove is formed in the bottom surface of the barrel, and the collecting opening is formed in the bottom surface of the barrel and located in the barrel bottom sliding groove. The rotating mechanism comprises a spiral slideway, fixing rods, a top cover and a bottom cover. Traditional Chinese medicines are continuously conveyed from top to bottom through the spiral slideway, the conveying effect is improved in cooperation with an electromagnetic vibrator, and thus traditional Chinese medicines are evenly heated and prevented from blocking the spiral slideway; and then according to the humidity of traditional Chinese medicines, the rotating speed of a motor and the temperature of a heating body are regulated, and thus traditional Chinese medicines can be dried rapidly.

Owner:岳西县圣锦生态农业科技发展有限公司

Dryer for textile processing and production

InactiveCN111928618AEasy to spread outAvoid affecting the drying effectDrying gas arrangementsDrying machines with progressive movementsMechanical engineeringIndustrial engineering

The invention relates to the technical field of textile auxiliary equipment, and discloses a dryer for textile processing and production. The dryer comprises a drying box body, wherein a placement frame plate is fixedly arranged on one side of the bottom of an inner cavity of the drying box body, and the inner cavity of the drying box body is fixedly provided with a dryer body located above the placement frame plate in a sleeving mode; movable rods located between the placement frame plate and the dryer body are arranged inside the drying box body, and the outer portions of the movable rods are fixedly provided with rotating rollers in a sleeved mode; and one side of the drying box body is fixedly provided with a ventilation exhaust window located between the placement frame plate and thedryer body in a sleeved mode, and the bottoms of the two sides of the drying box body are fixedly connected with fixing frames. According to the dryer for textile processing and production, through aplacement sleeve plate, a positioning plate, an adjusting device and a flattening plate, to-be-dried textile fabric is conveniently spread, so that the situation that the drying effect is affected dueto the fact that the textile fabric is wrinkled together before entering the drying box body is avoided, normal drying is guaranteed, and the practicability of the device is improved.

Owner:东阳市川泽户外用品有限公司

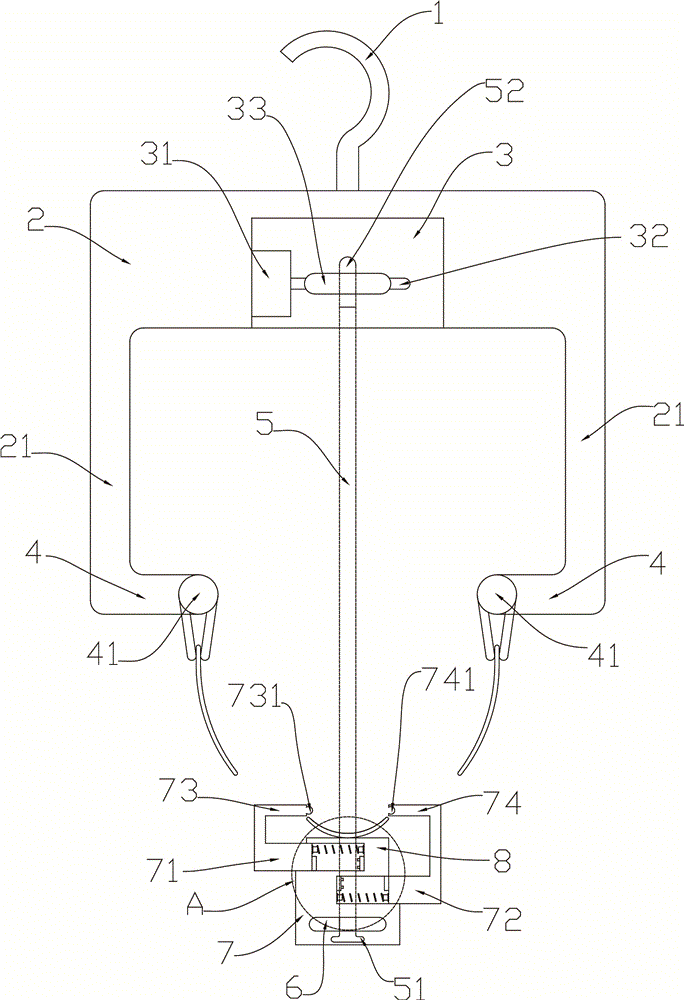

Improved type underpants airing device

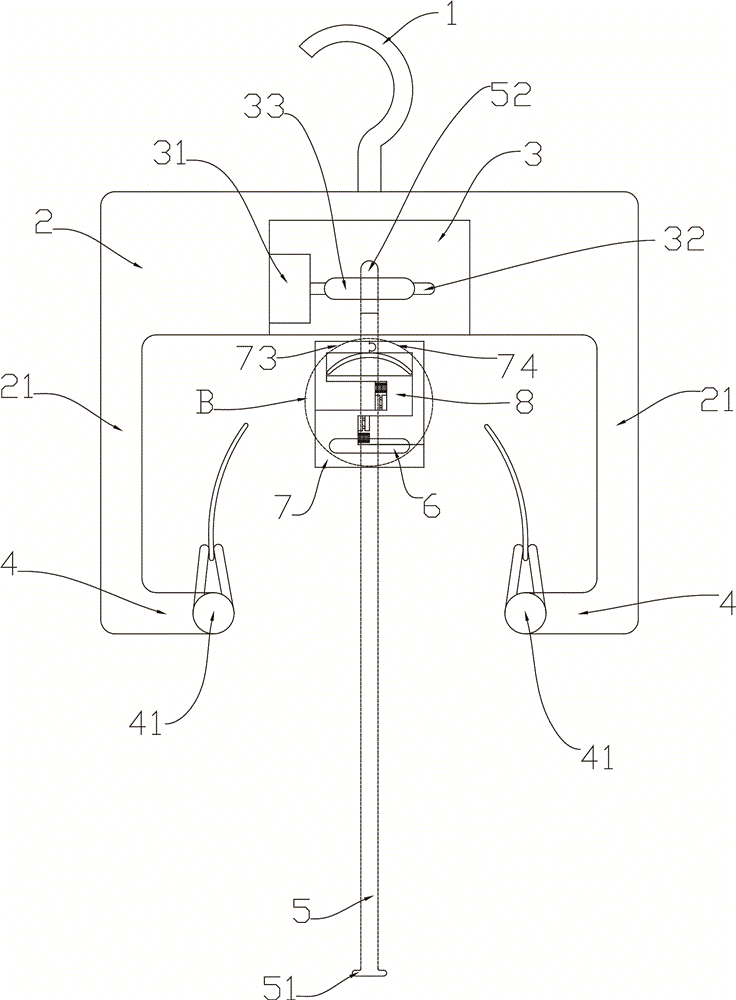

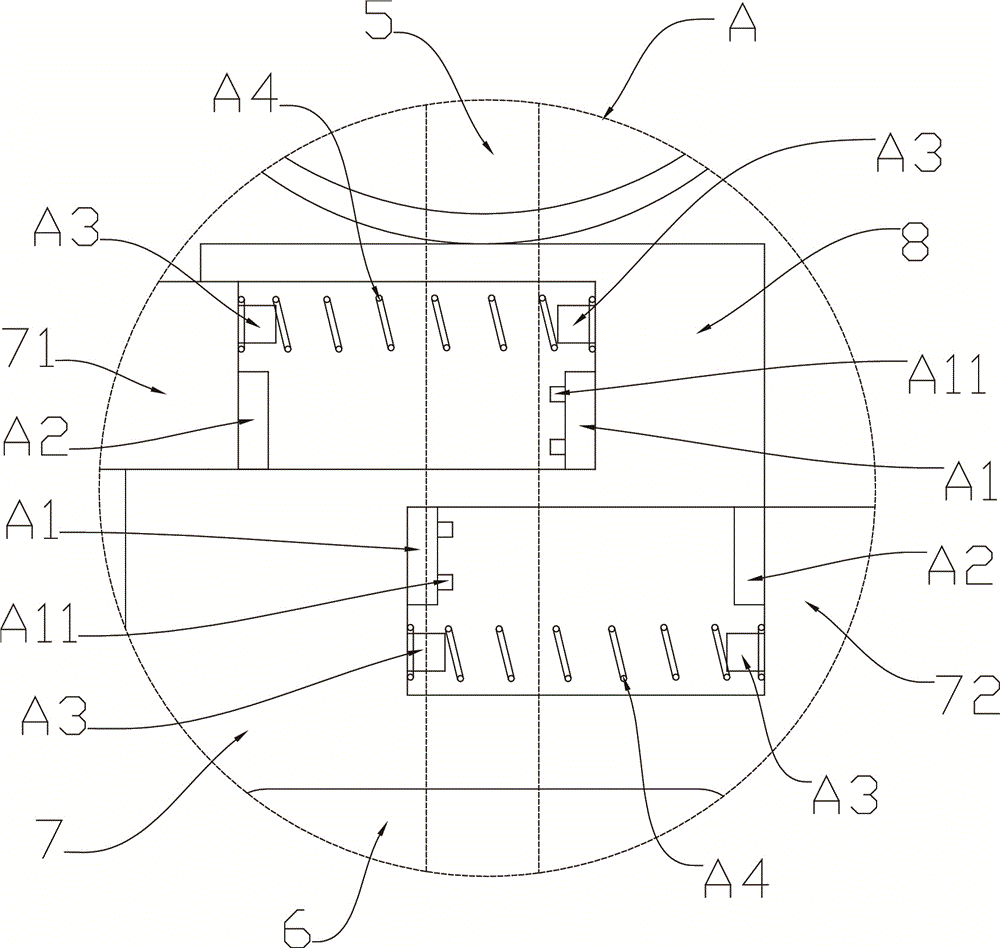

ActiveCN106676847AGuaranteed efficiencyImprove efficiencyOther drying apparatusTextiles and paperEngineeringCrotch

The invention discloses an improved type underpants airing device. According to the improved type underpants airing device, the displacements of a second pushing block and a first pushing block are pulled through the attracting of an electromagnet device so that a first bent connecting rod above the first pushing block and a second bent connecting rod above the second pushing block can penetrate through the two trouser leg holes of the underpants and be clamped, the situation that the first bent connecting rod and the second bent connecting rod which are clamped are arranged above the crotch of the underpants is guaranteed, then the rotation of a lead screw is driven through the rotation of a motor inside an auxiliary support so that an auxiliary shell body which is provided with a nut screw thread hole can rise, then an upper shell body and a lower shell body which are connected to the auxiliary shell body can be driven to rise together, the crotch of the underpants can be jacked up or pulled down through the bent connecting rods and the shell bodies, and the automatic overturn of the underpants is achieved; the situation that both the interior and exterior sides of the underpants can get the irradiation of the sun when the underpants are aired is guaranteed so that effective ultraviolet ray virus killing can be conducted, the airing efficiency is guaranteed, and the situation that people's health is affected due to the fact that the interior side of the underpants does not get the sunlight and is moist after the underpants are aired is avoided.

Owner:徐州天骋智能科技有限公司

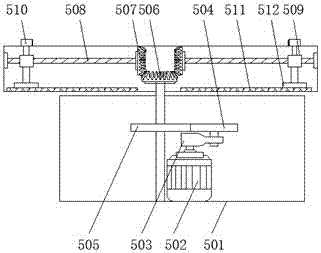

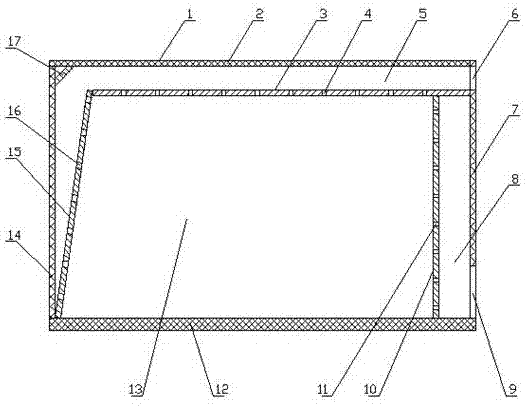

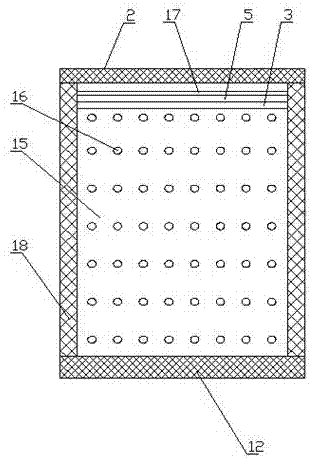

Flow guiding device for heat pump drying box

PendingCN106871629AStable flowGuaranteed drying efficiencyDrying gas arrangementsInlet channelEngineering

The invention provides a flow guiding device for a heat pump drying box. The flow guiding device comprises the drying box as well as a front flow guiding plate, a back flow guiding plate and an upper flow guiding plate which are arranged inside the drying box; an air inlet and an air outlet are formed in the upper part and the lower part of the front wall of the drying box respectively; the back flow guiding plate and the upper flow guiding plate are mounted on the back side and the upper side of the inside of the drying box respectively; the upper flow guiding plate is located below the air inlet; the drying box is separated into an air inlet channel and a drying area by the back flow guiding plate and the upper flow guiding plate; and air outlet holes are formed in the back flow guiding plate and / or the upper flow guiding plate. By the aid of the flow guiding device, hot air in the drying box can be uniformly distributed, the drying uniformity of the drying box for a to-be-dried material can be guaranteed, the drying efficiency of the drying box can be improved, and the energy consumption can be reduced.

Owner:HUNAN XIAWEIQI DOMESTIC FUNGUS DEV CO LTD

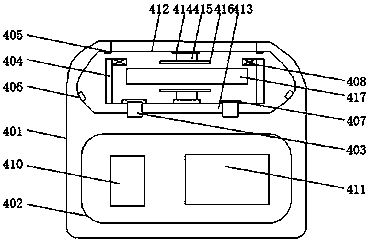

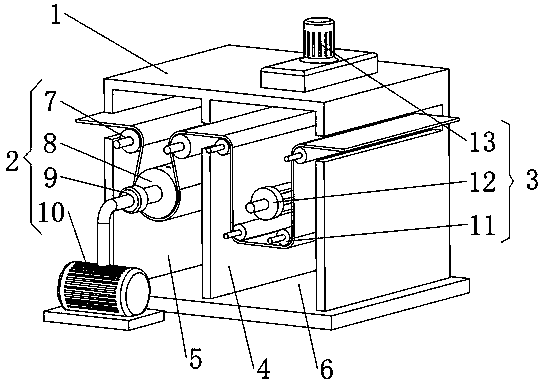

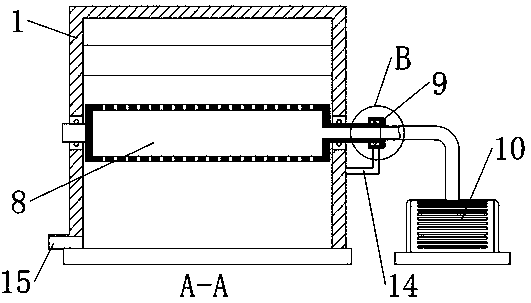

Medicine vacuum dryer

InactiveCN105352299AGuaranteed drying efficiencyGuaranteed drying qualityDrying machines with progressive movementsHeating arrangementMicrocomputerSocial benefits

The invention relates to the field of general pharmaceutical equipment, in particular to a medicine vacuum dryer. The medicine vacuum dryer comprises a dryer body, a conveying belt and a programmable logic controller (PLC). The PLC is connected with the dryer body. A feeding hopper is arranged at the left end of the dryer body. A feeding power pump is arranged between the feeding hopper and the dryer body. The feeding power pump is connected with a mechanical distributor. The conveying belt is arranged inside the dryer body. A heating block is arranged below the conveying belt. The heating block is connected with a heating control system. A cooling block is arranged at the right end of the heating block. The cooling block is connected with a cooling control system. According to the medicine vacuum dryer, microcomputers and the mechanical-electrical integration technique are adopted, the number of pollution links is reduced, the production efficiency, the economic benefits and the social benefits are improved, the medicine vacuum dryer is quite ideally linked, intelligent and automatic drying equipment for conducting vacuum low-temperature heating and drying on various extracts by large-sized, middle-sized and small sized Chinese medicine factories and hospital preparation rooms, and the whole equipment is compact in structure, simple in theory and worthy of popularization.

Owner:WUXI MEDICAL INSTR FACTORY

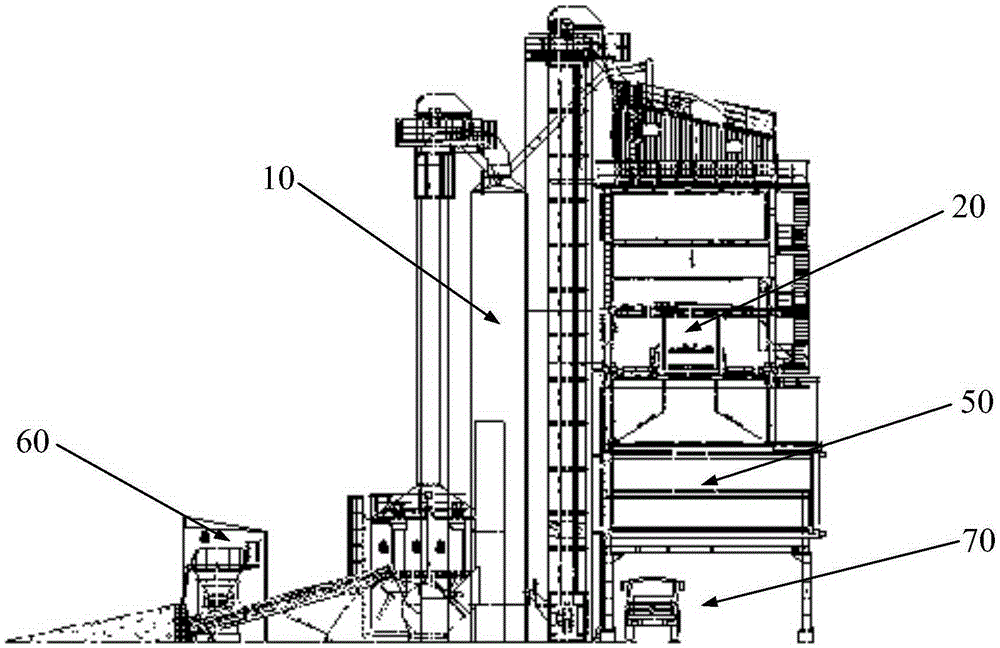

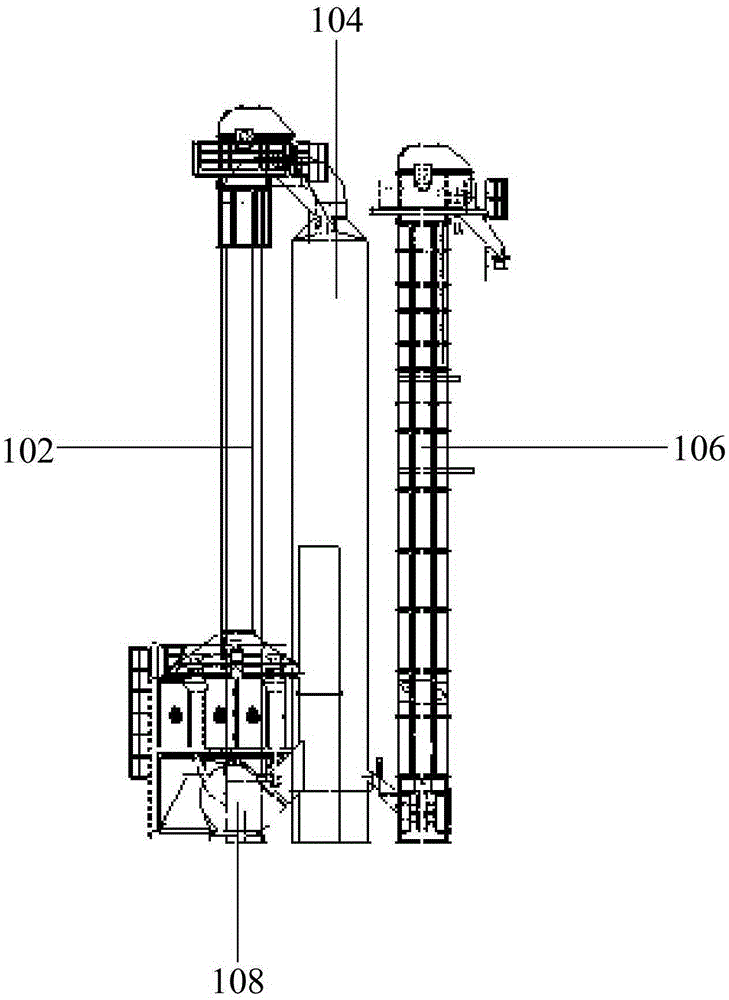

Asphalt mixing plant

The invention provides an asphalt mixing plant. The asphalt mixing plant comprises a charging device, a drying device, a mixing device and a finished product warehouse which are in sequential communication, wherein the drying device comprises a cold aggregate elevator, a sealing drying tower and a hot aggregate elevator which are in sequential communication; the cold aggregate elevator communicates with a discharge opening of the charging device, and a discharge opening of the hot aggregate elevator communicates with a feed opening of the mixing device; the sealing drying tower is arranged between the cold aggregate elevator and the hot aggregate elevator, so that in the drying process, dust and smoke can be effectively prevented from overflowing, the pollution of the dust and flue gas is eliminated, the requirement for environmental protection in the production process is met, and the environmental protection performance in the production process is improved.

Owner:HUNAN SANY ROAD MACHINERY

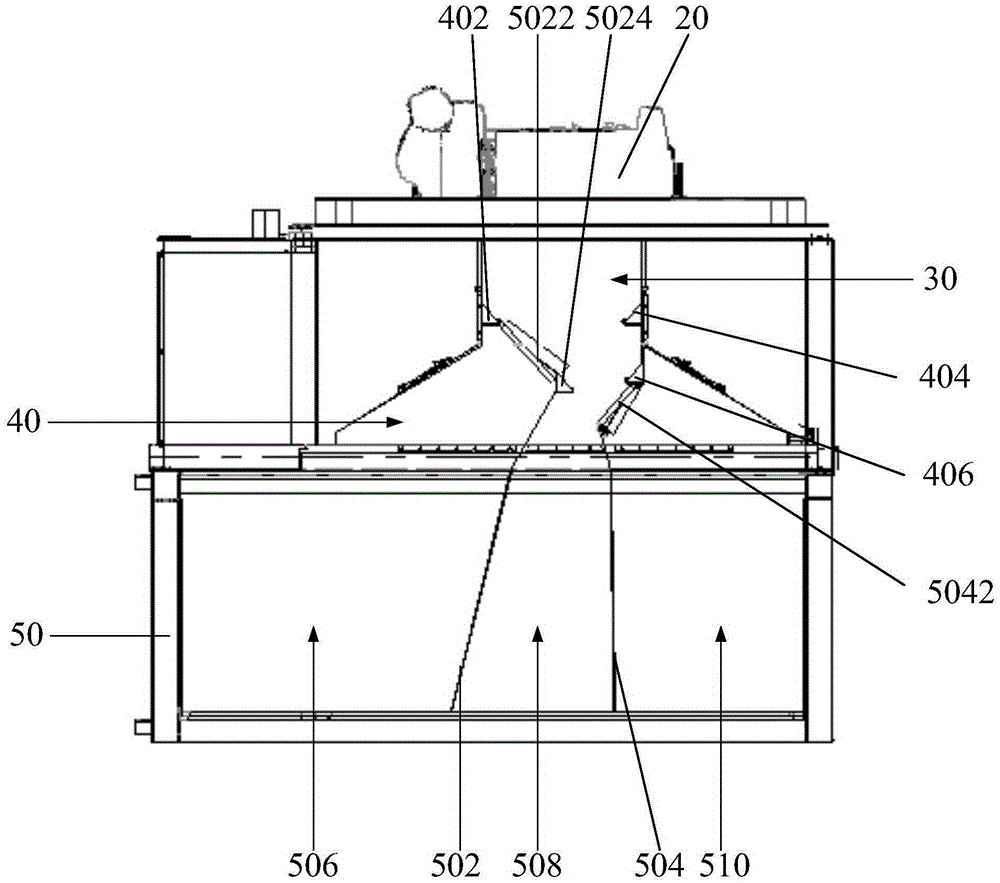

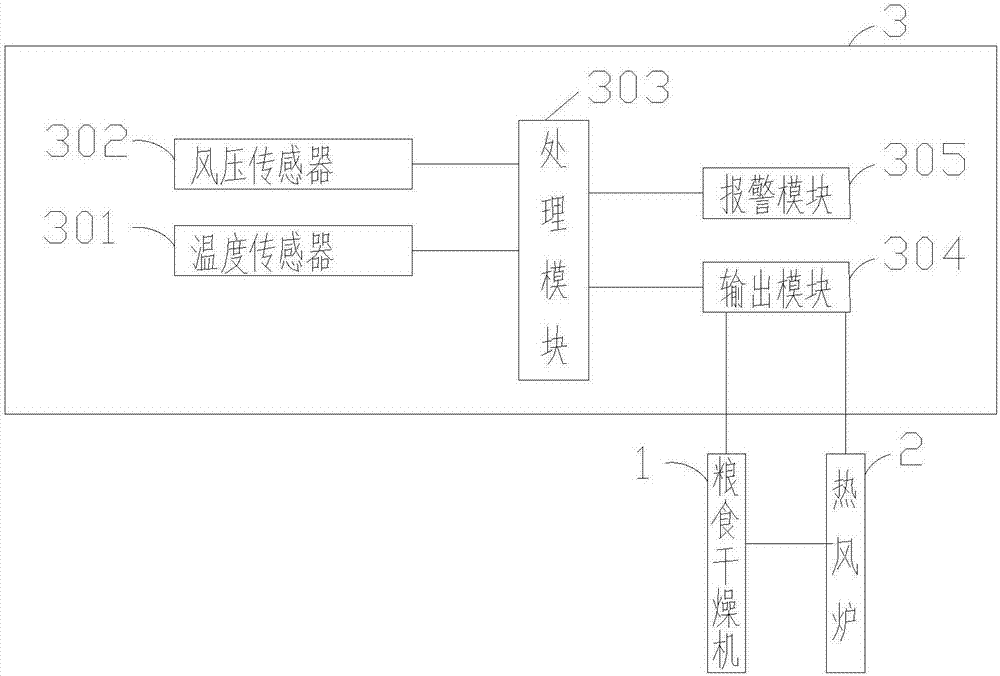

Grain drying system

PendingCN106907918AGuaranteed drying efficiencyReduce humidityDrying gas arrangementsDrying safety systemsControl systemAgricultural engineering

The invention provides a grain drying system, which includes a grain dryer, a hot air stove and a grain drying control system; the grain drying system includes a humidity sensor for detecting the humidity of hot air, a wind pressure sensor for hot air pressure, a processing module and an output module; The temperature sensor, the wind pressure sensor and the output module are respectively connected to the processing module; the grain dryer is connected to the hot stove, and the grain dryer is provided with an exhaust fan; the output module is connected to the The hot blast stove and the exhaust fan. This scheme can improve the drying efficiency of grain.

Owner:安徽省沃昇机电科技有限公司

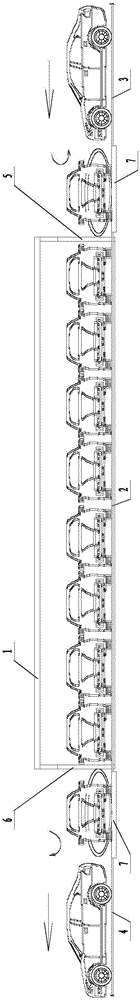

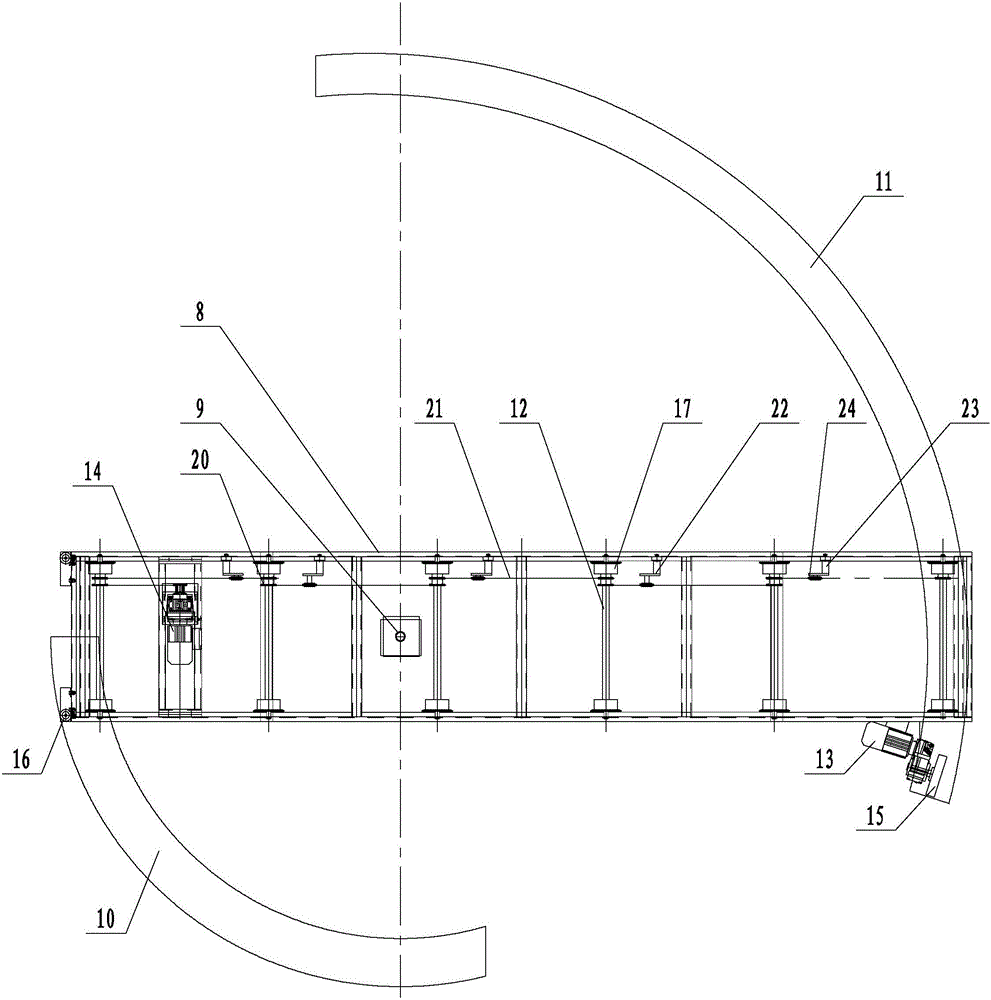

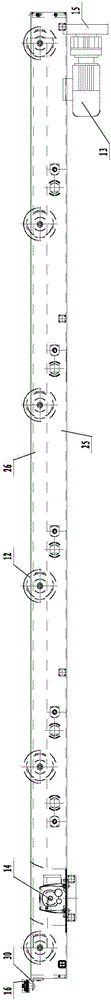

Intensive vehicle body drying system and drying method

InactiveCN106583200AImprove production taktImprove compactnessConveyorsPretreated surfacesThermal energyDrive wheel

The invention discloses an intensive vehicle body drying system and drying method, and aims at overcoming the defects that a vehicle body drying room is poor in length, large in occupied area, low in heat energy utilization rate, large in power consumption and low in working efficiency. The intensive vehicle body drying system comprises a drying room, a conveying ground chain, an input conveying mechanism and an output conveying mechanism, the drying room is provided with an input port and an output port, and type shifting mechanisms are installed on the portion between the input port and the input conveying mechanism and on the portion between the output port and the output conveying mechanism outside the drying room respectively; and each type shifting mechanism comprises a type shifting frame, a steering supporting column, a front-end sliding rail and a rear-end sliding rail, wherein the steering supporting column is rotatably connected to the lower end of the type shifting frame, multiple wheel rollers which are arranged in parallel are rotatably connected to the type shifting frame, a vehicle body conveying motor and a driving motor are installed on each type shifting frame, the front-end sliding rail and the rear-end sliding rail are each of an arc-shaped structure, the driving motor is in drive connection with a driving wheel which is connected to the rear-end sliding rail in an abutted mode, a guide wheel is installed at the front end of the type shifting frame, and the guide wheel is connected in the front-end sliding rail in a matched mode.

Owner:浙江福林国润汽车零部件有限公司 +1

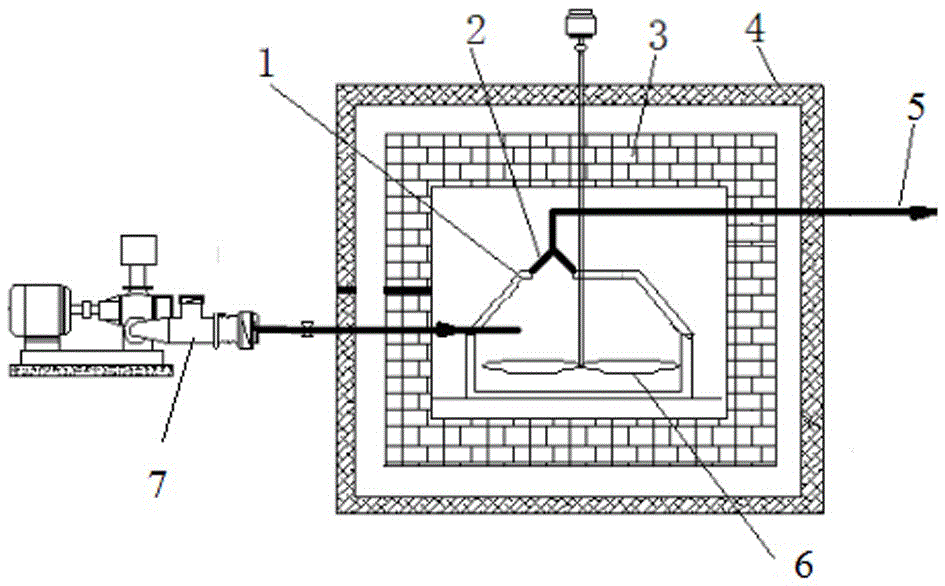

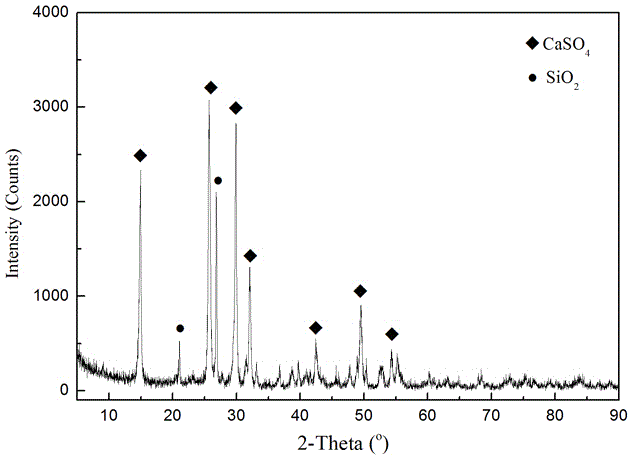

Reductive decomposition method of phosphogypsum by microwave process

ActiveCN106477529AReduce energy consumptionShorten drying timeCarbon compoundsAlkaline-earth metal silicatesHeating efficiencyDirect heating

The invention discloses a reductive decomposition method of phosphogypsum by a microwave process. The method comprises the following steps: A. pretreatment; B. proportioning; and C. phosphogypsum decomposition. The microwave drying technique is adopted to effectively lower the energy consumption, shorten the drying time and enhance the drying efficiency. The wave-absorbing auxiliary material is added to enhance the wave-absorbing property of the raw material, and thus, microwave direct heating and silicon carbide or graphite reactor assisted heating are adopted to ensure the heating efficiency, thereby effectively solving the problem of poor raw material wave-absorbing property in the wave heating process. Compared with the traditional technique in which the phosphogypsum decomposition temperature is up to 1250-1300 DEG C, the phosphogypsum decomposition temperature in the microwave technique is lowered to 950-1000 DEG C (by about 300 DEG C). The microwave heating mode obviously lowers the energy consumption in the phosphogypsum decomposition process, and enhances the economic benefits of the phosphogypsum recycling technique.

Owner:KUNMING METALLURGY INST

Screening and drying device for bract of globe artichoke

The invention discloses a screening and drying device for the bract of globe artichoke. The screening and drying device comprises a machine body, a feeding hopper a sliding plate, a slag discharging pipe and a discharging pipe, wherein the feeding hopper is mounted on the side of the machine body; a horizontally distributed cross shaft is arranged inside an accommodating groove; the two ends of the cross shaft are rotationally connected with a drying disk; the discharging pipe is mounted at the bottom end of the machine body; a power box is fixedly mounted on the surface of the outer part of the machine body; the end of a rotating shaft penetrates through the side wall of the machine body and extends into the power box; a fan shaft and a transmission shaft which are parallel to each otherare fixed into the power box; and a cavity is formed in the rotating shaft. According to the screening and drying device, a screening and drying structure in an all-in-one machine is redesigned, so that the quantitative screening and drying operation of the bract is ensured, the bract is synchronously and gently stirred by the self rotation of the drying disk in the drying process, the drying efficiency is ensured, and the treatment effect is good.

Owner:HUNAN UNIV OF ARTS & SCI

Automatic feeding and drying device for cutting plates of mahogany furniture

InactiveCN107655313ADry evenlyReduce workloadDrying machine combinationsDrying gas arrangementsCouplingEngineering

The invention discloses an automatic feeding and drying device for mahogany furniture cutting boards. There is a first pulley, the first pulley is rotatably connected to a second pulley through a belt, the second pulley is fixedly connected with a coupling through a flat key, and both ends of the coupling are fixedly connected with threaded rods, the The outer wall of the threaded rod is sleeved with a sliding block, the bottom of the sliding block is rotatably connected with a rotating rod through a pin shaft, and the invention relates to the technical field of mahogany furniture cutting board processing. The automatic feeding and drying device for mahogany furniture cutting boards solves the problem of uniform drying of mahogany furniture cutting boards and stable transmission of mahogany furniture cutting boards, ensuring drying quality and drying efficiency, reducing the workload of workers and reducing Labor costs and production costs, the efficiency of faster production and transfer, and the adaptability of different workpieces.

Owner:湖州南浔雷欧木制品厂

Process for preparing dried apple by microwave hot air combined drying

ActiveCN109259138AExtended softening timeLong softening timeFruits/vegetable preservation by dehydrationFlavorMicrowave

The invention discloses a process for preparing dried apple by microwave hot air combined drying. The process comprises cleaning, peeling, removing pits and slicing the pulp into apple slices; immersing the apple slices in a color protection liquid for 3-5 hours; conducting staged microwave drying and staged hot air drying after immersion; drying the apple slices till a dried apple finished product with the moisture content of less than 5% is obtained; finally conducting aseptic packaging on the dried apple. The microwave hot air combined drying is adopted. The hot air drying is easier to operate than the microwave drying, and the microwave puffing process is more optimized, so that the prepared dried apple preserves the original flavor of apples and is convenient to preserve.

Owner:雅安职业技术学院 +1

Multi-stage internal circulation drying machine for biomass fuel preparation

InactiveCN111102821AIncrease the lengthAvoid it happening againDrying gas arrangementsDrying machines with progressive movementsHot air ovenProcess engineering

The invention relates to a multi-stage internal circulation drying machine for biomass fuel preparation. The drying machine comprises a drying box body, a feeding port is formed in the top of one sideof the drying box body, a first-stage material conveying belt extends out of the position where the feeding port is formed, and the first-stage material conveying belt located outside the drying boxbody is connected with a material lifting device used for supplying materials to be dried. A second-stage material conveying belt, a third-stage material conveying belt, a fourth-stage material conveying belt and a fifth-stage material conveying belt are arranged in the drying box body and sequentially located below the first-stage material conveying belt from top to bottom. A plurality of parallel hot air pipes are arranged at the bottom of the side face of the drying box body, the hot air pipes extend into the drying box body, and the other end of each hot air pipe is connected with a hot-blast stove device used for providing hot air. The drying machine can be used for improving the operation safety of equipment under the condition of ensuring the drying efficiency during drying work ofpowder materials in the biomass fuel preparation process.

Owner:宜昌利农秸秆生物质燃料有限公司

Automatic marine product processing production line

InactiveCN107156692AGuaranteed drying effectGuaranteed drying efficiencyFood dryingFood ingredient functionsProduction lineSpray nozzle

The invention discloses an automatic marine product processing production line. The automatic marine product processing production line is composed of a boiling mechanism, a color protecting mechanism, an air cooling and drying mechanism and a heating and drying mechanism, wherein the boiling mechanism comprises a first long bin, inside which a first conveying belt with the bottom inclined upwards is mounted; material claws are arranged at interval onto the first conveying belt; the bottom of the first long bin is provided with a long pipe which is provided with a plurality of spray nozzles, one end of the long pipe extends out of the first long bin and provided with a three-way valve, the second end of the three-way valve is connected to the upper portion of the first long bin through a circulating pump, and the third end of the three-way valve is connected to a heating boiler. The automatic marine product processing production line, namely, a marine product boiling and drying integrated device, achieves integration of boiling, color protecting, air cooling and drying, saves manual operation during processing and achieves air cooling and then high-temperature segmented heating during drying, thereby ensuring drying effects and drying efficiency.

Owner:莆田市秀屿区睿思海洋渔业有限公司

Textile fabric drying device for spinning

InactiveCN109838987AAvoid corrosionGuaranteed drying efficiencyDrying gas arrangementsDrying machines with progressive movementsWater vaporPulp and paper industry

The invention discloses a textile fabric drying device for spinning, and relates to the field of textile fabric production equipment. The textile fabric drying device comprises a case, a dehydration mechanism and a drying mechanism; an inner cavity of the case is divided into a dehydration cavity and a drying cavity by a partition plate; the dehydration mechanism comprises a dehydration guide roller, a dehydration air cylinder, an air guide pipe adapter and a high-pressure fan; and the drying mechanism comprises a drying guide roller, a heating pipe and an exhaust fan. According to the textilefabric drying device for spinning, textile fabric is subjected to primary dewatering through the dehydration mechanism and dried through the drying mechanism, and the situation that water in the textile fabric drops for a long time, and the drying equipment is corroded is prevented; vapor generated in the drying cavity during drying can be exhausted through the exhaust fan, and the drying efficiency is ensured; and the dehydration and drying processes are completed in the closed dehydration cavity and the closed drying cavity, water drop splashing can be prevented, and moreover, the temperature can be adjusted and controlled advantageously.

Owner:杭州米娅纺织品有限公司

Horizontal type new material color master batch drying device

The invention provides a horizontal type new material color master batch drying device. The device comprises a drying machine body, a material feeding barrel, a rotary shaft, a baffle, hand wheels, a servo motor, a transmission shaft, stirring paddles, an electric cylinder, push rods and oblique material feeding plates. The material feeding barrel is fixed on the upper end face of the drying machine body, the rotary shaft is installed in the material feeding barrel, the baffle is assembled to the outer ends of the rotary shaft and arranged at the inner end of the material feeding barrel, the hand wheels are fixed to the outer ends of the rotary shaft respectively, and the flow control function is achieved due to the design; the servo motor is fixed to the right end face of the drying machine body, the transmission shaft is arranged on the left wall in the material feeding barrel, the stirring paddles are installed at the outer end of the transmission shaft, the electric cylinder is installed at the bottom in the drying machine body, the push rods are arranged at the inner end of the electric cylinder, the oblique material feeding plates are fixed to the inner ends of the push rods respectively, and the stirring function is achieved due to the design. By means of the horizontal type new material color master batch drying device, the flow control function and the stirring function are achieved; besides, the horizontal type new material color master batch drying device is high in practicality, convenient to use, good in stability and high in reliability.

Owner:曹学虎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com