Automatic cleaning method and automatic cleaning device of scraped car

A technology for automatic cleaning and scrapping of automobiles, applied in the direction of vehicle exterior cleaning devices, etc., can solve the problems of expansion of dismantling area, tight space, reduction of land occupation cost, etc. Reduced, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

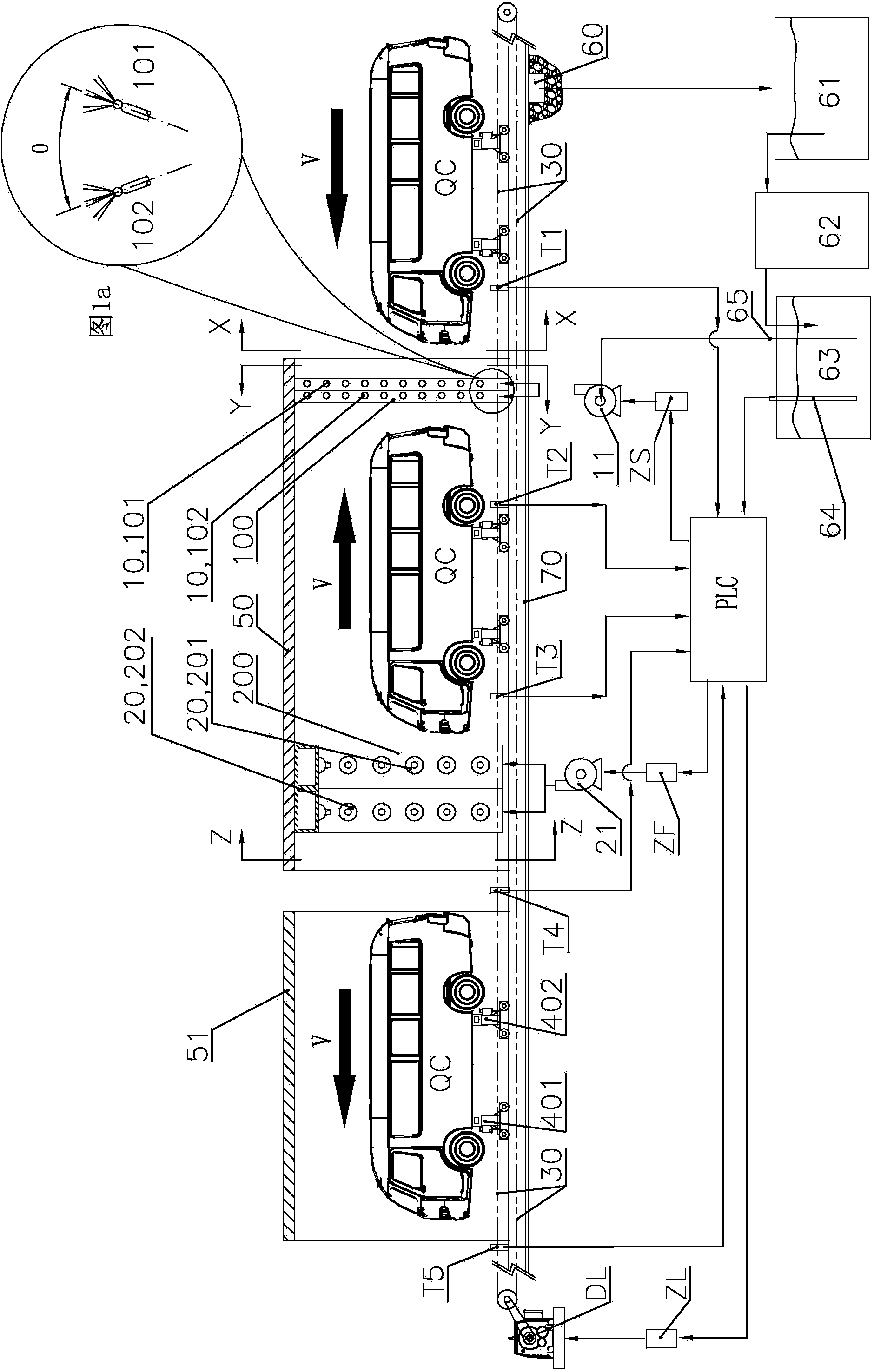

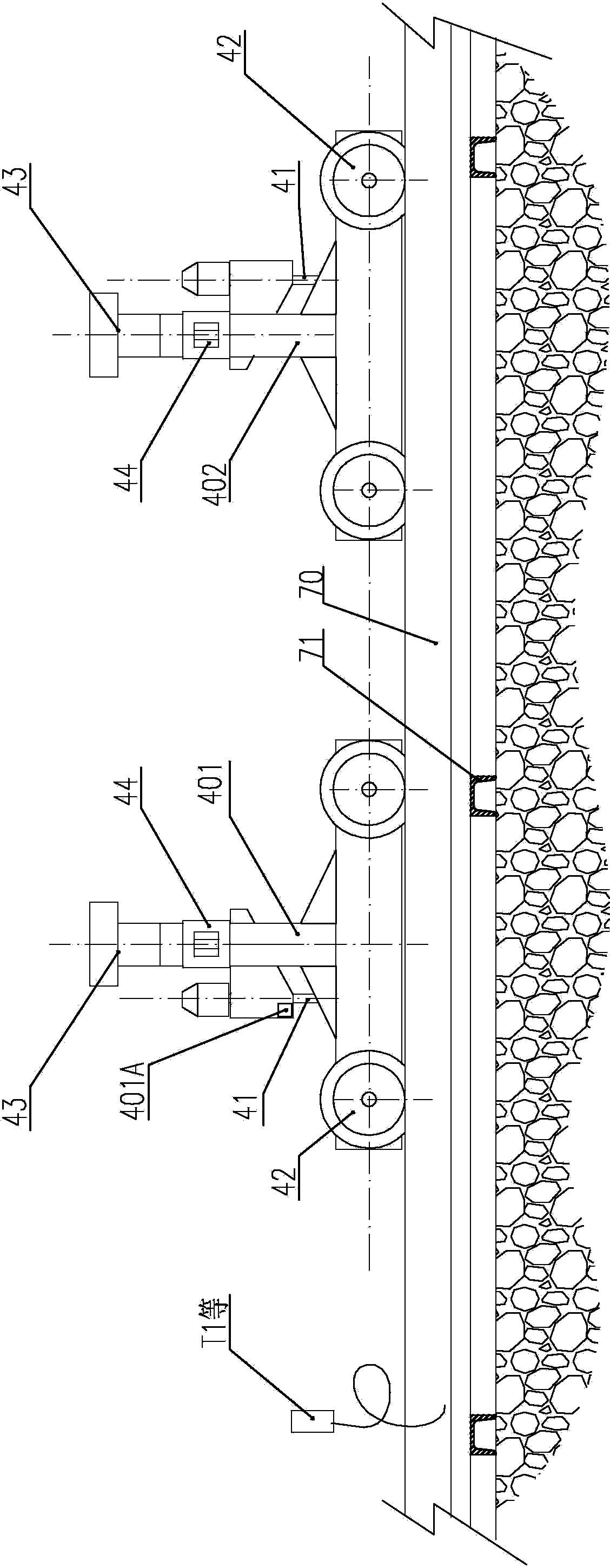

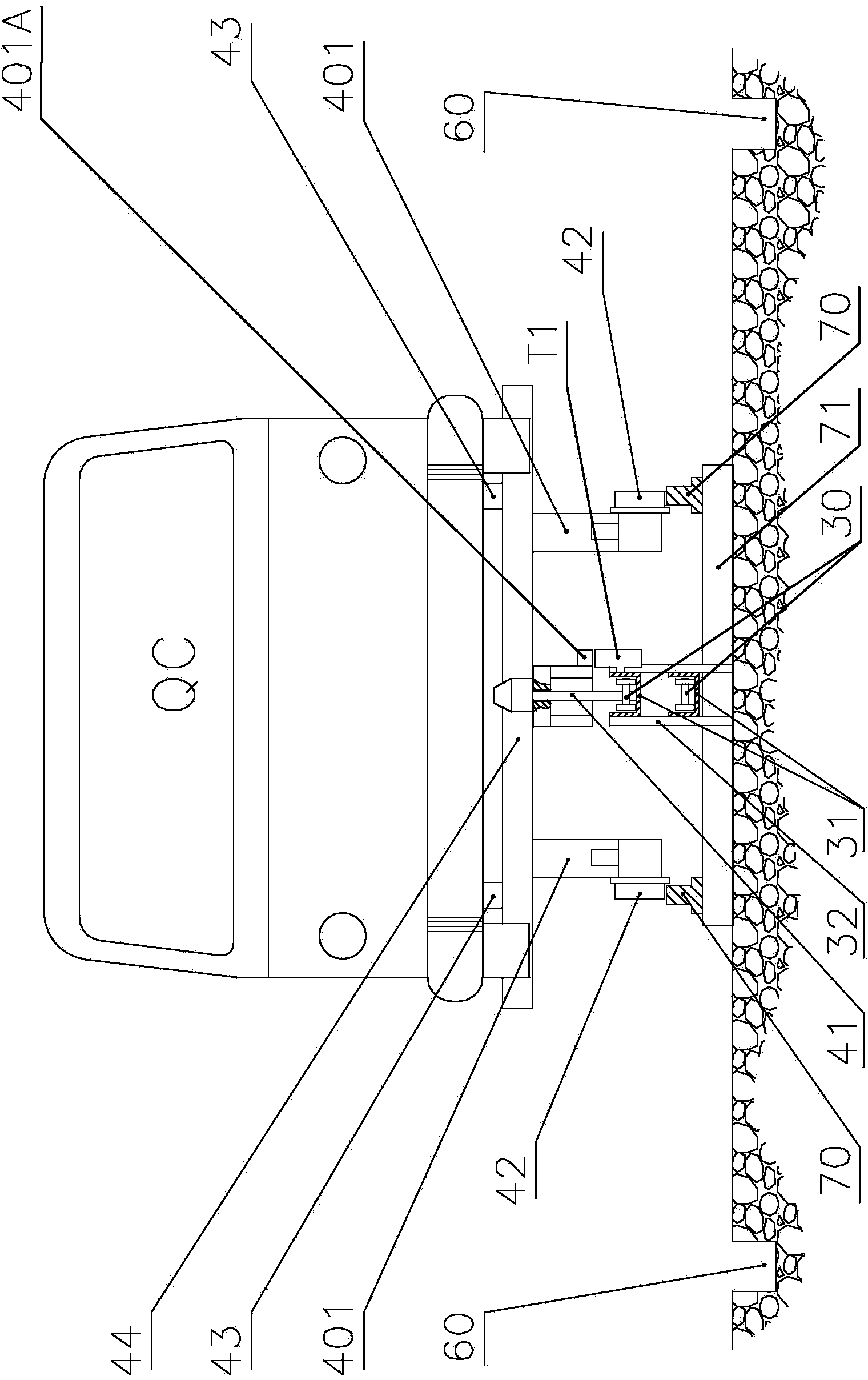

[0056] Such as Figure 1-5 , which are structural schematic diagrams from different perspectives of the embodiment of the automatic cleaning device for scrapped automobiles according to the present invention. The embodiment of the automatic cleaning device is sequentially provided with: a nozzle 10 for providing flushing water to the scrapped car QC drawn in different positions, a water pump 11 for providing a pressure water source for the flushing water, and an actuator ZS for controlling the water pump motor The air throat 20 of the drying wind, the blower 21 that provides the pressure gas source for the dry wind, the actuator ZF that controls the blower motor; Sensor T1 and rear sensor T2 are respectively equipped with front sensor T3 and rear sensor T4 for monitoring the passing of the car body before and after the drying air throat 20, and the stroke at the end of the double-strand parallel track 70 arranged on the track. Switch T5, and use a programmable logic controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com