Special ultrasonic cleaning machine for spinneret plate

An ultrasonic and spinneret technology, used in spinneret assemblies, textiles and papermaking, etc., can solve the problems of small spinneret holes, unsatisfactory spinneret cleaning effect and efficiency, and high spinneret replacement frequency. , to achieve the desired effect, facilitate the processing process, and ensure the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

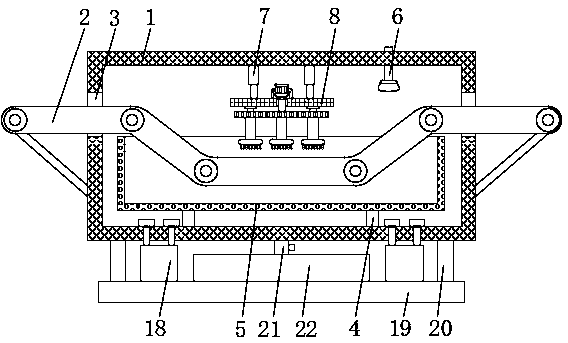

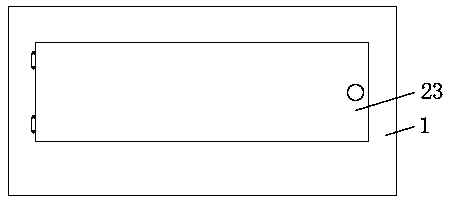

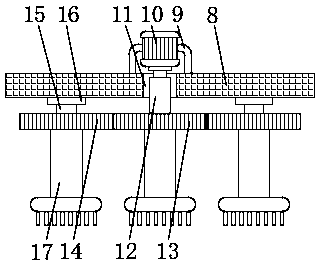

[0024] Such as Figure 1-3 As shown, the present invention provides a technical solution: a special ultrasonic cleaning machine for spinnerets, including a cleaning cabinet 1, the left and right sides of the cleaning cabinet 1 are provided with connecting holes 3, and the transmission assembly 2 is located in the two connecting holes 3 , By setting the connecting hole 3, it is convenient for the transfer assembly 2 to control the spinneret to pass through the cleaning cabinet 1. The outer surface of the cleaning cabinet 1 is fixedly connected with the transfer assembly 2. By setting the transfer assembly 2, and the transfer assembly 2 is provided with a bending angle, To realize the control of the spinneret smoothly passing through the cleaning liquid in the cage 5, it is convenient to realize the ultrasonic cleaning process of the spinneret. The tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com