Plate-cleaning device for spinneret plate

A spinneret and ejection hole technology, which is used in spinneret assemblies, textiles and papermaking, etc., can solve problems such as uneven evenness, lower monomer concentration, and lower spinneret surface temperature, and achieve high-efficiency cleaning. board, ensure the efficiency of board cleaning, and the effect of reasonable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the embodiments shown in the drawings:

[0023] The up and down direction in this manual refers to the up and down direction when the cleaning device is working normally, that is, the attached figure 2 In the up and down direction.

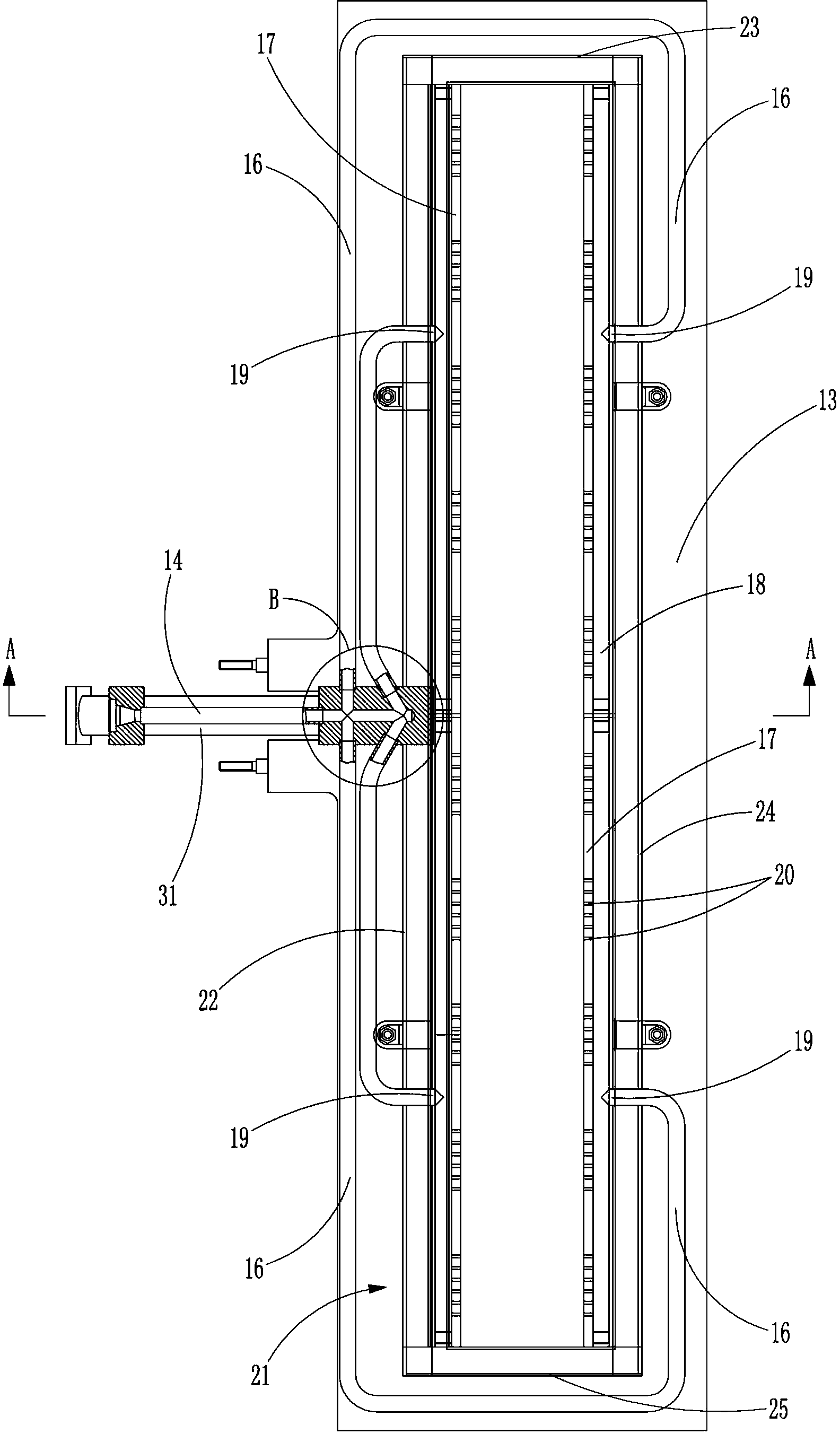

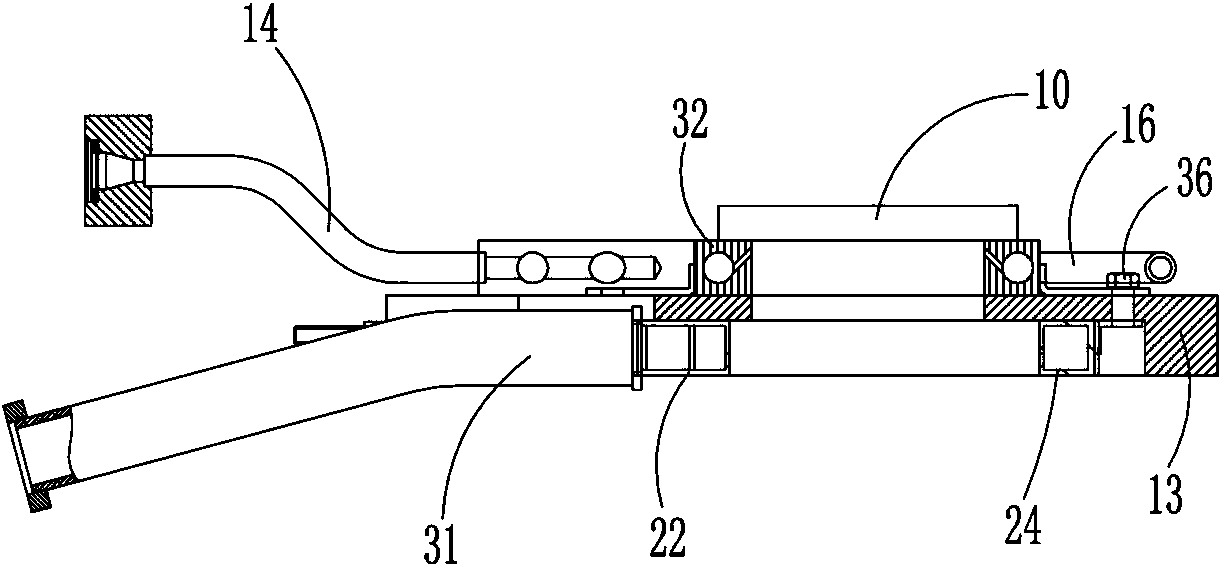

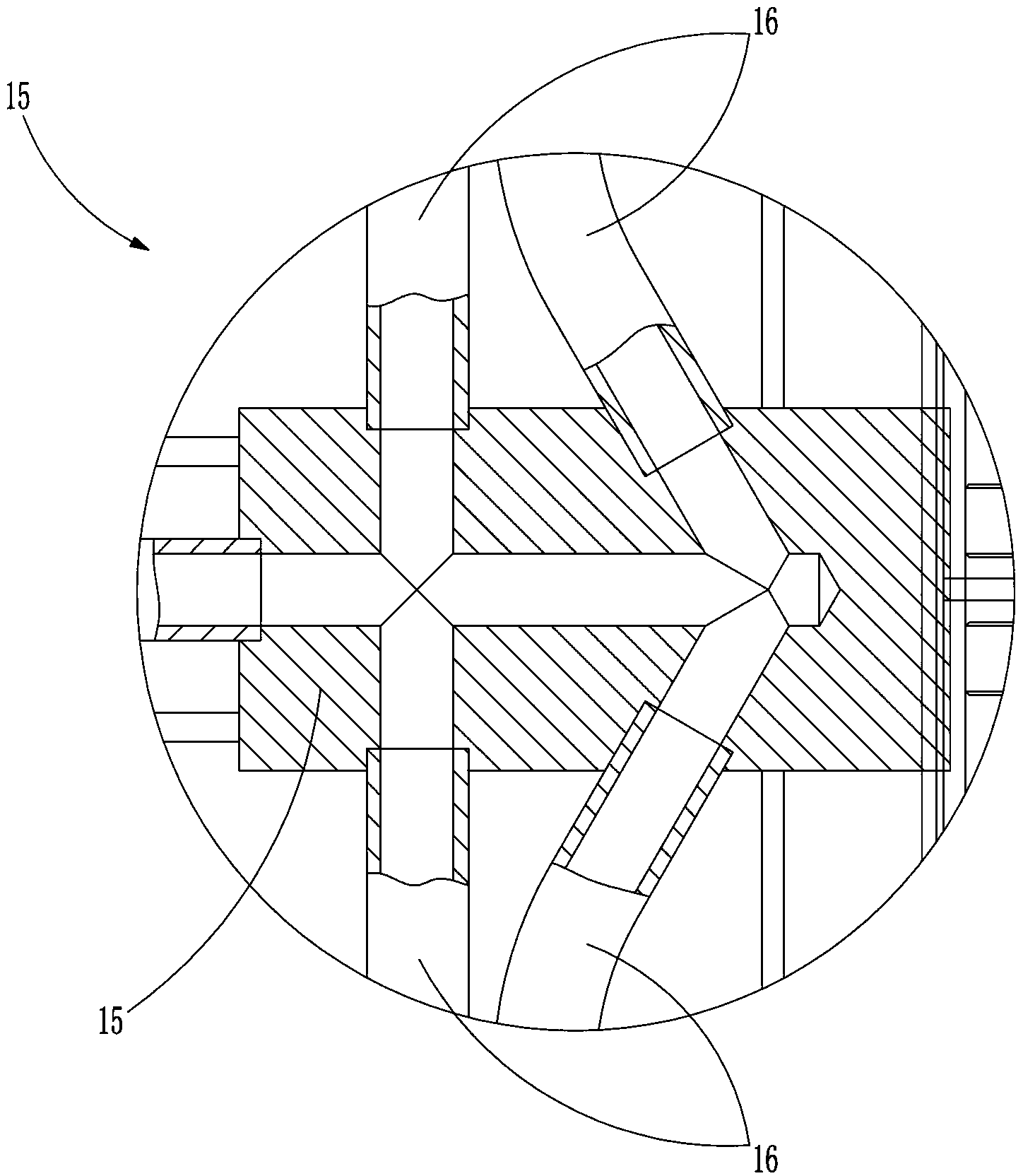

[0024] As attached figure 1 And figure 2 As shown, a cleaning device for a spinneret includes a blowing unit 11 (attached Figure 4 And Figure 5 Shown), suction unit 12 (attached Image 6 , Attached Figure 7 And Picture 8 As shown), a slow cooling plate 13 that can be energized and heated is provided between the blowing unit 11 and the suction unit 12. The blowing unit 11 includes a steam supply part and a steam injection part, and the steam supply part includes a steam source connected to Intake pipe 14, a steam distributor 15 (attached) with multiple steam output channels connected to the intake pipe 14 image 3 As shown), one end is connected to the steam deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com