Patents

Literature

61results about How to "Prevent containing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

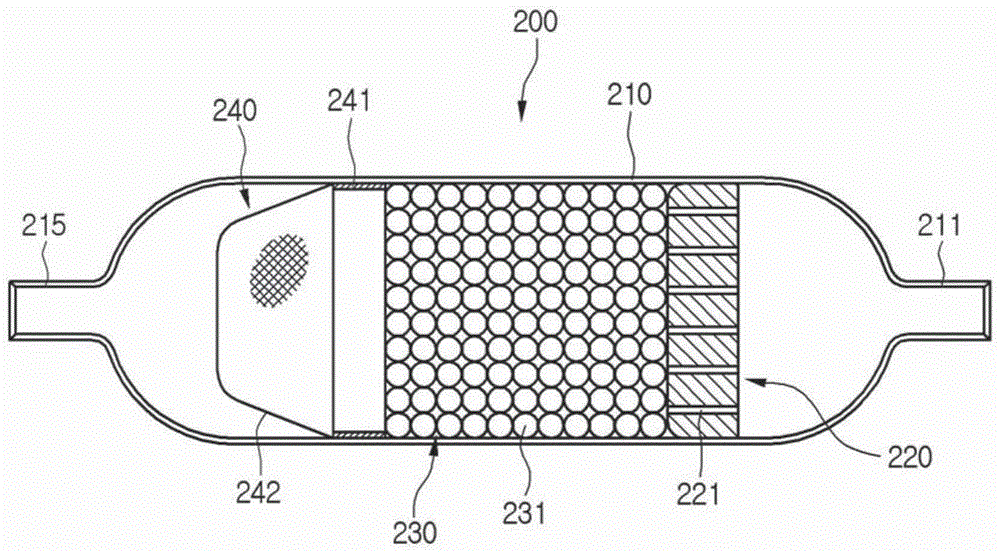

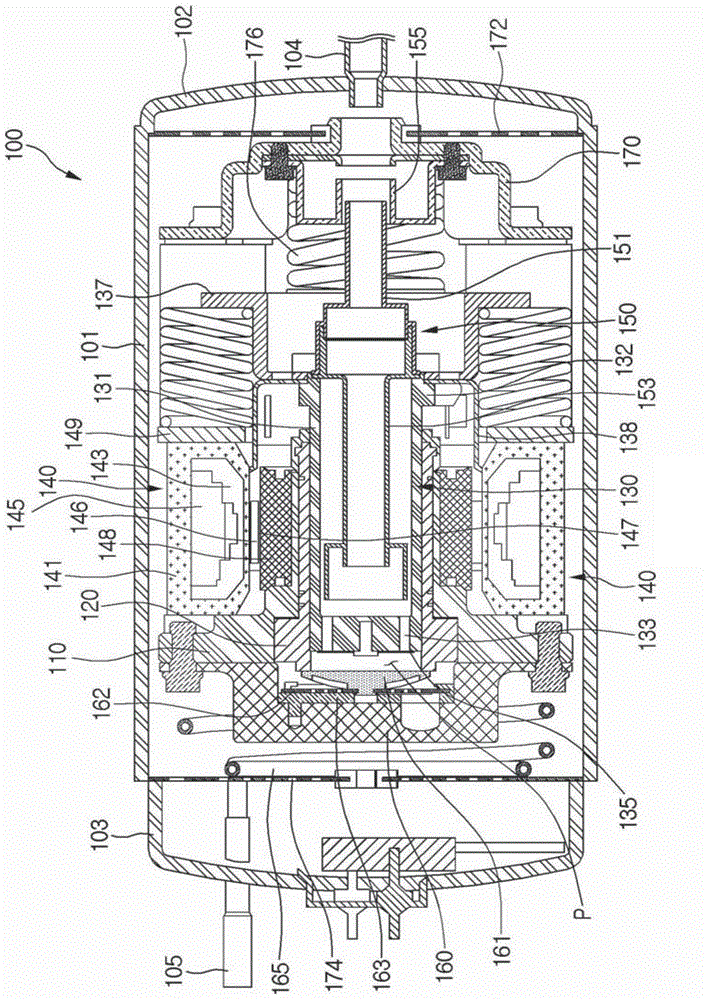

Linear compressor and refrigerator including a linear compressor

ActiveCN105298794AReduce sizeIncreased internal storage spacePositive displacement pump componentsPiston pumpsReciprocating motionLinear compressor

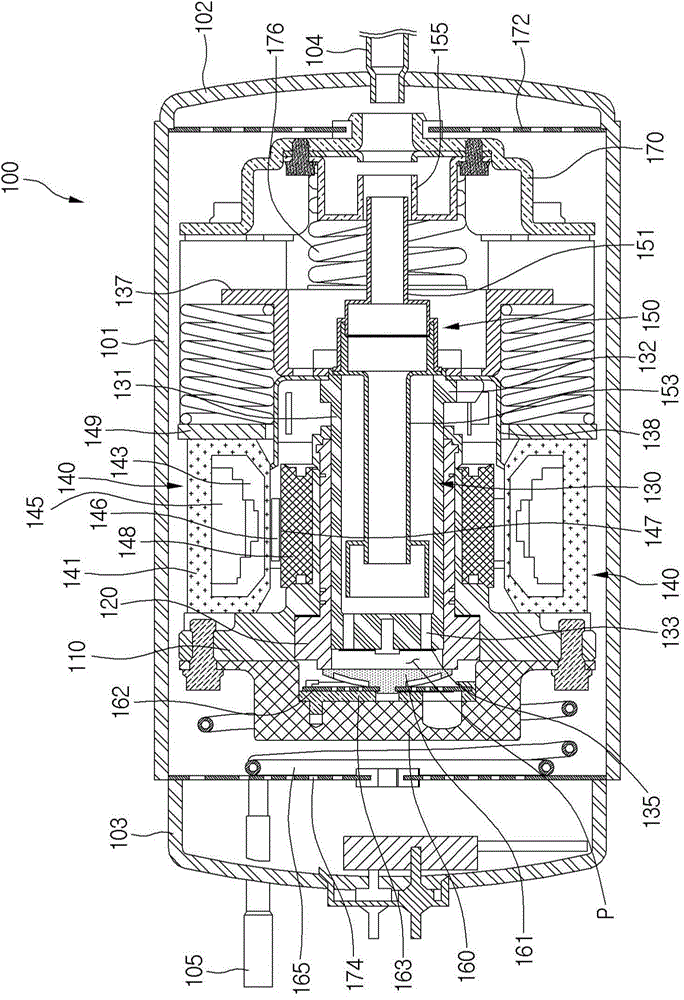

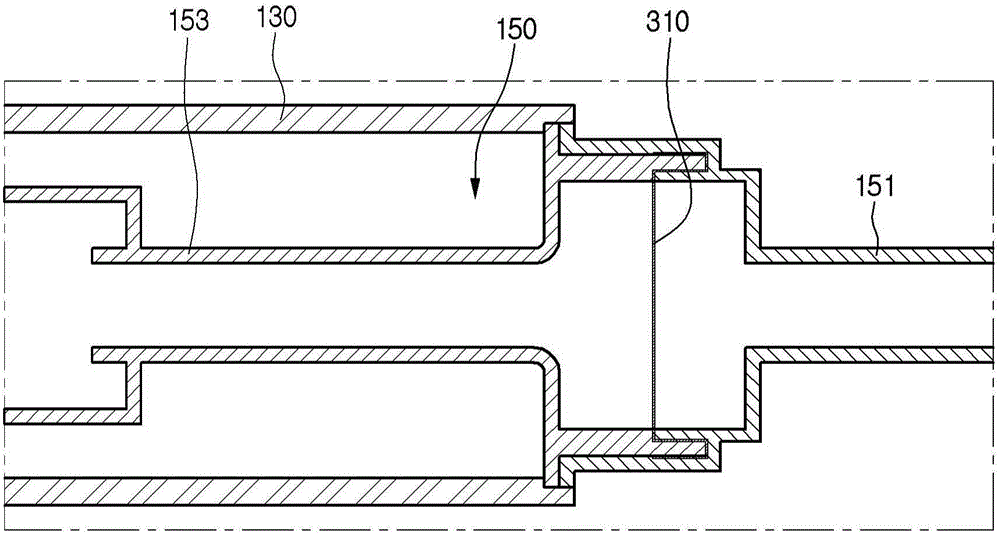

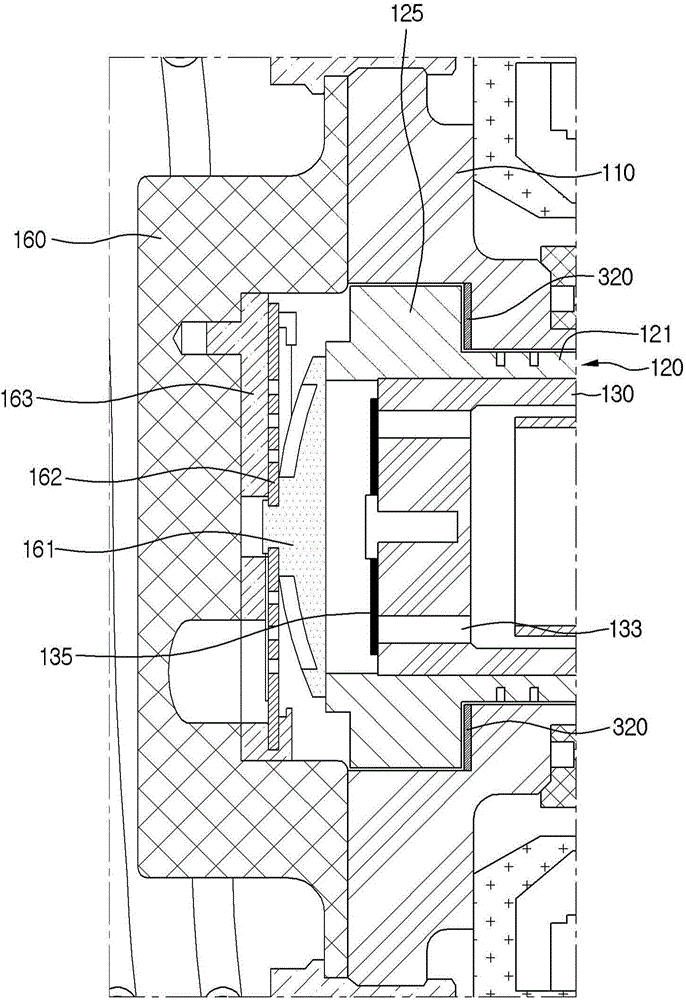

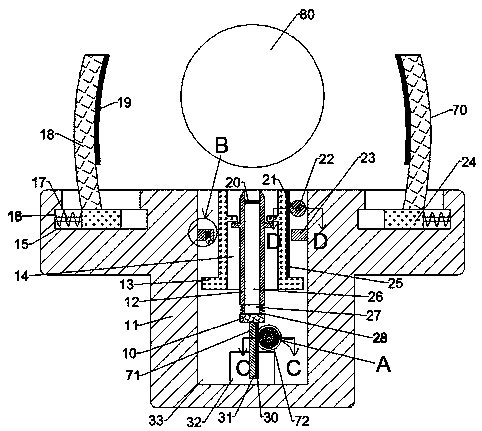

A linear compressor and a refrigerator including a linear compressor is provided. The linear compressor may include a shell including a suction inlet, a cylinder provided in the shell to define a compression space for a refrigerant, a piston reciprocated in an axial direction within the cylinder, a discharge valve provided at one side of the cylinder to selectively discharge the refrigerant compressed in the compression space, at least one nozzle disposed in the cylinder to introduce at least a portion of the refrigerant discharged through the discharge valve into the cylinder, and at least one filter provided in the shell. The at least one filter may be disposed in a refrigerant passage defined from the suction inlet to the at least one nozzle via the discharge valve. Foreign substances or oil contained in the refrigerant introduced into the at least one nozzle may be filtered while passing through the at least one filter.

Owner:LG ELECTRONICS INC

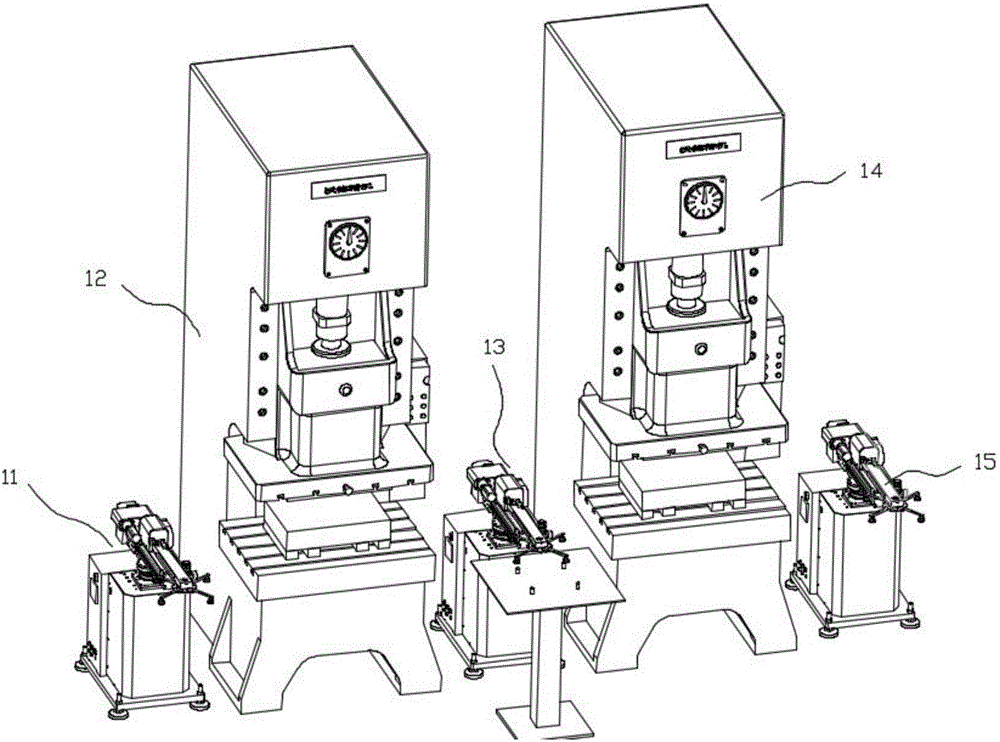

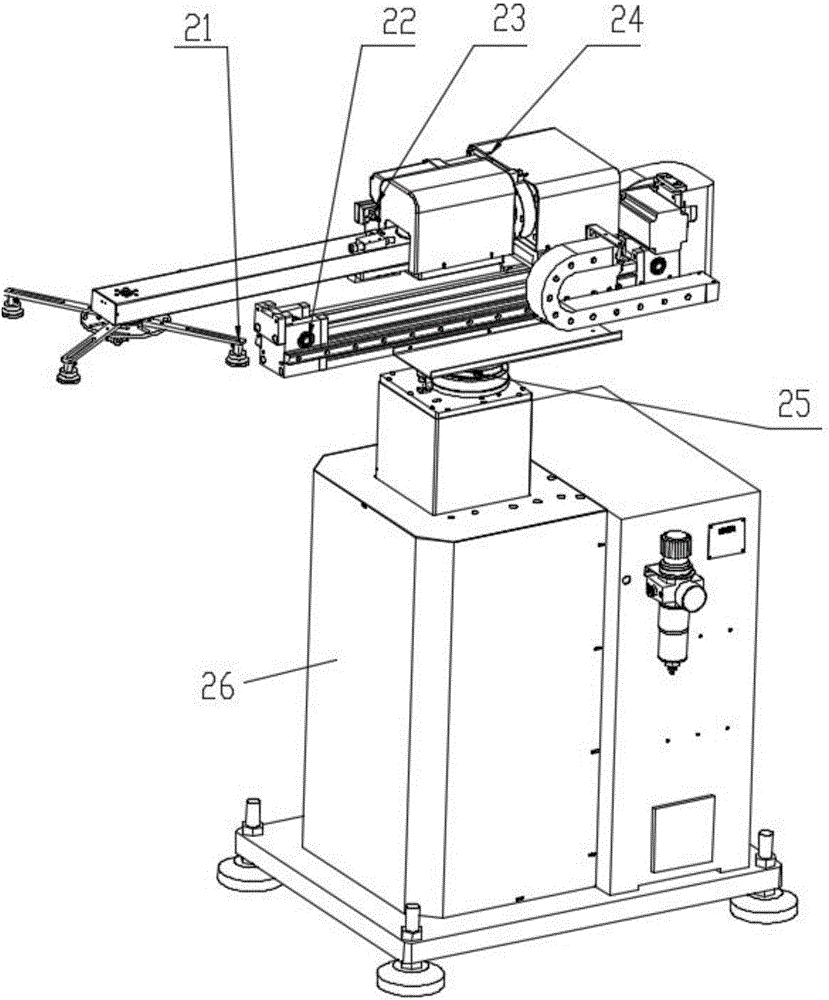

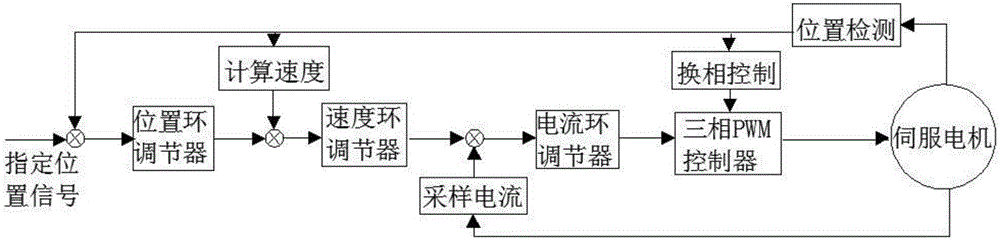

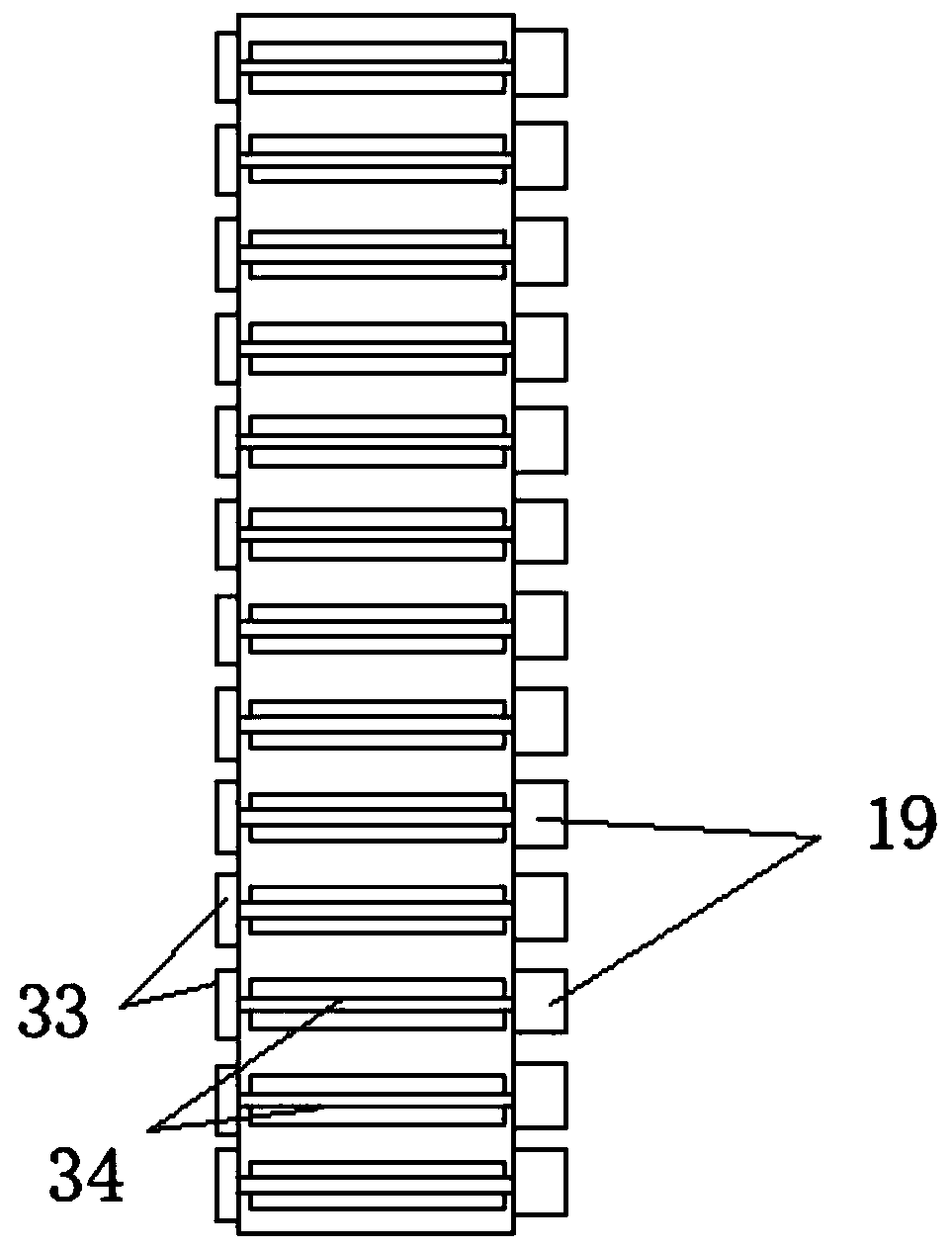

Punching five-axis vertical type mechanical arm multi-machine interconnected control method and punching production line

ActiveCN106444674APrevent containingRealize automated productionTotal factory controlProgramme total factory controlLaser scanningMachine

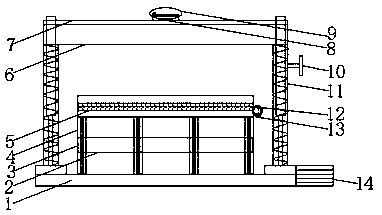

The invention discloses a punching five-axis vertical type mechanical arm multi-machine interconnected control method and a punching production line. Centralized management and decentralized control are realized by a CAN control bus and a visual inspection system; a main controller controls operation of five-axis vertical type mechanical arms and punching machine tools, which are positioned on the same production line, through the CAN control bus; a first action capture camera and a second action capture camera correspondingly monitor whether the action of the first five-axis vertical type mechanical arm and the action of the second five-axis vertical type mechanical arm are in place as well as whether the first punching machine tool and the second punching machine tool are in a safe state during punching; and a camera of a third product quality detection device performs size and appearance detection on the punched product, and a three-dimensional laser scanner performs punching structure detection on the punched product and detects whether the produced punched product is qualified or not so as to realize automatic production. The invention also discloses the punching production line. The punching production line is provided with the vertical type mechanical arms.

Owner:伯朗特机器人股份有限公司

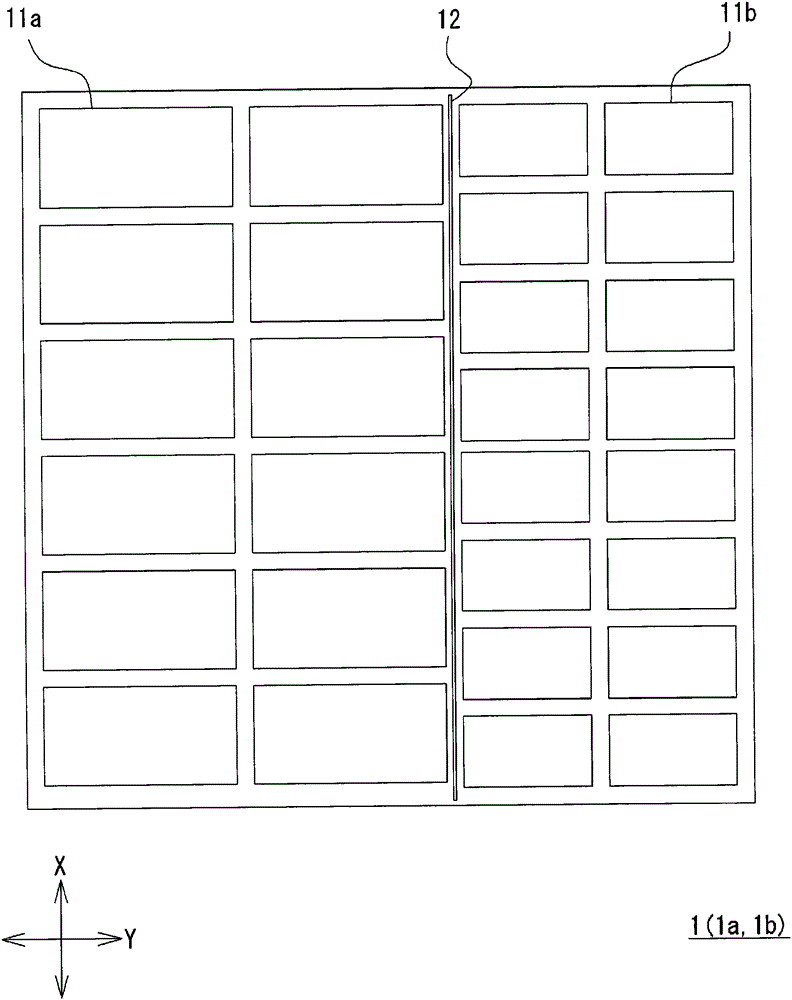

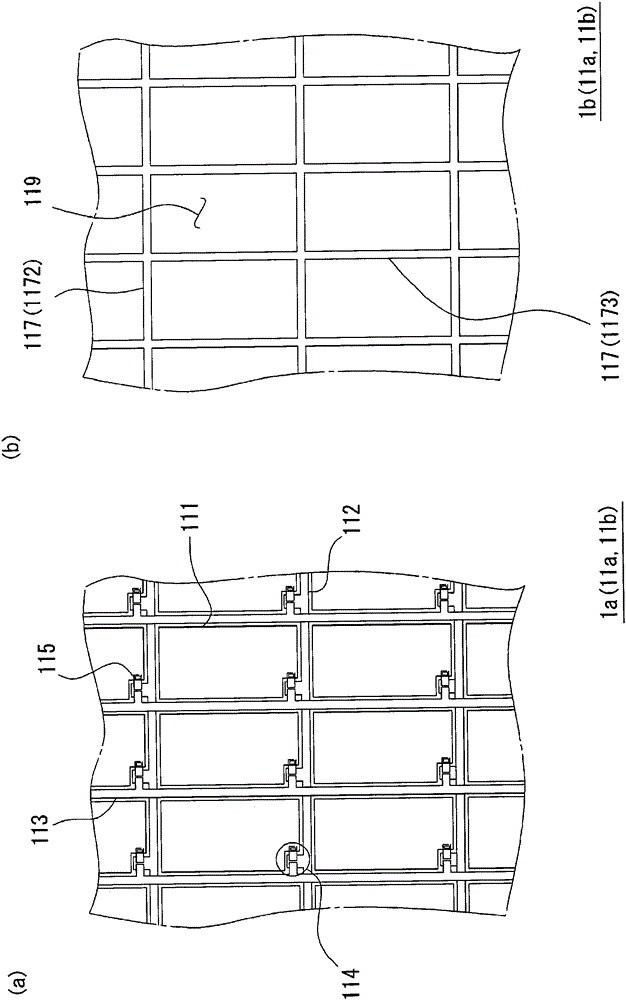

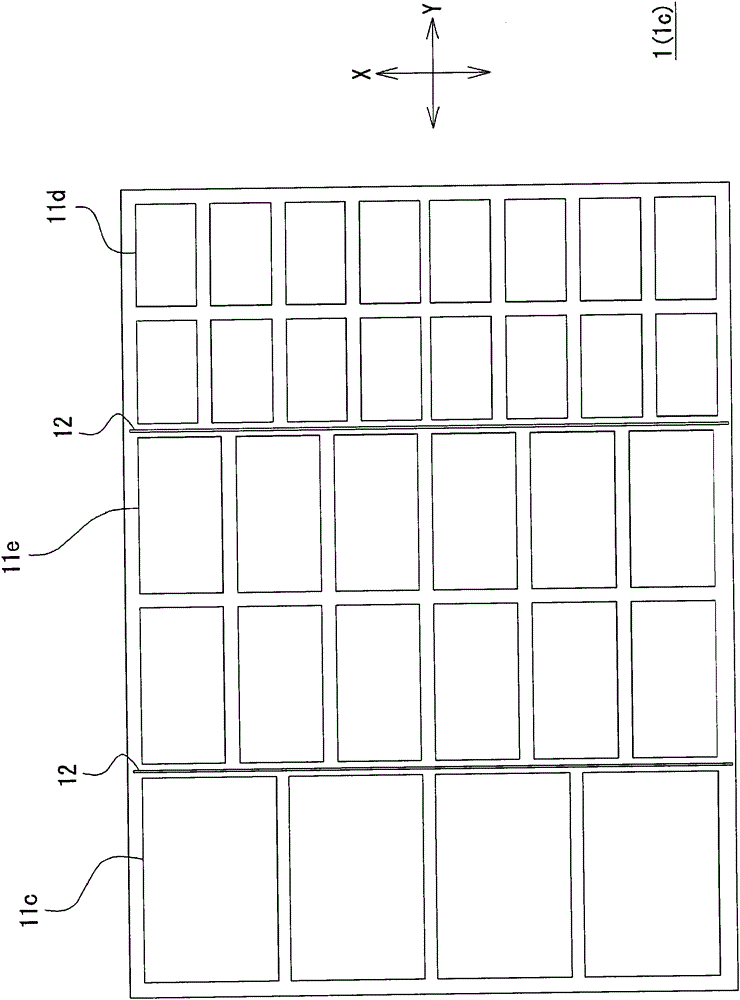

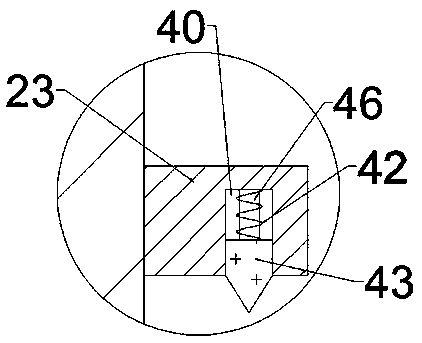

Substrate, method for exposure of substrate to light, and photo-alignment treatment method

InactiveCN102725680AReduce precisionAvoid disorderPhotomechanical apparatusNon-linear opticsLight exposureLight source

Disclosed are: a substrate in which all of regions to be exposed to light can be irradiated with a light energy with high accuracy; and a light exposure method. Using a light exposure device (5) that is equipped with multiple light exposure units (52) each comprising a light source (521) and a mask (522) having, formed therein, a light-transmissive pattern (5221) that can transmit a light energy emitted from the light source (521), a substrate (1) is irradiated with the light energy through the light-transmissive pattern (5221) formed in the mask (522) while moving the substrate (1) and the light exposure units (52) relatively to each other. At the same time, in one of the light exposure units (52) in which the mask (522) straddles a display region (11a) having a predetermined size and a display region (11b) having a different size from the predetermined size, both the display region (11a) having the predetermined size and the display region (11b) having the different size are irradiated with the light energy using an alignment pattern (12) formed on the substrate (1) as a benchmark for the control of alignment of mask (522).

Owner:SHARP KK

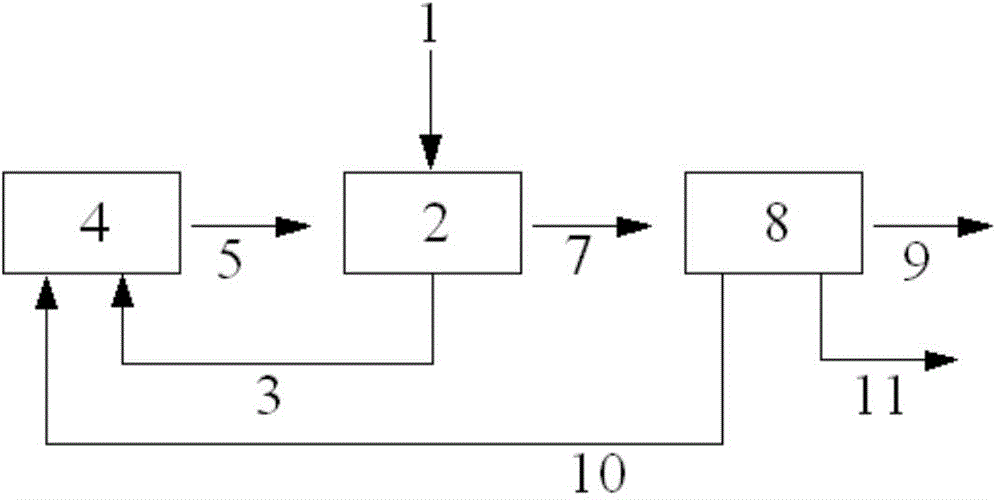

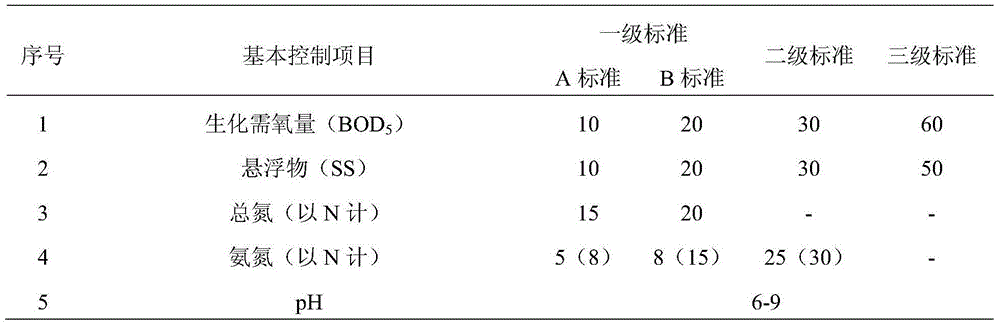

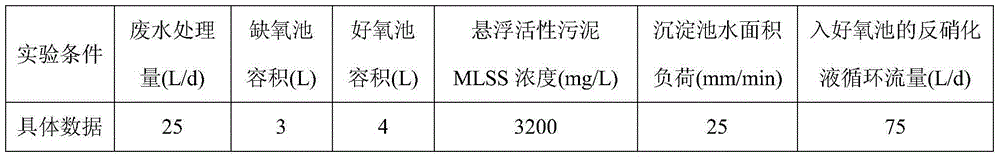

Biochemical denitrifying method for wastewater

ActiveCN104445833AImprove denitrification efficiencyImprove mud ageWater treatment compoundsSpecific water treatment objectivesTotal nitrogenOxygen

The invention dislcoses a biochemical denitrifying method for wastewater. According to the biochemical denitrifying method, an improved A / O biochemical denitrifying process is combined with a chemical method (namely a zeolite adsorption ammonia nitrogen method) to efficiently remove ammonia nitrogen in wastewater, denitrification liquid flowing from an anoxic denitrification tank enters an aerobic nitrification tank to form internal circulation, and residual denitrification liquid directly enters a sedimentation tank to be subjected to solid-liquid separation; by combining ionic adsorption with biologic regeneration, total nitrogen in effluent water is less than or equal to 5mg / L, the removal rate of total nitrogen is higher than 90%, and thus the requirement that total nitrogen in effluent water of a chemical industrial park of a Tai Lake area is superior to the standard A of 'discharge standard of pollutants for municipal wastewater treatment plant' (GB18918-2002) is stably met.

Owner:江苏艾特克环境工程设计研究院有限公司

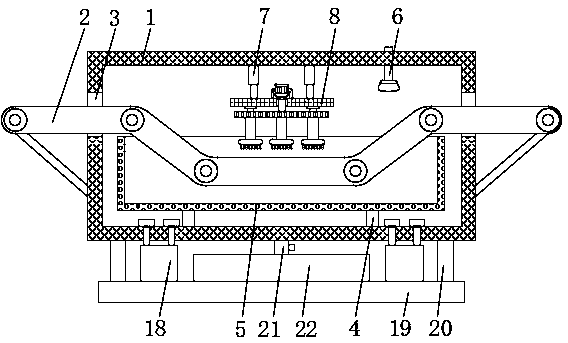

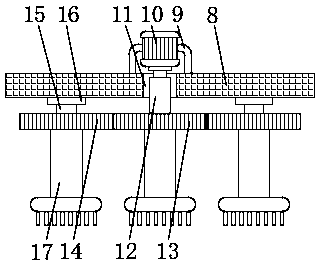

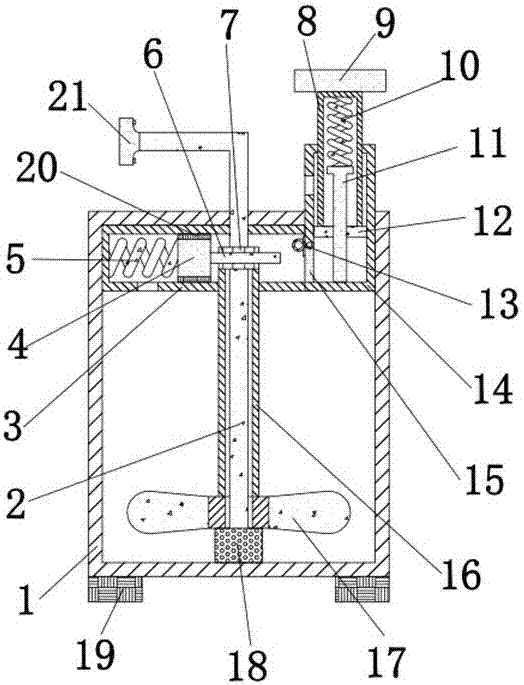

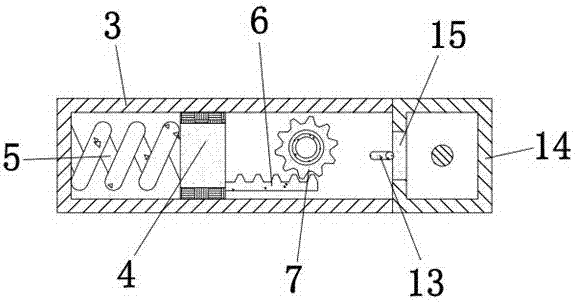

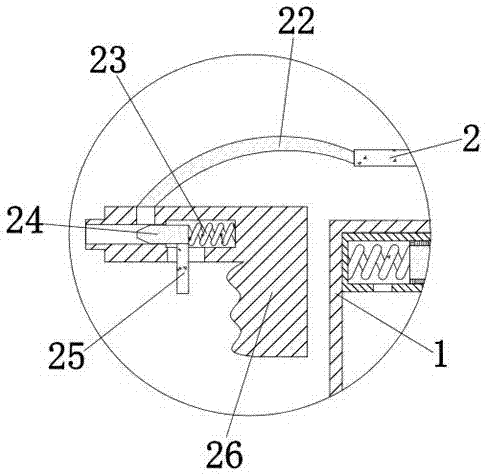

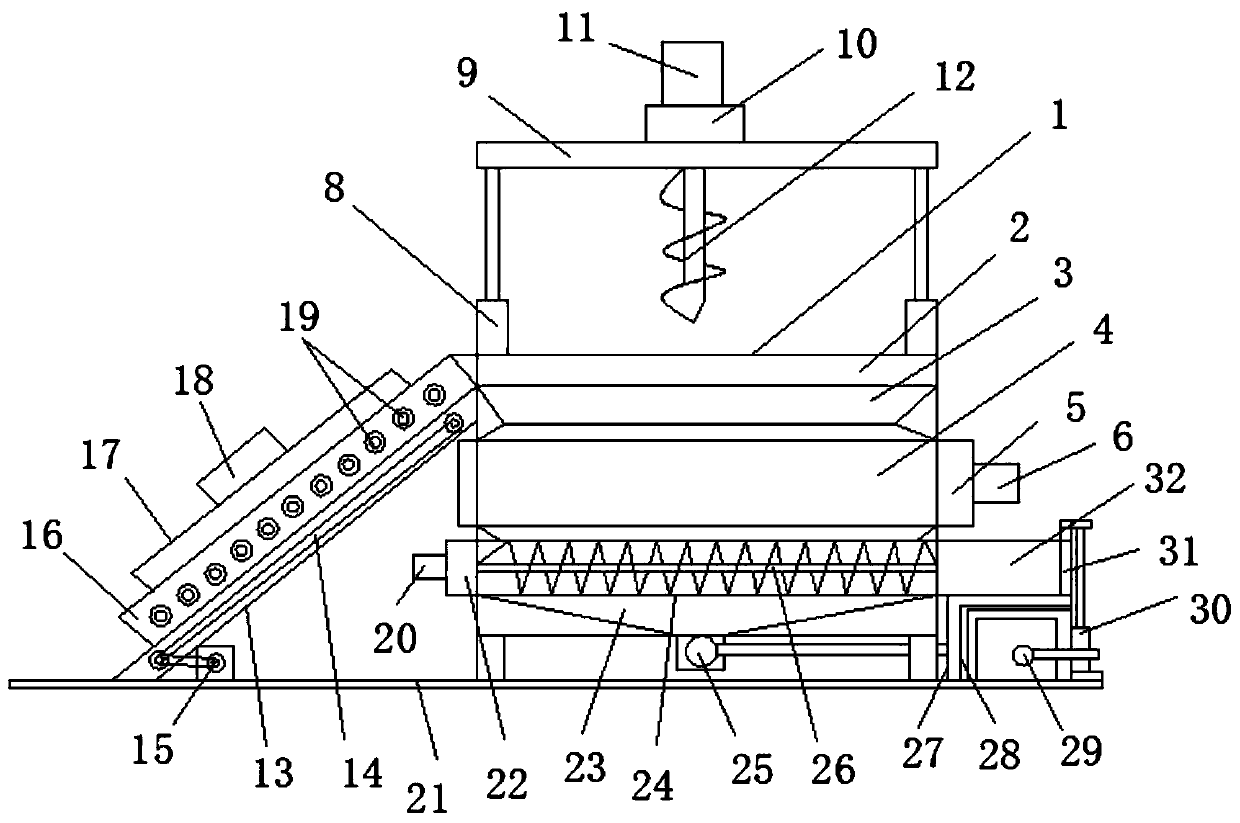

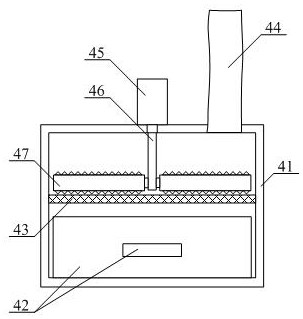

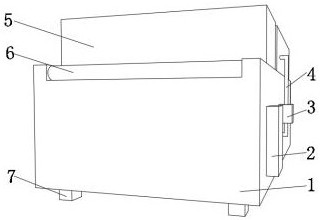

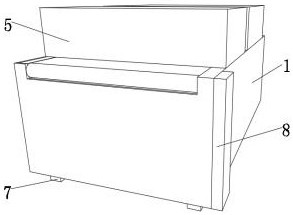

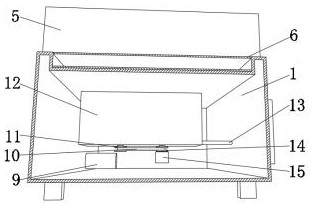

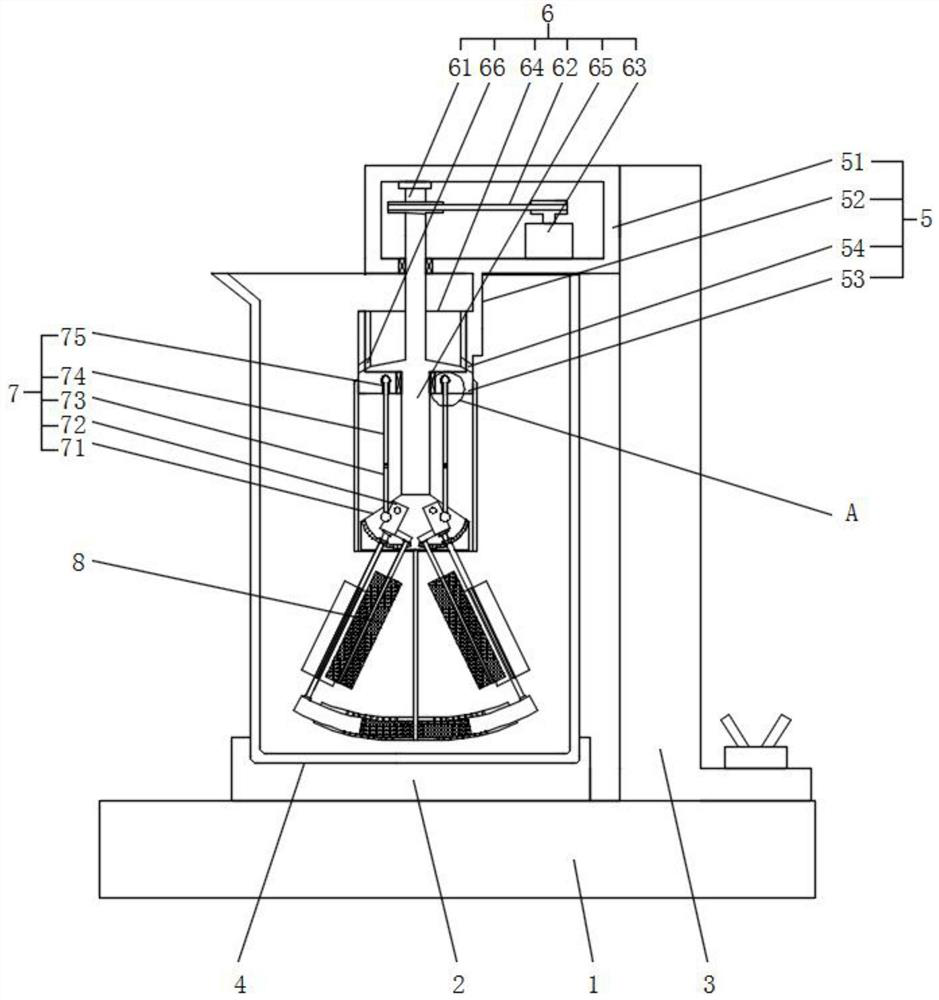

Special ultrasonic cleaning machine for spinneret plate

InactiveCN110820056AGuaranteed cleaning efficiencyEasy to cleanSpinnerette packsSprayerMegasonic cleaning

The invention discloses a special ultrasonic cleaning machine for a spinneret plate, and belongs to the technical field of spinneret plates. The special ultrasonic cleaning machine comprises a cleaning cabinet, a conveying component is fixedly connected on the outer surface of the cleaning cabinet and positioned in the cleaning cabinet, and a placing block is arranged on the lower surface of the inner wall of the cleaning cabinet. According to the special ultrasonic cleaning machine for the spinneret plate, the conveying component, a cage, an ultrasonic generator, a motor, a hairbrush, a flushing sprayer and the cleaning cabinet are matched each other, working of the conveying component and the ultrasonic generator is controlled, the spinneret plate can be moved into the cage by the conveying component, the motor drives the hairbrush to scrub the surface of the spinneret plate, the spinneret plate can be separated from bound materials in an ultrasonic cleaning manner, cleaning effect can be more ideal by a scrubbing mode of the spinneret plate, a lot of spinneret plates can be continuously cleaned, and the cleaning efficiency of the spinneret plate is ensured to some extent.

Owner:XUZHOU ZHENFENG ULTRASONIC ELECTRONICS CO LTD

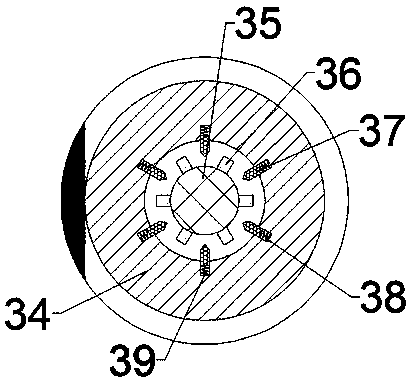

Rice processing equipment

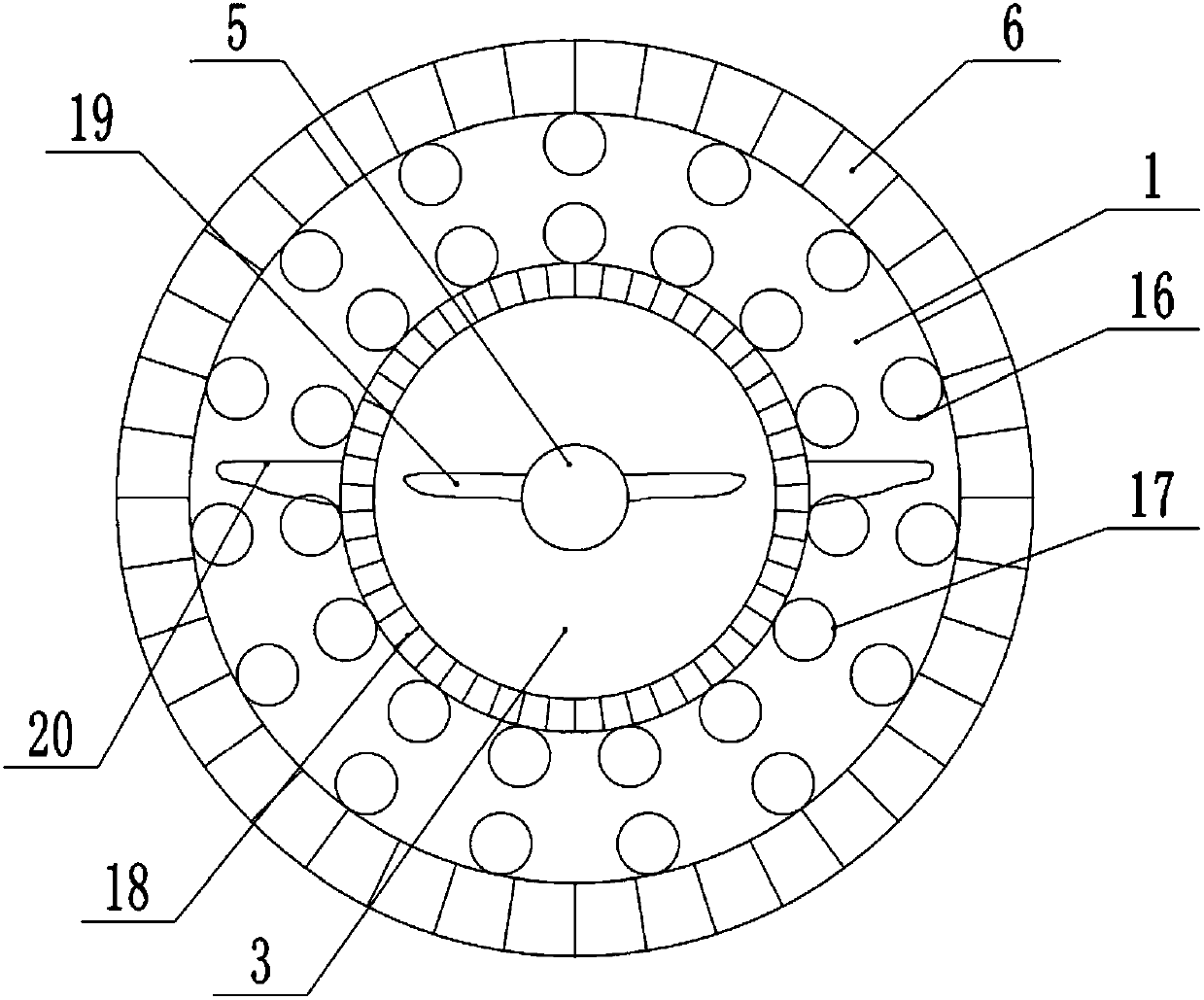

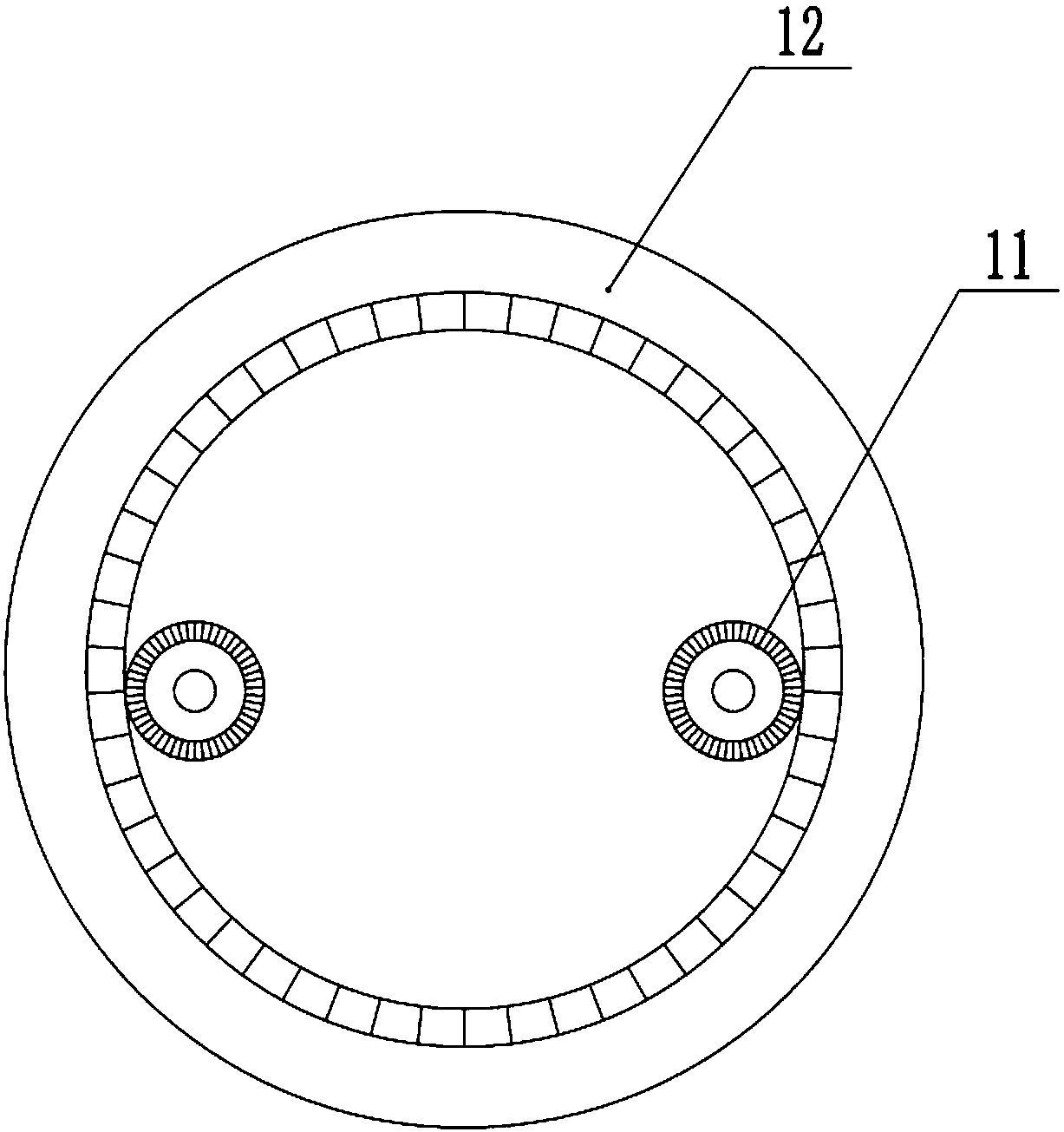

ActiveCN108043491APrevent containingKeep the relative position unchangedGrain huskingGrain polishingTransverse planeBroken rice

The invention relates to rice processing equipment. The rice processing equipment comprises an outer cylinder and an inner cylinder, and an annular cavity is formed between the inner cylinder and theouter cylinder; a transverse filter plate is inserted in the cavity; a first cavity body is formed above the filter plate and internally provided with a first negative pressure fan connected to the outer wall of the inner cylinder, and a bran shell recycling box is arranged on the outer side of the first cavity body; a second cavity body is formed below the filter plate, a discharging opening is formed in the bottom of the second cavity body, and inner polishing pellets and outer polishing pellets are arranged in the second cavity body; a third cavity body is formed in the inner cylinder, anda vertical rod penetrates through the interior of the third cavity body; the bottom end of the vertical rod is connected with a motor, and the top end of the vertical rod is connected with a transverse plate; the vertical rod is connected with a second negative pressure fan; an inner gear ring is arranged between the transverse plate and the outer cylinder, and a vertical rotating shaft is rotatably arranged on the transverse plate; the rotating shaft is connected with a straight gear engaged with the inner gear ring, and the bottom of the rotating shaft is rotatably connected with a transverse shaft; and one end of the transverse shaft is connected with a third negative pressure fan. According to the scheme, both bran shells and broken rice are prevented from entering the bran shell recycling box, and thus the bran shells and the broken rice are separated.

Owner:重庆市合川区云天食品科技有限公司

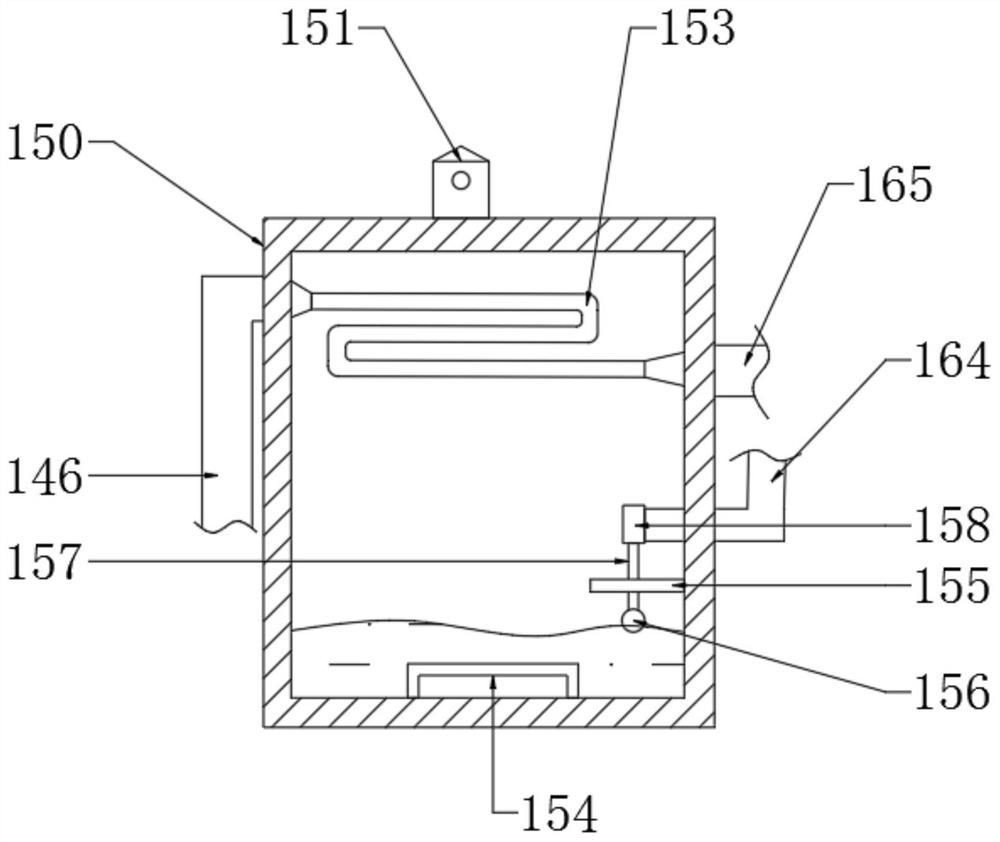

Linear compressor

InactiveCN105275775AReduce sizeIncreased internal storage spacePositive displacement pump componentsPiston pumpsReciprocating motionLinear compressor

A linear compressor is provided. The linear compressor may include a shell including a suction inlet, a cylinder provided in the shell to define a compression space for a refrigerant, a piston reciprocated in an axial direction within the cylinder, a discharge valve provided at one side of the cylinder to selectively discharge the refrigerant compressed in the compression space, and at least one nozzle, through which at least a portion of the refrigerant discharged through the discharge valve may flow, the at least one nozzle being disposed in the cylinder. The at least one nozzle may include an inlet, through which the refrigerant may be introduced, and an outlet having a diameter less than a diameter of the inlet.

Owner:LG ELECTRONICS INC

Storage tank for efficient preservative for metal surface

The invention discloses a storage tank for an efficient preservative for the metal surface. The storage tank comprises a tank body and a third sleeve; the third sleeve is mounted at the top end of the right side inside the tank body and penetrates through the tank body; a handle is arranged at the top end of the third sleeve; the handle is connected with the third sleeve through a second sleeve; a second piston is arranged in the third sleeve; and the second sleeve penetrates through the third sleeve and is connected to the second piston in a lap joint mode. According to the storage tank for the efficient preservative for the metal surface, through matching of the second sleeve and a second compression spring, the working strength of operating worker is relieved; through matching of a baffle and a torsion spring, air backflow can be prevented; through matching of a first piston and a first compression spring, air and medicament backflow under the air pressure effect can be prevented; and through matching of a gear and a transmission shaft, the gear rotates in pressurization, a fan blade is rotated through a rotating shaft to stir a medicament, and thus the situation that the medicament contains a precipitate is prevented.

Owner:柴卓

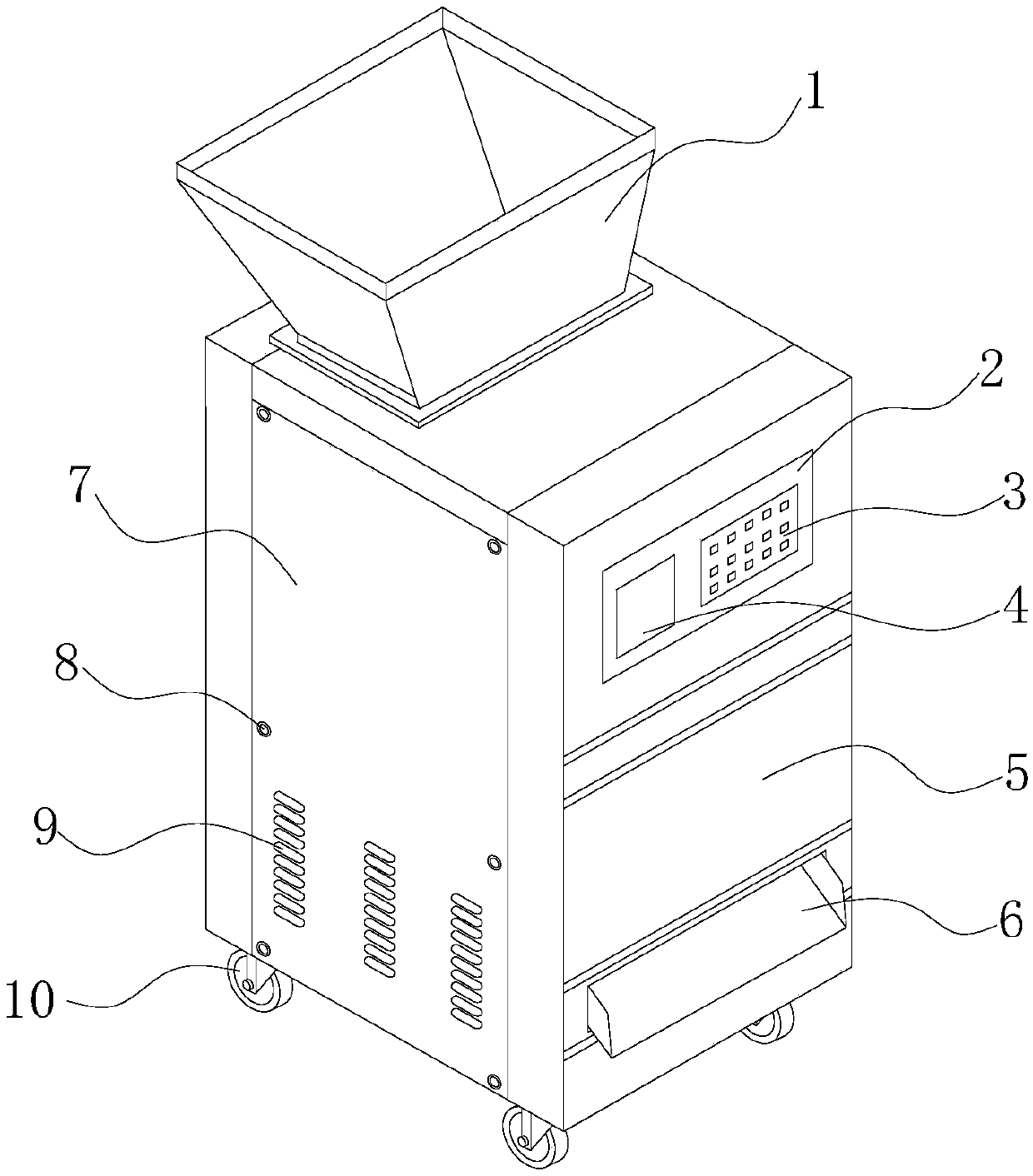

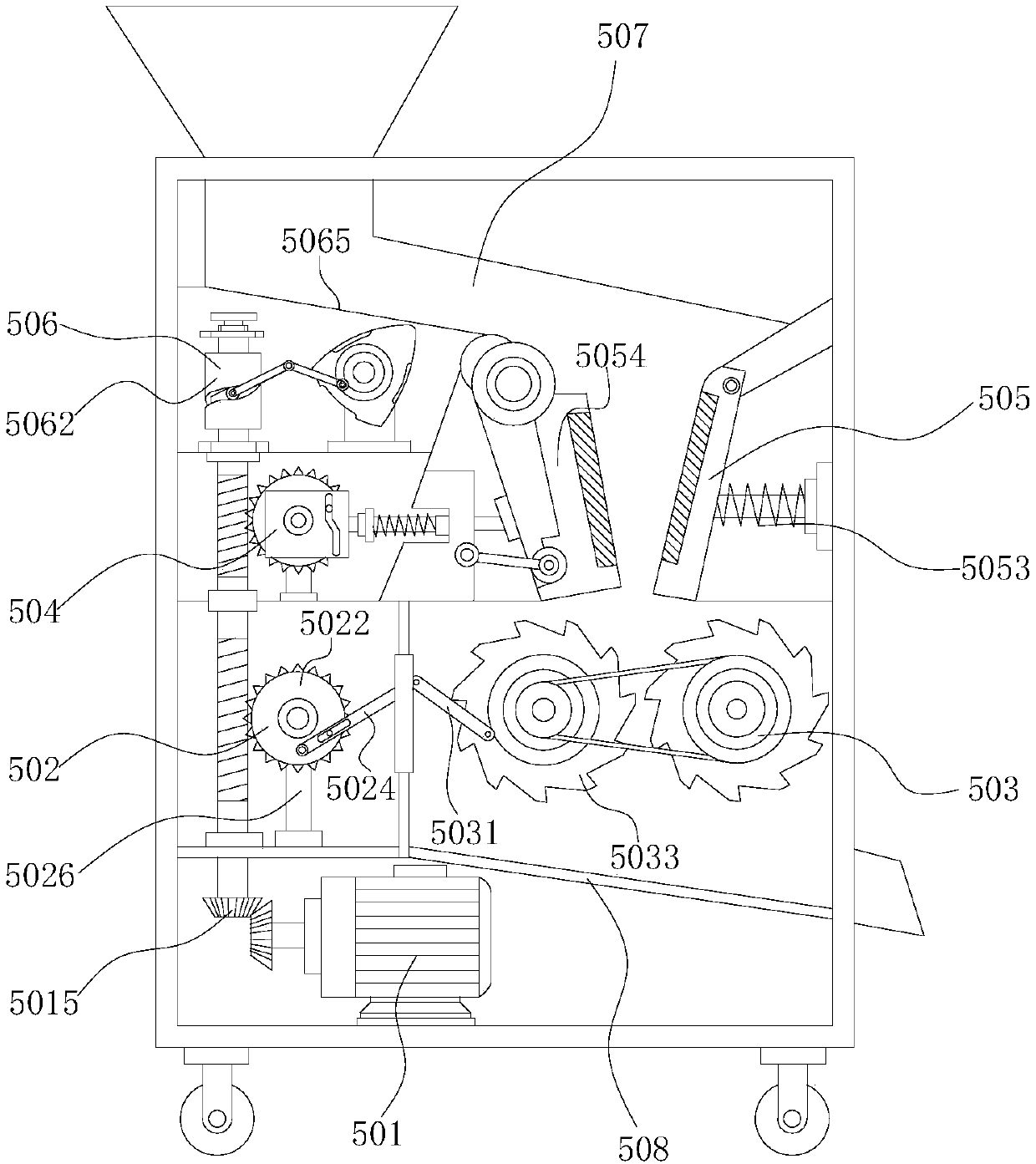

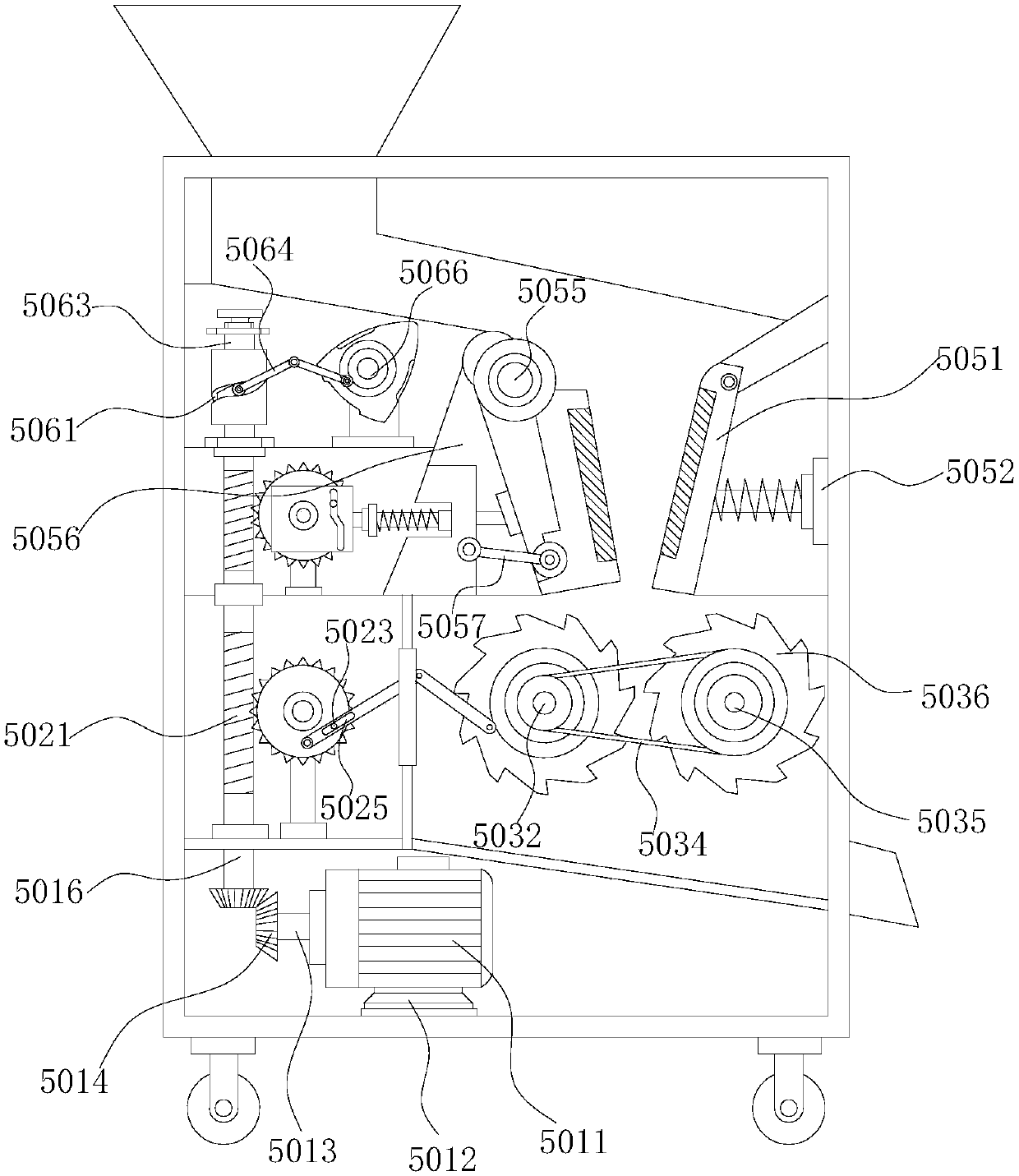

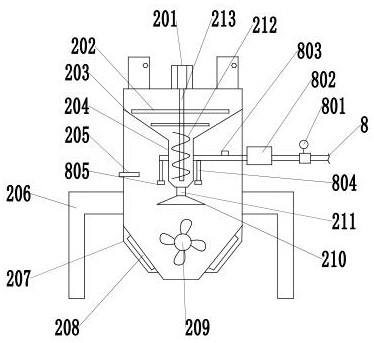

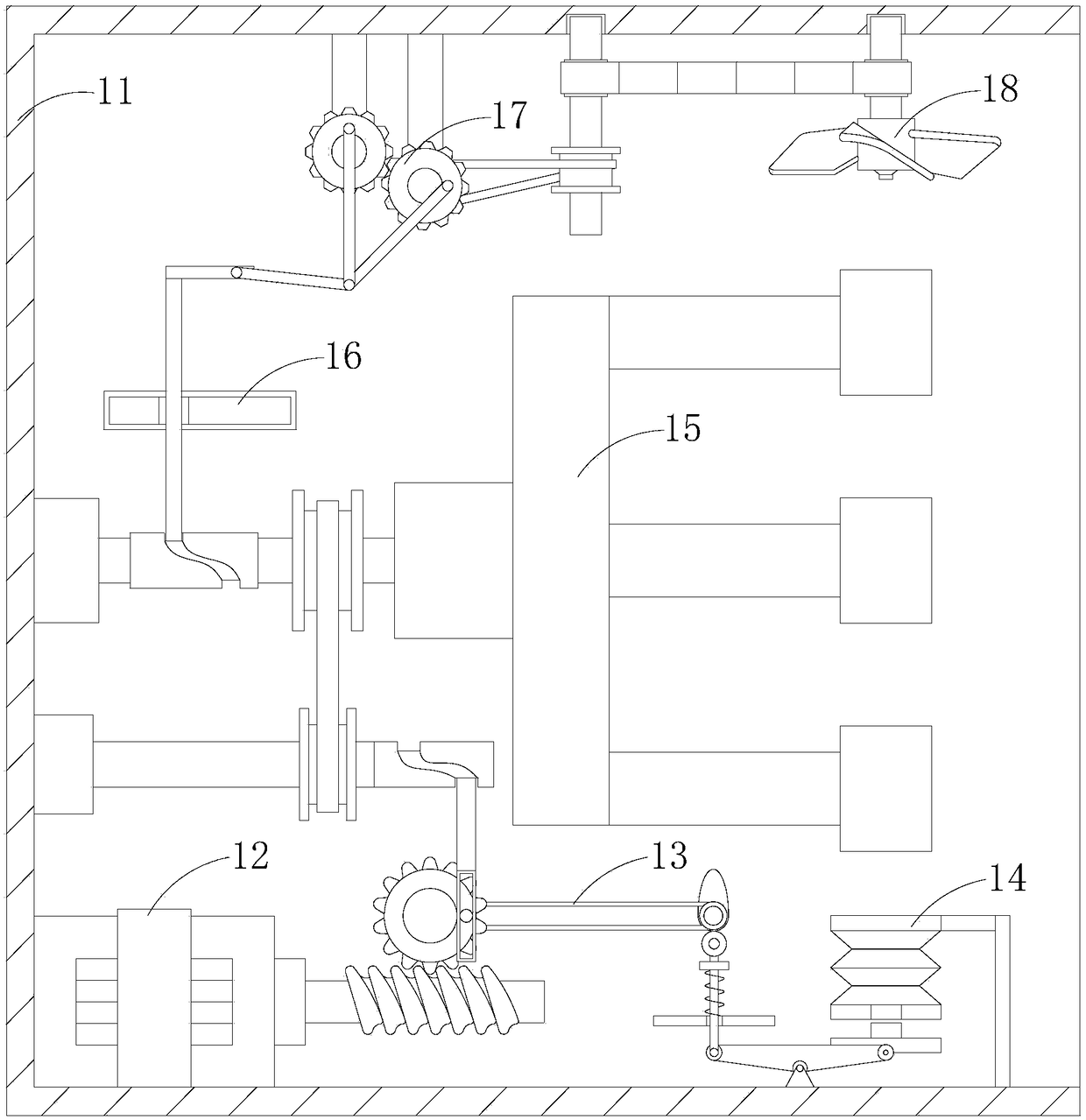

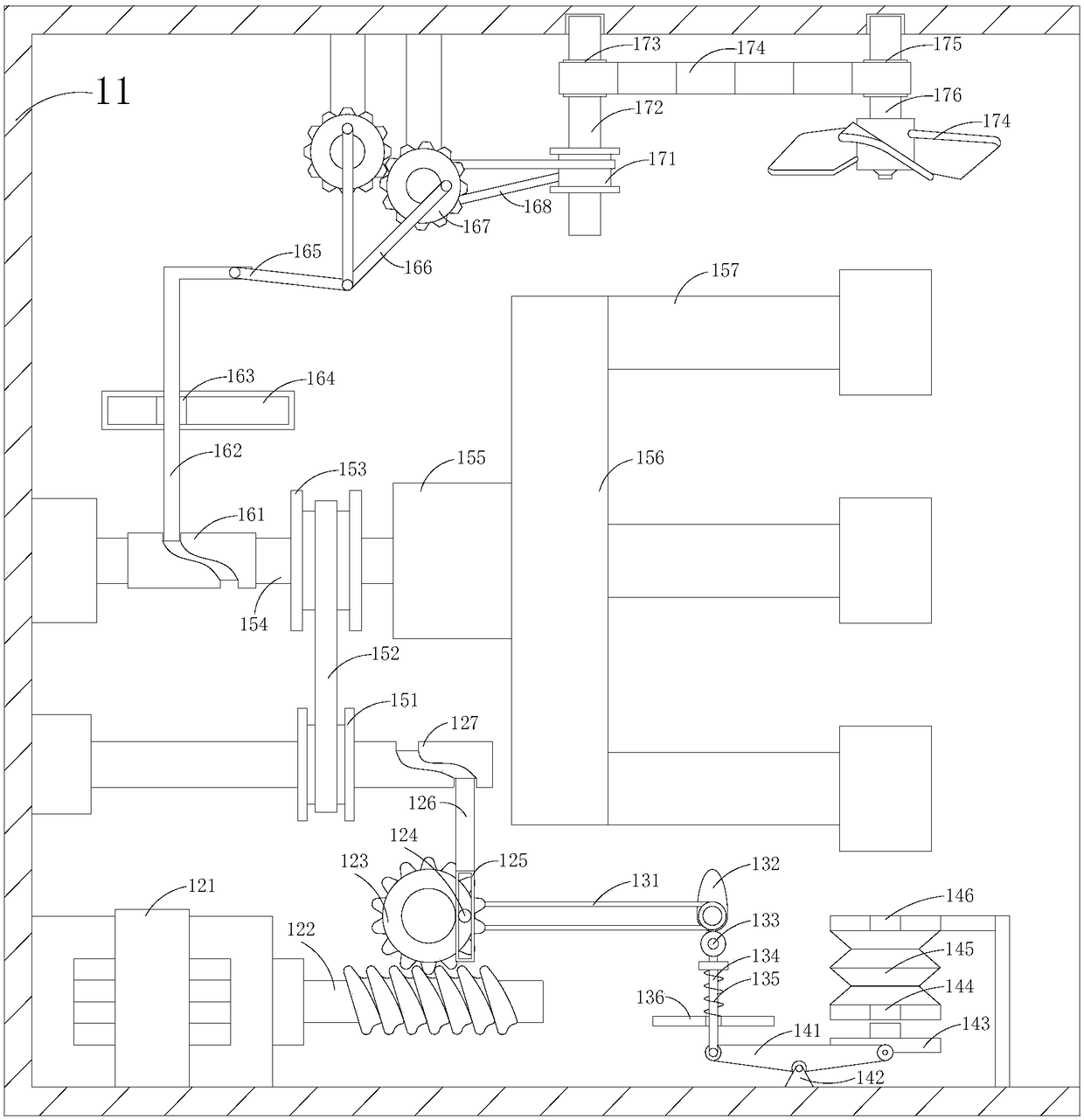

Tea and tea additive uniform mixing and crushing device

InactiveCN108671990AGood lookingImprove qualityPre-extraction tea treatmentRotary stirring mixersAgricultural engineeringEngineering

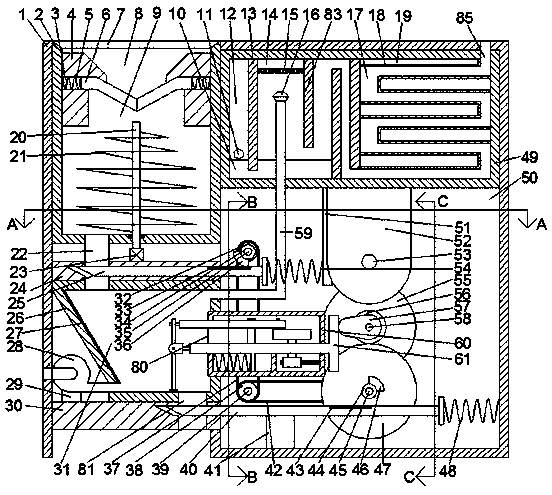

The invention discloses a tea and tea additive uniform mixing and crushing device. The structure of the device comprises: a feeding hopper, an operation panel, buttons, a display screen, a main device, a discharge hopper, a device shell, fixation screws, a heat dissipation grille and universal wheels. The main device comprises a driving mechanism, a transmission mechanism, a mixing mechanism, a horizontal reciprocating mechanism, an additive crushing mechanism, an oscillation mechanism, a material channel and a blanking plate. According to the tea and tea additive uniform mixing and crushing device provided by the invention, the main device is internally equipped with the driving mechanism, the transmission mechanism, the mixing mechanism, the horizontal reciprocating mechanism, the additive crushing mechanism and the oscillation mechanism, can realize synchronous crushing of the additive powder solid in the mixing process of tea and additives, and reduce the stock of additive powder solid, so that tea and additives can be mixed evenly, and the appearance color and quality of tea can be improved.

Owner:刘钰婷

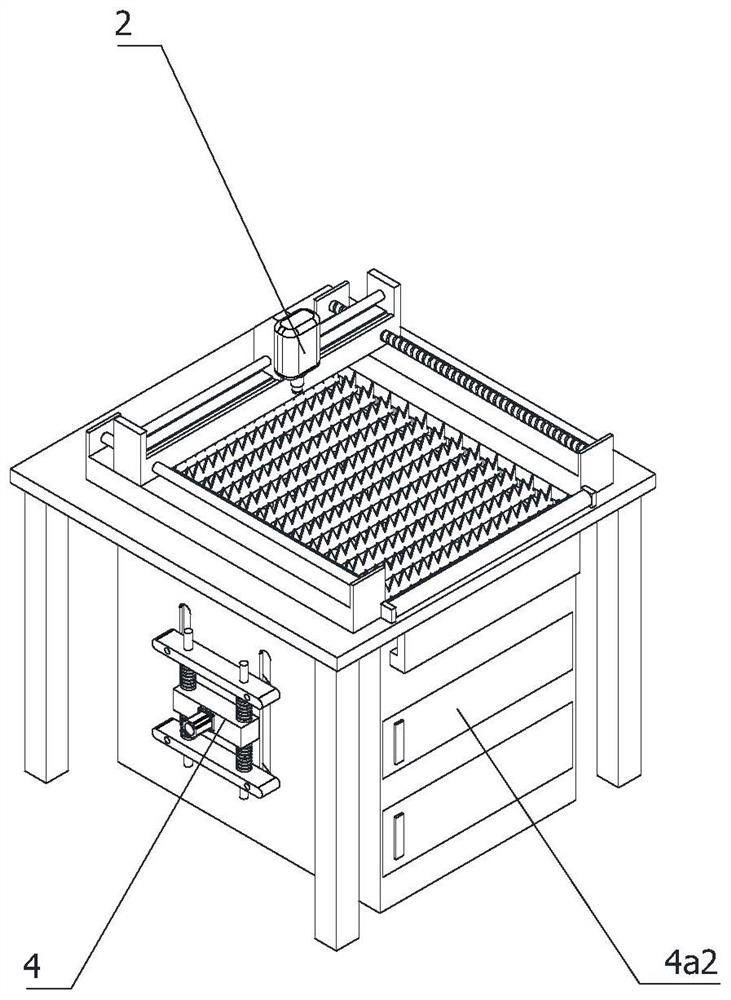

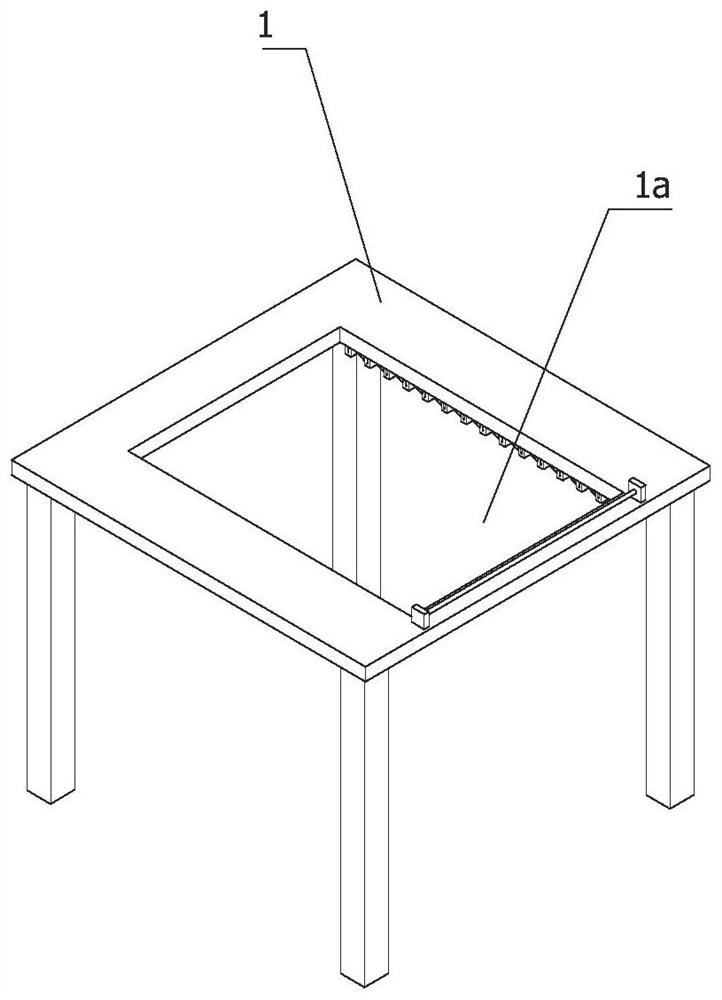

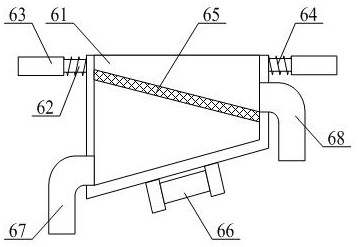

Laser cutting machine facilitating waste treatment

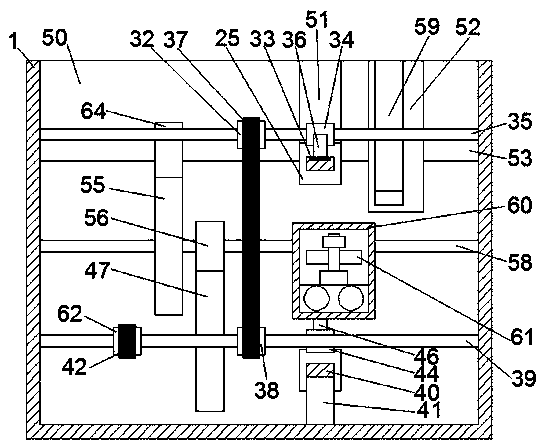

InactiveCN114289893AEasy to collectEasy to collect separatelyLaser beam welding apparatusThermodynamicsFresh air

The invention relates to the technical field of laser cutting, in particular to a laser cutting machine convenient for waste treatment, which comprises a workbench and a cutting assembly, the cutting assembly is located above the workbench, the center of the workbench is provided with a blanking groove, and the workbench is provided with a sealing cover, a fresh air assembly, a collecting mechanism and an adjusting assembly. When a workpiece is cut through the cutting assembly, the workpiece is placed above the blanking groove, after being cut, the workpiece falls into the collecting mechanism through the blanking groove, waste and finished products are screened through the collecting mechanism, the waste cannot be scattered while the finished products are conveniently collected, and through the arrangement of a sealing cover, in the cutting process, the cutting efficiency is greatly improved. Smoke dust and molten slag do not fly up, the interior of the sealing cover is always kept in a re-pressing state through the fresh air assembly, the smoke dust and the molten slag are discharged from the lower end of the equipment, damage of the smoke dust to workers is reduced, the adjusting assembly is used for controlling the size of the discharging groove, and finished products and waste materials can be conveniently and separately collected.

Owner:苏艺

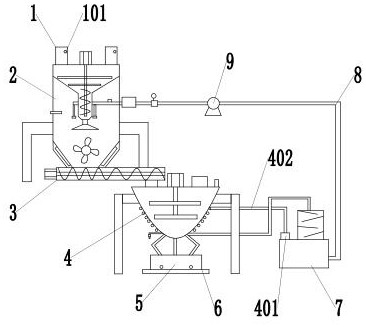

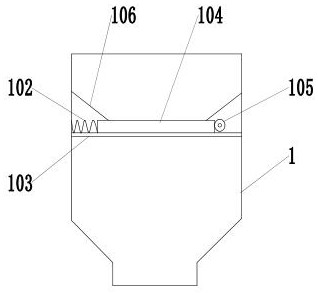

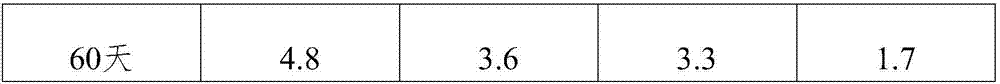

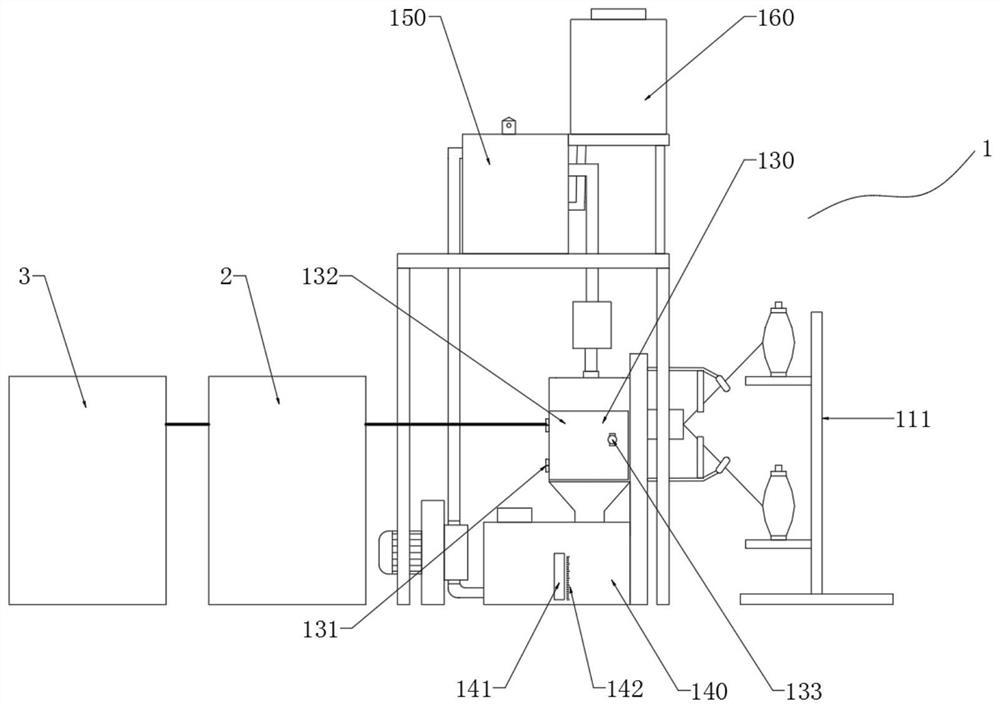

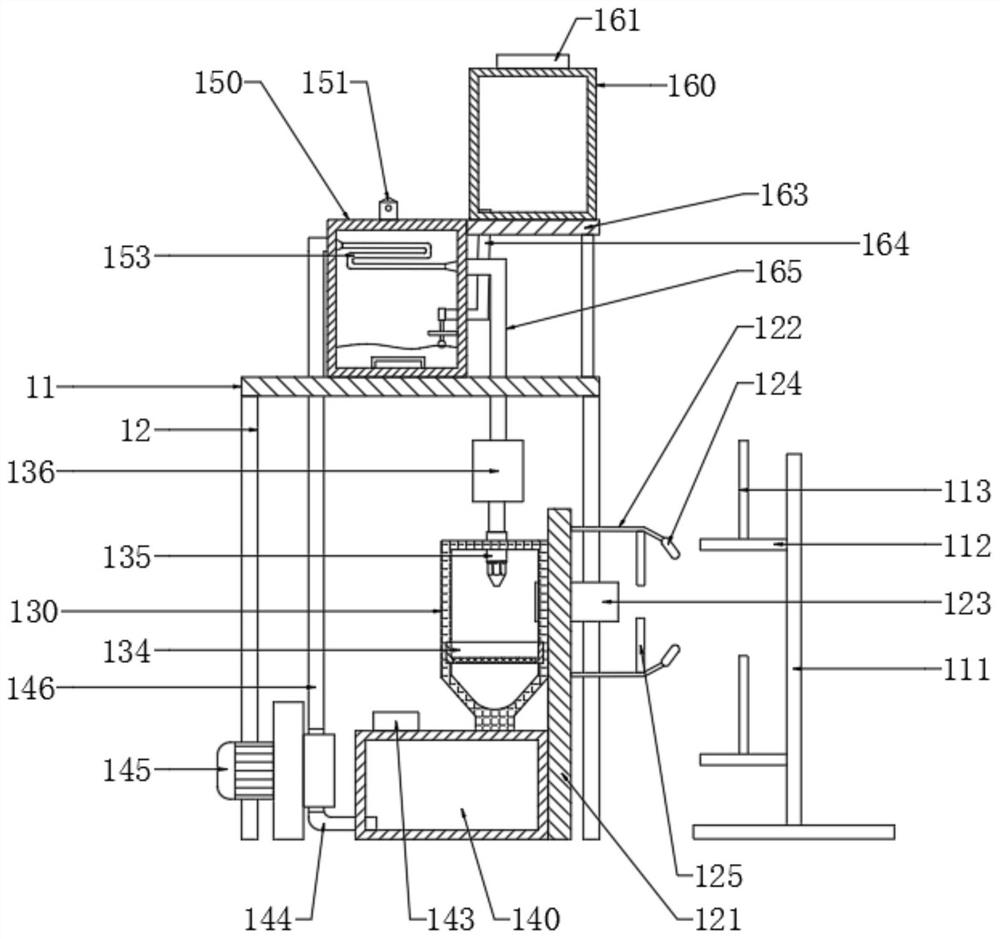

Automatic production equipment for corrugated board adhesive

PendingCN111672401AQuality assuranceWell mixedTransportation and packagingRotary stirring mixersAdhesive glueProcess engineering

The invention discloses automatic production equipment for a corrugated board adhesive. The equipment comprises a raw material adding barrel, a raw material mixing barrel, a spiral conveyor, a stirring forming barrel, a glue receiving barrel and a cooling water tank, the raw material adding barrel is arranged at the upper end of the raw material mixing barrel, a support frame is arranged outside the raw material mixing barrel, water inlet pipes are arranged in the raw material mixing barrel, the water inlet pipe is connected with the cooling water tank, the bottom of the raw material mixing barrel is connected with the stirring forming barrel through the spiral conveyor, the cold water inlet pipe is wound outside the stirring forming barrel and connected with the cooling water tank, the cooling water pump is arranged on the cold water inlet pipe, and the bottom of the stirring forming barrel is connected with a glue receiving tank. The raw material mixing barrel can heat a mixture, thestirring forming barrel can cool the mixture, step-by-step mixing, targeted heating and cooling are achieved, the quality of prepared glue is guaranteed, and the problems that glue prepared through existing equipment is poor in quality and low in adhesion degree are solved.

Owner:昆山鸣朋新材料科技有限公司

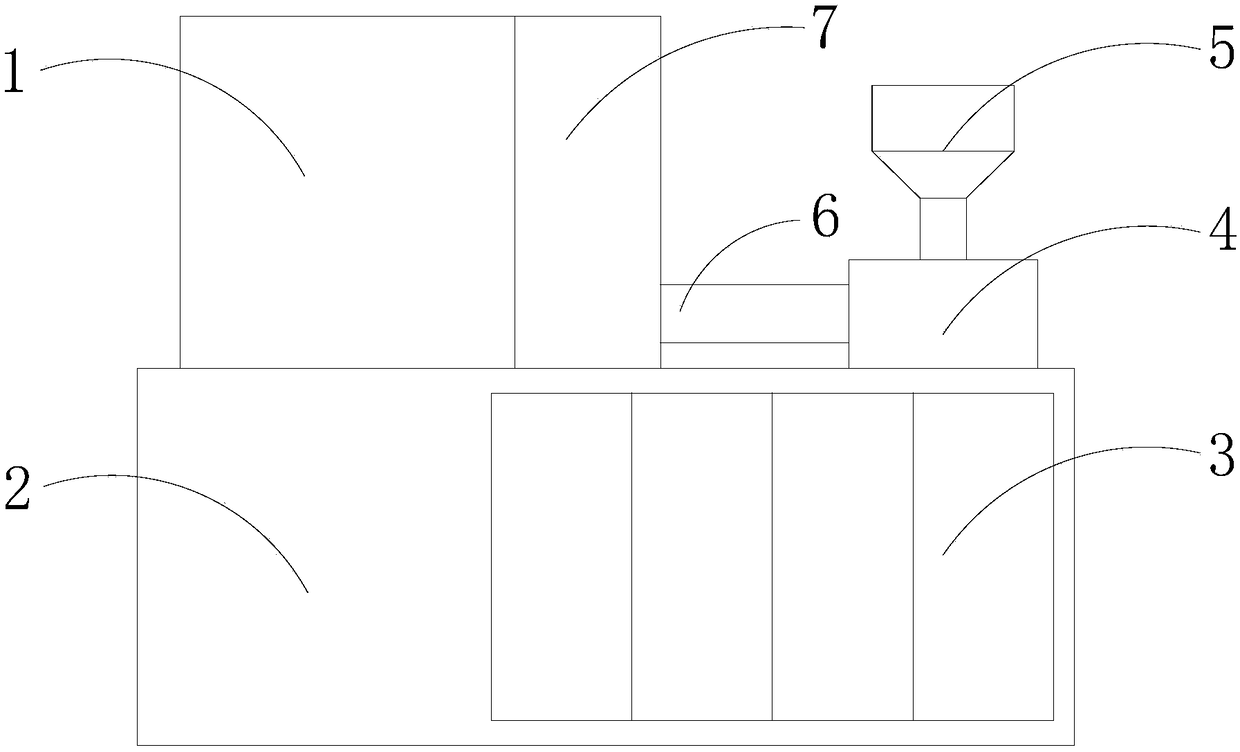

Automatic die switching device for injection molding machine

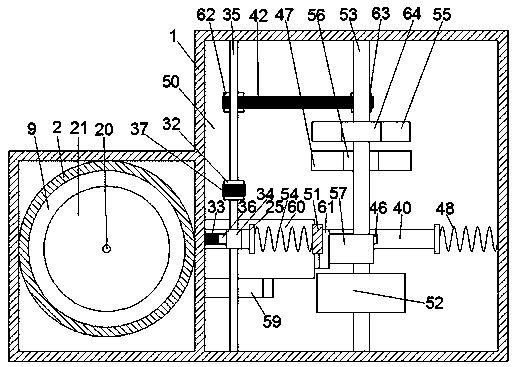

The invention discloses an automatic die switching device for an injection molding machine. The device structurally comprises a die switching main machine, a base, a cabinet, a propeller, a feeding bucket, a feeding pipe and a die closing main machine, wherein the lower surface of the die switching main machine is fixedly mounted at one end of the base, and the base is integrally structured with the cabinet; the propeller is mounted at the other end of the base, and the lower end of the feeding bucket is mounted on the propeller; and the propeller is in end-to-end connection with the feeding pipe. According to the device, a rotary die switching mechanism is driven to switch dies through a power mechanism; the device is simple in structure, and simple and convenient to operate; the four sides of the dies are reinforced through a reinforcing mechanism, and clamping force is supplied to the four sides of the dies, so that the dies cannot be highly deformed and abraded during working; after being switched, the die to be put into work is cleaned through a dust removing mechanism, and thus the injection molding is performed on the die without any dust, and as a result, a finished productobtained by injection molding is free from impurities; the die after using can be cooled through a cooling mechanism, so that the die can be prevented from damage due to working under high temperature, and as a result, the service life of the die is prolonged.

Owner:沈国强

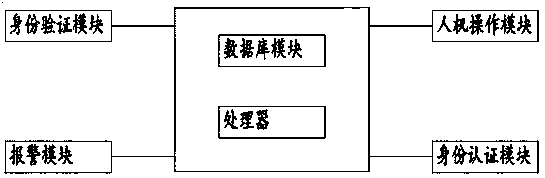

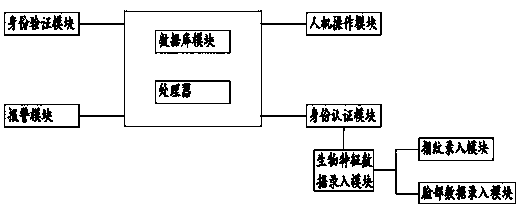

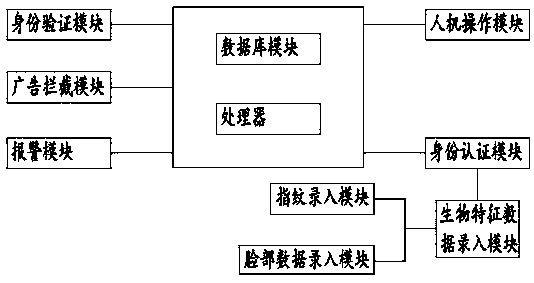

Computer information security system

InactiveCN109697348AIncreased operating comfortPrevent virusInternal/peripheral component protectionDigital data authenticationData securityBiometric data

The invention discloses a computer information security system, and relates to the technical field of computer security. The system comprises a man-machine operation module; an identity authenticationmodule used for comparing the received biological characteristic data with biological characteristic data in a user registration database and sending a comparison result to the processor; an identityverification module; wherein the identity verification module is used for intermittently sending an identity verification request for requesting to verify an operator to the processor; an alarm module; a database module is used for storing data; a processor. The computer information security system ensures that the operator is consistent with the login user and ensures the data security.

Owner:广州破折号信息科技有限公司

Rapeseed oil full-automatic squeezing device

PendingCN111016252ARealize automatic feeding processQuality improvementPressesOil canElectric machinery

The invention discloses a rapeseed oil full-automatic squeezing device, comprising a device body, wherein a feeding hole is formed in the top part of the device body; first electric telescopic rods are fixed to the two sides of the top part of the feeding port correspondingly; a top plate is mounted at the top parts of the first electric telescopic rods; a second gearbox is mounted in the middle of the top part of the top plate; a second motor is mounted at the top part of the second gear box; and a first auger is mounted at the bottom part of the second gear box. According to the rapeseed oilfull-automatic squeezing device, automatic feeding of rapeseeds can be achieved; in the feeding process, the rapeseeds can be subjected to dust removal and drying treatment, thereby improving rapeseed quality, and preventing the phenomenon of blockage caused by excessive rapeseeds during feeding; the rapseeds can be heated to improve the oil yield while being squeezed, and the rapeseed waste residues generated during oil squeezing can be subjected to oil filtering treatment, so that oil in the waste residues can be treated more cleanly; and the rapeseed oil can be filtered multiple times, impurities are prevented from being contained in the oil, and the oil squeezing quality is improved.

Owner:兴化市荣宝油脂有限公司

Preparation method of 3D printing material containing corn straws

InactiveCN108440982AImprove compactnessImprove stabilityAdditive manufacturing apparatusPre treatmentMechanical property

The invention discloses a preparation method of a 3D printing material containing corn straws, and relates to the field of novel materials. The preparation method of the 3D printing material containing corn straws comprises the steps of pretreatment of the corn straws, raw material mixing, extrusion and granulating, 3D printing and the like. According to the preparation method, the corn straws aresubjected to surface modification treatment, the compactness and stability of a middle material are improved, granules are dried, and then are smashed into fine granules for 3D printing, smoothness of the surface of the material is ensured, and the prepared material has good corrosion resistance, dimension stability and mechanical property.

Owner:肥西县碧涛建材有限公司

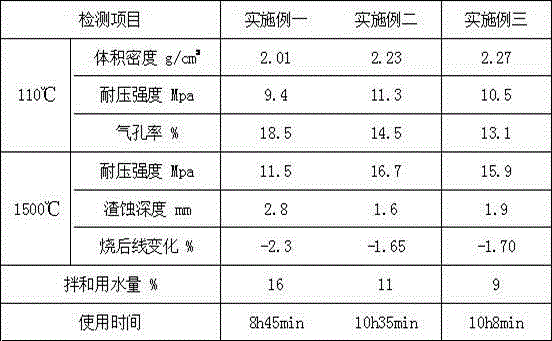

Tundish coating and preparation method thereof

The invention discloses tundish coating and a preparation method thereof. The tundish coating comprises 15-27% of 200-mesh waste magnesia brick powder, 28-34% of waste magnesia brick particles with the diameter of 0-1mm, 30-38% of waste magnesia brick particles with the diameter of 1-3mm, 5-13% of 200-mesh magnesite powder, 1-7% of silicon micropowder, 0.01-0.8% of water glass and 0.8-2% of jute fiber. The tundish coating provided by the invention uses the waste magnesia brick and the magnesia as main raw materials, and the silicon micropowder, the water glass and the jute fiber are added as auxiliary materials, so that a good bonding effect can be achieved and the bonding performance can be enhanced; the silicon micropowder is added, so that the stability of the tundish coating can be enhanced and shedding of the tundish coating can be prevented; the tundish coating is good in lubricating property; the tundish coating prevents impurities in molten steel so as to ensure the purity of the molten steel.

Owner:周九喜

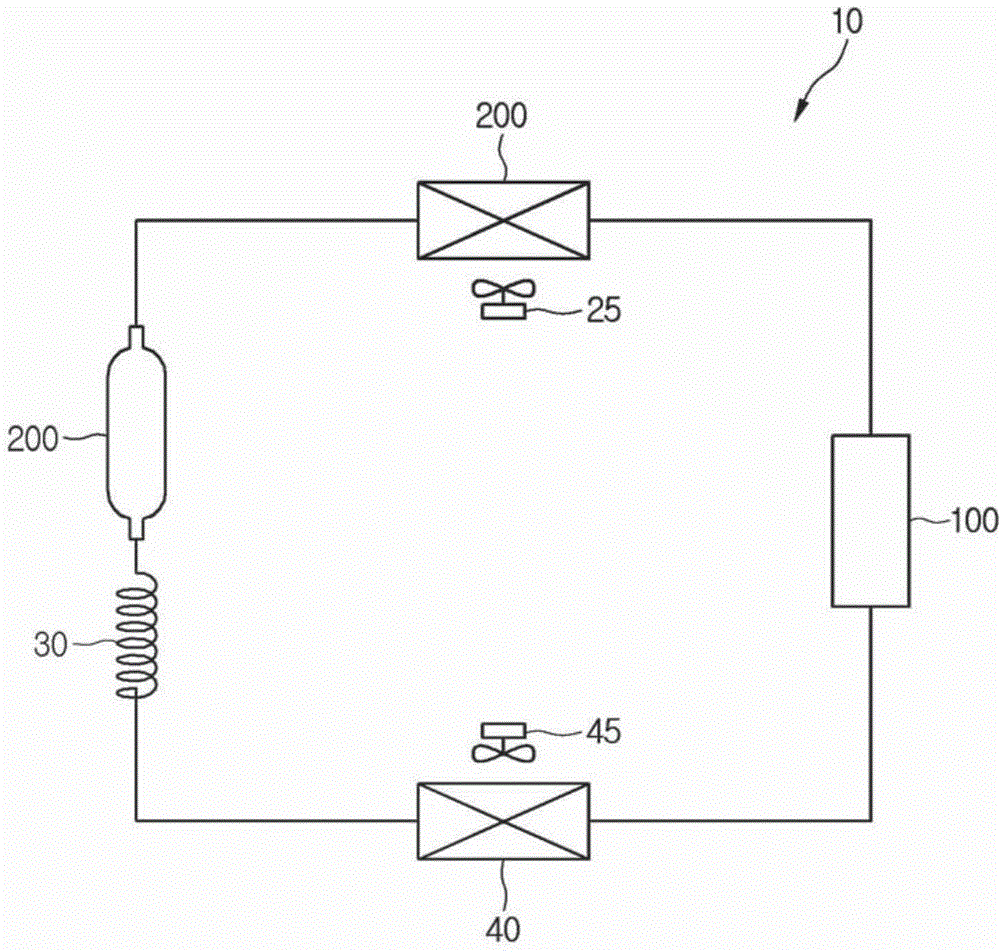

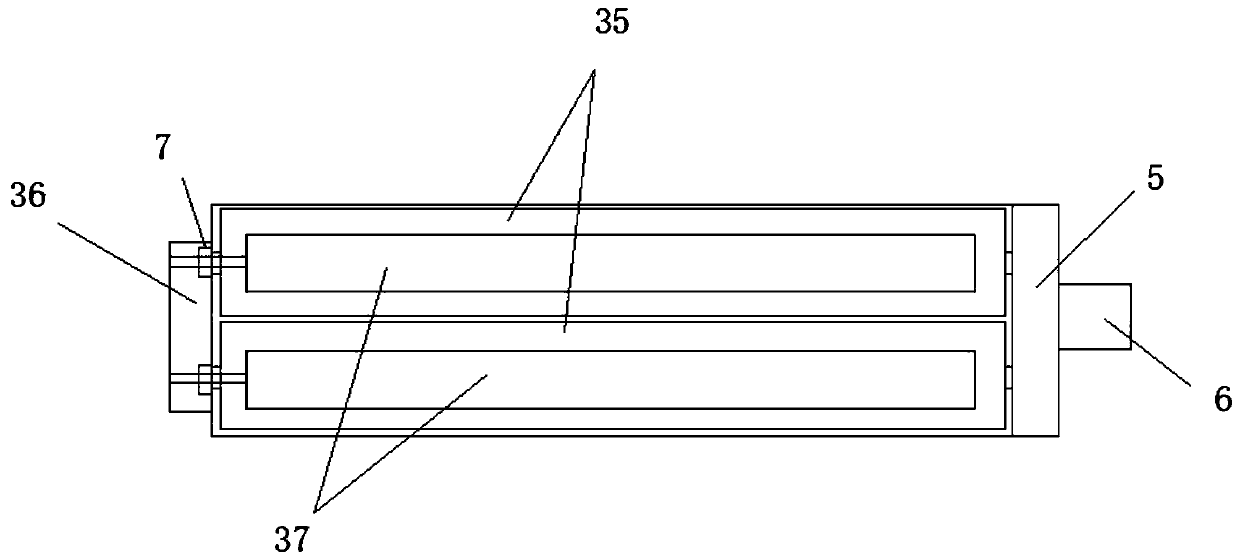

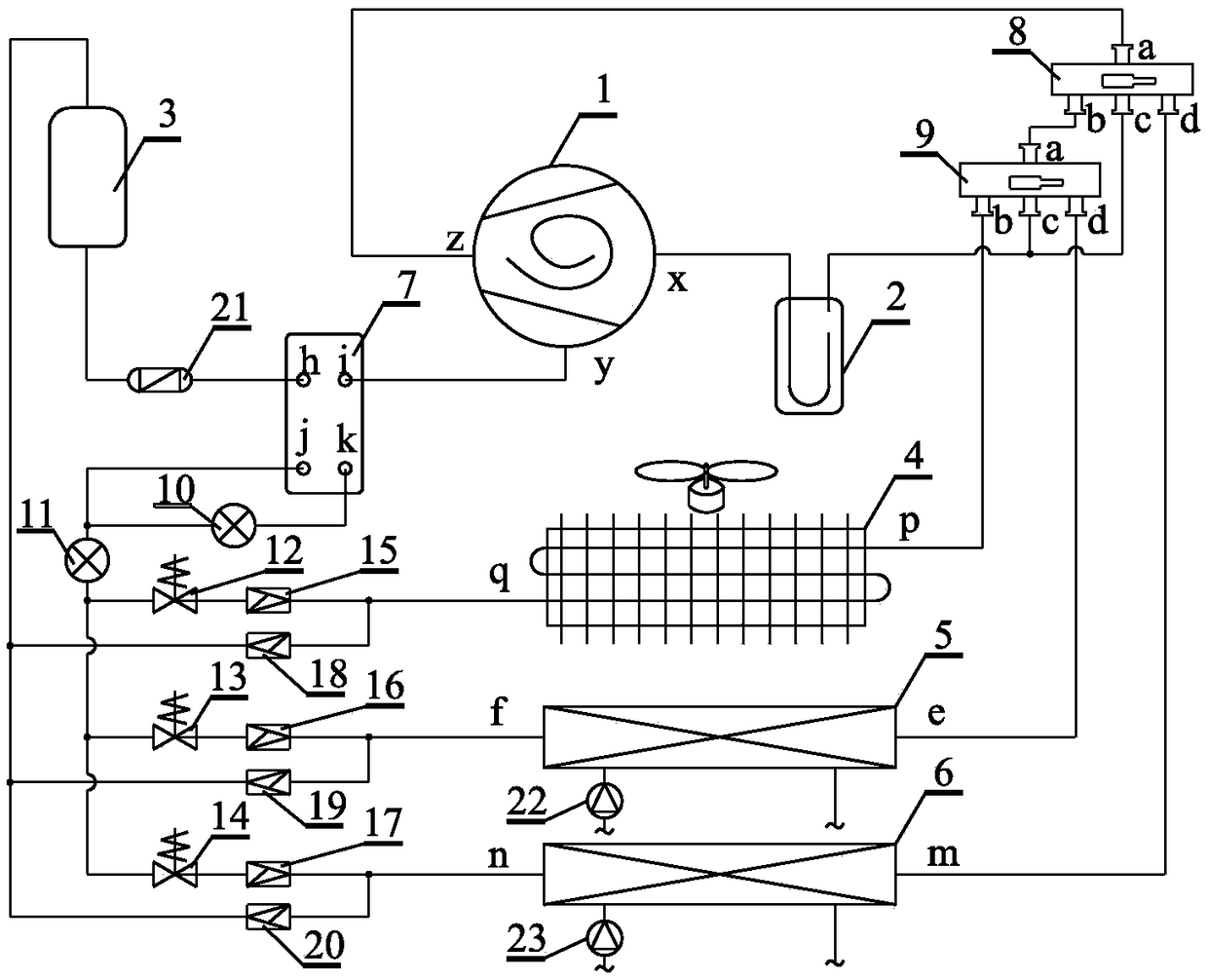

Air source-water source composite heat pump heat supply method with middle gas supplementation

InactiveCN109163476ALower usage limitLower specific enthalpyMechanical apparatusHeat pumpsWater source heat pumpWater source

The invention provides an air source-water source composite heat pump heat supply method with middle gas supplementation. An electrical controller in a system can compare a current outdoor environmenttemperature with a water source side temperature; under a heating mode, a water source heat pump heating way is selected when the water source side temperature is greater than a difference value obtained by subtracting a set deviation value from the outdoor environment temperature, and an air source heat pump heating way is selected when the water source side temperature is smaller than the difference value obtained by subtracting the set deviation value from the outdoor environment temperature or when the water source side temperature is lower than the set value; and under a refrigerating mode, the air source heat pump refrigerating way is selected when the water source side temperature is greater than the difference value obtained by subtracting the set deviation value from the outdoorenvironment temperature, and the water source heat pump refrigerating way is selected when the water source side temperature is smaller than the difference value obtained by subtracting the set deviation value from the outdoor environment temperature. The air source-water source composite heat pump heat supply method can effectively solve use limitation, in the northern cold region, of the air source heat pump.

Owner:DALIAN NATIONALITIES UNIVERSITY

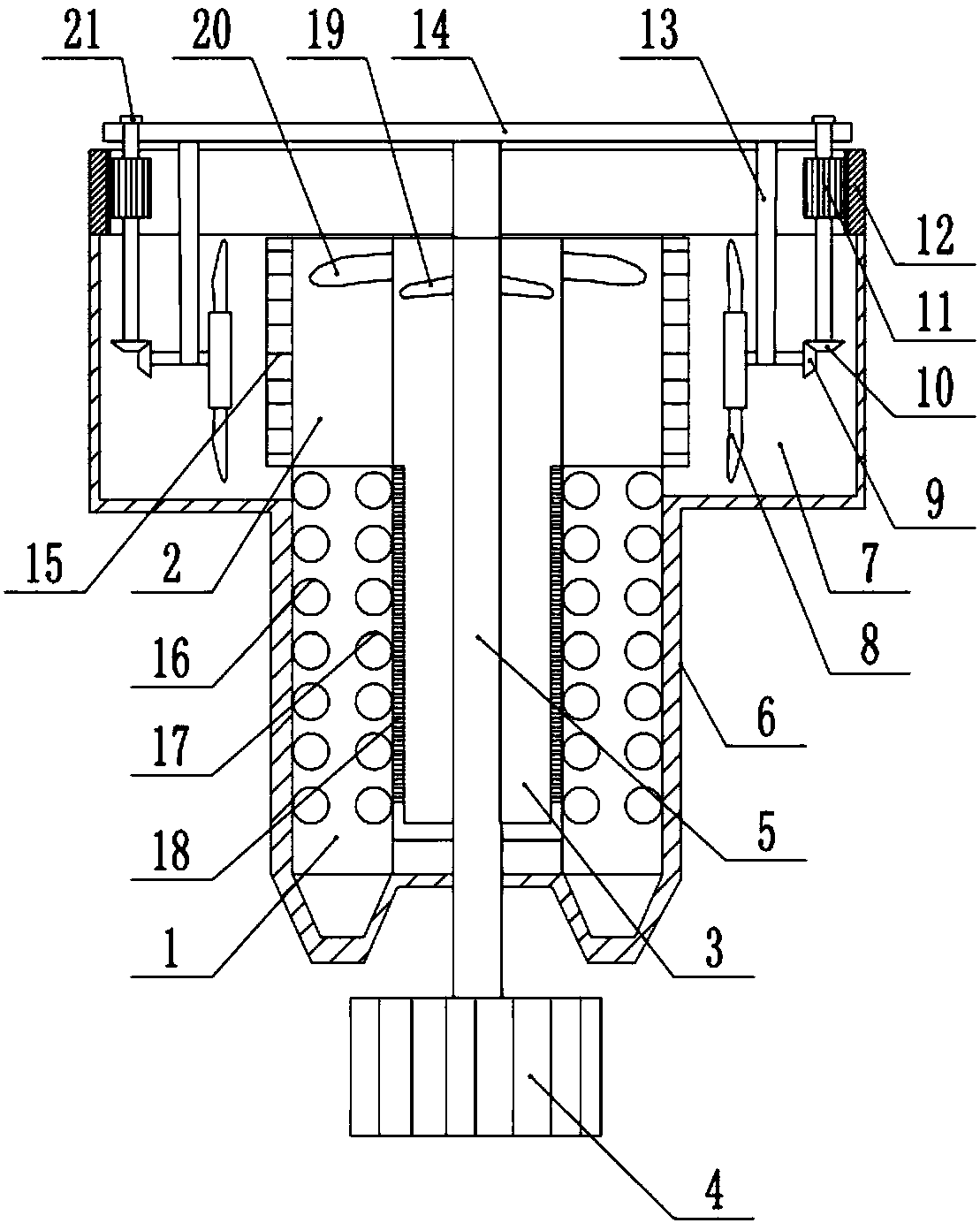

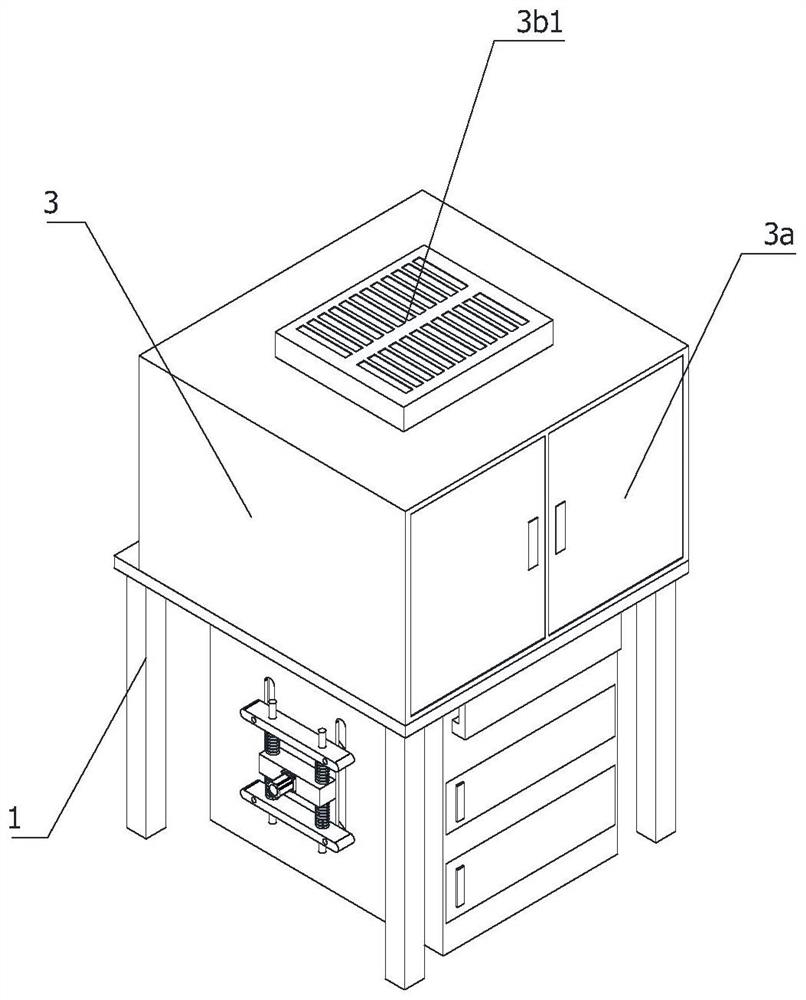

Medical waste incineration treatment device

InactiveCN111089292ABurn completelyIncrease profitIncinerator apparatusGrain treatmentsMedical wasteEnvironmental engineering

The invention provides a medical waste incineration treatment device. The medical waste incineration treatment device comprises a box body, wherein a crushing box body is fixedly arranged above the left wall of the box body; a feeding cavity, a buffer cavity and a crushing cavity are sequentially formed in the crushing box body from top to bottom; the feeding cavity communicates with the buffer cavity; buffer block supports are symmetrically and fixedly arranged on the left end wall and the right end wall of the buffer cavity; and buffer block sliding grooves are formed in the buffer block supports. According to the medical waste incineration treatment device, before incineration is started, medical waste is cut into small blocks by utilizing a crushing device, then movable stirring equipment is additionally arranged in an incinerator, so that large deposits which are not combusted in the center are prevented from being contained in the incinerator after the incineration is finished, the medical waste is guaranteed to be fully incinerated, only incombustible waste such as syringe needles can be left, meanwhile, the power sources for controlling the medical waste to fall, dischargeand stir are all from heat generated by the incinerator, and the utilization rate of energy is improved.

Owner:QUZHOU YOUCHENG MEDICAL EQUIP CO LTD

Belt injection mold

The invention relates to the technical field of belt injection molds, and discloses a belt injection mold. The belt injection mold comprises a supporting bottom plate. A fixing plate is arranged abovethe supporting bottom plate. Ejector pin guide rods are arranged in ejector pin sleeves. A lower mold is arranged above the ejector pin sleeves. A damping device is arranged on the side, close to thefixing plate, at the upper end of the supporting bottom plate. An upper mold is arranged at the upper end of the damping device and is above the lower mold. According to the belt injection mold, dustcan be prevented from entering the mold, the quality of a produced belt can be improved, harmful gas caused by melt due to high temperature can be filtered, harm to a human body by the harmful gas can be reduced, the upper mold can be buffered during mold closing, severe shaking of the mold during mold closing can be prevented, the service life of the mold can be prolonged, noise caused by quickmold closing can be effectively reduced, the discharged melt can be stored, economic cost can be reduced, and workers can be prevented from empyrosis due to the high-temperature melt.

Owner:湖州新峰塑业有限公司

Environment-friendly agricultural waste integrated treatment device

InactiveCN111604359AScientific and reasonable structureEasy to useSolid waste disposalCentrifugesRotational axisAgricultural science

The invention discloses an environment-friendly agricultural waste integrated treatment device which comprises a cleaning box. A fixed motor is mounted at the position, located at the low end of a mounting frame, of the outer side of a crushing box. The outer side of an output shaft of the fixed motor is fixedly connected with a vibration driving belt wheel in a sleeved manner. A vibration drivenbelt wheel is placed at the position, away from one end of the fixed motor, of one side of the vibration driving belt wheel. The vibration driven belt wheel and the vibration driving belt wheel are connected through rotating shafts. The vibration driving belt wheel and the vibration driven belt wheel are fixedly connected to one ends of the two rotating shafts in a sleeving manner, and the positions, located at the low end of the mounting frame, of the two ends of the rotating shafts are fixedly connected with cams in a sleeved manner. Compared with the prior art, the environment-friendly agricultural waste integrated treatment device has the beneficial effects that agricultural residues can be in contact with crushing shafts again, large agricultural residues are secondarily crushed, so that agricultural residues are crushed more completely, workers do not need to carry out secondary crushing, crushing efficiency is improved, the labor physical power of workers is reduced, and cost isreduced.

Owner:史玉净

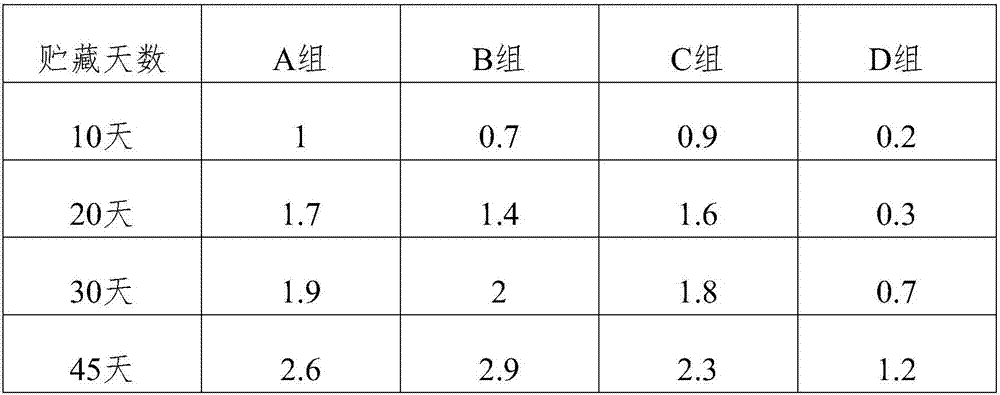

Preservative special for cordate houttuynia and preparation method thereof

InactiveCN107455456AEffective absorptionImprove securityFruit and vegetables preservationNon toxicityUltrasonic dispersion

The invention relates to the technical field of vegetable preservation and specifically relates to a preservative special for cordate houttuynia and a preparation method thereof. The preservative is prepared from cortex eucommiae extract, lonicerae flos extract, cabbage extract, buckwheat flower extract, rue leaf extract, acanthopanax senticosus extract, pueraria starch and nanometer zinc oxide. The preparation method comprises the following steps: firstly, stirring all the extracts and then performing microwave processing; adding soda water and uniformly stirring; adding nanometer zinc oxide and ultrasonically dispersing; and adding pueraria starch, ultrasonically dispersing and then centrifuging, thereby acquiring the preservative. After the preservative provided by the invention is utilized to treat the cordate houttuynia, the respiration intensity of cordate houttuynia and the activity of peroxidase and polyphenol oxidase can be restrained and the oxidized process of the mineral substance, vitamin, and the like, can be delayed. The preservative has the advantages of non-toxicity, high resource utilization ratio and convenience in use.

Owner:铜仁市万山区青蕴农业生态园有限公司

Preparation equipment of triazinone herbicide

InactiveCN112354323AAvoid pollutionExtended service lifeGas treatmentDispersed particle separationCalcium hypochloriteExhaust fumes

The invention provides preparation equipment of triazinone herbicide. The equipment comprises a bottom plate, an air compressor, a cooler, a crystal crushing frame structure, a condensation curing tank, a filtering and screening frame structure, a liquid outlet pipe, an atomizing nozzle, an anti-blocking air outlet pipe structure, a waste gas filtering frame structure, a water pump, a liquid conveying pipe, a distillation tank, a heating jacket, a rotating motor, a stirring frame, a feeding pipe and a steam outlet pipe. The air compressor is connected to the right side of the upper portion ofthe bottom plate through bolts. The device has the beneficial effects that through the arrangement of the calcium hypochlorite aqueous solution, the waste gas outlet pipe and the activated carbon filter screen, waste gas enters the inner side of the calcium hypochlorite aqueous solution through the waste gas outlet pipe, is filtered by the calcium hypochlorite aqueous solution, then enters the inner side of the transverse pipe and moves from the left side to the right side in the transverse pipe; the waste gas passes through the activated carbon filter screen, and harmful substances in the airare adsorbed by the activated carbon filter screen, so that the waste gas is filtered and purified, and is prevented from polluting the air environment.

Owner:SHANDONG BINNONG TECH

Technology for preparing feed from peony seed meal oil

InactiveCN107410673APrevent containingWell mixedFood processingAnimal feeding stuffCooking & bakingToxic material

The invention relates to the field of processing of agricultural and sideline products including peony seeds, in particular to a technology for preparing a feed from peony seed meal oil. The technology comprises the following specific steps of (1) performing mixing; (2) performing detoxifying; (3) performing screening; (4) adding water; (5) feeding bacteria; (6) performing fermentation; (7) performing air-drying; (8) performing milling to obtain powder; (9) forming balls; and (10) performing baking. Toxins are killed through lime, and meal is prevented from containing toxic substances; mixed meal is fermented, so that nutrient substances are rich; high gluten flour is used, so that ball formation is facilitated, and besides, mixing of other meal is facilitated; low-temperature baking is used, so that damage to protein by temperature is reduced; and toxins are killed through ultraviolet rays, so that the breeding of harmful bacteria is reduced.

Owner:芜湖市丹洋现代农业科技发展有限公司

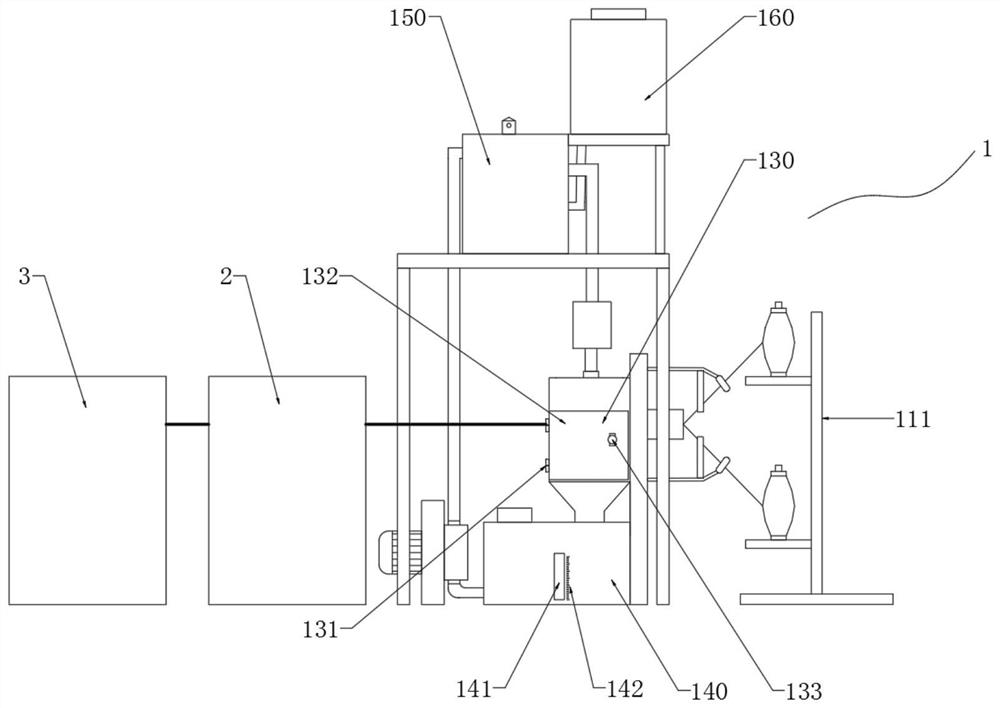

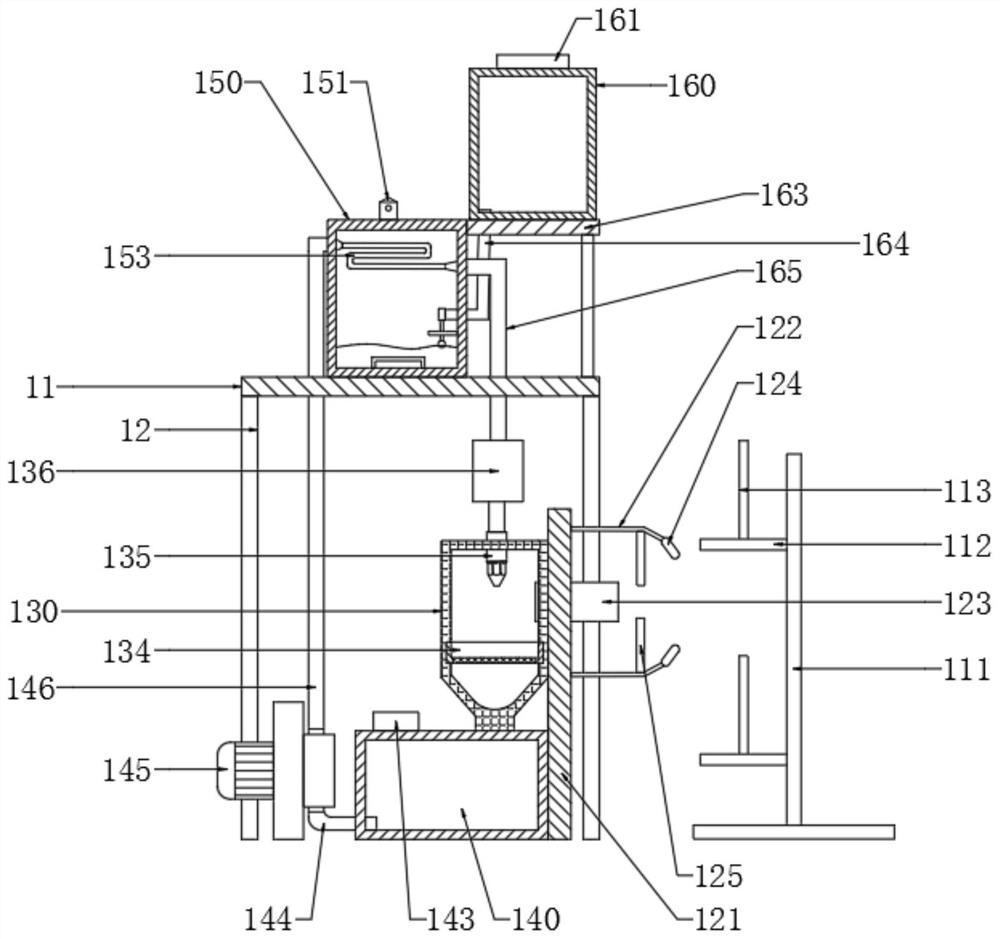

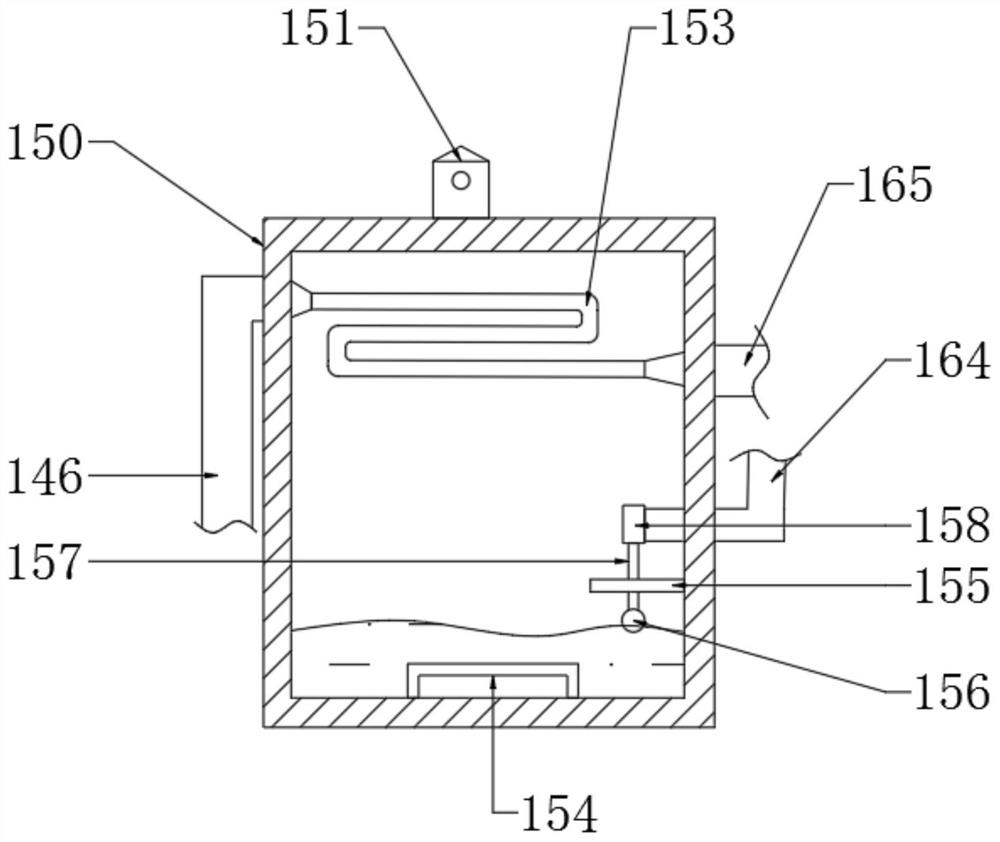

Regenerated fiber post-spinning device and using method thereof

ActiveCN112831870ANo drying operation requiredEasy to useTextile treatment machine arrangementsTextile treatment by spraying/projectingFiberPolymer science

The invention discloses a regenerated fiber post-spinning device and a using method thereof, and belongs to the technical field of regenerated fiber post-spinning. The regenerated fiber post-spinning device sprays a special silk-making oil agent to regenerated fiber original silk through an atomization nozzle, so that the sprayed special silk-making oil agent is not excessive while the regenerated fiber original silk is uniformly sprayed; the regenerated fiber original silk can be naturally air-dried before entering a twisting machine, so that the drying operation is not needed, the use is convenient, and the working efficiency is improved; a coil pipe is arranged in a heating box, so that when the special silk-making oil agent is heated through the coil pipe, the contact area with steam can be increased, heating is more uniform, the fluidity of the special silk-making oil agent is improved, and the special silk-making oil agent is conveniently atomized by the atomization nozzle; and a filter screen in an isolation box can intercept fiber silk on the regenerated fiber original silk, so that the special silk-making oil agent flowing back into an oil tank is kept clean, impurities are prevented from being contained in the recycled special silk-making oil agent, and components such as the atomization nozzle are prevented from being damaged.

Owner:广东源辉环保纤维有限公司 +1

Efficient gluing device for brake pad

InactiveCN112076936APrevent sedimentation and agglomerationSimple structureLiquid surface applicatorsRotary stirring mixersAdhesive glueElectric machinery

The invention discloses an efficient gluing device for a brake pad. The efficient gluing device comprises a box body, and four supporting legs are fixed to the bottom of the box body through bolts. Acontrol box is fixed to the outer wall of one side of the box body through bolts, and a shell is fixed to the outer wall of the other side of the box body through bolts; a conveying mechanism is arranged at the top of the box body; a glue storage box is fixed to the inner wall of the top of the box body through bolts; a stirring mechanism is arranged in the glue storage box; two protective coversare fixed to the outer wall of the top of the box body through bolts; and a dust removal mechanism, a gluing mechanism and a drying mechanism are respectively arranged in the two protective covers. According to the efficient gluing device for the brake pad provided by the invention, by starting a motor II, an output end of the motor II drives a belt wheel II to rotate, the belt wheel II drives a belt wheel I to rotate through a belt I, and therefore stirring rods on two rotating shafts are driven to rotate, protective glue in the glue storage box is evenly stirred and blended, and the protective glue is prevented from being precipitated and caked, and the phenomenon of non-uniform gluing or blockage of a gluing opening is avoided.

Owner:衡阳迈特制动系统有限公司

Rubber raw material collecting equipment

The invention discloses rubber raw material collecting equipment. The rubber raw material collecting equipment comprises a storage box. Two transverse grooves are symmetrically formed in a storage boxin the left-right direction, and a clamping mechanism is arranged in each transverse groove; a working cavity is formed in the storage box, and a lifting mechanism is arranged in the working cavity;the lifting mechanism comprises a protective sleeve capable of moving up and down in the working cavity; and a transmission mechanism is arranged in the working cavity and comprises a transverse shaftwhich is rotatably arranged on the rear end wall of the working cavity. By the equipment, a bark can be broken automatically. Compared with manual bark breaking, the rubber raw material collecting equipment has the advantages that a trunk can be protected well, a suction pipe is protected when latex is collected by the equipment, and the collected latex is prevented from containing a large amountof impurities due to wind; and compared with iron wire fixing, the equipment plays a more stable role and cannot be blown off by wind.

Owner:JIANGSHAN KONGPU ELECTRONICS TECH CO LTD

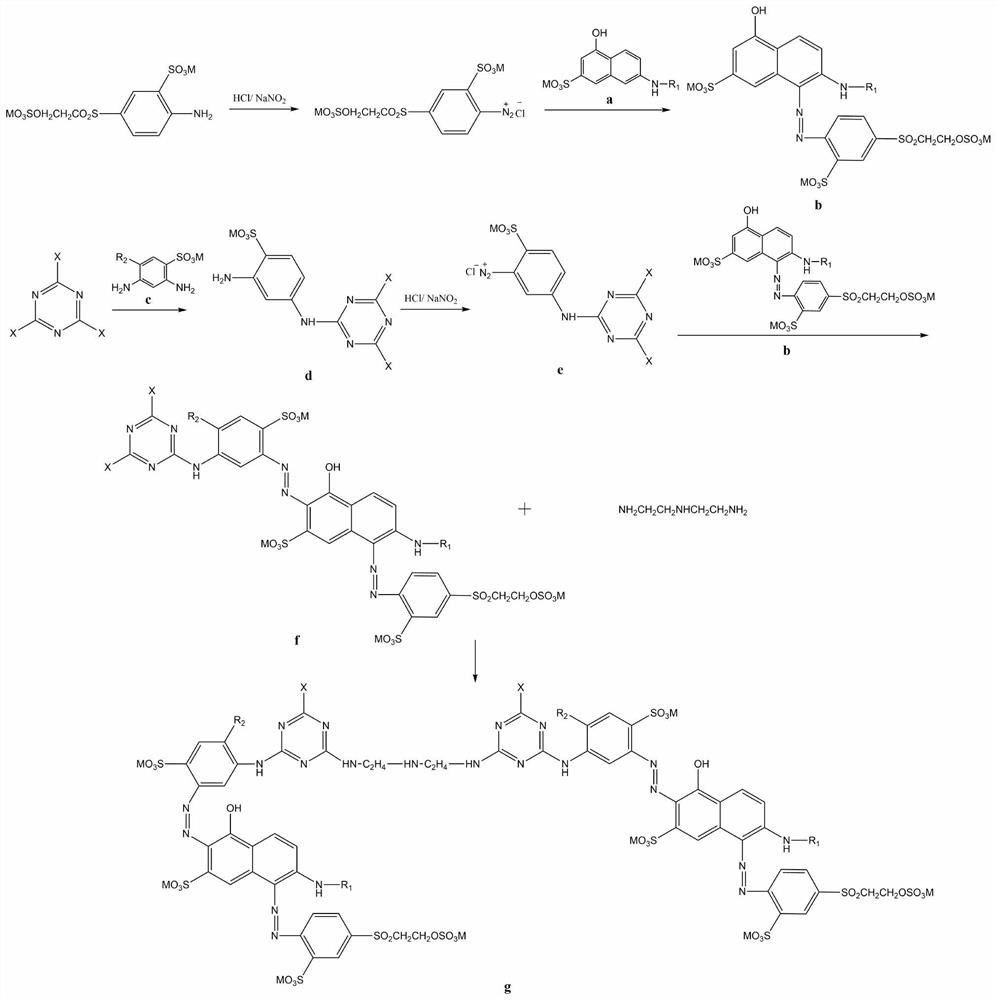

Multi-active-group red dye with high fixation rate and high chlorine fastness for printing and preparation method thereof

ActiveCN112679982AIncrease response rateHigh color fixing rateReactive dyesDyeing processEthyl groupAniline

The invention discloses a multi-active-group red dye with high fixation rate and high chlorine fastness for printing and a preparation method thereof, the multi-active-group red dye comprises a compound as shown in a structural general formula I, in the structural general formula I, R1 is-H or-AO3H; R 2 is-H; X is Cl; and M is Na. The method comprises the following steps: (1) preparing a J acid monoazo orange reactive dye; (2) preparing a J acid bisazo red reactive dye; and (3) preparing the multi-active-group red dye g with high fixation rate and high chlorine fastness. In order to improve the stability of azo bonds in a chromophoric body system of the reactive red dye, 4-beta-ethyl sulfuryl sulfate aniline-2-sulfonic acid and m-phenylenediamine compounds with sulfonic acid groups at the ortho-position of amino are selected as diazo components, and the azo bond ortho-positions in the final molecular structure of the prepared bis-azo active red dye all have sulfonic groups and can form hydrogen bonds with the azo bonds, so that the stability of the azo bonds is increased, and the azo active red dye can effectively resist the oxidation of effective chlorine in an environmental medium.

Owner:江苏德美科化工有限公司

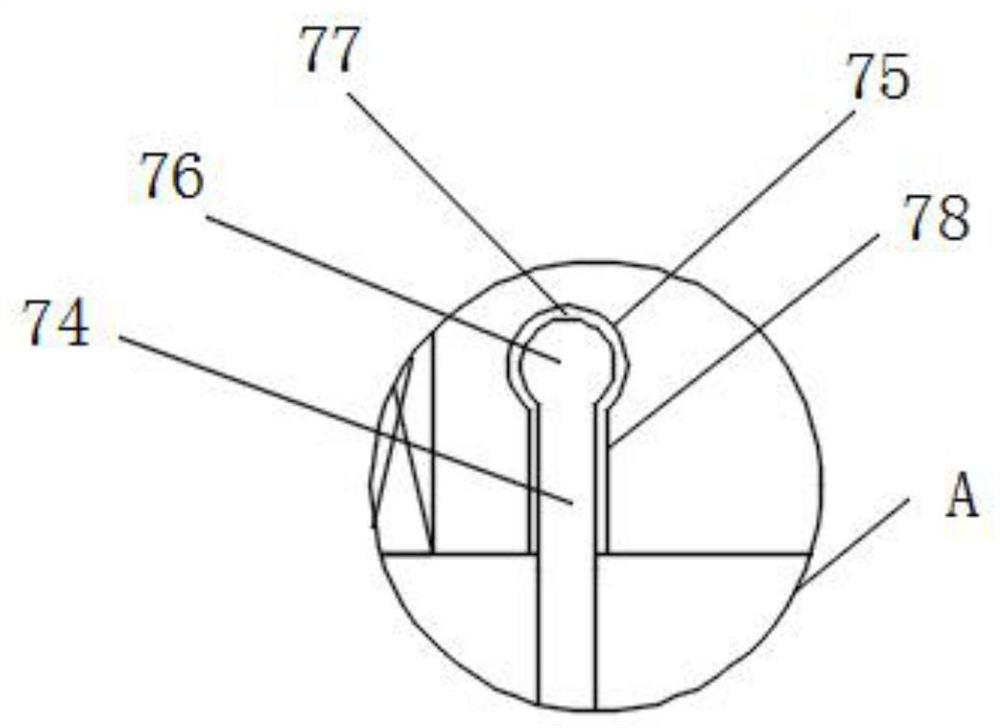

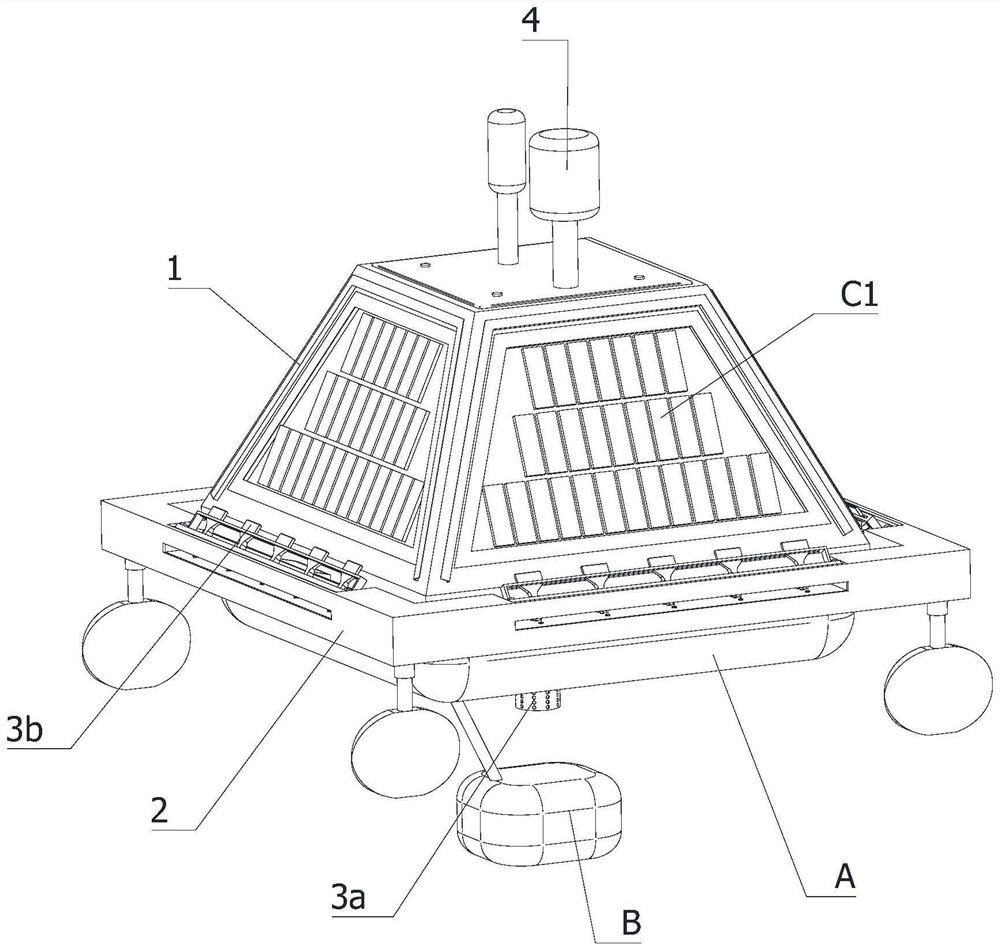

Photovoltaic energy lighting device for channel indication

ActiveCN113587031AAvoid affecting the photoelectric conversion efficiencyAvoid the problem of salt adhering to the surface of photovoltaic panelsPhotovoltaic supportsWith built-in powerLight equipmentMechanical engineering

The invention relates to the field of indication lighting equipment, in particular to a photovoltaic energy lighting device for channel indication, which comprises a floating block, a photovoltaic power generating system, a lighting navigation mark assembly, an inclined prismatic table shell, and a frame and a cleaning mechanism . The bottom end is provided with an anchor body; the photovoltaic power generating system comprises a photovoltaic panel, a photovoltaic controller and a storage battery; a photovoltaic controller and a storage battery; the inclined prismatic table shell is arranged on the floating block, the photovoltaic panel is arranged on the inclined plane of the inclined prismatic table shell, the photovoltaic controller and the storage battery are both arranged in the inclined prismatic table shell, and the lighting navigation mark assembly is arranged at the top end of the inclined prismatic table shell; the frame is arranged on the outer side of the wide end of the oblique prismatic table shell; the cleaning mechanism comprises a drainage assembly and a scouring assembly, the drainage assembly is arranged in the oblique prismatic table shell, the scouring assembly is arranged on the frame, and the scouring output end of the scouring assembly faces the oblique plane of the oblique prismatic table shell. Through the photovoltaic panel arranged on the inclined surface of the inclined prismatic table shell, energy can be provided for the lighting navigation mark assembly, meanwhile, salt is prevented from being attached to the surface of the photovoltaic panel due to seawater evaporation, and the seawater can be extracted through the cleaning mechanism to flush the surface of the photovoltaic panel.

Owner:SHENZHEN WOLUNTE NEW ENERGY TECH CO LTD

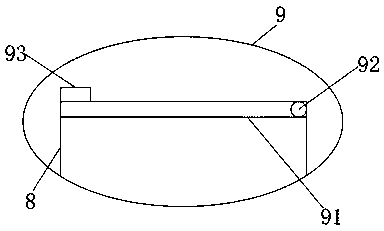

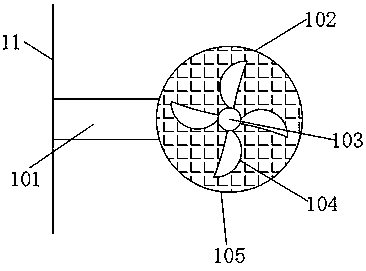

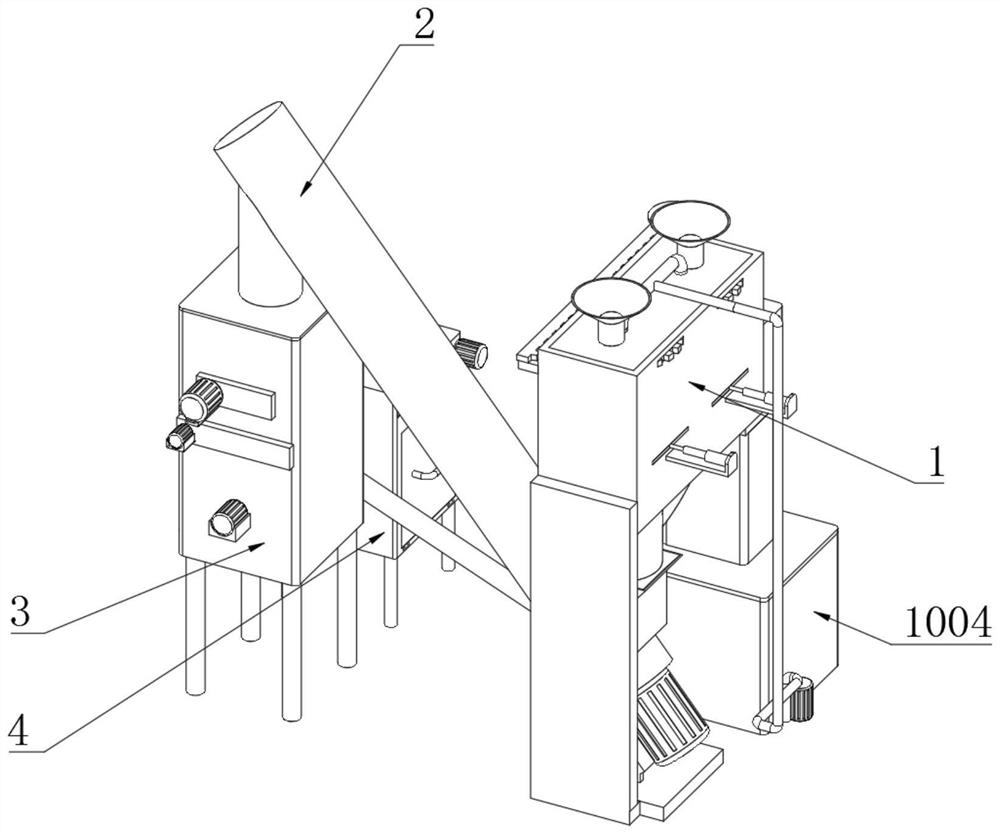

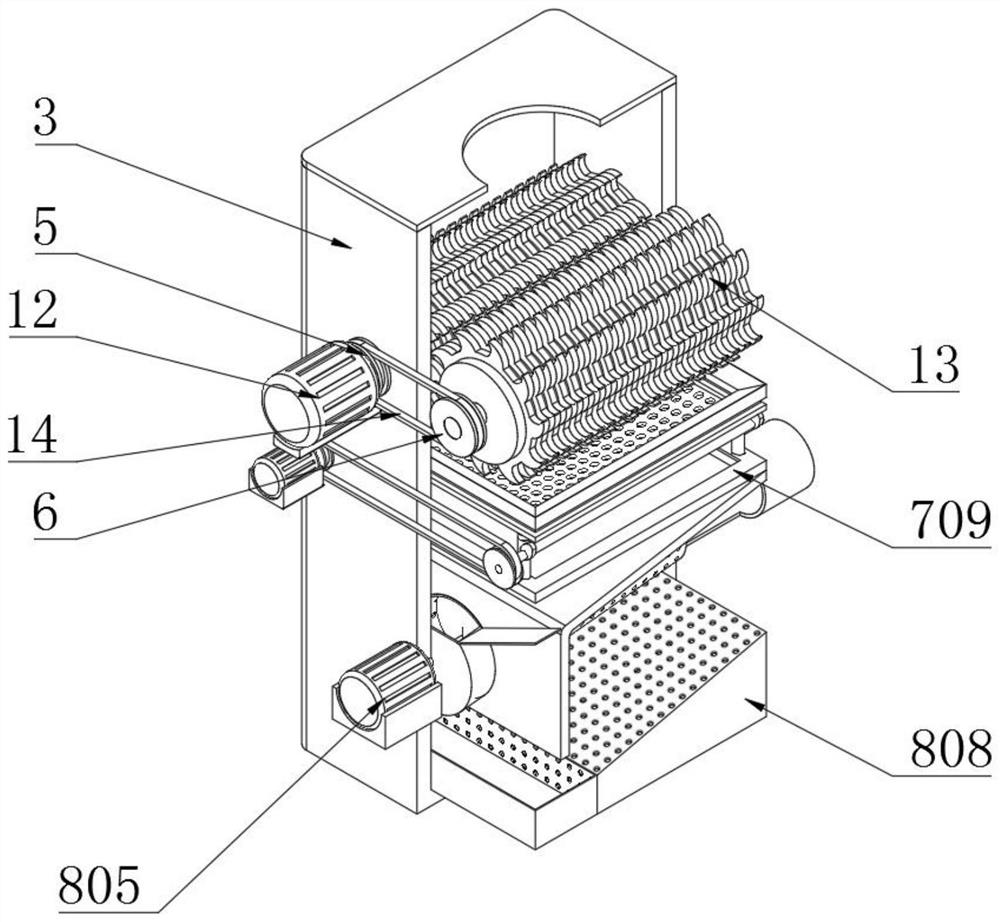

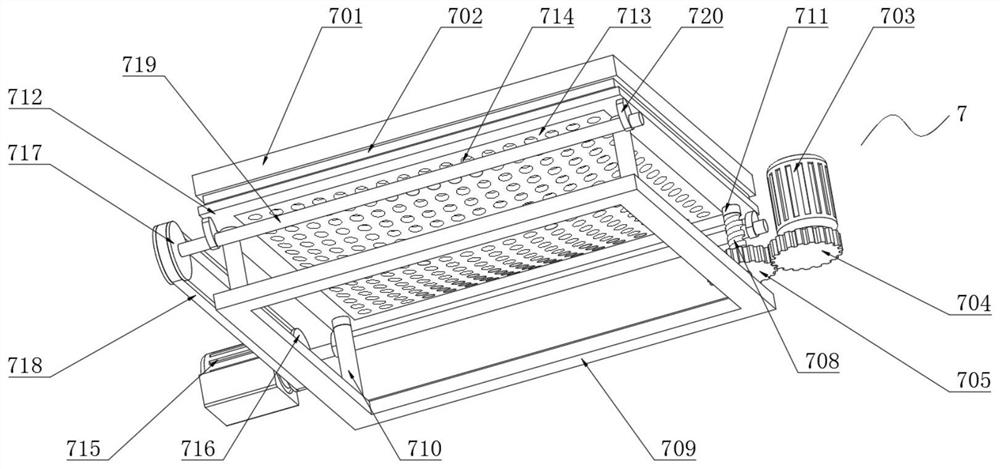

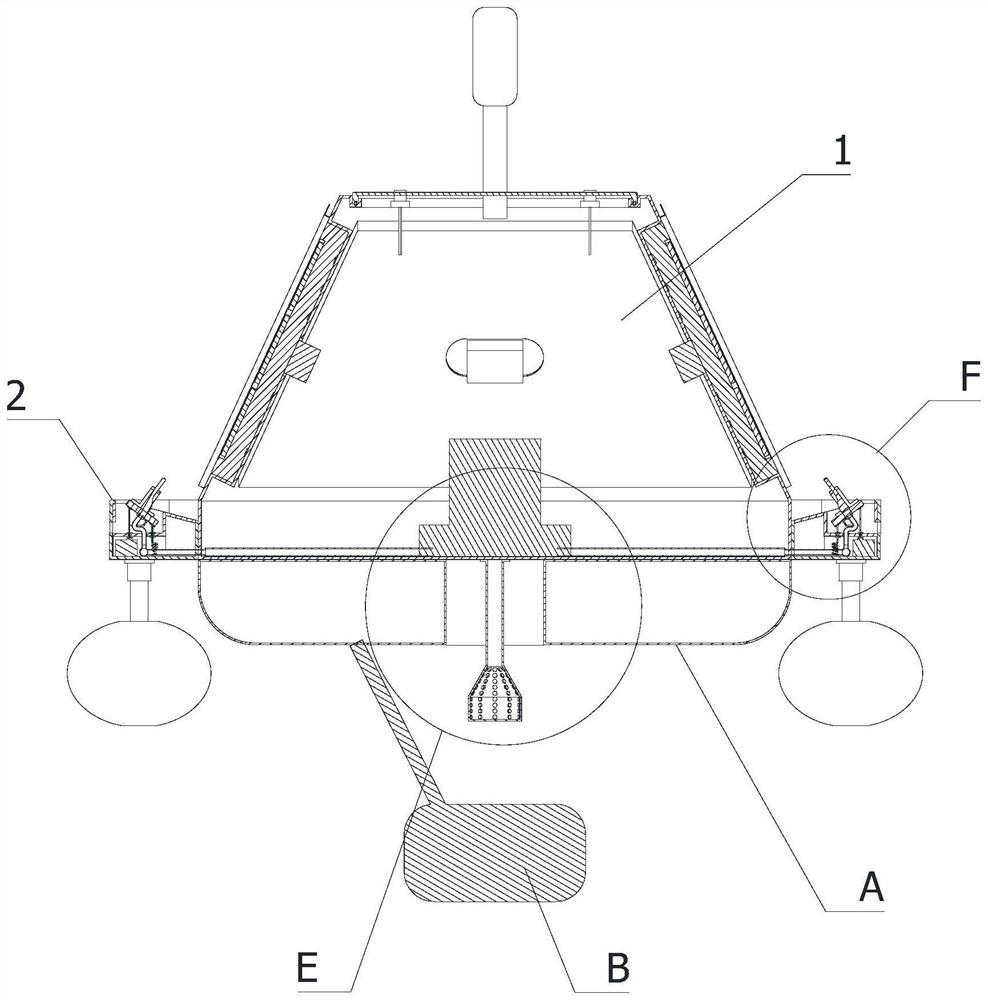

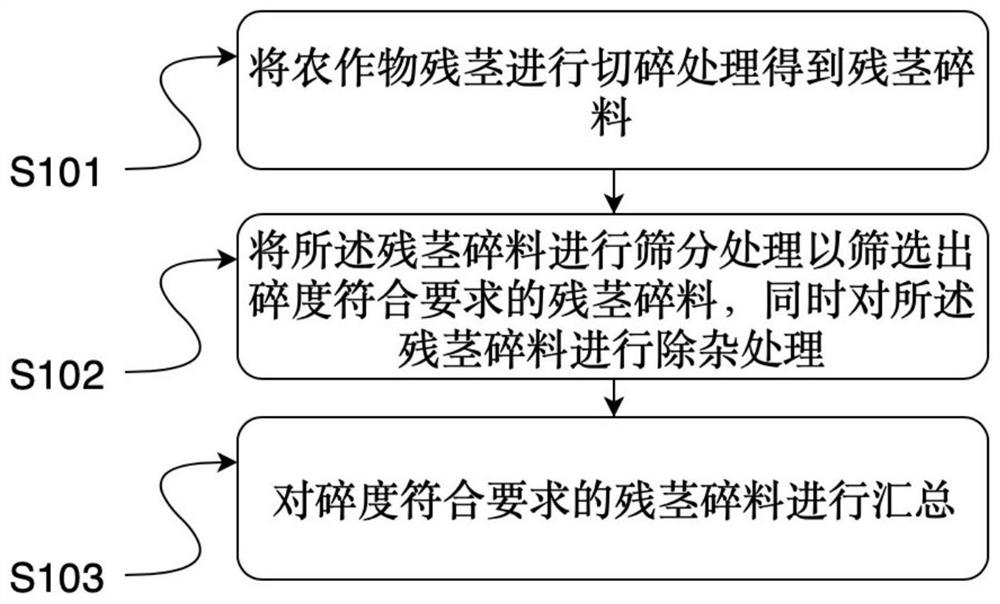

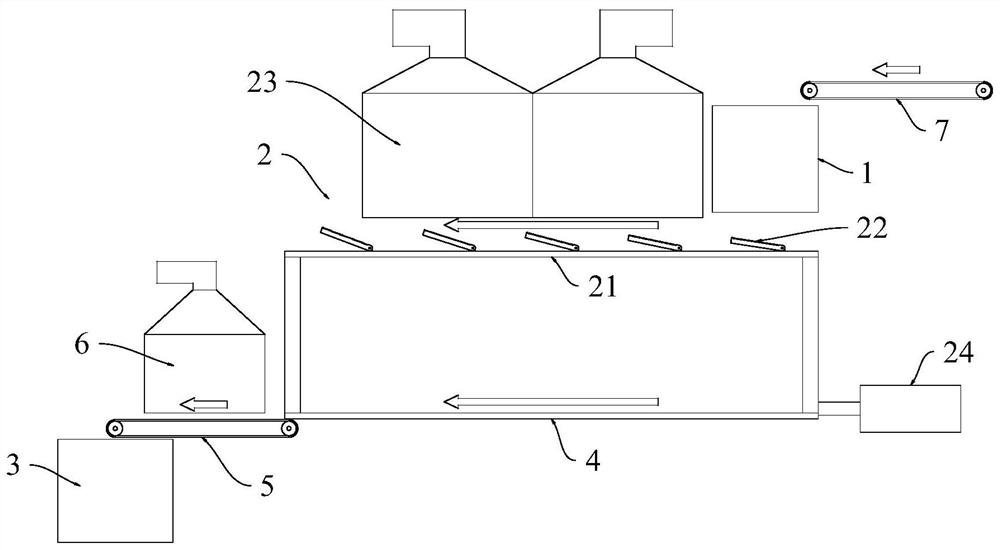

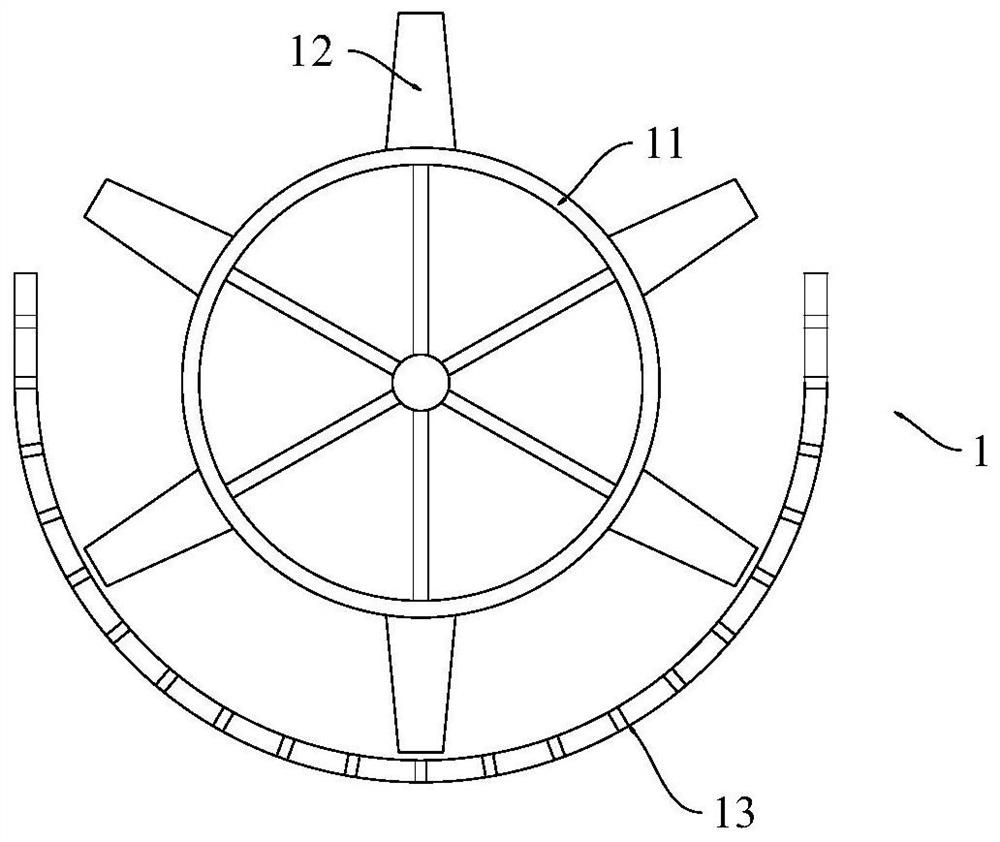

Crop residual stem post-treatment and impurity removal process and equipment

ActiveCN112973905AEfficient removalPrevent containingGrain treatmentsAgricultural scienceAgricultural engineering

The invention discloses a crop residual stem post-treatment and impurity removal process and equipment. The process comprises the following steps that crop residual stems are chopped to obtain residual stems crushed materials; screening treatment is conducted on the residual stems crushed materials to screen out residual stem crushed materials with the crushing degree meeting the requirement, and meanwhile, impurity removal treatment is conducted on the residual stems crushed materials; and the residual stem crushed materials with the crushing degree meeting the requirement are collected. The equipment comprises a chopping part, a screening and impurity removing part and a collecting part, wherein the chopping part, the screening and impurity removing part and the collecting part are used for chopping the crop residual stems, screening the residual stem crushed materials, removing impurities from the residual stem crushed materials and collecting the residual stem crushed materials with the crushing degree meeting the requirement. According to the crop residual stem post-treatment and impurity removal process and equipment, impurities originally mixed in the crop residual stems can be effectively removed, the impurity removal effect is good, the situation that feed obtained through the crop residual stems finally contains harmful substances can be prevented, and the residual stem crushed materials obtained after chopping and screening treatment are beneficial to subsequent continuous processing.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Regenerated fiber post-spinning device and method of use thereof

ActiveCN112831870BNo drying operation requiredEasy to useTextile treatment machine arrangementsTextile treatment by spraying/projectingFiberPolymer science

The invention discloses a regenerated fiber post-spinning device in the technical field of regenerated fiber post-spinning and a method for using the device. The device sprays a special oil agent for silk making on the regenerated fiber original thread through an atomizing nozzle. When the regenerated fiber original thread is sprayed evenly, it sprays The special oil for silk making will not be excessive, and it can be air-dried naturally before entering the twisting machine. When the coil is heated, the contact area with the steam can be increased, the heating is more uniform, and the fluidity of the special oil for silk making is increased, which is convenient for the atomizing nozzle to atomize it; the filter in the isolation box can intercept the regenerated fiber The fiber on the line keeps the special oil for silk making that returns to the oil tank clean, prevents impurities in the special oil for silk making that are reused, and prevents components such as atomizing nozzles from being damaged.

Owner:广东源辉环保纤维有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com