Air source-water source composite heat pump heat supply method with middle gas supplementation

An air source heat pump and intermediate air supply technology, which is applied in heat pumps, lighting and heating equipment, mechanical equipment, etc., can solve problems such as high exhaust temperature and low heating efficiency, improve working conditions, prevent wet compression, and meet winter conditions. Effect of heating and sanitary hot water requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

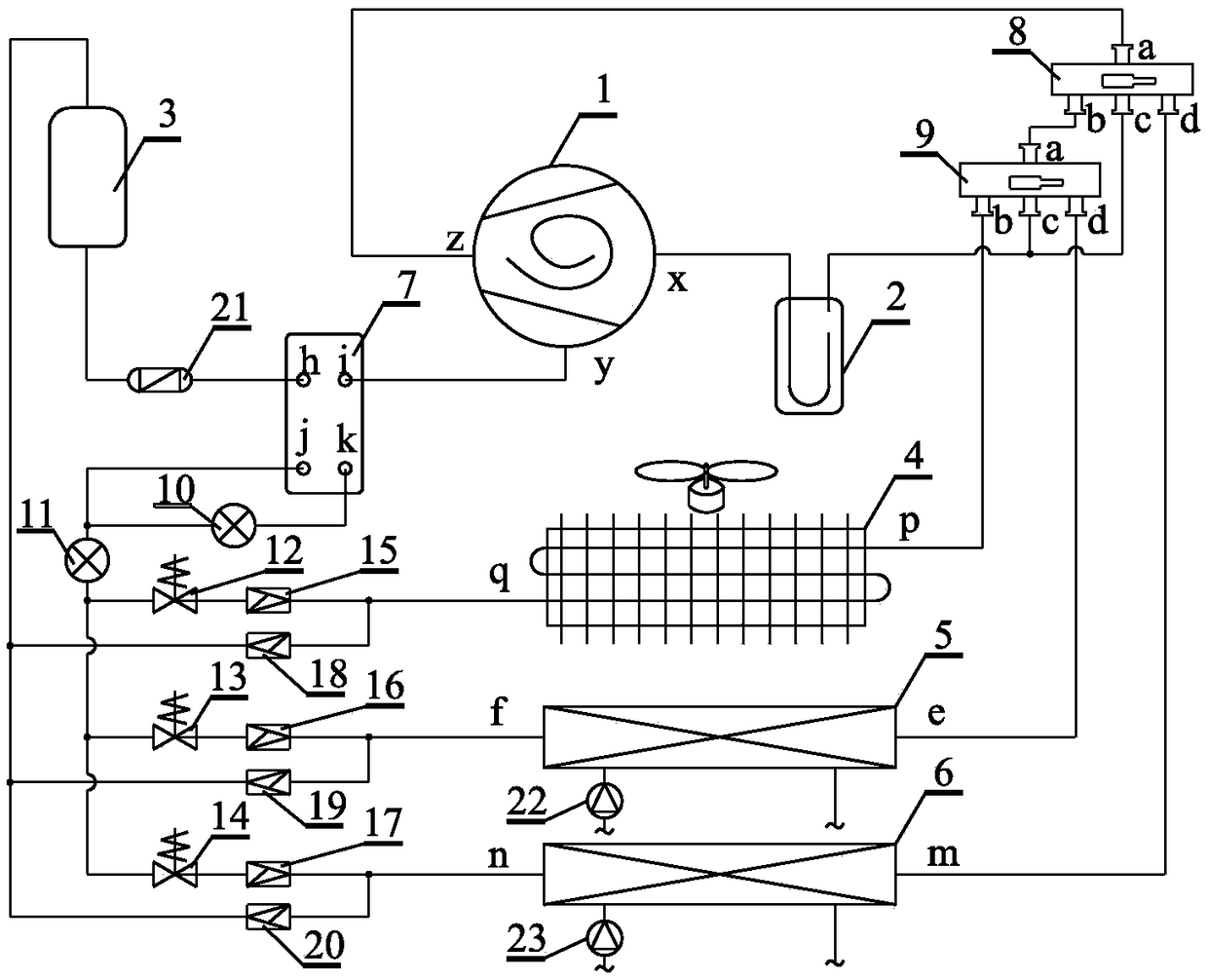

[0020] Such as figure 1 As shown, the exhaust port z of the intermediate air supplement scroll compressor 1 is connected to the port of the first four-way reversing valve 8a, the port of the first four-way reversing valve 8b is connected to the port of the second four-way reversing valve 9a, and the first The 8d port of the four-way reversing valve is connected with the m port of the heat exchanger 6 on the water source side, the 9d port of the second four-way reversing valve is connected with the e port of the air-conditioning side heat exchanger 5, and the 9b port of the second four-way reversing valve is connected with the The port p of the finned tube heat exchanger 4 is connected; the port 8c of the first four-way reversing valve and the port 9c of the second four-way reversing valve are connected in parallel to the inlet of the gas-liquid separator 2, and the outlet of the gas-liquid separator 2 is connected to the middle Supplementary air scroll compressor 1 is connecte...

Embodiment 2

[0023] Such as figure 1As shown, in the heating mode of the air source heat pump, the first solenoid valve 12 is energized to open, the second solenoid valve 13 and the third solenoid valve 14 are not energized to close, the second four-way reversing valve 9 is energized, and the middle air supply vortex The exhaust gas from the rotary compressor 1 enters the a port of the first four-way reversing valve 8, discharges from the b port, enters the a port of the second four-way reversing valve 9, and then discharges from the d port, and enters the air conditioner side heat exchanger 5 , after exchanging heat with the circulating water system, it enters the liquid reservoir 3 through the fifth one-way valve 19, comes out of the liquid reservoir 3, passes through the dry filter 21 and enters the port h of the economizer 7, and flows out from the port j after heat exchange. It is divided into two paths, one path enters the port k of the economizer 7 through the air supply electronic ...

Embodiment 3

[0026] Such as figure 1 As shown, in the heating mode of the water source heat pump, the first solenoid valve 12 and the second solenoid valve 13 are not powered and closed, the third solenoid valve 14 is opened, the second four-way reversing valve 9 is powered, and the middle supplementary air scroll compresses Exhaust from machine 1 enters port a of the first four-way reversing valve 8, is discharged from port b, enters port a of the second four-way reversing valve 9, and then is discharged from port d to enter the heat exchanger 5 on the air-conditioning side. After heat exchange in the water system, it enters the liquid reservoir 3 through the fifth one-way valve 19, comes out of the liquid reservoir 3 and enters the port h of the economizer 7 through the dry filter 21, and flows out from the port j after heat exchange, and is divided into two One way passes through the gas supply electronic expansion valve 10 and enters the port k of the economizer 7, and after heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com