Punching five-axis vertical type mechanical arm multi-machine interconnected control method and punching production line

A technology of multi-machine interconnection and control method, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of easy damage to operators, casualties and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

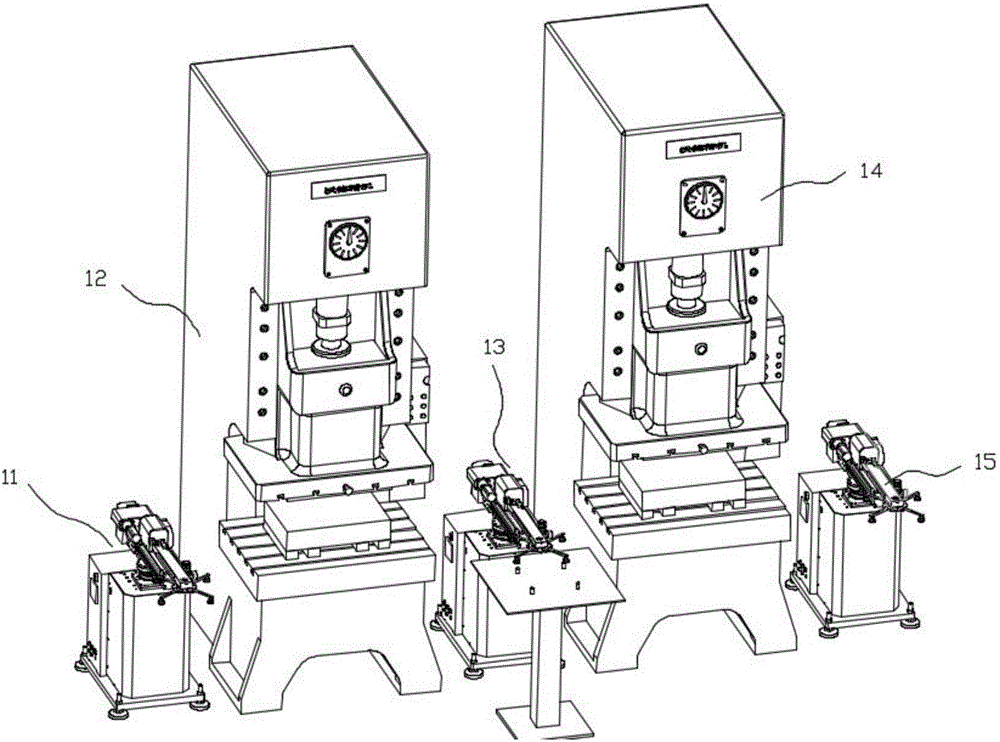

[0049] Examples, see figure 1 , the stamping five-axis vertical manipulator multi-machine interconnection control method provided in this embodiment includes the following steps:

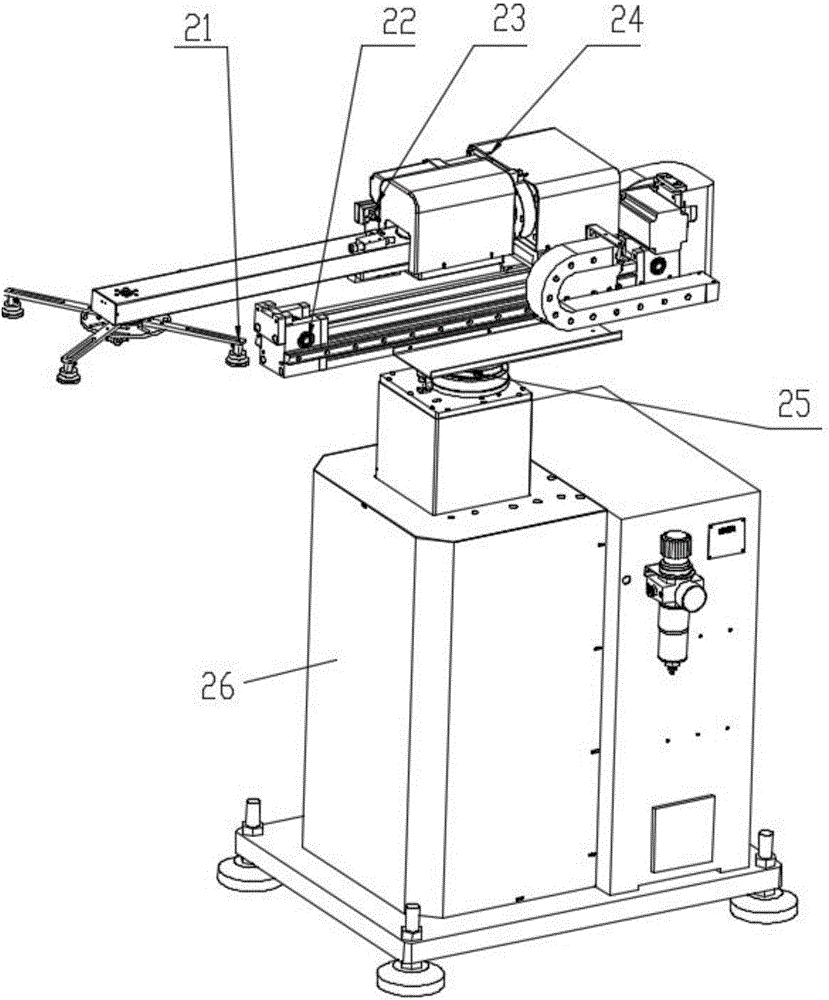

[0050] (1) The first five-axis vertical manipulator 11, the first stamping machine tool 12, the second five-axis vertical manipulator 13, the second stamping machine tool 14, and the third five-axis vertical manipulator 15 are arranged at intervals on a stamping production line; The five-axis vertical manipulator is provided with a central fixture 21, an arm part 22, a horizontal rotation shaft part 23, an arm turning part 24, a swing arm part 25 and a base part 26;

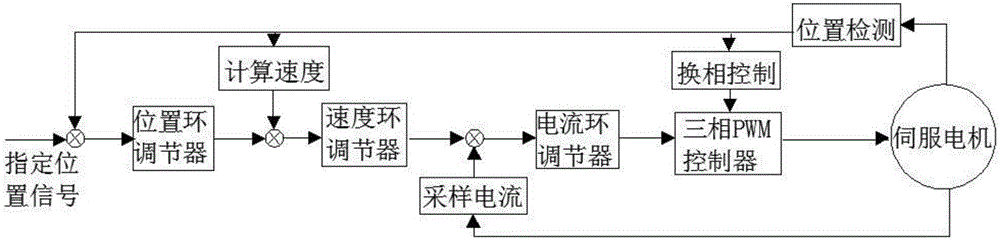

[0051] (2) The stamping production line is also provided with a control system, the control system includes a master controller and a plurality of slave controllers, and a plurality of slave controllers are respectively arranged in the five-axis vertical manipulator and the punch machine tool, and control its actions;

[0052] The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com