Rubber raw material collecting equipment

A technology for collecting equipment and raw materials, applied in forestry, application, agriculture, etc., can solve the problems of vulnerable trunks and a large number of impurities, and achieve the effect of protecting trunks and good trunks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

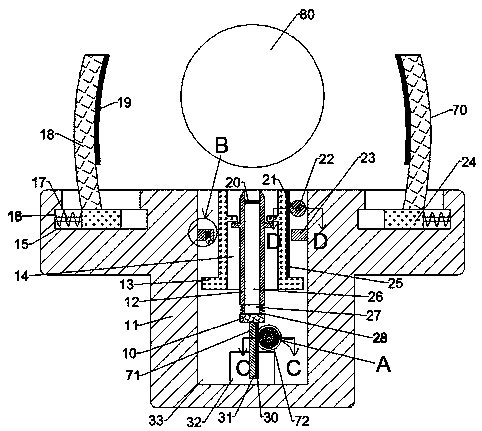

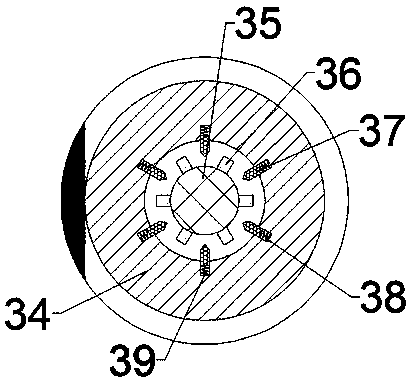

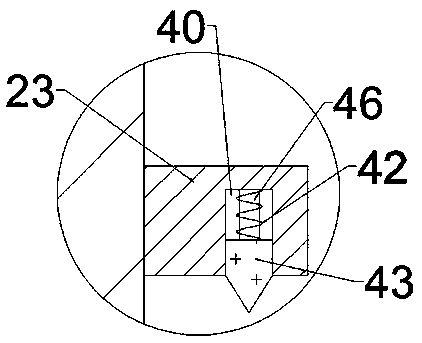

[0021] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0022] A rubber raw material collection device described in conjunction with accompanying drawings 1-6 includes a storage box 11, and two horizontal grooves 15 are arranged symmetrically in the left and right sides of the storage box 11, and a clamping mechanism 70 is arranged in the horizontal groove 15, The clamping mechanism 70 includes a clamping block 24 that can move left and right in the transverse groove 15, and the upper end surface of the clamping block 24 is fixed with a clamping rod 18, and the end surface close to the clamping rod 18 is fixed. A friction strip 19 is provided, and the two friction strips 19 are close to clamp the device on the rubber tree 80;

[0023] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com