Biochemical denitrifying method for wastewater

A waste water and denitrification technology, applied in the field of environmental engineering, can solve the problems that the denitrification effect is difficult to further improve, the biological denitrification sludge age is different, and the total nitrogen removal rate is not high, so as to achieve low operating cost, reduce operation steps, and replenishment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

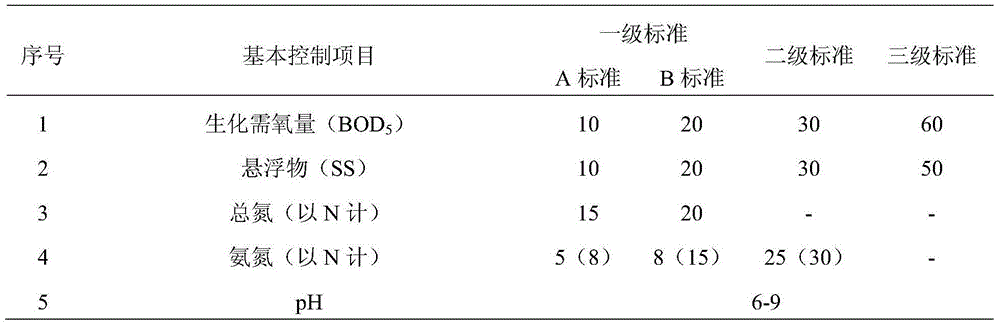

[0036] An enterprise in the chemical industry park in the Taihu Lake Basin selected the improved A / O biochemical denitrification process of the present invention to denitrify the wastewater entering the municipal sewage pipe network. Discharge requirements of the first-level standard A of the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002).

[0037] Table 2 Water quality of influent wastewater

[0038] water quality index

pH

SS(mg / L)

BOD(mg / L)

TN (mg / L)

NH 3 -N (mg / L)

content

25

7.8

120

110

42

27

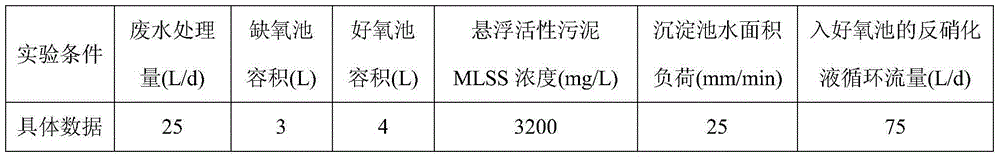

[0039] The specific experimental conditions are shown in Table 3. After 2 months of operation, the treated water obtained from the effluent of the sedimentation tank was tested again.

[0040] Table 3 Experimental conditions

[0041]

[0042] The specific process steps are as follows:

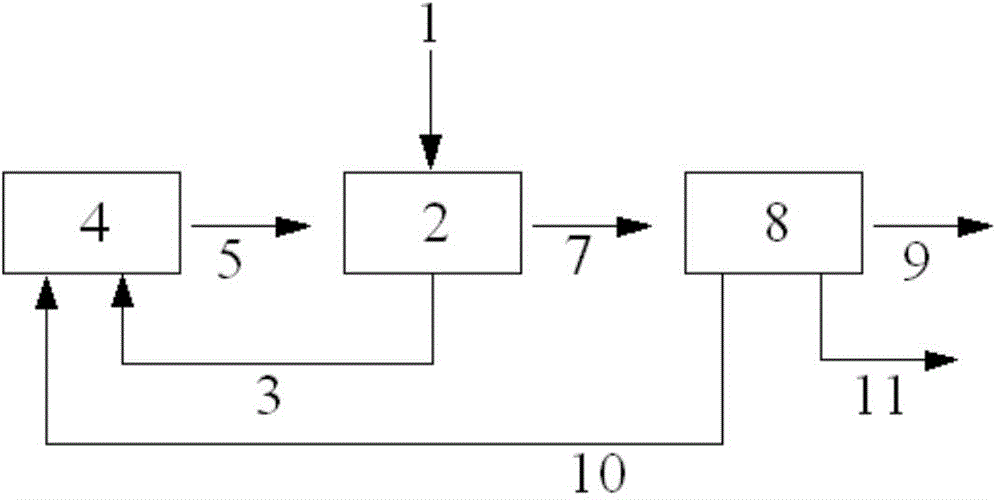

[0043] Such as figure 1 Shown, the method for biochemical denitr...

Embodiment 2

[0051] The same influent waste water quality and specific experimental conditions as in Example 1 were tested again with the treated water obtained from the effluent of the sedimentation tank after 2 months of operation.

[0052] The specific process steps are as follows:

[0053] 1), anoxic denitrification section: mainly in the anoxic denitrification tank 3 for denitrification and organic matter degradation, nitrogen-containing wastewater 1 enters the anoxic denitrification tank 2, and at the same time enters the nitrogen-containing wastewater 1 from the aerobic nitrification tank 4. The nitrifying liquid 5 of nitrate nitrogen is stirred to make the mud in the anoxic denitrification tank be in a suspended flow state; the activated sludge containing denitrifying bacteria and zeolite coexist in the anoxic denitrification tank 2, and the zeolite absorbs nitrogen-containing wastewater 1 ammonia nitrogen, under anoxic conditions, organic matter is oxidized and degraded by denitri...

Embodiment 3

[0057] The same influent waste water quality and specific experimental conditions as in Example 1 were tested again with the treated water obtained from the effluent of the sedimentation tank after 2 months of operation.

[0058] The specific process steps are as follows:

[0059] 1), anoxic denitrification section: mainly in the anoxic denitrification tank 3 for denitrification and organic matter degradation, nitrogen-containing wastewater 1 enters the anoxic denitrification tank 2, and at the same time enters the aerobic nitrification tank 4 The nitrifying liquid 5 containing nitrate nitrogen is stirred to make the mud in the anoxic denitrification tank be in a suspended flow state; the activated sludge containing denitrifying bacteria and zeolite coexist in the anoxic denitrification tank 2, and the zeolite absorbs nitrogen-containing wastewater 1 Under anoxic conditions, the organic matter is oxidized and degraded by using nitrate as an electron acceptor under the action o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com