Iron-based low-temperature SCR denitration catalyst and preparation method thereof

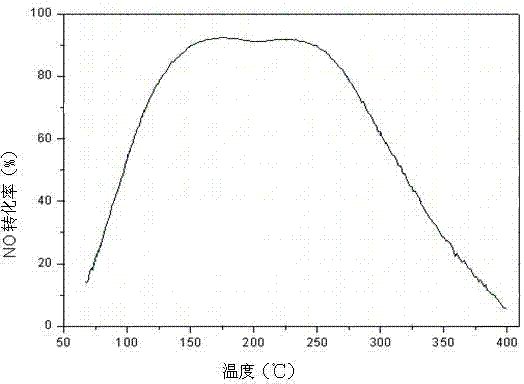

A denitration catalyst and low temperature technology, applied in the field of denitration catalysts, can solve the problems of limiting large-scale industrial application, immature preparation process, low low temperature denitration activity, etc., to reduce huge costs, widen the effective denitration temperature range, and simplify production and synthesis. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Compared with general catalyst preparation methods such as hydrothermal synthesis, sol-gel method, and template method, the co-precipitation method has the advantages of simple preparation process, low cost, easy synergy between active components, and easy large-scale industrial production. , so Fe-Ce / TiO in the invention 2 and Fe-Mn-Ce / TiO 2 The preparation of these two kinds of mixed catalysts adopts co-precipitation method.

[0030] Iron-based low-temperature SCR denitration catalyst Fe-Ce / TiO of the present invention 2 The preparation method is to dissolve ferric nitrate and cerium nitrate in deionized water, add titanium dioxide, stir vigorously for 1-3h to fully mix, then ultrasonically mix for 1-6h, put it in an oven at 100-110°C for 8-12h, and put it in an oven for 8-12h. Calcined in air atmosphere for 1.5-2.5h at a temperature of 500-600°C, and then ground into powder.

[0031] Iron-based low-temperature SCR denitration catalyst Fe-Mn-Ce / TiO of the present i...

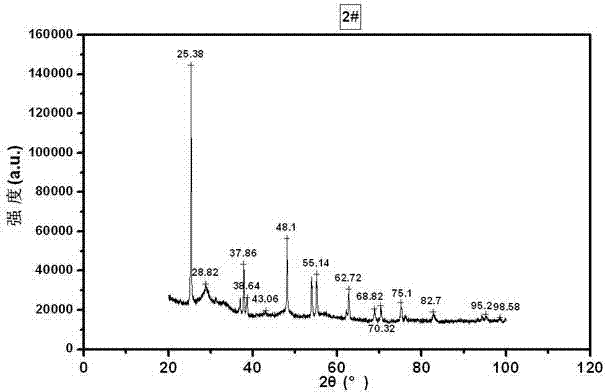

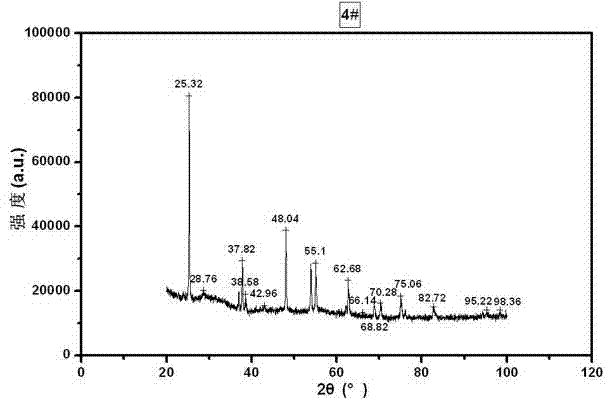

Embodiment 1-9

[0034] For convenience of expression, the catalyst of embodiment 1-9 is expressed as: Fe(x)-Mn(y)-Ce(z) / TiO 2, replaced by the label "n#", x represents the molar ratio of Fe / Ti, y represents the molar ratio of Mn / Ti, z represents the molar ratio of Ce / Ti, all molar ratios are based on the carrier TiO 2 The amount used is for reference. In the present invention, x is 0.2, y is 0-0.8, and z is 0.2, as shown in the following table.

[0035]

[0036] The preparation method is specifically: the Ce(NO 3 ) 3 , Mn(NO 3 ) 3 , Fe(NO 3 ) 3 Fully dissolve in a beaker filled with 50-80mL deionized water, and add insoluble titanium dioxide TiO 2 For mixing, stir magnetically in a round bottom flask for 1-3h to make it fully mixed, the mixture is foamy, and there is a small amount of precipitation at the bottom, which should be insoluble TiO 2 . Then put the mixed solution in an ultrasonic cleaner for 4 hours of ultrasonication, so that various metal compounds can be mixed evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com