Patents

Literature

106results about How to "Facilitate grafting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crosslinkable fluorosilicone resin, painting and super-amphiphobic coating prepared by same

ActiveCN103408762AUniversal and strong cross-linkingImprove surface energyFibre treatmentCoatingsResin coatingSolvent

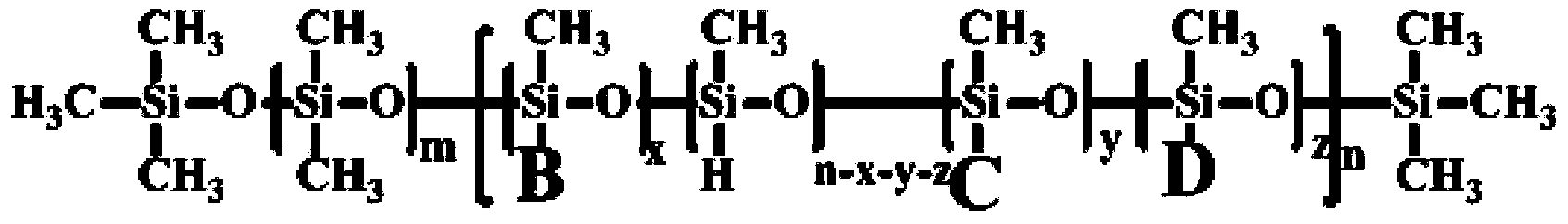

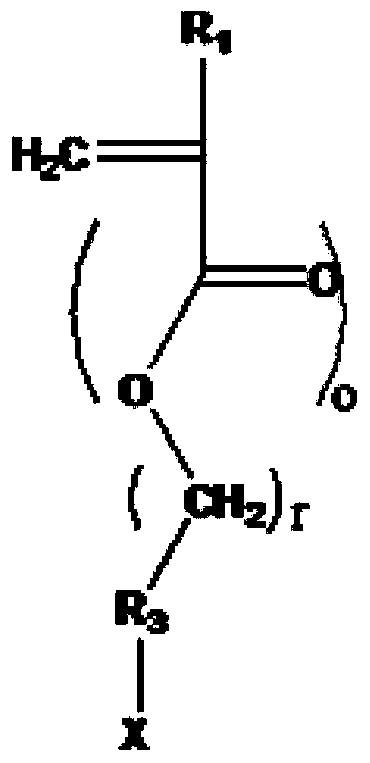

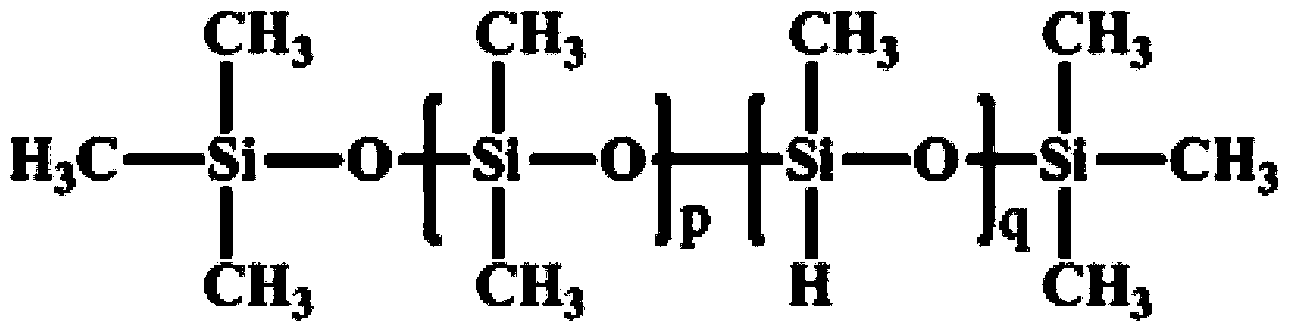

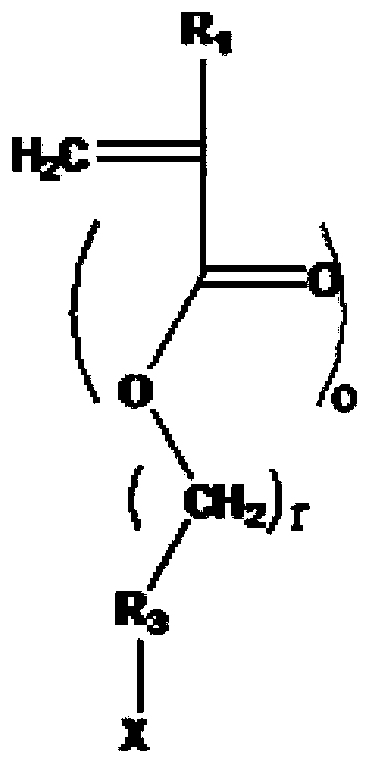

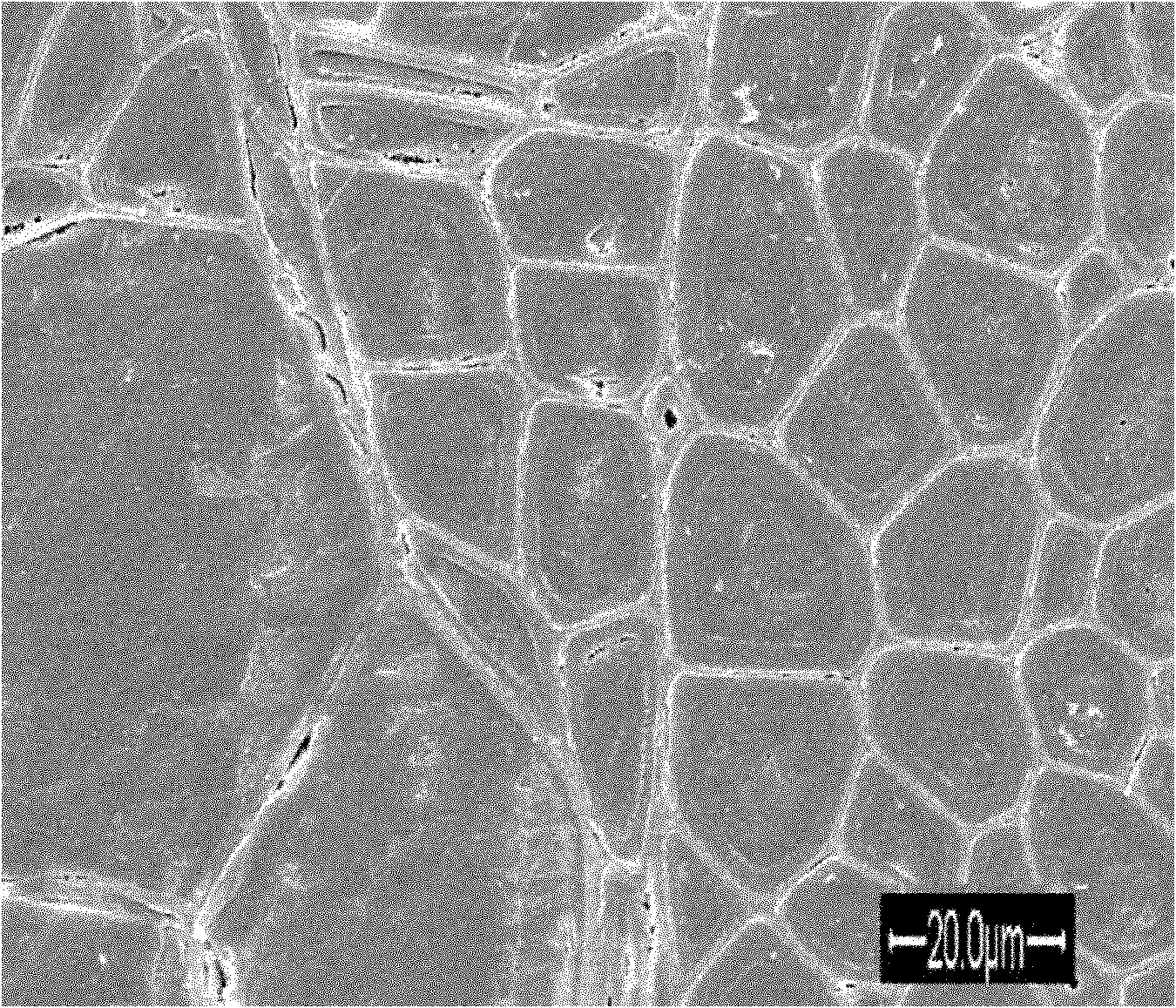

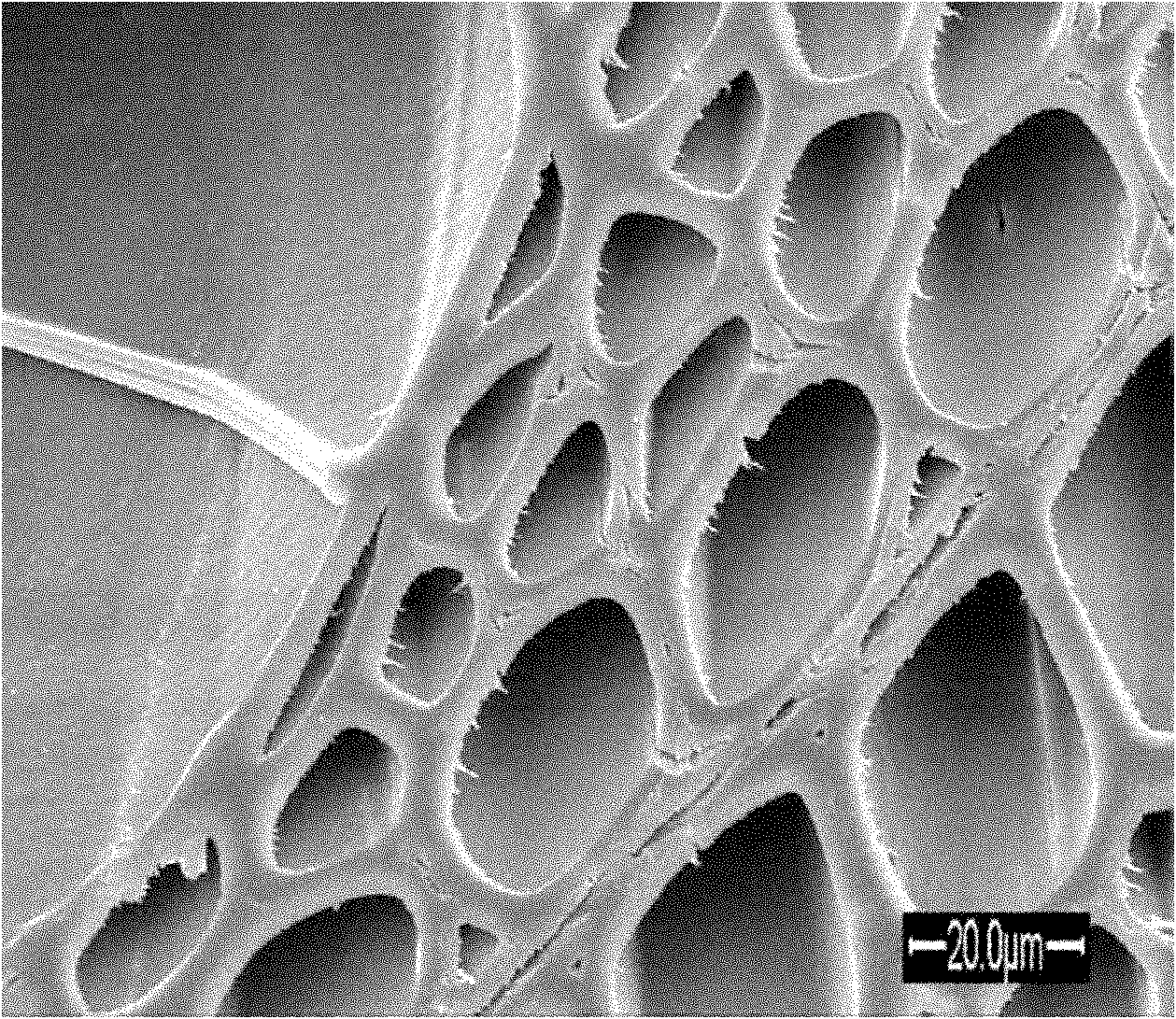

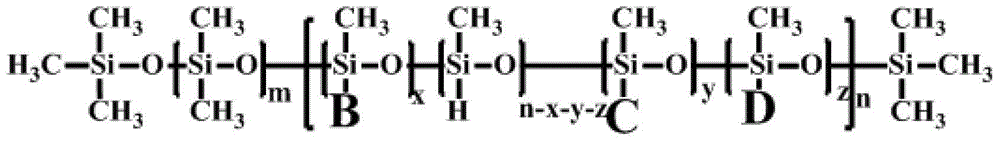

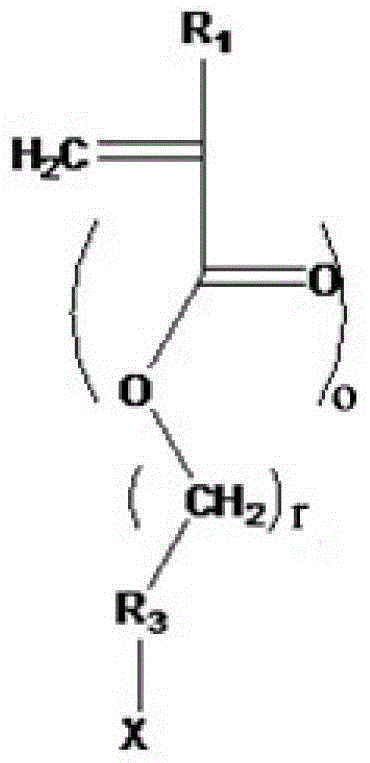

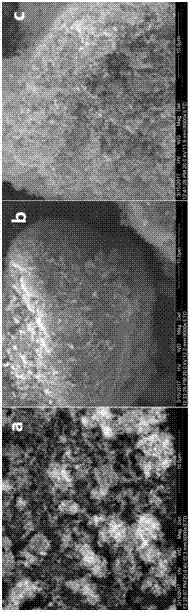

The invention belongs to the field of super-amphiphobic materials and discloses a crosslinkable fluorosilicone resin, a coating and a super-amphiphobic coating prepared from the crosslinkable fluorosilicone resin and the coating. The crosslinkable fluorosilicone resin is compared via the steps as follows: hydrogeneous organosilicon A, crosslinkable substance B, fluorine-containing substance C and modified silicon dioxide D are mixed in a dissolvent, added into a reactor, and introduced with inert gas, agitation is kept at a speed of 100-1,000 rpm, the temperature is raised to 60-140 DEG C, an activator is added and agitated for 5-24 h, the reagent is deposited into n-hexane or methanol. The crosslinkable fluorosilicone resin coating is formed by crosslinkable fluorosilicone resin, a curing agent, an activator and a dissolvent; the super-amphiphobic coating is formed by that a substrate is immersed in the crosslinkable fluorosilicone resin painting, or the crosslinkable fluorosilicone resin painting is sprayed on the surface of the substrate and baked in a baking oven for 1-20 h at 40-120 DEG C.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Amphiphilic crosslinkable fluorosilicon resin, water-borne coating and super-amphiphobic coating prepared through water-borne coating

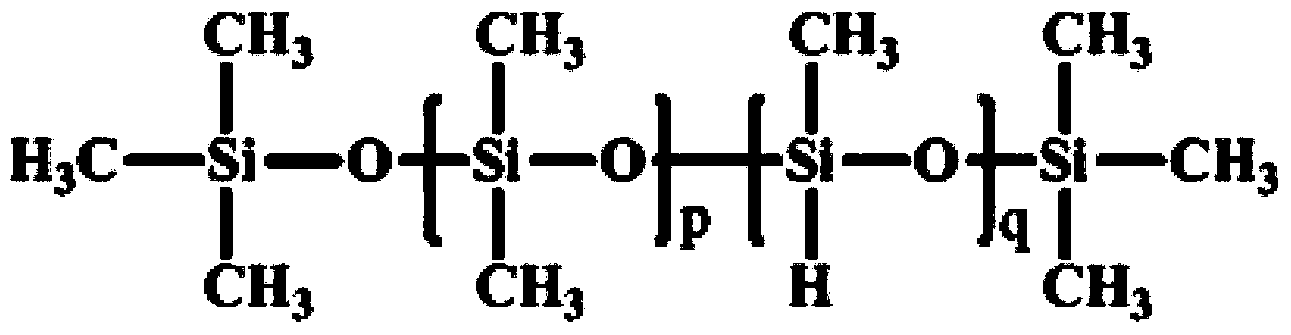

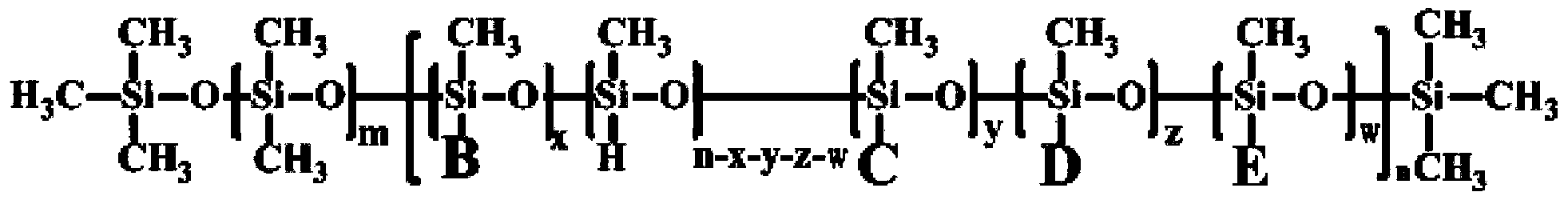

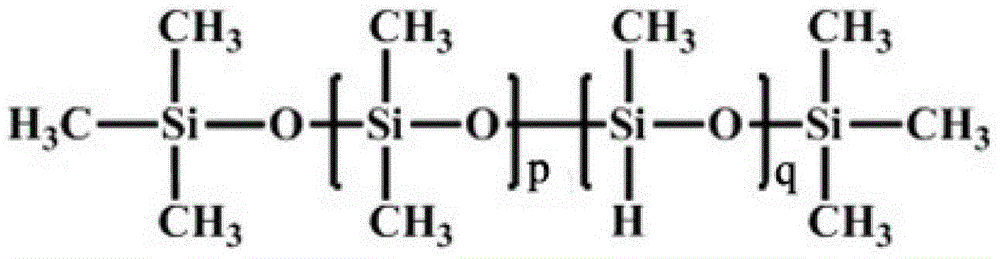

ActiveCN103408707AAchieving water dispersibilityCross-linking is widespread and strongFibre treatmentPaper coatingSolventWater soluble

The invention belongs to the field of super-amphiphobic materials, and discloses amphiphilic crosslinkable fluorosilicon resin, a water-borne coating and a super-amphiphobic coating prepared through the water-based paint. The amphiphilic crosslinkable fluorosilicon resin is prepared by the means that hydrogen containing organic silicon A, the epoxy containing substance B, the fluorine containing substance C, modified silicon dioxide D and the hydrotropic substance E are mixed into a solvent, the mixture is added into a reaction kettle, inert gas is bubbled into the reaction kettle, the temperature is increased to 60-140 DEG C under the stirring condition, then the catalyst F is added, stirring is performed for 5-24 hours, and the reactant is precipitated into normal hexane or methyl alcohol; the amphiphilic crosslinkable fluorosilicon resin coating is dissolved in a aqueous-organic solvent, water is dropwise added into the maxture, so that the amphiphilic crosslinkable fluorosilicon resin coating is obtained; curing agent is added into the amphiphilic crosslinkable fluorosilicon resin water-borne coating, the mixture is stirred uniformly, then a base material is soaked into the amphiphilic crosslinkable fluorosilicon resin coating, or the amphiphilic crosslinkable fluorosilicon resin coating is sprayed on the surface of the base material, and drying operation is performed, so that the super-amphiphobic coating is obtained.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

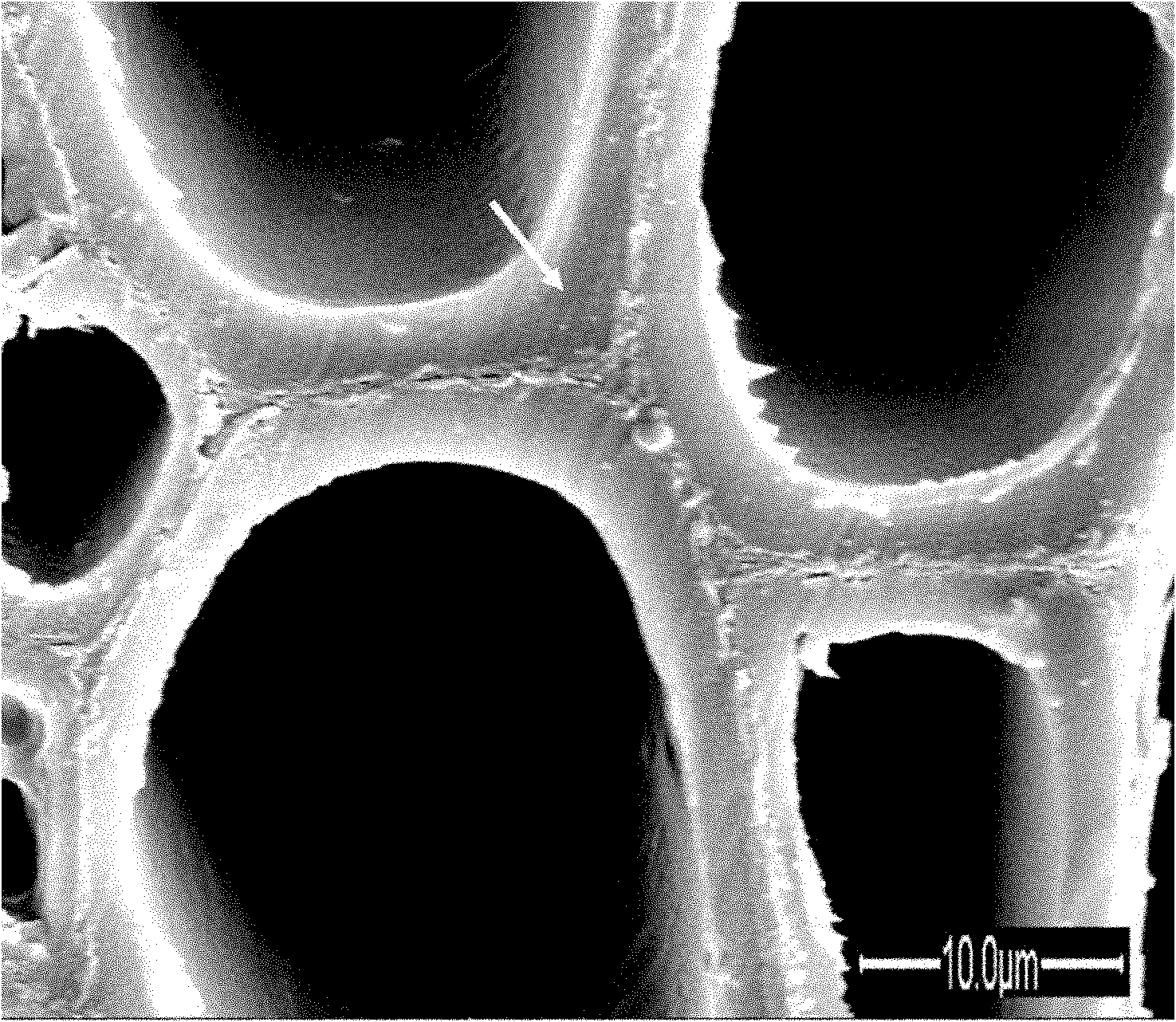

Method for modifying wood by filling grafted cell walls with organic monomers and polymerization-filling cell cavities

InactiveCN101954662AIncreased durabilityImprove mechanical propertiesPressure impregnationWood impregnation detailsCell cavityCell wall

The invention discloses a method for modifying wood by filling grafted cell walls with organic monomers and polymerization-filling cell cavities, which relates to a wood modification method. The invention solves the problem of difficulty in simultaneously enhancing mechanical properties and durability of wood in the existing wood modification method. The method comprises the following steps: 1, preparing organic acid anhydride solution; 2, soaking the wood with the organic acid anhydride solution; 3, filling grafted wood cell walls with organic acid anhydride by heating; 4, preparing the organic polymerizable monomer solution; 5, soaking the wood with the organic polymerizable monomer solution; and 6, carrying out polymerization-filling on the wood cell cavities with the monomers by heating. Since organic function micromolecules firstly enter the wood cell walls, the method realizes filling and bonding and eliminates a great deal of hydroxyl groups in the cell walls, thereby enhancing wood durability; and the wood cell cavities are soaked by the organic polymerizable monomers to initiate the polymerization and realize the filling of the cell cavities, so that the wood has higher mechanical properties and durability.

Owner:NORTHEAST FORESTRY UNIVERSITY

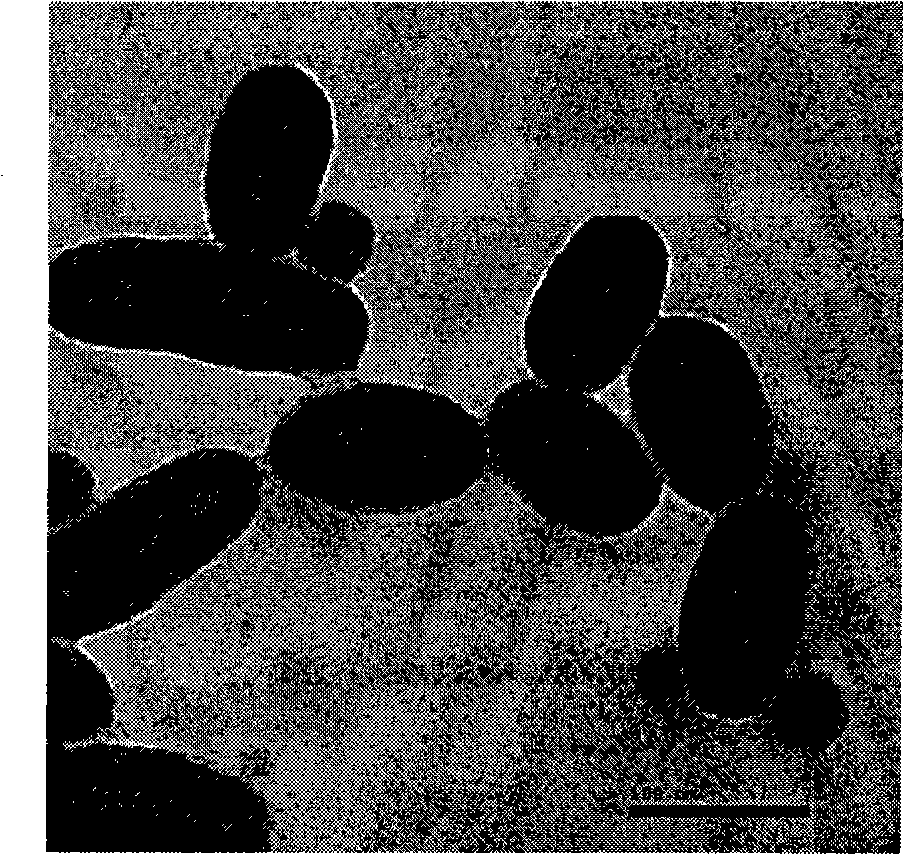

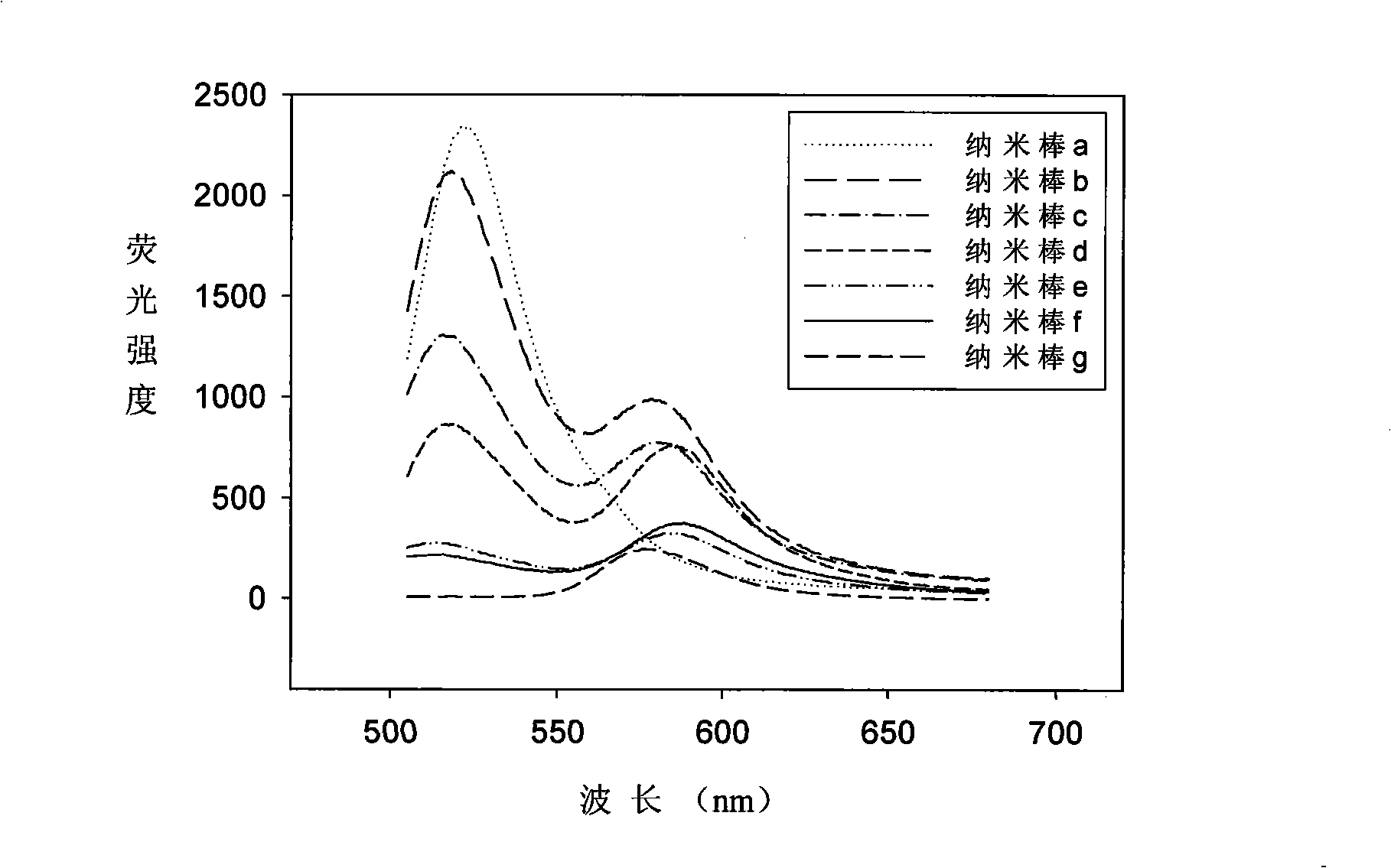

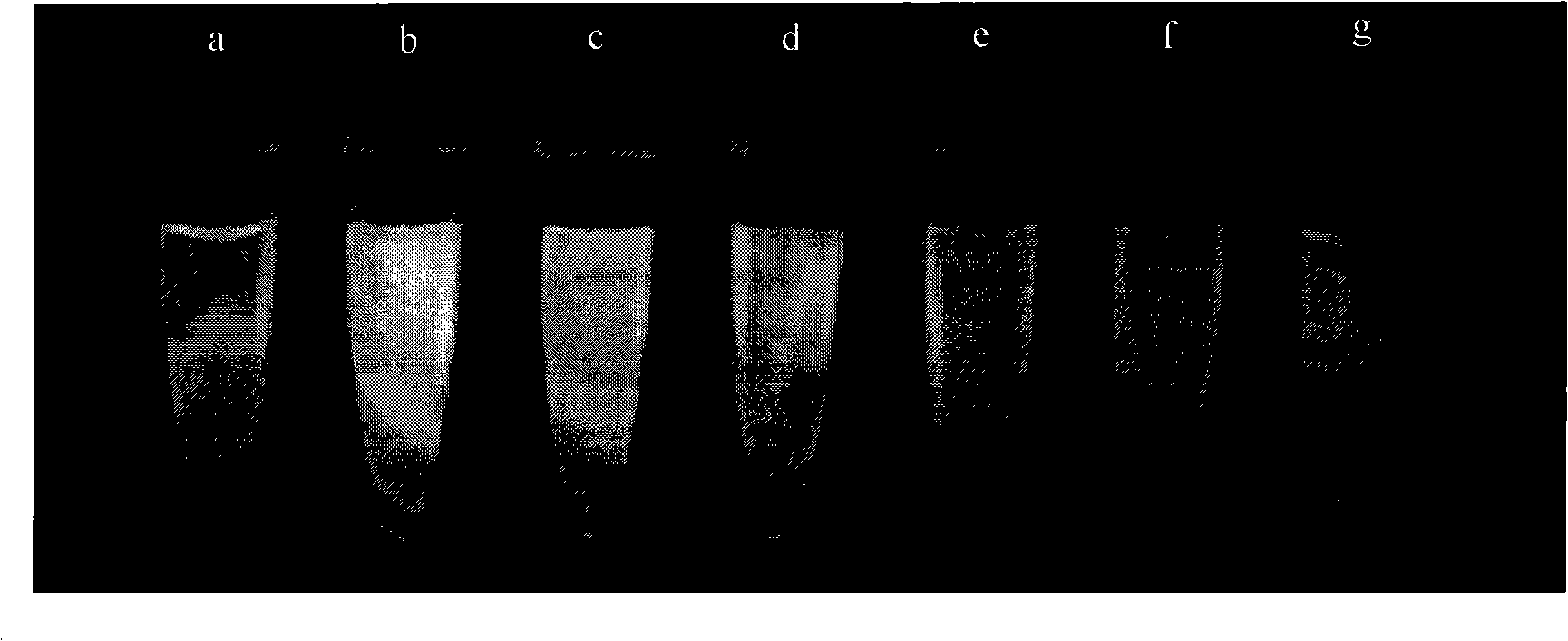

Multi-color optic-encoding siliceous skin nano-rods and method for preparing same

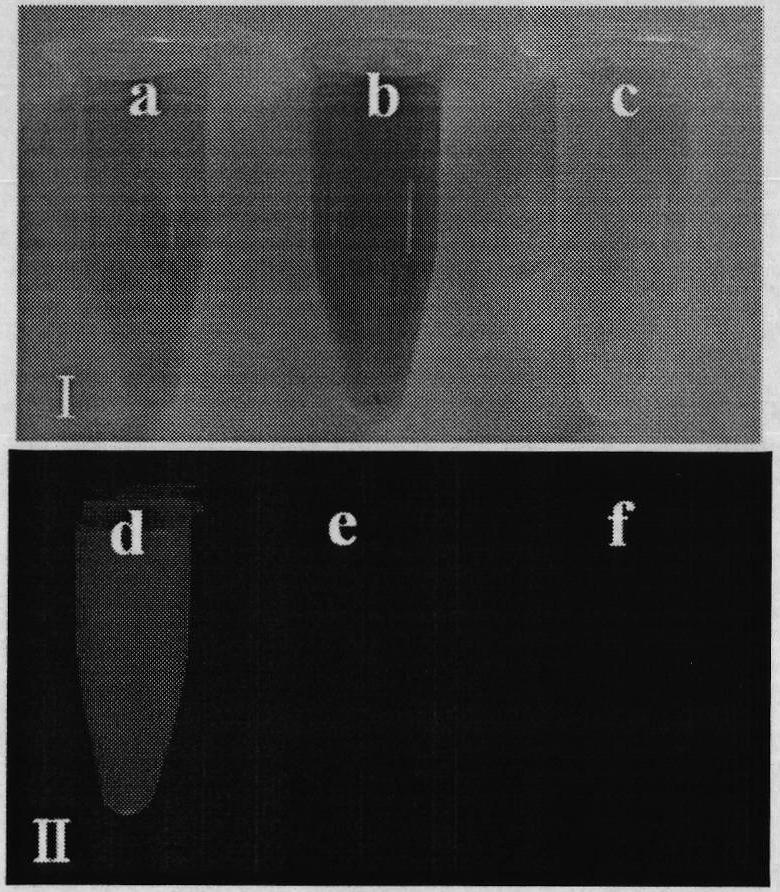

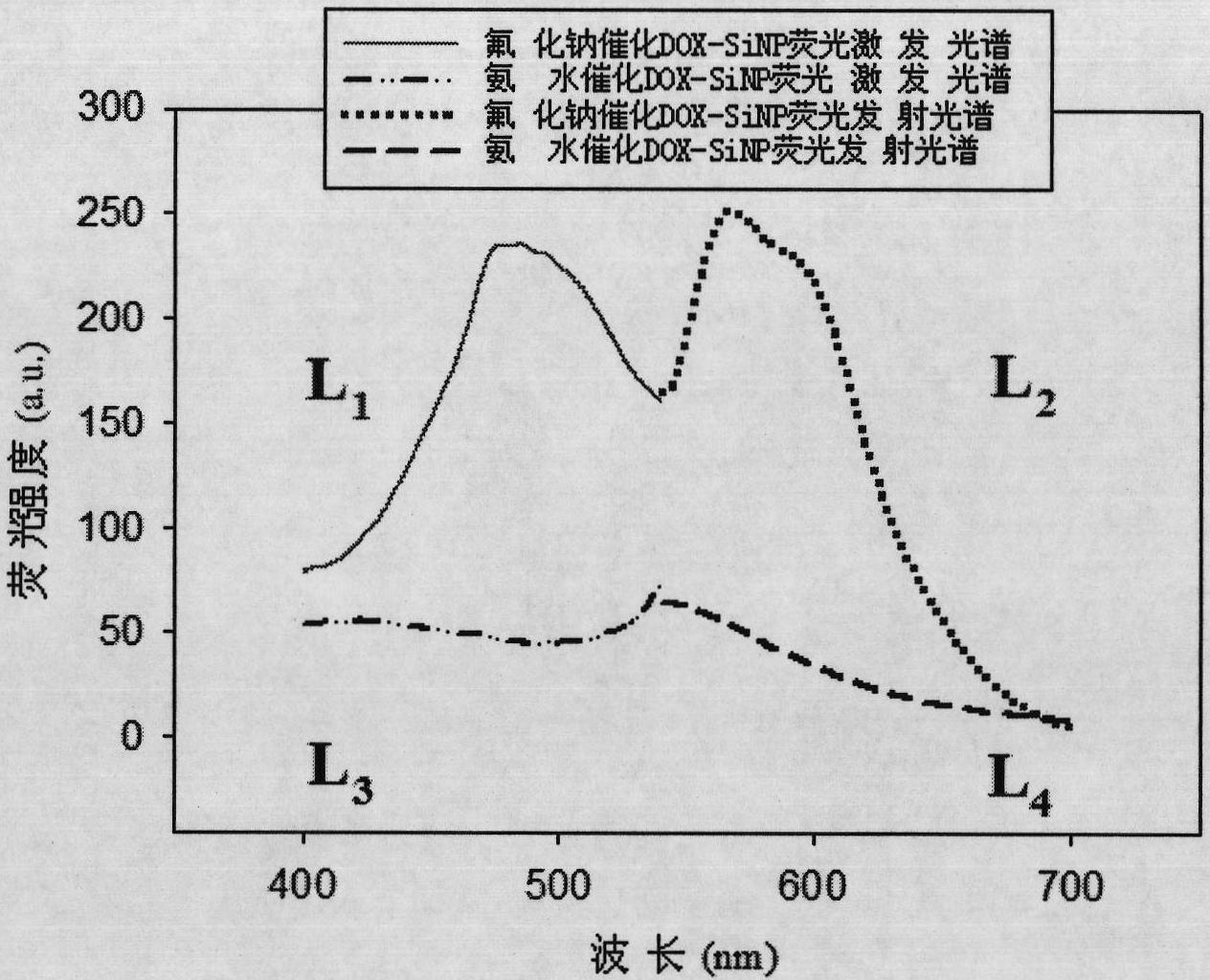

InactiveCN101333436AGood package efficiencyImprove packaging efficiencyBiological testingFluorescence/phosphorescenceEnergy transferResonance

The invention discloses a multi-color optical encoding nano-rod with silica shell. The multi-color optical encoding nano-rod takes the shape of a core shell, the shell is made of silicon dioxide and the kernel is fluorescence-encoded polylysine which contains fluorescent dye A and fluorescent dye B; the fluorescent dye A and fluorescent dye B are a fluorescence resonance energy transfer supplier-receptor pair. The invention also discloses a method for preparing the multi-color optical encoding nano-rod with silica shell, which includes the steps of enabling the fluorescent dye A and fluorescent dye B to react with the polylysine to prepare fluorescence-encoded polylysine, and wrapping the fluorescence-encoded polylysine, used as kernel material, in a silicon dioxide substrate through reverse microemulsion method; in this way, the multi-color optical encoding nano-rod with silica shell can be prepared. The multi-color optical encoding nano-rod with silica shell has the advantages of strong fluorescence intensity, good biological compatibility, good hydrophilicity, little leakage of dye and stable property.

Owner:HUNAN UNIV

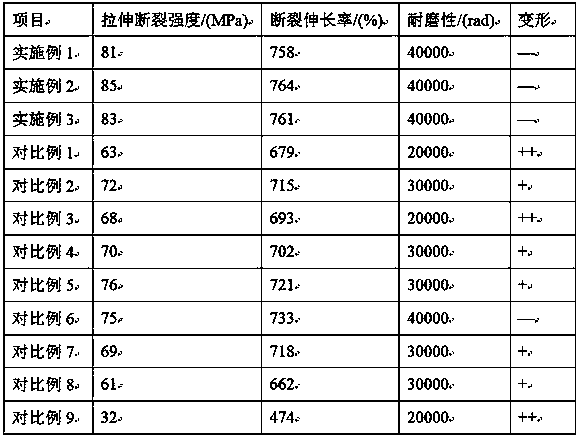

Heat-resistant and oil-resistant butadiene-acrylonitrile rubber material as well as preparation method and application thereof

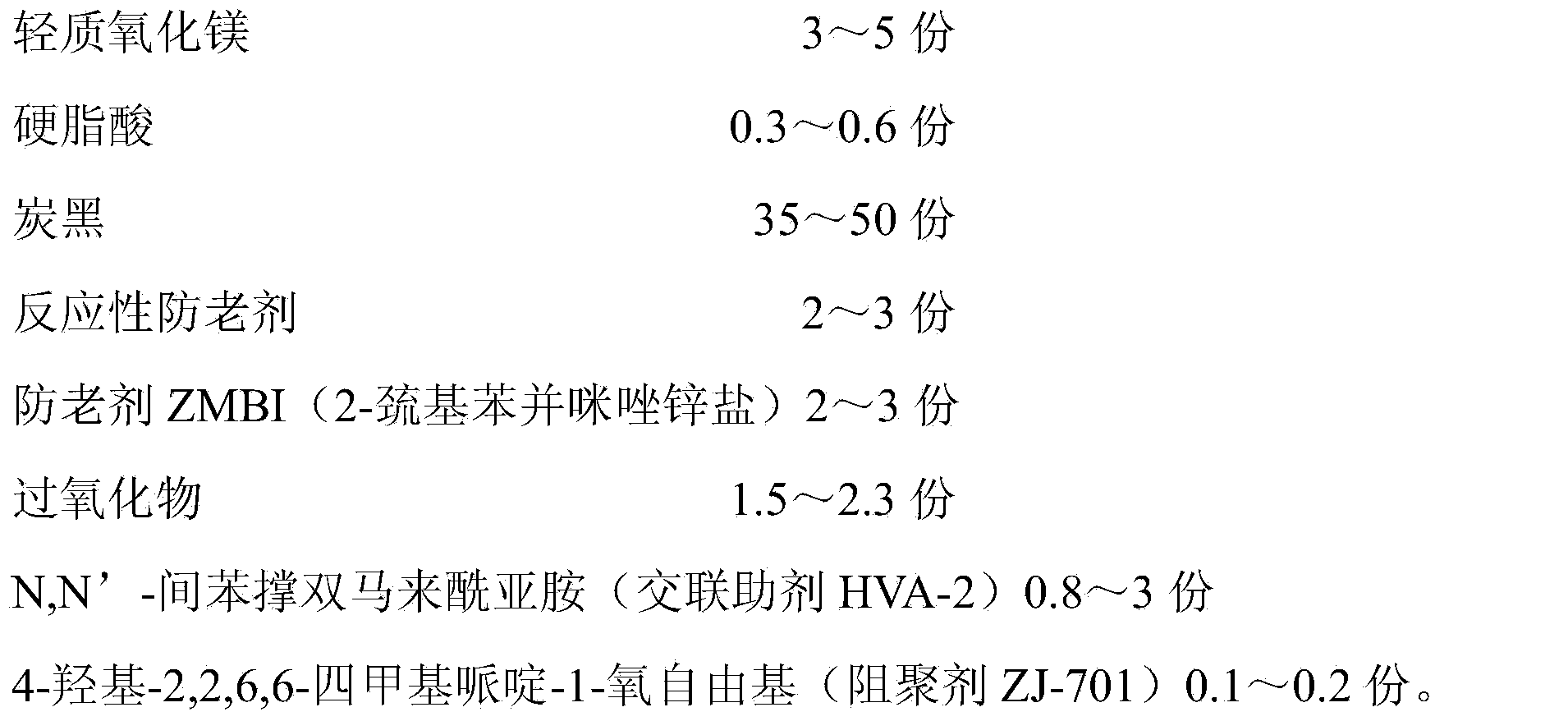

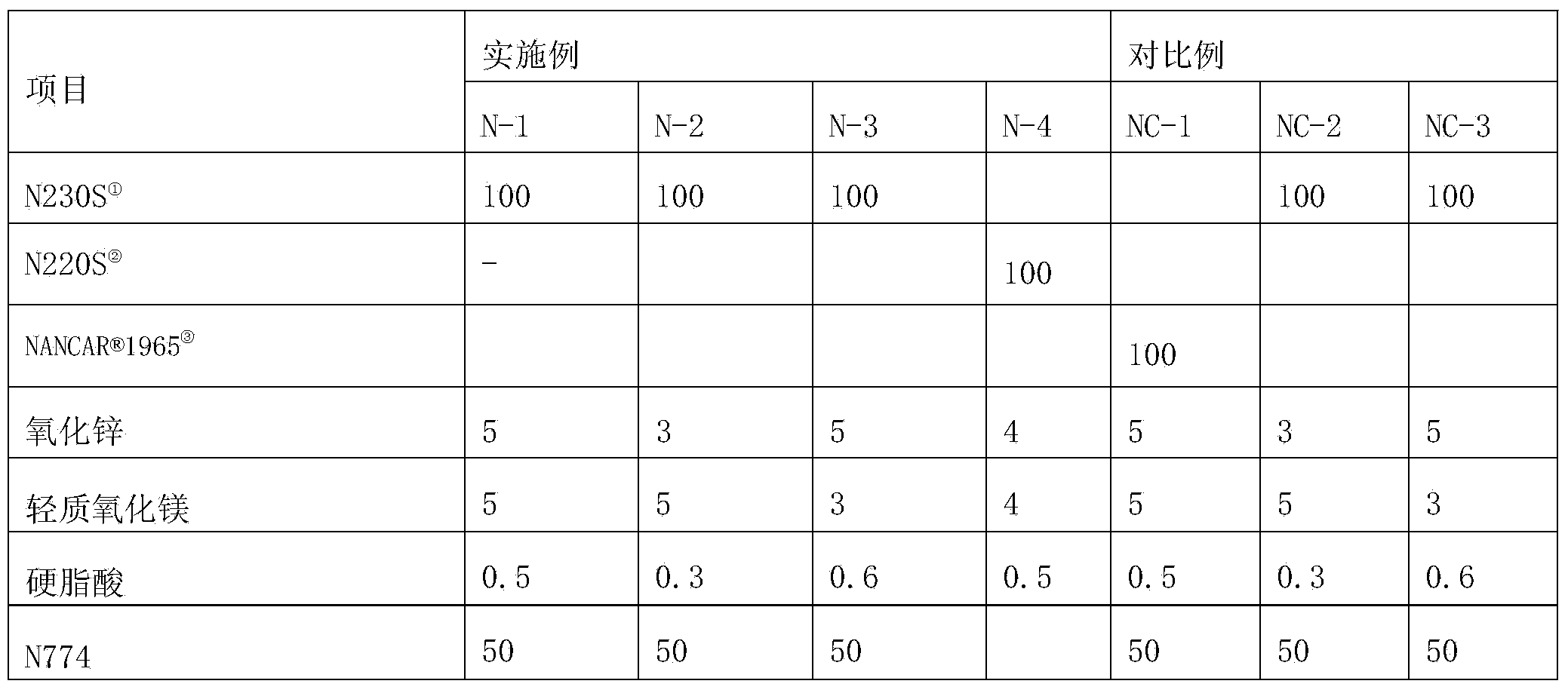

The invention belongs to the technical field of rubber seal and discloses a heat-resistant and oil-resistant butadiene-acrylonitrile rubber material as well as a preparation method and application thereof. The butadiene-acrylonitrile rubber material comprises the following components in parts by mass: 100 parts of butadiene-acrylonitrile rubber,3-5 parts of zinc oxide, 3-5 parts of light magnesium oxide, 0.3-0.6 part of stearic acid, 35-50 parts of carbon black, 2-3 parts of a reactive antioxidant, 2-3 parts of 2-mercapto benzimidazole zinc salt, 1.5-2.3 parts of peroxide, 0.8-3 parts of N,N'-m-phenylene dimaleimide and 0.1-0.2 part of 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxygen radical. After the rubber material is subjected to hot-air ageing at 120 DEG C for 70 hours, the permanent compression deformation rate (a type B sample) is not more than 18% and the break elongation rate and the retention rate are more than 90%. The rubber material is especially suitable for manufacturing oil-resistant static seal parts capable of being used at 100-120 DEG C for a long term, and can endow seal products with excellent durability.

Owner:GUANGZHOU MECHANICAL ENG RES INST

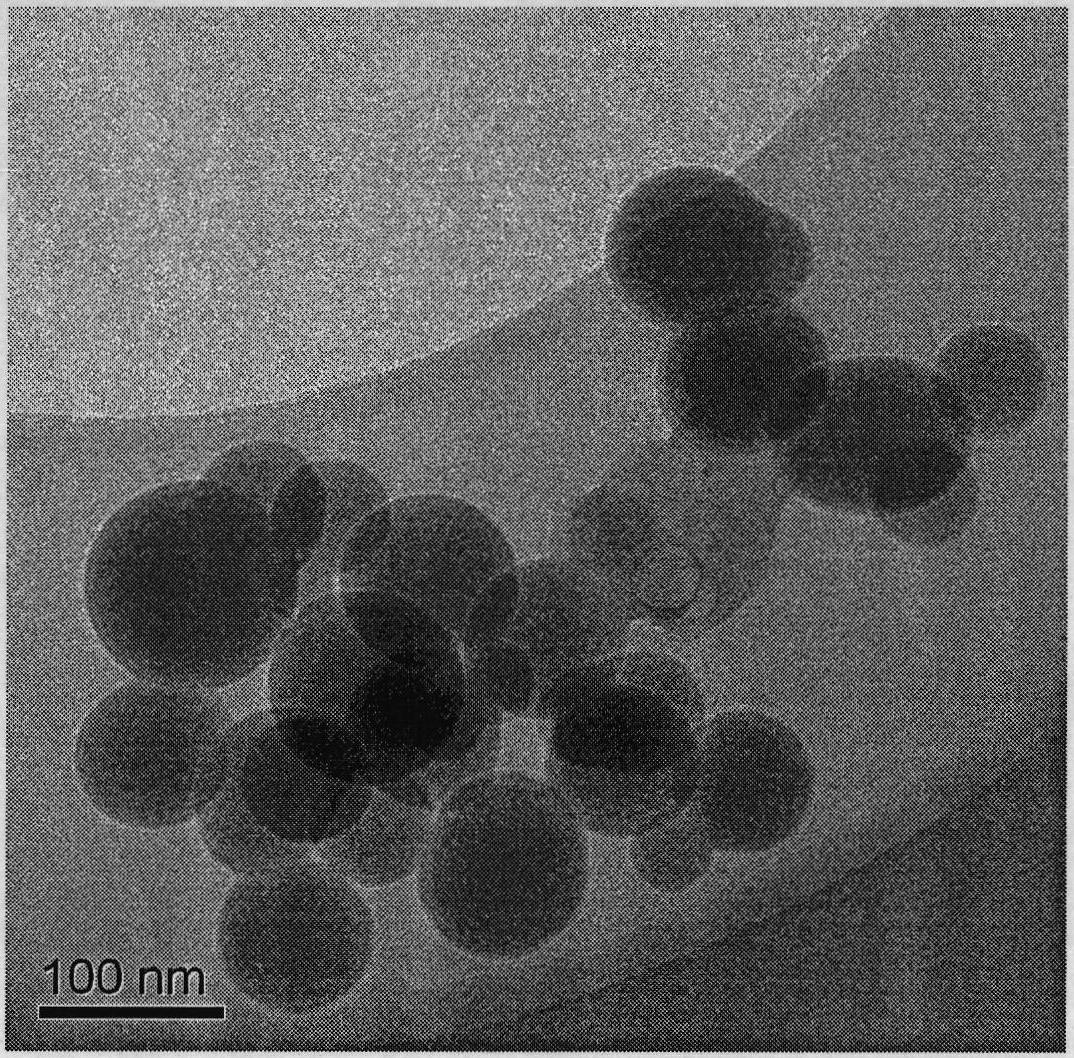

Nanoparticle for embedding medicinal Adriamycin as well as preparation method and application thereof

InactiveCN101785759AImprove packaging efficiencyImprove stabilityOrganic active ingredientsPowder deliveryTreatment fieldBiocompatibility Testing

The invention belongs to the technical field of composite medicine materials as well as a preparation method and application thereof, more particularly discloses a nanoparticle for embedding medicinal Adriamycin. The nanoparticle has a core-shell type structure with an inner core embedded by an outer shell, wherein the inner core is embedded medicinal adriamycin, and the material for the outer shell is silicon dioxide; and the preparation method of the nanoparticle comprises the following steps of: evenly mixing cyclohexane, a surfactant and n-hexylalcohol, adding a sodium fluoride solution into the mixed solution after being evenly mixed to form a reverse-phase microemulsion; adding adriamycin and tetraethoxysilane into the reverse-phase microemulsion, and reacting to obtain a nanoparticle microemulsion system for embedding the adriamycin; adding a silylanization reagent containing functional groups into the microemulsion system, stirring for reacting, adding ethanol and demulsifying, centrifuging and then preparing the nanoparticle for embedding the medicinal adriamycin and modifying the functional groups. The nanoparticle embedding for the adriamycin has good stability, good biocompatibility, long slow-release time, large drug-loading rate, high medicine packaging rate, and the like, and has application prospect in the fields of tumor imaging and treatment.

Owner:HUNAN UNIV

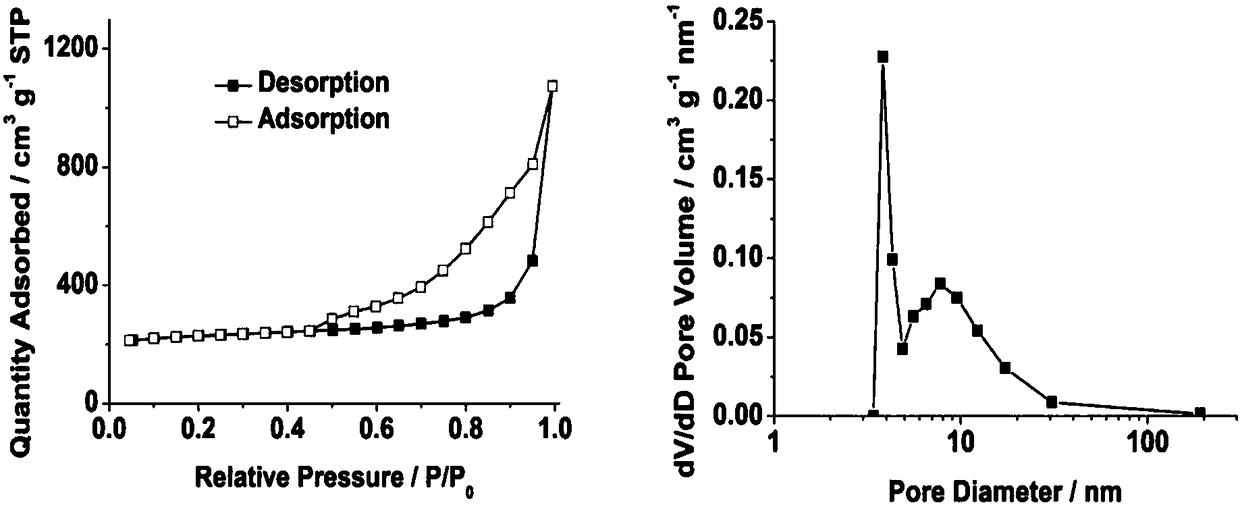

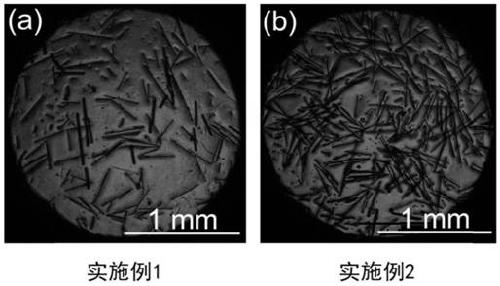

Polymer porous microsphere, carbon sphere and ultra-black material prepared from the same, and applications

ActiveCN109280209AAchieve functionalizationHigh crystallinityOther chemical processesDispersed particle separationPolymer scienceHalogen

The invention discloses a polymer porous microsphere, and a preparation method and applications thereof. A carbon sphere, and a preparation method and applications thereof are also disclosed. The carbon sphere is prepared from the polymer porous microsphere. An ultra-black material composition, and a ultra-black material prepared from the same and applications are disclosed as well. The ultra-black material composition includes the carbon sphere. As a linear polymer containing groups like halogen and hydroxy and having no heteroatom on a main chain has high degree of crystallinity and abundantcrystal types, the morphology of the obtained microsphere is also special, and a composition structure can include a sheet structure, a bicontinuous structure and a fibrous structure. The morphologyof the polymer porous microsphere can maintain unchanged through carbonization, so that the prepared carbon sphere can well maintain the morphology structure and porosity of the polymer porous microsphere; and a graphite structure with multiple defects can be formed during carbonization, so that the pore canal structure can be more abundant, and especially, the volumes of micropores can be greatlyenhanced.

Owner:INST OF CHEM CHINESE ACAD OF SCI

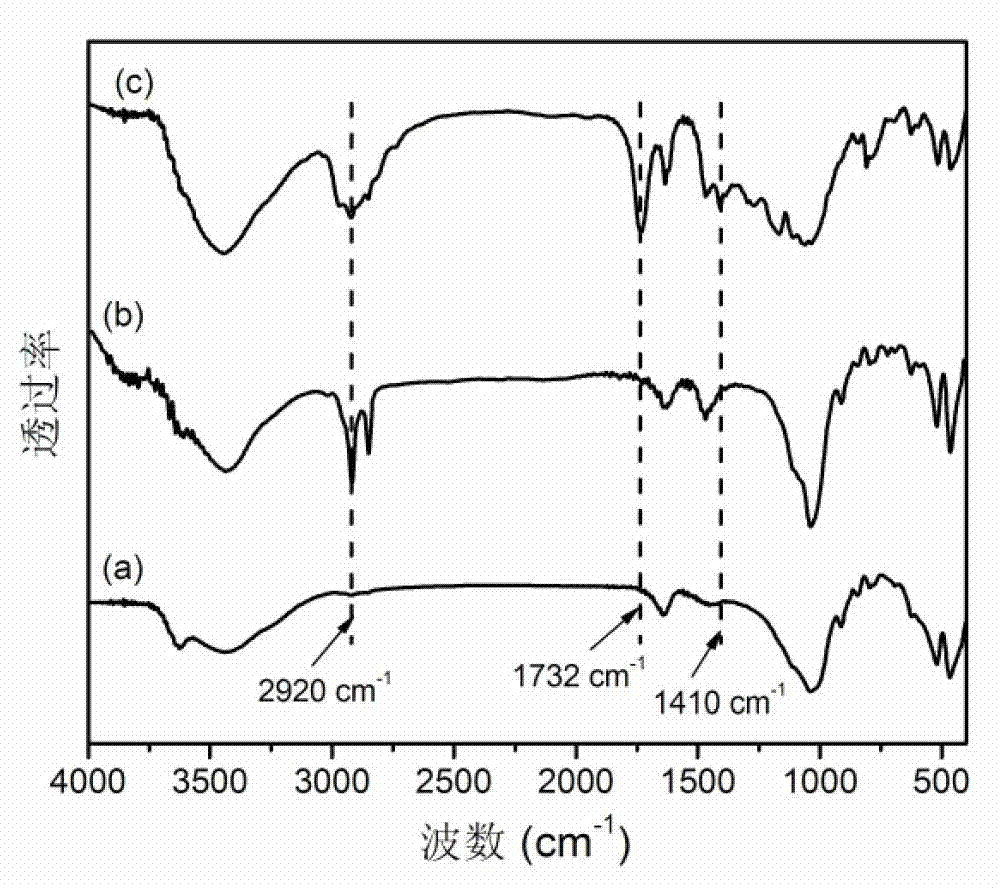

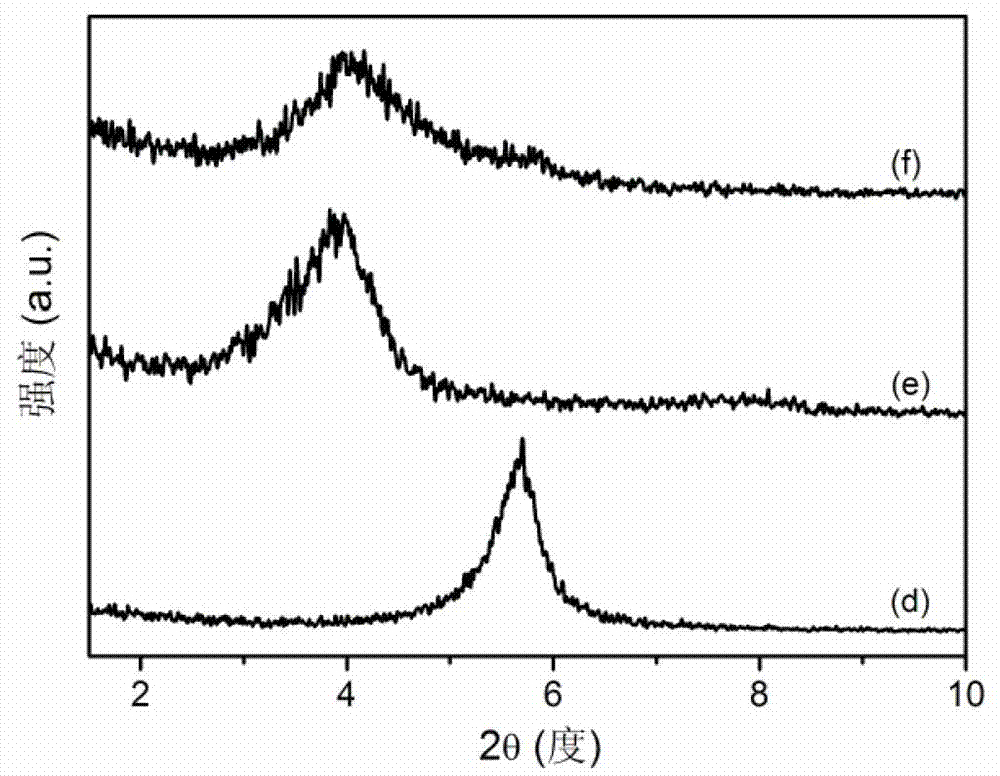

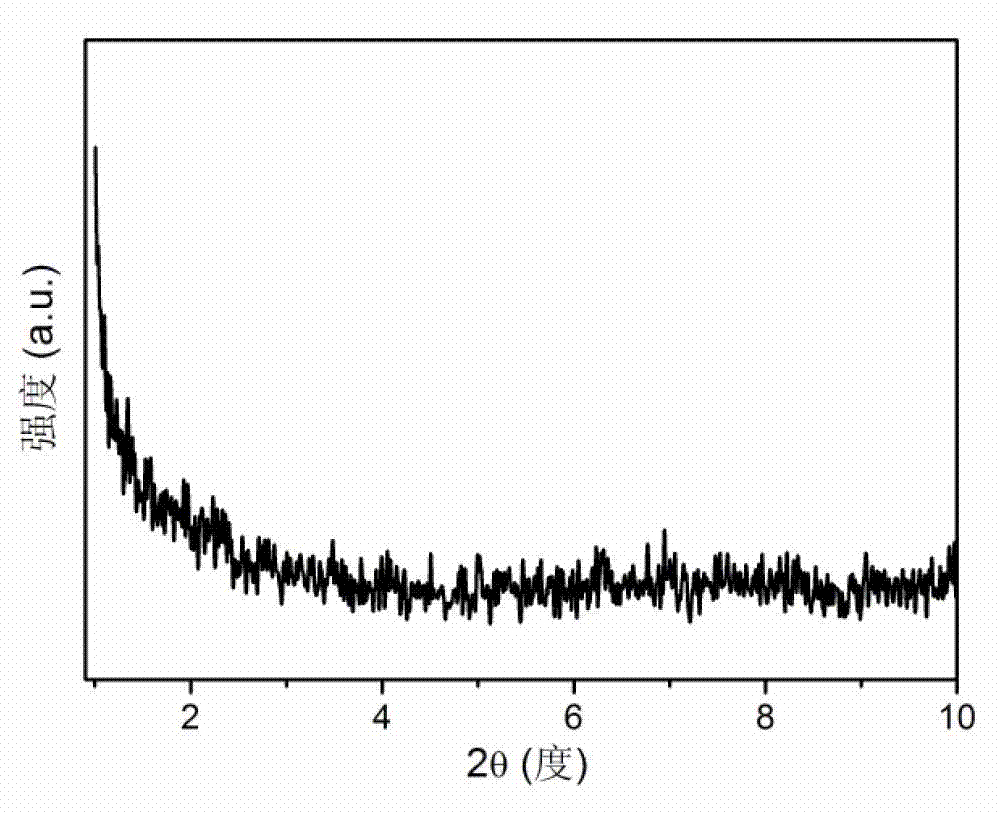

Sulfhydryl-double bond reaction-based acrylate ester/montmorillonite composite and preparation method

The invention discloses a sulfhydryl-double bond reaction-based acrylate ester / montmorillonite composite and a preparation method. The preparation method is characterized by comprising the steps of: firstly, forming intercalation modification chemical bond grafted acrylic ester functionalized nano-montmorillonite, then mixing the synthesized polyfunctional group sulfur alcohol, acrylate ester oligomer, acrylate monomer and a light initiator, and finally performing ultraviolet light irradiation to obtain the acrylate ester / montmorillonite ultraviolet cured nano composite. A line for synthesizing a polyfunctional group acrylate ester silane coupling agent and the polyfunctional group sulfur alcohol is simple and easy without toxicity; compared with the traditional method in which the initiator takes up 3 to 5% of total mass, the preparation method disclosed by the invention has the advantages that the usage amount of the light initiator is greatly reduced and only takes up 0.1-0.8% of the total mass, the residual light initiator can be effectively reduced, the harm of fragments to the environment and the health of a human body can be reduced, and higher reaction activity and conversion rate can be achieved; and the compatibility between inorganic components and organic components in the composite is good, and the mechanical property and heat-resistant property are obviously improved.

Owner:ZHANGJIAGANG DAWN CHEM

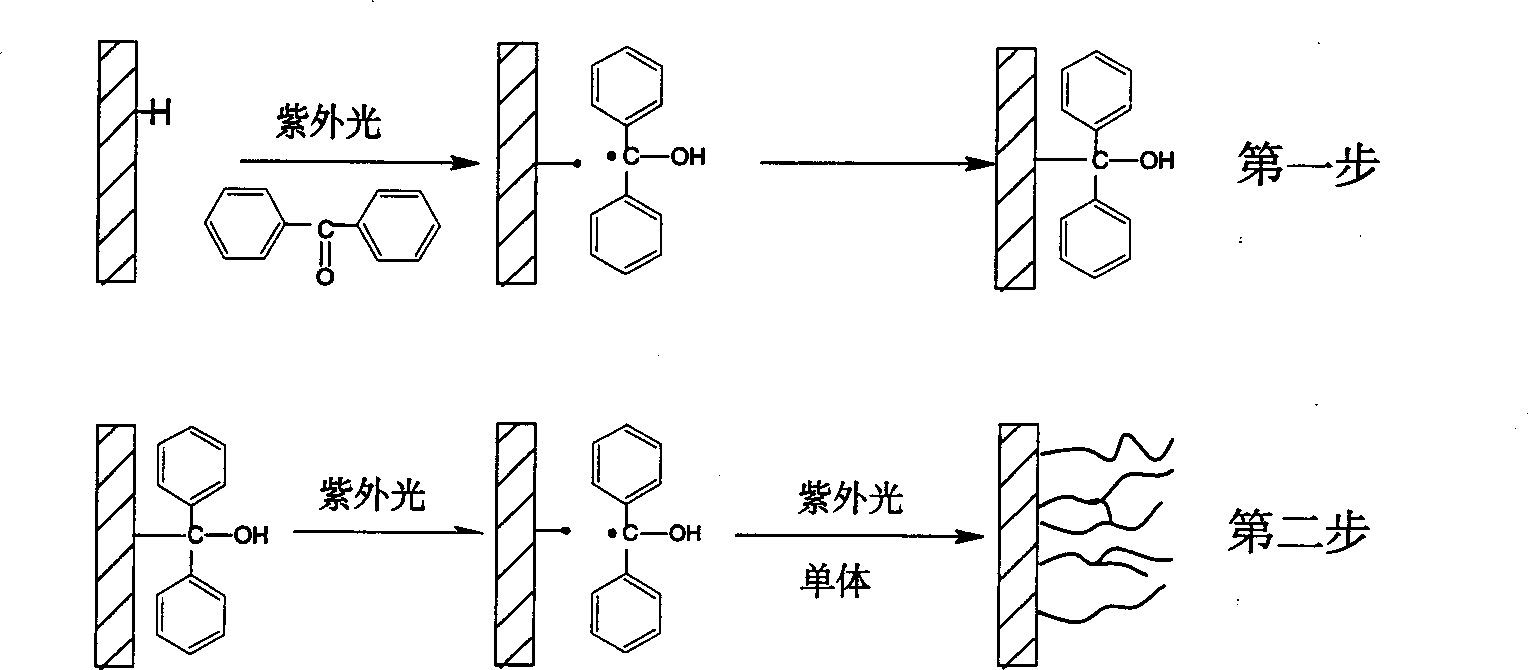

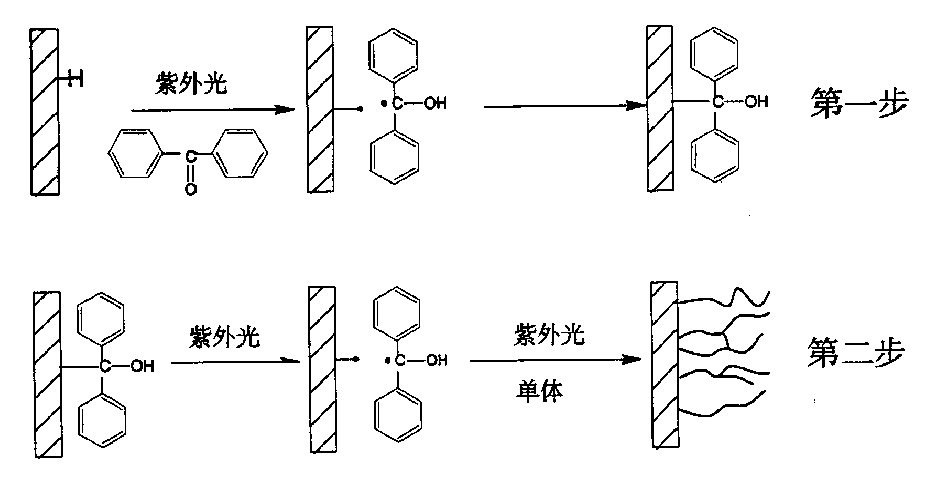

Process for preparing high-water-absorption flexible material by ultraviolet surface graft method

A process for preparing the high-water-absorption flexible material by ultraviolet surface graft method includes immersing polyacrylic film in organic solvent, drying in air, loading it in reactor, adding solution of photosensitive agent, closing the reactor, introducing chlorine gas into it while ultraviolet ray radiation for graft, extracting the polyacrylic film with organic solvent, adding deionized water to acrylic acid, partial neutralization with NaOH, adding acrylamide, adding photosensing agent, taking out the polyacrylic film and ultraviolet graft. Its advantages are short reaction time, simple reaction condition, and high flexibility of product.

Owner:TSINGHUA UNIV

Acrylic graft-modified high hydroxyl value dry oil short oil alkyd resin and preparation method thereof

InactiveCN101392044ACompact structurePromote infiltrationCoatingsOptical elementsCross-linkManufacturing technology

The invention relates to a high-hydroxyl-value dry short-oil alkyd resin grafted and modified by acrylic acid, and a preparation method thereof. The compositions and weight percentages of the resin are as follows: 28 percent to 33 percent of dry oil, 26 percent to 35 percent of polyatomic alcohol, 26 percent to 43 percent of polyprotic acid, 13 percent to 20 percent of acrylic monomers, 1.2 percent to 2 percent of initiators and trace catalysts. The short-oil alkyd resin prepared by the preparation method can react with a cross-linked resin to form a mesh spatial structure with large cross linking degree so that coating structures are quite compact and not easy to be penetrated by chemical substances. The short-oil alkyd resin has fast curing performance under low temperature and high corrosion prevention performance, and the assembly line work thereof can be realized, thus being helpful to promoting the manufacturing technology levels of protective coating at the back of eyeglasses in China, breaking the monopoly of products of large foreign companies and reducing the production cost and operating cost of the eyeglass manufacturing industry in China.

Owner:TIANJIN CITY XINLIHUA COLOR MATERIAL

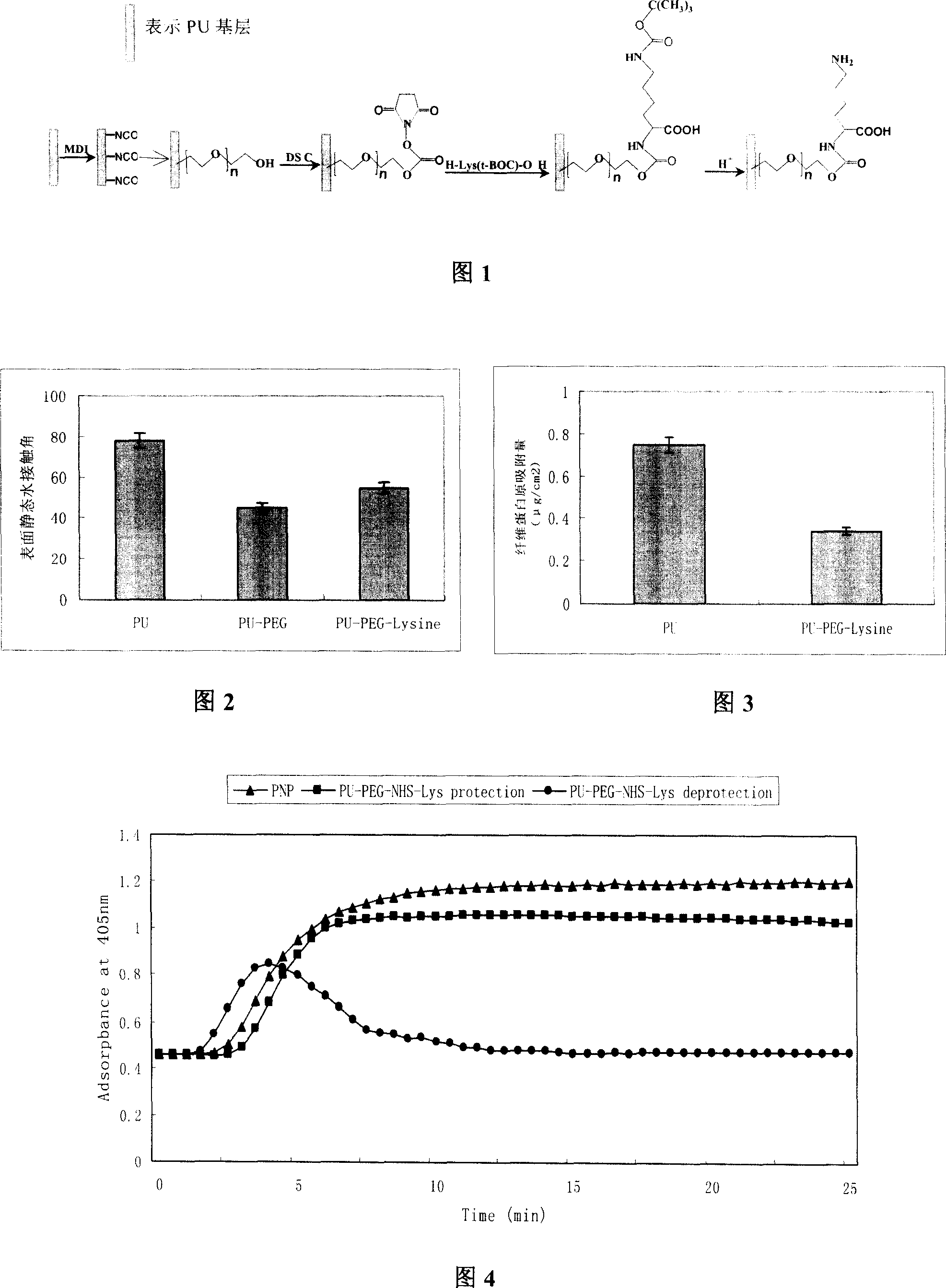

Anticoagulant polyurethane material, and preparation and usage thereof

InactiveCN101011605AReduce adsorptionReduce adhesionSurgeryPharmaceutical containersAnticoagulantIntroduced organisms

The invention relates to an anticoagulant polyurethane material formed by a decorate layer and a base layer, wherein, the base layer is formed by general commercial polyurethane material or composite polyurethane material, and the decorate layer is formed by chemically decorating the face of base layer. The decorate layer contains the PEG flexible distant group connected with the polyurethane base via covalence key and the active lycine lead by the NHS via surface grafting and the function group covalence key at the end of PEG. The inventive preparation comprises that using MDI to function the PU material, surface grafting the PEG, leading in NHS active reaction group, grafting lycine, and de-protecting theepsilon-NH2 of lycine. The invention has better anticoagulant and plug-dissolving functions, to eliminate the blood plug.

Owner:WUHAN UNIV OF TECH

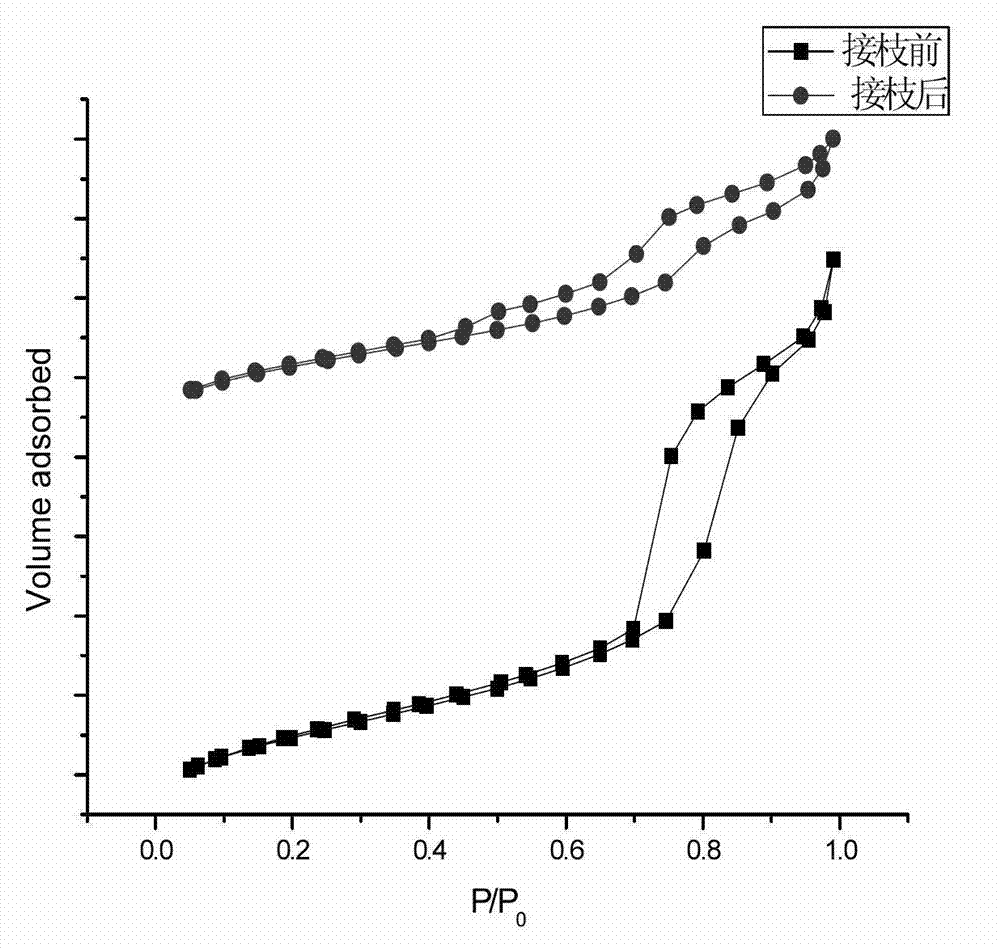

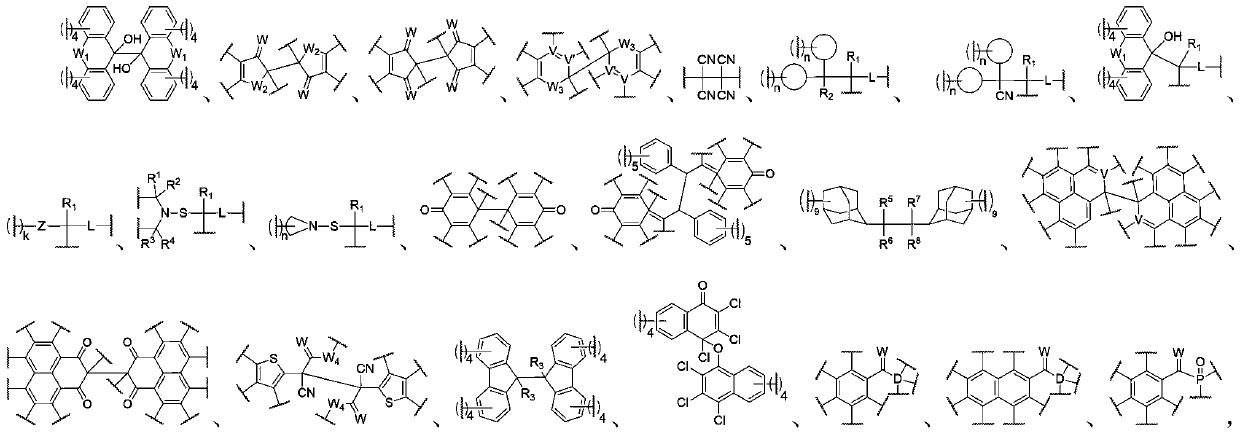

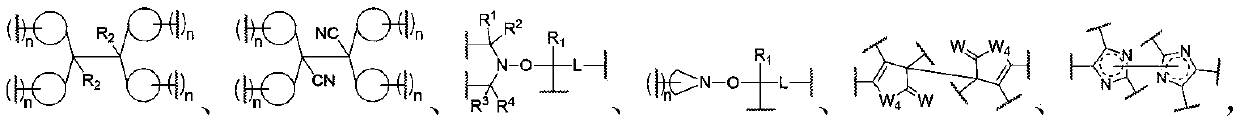

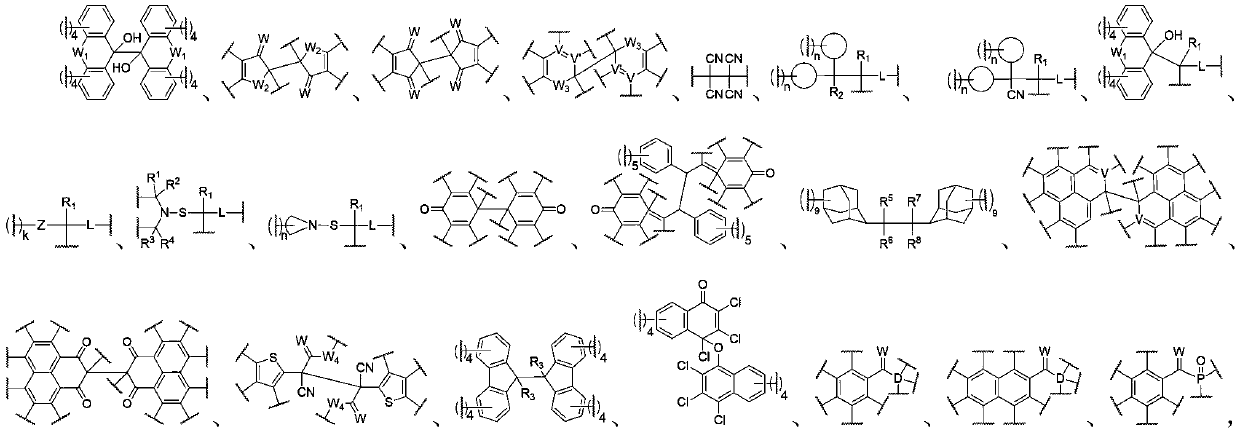

Porous organic-inorganic composite material and method for preparing same

ActiveCN102774842ASimple grafting processHigh reaction yieldSilicaSimple Organic CompoundsMethylene Dichloride

The invention relates to a porous organic-inorganic composite material and a method for preparing the porous organic-inorganic composite material. The method comprises the following steps: subjecting a compound of formula (1) and a compound of formula (2) to reaction in the methylene dichloride solvent in the alkaline environment provided by the triethylamine to generate a compound of formula (3), subjecting the compound of formula (3) to reaction with a compound of formula (4) under the catalysis of the Pt which serves as a catalyst to generate a functional organic compound of formula (5), subjecting the functional organic compound of formula (5) to reaction with the porous-silicon based vesicle material to generate an organic-inorganic composite material, filtering the organic-inorganic composite material, washing by a washing solvent, and drying in vacuum to obtain the porous organic-inorganic composite material. The raw materials adopted by the method for preparing the porous organic-inorganic composite material are easy to obtain, and the functional compound is easy to synthesize, has high reaction yield and is easy to purify.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Super fast curing silver mirror back priming paint coating

The invention relates to a primer base for the back of ultra fast curing glasses, the components of which by weight percentages are respectively: 28 percent to 35 percent of propyl modified resin mixed solution, 7 percent to 12 percent of crosslinking resin, 3 percent to 8 percent of epoxy resin, 24 percent to 28 percent of pigment, 2 percent to 4 percent of promoter and 14 percent to 18 percent of solvents. The materials are mixed evenly, stirred and ground until the fineness is qualified, thus obtaining the finished product of the primer base for the back of the glasses. The primer base for the back of the glasses prepared by the invention takes the propyl modified resin as a basic film forming substance and adopts amino resin as the crosslinking resin and the epoxy resin, the coloring pigment, the antirust pigment, a filler, the promoter and the various mixed solvents are added, so that the primer base after film forming has level and smooth surface, good adhesion, proper degree of hardness and brittleness, improved water and chemical resistance, good moisture and heat resistance and salt-mist resistance and especially obviously improved xylene wiping resistance and CASS resistance. During the process of application, curtain coating is stable, does not branch off and is totally dried during 6 minutes to 10 minutes of curing process at the temperature of 130 DEG C to 140 DEG C.

Owner:TIANJIN CITY XINLIHUA COLOR MATERIAL

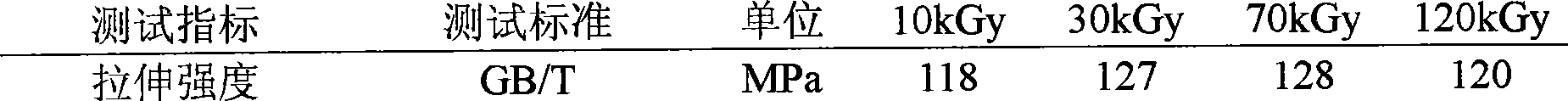

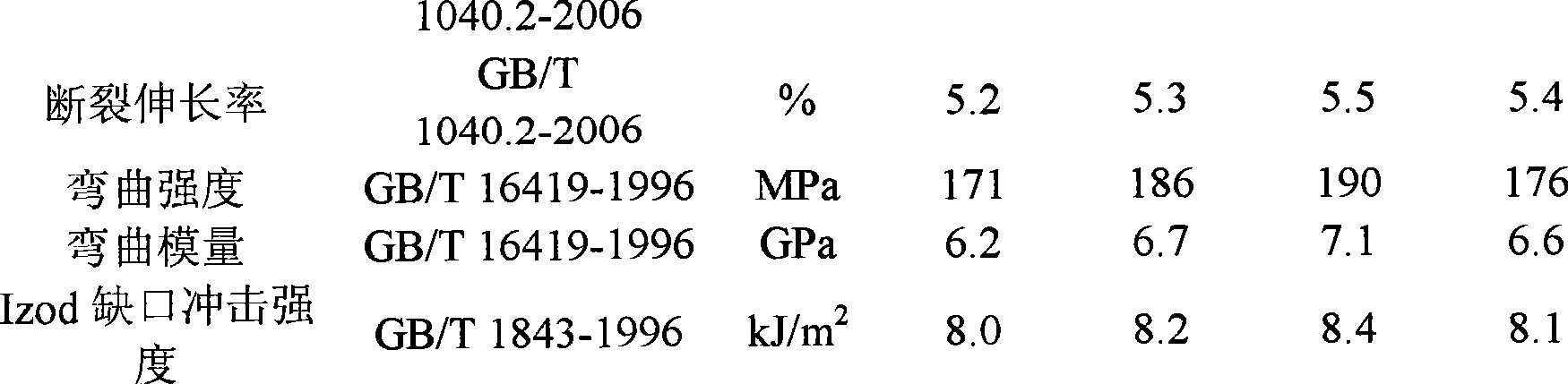

Fiber-reinforced polyethylene glycol terephthalate composite material and preparation method thereof

InactiveCN101519481AHigh tensile strengthImprove bending strengthPolyethylene glycolFlexural strength

The invention relates to a fiber-reinforced polyethylene glycol terephthalate composite material and a preparation method thereof. The composite material is prepared from the following raw materials: 65 to 85 weight parts of PET, 15 to 35 weight parts of fiber, 1 to 10 weight parts of vinyl-group multifunctional-group monomer and 2 to 10 weight parts of composite auxiliary. The raw materials PET and fiber are dried, and the PET, the vinyl-group multifunctional-group monomer and the composite auxiliary are uniformly mixed to be added into a material cooling cut granules extruded out by a double-screw extruder, the granules are dried, under the protection of N2, a Co-60 source or an electronic beam is used for irradiation, and the irradiation dosage is from 10 to 120kGy to obtain the fiber-reinforced high-performance PET composite material. The dynamic performance of the material is higher than that of the glass-fiber-reinforced product, wherein the tensioning strength is 156MPa, the breaking elongation rate is 3.8 percent, the bent strength is 236MPa, the bent modulus is 11.6GPa, and the impact strength of a Izod gap is 9.1kJ / m<2>.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of carbon fiber reinforced polylactic acid 3D printing material

InactiveCN112266591AGood compatibilityImprove mechanical propertiesAdditive manufacturing apparatusCarbon fibresCarbon fibersMelt extrusion

The invention discloses a preparation method of a carbon fiber reinforced polylactic acid 3D printing material, which relates to the field of high polymer materials. The preparation method specifically comprises the following steps of (1) surface activation of carbon fibers, (2) surface modification of carbon fibers, (3) grafting the surface of the natural rubber, (4) modifying polylactic acid particles, and (5) preparing the carbon fiber reinforced polylactic acid 3D printing material. According to the method, after the surfaces of the carbon fibers are activated, the styrene-maleic anhydridecopolymer is introduced, so that the compatibility of the carbon fibers and polylactic acid is improved, the mechanical property of the composite material is greatly improved, meanwhile, monomers aregrafted with natural rubber and then are blended, melted and extruded with the polylactic acid, and the toughness of the polylactic acid is improved; and the comprehensive mechanical property of thecomposite material is improved through double modification.

Owner:合肥通融新型材料科技有限公司

A kind of cross-linkable fluorosilicone resin, coating and super amphiphobic coating prepared therefrom

ActiveCN103408762BUniversal and strong cross-linkingImprove surface energyFibre treatmentCoatingsCooking & bakingCross-link

The invention belongs to the field of super-amphiphobic materials and discloses a crosslinkable fluorosilicone resin, a coating and a super-amphiphobic coating prepared from the crosslinkable fluorosilicone resin and the coating. The crosslinkable fluorosilicone resin is compared via the steps as follows: hydrogeneous organosilicon A, crosslinkable substance B, fluorine-containing substance C and modified silicon dioxide D are mixed in a dissolvent, added into a reactor, and introduced with inert gas, agitation is kept at a speed of 100-1,000 rpm, the temperature is raised to 60-140 DEG C, an activator is added and agitated for 5-24 h, the reagent is deposited into n-hexane or methanol. The crosslinkable fluorosilicone resin coating is formed by crosslinkable fluorosilicone resin, a curing agent, an activator and a dissolvent; the super-amphiphobic coating is formed by that a substrate is immersed in the crosslinkable fluorosilicone resin painting, or the crosslinkable fluorosilicone resin painting is sprayed on the surface of the substrate and baked in a baking oven for 1-20 h at 40-120 DEG C.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

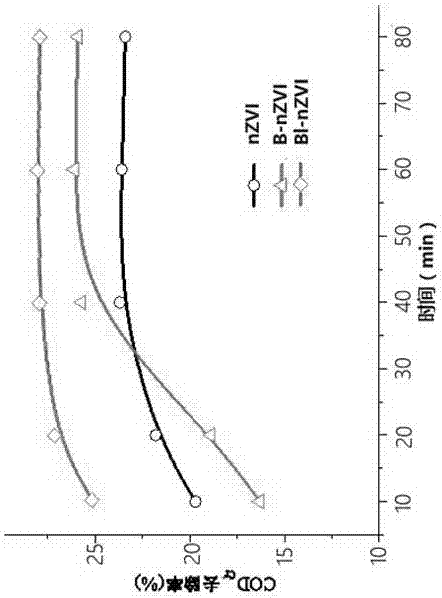

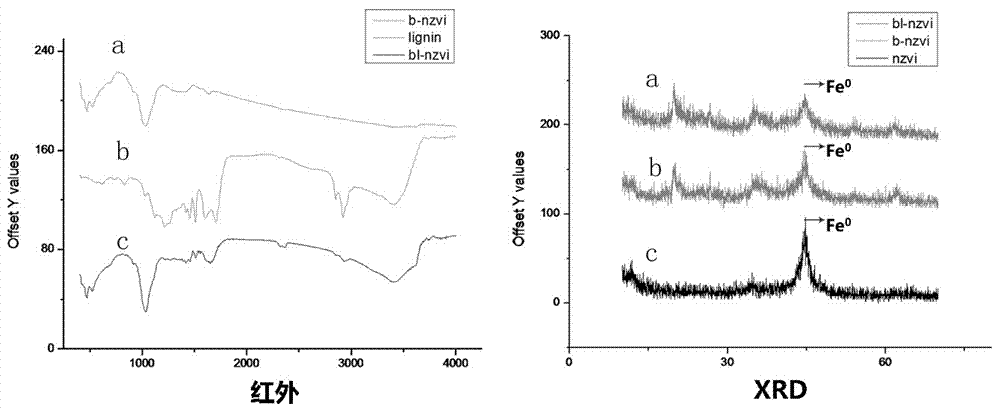

Nanometer zero-valent iron-loaded lignin-grafted bentonite composite material and preparation method thereof

InactiveCN107081137AGood dispersionImprove stabilityOther chemical processesWaste water treatment from plant processingWastewaterFerric

The invention discloses a nanometer zero-valent iron-loaded lignin-grafted bentonite composite material and a preparation method thereof, belonging to the technical field of functional materials. The composite material is characterized in that bentonite is grafted with lignin and is then loaded with nanometer zero-valent iron. Compared with the prior art, the composite material provided by the invention has the following advantages: nanometer zero-valent iron in the composite material has obviously improved dispersibility and stability, good wastewater treatment capability, and good promotion and application value.

Owner:QILU UNIV OF TECH

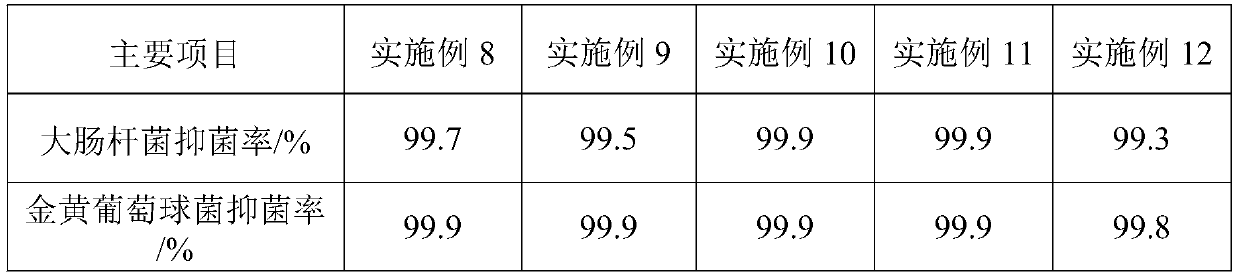

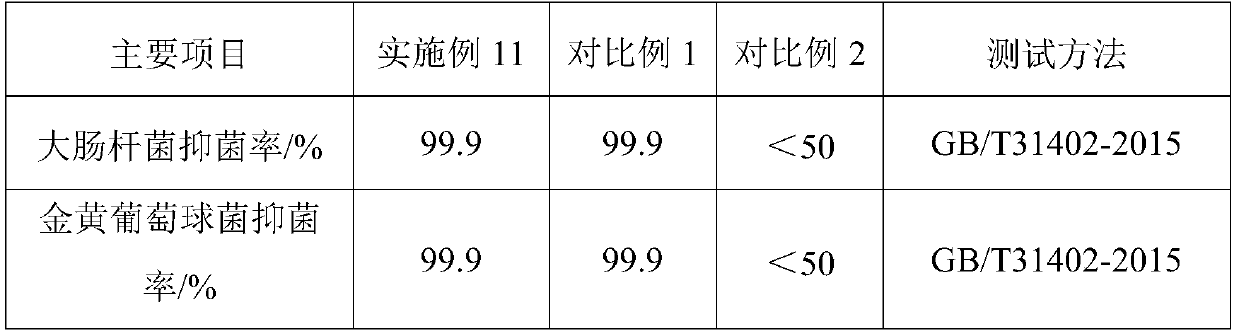

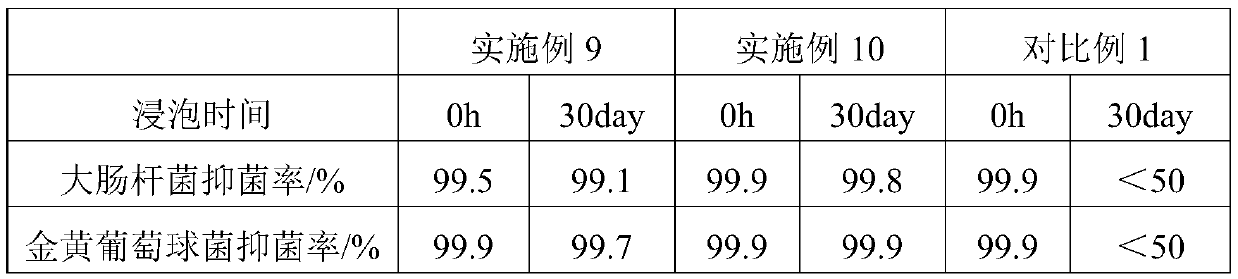

Dissolution-resistant guanidine antibacterial agent and preparation method thereof

The invention relates to a dissolution-resistant guanidine antibacterial agent and a preparation method thereof. The preparation method comprises the following specific steps: preparing any one or a mixture of two of polyhexamethylene guanidine hydrochloride and polyhexamethylene biguanidine hydrochloride into a guanidine salt solution with a certain concentration, adding an organic acid salt sodium salt or potassium salt into the guanidine salt solution, and reacting for a period of time to obtain a water-insoluble product; and washing the product, drying, grinding and crushing to obtain thepowdery dissolution-resistant guanidine antibacterial agent. The dissolution-resistant guanidine antibacterial agent prepared by the method has a relatively good long-acting antibacterial effect and is simple in preparation process, green and environment-friendly and is suitable for industrial production and can be widely applied to TPU, PP, PE and other high polymer materials.

Owner:安阳崇高纳米材料科技有限公司

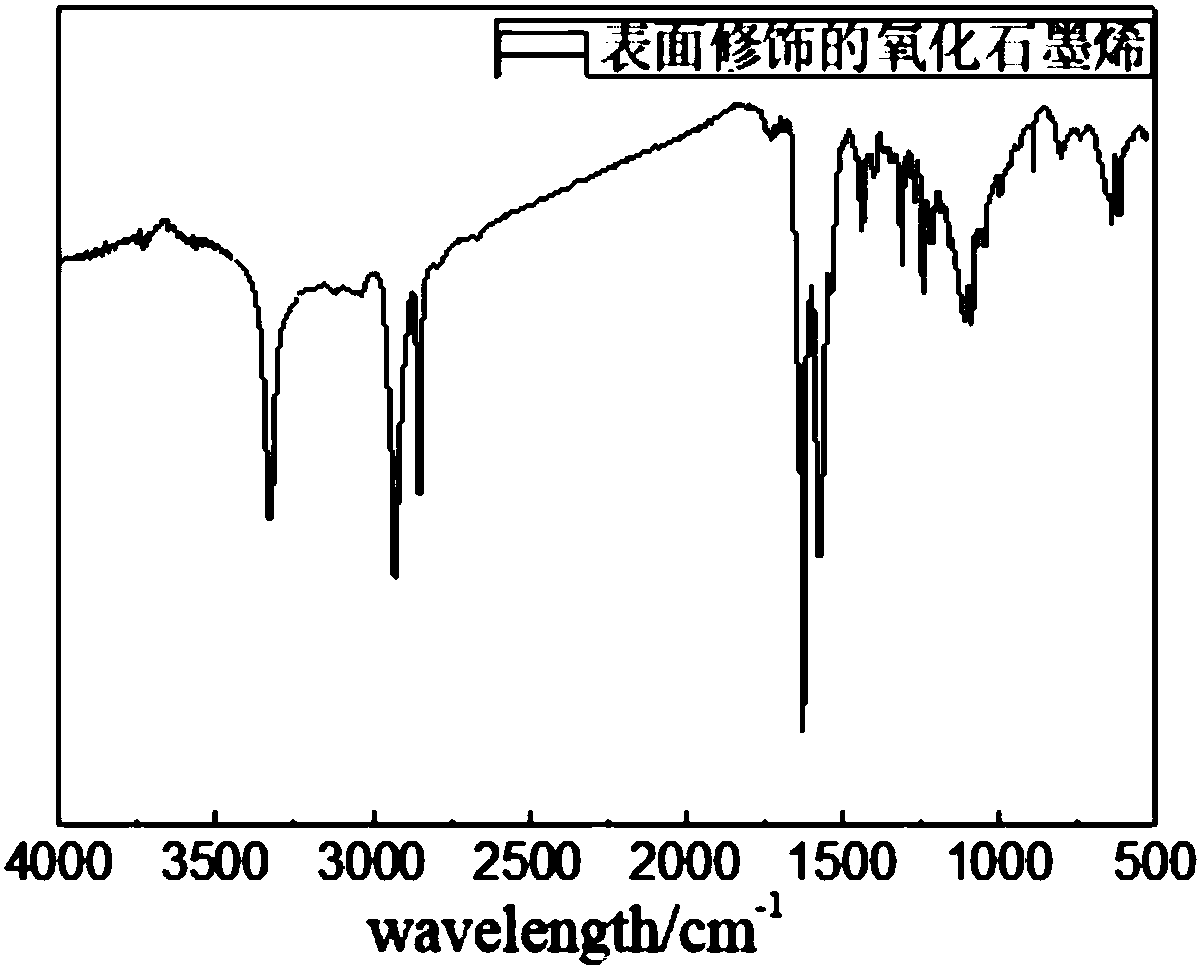

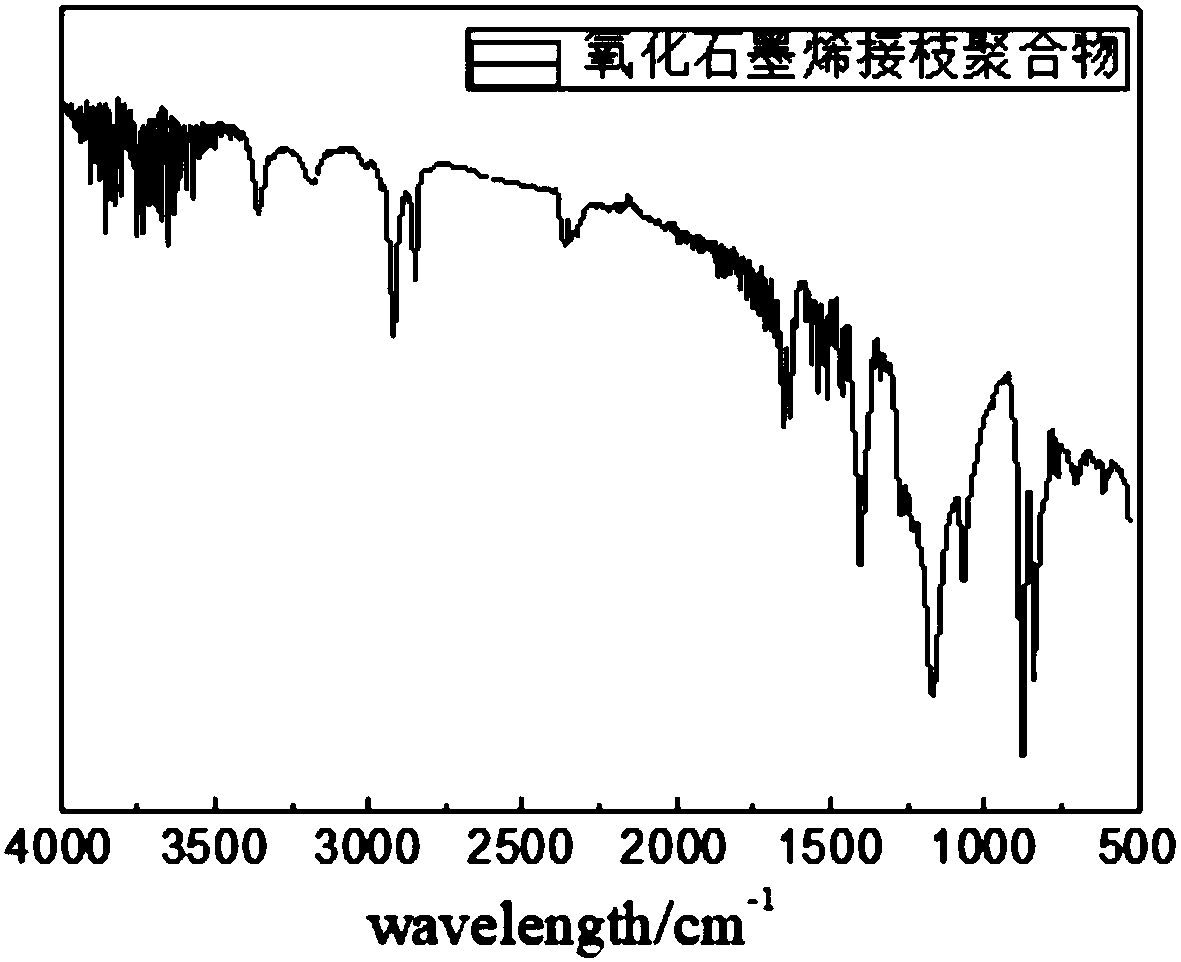

Method for preparing grafting polyvinylidene fluoride on graphene oxide

ActiveCN108557812AFacilitate graftingGood dispersionCarbon compoundsCvd graphenePolyvinylidene fluoride

The invention discloses a method for preparing grafting polyvinylidene fluoride on graphene oxide, and belongs to the field of materials. The method for preparing the grafting polyvinylidene fluorideon graphene oxide comprises the steps of 1, adopting an improved Hummer's method for preparing graphene oxide; 2, modifying the surface of graphene oxide; 3, preparing a polymer of grafting polyvinylidene fluoride on graphene oxide. According to the method, the grafting rate can be obviously increased, and the preparing technology is simple, and the method suitable for industrial production; the prepared material has the advantages of being high in tensile strength, good in heat stability and high in mechanical strength.

Owner:UNIV OF JINAN

Modified carbon fiber reinforced polyamide 6 composite material for 3D printing, and preparation method and application thereof

InactiveCN111423720AControl wire diameter accuracyUniform wire diameterAdditive manufacturing apparatusFiberWire rod

The invention provides a modified carbon fiber reinforced polyamide 6 wire for 3D printing, and a preparation method and application thereof. A modified carbon fiber reinforced polyamide 6 composite material of the invention is prepared from the following components in parts by weight: 85-95 parts of a polyamide 6 material, 5-15 parts of carbon fibers and 1-3 parts of a modified silane coupling agent. According to a technical scheme provided by the invention, carbon fiber grafting is facilitated by utilizing the modified silane coupling agent; the prepared composite material has the characteristics of uniform wire diameter, smooth surface, excellent mechanical property and relatively small material shrinkage rate, can be applied to the field of 3D printing consumables, and overcomes the technical defects that a polyamide 6 material is prone to buckling deformation in the printing process, the mechanical property of a printed member is poor and wires are prone to generation of bubbles in the prior art. The polyamide 6 printing wire of the invention has practical value, the maximum tensile strength of the polyamide 6 printing wire can exceed 110 MPa under the condition of a low carbon fiber content (10-15%), and the polyamide 6 printing wire is far superior to many polyamide 6 printing wires on the market.

Owner:DALIAN UNIV OF TECH

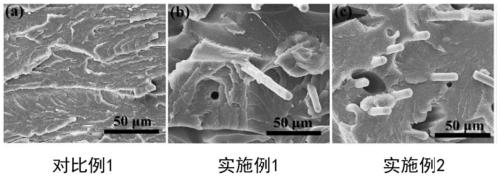

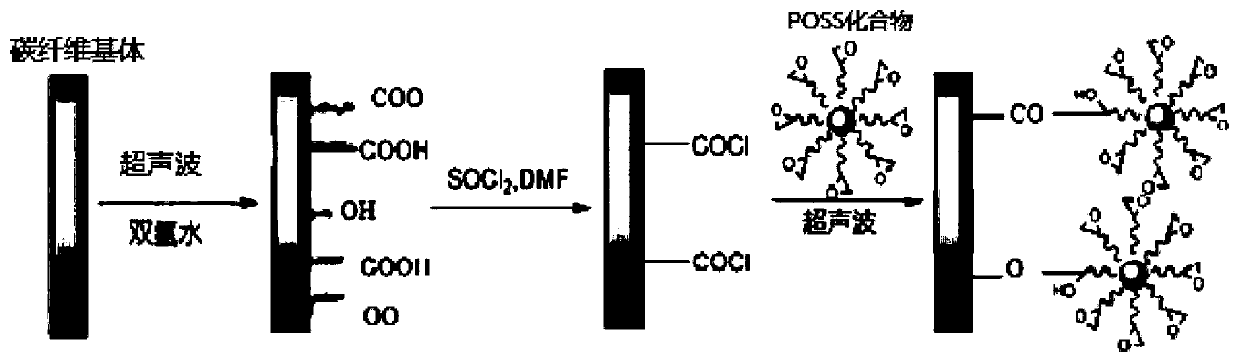

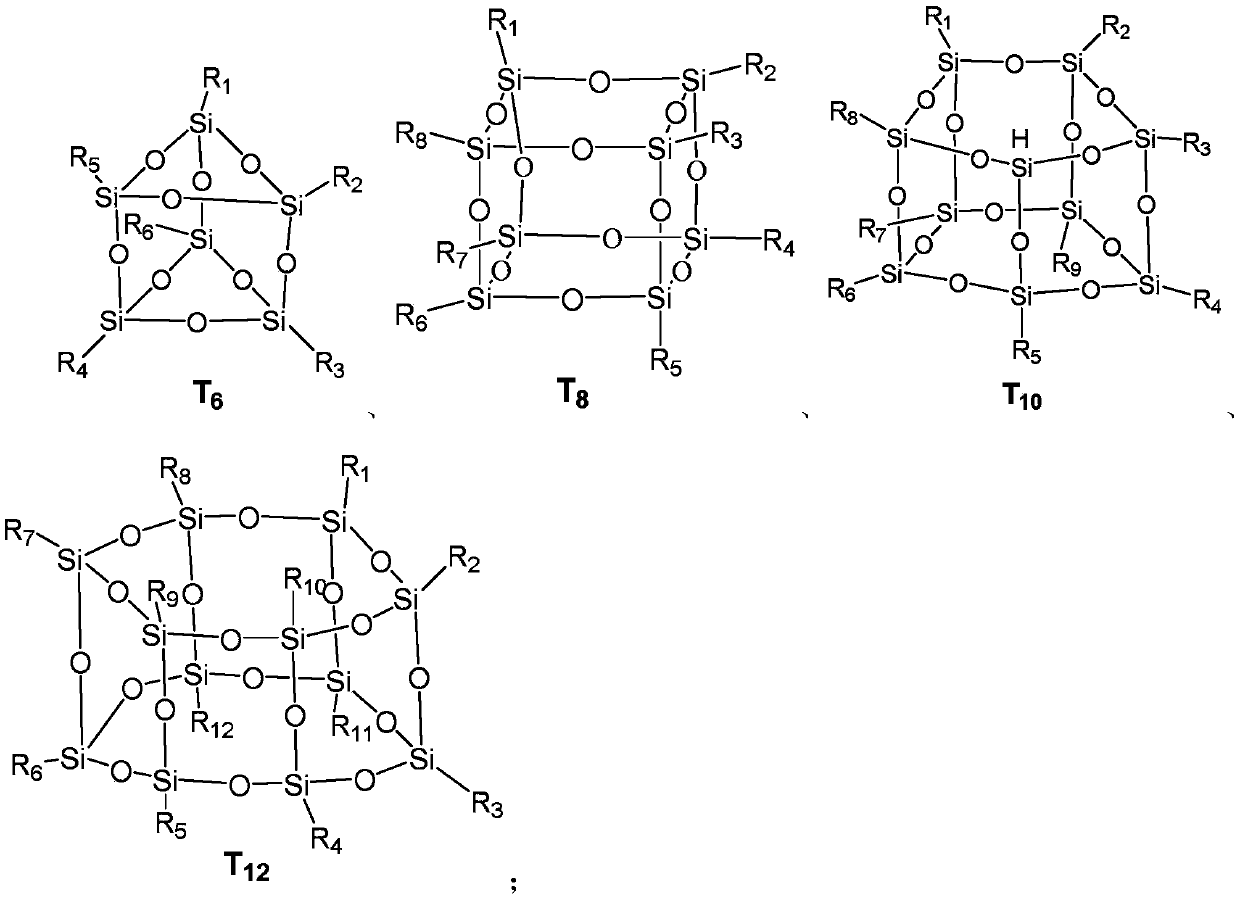

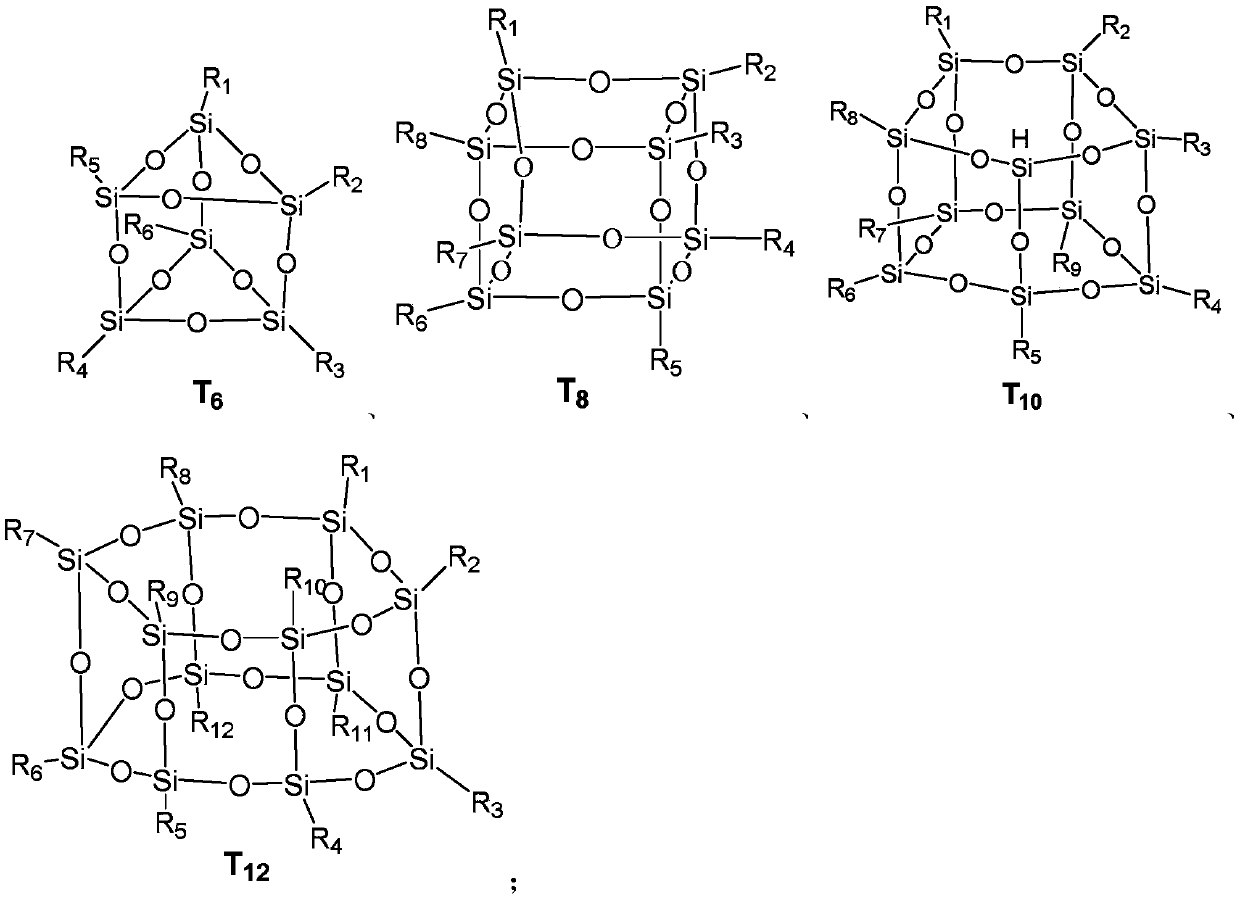

Method for improving volume resistivity of carbon fiber, modified carbon fiber and application of modified carbon fiber

The invention relates to a method for improving the volume resistivity of a carbon fiber, the modified carbon fiber and application of the carbon fiber. The method includes the following steps of firstly, oxidizing a carbon fiber base body to obtain a pre-oxidized carbon fiber; secondly, conducting grafting reaction on the pre-oxidized carbon fiber and a cage-shaped polysilsesquioxane compound with an active group to obtain the modified carbon fiber, wherein the active group includes arbitrary one of or the combination of at least two of an epoxy group, a vinyl group, an amino group, a sulfydryl group, a silanol group, a hydroxyl group and a carboxylic acid group, and the modified carbon fiber is used for insulating engineering plastic. Through the method, the modified carbon fiber with high volume resistivity and low dielectric constant can be obtained and can be applied in the insulating engineering plastic.

Owner:SHENZHEN HALCYON NEW MATERIALS

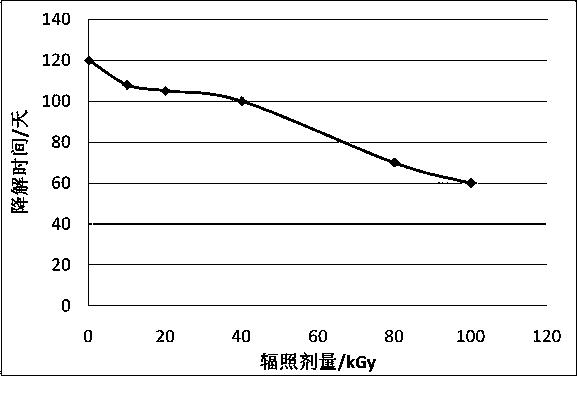

Preparation method for controllable biodegradable material

The invention discloses a preparation method for a controllable biodegradable material. The preparation method is characterized by comprising the following steps of: 1) starch radiation modification; 2) mixing: adding a nanometre assistant, polyvinyl alcohol, stearic acid, polylactic acid, a radiation sensitizer and an accelerant in the treated modified starch, adequately stirring, and uniformly mixing; 3) radiation copolymerization: placing the mixed sample in an aluminium foil bag carrying out packaging and sealing treatment in a vacuum or by charging nitrogen, and then carrying out radiation treatment on the packaged sample; 4) granulation / membrane preparation: uniformly pouring the mixture subjected to radiation copolymerization in a double-screw double-exhaust extrusion granulator group or a double-screw double-exhaust extrusion pelletizer group, and carrying out extrusion granulation or pelletizing; 5) radiation degradation rate control: radiating the product obtained by granulation / membrane preparation while controlling the dosage to be 10-100 kGy and controlling the dosage non-uniformity U of the product to be not greater than 1.3. According to the preparation method disclosed by the invention, the problems of cumbersome process, high-temperature energy consumption, and inevitably-brought pollutant discharge of a common chemical method are overcome, and the object of controlling the decomposition rate is realized.

Owner:赵永富

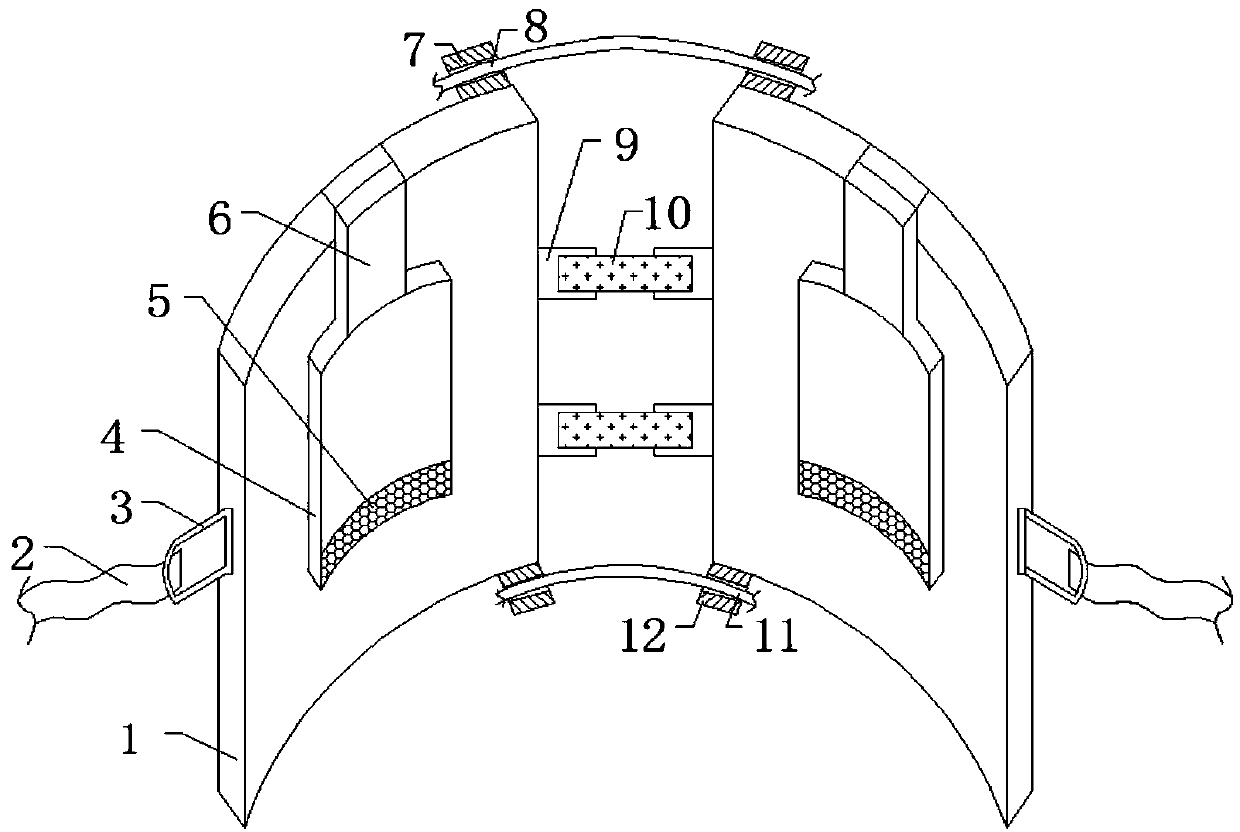

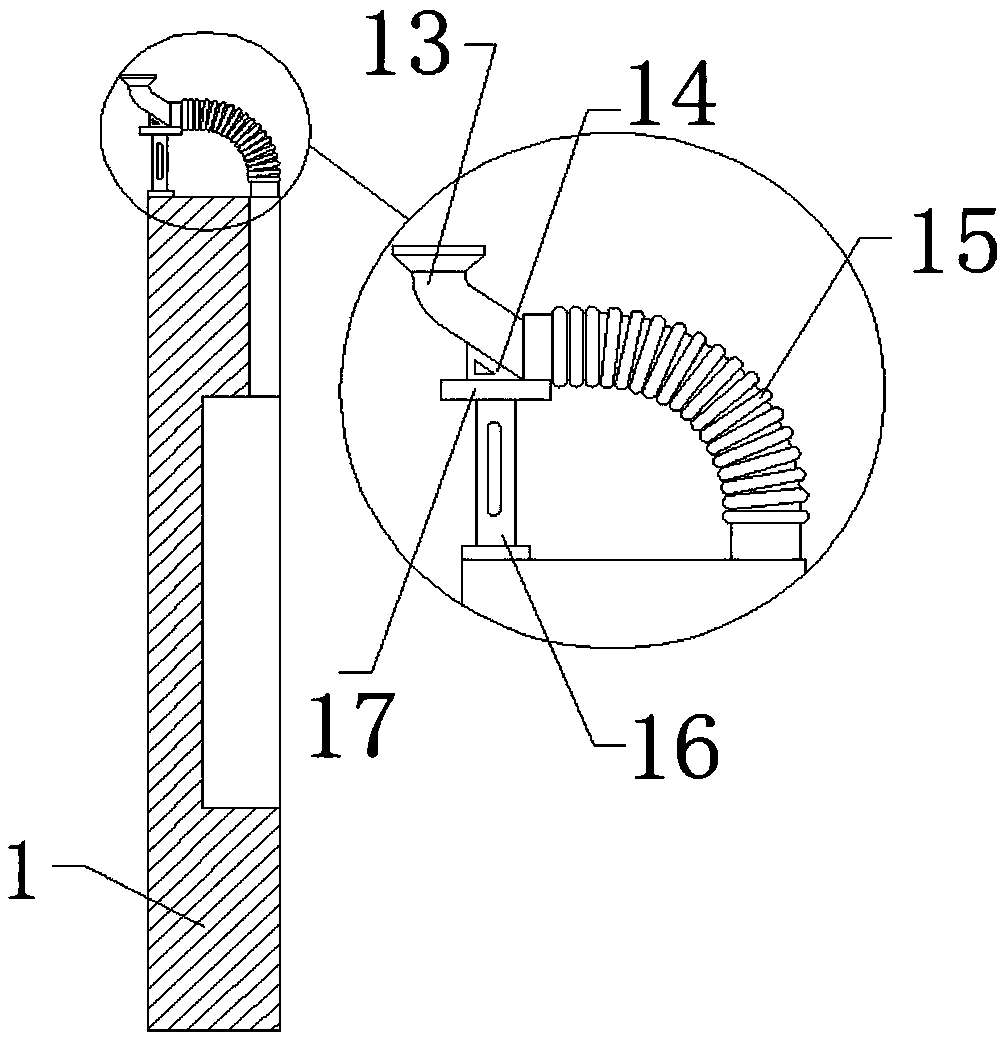

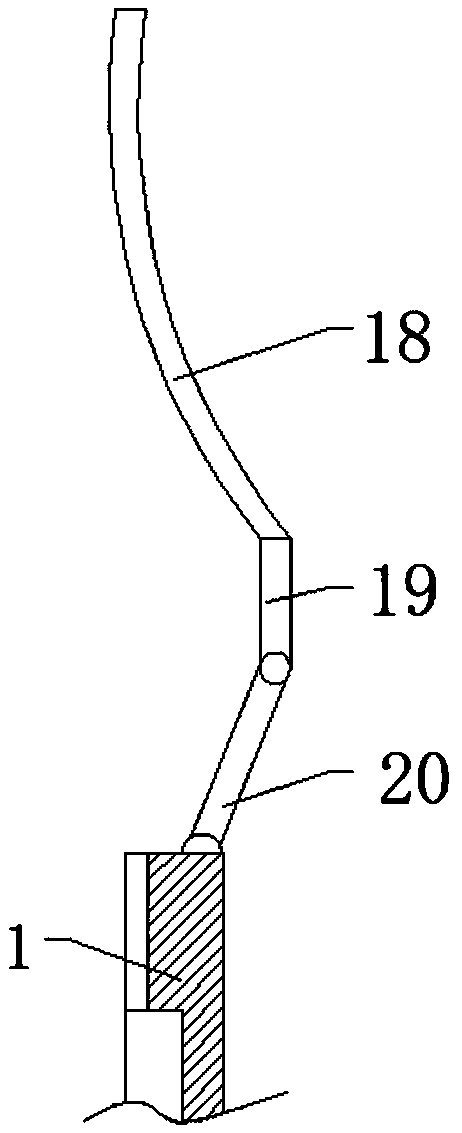

Grafting assistant device for apple tree planting

PendingCN109089586AImprove survival rateIncrease the scope of applicationGraftingHorticulture methodsEngineeringGrafting

The invention discloses a grafting assistant device for apple tree planting. The grafting assistant device comprises two clamping plates, a fixing ring is fixed on the outer wall of one side of each of the clamping plates through a bolt, a binding belt is socketed on the outer wall of one side of each fixing ring, a first fixing seat is fixed on one side of the top outer wall of each clamping plate through bolts, a first through hole is formed in the outer wall of one side of each first fixing seat, a same first iron wire is connected on the circumferential inner wall of each first through hole, and a second fixing seat is fixed on one side of the bottom outer wall of each clamping plate through bolts. The clamping plates are fixed more stably through constraining from the above, the middle and the below, convenience is brought to scion grafting, and the grafting assistant device is more fitted to an apple tree, so that survival rate is increased; length of a moving rod can be adjustedto suit branches different in thickness, development is accelerated, development period is shortened, the survival rate is increased, midway death is reduced, direct sunlight is avoided, convenienceis brought to protecting branches and leaves, and grafting success is ensured.

Owner:GUIYANG JINDUN SOUTH APPLE

Hybrid dynamic polymer containing reversible free radical type dynamic covalent bonds and application thereof

PendingCN111378183AVarious forms of activationWide activation temperature rangePolymer scienceThermal insulation

The invention discloses a hybrid dynamic polymer containing reversible free radical type dynamic covalent bonds. The hybrid dynamic polymer contains at least one reversible free radical type dynamic covalent bond and at least one hydrogen-bond interaction; based on dynamic reversible characteristics of reversible free radical type dynamic covalent bonds and hydrogen-bond interaction, the hybrid dynamic polymer material is endowed with good self-repairing performance, reprocessability, recoverability and the like, so that the hybrid dynamic polymer material is widely applied to self-repairing materials, ductile materials, shape memory materials, thermal insulation materials, toy materials, energy storage device materials, organic heat-sensitive materials, temperature sensing materials and the like.

Owner:厦门逍扬运动科技有限公司

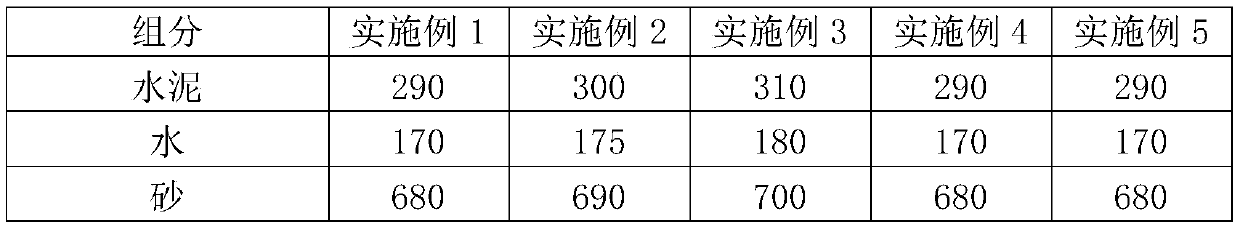

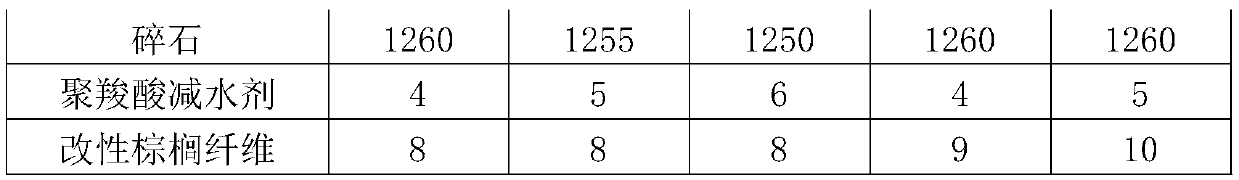

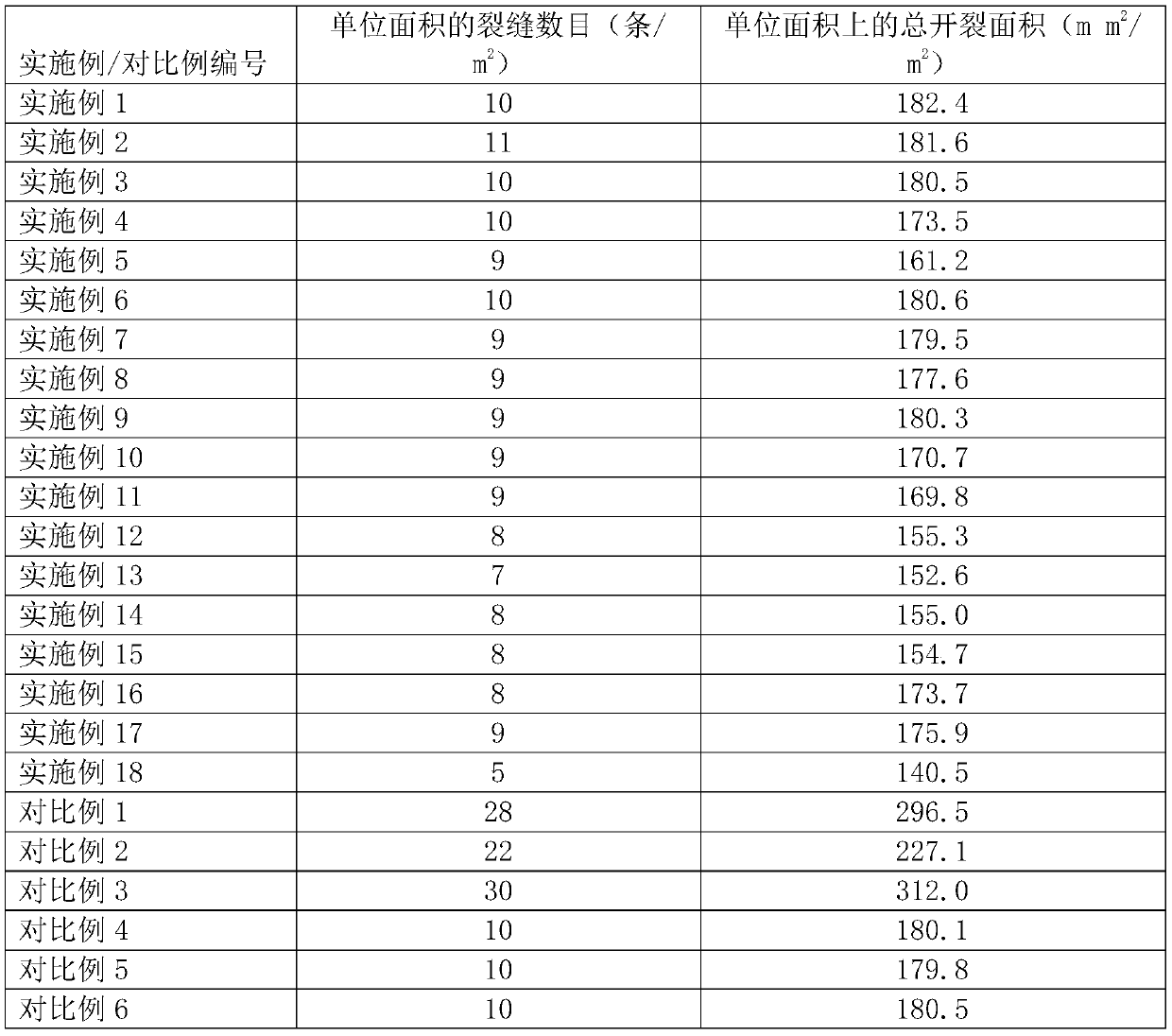

C30 concrete and production process thereof

InactiveCN111517731AImprove mechanical propertiesLarge specific surface areaSolid waste managementSuperplasticizerCarboxylic acid

The invention discloses C30 concrete and a production process thereof, belonging to the technical field of concrete. According to main points of a technical scheme in the invention, the C30 concrete comprises the following raw materials in parts by weight: 290 to 310 parts of cement, 170 to 180 parts of water, 680 to 700 parts of sand, 1250 to 1260 parts of broken stone, 4-6 parts of a polycarboxylate superplasticizer, and 8-10 parts of modified palm fiber. The C30 concrete has the advantage of being not prone to cracking.

Owner:陕西汇丰高性能粉体材料有限公司

Graphene modified epoxy resin material and preparation method thereof

The invention relates to a graphene modified epoxy resin material and a preparation method thereof.The preparation method comprises the steps that firstly, carboxylated graphene is obtained after graphene is acidized, a graphene grafted silane coupling agent and graphene doped epoxy resin are prepared from the carboxylated graphene, and the graphene doped epoxy resin and an inorganic nano filler are heated and mixed; and the graphene grafted silane coupling agent and a curing agent are added, uniformly stirred, and vacuum degassing treatment is carried out to finally obtain the modified epoxyresin material. The shrinkage rate of the epoxy resin in the curing process is effectively reduced by utilizing the large specific surface area of the graphene and the nano-size effect of the nano inorganic filler, and the graphene of the layered structure is doped in the epoxy resin, so that the resin and the filler are mixed more sufficiently; in the curing process, the silane coupling agent grafted and modified by graphene participates in epoxy resin copolymerization, so that the structural stability of the resin material is improved, peeling or cracking caused by resin expansion at high temperature is avoided, and the bonding strength and the heat-resistant stability of the resin material are effectively improved.

Owner:YANGZHOU POLYTECHNIC INST

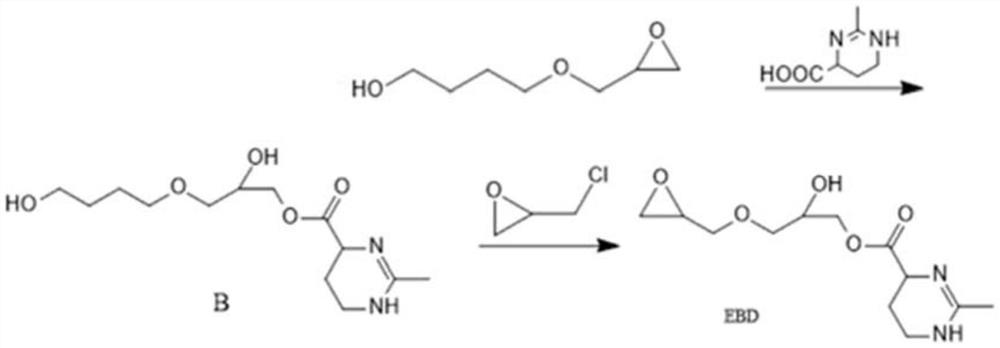

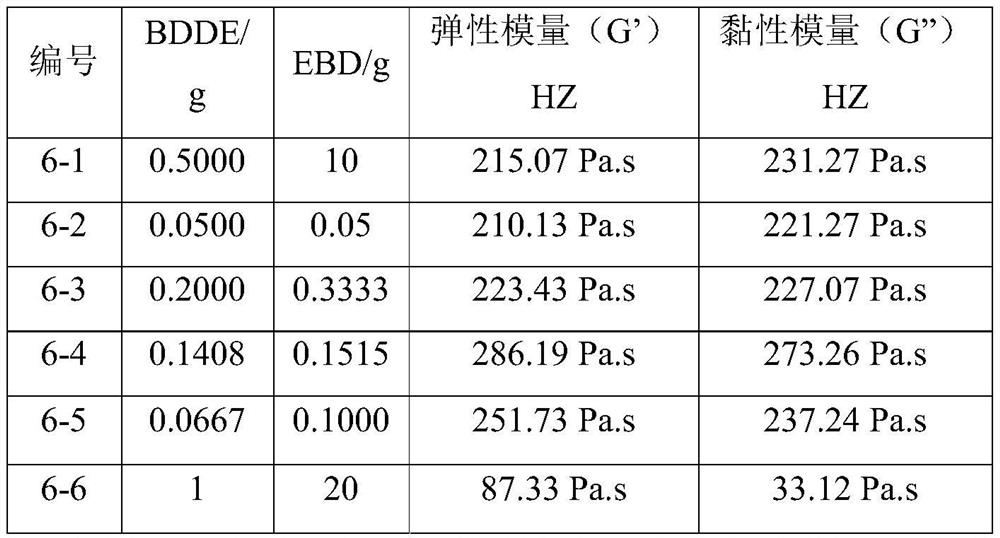

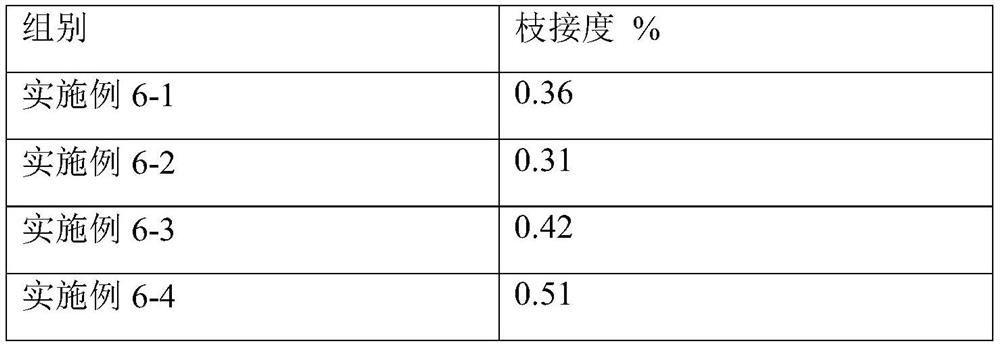

Preparation method of ectoin-hyaluronic acid composite gel and obtained product

ActiveCN112480483AImprove the degree of graftingImprove immune defenseOrganic chemistrySurgeryBiomedical engineeringSkin repair

The invention discloses a preparation method of ectoin-hyaluronic acid composite gel and an obtained product. The preparation method comprises the following steps: firstly, preparing a cross-linking agent EBD by a step-by-step method; then, subjecting the EBD and BDDE, used as mixed cross-linking agents, to a cross-linking reaction with hyaluronic acid or salt thereof to prepare cross-linked hyaluronic acid gel, adding free epsilon-polyine to the cross-linked hyaluronic acid gel again, and mixing the components to prepare the ectoin-hyaluronic acid composite gel. The composite gel provided bythe invention contains free and cross-linked ectoin, not only has a filling effect, but also can achieve anti-aging and skin repair and regeneration effects in the whole hyaluronic acid gel filling period through the matching of the two forms of ectoin; in addition, the product, as a viscoelastic agent for adjuvant therapy in glaucoma surgery, lacrimal passage occlusion surgery, vitrectomy and other surgeries, has higher potential and effect.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

High-temperature-resistant medical gloves

InactiveCN109456526AEasy to makeIncrease elasticityGlovesBulk chemical productionLow-density polyethyleneNano catalyst

The invention relates to the technical field of medical appliances, and discloses high-temperature-resistant medical gloves, which are prepared from 52-54 parts of low-density polyethylene, 33-35 parts of epoxy resin, 27-29 parts of polyvinyl alcohol, 6-8 parts of sodium polyacrylate, 7-9 parts of nanometer titania, and 11-13 parts of egg-shell type nano-catalyst. The high-temperature-resistant medical gloves are easy to prepare, high in high temperature resistance performance and capable of being reused, and accordingly can save a great amount of medical cost and reduce pollution to environment. As modified low-density polyethylene and epoxy resin are mixed and then heated and molten rapidly, grafting between the modified low-density polyethylene and epoxy resin is improved, stability andheat resistance of raw materials are improved, the gloves can bear repeated high-temperature sterilization, and durability of the gloves is improved. Further, with adding of heated sodium polyacrylate and nanometer titania for grafting based on full stirring, film formation property and wear resistance property of the raw materials are improved, and the shaped gloves have smooth surface, and accordingly are not easy to be broken by scraping or be infected crossly by germs.

Owner:安徽一升医疗设备有限公司

Method for preparing super-hydrophobic surfaces

ActiveCN105648770ALong-lasting superhydrophobic effectStable super hydrophobic performanceUltrasonic/sonic fibre treatmentLiquid repellent fibresWeather resistanceMetallurgy

The invention discloses a method for preparing super-hydrophobic surfaces. The method includes steps of 1), pre-treating stock solution, to be more specific, injecting the stock solution into a pipeline and preheating the stock solution under the condition of the temperatures of 80-150 DEG C to vaporize the stock solution; 2), carrying out plasma treatment on the surfaces of base materials in the atmosphere of inert gas; 3), carrying out grafting treatment, to be more specific, uniformly spraying the stock solution on the surfaces of the base materials in a mist spray manner, and simultaneously carrying out plasma treatment on the surfaces of the base materials to form super-hydrophobic layers with nano-structures on the surfaces of the base materials. The method for preparing the super-hydrophobic surfaces has the advantages that the method is simple and is high in operability, and the super-hydrophobic surfaces prepared by the aid of the method are good in weather resistance, high in mechanical strength and long in service life.

Owner:GUANGZHOU BIOFIL AIR PURIFICATION MATERIAL CO LTD

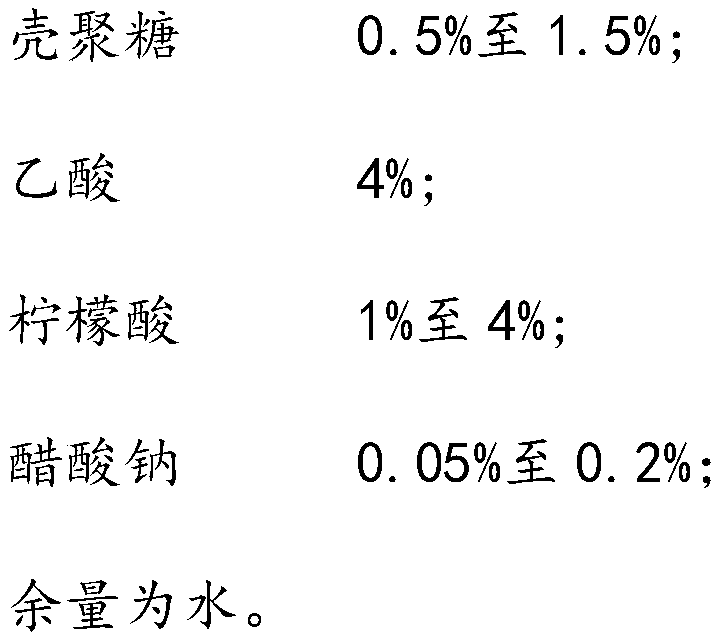

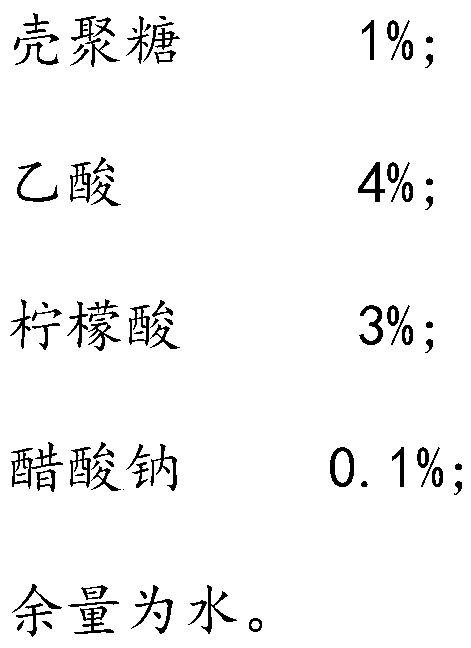

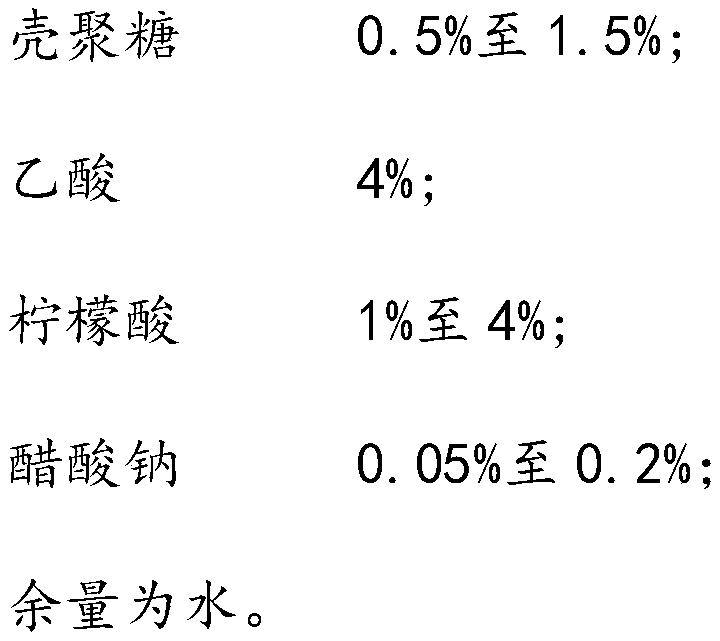

Method of improving water absorption of chenille blanket

ActiveCN109736074ASmall molecular weightEvenly distributedPhysical treatmentFibre typesFiberAntibacterial property

The invention discloses a method of improving water absorption of a chenille blanket. The method comprises the following steps: S1, immersing a to-be-treated chenille blanket in an alkali solution, and cleaning and drying coarse fiber surfaces for later use; S2, puncturing the chenille blanket, wherein liquid penetrating holes are formed in base cloth and fluff of the chenille blanket; S3, spraying a nano titanium dioxide suspension to the chenille blanket treated in the S2; S4, preparing a treatment solution, wherein chitosan is uniformly dissolved in the treatment solution; and spraying thetreatment solution to the surface of the chenille blanket treated in the S3 under ultraviolet radiation; and S5, rolling the chenille blanket to uniform the treatment solution in the chenille blanket;and then drying, cleaning and spin-drying the chenille blanket to obtain an expected product. The method is environment-friendly and feasible. The prepared chenille blanket is fluffy, has good wateradsorption and has a certain antibacterial property.

Owner:JINHUA JIELING HOUSE WARES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com