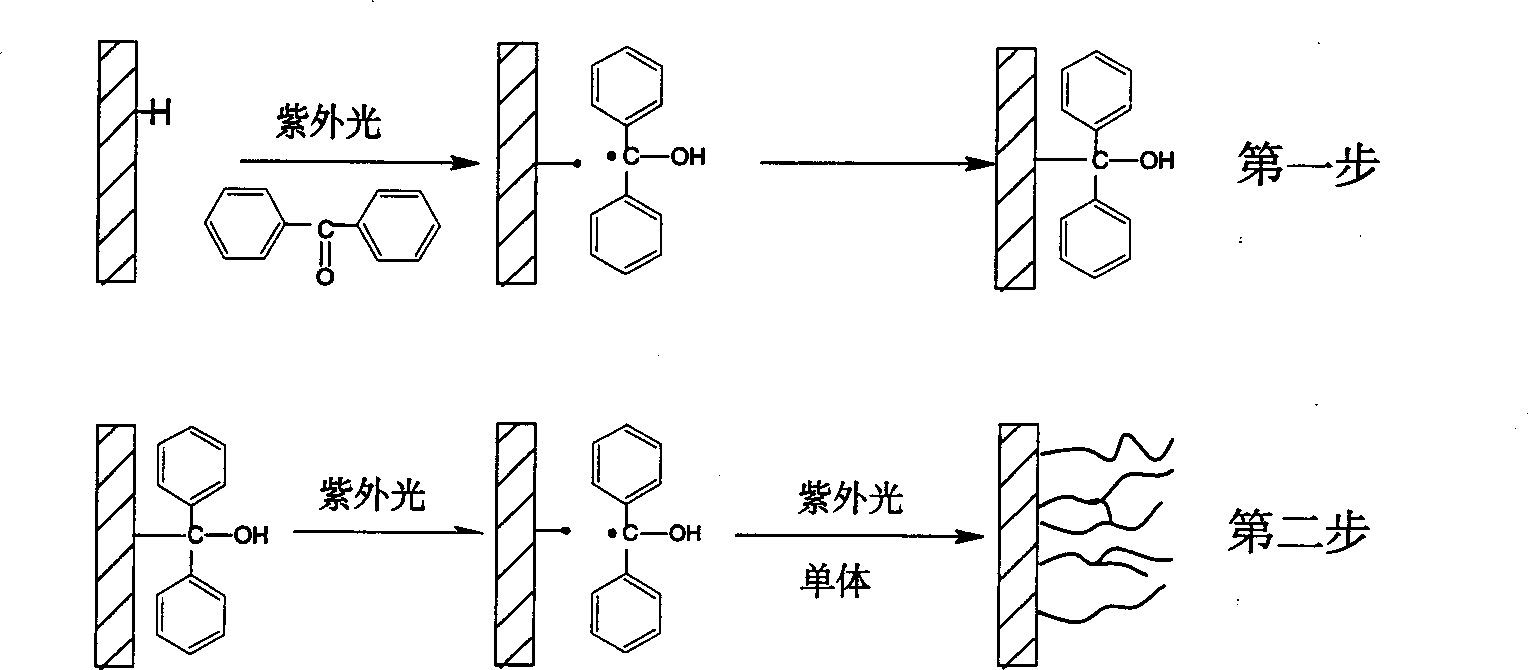

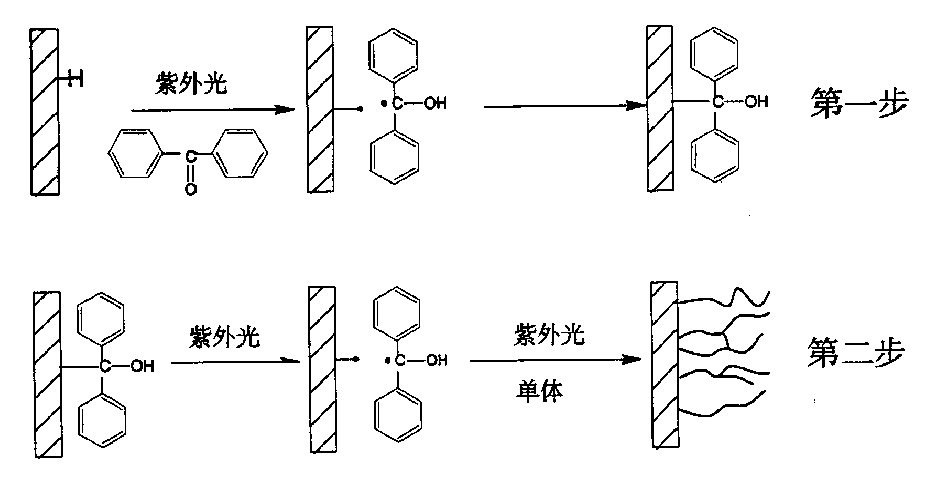

Process for preparing high-water-absorption flexible material by ultraviolet surface graft method

A super absorbent material and surface grafting technology, applied in the field of polymer materials, can solve problems such as uniformity and difficulty in coating, and achieve the effects of promoting grafting, short reaction time, and simple and easy reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Rinse the polypropylene homopolymer film with acetone, dry it in the air to constant weight, put it into the reactor, and cut the polypropylene homopolymer film into 4×2cm 2 , the thickness is 0.05mm. Add 2ml of benzene solution of photosensitizer benzophenone with a mass percentage of 25% on the polypropylene film at the bottom of the reactor. The distance is 35cm, and the nitrogen flow rate is 25L / h. Extract the reacted polypropylene film with acetone, air-dry to constant weight, and spread it on the bottom of the reactor after weighing.

[0019] Add 0.5 times the volume of deionized water to acrylic acid, partially neutralize it with sodium hydroxide, prepare an acrylic acid solution with a neutralization degree of 50%, add a certain amount of acrylamide, so that the molar ratio of acrylamide and acrylic acid is 1 : 3. The photosensitizer benzophenone was added to saturate the solution with benzophenone. Pass the prepared acrylic acid and acrylamide solution thro...

Embodiment 2

[0021] The polypropylene film homopolymer is soaked with acetone, dried in a vacuum oven to constant weight, put into the reactor, and the polypropylene homopolymer film is cut into 4×2cm 2 , the thickness is 0.1mm. Add 4ml of benzene solution of photosensitizer benzophenone with 20% mass percentage on the polypropylene film at the bottom of the reactor, seal the reactor, feed nitrogen and graft it with ultraviolet light for 3min, the distance between the lamp tube and the sample The distance is 30cm, and the nitrogen flow rate is 20L / h. Extract the reacted polypropylene film with acetone, dry it in a vacuum oven to constant weight, and spread it on the bottom of the reactor after weighing.

[0022] Add deionized water 1 times its volume to acrylic acid, partially neutralize it with sodium hydroxide, prepare an acrylic acid solution with a neutralization degree of 60%, add a certain amount of acrylamide, so that the molar ratio of acrylamide and acrylic acid is 1 : 4. The p...

Embodiment 3

[0024] Rinse the polypropylene copolymer film with methanol, dry it in the air to constant weight, put it into the reactor, and cut the polypropylene copolymer film into 4×2cm 2 , the thickness is 0.2mm. Add the benzene solution of 15% photosensitizer xanthone to the polypropylene film at the bottom of the reactor by adding 4ml of mass percentage of prepared 4ml on the polypropylene film at the bottom of the reactor. The distance is 25cm, and the nitrogen flow rate is 15L / h. Extract the reacted polypropylene film with methanol, air-dry to constant weight, and spread it on the bottom of the reactor after weighing.

[0025] Add deionized water three times its volume to acrylic acid, partially neutralize it with sodium hydroxide, prepare an acrylic acid solution with a neutralization degree of 65%, add a certain amount of acrylamide, so that the molar ratio of acrylamide and acrylic acid is 1 : 5. The photosensitizer xanthone is added so that the mole percentage of the photose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com