Anticoagulant polyurethane material, and preparation and usage thereof

A polyurethane material and anti-coagulation technology, applied in anti-coagulation treatment, transportation and packaging, types of packaging items, etc., can solve the problems of endangering patient safety, unsatisfactory anti-coagulation performance, etc., to eliminate thrombosis, Solve blood compatibility problems, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] 2. Preparation method of anticoagulant polyurethane material

[0025] 1. Preparation:

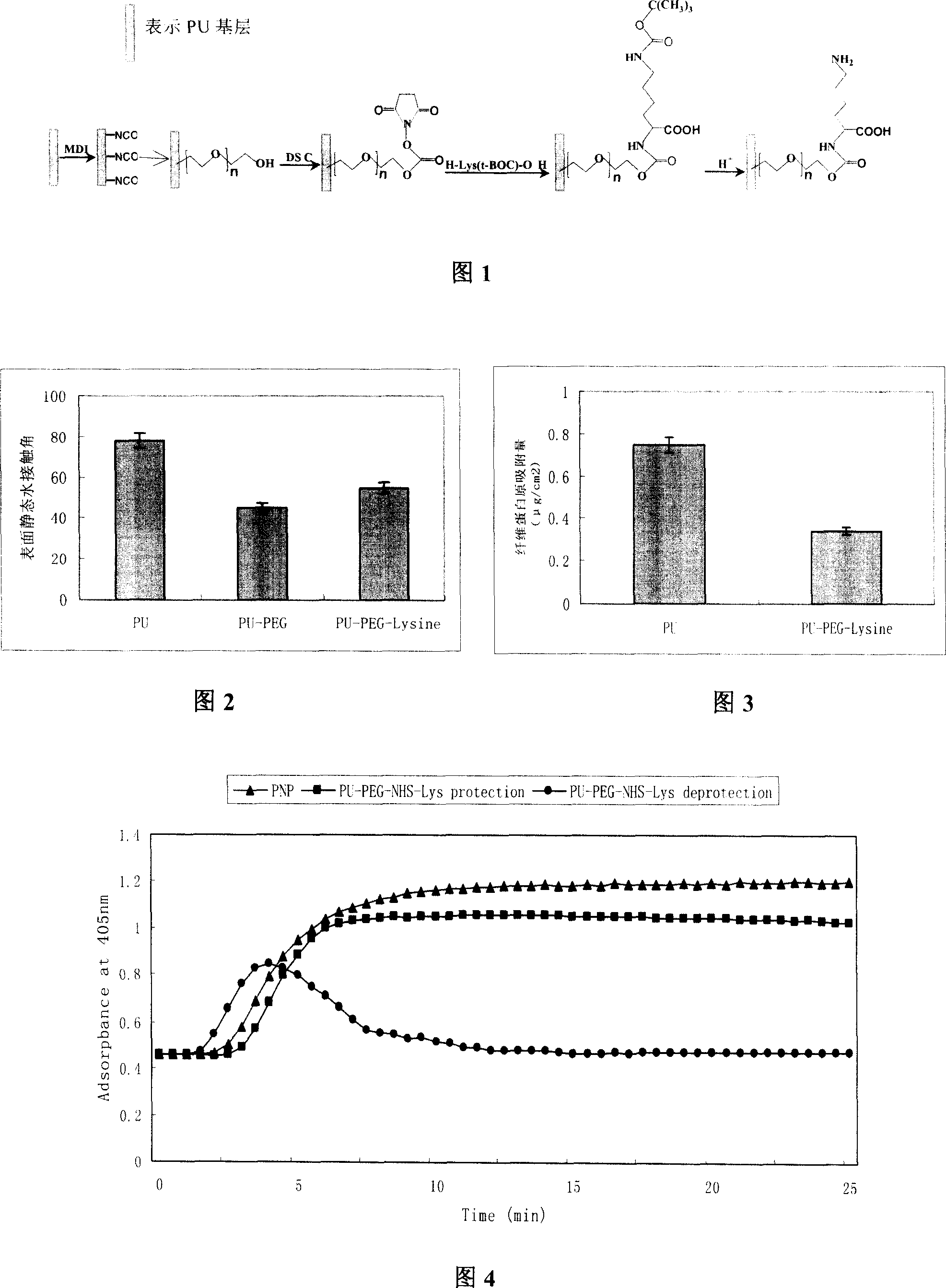

[0026] Through chemical modification method, first graft polyethylene glycol flexible spacer with active groups on the surface of the base layer in a covalent way to make it have anticoagulant function; then use the functional groups on polyethylene glycol and DSC The reaction is carried out to generate a lively reactive group NHS, and then the biologically active substance lysine is grafted on the surface of the NHS to activate the fibrinolytic pathway, so that it has the function of dissolving thrombus, thereby forming a modified layer. The base layer is made of common commercial polyurethane material or synthetic polyurethane material. The base layer and finishing layer constitute an anti-clotting polyurethane material.

[0027] See Figure 1, the specific steps include: functionalization of PU material with MDI, surface grafting of PEG, introduction of NHS active reactive groups...

Embodiment 1

[0042] First, dissolve the purified granular commercial polyurethane material (product of Shanghai Pengbosheng Polyurethane Co., Ltd.) in N, N-dimethylformamide (DMF), pour it into a flat-bottomed mold, and vacuum dry it after the solvent evaporates. To obtain the PU film, cut the PU film into small pieces with a diameter of 10 mm and a thickness of 0.5 mm, put it into a toluene solution of 5% MDI by mass ratio, stir and heat to 50 ° C, and then pass through N 2 Protection, triethylamine (TEA) according to mass ratio M TEA / M Toluene =2.5% was added to the reaction system, and the reaction was started after mixing evenly. After 60 minutes, it was washed several times with dry toluene. Put the above-mentioned functionalized PU film into the toluene solution of polyethylene glycol with a mass ratio of 10%, add 2 drops of dibutyloctyltin laurate as a catalyst, heat to 40°C for reaction under stirring, and use it after 24 hours Wash with distilled water several times, then soak ...

Embodiment 2

[0044] Add a magnet in the there-necked flask, weigh 5 grams of polytetrahydrofuran ether glycol (molecular weight is 1000), 5 grams of toluene, and measure 25 mL of DMF, then heat it to 110 ° C with a constant temperature magnetic stirrer and keep it warm for 1 hour. Parts were removed as a toluene azeotrope. Then, its temperature is controlled at 60°C to 65°C, and 3 drops (0.05wt%) of catalyst dibutyltin dilaurate are added dropwise to the there-necked flask with a dropper, and then the weighed 4.0 grams of MDI and the measured 25mL of DMF mixed solution was added into the reaction three-neck flask, and the temperature was controlled at this temperature range for 1.5 hours. Then slowly add 0.9 g of chain extender 1,4-butanediol into the three-necked flask with a dropper, raise the temperature to 80-85° C., and control the temperature to react for 3.5 hours. Then pour the reaction solution in the three-neck bottle into the prepared large beaker filled with distilled water al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com