C30 concrete and production process thereof

A technology of concrete and palm fiber, applied in the field of concrete, can solve the problems of easy cracking and reduced interface adhesion, and achieve the effects of not easy cracking, enhanced bonding force, and increased specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

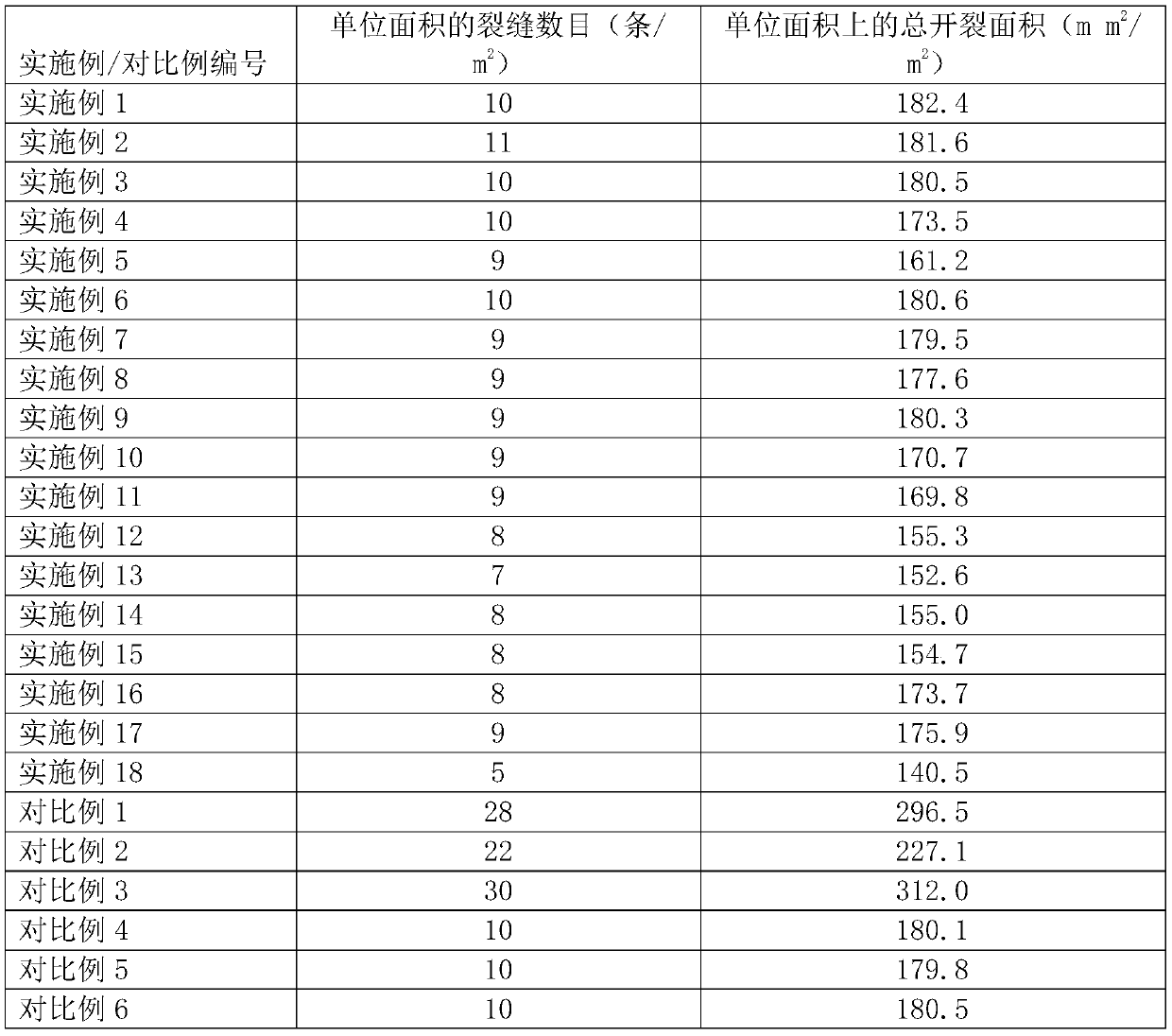

Examples

Embodiment 1

[0038] Embodiment 1: A kind of C30 concrete, the components of its raw materials and their corresponding parts by weight are shown in Table 1. Wherein, the cement is ordinary Portland cement, and the polycarboxylate water reducer is a commercially available polycarboxylate water reducer,

[0039] The preparation method of modified palm fiber is as follows: take off 15 parts of reticular palm fiber from the periphery of palm tree bar, dry after washing with water, extract single palm fiber, the length of single palm fiber is 20-30cm, in this In the embodiment, it is 20cm. Add sodium hydroxide and non-ionic fluorocarbon surfactant into water, immerse the palm fiber, mix and stir evenly to obtain a modified liquid, add palm fiber to the modified liquid, heat up to 90°C, and process After 20 minutes, filter to obtain palm fiber, rinse with water, and dry at 120° C. for 20 minutes to obtain modified palm fiber.

[0040] The weight percentage of sodium hydroxide, non-ionic fluorocarb...

Embodiment 2-5

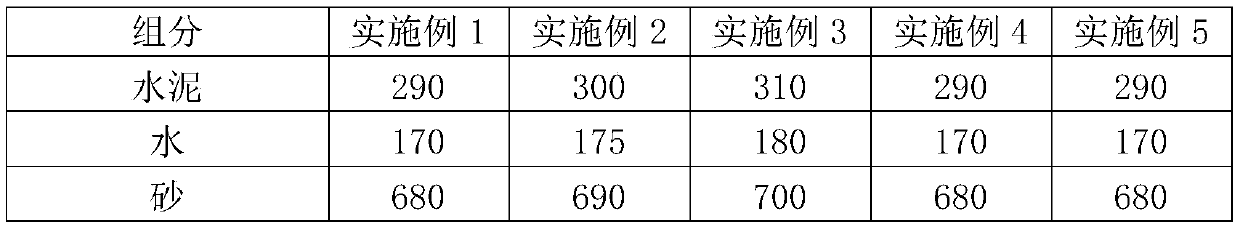

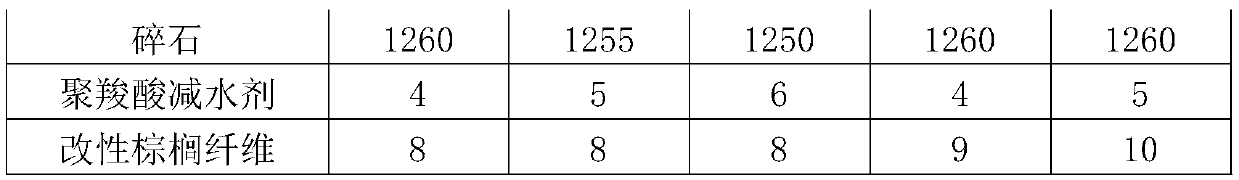

[0042] Example 2-5: A C30 concrete, the difference from Example 1 is that the components of the raw materials and their parts by weight are shown in Table 1.

[0043] Each component of raw material and parts by weight thereof in table 1 embodiment 1-5

[0044]

[0045]

Embodiment 6

[0046] Embodiment 6: a kind of C30 concrete, the difference with embodiment 1 is that the preparation method of modified palm fiber is as follows: remove 20 parts of reticular palm fiber from the palm tree bar periphery, dry after washing with water, Take out a single palm fiber, add sodium hydroxide and non-ionic fluorocarbon surfactant into water, immerse the palm fiber, mix and stir evenly to obtain a modified solution, add the palm fiber to the modified solution, raise the temperature to 100°C, and process After 10 minutes, the palm fiber was obtained by filtering, washed with water, and dried at 130° C. for 10 minutes to obtain the modified palm fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com