Crosslinkable fluorosilicone resin, painting and super-amphiphobic coating prepared by same

A technology of fluorosilicone resin and coating, applied in the field of super-amphiphobic materials, can solve the problems of poor durability and friction resistance of super-amphiphobic coatings, narrow application areas, toxic organic solvents, etc., and achieve improved roughness and good surface energy , the effect of strong cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Preparation of cross-linkable fluorosilicone resin: Mix hydrogen-containing silicone A, cross-linkable substance B, fluorine-containing substance C, and modified silica D in solvent E, and add it to the reaction kettle. Inert gas was introduced, then the stirring speed was kept at 100 rpm, the temperature was raised to 60 degrees Celsius, and catalyst F was added. Stirring was maintained for up to 5 hours. Then the reactant is precipitated into n-hexane or methanol to obtain a cross-linkable fluorosilicone resin. Among them, the mass ratio of hydrogen-containing silicone A, cross-linkable substance B, fluorine-containing substance C, modified silica D, catalyst F and solvent E is: 1:0.5:0.5:0.1:0.00001:1;

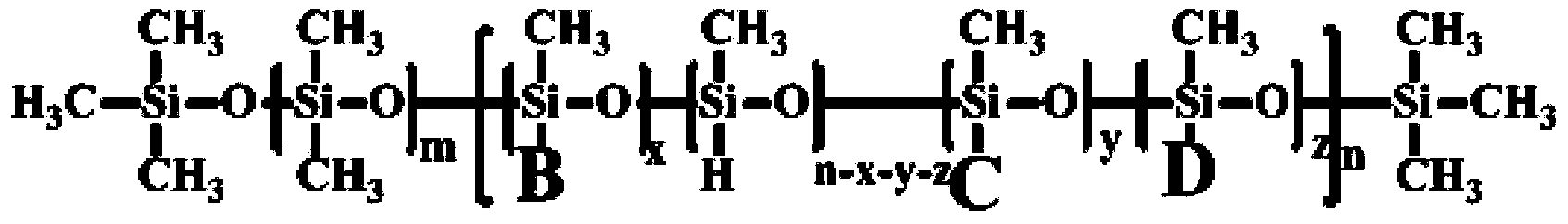

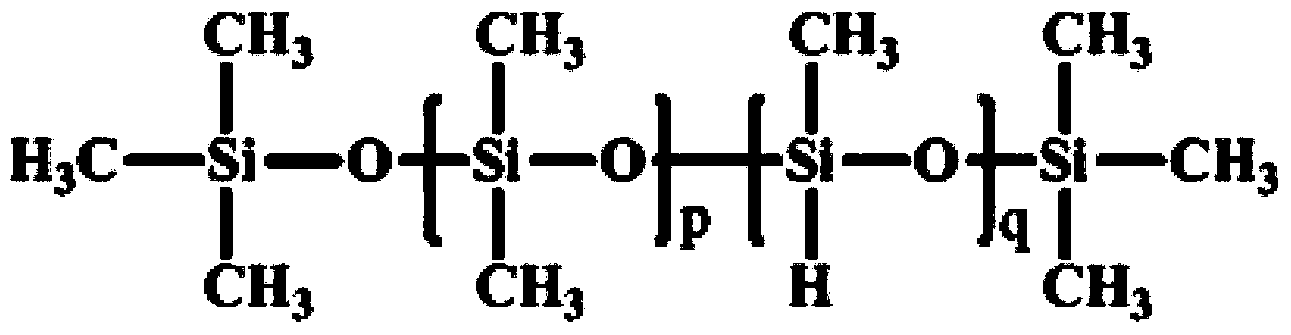

[0052] The hydrogen-containing silicone A has the hydrogen-containing silicone oil of the following structural formula:

[0053] where p=10; q=800;

[0054] The cross-linkable substance B is glycidyl methacrylate (GMA);

[0055] The fluorine-containing mono...

Embodiment 2

[0064] (1) Preparation of cross-linkable fluorosilicone resin: Mix hydrogen-containing silicone A, cross-linkable substance B, fluorine-containing substance C, and modified silica D in solvent E, and add it to the reaction kettle. Pass in an inert gas, then keep the stirring speed at 500 rpm, raise the temperature to 100 degrees Celsius, then add catalyst F, keep stirring for 5 hours; then precipitate the reactant into n-hexane or methanol to obtain a cross-linkable fluorosilicone resin. Among them, the mass ratio of hydrogen-containing silicone A, cross-linkable substance B, fluorine-containing substance C, modified silica D, catalyst F and solvent E is: 1:20:50:2:0.0001:100;

[0065] The hydrogen-containing silicone A has the following structural formula:

[0066] where p=100; q=5000;

[0067] The cross-linkable substance B is propenyl glycidyl ether (AGE);

[0068] The fluorine-containing monomer C is heptadecafluoroethyl methacrylate;

[0069] The catalyst F is chloro...

Embodiment 3

[0077] (1) Preparation of crosslinkable fluorosilicone resin: Mix hydrogen-containing silicone A, crosslinkable substance B, fluorine-containing substance C and modified silica D in solvent E, add to the reaction kettle, and pass Inject an inert gas, then keep the stirring speed at 1000rpm, raise the temperature to 60 degrees Celsius, then add catalyst F, keep stirring for 5 hours; then precipitate the reactant into n-hexane or methanol to obtain the required crosslinkable fluorosilicone resin. Among them, the mass ratio of hydrogen-containing silicone A, cross-linkable substance B, fluorine-containing substance C, modified silica D, catalyst F and solvent E is: 1:10:20:1:0.00008:80;

[0078] The hydrogen-containing silicone A has the following structural formula:

[0079] where p=30; q=1000;

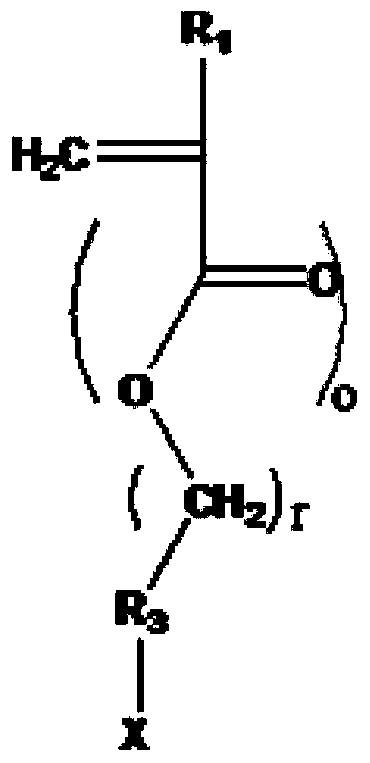

[0080] The cross-linkable substance B is polyglycidyl methacrylate (PGMA) containing alkyne at the end, and its structural formula is:

[0081] t is 1000;

[0082] The structura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com