Paint used for cosmetic packaging bottles, and preparation method and coating technology thereof

A technology for packaging bottles and cosmetics, applied in the direction of antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of cosmetic pollution, low barrier properties of coatings, and poor effective antibacterial ability, so as to improve the attachment Strong force, excellent surface energy, and good antibacterial durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

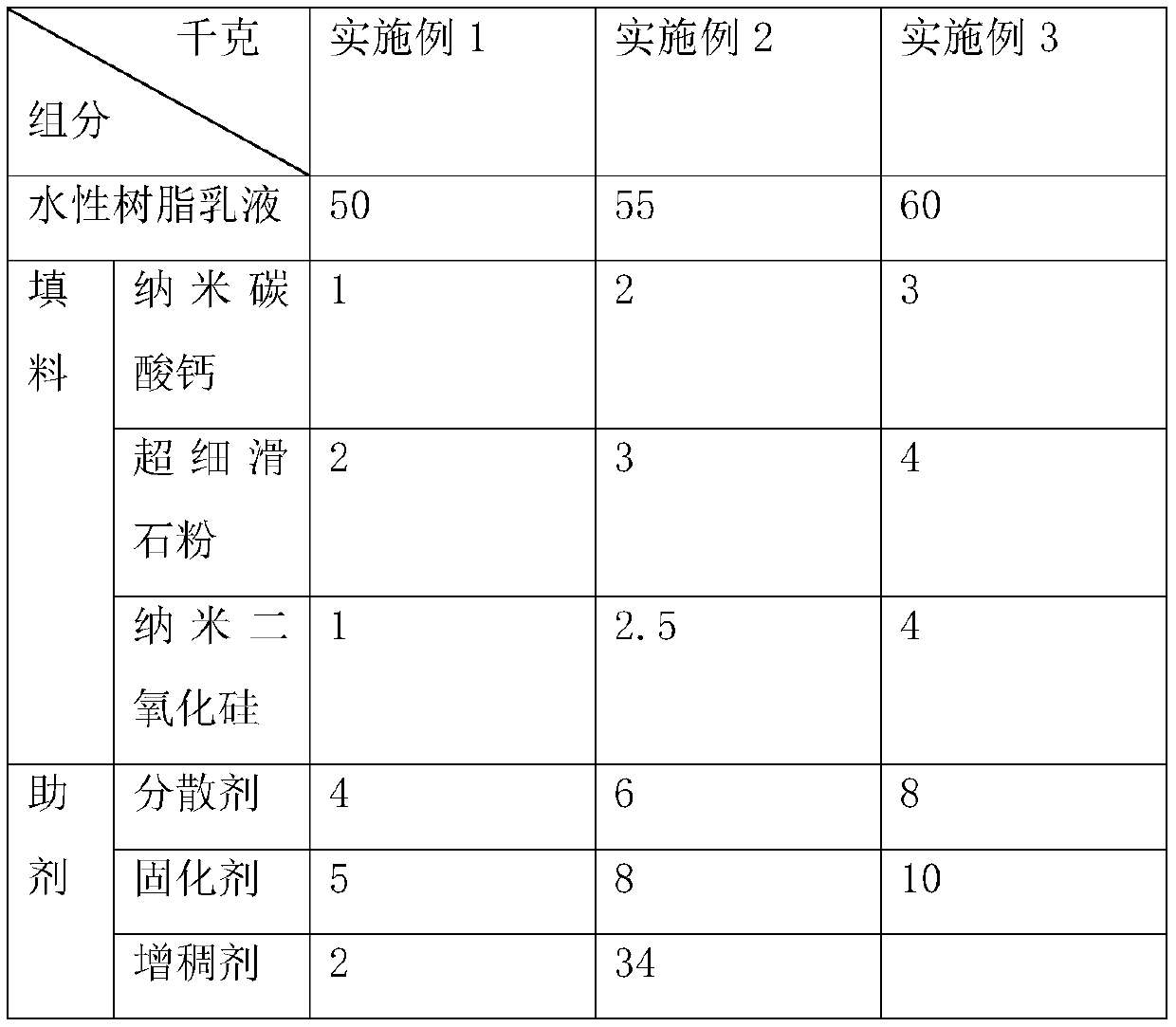

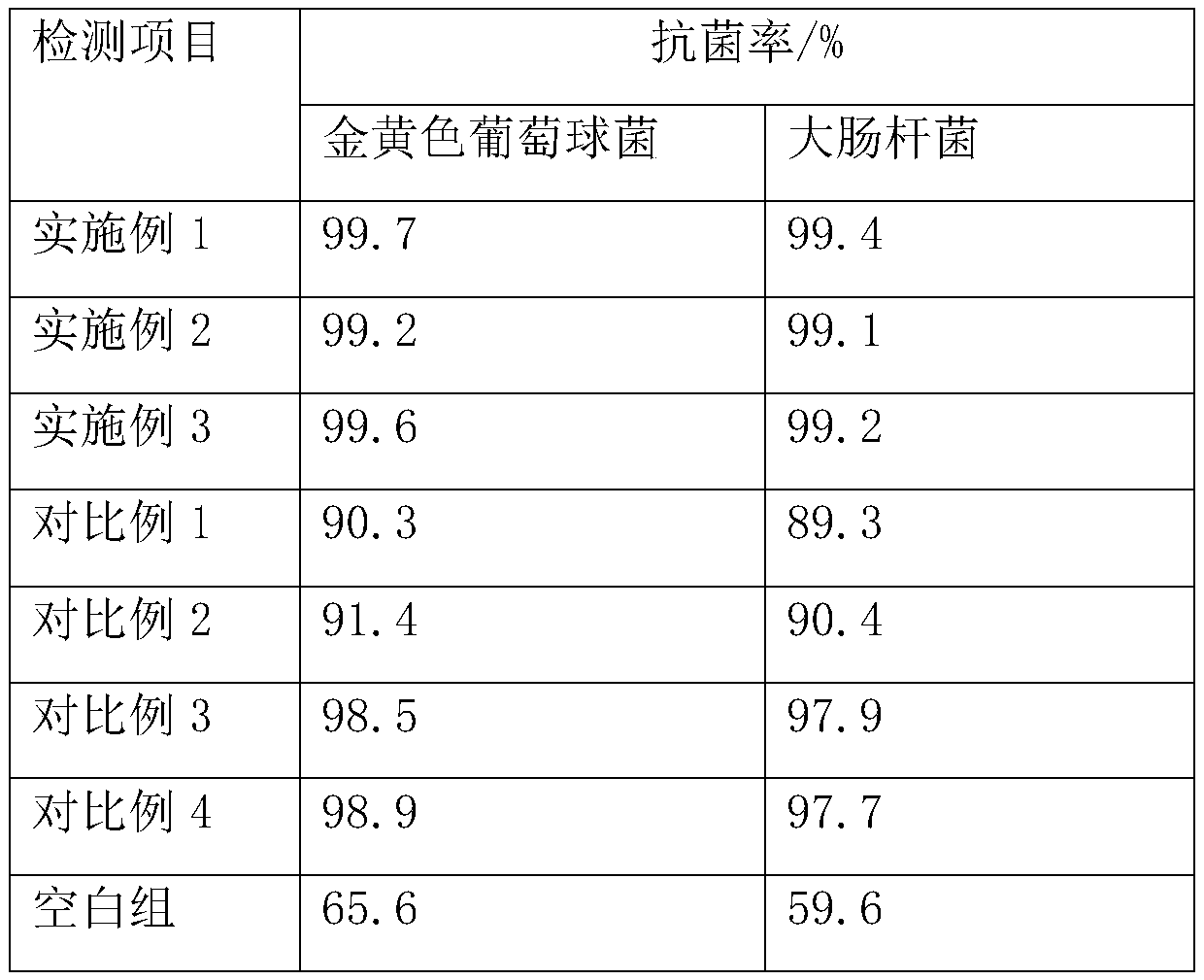

Examples

preparation example 1-3

[0042] In the preparation example 1-3, the epoxy resin emulsion is selected from the epoxy resin emulsion of QG-627 sold by Wuxi Qianguang Chemical Raw Materials Co., Ltd., and the lotus leaf hydrophobic agent is selected from the model sold by Shanghai Weipu Chemical Technology Service Co., Ltd. The lotus leaf hydrophobic agent of W-964, chitosan is selected from the chitosan sold by Henan Longwei Biotechnology Co., Ltd., the product number is LW104, and the silver-loaded zeolite is selected from the model sold by Gongyi Elman Water Purification Material Co., Ltd. The silver-loaded zeolite of AEM-01, eucalyptus oil is selected from the eucalyptus oil of 102 sold by Jiangsu Fushengde Biological Engineering Co., Ltd., and the lemon oil is selected from the lemon oil of TC1901 sold by Jiangxi Taicheng Natural Perfume Co., Ltd. Tamarind gum is selected from the tamarind gum sold by Wuhan Shengruiyuan Biotechnology Co., Ltd. with the item number of 698.

preparation example 1

[0043] Preparation Example 1: Preheat 20kg of epoxy resin emulsion to 40°C, add 2kg of lotus leaf hydrophobic agent, 1kg of chitosan and 5kg of antibacterial liquid, after mixing evenly, add 3kg of film-forming aid, stir evenly, and cool to room temperature to prepare Obtain barrier type antibacterial agent, film-forming aid comprises 3kg terpineol, 3kg propylene glycol and 6kg tamarind gum, and antibacterial liquid is mixed by the silver-loaded zeolite, eucalyptus oil and lemon oil of 1:0.5:0.6 by mass ratio, grinds to Made with particle size ≤1μm.

preparation example 2

[0044] Preparation Example 2: Preheat 25kg of epoxy resin emulsion to 45°C, add 3kg of lotus leaf hydrophobic agent, 2kg of chitosan and 8kg of antibacterial liquid, after mixing evenly, add 4kg of film-forming aid, stir evenly, and cool to room temperature to prepare Obtain barrier type antibacterial agent, film-forming aid comprises 4kg terpineol, 4kg propylene glycol and 8kg tamarind gum, and antibacterial liquid is mixed by the silver-loaded zeolite of 1:0.7:0.8, eucalyptus oil and lemon oil by mass ratio, grinds to Made with particle size ≤1μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com