Method for preparing grafting polyvinylidene fluoride on graphene oxide

A polyvinylidene fluoride and vinylidene fluoride technology, applied in the field of materials, can solve the problems of poor compatibility and low flexibility, and achieve the effects of good thermal stability, high tensile strength and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of graphene oxide grafted polyvinylidene fluoride includes the following steps:

[0035] 1) Preparation of graphene oxide using improved Hummer’s method

[0036] Under ice water bath conditions, 3g graphite powder, 15g KMnO 4 Add 115mL of concentrated H with a mass concentration of 98% 2 SO 4 Stir in a beaker, heat to 45°C, and stop the reaction after 12 hours; under ice-water bath conditions, pour the reaction product into a large beaker containing 200 mL of distilled water, and add 15 mL of 30% H 2 O 2 , The color of the solution changes from dark brown to golden brown; use 100mL of diluted H with a molar concentration of 1mol / L 2 SO 4 Washing with distilled water repeatedly until the solution is neutral, drying in vacuum to obtain graphene oxide;

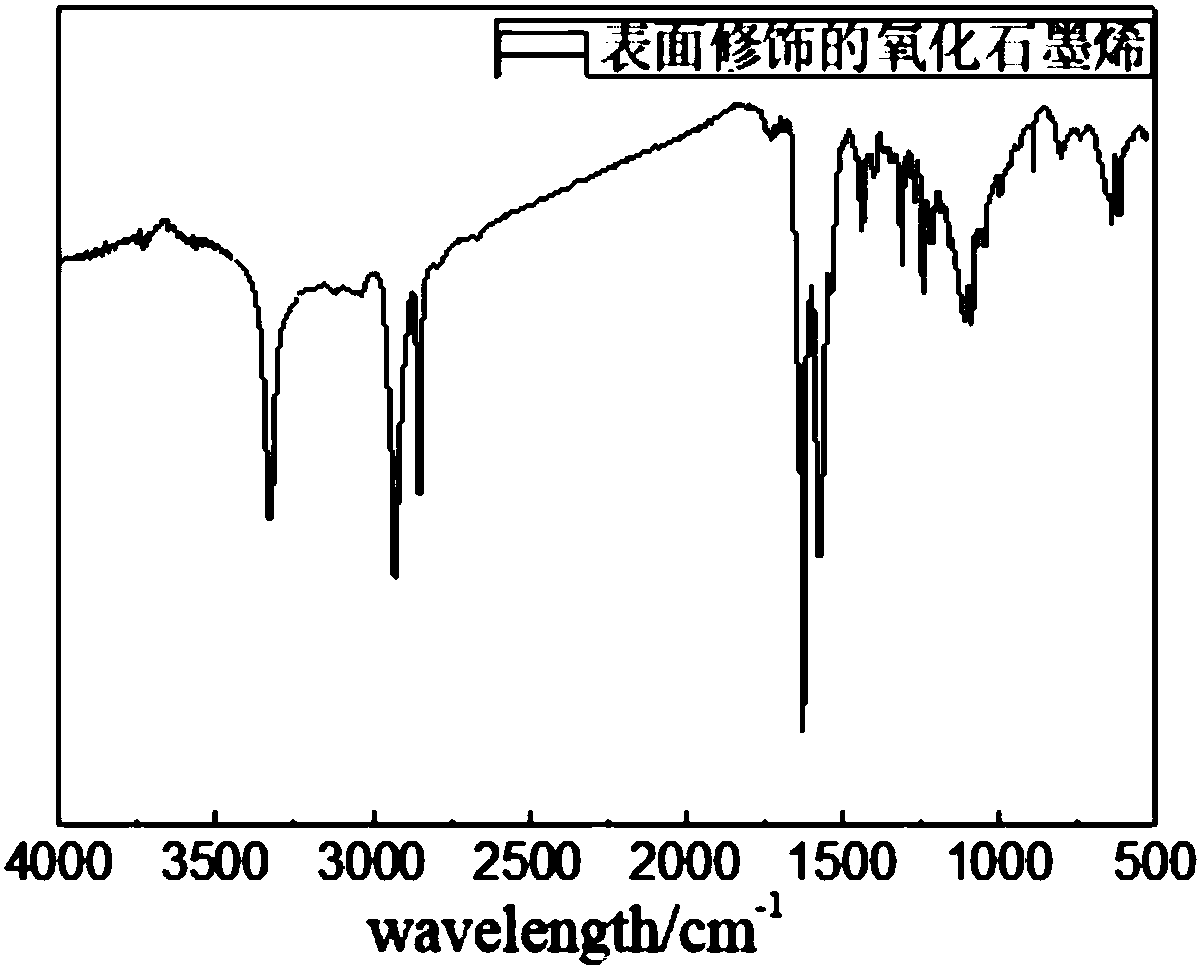

[0037] (2) Surface modification of graphene oxide

[0038] Under ice-water bath conditions, add the graphene oxide (0.2g) obtained in step (1) into dewatered tetrahydrofuran (20mL), ultrasonically disperse fo...

Embodiment 2

[0046] The preparation method of graphene oxide grafted polyvinylidene fluoride includes the following steps:

[0047] (1) The improved Hummer’s method is used to prepare graphene oxide, and the preparation process is the same as that of the above-mentioned Example 1;

[0048] (2) Surface modification of graphene oxide

[0049] Under ice-water bath conditions, add the graphene oxide (0.2g) obtained in step (1) to dewatered tetrahydrofuran (10mL), ultrasonically disperse for 5min, add to the reaction flask and stir, add 0.3g carboxyxanthate in turn , 0.0453g 4-dimethylaminopyridine and 0.1532g dicyclohexylcarbodiimide, react at room temperature for 12 hours, filter, and vacuum dry at 60°C for 12 hours to obtain surface-modified graphene oxide;

[0050] The preparation method of the carboxyxanthogenate is the same as in Example 1;

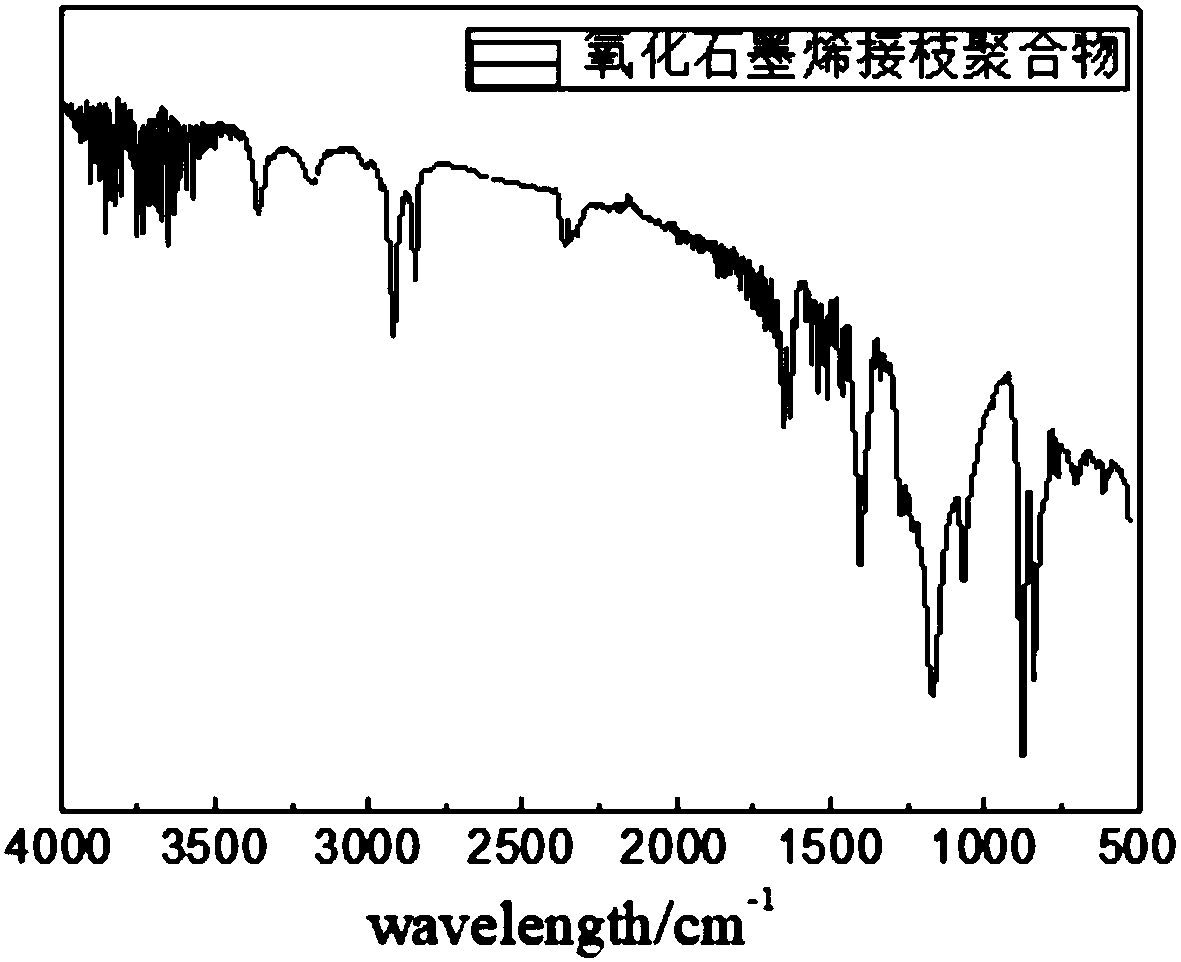

[0051] (3) Preparation of graphene oxide grafted polyvinylidene fluoride polymer

[0052] Add the surface-modified graphene oxide (0.01g) obtained in step (2)...

Embodiment 3

[0055] The preparation method of graphene oxide grafted polyvinylidene fluoride includes the following steps:

[0056] (1) The improved Hummer’s method is used to prepare graphene oxide, and the preparation process is the same as that of the above-mentioned Example 1;

[0057] (2) Surface modification of graphene oxide

[0058] Under ice-water bath conditions, add the graphene oxide (0.2g) obtained in step (1) to dewatered tetrahydrofuran (10mL), ultrasonically disperse for 5min, add to the reaction flask and stir, add 0.1g carboxyxanthate in turn , 0.0453g 4-dimethylaminopyridine and 0.1532g dicyclohexylcarbodiimide, react at room temperature for 12 hours, filter, and vacuum dry at 60°C for 12 hours to obtain surface-modified graphene oxide;

[0059] The preparation method of the carboxyxanthogenate is the same as in Example 1;

[0060] (3) Preparation of graphene oxide grafted polyvinylidene fluoride polymer

[0061] Add the surface-modified graphene oxide (0.02g) obtained in step (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com