Patents

Literature

50results about How to "Uniform wire diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

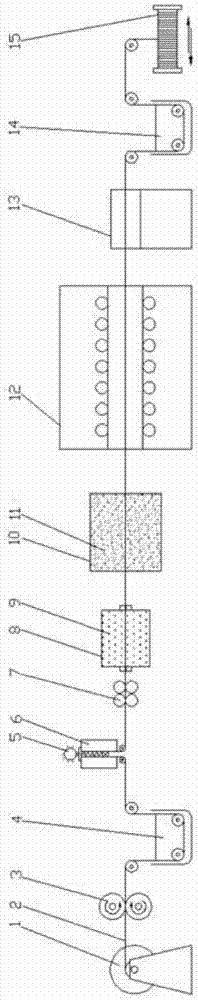

Method for manufacturing ultrafine metal fibers

ActiveCN101607367AUniform wire diameterLow costOther manufacturing equipments/toolsSingle phaseMetal

The invention relates to a method for manufacturing ultrafine metal fibers, which mainly comprises the steps of: carrying out drawing and compaction on metal micro-wires, then carrying out annealing treatment and adopting down quenching when composite wires exit a heating region; further carrying out the drawing and the annealing link on the composite wires, repeatedly carrying out the operation and carrying out finish drawing till achieving the size and the dimension required by the process; and carrying out electrolytic stripping, cleaning, drying, packaging and storage on the well drawn composite metal wires. The ultrafine metal fibers which adopt the micro-wire bundle cold reducing-diameter drawing technology can achieve 2 mu m and have the advantages of uniform wire diameter, continuous production, low cost, high efficiency and the like; the method utilizes the rapid rise method for avoiding a brittle zone and utilizes the sharp drop method for keeping the high-temperature single-phase tissues of the composite wires, thereby achieving the state of softest composite wires and greatest ductility; and the method solves the problem of matching compression ratio with drawing speed and realizes the purposes of uniform fiber diameter and small coefficient of variation.

Owner:河北丝维特金属纤维有限公司

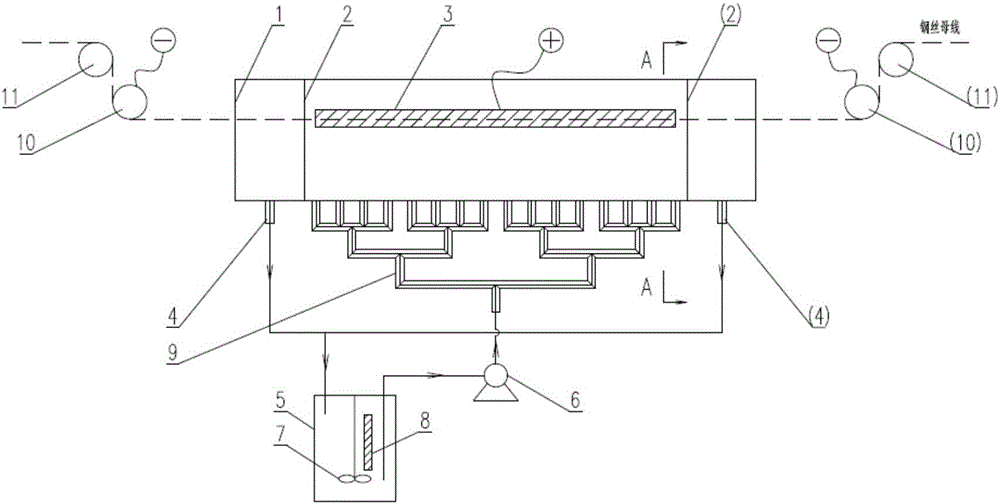

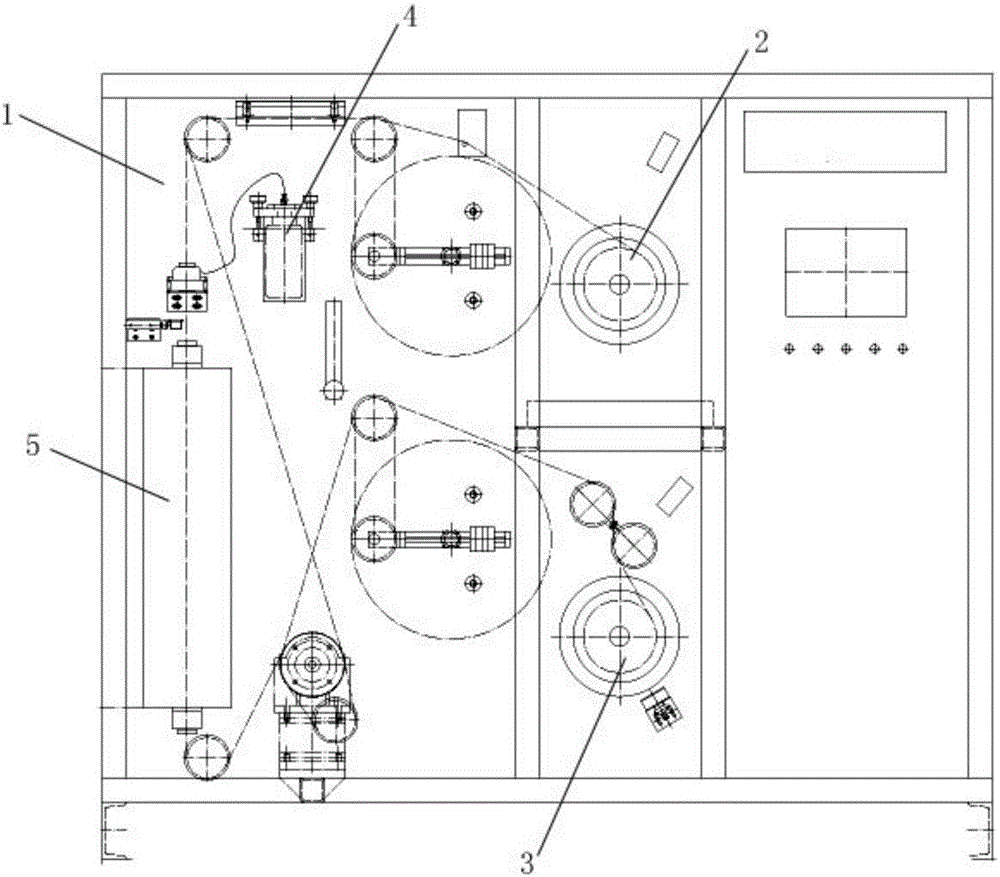

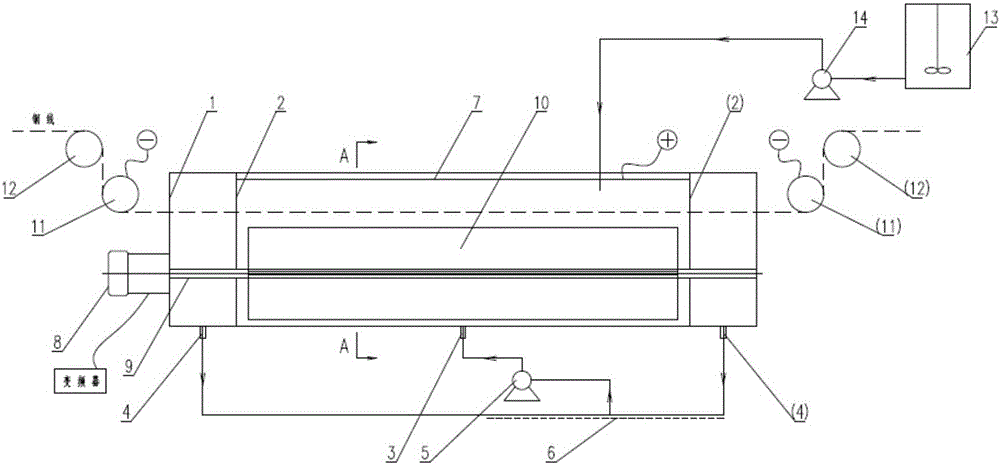

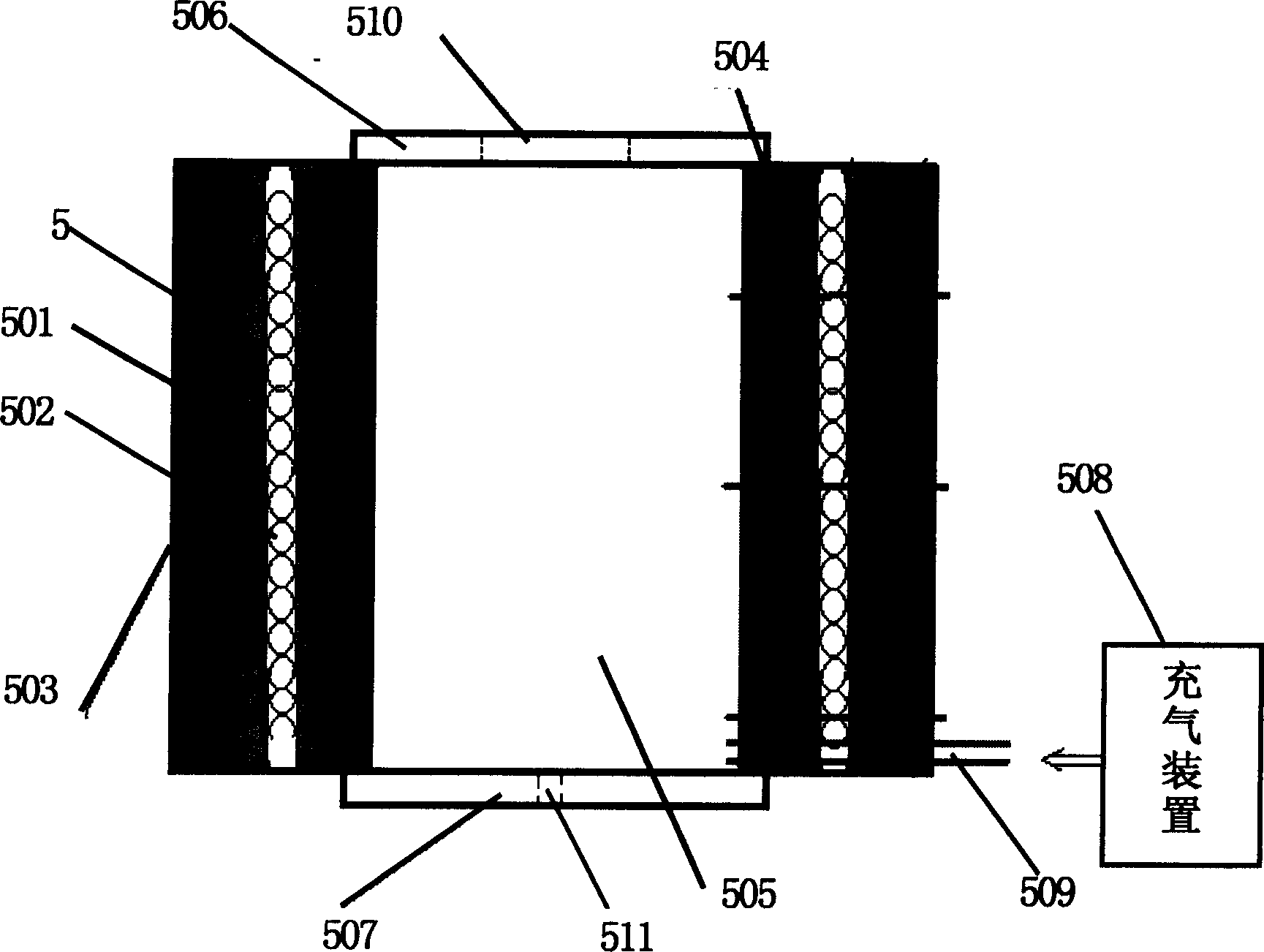

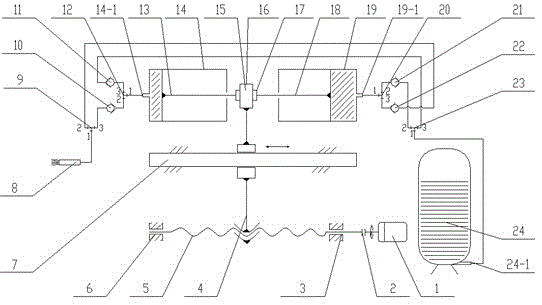

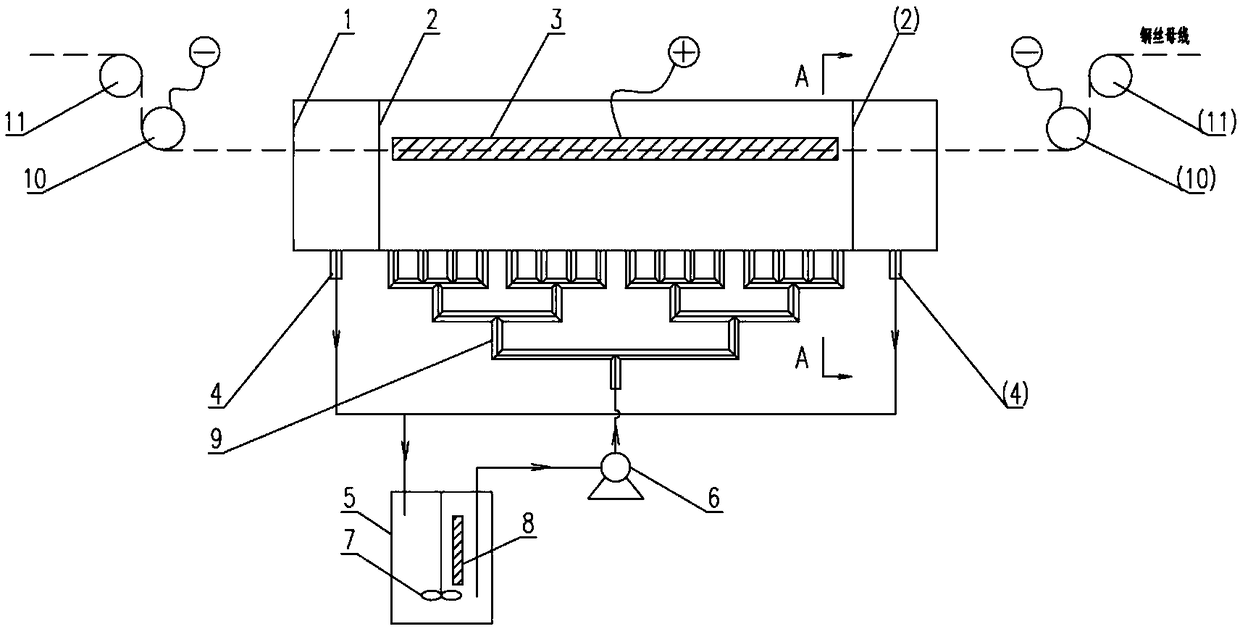

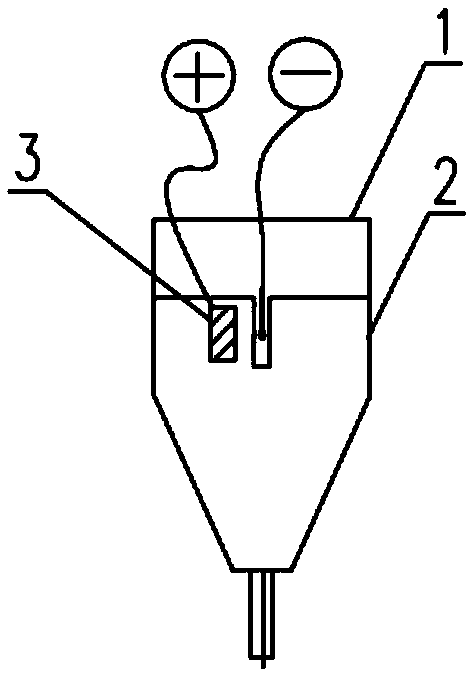

Sanding tank for production of composite electroplated diamond wires and utilization method of sanding tank

ActiveCN106283163AGuaranteed initial dispersion effectReasonable structureElectrolytic coatingsBusbarEngineering

The invention provides a sanding tank for production of composite electroplated diamond wires and a utilization method of the sanding tank. The sanding tank mainly comprises a sanding tank body, a liquid inlet circulation device, a liquid inlet distribution device and a steel wire conveying device. The liquid inlet distribution device with multi-stage distribution pipes is adopted for feeding liquid through the bottom of a sanding area, liquid inlet flow fields of a longitudinal area of the whole sanding area are basically uniform in distribution, flow rate controllability is realized, and diamond particles close to a steel wire busbar immersed in the whole sanding area are uniform in longitudinal distribution; after electrification for electroplating, sanding speed of the diamond particles on the steel wire busbar is controllable, and the particles are less prone to clustering and well distributed. The sanding tank can be used for continuous production of the electroplated diamond wires which are great in diamond particle distribution, uniform in wire diameter and excellent in cutting performance, and structural reasonability, high production efficiency and high raw material utilization rate are realized.

Owner:张家口原轼新型材料股份有限公司

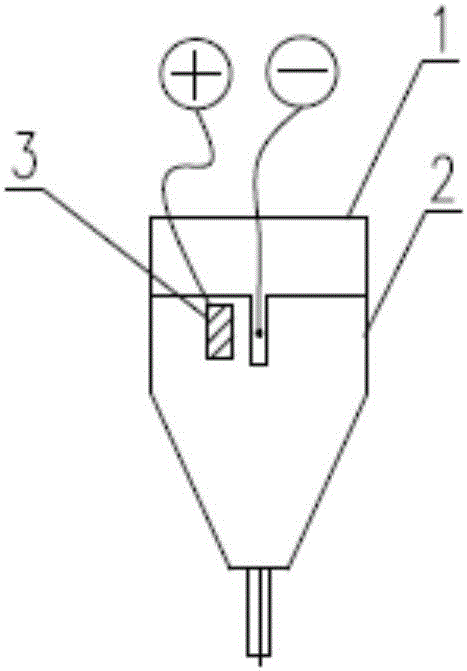

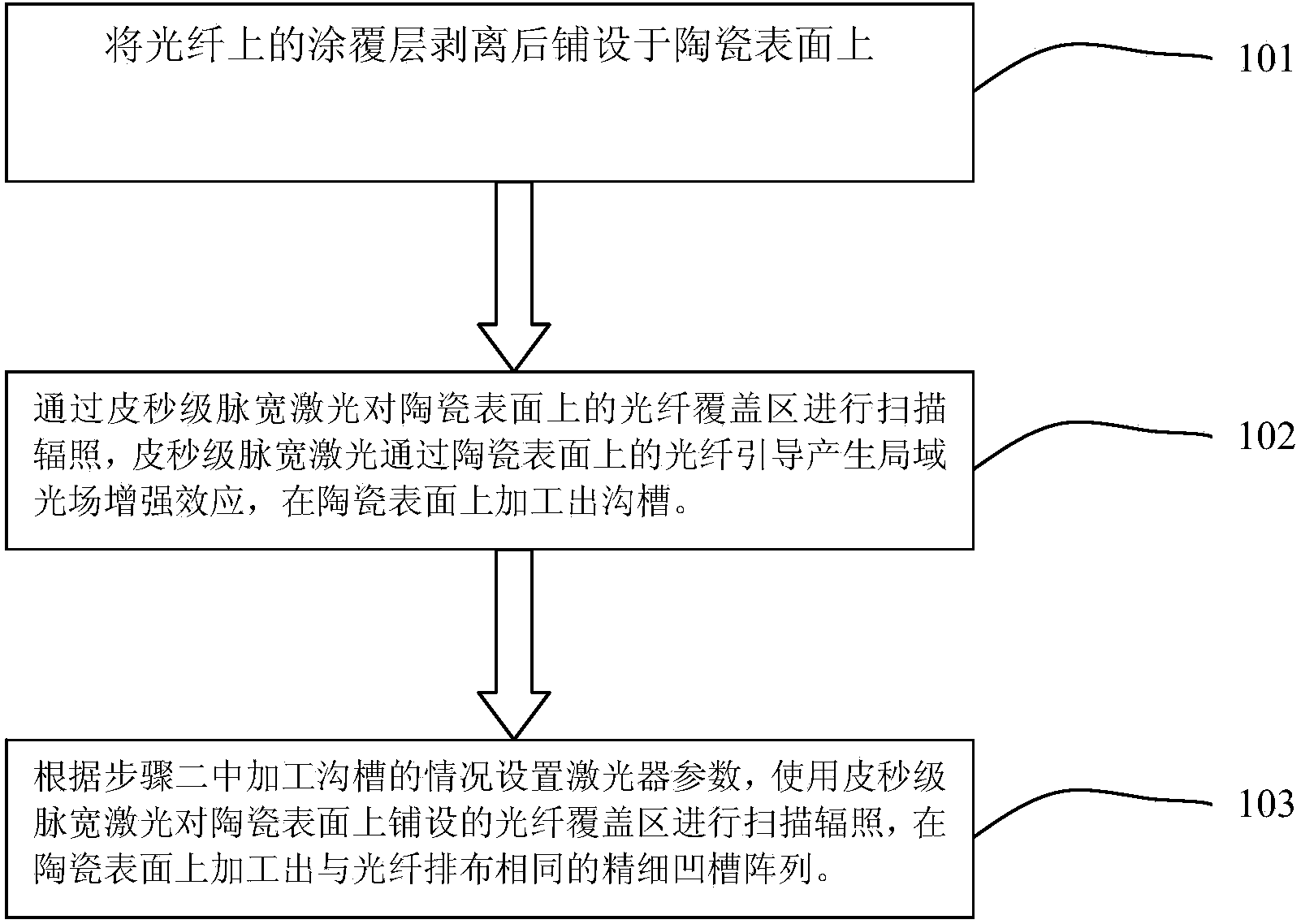

Laser machining method for fine scribing structure at ceramic surface

InactiveCN103862179AUniform wire diameterEasy to operateWelding/soldering/cutting articlesLaser beam welding apparatusHardnessOptical fiber cable

The invention discloses a laser machining method for a fine scribing structure at a ceramic surface. The method comprises the steps of peeling coatings on optical fibers and paving onto the ceramic surface; scanning and radiating an optical fiber covering area on the ceramic surface with a picosecond pulse width laser, using the picosecond pulse width laser to generate a local optical field enhancing effect by the guide of the optical fibers on the ceramic surface and machining grooves at the ceramic surface; setting laser parameters according to the groove machining conditions in the step II, scanning and radiating the optical fiber covering area paved on the ceramic surface by using the picosecond pulse width laser, and machining a fine groove array same as the optical fibers in arrangement on the ceramic surface. The picosecond pulse width laser beam is guided by adopting the optical fibers, the ceramic surface with high-melting point, high-hardness and high-brittleness physical properties is obtained, multiple fine scribing lines can be obtained at the same time, edges of the scribing lines have no cracks and heat affected zones and are smooth, the size diameters of the lines are uniform, and the minimal diameter limitation of the focus light beams on the scribing line diameter is broken through.

Owner:BEIJING UNIV OF TECH

Automatic wrapping device of insulation layer of wire and cable

InactiveCN104282398ANo uneven thicknessMeet the requirementsInsulating conductors/cablesInsulation layerEngineering

The invention discloses an automatic wrapping device of an insulation layer of a wire and cable. The automatic wrapping device of the insulation layer of the wire and cable comprises a screw extruder, and is characterized in that a rubber wrapping device is arranged at a rubber outlet of the screw extruder, the rubber wrapping device is fixedly connected with the screw extruder through a support, a paying off device and a taking up device are arranged on the front side and the rear side of the rubber wrapping device respectively, and a cable copper core is wound between the paying off device and the taking up device and penetrates through the rubber wrapping device. Pressure of liquid rubber is ensured by the adoption of the screw extruder, porous liquid rubber permeates and fills a cable passing channel, a front cable guide pipe and a rear cable guide pipe position the position of the copper core, a rubber scraper amends the insulation layer outside the wire and cable and controls the diameter of the insulation layer outside the wire and cable, the mode that the paying off device takes up the wire and cable in a damping mode is adopted so that the copper core can be located in the core portion of the wire and cable when wrapping the insulation layer, and it is ensured that the insulation wrapping of the wire and cable meets the use requirement. The insulation layer of the wire and cable is bright and clean in appearance, wire diameters are uniform, and the phenomena that a wire core deflects and insulation layers are not uniform in thickness are avoided.

Owner:FOSHAN YUEJIAXIN WIRE & CABLE

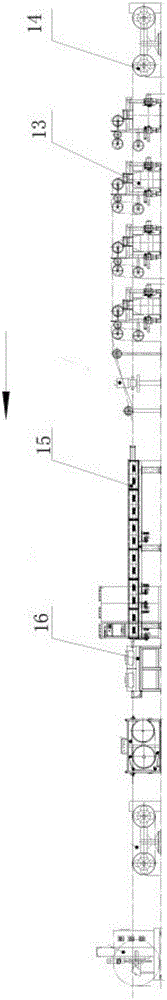

Cable production system

InactiveCN105070410AUniform wire diameterImprove anti-interference abilityCable/conductor manufactureBeam tubeEngineering

The invention proposes a cable production system which comprises a tinting machine, a plastic shielding system, a cabling system and a clamping system, wherein the tinting machine comprises a machine body, a wire outlet roller, a wire collection roller, an ink spraying tank and a curing machine are arranged on the machine body, the wire outlet roller is arranged above the wire collection roller, an optical fiber sleeves the wire outlet roller and sequentially passes through the ink spraying tank and the curing machine until the wire collection roller to collect a wire. The system is clear in process; with the arrangement of an excess-length traction device, a beam tube and the optical fiber are consistent in curvature, cable production is ensured, cable diameters are uniform, and production requirement are met; and embossing aluminum sheets wrap outside a cable core, and thus, the interference resistant capability and the mechanical bearing capacity of the cable are improved.

Owner:JIANGSU VANHUA COMM TECH CO LTD

Preparation method for resin diamond wire capable of improving diamond holding force

InactiveCN106112839AImprove bindingImprove cutting effectGrinding devicesEpoxy resin coatingsFiberOrganic solvent

The present invention relates to the preparation method of the resin diamond wire which can improve the diamond holding force, comprising the following steps: (1) preparation of diamond powder treatment solution: 1-10% silane coupling agent, 85-92% organic solvent, 1- 10% water; (2) diamond treatment; (3) preparation of diamond wire resin liquid: 20-50% resin powder, 10-30% organic solvent, 10-30% silicon carbide powder, 1-10 % of nanofibers, 20-40% of diamond powder treated in step (2); (4) coating of steel wire; (5) curing: primary curing, curing temperature is 500-900°C, secondary curing, A stepwise heating process is adopted, and finally the temperature is naturally lowered to room temperature with the furnace to obtain the finished resin diamond wire. The method of the invention can improve the binding force between the resin liquid and the diamond, has low energy consumption, little environmental pollution and low production cost.

Owner:HENAN XINDAXIN SCI & TECH

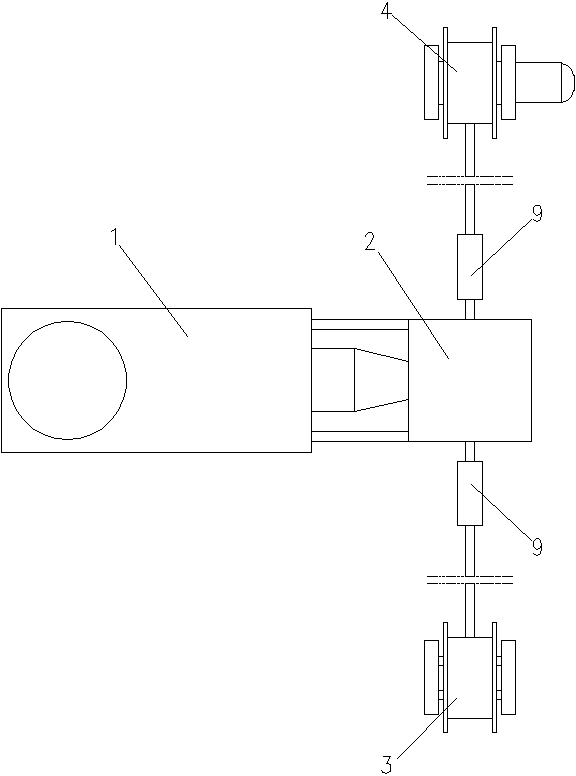

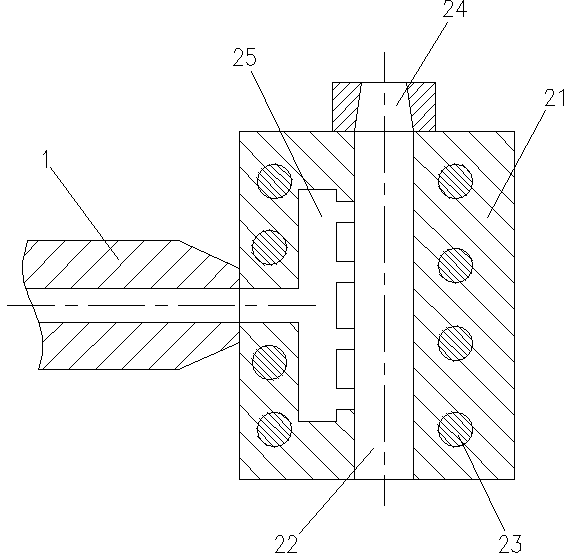

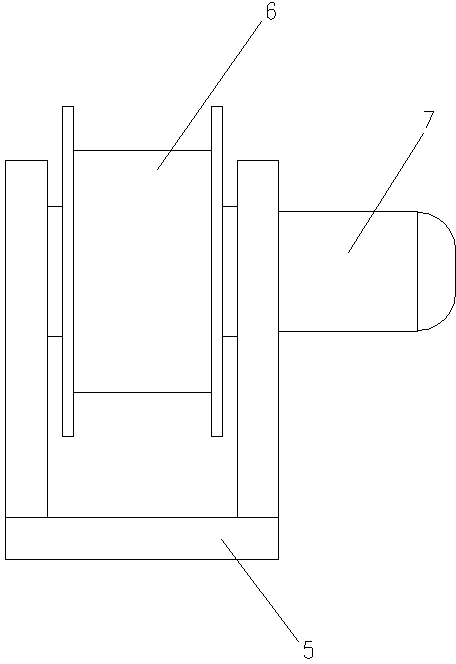

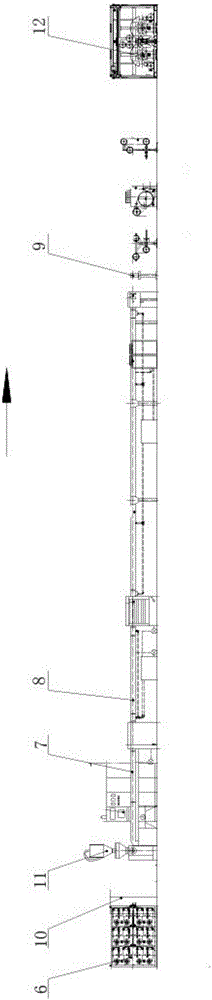

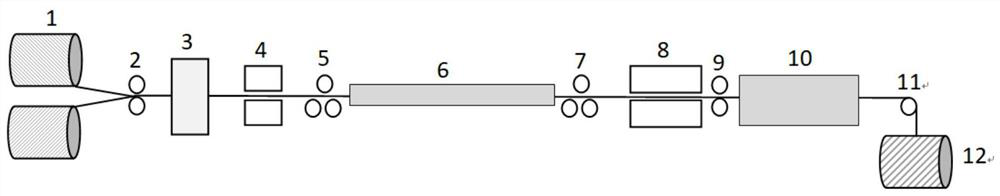

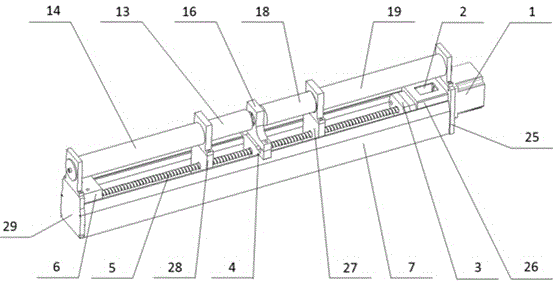

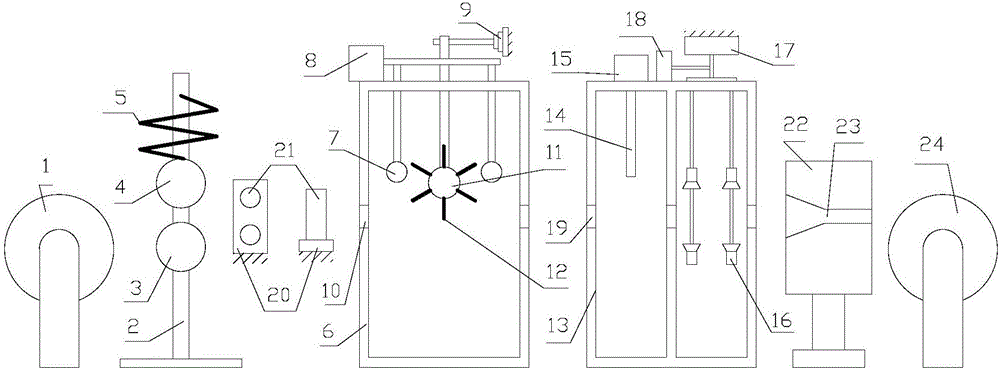

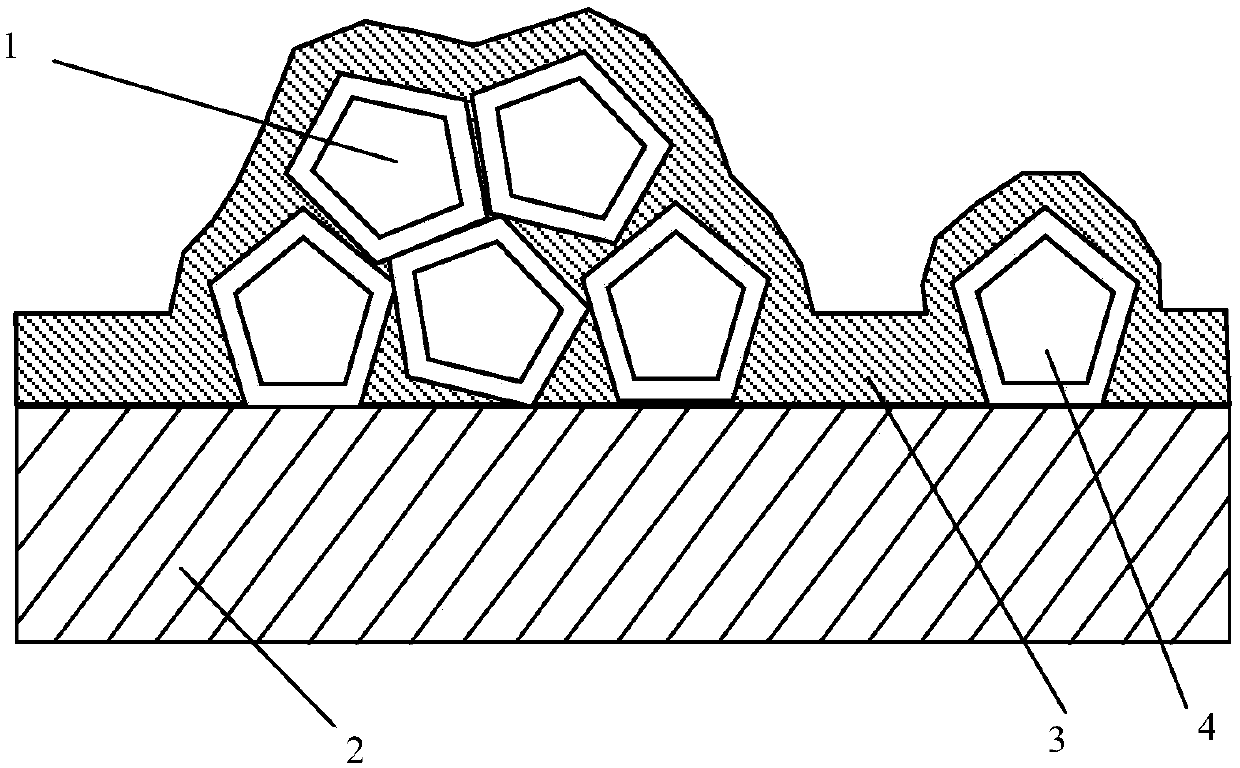

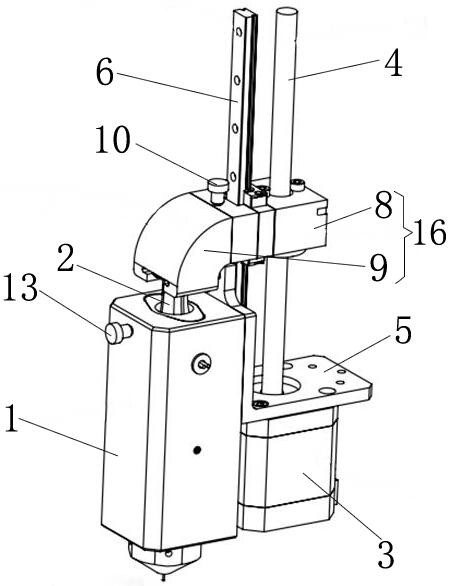

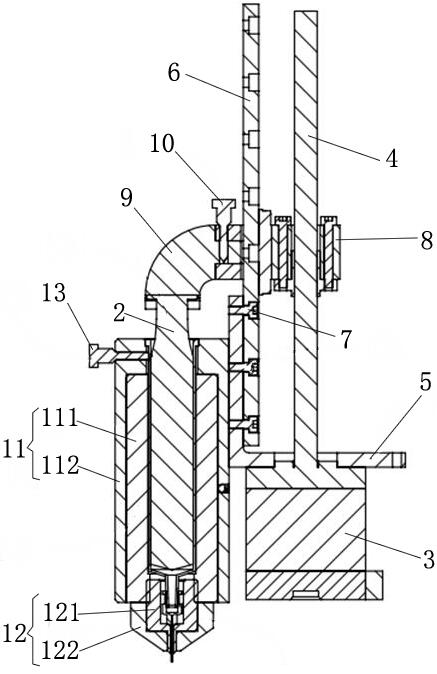

Method and device for manufacturing continuous long-distance braze-welded wire saw

ActiveCN103586538AImprove performanceUniform wire diameterMetal sawing tool makingEngineeringThermal treatment

The invention relates to a method and device for manufacturing a continuous long-distance braze-welded wire saw. According to the method and device, a wire is paid off through a pay-off wheel to sequentially pass through a texturing device, a washing device, a tensioning device, a straightener, a coating device, a sand applying device, a heating device, a thermal treatment device, a washing tank and a power wiring device, and then the complete manufacturing process route of the braze-welded wire saw including texturing, washing, straightening, coating, sand applying, heating and braze welding, posterior thermal treatment, washing and wire take-up is completed. The wire saw manufactured with the device is continuous, long in distance, uniform in diameter, stable in performance and capable of being used for precision machining. Meanwhile, the device is complete in function and high in automation degree, labor consumed time is greatly shortened, the manufacturing efficiency of the braze-welded wire saw is improved, and the manufacturing cost is reduced. The method and device for manufacturing the continuous long-distance braze-welded wire saw makes the braze-welded wire saw have more extensive application prospects and pushes the manufacturing application process of the braze-welded wire saw.

Owner:HUAQIAO UNIVERSITY

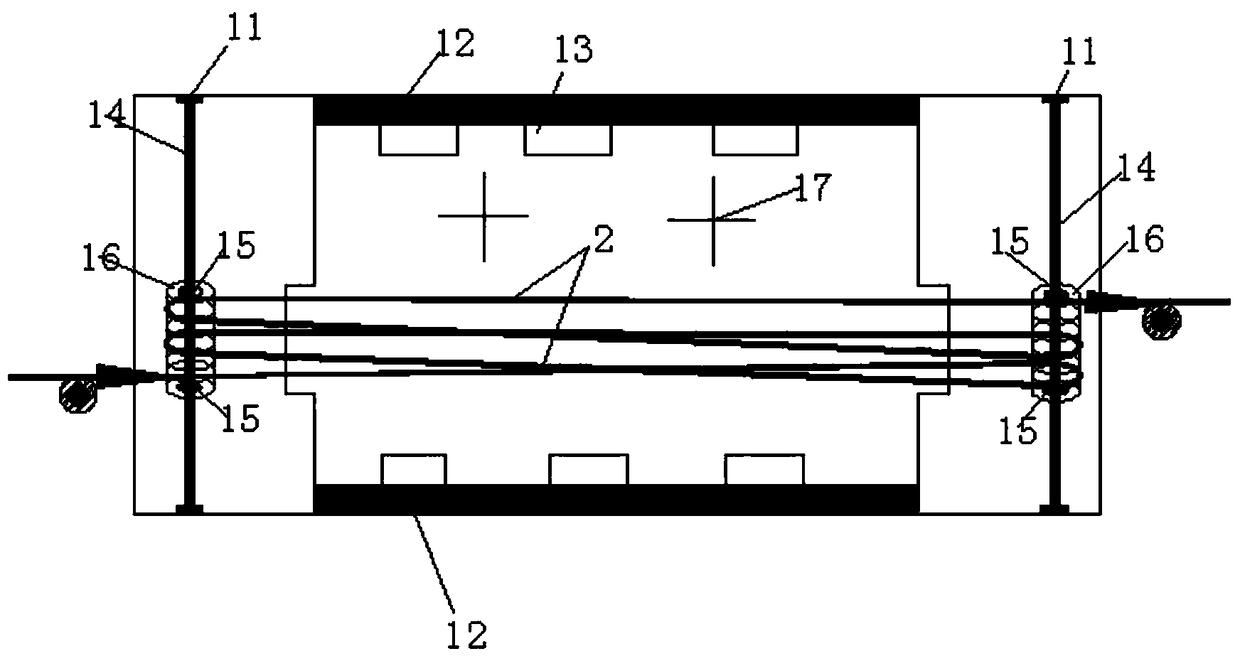

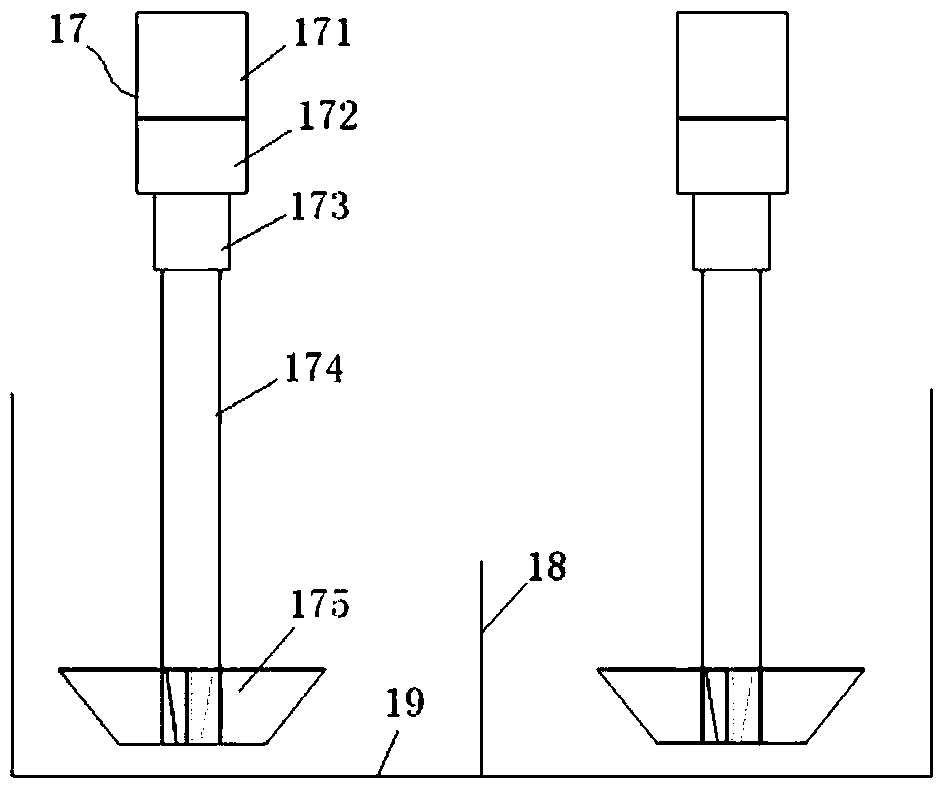

Horizontal type stirring sanding groove for producing efficient composite electroplated diamond wire and use method

ActiveCN106319590AEvenly distributedUniform wire diameterCellsElectrolytic coatingsEngineeringDiamond

The invention provides a horizontal type stirring sanding groove for producing an efficient composite electroplated diamond wire and a use method. A horizontal type stirring sanding groove device mainly comprises a sanding groove body, an overflow liquid circulating device, a horizontal type stirring device, a steel wire conveying device, an automatic material supplementing device and the like. The horizontal type stirring device of a stirring paddle with the wide axial covering area is adopted in the sanding groove device, a liquid flow field of the whole axial area of the sanding area is uniform and consistent in distribution, diamond micro powder has the good dispersion effect in a plating solution, the diamond micro powder is not likely to be united on a steel wire, distribution is good, and finished product wires are uniform in diameter; the electroplated diamond wire which is controllable in diamond sanding amount and good in distribution can be continuously produced, the structure is reasonable, operation is convenient and rapid, and running is efficient.

Owner:镇江原轼新型材料有限公司

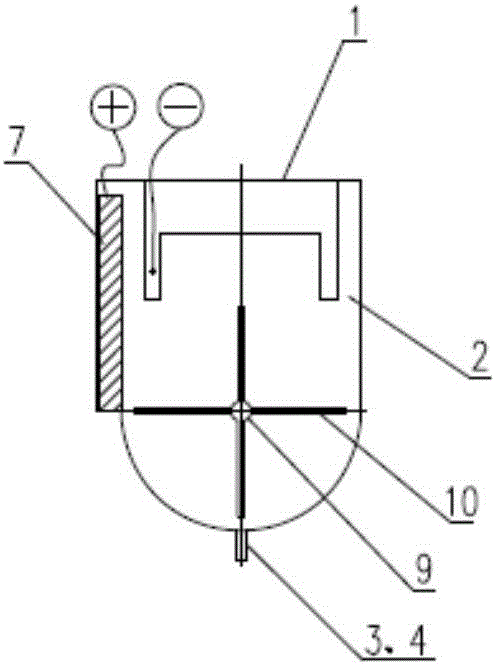

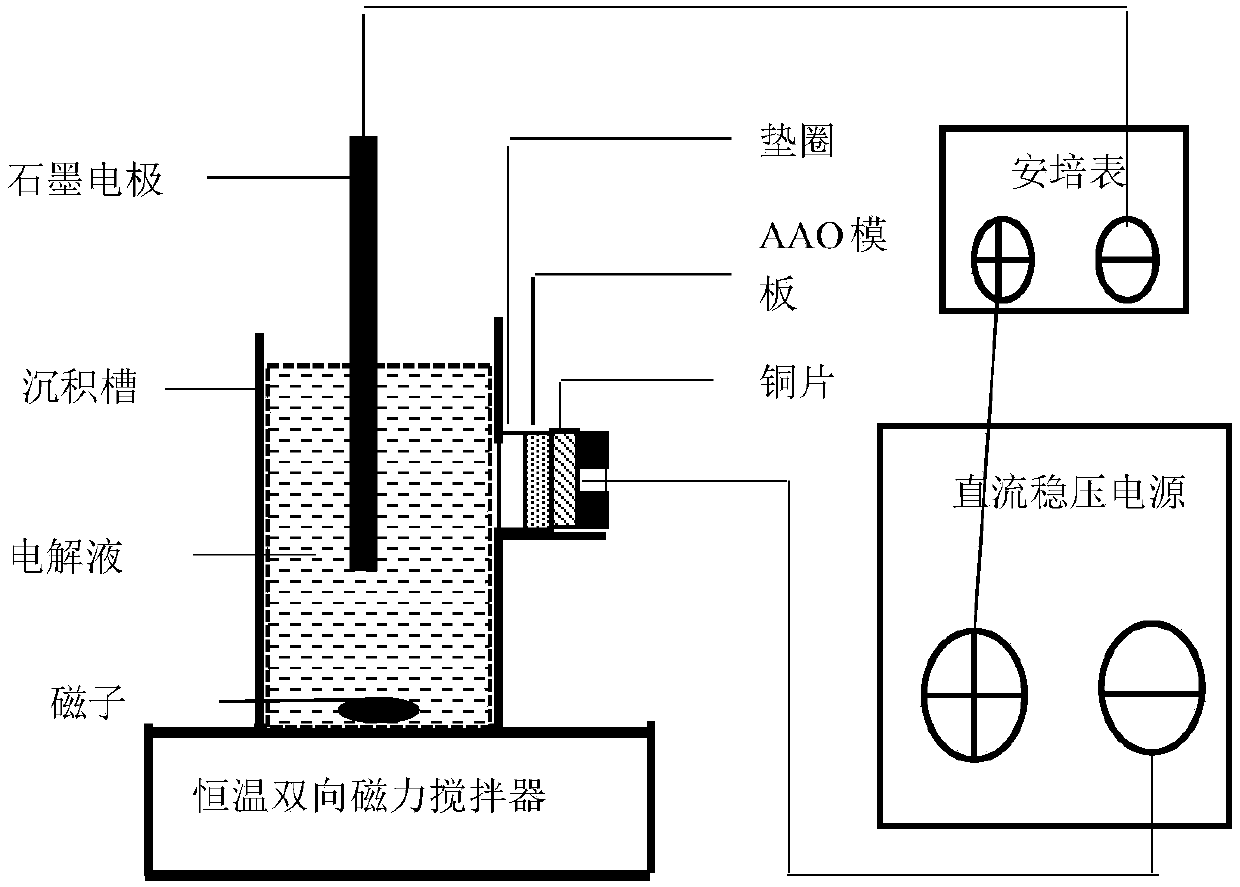

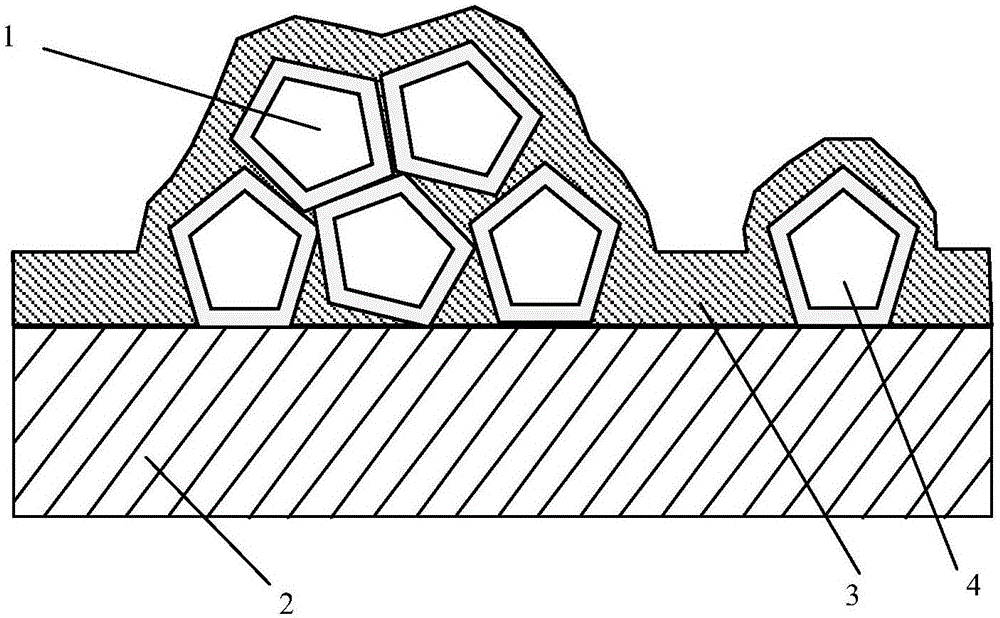

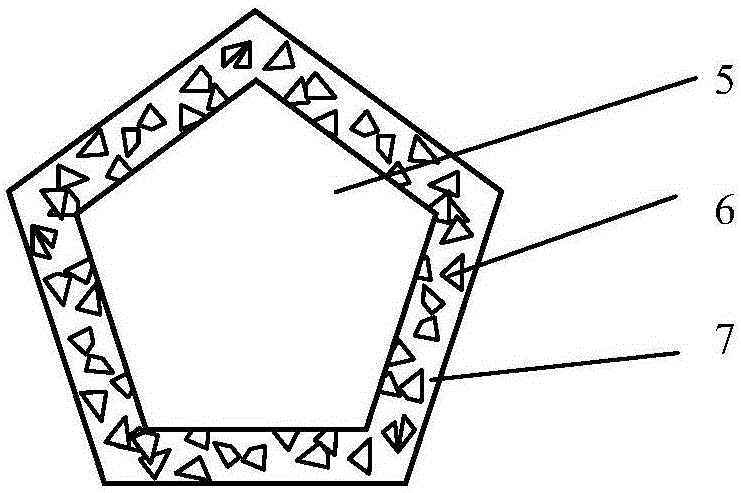

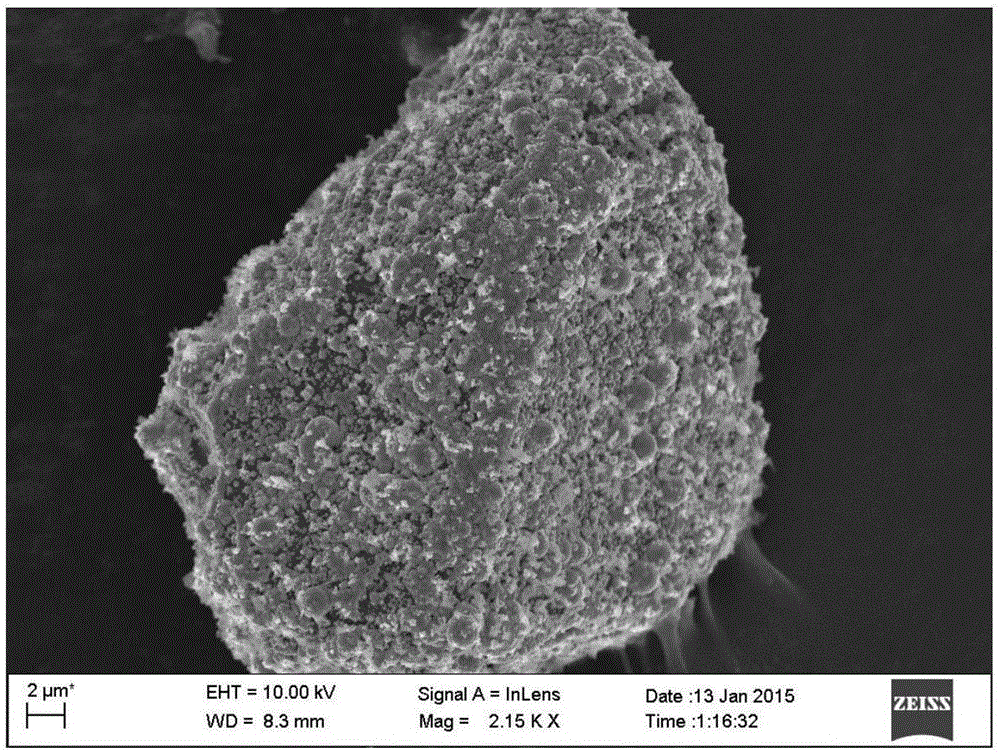

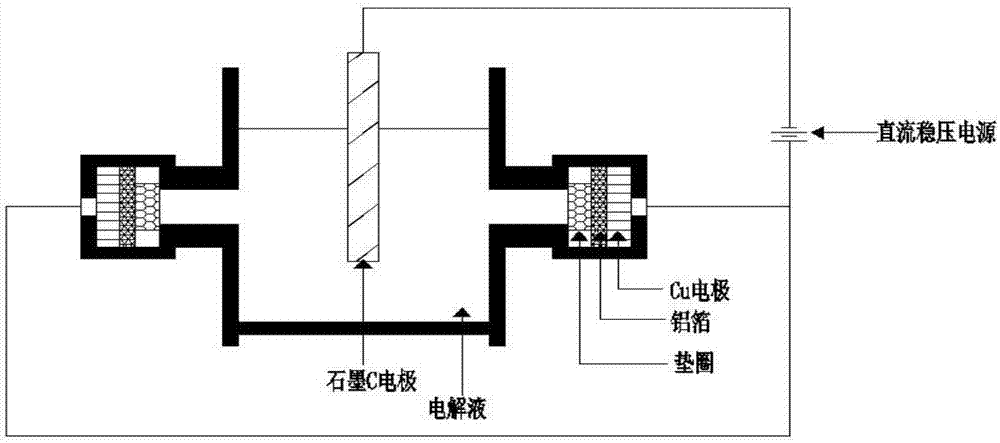

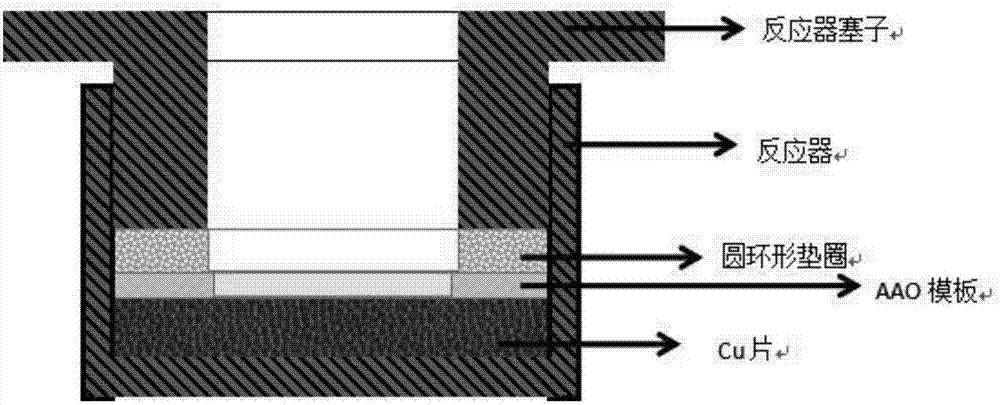

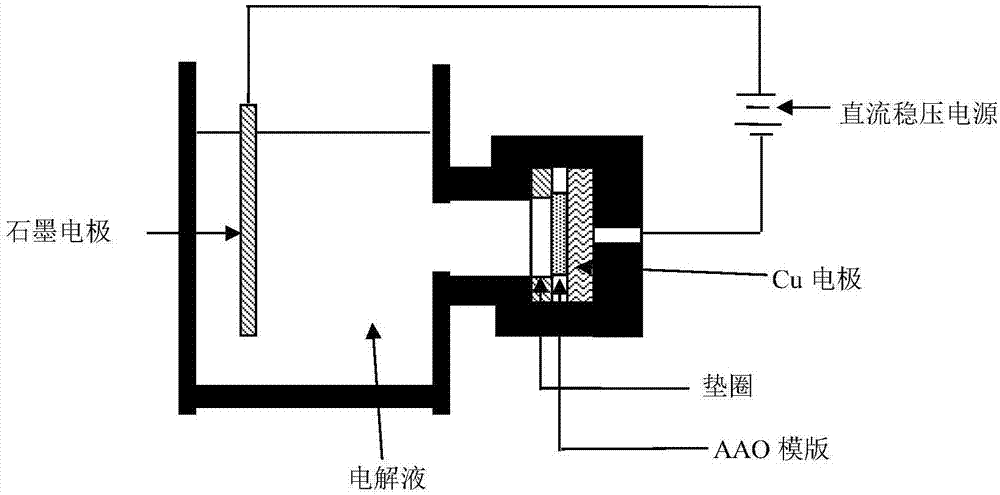

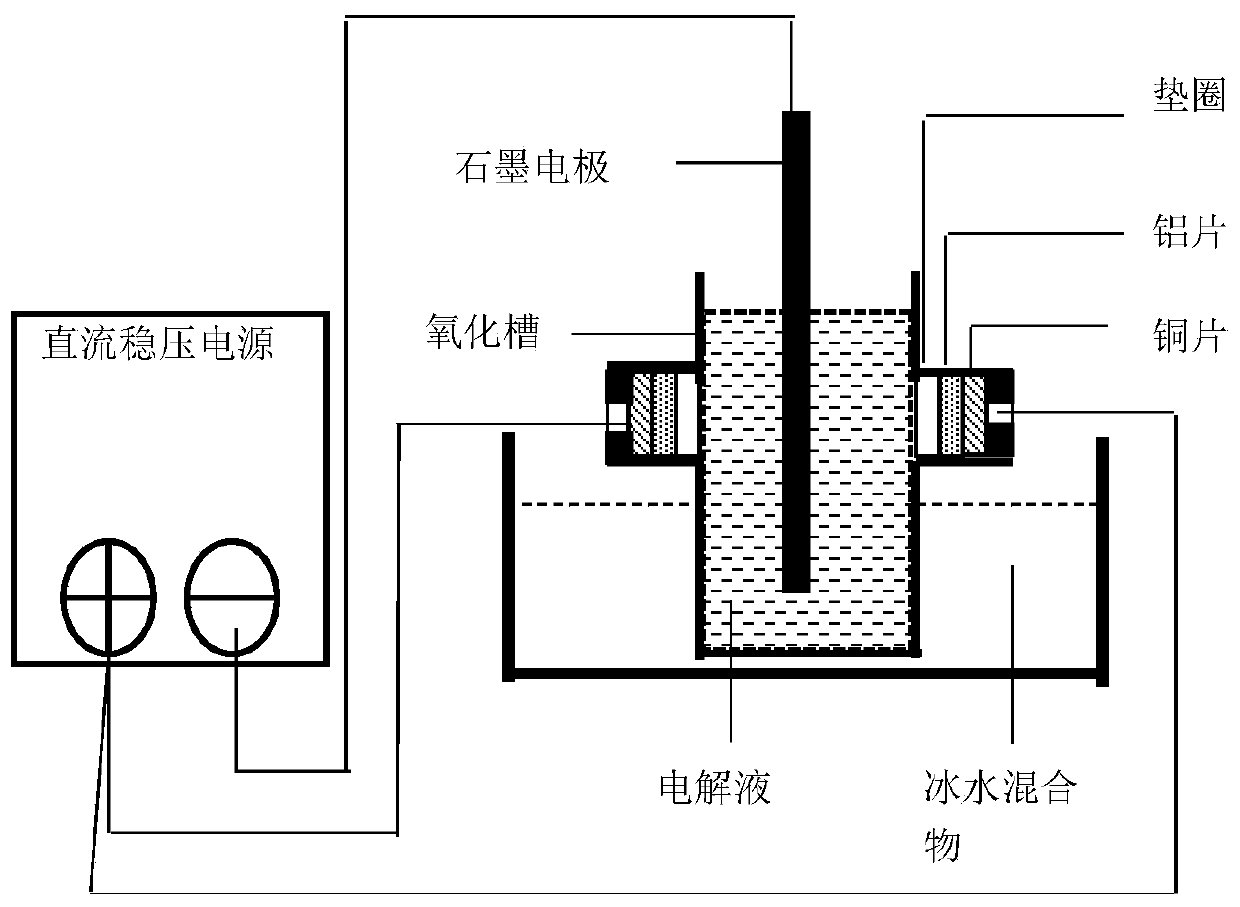

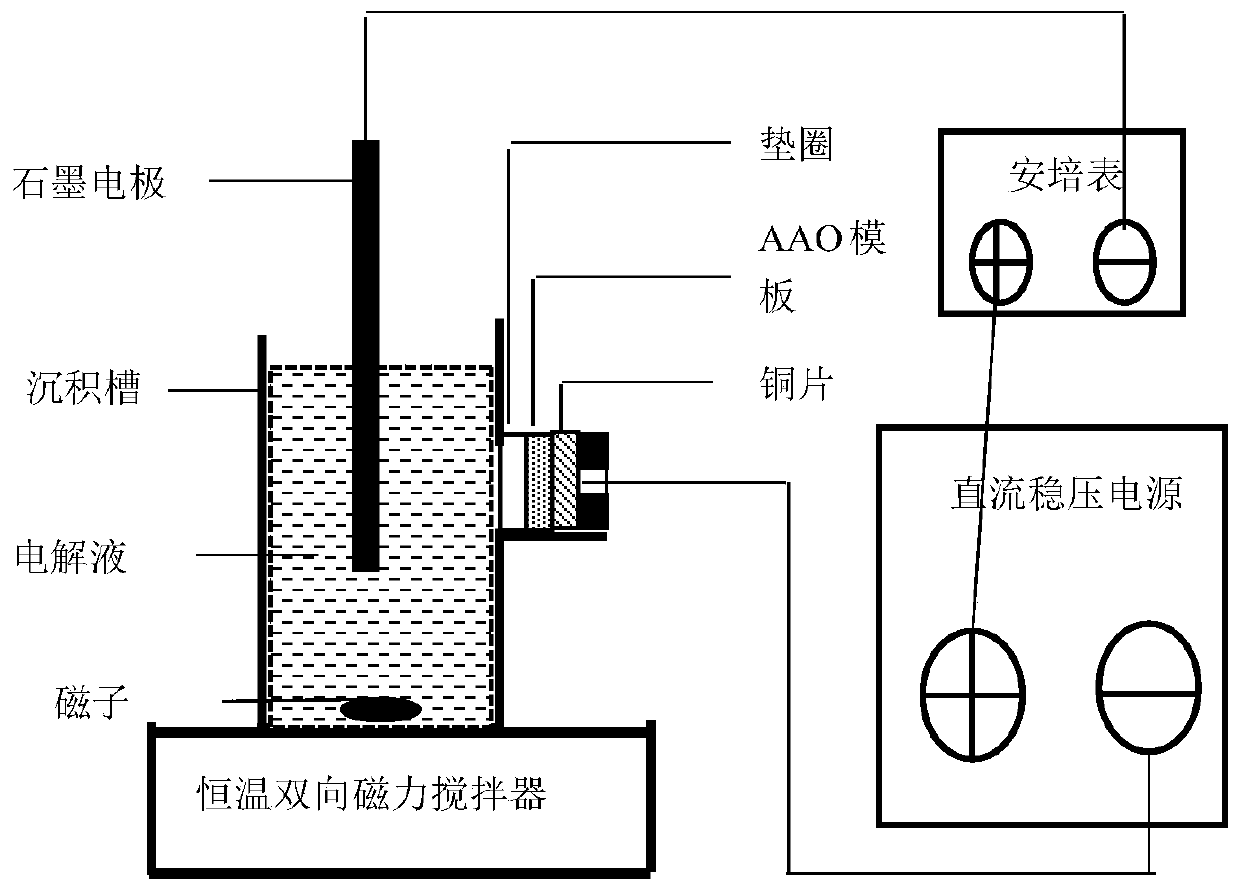

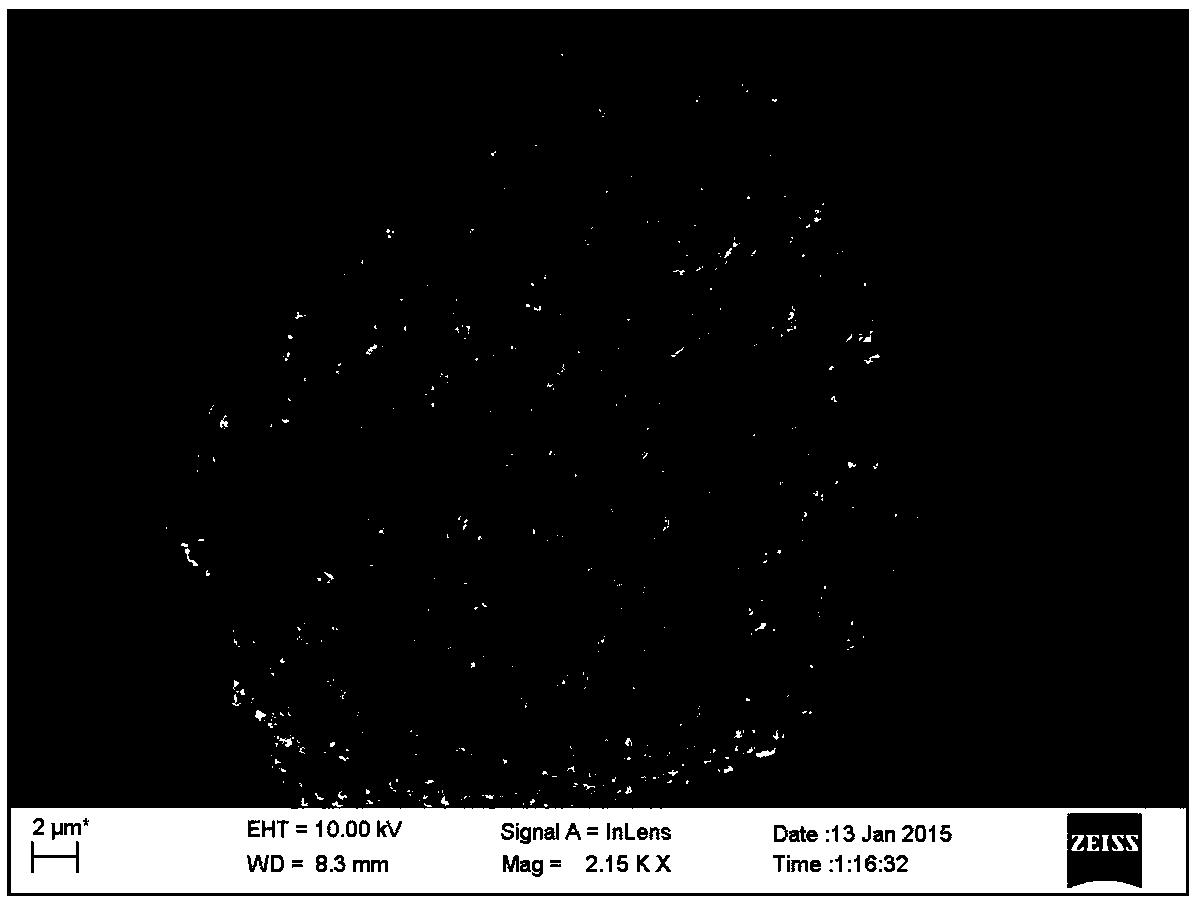

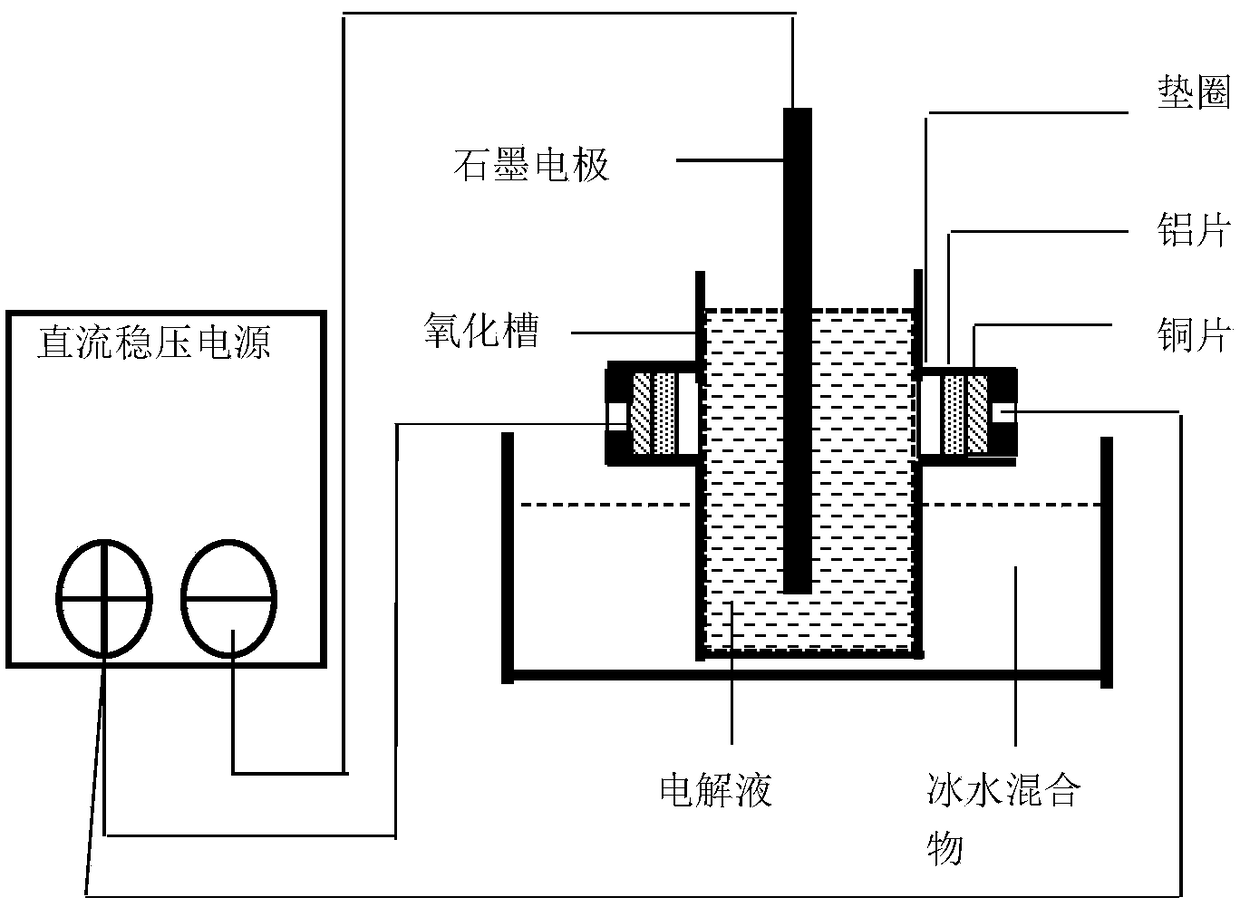

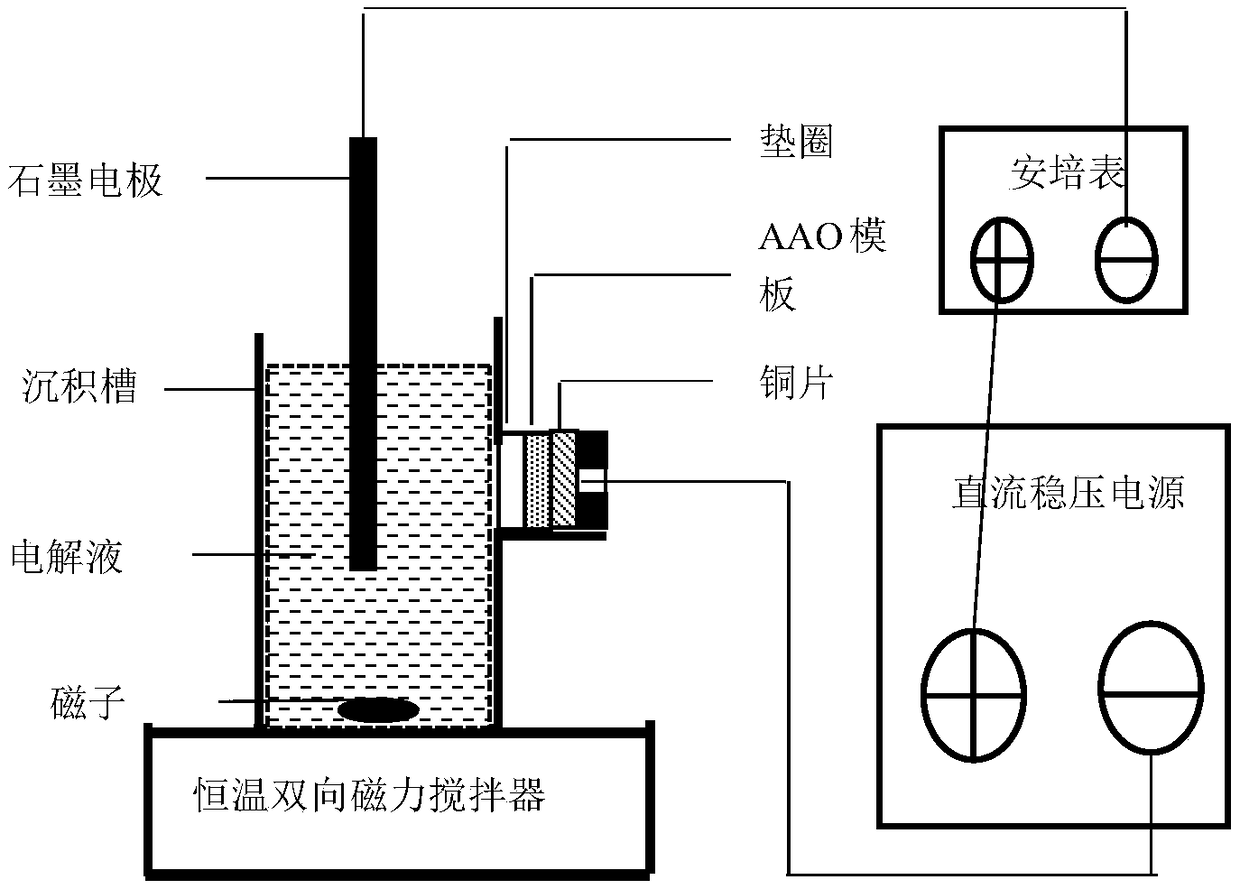

Preparation method of Nd-Fe-Co ternary alloy magnetic nanowire

ActiveCN107705980AA large amountIncrease deposition rateNanostructure applicationElectrolytic agentGraphite

The invention relate to a preparation method of an Nd-Fe-Co ternary alloy magnetic nanowire. The method comprises the following steps of (1) mixing NdC<13>.6H<2>O, FeC<12>.4H<2>O, CoC<12>.6H<2>O and deionized water to prepare a Nd<x>Fe<y>Co<z> deposition liquid; and (2) performing electrochemical deposition by employing a DC voltage-stabilization power supply under a DC voltage of 1.5-2V and by taking graphite as a positive electrode, an AAO template as a negative plate and the Nd-Fe-Co deposition liquid prepared in the previous step as an electrolyte, and finally obtaining the Nd-Fe-Co ternary alloy magnetic nanowire, wherein a deposition current is (0.5-20) mA, and deposition time is 1-2 hours. The nanowires are huge in quantity and high in deposition rate, and the nanowires are arrangedin parallel, are high in order, uniform in diameter and large in length-diameter ratio.

Owner:HEBEI UNIV OF TECH

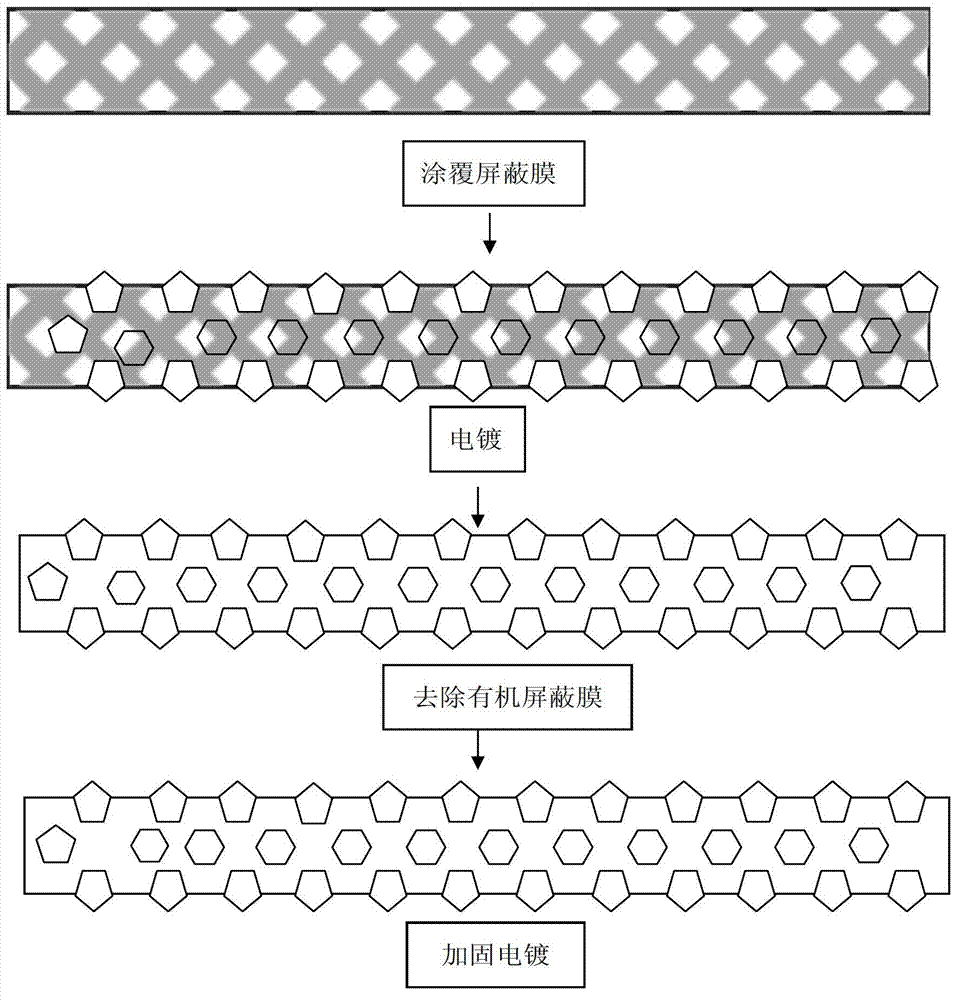

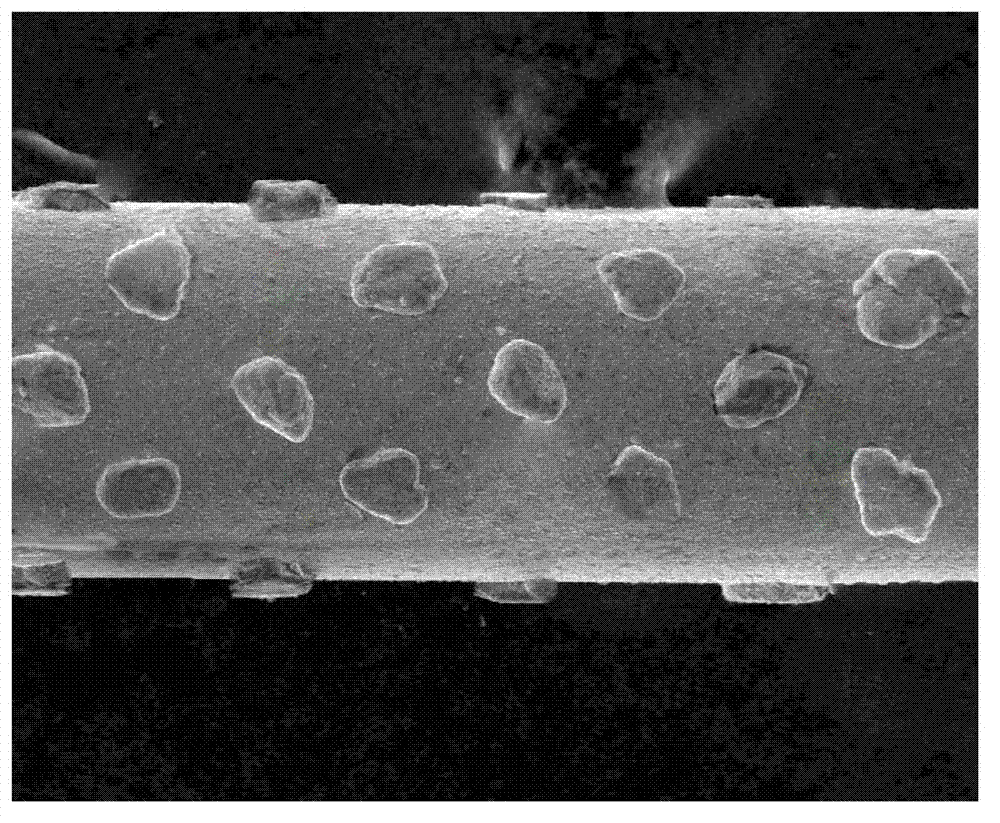

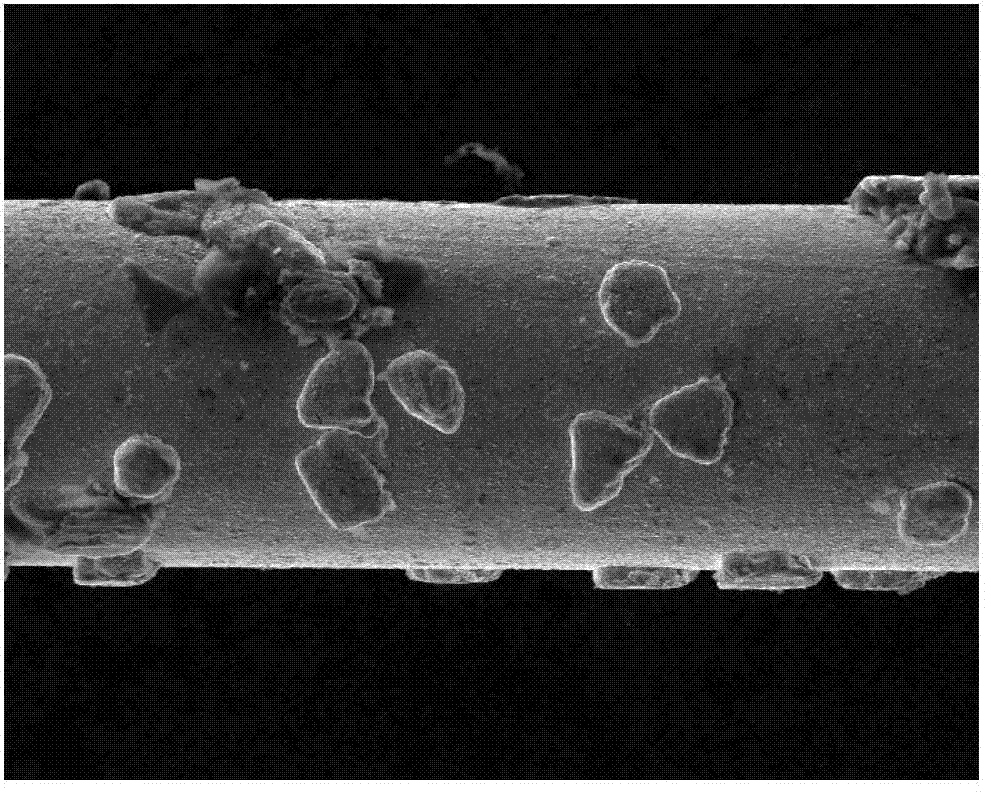

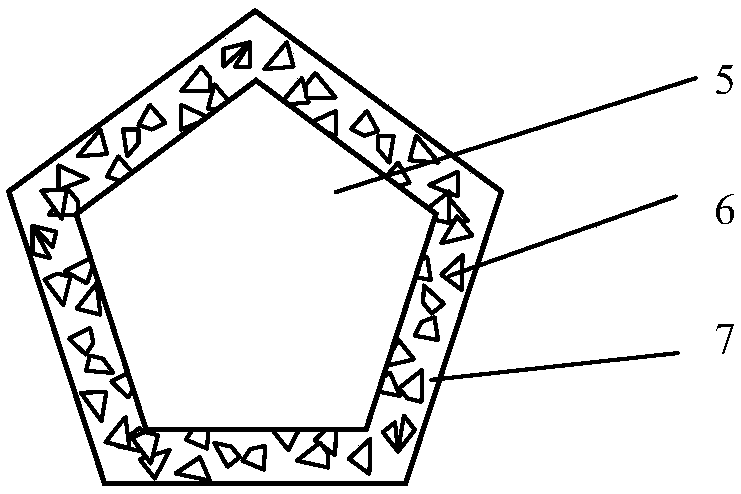

Manufacturing method of electroplating super-hard abrasive cutting line

The invention discloses a manufacturing method of an electroplating super-hard abrasive cutting line. The method comprises an electroless composite plating method of the surface of super-hard abrasive. The surfaces of super-hard abrasive particles are wrapped with a nickel and phosphorus alloy layer through the electroless composite plating method, the nickel and phosphorus alloy layer contains solid particles, and the solid particles are non-conductive particles. The nickel and phosphorus coating containing the solid particles is formed on the surface of the super-hard abrasive through the electroless plating method, the solid particles in the coating are the non-conductive bodies, are doped in the nickel and phosphorus alloy and occupy a certain volume space, the electrical conductivity of the nickel and phosphorus alloy is reduced, the cathode discharge reaction of the surface of the super-hard abrasive depositing on a steel wire in the electro-deposition process is restrained, and accordingly the agglomeration phenomenon of the super-hard abrasive on the cutting line is avoided, the diameter of the cutting line is uniform, removal of the agglomerated super-hard abrasive in the subsequent procedure is not needed, the line diameter is amended, the production cost is reduced, and the production efficiency is improved.

Owner:QINGDAO GAOCE TECH CO LTD

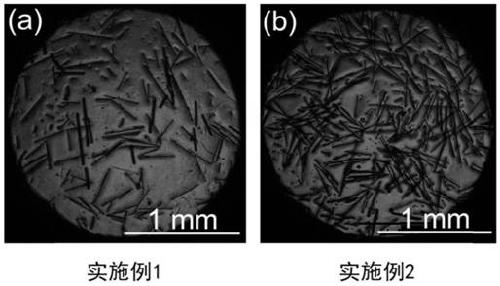

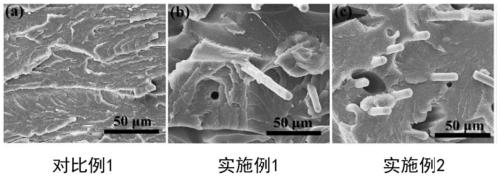

Modified carbon fiber reinforced polyamide 6 composite material for 3D printing, and preparation method and application thereof

InactiveCN111423720AControl wire diameter accuracyUniform wire diameterAdditive manufacturing apparatusFiberWire rod

The invention provides a modified carbon fiber reinforced polyamide 6 wire for 3D printing, and a preparation method and application thereof. A modified carbon fiber reinforced polyamide 6 composite material of the invention is prepared from the following components in parts by weight: 85-95 parts of a polyamide 6 material, 5-15 parts of carbon fibers and 1-3 parts of a modified silane coupling agent. According to a technical scheme provided by the invention, carbon fiber grafting is facilitated by utilizing the modified silane coupling agent; the prepared composite material has the characteristics of uniform wire diameter, smooth surface, excellent mechanical property and relatively small material shrinkage rate, can be applied to the field of 3D printing consumables, and overcomes the technical defects that a polyamide 6 material is prone to buckling deformation in the printing process, the mechanical property of a printed member is poor and wires are prone to generation of bubbles in the prior art. The polyamide 6 printing wire of the invention has practical value, the maximum tensile strength of the polyamide 6 printing wire can exceed 110 MPa under the condition of a low carbon fiber content (10-15%), and the polyamide 6 printing wire is far superior to many polyamide 6 printing wires on the market.

Owner:DALIAN UNIV OF TECH

Hot-sprayed zinc-aluminum alloy wire and preparation method thereof

The invention relates to a hot-sprayed zinc-aluminum alloy wire and a preparation method thereof. The hot-sprayed zinc-aluminum alloy wire comprises the following components in percentage by weight: 2-20% of aluminum and the balance of zinc. The preparation method of the hot-sprayed zinc-aluminum alloy wire comprises the following steps of: feeding zinc and aluminum according to a component ratio, smelting and casting to form cylindrical zinc-aluminum alloy ingot materials; producing bar stocks by using a hot extrusion machine, and rolling the bar stocks by using a wire rolling machine to produce wire materials with the diameter phi of 3.0-4.5 mm; and then, repeatedly carrying out cold drawing on the wire materials by using a drawing die, so as to produce zinc-aluminum alloy wires with the diameter phi of 1.6-4 mm.. According to the preparation method, the drawing frequency during the forming of the zinc-aluminum alloy wires is greatly reduced, the alloy structure becomes more uniform during the process of rolling zinc-aluminum alloy, the tensile strength of the rolled wires is reduced by 8-10%, and the percentage elongation is increased by 12-15%, wire break can be avoided in a drawing process, the diameter of finished product wires is uniform, the production efficiency is greatly increased, the energy consumption and production cost are reduced, and the environmental pollution is lightened. Thus, the invention successfully provides an economical and feasible technology for the large-scale industrial production of the hot-sprayed zinc-aluminum alloy wires.

Owner:长兴县华峰喷焊材料电炉有限公司

Magnetically-controlled wire unwinding spindle

The invention provides a magnetically-controlled wire unwinding spindle, belonging to the technical field of wire unwinding equipment. The magnetically-controlled wire unwinding spindle comprises a wire wheel, an external shaft and a magnetic control mechanism, wherein the periphery of the wire wheel is wound with a wire harness in advance; the external shaft is arranged in the middle part of the wire wheel in a penetrating manner, and is hinged to the wire wheel; the magnetic control mechanism is arranged in the wire wheel, and is used for releasing a tension force to the wire wheel. The magnetically-controlled wire unwinding spindle has the advantages of reasonable design and reliability in work.

Owner:NINGBO LONG WALL FLUID KINETIC SCI TECH

Fluffy chinlon filament and preparation method thereof

The invention discloses a fluffy chinlon filament and a preparation method thereof. The fluffy chinlon filament is formed by processing two or more chinlon filaments with different dry heat shrinkage rates, and the dry heat shrinkage rate difference value between the chinlon filaments is not less than 10%. Compared with traditional chinlon filaments with a certain fluffy effect manufactured by directly performing air deformation on conventional chinlon FDY or POY, the fluffy chinlon filaments have the advantages that chinlon with different thermal shrinkage rates is twisted and combined, pre-shrunk after a network is added, and then subjected to air deformation processing to manufacture fluffy chinlon filaments, and the fluffy chinlon filament has the beneficial effects that the prepared fluffy chinlon filament is more uniform in diameter, better in fluffiness and less in long looped pile, and a prepared fabric product is fuller in hand feeling.

Owner:海安中纺院纤维新材料科技有限公司

Composition and method for preparing diamond wire saw with composition

ActiveCN103031012AUniform wire diameterImprove cutting performanceElectrolytic coatingsMetal sawing tool makingDiamond cuttingEthyl acrylate

The invention provides a composition and a method for preparing diamond wire saw with the composition. The composition comprises the following raw materials by weight: 85-95wt% of alpha cyan ethyl acrylate, 3-8wt% of a tackifier, 1-3wt% of a stabilizer and 2-4wt% of a polymerization inhibitor. The method solves the technical problems of irregular arrangement of diamonds, uneven wire diameter, poor processing precision and low diamond cutting utilization rate in the prior art.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

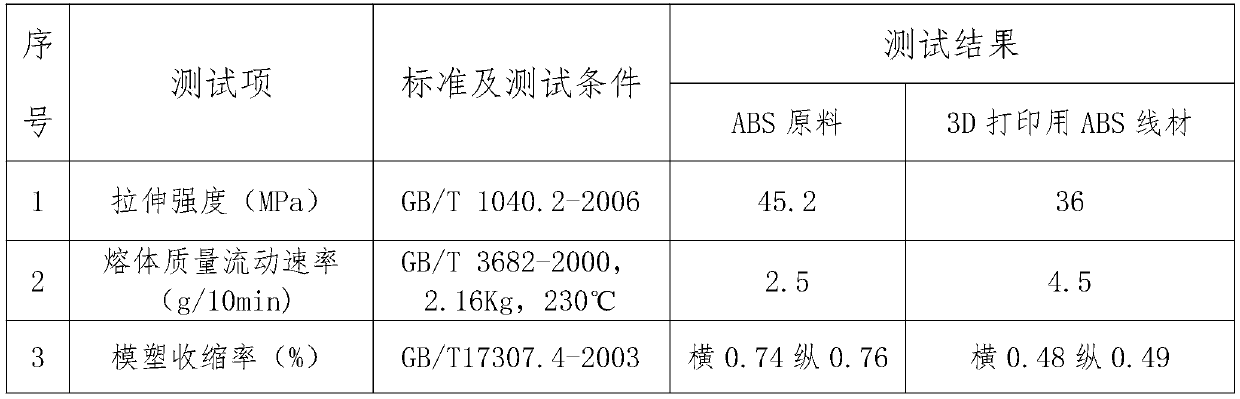

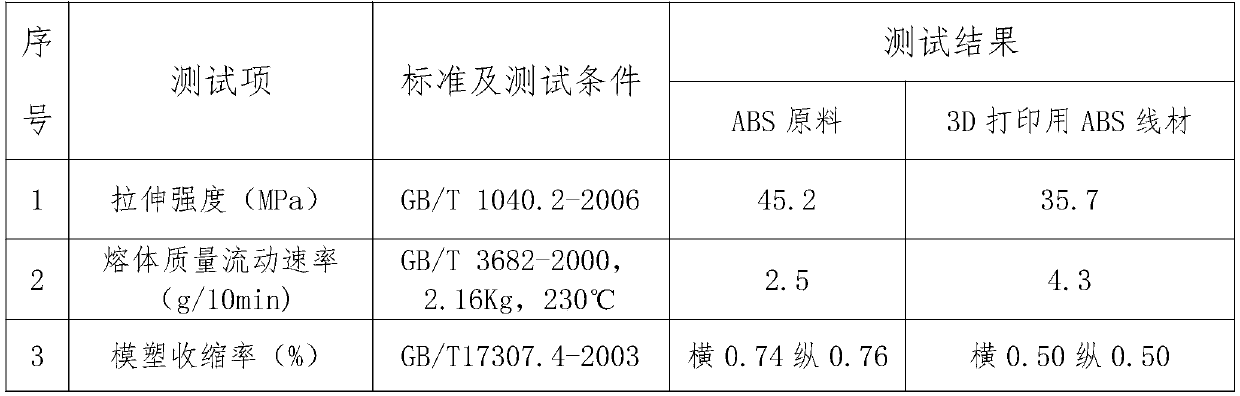

ABS consumable for 3D printing, and preparation method thereof

InactiveCN109651752AImprove performanceLow priceAdditive manufacturing apparatusPolymer scienceAntioxidant

The invention provides an ABS consumable for 3D printing, and a preparation method thereof. The ABS consumable for 3D printing comprises acrylonitrile-butadiene-styrene resin, talcum powder master batches, calcium carbonate, a styrene-butadiene-styrene block copolymer, an antioxidant, a lubricant, a compatibilizer and color master batches. The preparation method comprises the following steps: rawmaterial drying, high-speed mixing, blending extrusion granulation, secondary drying and wire extrusion preparation. The product has the characteristics of low production cost, high mechanical strength, excellent processing fluidity, good impact resistance, long service life, uniform wire diameter, smooth surface, high glossiness and low shrinkage rate.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

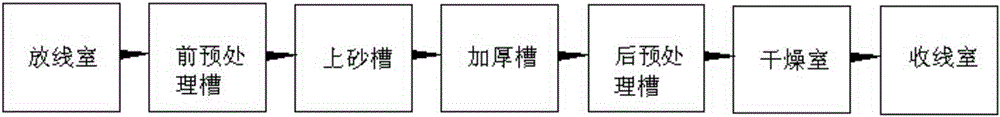

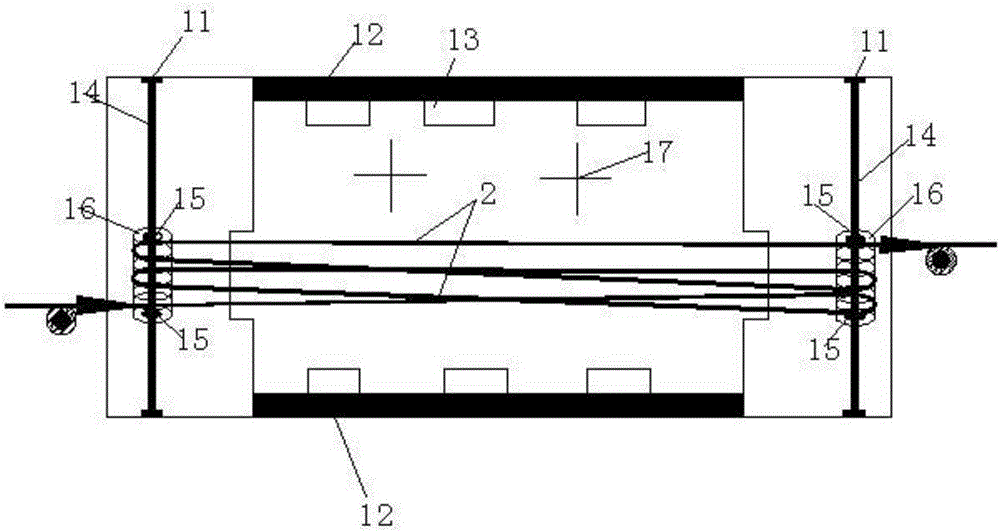

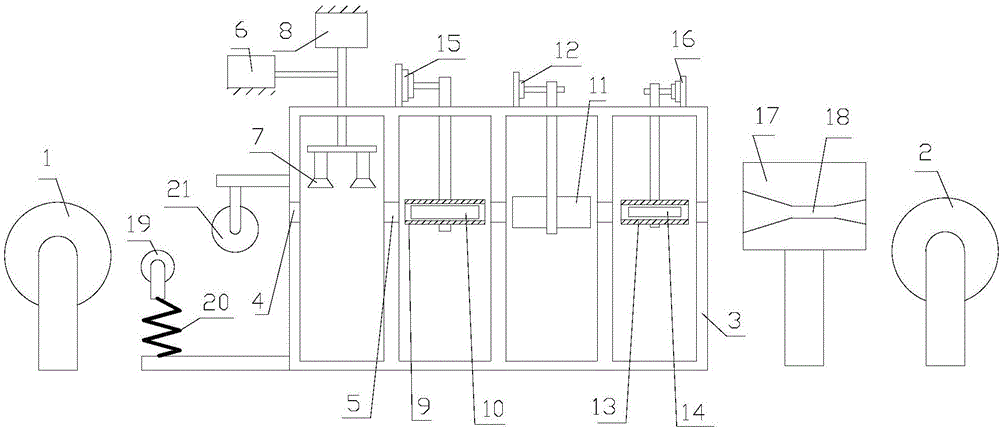

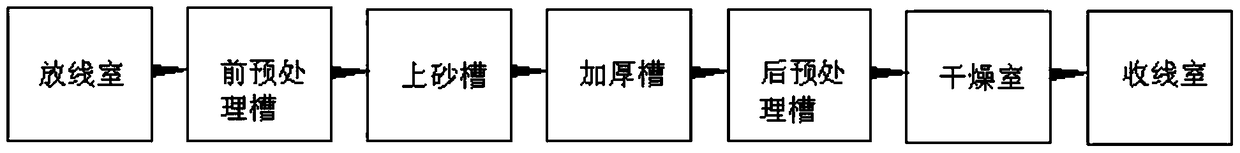

Device for manufacturing electroplated diamond wire saw

The invention discloses a device for manufacturing an electroplated diamond wire saw. The device comprises a wire unwinding chamber, a pretreatment tank, a sand feeding tank, a thickening tank, a drying chamber and a wire winding chamber; a cathode of the sand feeding tank is connected with a negative electrode of a power supply through a conductive shaft; a conductive cathode wheel is connected to the conductive shaft through a metal bearing; a base wire is wound on the conductive cathode wheel; the cathode of the thickening tank is also connected with the negative electrode of the power supply through the conductive shaft; the conductive cathode wheel is connected to the conductive shaft through the metal bearing; the base wire is wound on the conductive cathode wheel. According to the device disclosed by the invention, in the sand feeding tank and the thickening tank, each base wire is wound on the cathode wheel of the corresponding cathode so that the base wire becomes a negative electrode; each metal bearing mounted between the corresponding cathode wheel and the corresponding conductive shaft is capable of guaranteeing good electric conductivity and is also capable of making the corresponding cathode wheel rotate freely, so breakage of each base wire is prevented. In comparison with the previous conduction ways such as electric brush, the conduction way of the device disclosed by the invention is capable of enhancing the electric conductivity, free of loss, free of generation of graphite dust, and conductive to uniformity and wire diameter consistency of electroplated diamond particles on each base wire.

Owner:SHANGHAI FENGXUN PRECISION MACHINERY PARTS

Special polyvinyl alcohol butyral resin for 3D printing and preparation method thereof

InactiveCN108440690AImprove flow processabilityEasy to processAdditive manufacturing apparatusPolymer scienceSolvent

The invention belongs to the technical field of 3D printing, and relates to special polyvinyl alcohol butyral resin for 3D printing. The viscosity of the resin in an ethanol solution at a concentration of 10 percent is 40 to 250 Pa.s; the residual butyraldehyde content is less than or equal to 10 ppm, and the residual diethylhexenal content is less than or equal to 1,000 ppm. The invention furtherprovides a preparation method of the polyvinyl alcohol butyral resin. The preparation method comprises the following steps: dissolving polyvinyl alcohol which has a polymerization degree of 300 to 1,000 and an alcoholysis degree of 90 to 99 percent and is used as a raw material, and generating condensation reaction with aldehyde under the catalysis of acid, thereby obtaining polyvinyl alcohol butyral resin powder through neutralization reaction, washing and drying. When the special polyvinyl alcohol butyral resin for 3D printing provided by the invention is applied, no auxiliary resin is required to be added, and no solvent or plasticizer is needed; in a process of producing a 3D printing wire and a 3D printing process, no exhaust gas and odor are generated; and in addition, the product is relatively high in mechanical property and environmental aging resistance.

Owner:ZHEJIANG DECENT PLASTIC

Fluorocarbon monofilament and production method thereof

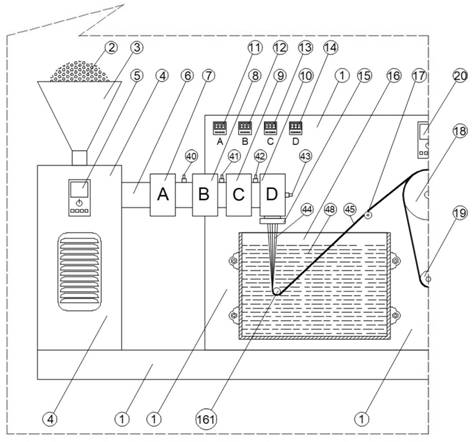

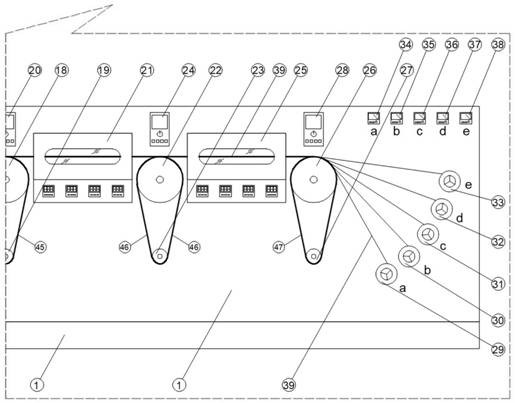

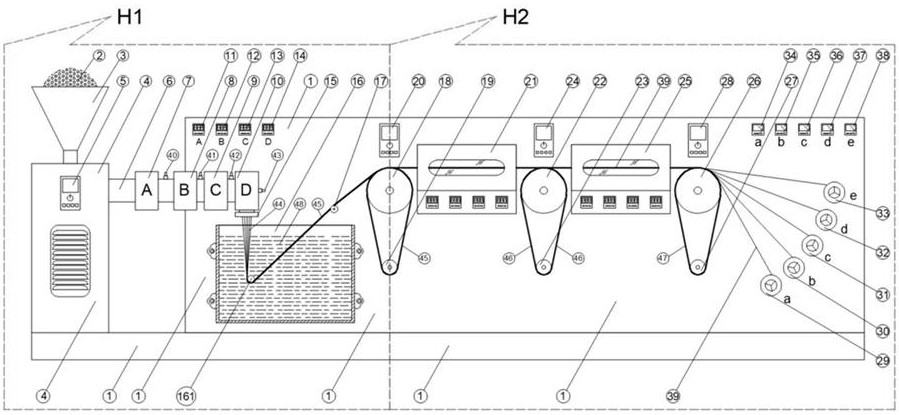

ActiveCN113005546AUniform wire diameterHigh transparencyArtificial thread manufacturing machinesFilament/thread formingGlycerolFluorocarbon

The invention discloses fluorocarbon monofilament and a production method thereof. The production method involves a seat frame, PVDF particles, a funnel, a speed reducer, a screw extruder, an A-section heater, a D-section heater, an A-section temperature controller, a D-section temperature controller, a spinneret plate, a liquid cooling box, a front traction roller, a front constant-temperature box, a middle traction roller, a rear constant-temperature box (25), a rear traction roller, a filament winding disc a, a filament winding disc d, a temperature sensor A, a temperature sensor D, molten filament, coarse-grade fluorocarbon filament, fine-grade fluorocarbon filament, ultrafine-grade fluorocarbon filament and cooling liquid; the method is characterized in that the passing time and the passing stroke of the molten filament from the spinneret plate to the cooling liquid are controlled as follows: when the filament diameter of the fluorocarbon monofilament is 0.8-2 mm, the passing time of the molten filament from the spinneret plate to the cooling liquid is 6-12 seconds, and the passing stroke is 200-300 mm; the cooling liquid comprises glycerin, silicone oil and water; and the defects that the surface of the monofilament is uneven and the filament diameter is uneven can be effectively overcome, and the purpose of high-quality mass production can be achieved.

Owner:连云港耐特网具有限公司

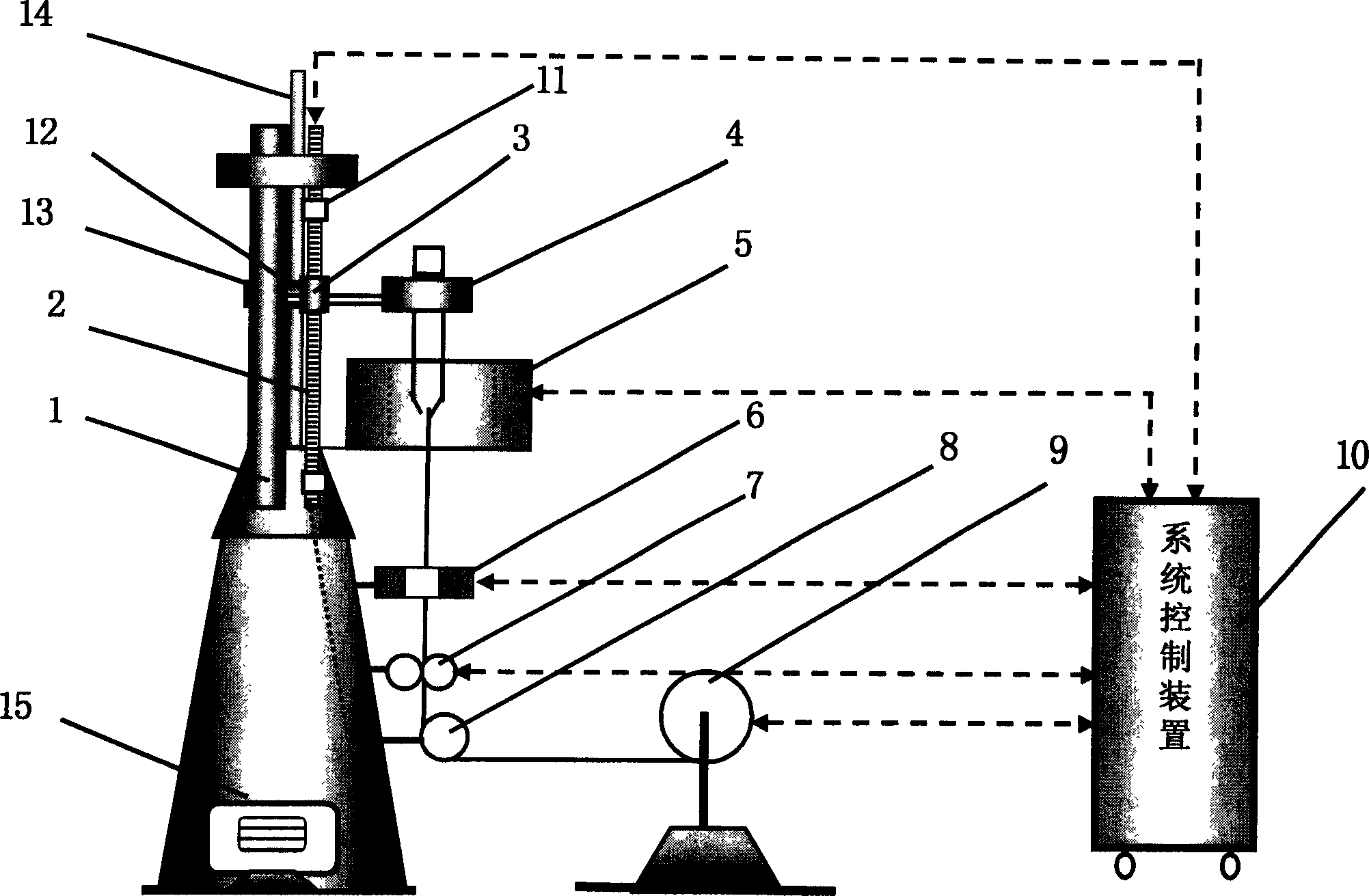

Wire-drawing equipment for polymer photon crystal optical fiber preformed rod

The invention relates to a device for drawing the fiber v rod of polymer photon crystal into polymer photon crystal fiber, which comprises a system control device, a diameter-measure device, a prefabricated-rod clamp is fixed on the upright post, a heating furnace under the prefabricated-rod clamp, a wire-drawing device under the heating furnace, a guide wheel under the wire-drawing device, and a wire-coiling device at the back of guide wheel. Wherein, the clamp head of prefabricated-rod clamp is connected with a sliding block; the sliding block is connected a lead-screw thread; and the lead-screw thread is connected to motor and vertical arranged on the upright post. The invention can solve the problems of present technique which needs high heating temperature, bigger device volume, high cost, and lower productivity. Said invention has the advantages of tight structure, easy process control, high property and high quality while the temperature of heating furnace is around 200Deg. C.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Preparation method for Tb-Fe-Co ternary rare earth alloy magnetic nano-wire film

ActiveCN107460505AFacilitate depositionAvoid hydrolysisNanotechnologyElectroforming nanostructuresGlycineNanowire

The invention discloses a preparation method for a Tb-Fe-Co ternary rare earth alloy magnetic nano-wire film. The method comprises the following steps: preparing a Tb-Fe-Co nano-wire film in an aqueous solution by utilizing an electrochemical deposition method; adding glycine into a Tb-Fe-Co solution system, so that the glycine and Tb form a complex compound; and enabling reducing potential to move positively, simultaneously, increasing a pH value, weakening a hydrogen evolution reaction, so that Tb<3+> is reduced from the solution. The preparation method is simple in process, low in cost and high in success rate; and the compositions of an alloy deposition film are regulated by controlling the proportions of electrolyte compositions and deposition process conditions.

Owner:HEBEI UNIV OF TECH

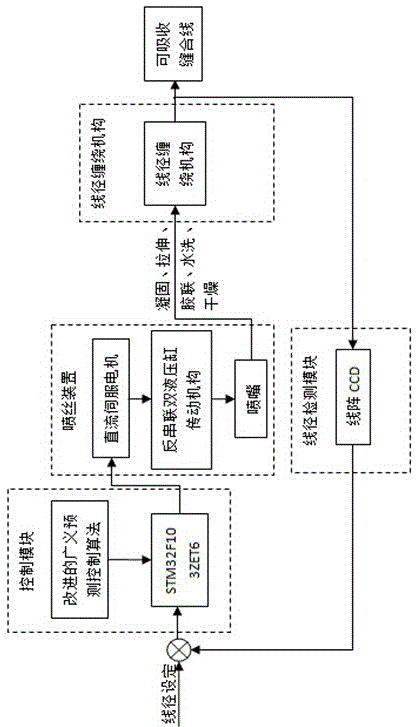

System and method for controlling diameter of absorbable suture lines in spinning forming process

InactiveCN105463590AImprove stabilityRecognition speed is fastSpinning head liquid feederArtificial thread manufacturing machinesYarnDevice form

The invention relates to a system and method for controlling the diameter of absorbable suture lines in the spinning forming process. A spinning device formed by the structure of a reverse series connection double-hydraulic-cylinder transmission mechanism is adopted, and every time forward rotation and backward rotation of a direct-current servo motor are switched, a cylindrical piston A and a cylindrical piston B reciprocate once. The flowing speed of a stock solution sprayed out by a nozzle can be controlled by adjusting the rotating speed of the forward rotation and the backward rotation of the direct-current servo motor, the nozzle can be controlled to spray out nascent state yarns with the corresponding diameter according to the set flowing speed value accordingly, the yarns are treated through the working procedures of solidification liquid passing, stretching, crosslinking, washing and drying, and then the absorbable suture lines are formed through winding of a yarn winding mechanism. It is guaranteed that the input stock solution and the output stock solution are uninterrupted in the spinning process and the flowing speed of the output stock solution is almost free of fluctuation, and the absorbable suture lines with the line diameter meeting the requirement are obtained. The diameter of the detected absorbable suture lines is controlled with an improved generalized predictive control algorithm, the calculation process of the algorithm is simplified, the stability of the control system is improved, and a better control effect is achieved.

Owner:TIANJIN POLYTECHNIC UNIV

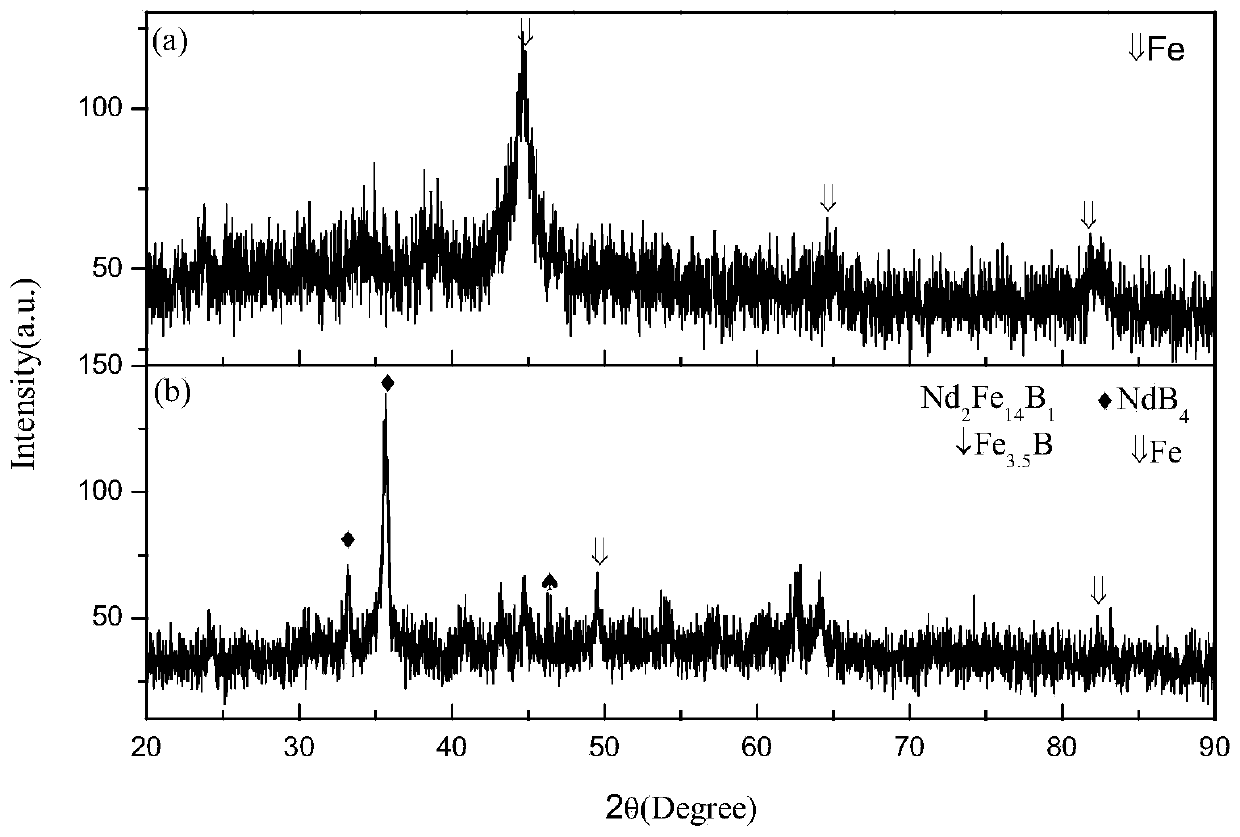

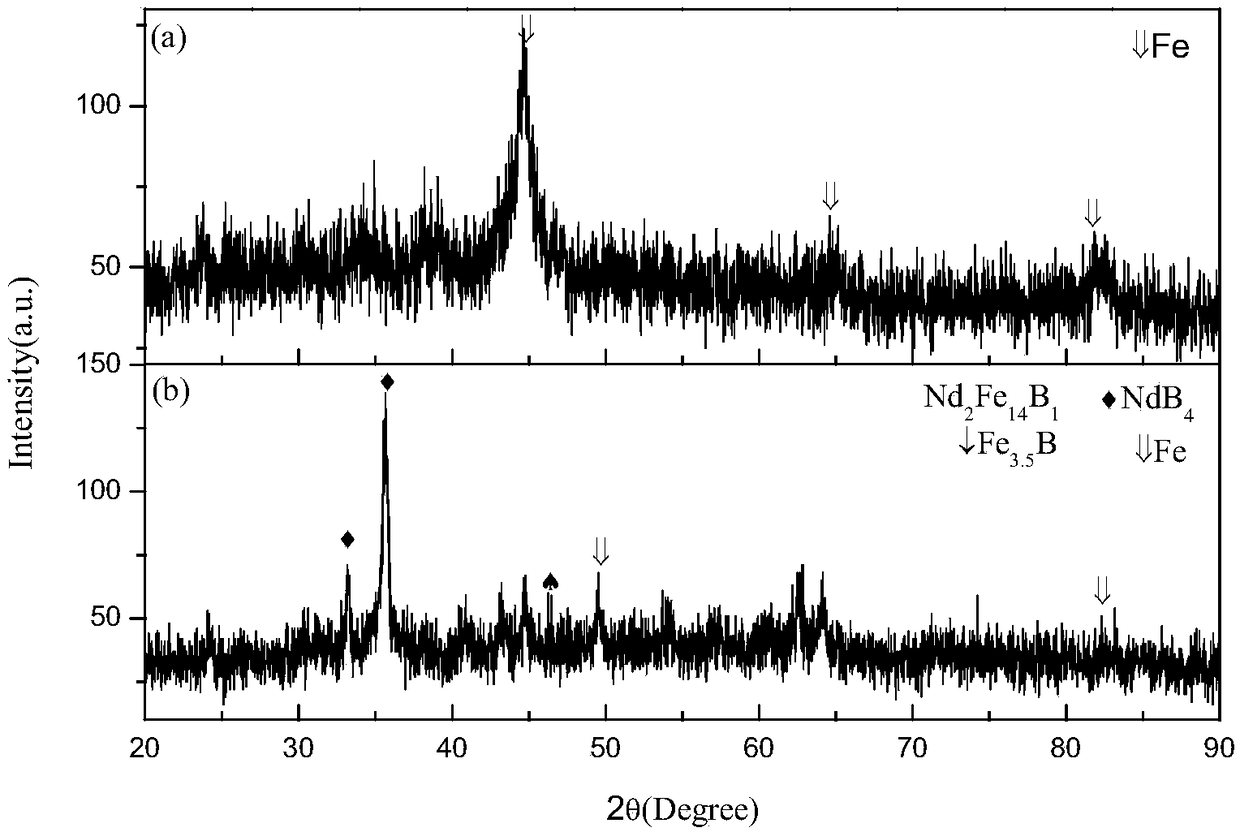

Preparation method of nd-fe-b magnetic nanowire array

ActiveCN108660487BA large amountIncrease deposition rateSurface reaction electrolytic coatingNanotechnologyElectrolytic agentNeodymium chloride

Owner:HEBEI UNIV OF TECH

Welding wire machining device

InactiveCN106624469AGood lubricityNot easy to disconnectWelding/cutting media/materialsSoldering mediaEngineeringMachining

The invention discloses a welding wire machining device. The welding wire machining device comprises a wire releasing part, a pressing and holding part, a cleaning part, a lubricating part, a forming part and a winding part which are distributed in sequence. The wire releasing part is used for releasing metal wires. The pressing and holding part comprises a bracket, a supporting shaft, a pressing shaft and a spring; the bracket is provided with a chute which is formed in the vertical direction; the supporting shaft is horizontally installed on the bracket; the pressing shaft is arranged above the supporting shaft, horizontally arranged and movably connected with the chute; a threading channel is formed between the pressing shaft and the supporting shaft; and one end of the spring is connected with the pressing shaft, the other end of the spring is connected with the bracket, and the spring is used for applying downward acting force to the pressing shaft.

Owner:天长市通联焊业有限公司

Device for processing and producing welding wires

InactiveCN106623454AImprove the lubrication effectReduce wearExtrusion cleaning devicesEngineeringElectrical and Electronics engineering

The invention discloses a device for processing and producing welding wires. The device for processing and producing the welding wires comprises a pay-off mechanism, a lubricating mechanism, a shaping mechanism and a wire drawing mechanism arranged sequentially. The lubricating mechanism comprises a box body, a spraying assembly, a cleaning assembly, a lubricating assembly and a leveling assembly; a first wire threading hole, a first connecting hole, a second connecting hole, a third connecting hole and a second wire threading hole are formed in the box body and are arranged coaxially; a first chamber, a second chamber, a third chamber and a fourth chamber are arranged in the box body; the first wire threading hole and the first connecting hole are connected with the first chamber; the first connecting hole and the second connecting hole are connected with the second chamber; the second connecting hole and the third connecting hole are connected with the third chamber; and the third connecting hole and the second wire threading hole are connected with the fourth chamber.

Owner:天长市通联焊业有限公司

A device for preparing electroplated diamond wire saw

ActiveCN106467976BEvenly distributedSmall footprintElectrolytic coatingsDiamond wire sawPre treatment

The invention discloses a device for manufacturing an electroplated diamond wire saw. The device comprises a wire unwinding chamber, a pretreatment tank, a sand feeding tank, a thickening tank, a drying chamber and a wire winding chamber; a cathode of the sand feeding tank is connected with a negative electrode of a power supply through a conductive shaft; a conductive cathode wheel is connected to the conductive shaft through a metal bearing; a base wire is wound on the conductive cathode wheel; the cathode of the thickening tank is also connected with the negative electrode of the power supply through the conductive shaft; the conductive cathode wheel is connected to the conductive shaft through the metal bearing; the base wire is wound on the conductive cathode wheel. According to the device disclosed by the invention, in the sand feeding tank and the thickening tank, each base wire is wound on the cathode wheel of the corresponding cathode so that the base wire becomes a negative electrode; each metal bearing mounted between the corresponding cathode wheel and the corresponding conductive shaft is capable of guaranteeing good electric conductivity and is also capable of making the corresponding cathode wheel rotate freely, so breakage of each base wire is prevented. In comparison with the previous conduction ways such as electric brush, the conduction way of the device disclosed by the invention is capable of enhancing the electric conductivity, free of loss, free of generation of graphite dust, and conductive to uniformity and wire diameter consistency of electroplated diamond particles on each base wire.

Owner:SHANGHAI FENGXUN PRECISION MACHINERY PARTS

A method of making electroplated superabrasive cutting wire

The invention discloses a method for making an electroplated superabrasive cutting wire, which includes a method for chemical composite plating on the surface of a superhard abrasive, wherein the surface of superhard abrasive particles is coated with a layer of nickel-phosphorus alloy by the method of chemical composite plating , the nickel-phosphorus alloy layer contains solid particles, and the solid particles are non-conductive particles. In the present invention, the surface of the superhard abrasive forms a nickel-phosphorus coating containing solid particles by electroless plating. The solid particles in the coating are non-conductors, doped in the nickel-phosphorus alloy, occupy a certain volume space, and reduce the conductivity of the nickel-phosphorus alloy. It can suppress the cathodic discharge reaction on the surface of the superabrasive deposited on the steel wire during the electrodeposition process, thereby avoiding the agglomeration of the superabrasive on the cutting line, making the diameter of the cutting line uniform, and eliminating the need for subsequent processes to remove The agglomerated superhard abrasive can correct the wire diameter, reduce the production cost and improve the production efficiency.

Owner:QINGDAO GAOCE TECH CO LTD

Upper sand tank for producing composite electroplating diamond line and its usage method

ActiveCN106283163BGuaranteed initial dispersion effectReasonable structureElectrolytic coatingsBusbarEngineering

The invention provides an upper sand tank for producing a composite electroplating diamond wire and a use method thereof. The electroplating sand tank mainly includes the sand tank body, liquid inlet circulation device, liquid inlet distribution device, steel wire transmission device, etc. The device adopts the liquid inlet distribution device of the multi-stage distribution pipe to enter the liquid from the bottom of the upper sand area. The longitudinal distribution of diamond particles near the steel wire busbar inside is uniform, and the sanding rate of diamond micropowder on the steel wire busbar after electrification and electroplating is controllable, and the fine powder is not easy to agglomerate and is well distributed. The invention can continuously produce the electroplated diamond wire with good distribution of diamond micropowder, uniform wire diameter and excellent cutting performance, and has reasonable structure, high production efficiency and high utilization rate of raw materials.

Owner:张家口原轼新型材料股份有限公司

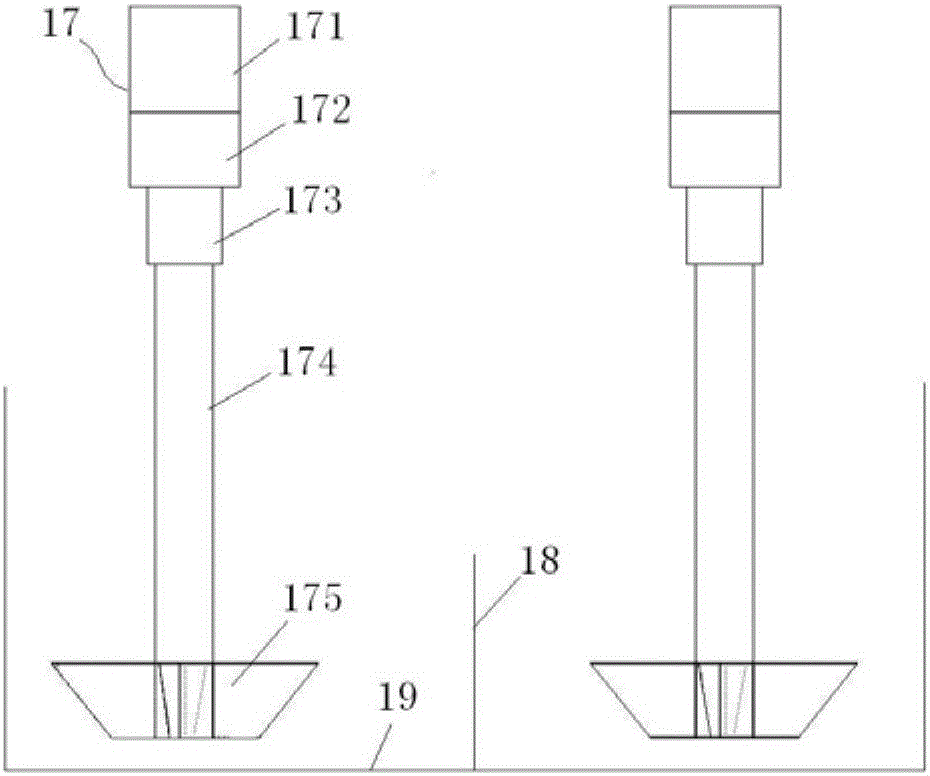

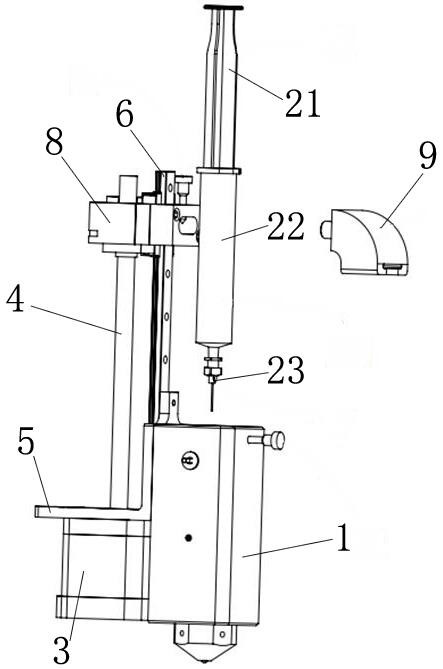

A piston extrusion nozzle for a 3D printer

ActiveCN108891026BNo need to clean upAvoid the possibility of exposure to germsManufacturing driving meansManufacturing heating elementsComputer printingThermal insulation

The invention provides a piston extrusion nozzle of a 3D printer, which includes a heat preservation sleeve assembly, a detachable piston syringe inserted in the heat preservation sleeve assembly, and a piston rod for driving a piston rod to move linearly in a piston cylinder of the piston syringe. The drive module; the drive module includes a module motor arranged on one side of the insulation cover assembly, a lead screw connected to the output shaft of the module motor, and a slider pierced on the lead screw an assembly, wherein one end of the slider assembly close to the thermal insulation sleeve assembly is detachably connected to the tail end of the piston rod. The piston extrusion nozzle of the 3D printer of the present invention uses a detachable piston syringe to replace the conventional non-detachable piston cylinder, which can avoid the process of secondary transfer of biological materials and ensure that the biological materials are not polluted. One side of the insulation cover assembly reduces the overall height of the nozzle and increases the printing size.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Preparation method of Nd-Fe-B magnetic nanowire array

ActiveCN108660487AA large amountIncrease deposition rateSurface reaction electrolytic coatingNanotechnologyNeodymium chlorideIron(II) chloride

The invention discloses a preparation method of a Nd-Fe-B magnetic nanowire array. The preparation method comprises the following steps: neodymium chloride (NdCl3.6H2O), ferrous chloride (FeCl2.4H2O),boric acid (H3BO3) and de-ionized water are mixed to prepare NdFeB alloy solution; a complexing agent is added to obtain depositing liquid, wherein the complexing agent is glycine (NH2CH2COOH), ammonium chloride (NH4Cl) and ascorbic acid (C6H8O6); and graphite is used as an anode, an AAO template is used as a cathode, the Nd-Fe-B depositing liquid prepared in the last step is electrolyte, and a direct-current voltage-stabilization power supply is used for electrochemical deposition to finally obtain Nd-Fe-B ternary alloy magnetic nanowires. The obtained nanowires are high in number and deposition rate, arranged in parallel, ordered in height, uniform in diameter and higher in length-diameter ratio.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com