Automatic wrapping device of insulation layer of wire and cable

A wire and cable and coating device technology, which is applied in the direction of conductor/cable insulation, etc., can solve the problems of uneven thickness of insulation layer, deviation of wire core, uneven thickness of coating, etc., and achieve smooth appearance and uniform wire diameter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

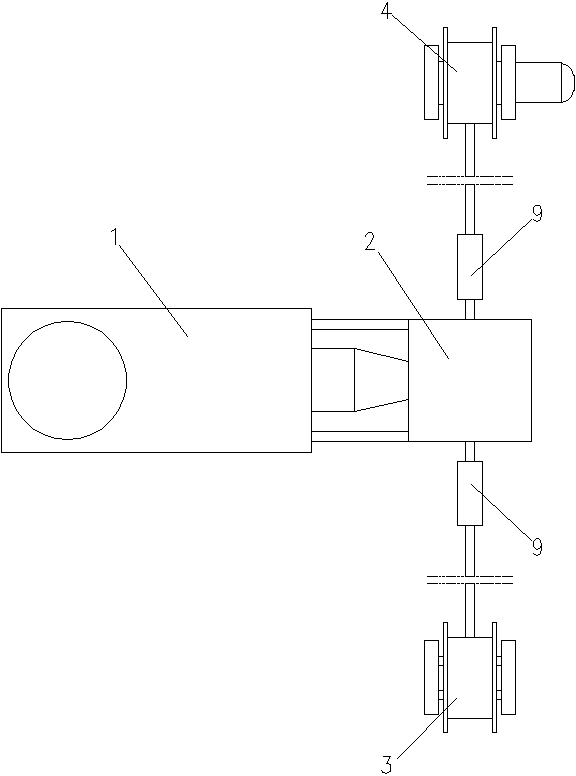

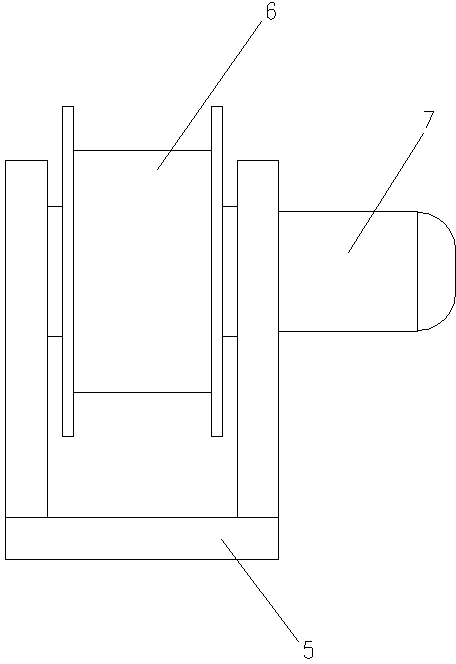

[0022] As shown in the figure, the automatic coating device for the insulation layer of wires and cables includes: a screw extruder 1, which is characterized in that: a rubber coating device 2 is provided at the glue outlet of the screw extruder 1, and the rubber coating The device 2 is fixedly connected to the screw extruder 1 through a bracket. The front and rear sides of the rubber covering device 2 are respectively provided with a wire release device 3 and a wire take-up device 4. The copper core of the cable is wound between the wire release device 3 and the wire take-up device. between the devices 4 and pass through the lagging device 2 at the same time.

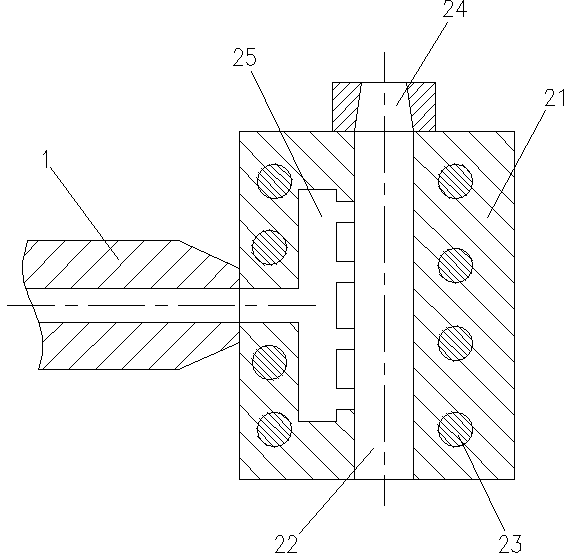

[0023] Preferably, the encapsulation device 2 is composed of an encapsulation base body 21, a wire passing channel 22, a heater 23, a glue flow chamber 25 and a rubber scraping head 24, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com