Antenna and its mfg. method

A technology for antennas and antenna units, applied to antennas, antenna parts, and other household appliances, can solve the problem of uneven thickness of resin coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

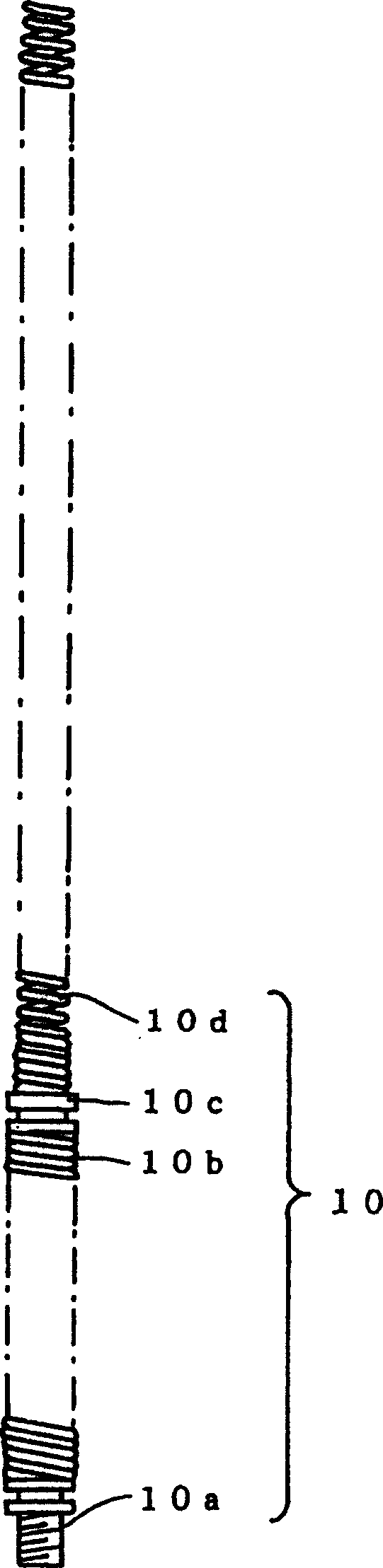

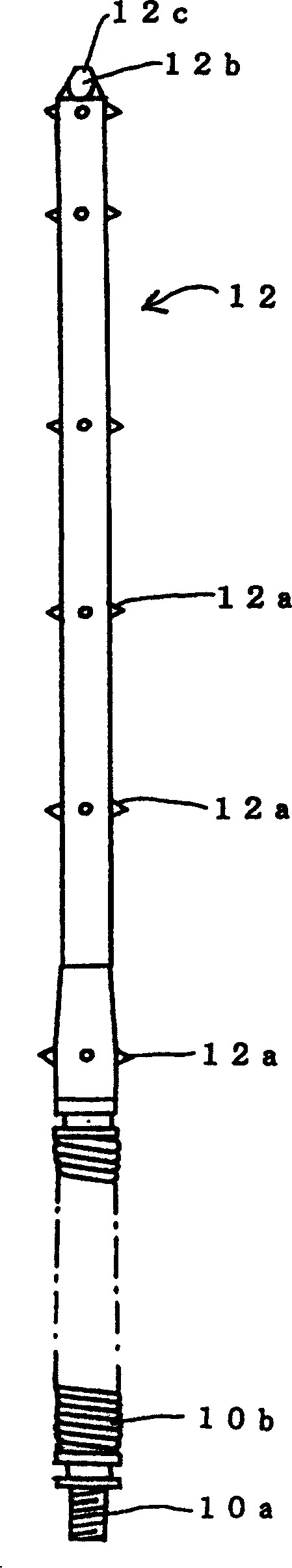

[0036] like figure 1 As shown, an antenna unit 10 includes: a fastening screw 10a on the bottom end; a spring portion 10b of a solid coil located above the fastening screw 10a; a connecting fitting 10c; Helical coil element 10d on top of portion 10b. The fastening screw 10a, the spring portion 10b, the connection fitting 10c and the helical coil element 10d are integrally connected electrically to operate as an antenna.

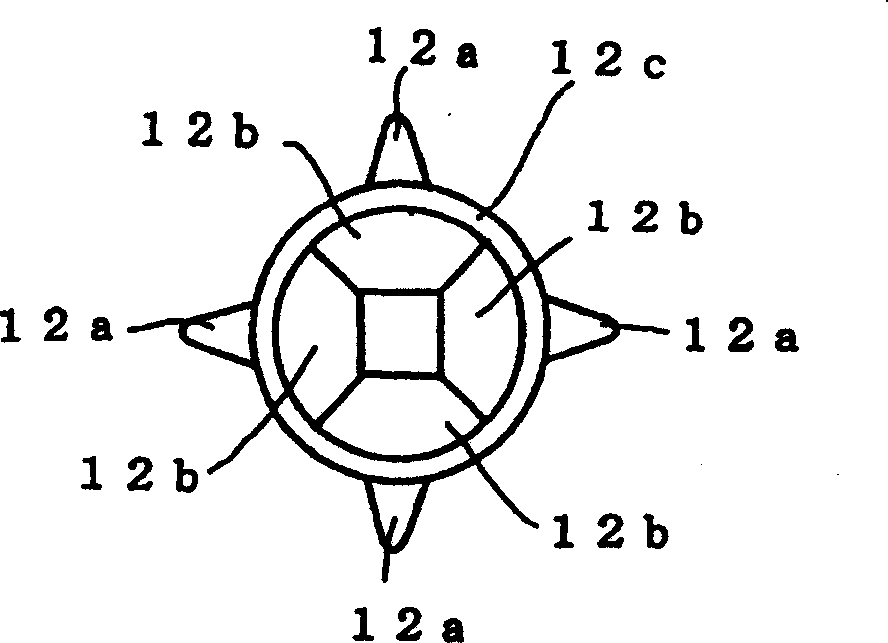

[0037] Portions of the antenna unit 10 corresponding to the connection fitting 10c and the helical coil element 10d are inserted into an unshown mold to form a resin molded part. The outer circumference of the helical coil element 10d just comes into contact with the inner surface of the mold to be placed in a predetermined position. Insulating resin is injected into the mold so that a resin molded part 12 is integrally mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com