A device for preparing glutinous rice balls with patterns on the surface

A pattern and color technology, which is applied in the field of devices for preparing glutinous rice balls with patterns on the surface, can solve the problems of disordered texture and lack of aesthetics of colored glutinous rice balls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

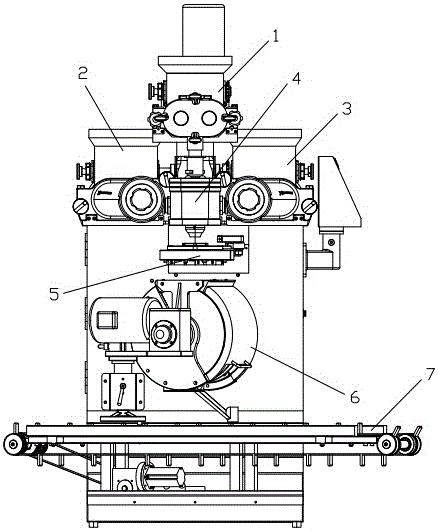

[0061] A device for preparing glutinous rice balls with patterns on the surface comprises a filling device 1, a noodle supply device 2, a color material device 3, a compound head device 4, a cutter device 5 and a rounding device 6, the filling device 1, the feeding device The noodle device 2 and the color material device 3 are respectively communicated with the composite head device 4, a cutter device 5 is arranged below the composite head, and a rounding device 6 is arranged below the cutter device 5;

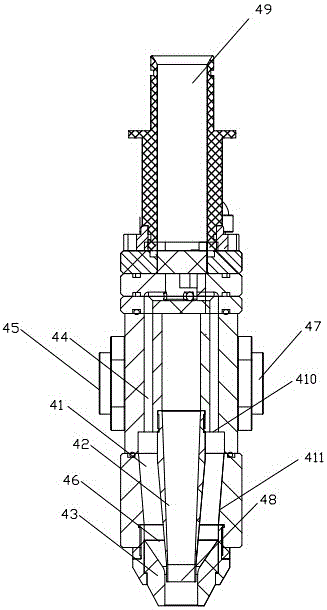

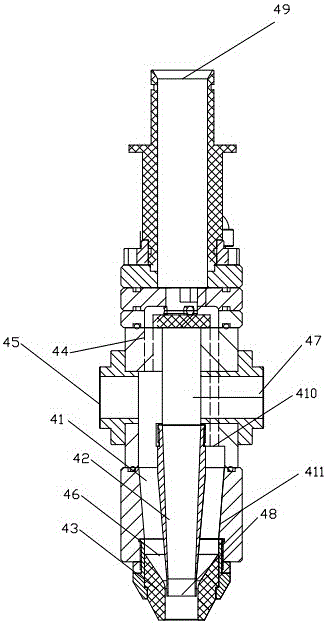

[0062] The compound head device 4 includes a noodle supply pipeline 41, a filling supply pipeline 42 is arranged in the noodle supply pipeline 41, a noodle nozzle 43 is arranged at the lower end of the noodle supply pipeline 41, and the lower end of the filling supply pipeline 42 is located on the surface of the surface. In the mouth 43 , a plurality of color material pipelines 44 are arranged on the surface supply pipeline 41 , and the multiple color material pipelines 44 comm...

Embodiment 2

[0066] On the basis of Embodiment 1, the color material pipeline 44 is arranged on the upper end surface of the noodle supply pipeline 41 , and the color material outlet 410 at the lower end of the color material pipeline 44 communicates with and is flush with the upper end surface of the noodle supply pipeline 41 . When the color material pipeline 44 is arranged on the upper end surface of the noodle supply pipeline 41, and when the color material outlet 410 is flush with the upper end surface of the noodle supply pipeline 41, the color material will flow into the noodle supply pipeline 41 from top to bottom, and adhere to the surface of the dough , form a colored skin, and then wrap the filling.

Embodiment 3

[0068] On the basis of Embodiment 1, the color material pipeline 44 is arranged on the upper end surface of the surface supply pipeline 41, and the color material outlet 410 at the lower end of the color material pipeline 44 communicates with the upper end surface of the surface supply pipeline 41 and extends into the surface supply. Inside the pipeline 41. When the color material pipeline 44 is arranged on the upper end surface of the noodle supply pipeline 41, and the color material outlet 410 stretches into the noodle supply pipeline 41, the color material will flow into the noodle supply pipeline 41 from top to bottom, and mix in the inside and the surface of the dough , form a colored skin, and then wrap the filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com