Patents

Literature

102results about How to "Composite tight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

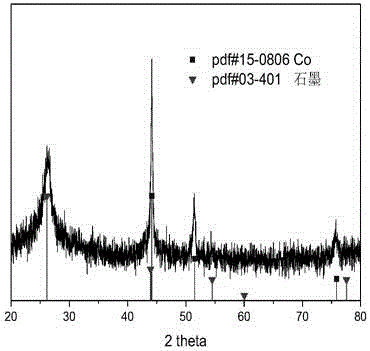

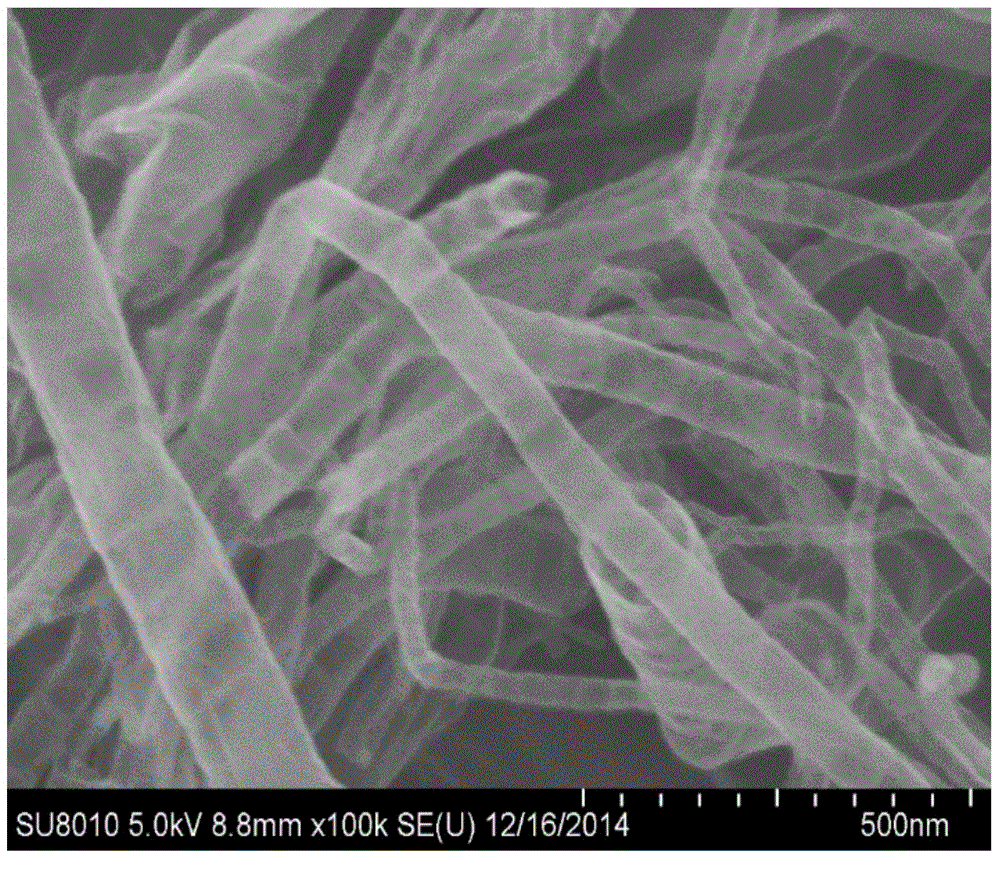

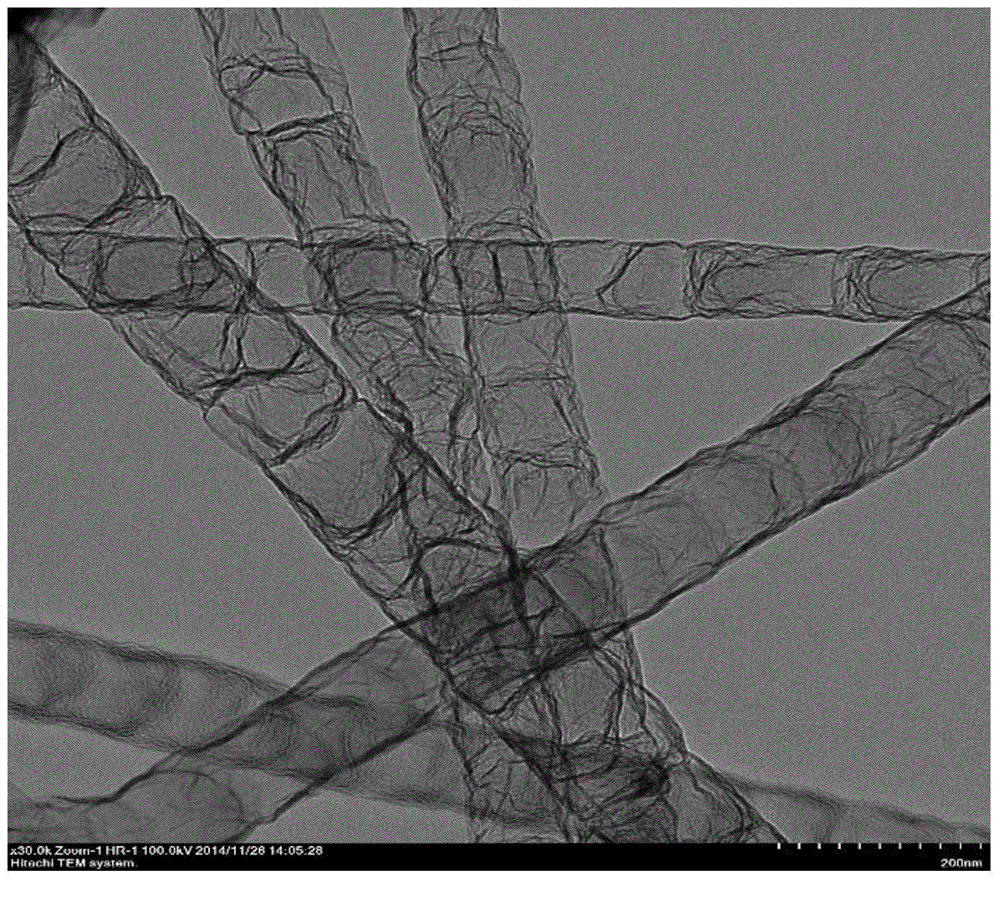

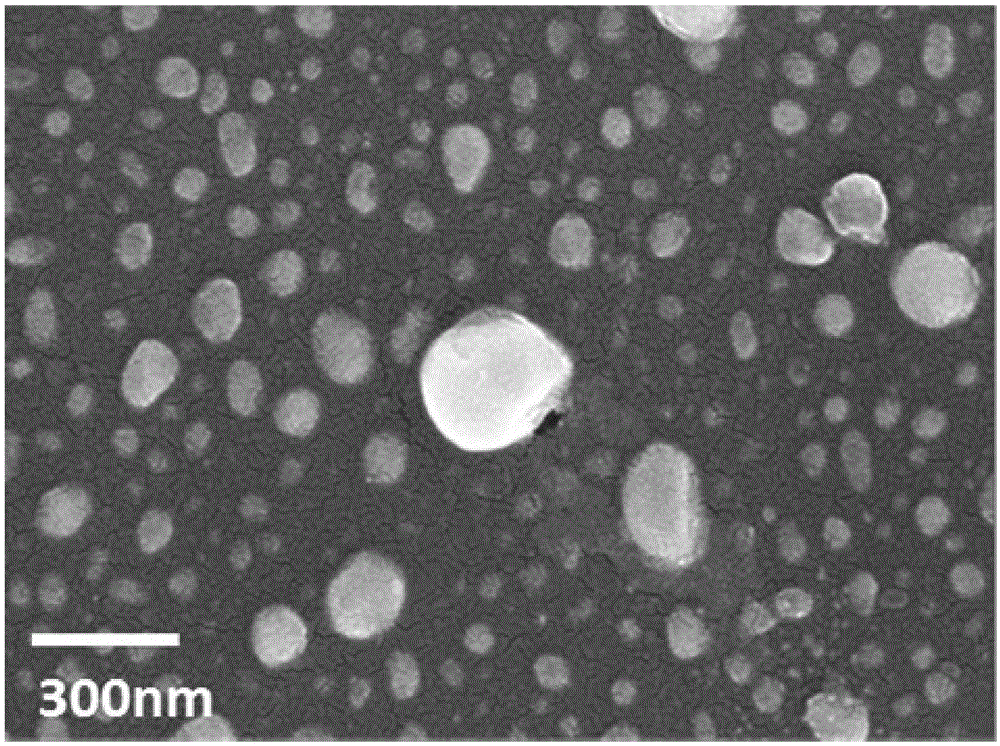

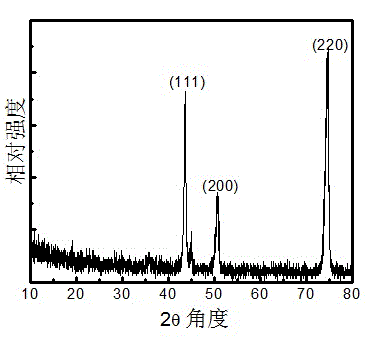

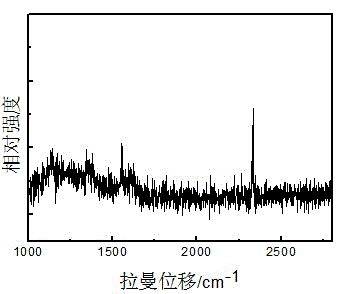

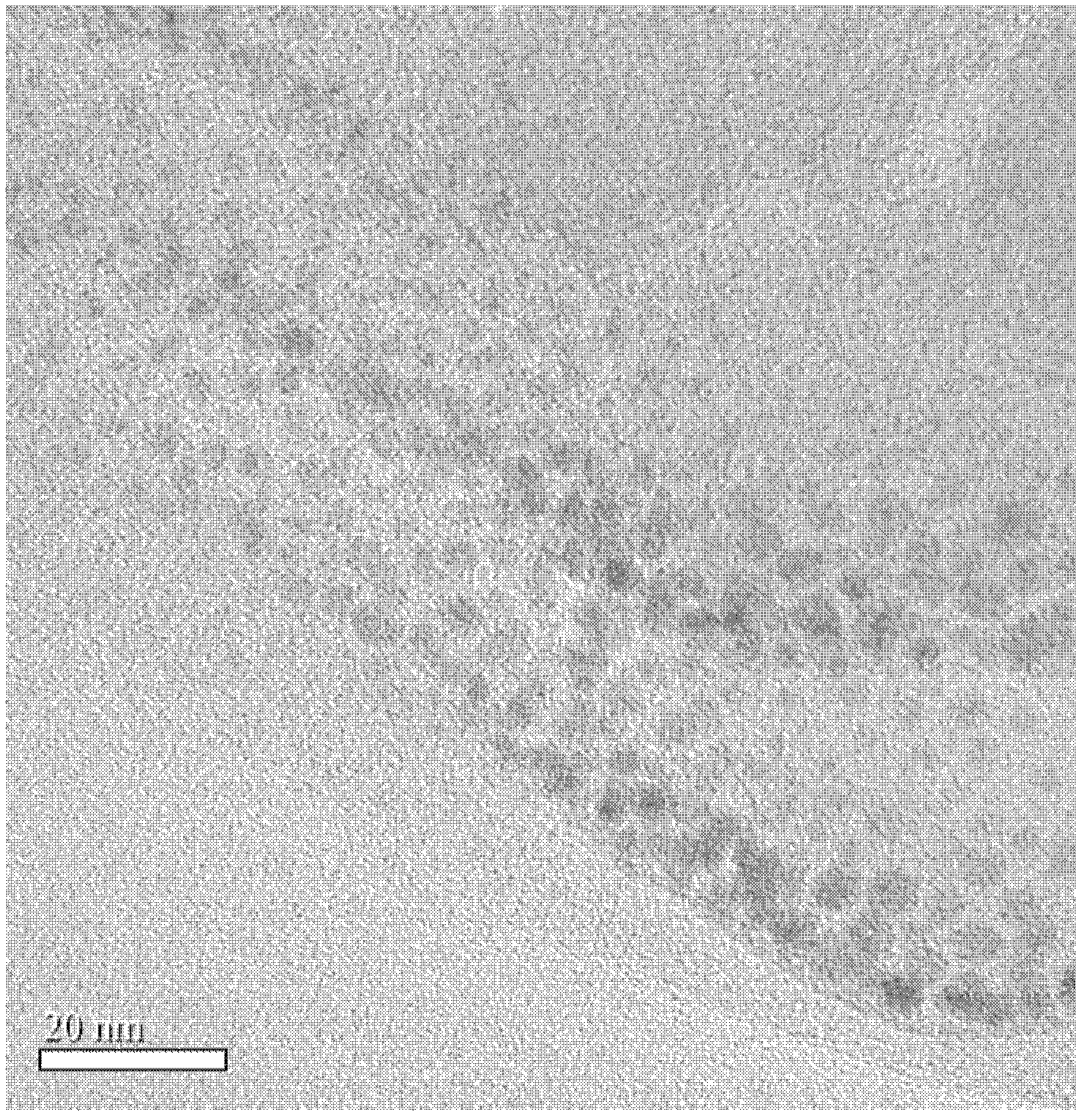

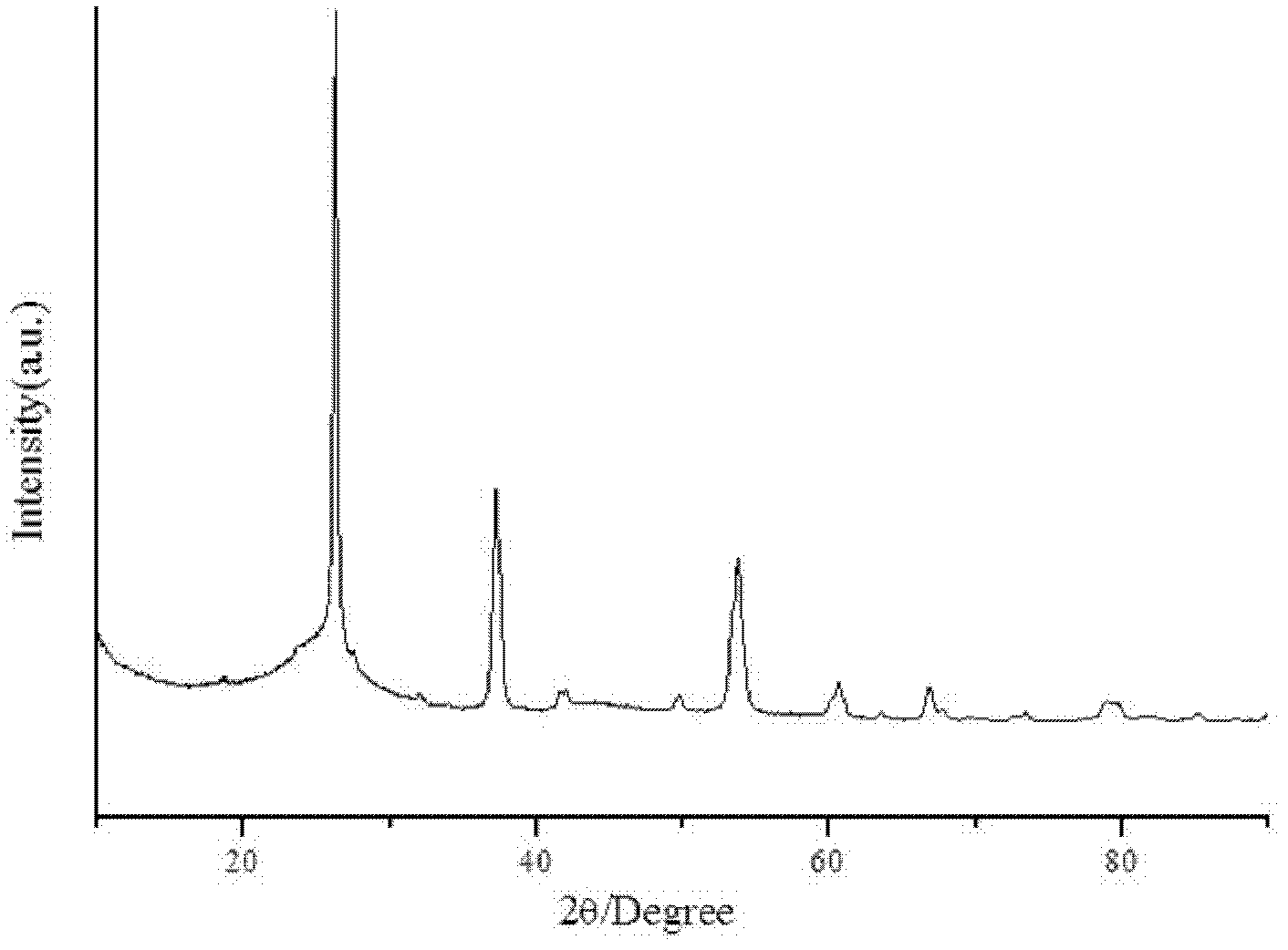

Method for synthesis of cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material

The invention discloses a method for synthesis of a cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The method includes: dissolving a soluble cobalt salt and an amine polymer in a hydrophilic reagent according to a mole ratio of 1:(2-200), performing evaporation at 60DEG C, conducting grinding after cooling, performing calcination at 400-1400DEG C under nitrogen atmosphere, then treating the sample with acid, and carrying out washing, centrifugation and drying so as to obtain the cobalt nanoparticle and bamboo-like nitrogen doped carbon nanotube composite material. The obtained cobalt nanoparticles have small particle size and are employed to coat the head of a carbon nanotube evenly so as to combine tightly with the carbon nanotube. The composite material has application prospects in fuel cell anode materials, lithium ion battery cathode materials and the like. The method designed by the invention has the advantages of easily available raw materials, simple process and no pollution, short preparation period, mild reaction conditions, low cost, and mass synthesis capability, etc.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

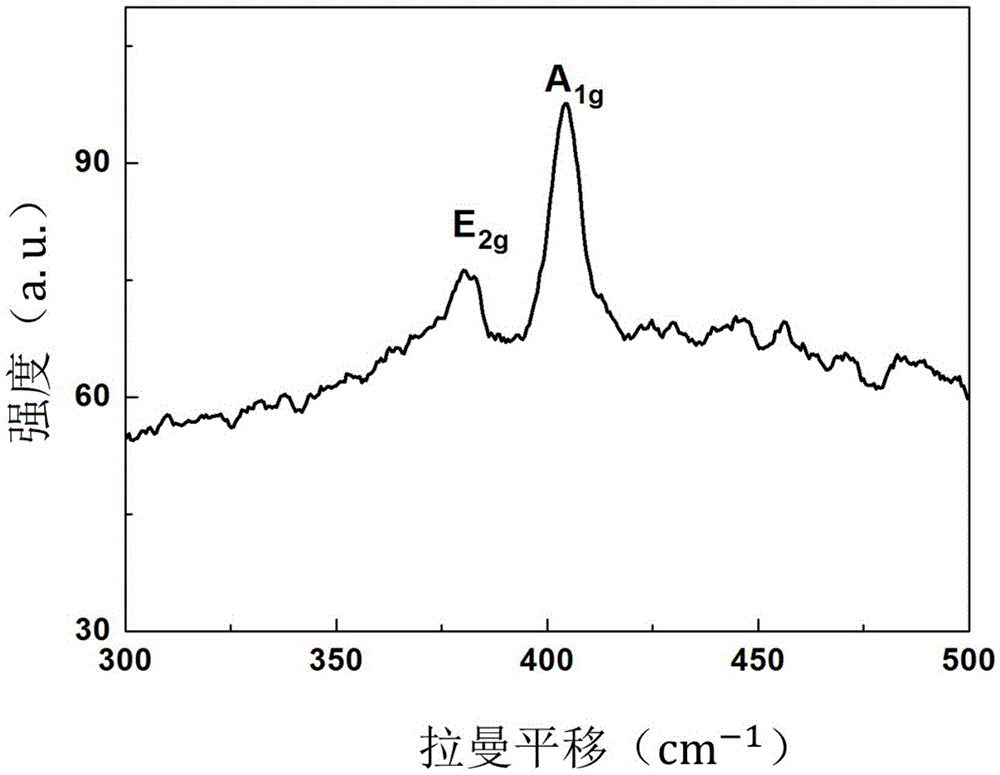

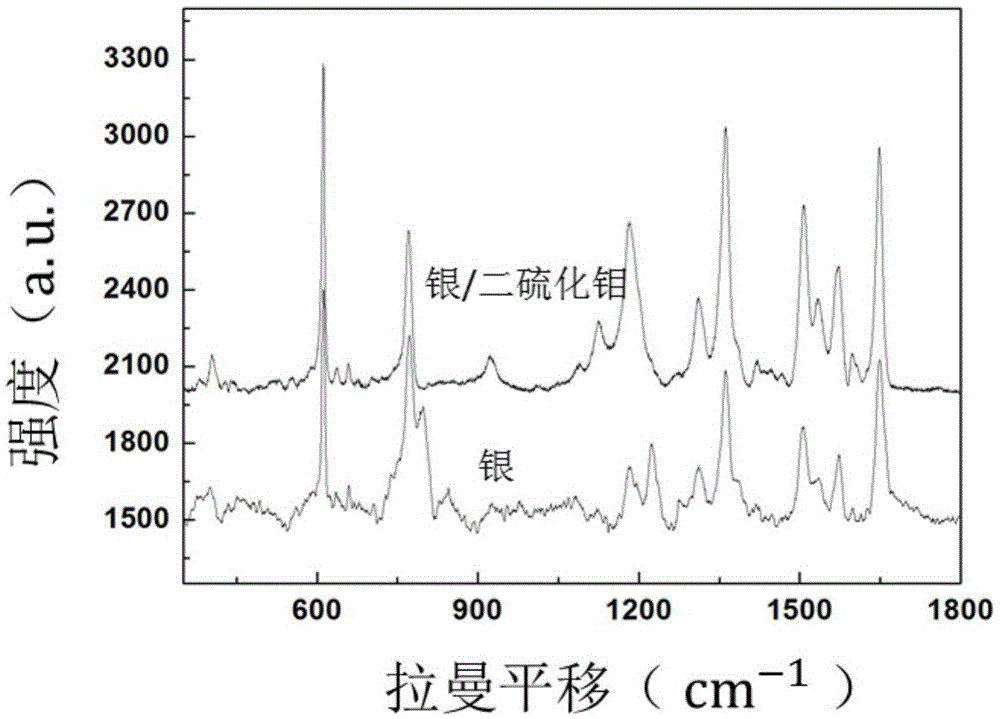

Raman enhanced base for amplifying raman signal, and preparation method and application thereof

ActiveCN105651756AReduce the temperatureReduce energy consumptionRaman scatteringThermal decompositionAmmonium tetrathiomolybdate

The invention relates to a raman enhanced base for amplifying a raman signal. A layer of MoS2 film is coated on the outer side of a substrate plated with an Ag film. A preparation method comprises the following steps: evaporating a layer of Ag film on an SERS substrate; annealing; coating an ammonium tetrathiomolybdate solution on the Ag film; performing thermal decomposition and cooling, thereby acquiring the raman enhanced base. According to the method provided by the invention, the technique is simple; the raman enhanced base can be prepared in batches; the cost can be saved while excellent raman enhanced effect can be acquired; and the practical application and popularization of the SERS substrate can be greatly promoted.

Owner:SHANDONG NORMAL UNIV

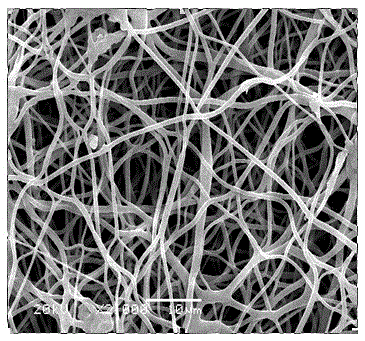

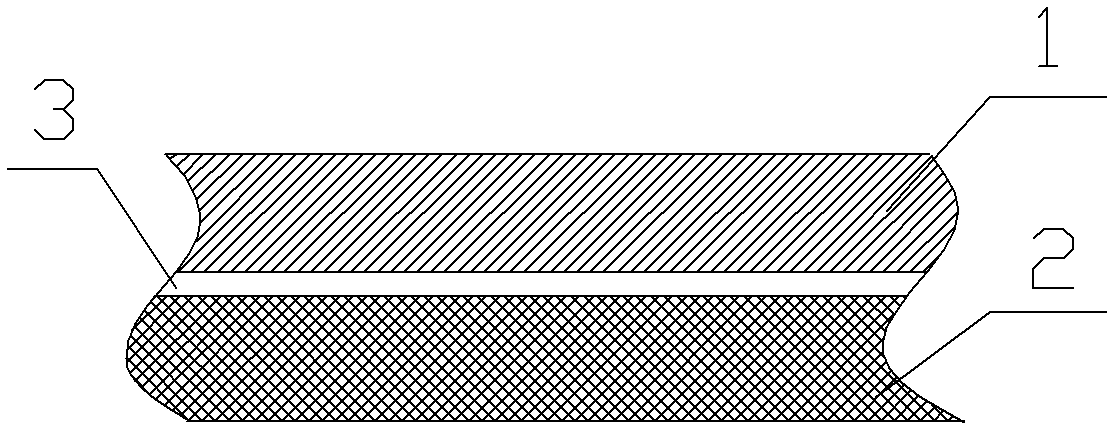

Preparation method of high-safety lithium-ion battery separator

ActiveCN105576176AHigh mechanical strengthImprove thermal stabilityFinal product manufactureCell component detailsFiberComposite film

The invention discloses a preparation method of a high-safety lithium-ion battery separator. The method comprises the following main steps: dissolving a polybasic organic carboxylic acid anhydride and organic diamine to obtain a precursor solution; preparing a polyamide acid film by an electrospinning technique; carrying out gradient heating imidization on the polyamide acid film to obtain a polyimide film; preparing a polyvinylidene fluoride film by a nonsolvent-induced phase separation method; and putting two soaked polyimide alignment films in the direction in which film fibers are vertical to each other in an overlapping manner, putting one soaked polyvinylidene fluoride film in the middle and preparing a PI / PVDF / PI composite film by a hot pressing compound method. By a three-layer composite structure, a PVDF middle layer is introduced to reduce the amount of a PI raw material; and meanwhile, the self-closing function is provided for the separator. Pretreatment is carried out on the film before the composite film is prepared, so that separator composition is relatively tight. A structure that the fibers of the two PI alignment films are vertical to each other is adopted for film composition, so that the strength of the composite film is significantly improved.

Owner:湖北江升新材料有限公司

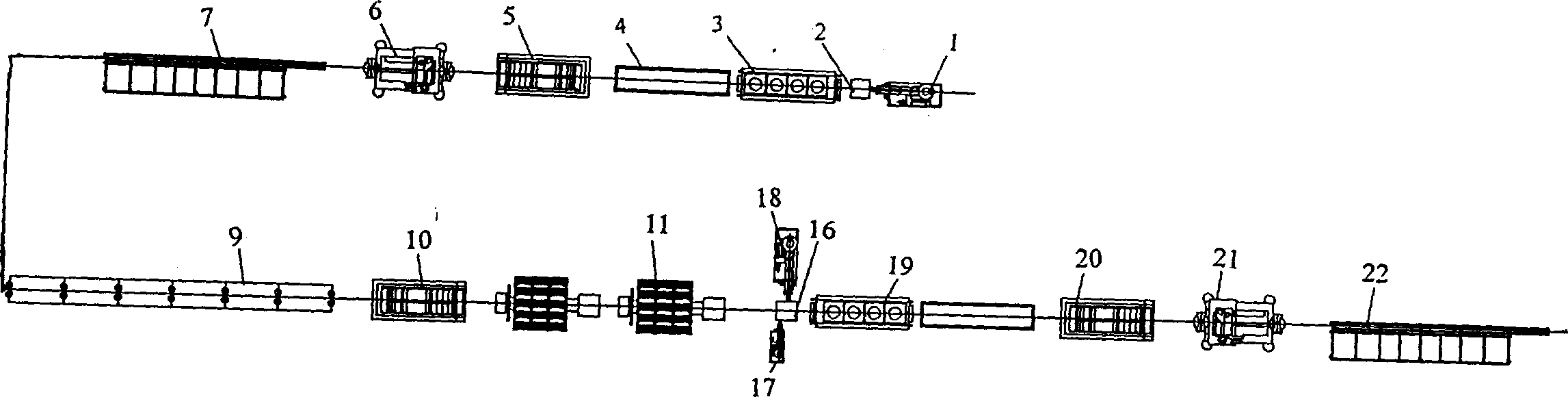

Inflating making process and apparatus of spiral wound steel wire reinforced composite plastic pipe

The production method of spiral wrapped steel wire reinforced composite plastic pipe material by using air inflation process includes the following steps: continuously extruding formed polymer core pipe, cutting it into the pipe material with a certain length; charging pressure gas into the core pipe, and sealing to obtain rigid straight sealed gas-charged core pipe, feeding said core pipe into steel wire wrapping machine, right-hand and / or left-hand wrapping steel wire round the core pipe, at least wrapping one layer of steel wire as reinforcing body, then feeding said material into polymer outer layer combination device to obtain composite pipe material, diameter-setting and forming, cooling to obtain the invented product with high quality. Said pipe material is long in service life.

Owner:甘国工

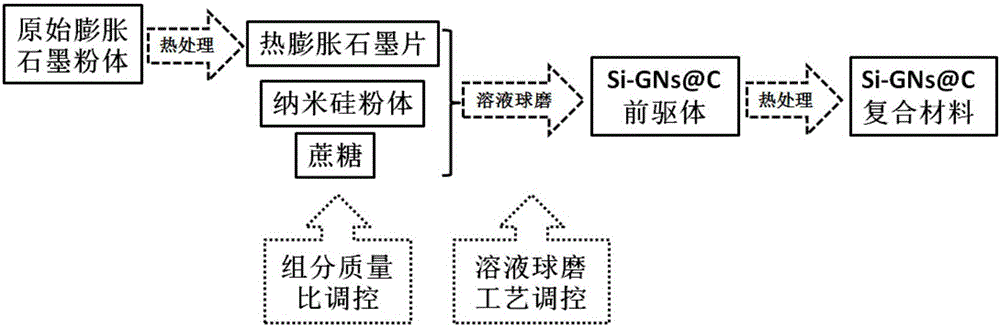

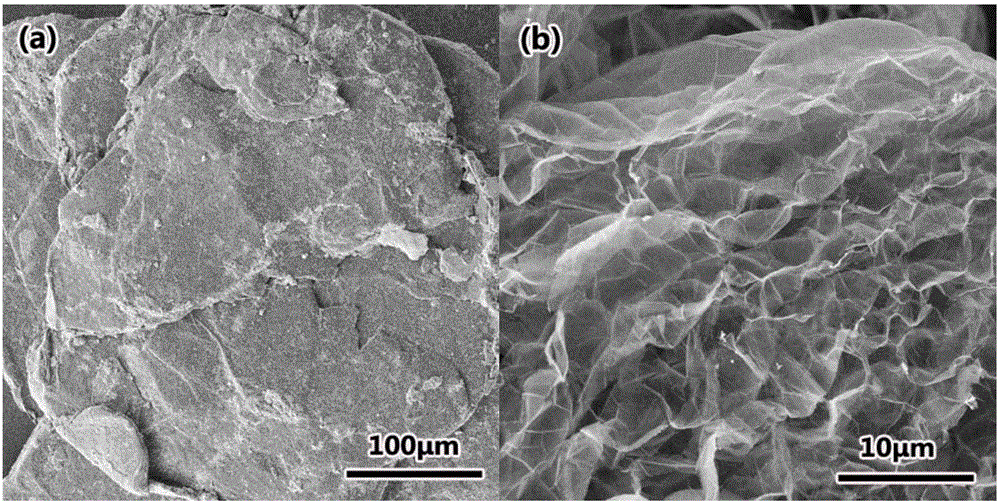

Lithium ion battery anode material and preparation method thereof

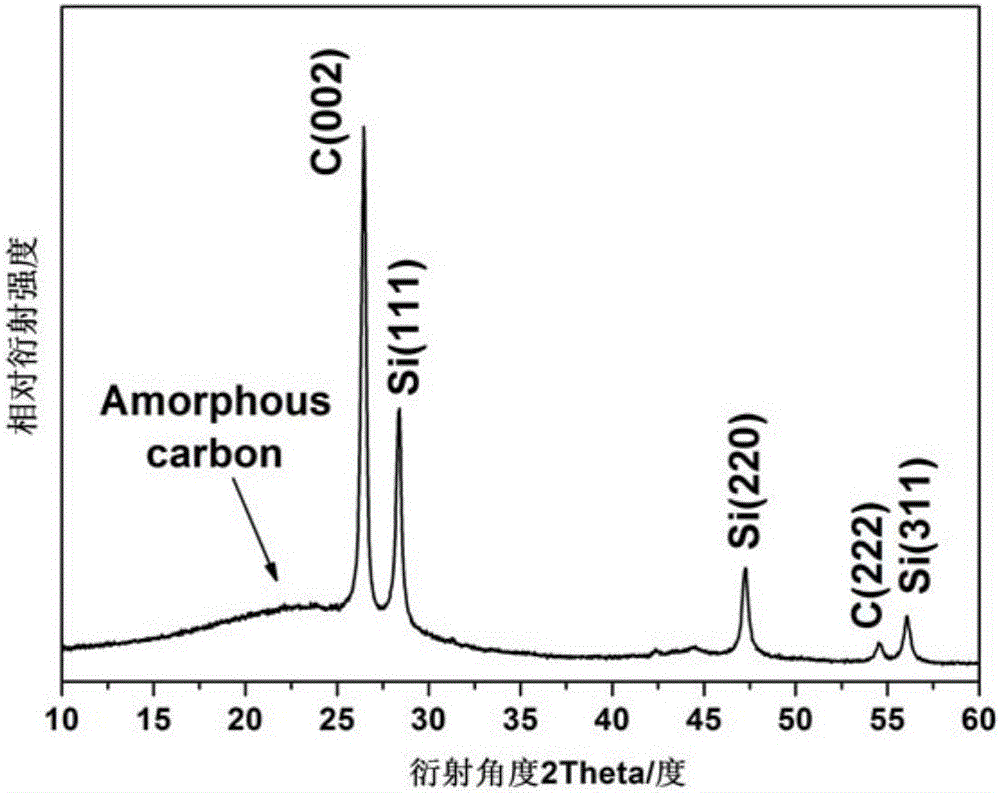

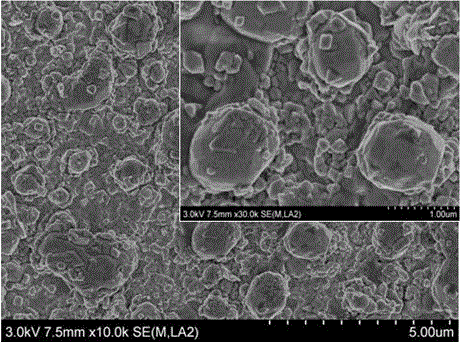

ActiveCN105047888ALow priceSufficient materialCell electrodesSecondary cellsNano siliconCarbonization

The invention discloses a lithium ion battery anode material and a preparation method thereof. The preparation method comprises the following steps: (1), preparing thermal expansion graphite sheets; (2), mixing nano silicon powder, cane sugar and the thermal expansion graphite sheets, adding the obtained mixture to a mixed solution of ethanol and deionized water, stirring and then carrying out solution ball-milling, wherein the ball-milling speed is 800-1600rpm and the ball-milling time is 2-4 hours, so as to obtain an anode material precursor solution; and (3), drying the anode material precursor solution, and carrying out carbonization heat treatment in the atmosphere of a protective gas, so as to obtain the lithium ion battery anode material. The structure characteristics of the lithium ion battery anode material are that nano silicon particles are evenly dispersed on a graphene nanosheet base body and the outermost layer is coated with carbon. The preparation method disclosed by the invention is a method of combining heat treatment with solution ball-milling, and has the characteristics of being simple, efficient and the like; industrialized production is easy to realize; and the lithium ion battery anode material prepared by the method has the advantages of stable structure, good cycle performance and the like.

Owner:SOUTH CHINA UNIV OF TECH

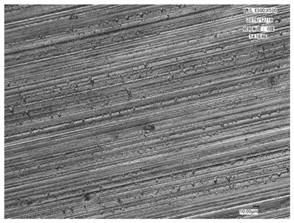

Metal graphene composite material and preparation method thereof

ActiveCN104085150AComposite tightImprove the lubrication effectVacuum evaporation coatingSputtering coatingMetallic materialsThin membrane

The invention provides a metal graphene composite material and a preparation method thereof, relating to the field of materials. The metal graphene composite material comprises a metal substrate, a copper infiltration layer and a graphene film, wherein the metal substrate is in metallurgical bonding with the copper infiltration layer; the graphene film grows on the outer surface of the copper infiltration layer. The preparation method of the metal graphene composite material comprises the following steps: forming the copper infiltration layer on the surface of the substrate, and forming the graphene film on the surface of the copper infiltration layer. According to the metal graphene composite material, because graphene has excellent mechanical property, the lubricating performance of the graphene film on the surface of pure metals or alloys is greatly improved, the friction force on the surfaces of the pure metals or alloys is reduced, and the lubricating life of the pure metals or alloys is prolonged. According to the preparation method of the metal graphene composite material, graphene can grow on large-area metal materials, a copper foil does not need to be corroded, the preparation process is simple, the production cost is low, and industrial production is convenient.

Owner:常熟紫金知识产权服务有限公司

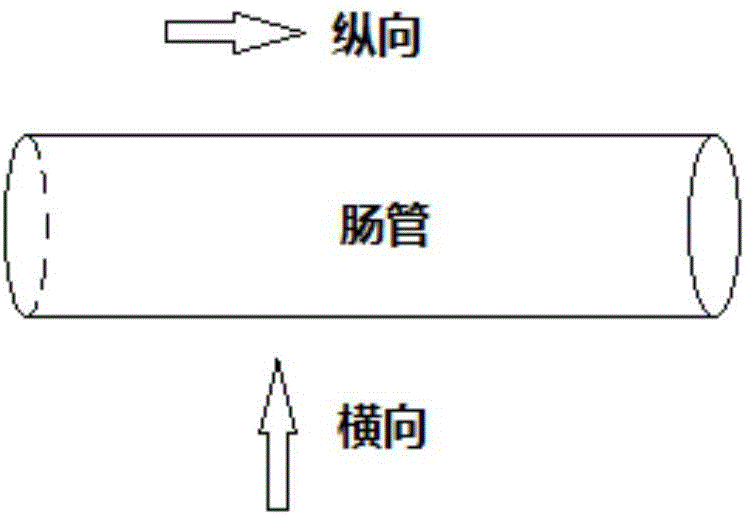

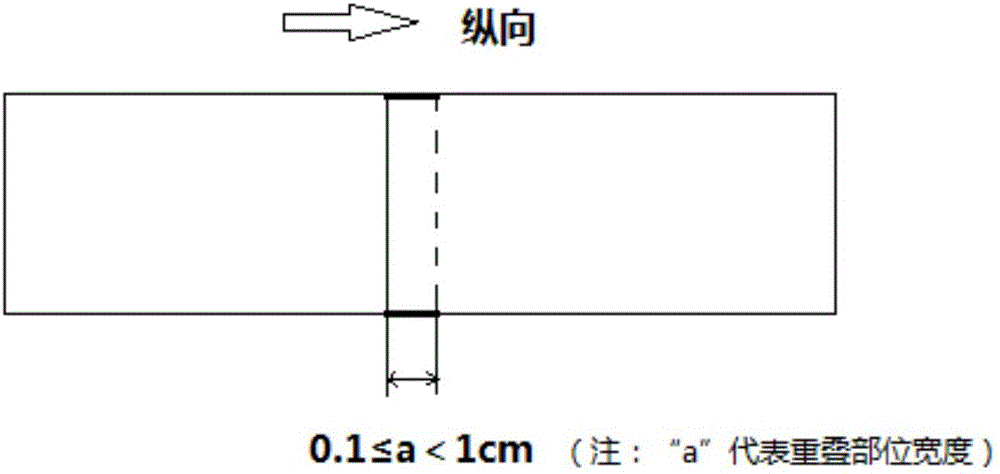

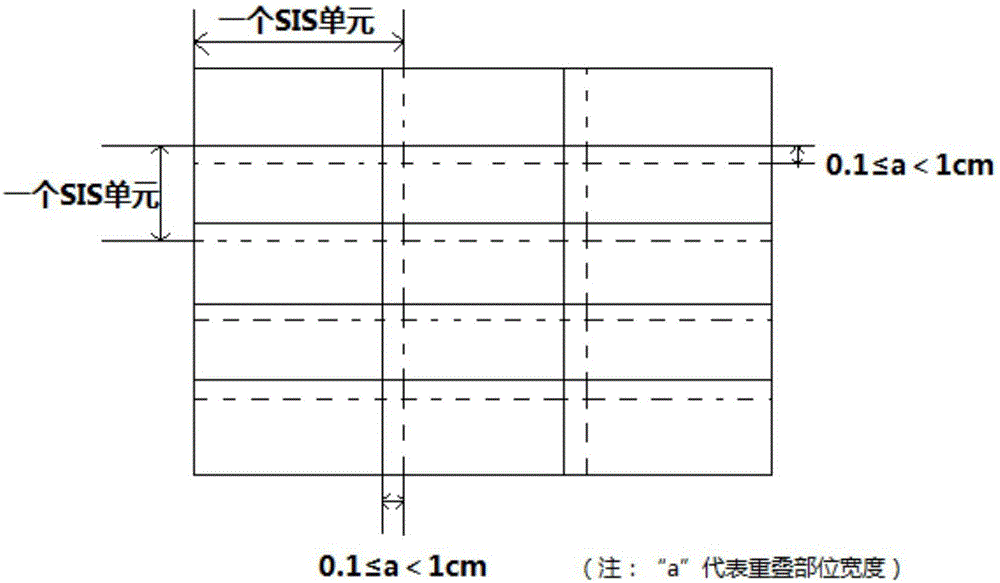

Preparation method for extracellular matrix (ECM) composite biological patch

Owner:SHANGHAI HONGCHUANG MEDICAL TECH CO LTD

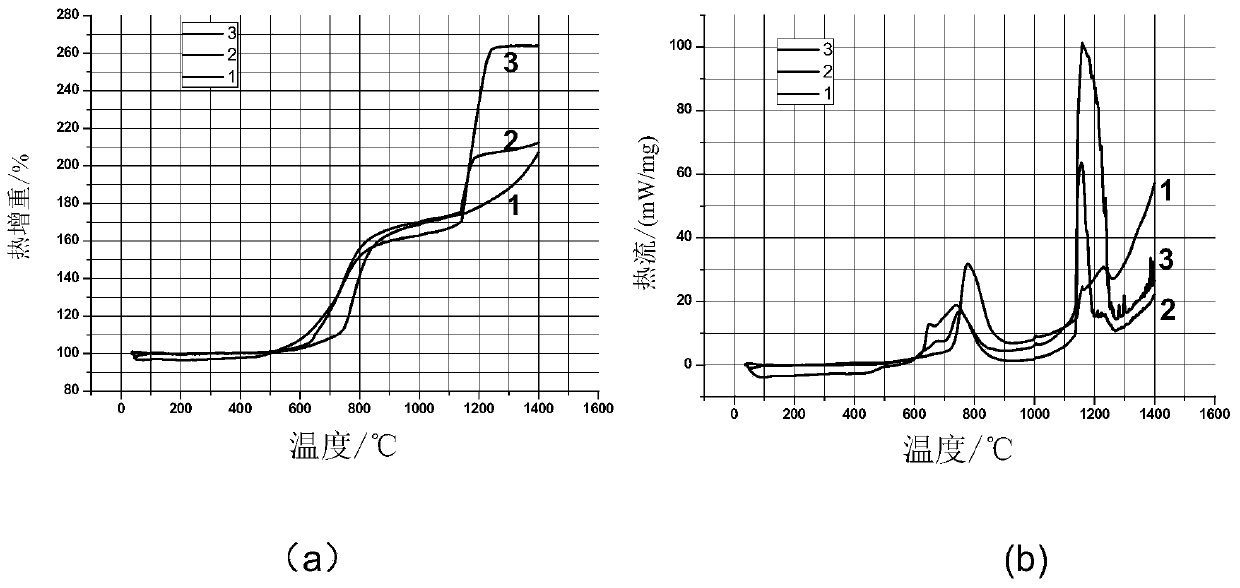

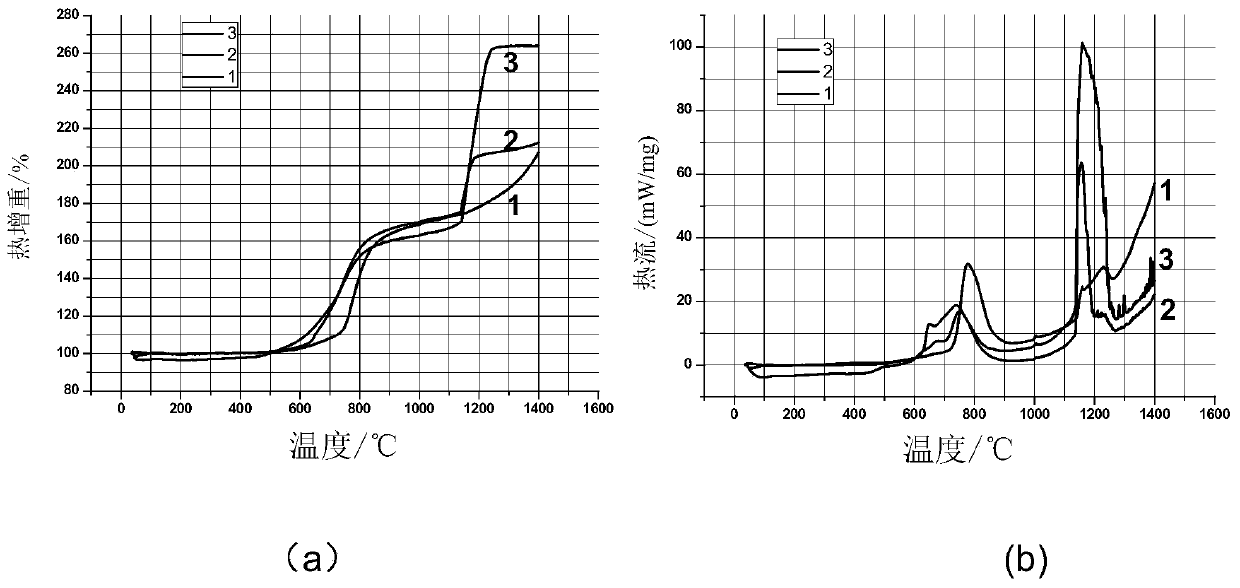

Preparation method for carbon fiber material with composite nano structure

InactiveCN103088648AComposite tightImprove performanceCarbon fibresCarbon fibersTithonia longiradiata

The invention relates to a preparation method for a carbon fiber material with a composite nano structure. The preparation method comprises the following steps of: pretreating carbon fiber cloth, adhering a layer of thin iron film catalyst on the carbon fiber cloth by a liquid-phase method or a physical deposition method, in a chemical gas-phase reaction chamber, carrying out in-situ growth of carbon nanotubes on the carbon fiber cloth by using argon or nitrogen as a carrier gas, ethylene or acetylene gas as a carbon source gas, and hydrogen as a reducing gas, then carrying a gas containing titanium organism into the chemical gas-phase deposition reaction chamber through the carrier gas, growing titanium dioxide at the peripheries of the carbon nanotubes to form titanium dioxide nanoshells which wrap the carbon nanotubes, thus obtaining the carbon fiber material with the composite nano structure. The carbon fiber material obtained by the preparation method has the advantages of high mechanical strength, high thermal stability, good chemical inertness and high adsorption property, supernormal strength of carbon nanotubes, large length-diameter ratio, high thermal conductivity, good catalytic activity, high chemical stability, non-toxicity and super-hydrophilicity. The carbon fiber material with the composite nano structure can have important applications in photocatalysis, electrocatalysis and other aspects.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

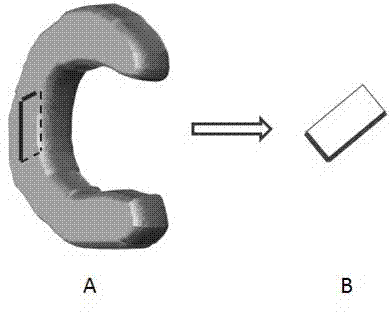

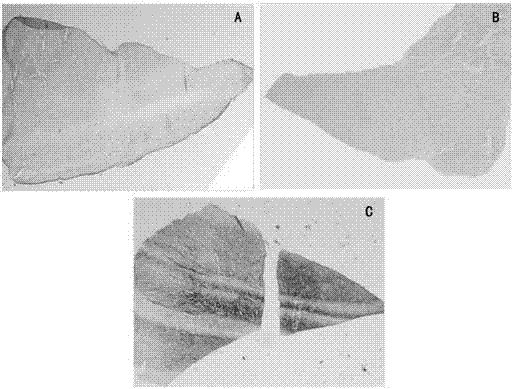

Tissue engineering meniscus repair sheet and preparation method thereof

ActiveCN103920188AProlong the action timeInduced regenerationProsthesisCell phenotypeMeniscal repair

The invention relates to a tissue engineering meniscus repair sheet and a preparation method thereof. The prepared tissue engineering meniscus repair sheet comprises an acellular meniscal thin sheet, seed cells and growth factor slow-release carriers, wherein blind micro vias are uniformly distributed on two surfaces of the acellular meniscal thin sheet, and the seed cells and the growth factor slow-release carriers are combined on two surfaces of the acellular meniscal thin sheet. The blind micro vias distributed on the acellular meniscal thin sheet increase the area of a support material, and can be used as a storage pool of the seed cells and the growth factor slow-release carriers, so that the seed cells and the growth factor slow-release carriers can be firmly attached and are not easy to fall off. Nutrition can be persistently released through the slow-release carrier by multiple growth factors, the cell amplification efficiency is improved, the cell phenotype is also maintained, cell ageing is inhibited, and fusion of the tissue engineering meniscus repair sheet and self tissue is promoted. The prepared tissue engineering meniscus repair sheet has the structure characteristic similar to the structure characteristic of natural meniscus, and is applicable to repair meniscus injure and induce regeneration of meniscus fibrous cartilage tissue.

Owner:西安博鸿生物技术有限公司

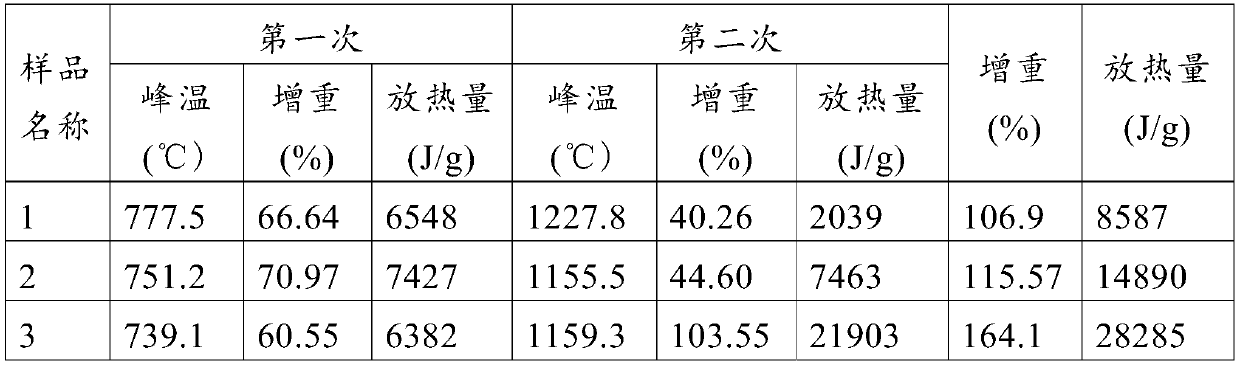

Boron-containing fuel-rich propellant

PendingCN111170816AImprove combustion efficiencyMeeting the Demand for High-Performance Fuel-Rich PropellantsExplosivesPressure gas generationRamjetEngineering

The invention relates to a boron-containing fuel-rich propellant for a ramjet engine. Core-shell type composite boron powder containing a boron-metal oxide core-shell structure is adopted to replace apart of common boron powder; boron is taken as the core of the composite boron powder, a transition metal oxide is takenas a surface layer, in the combustion process, boron is combusted, the metal oxide is reduced into simple substance metal or a low-valence oxide, and then a reduction product is oxidized again by oxygen in the environment to generate the metal oxide. The metal oxide is taken asthecarrier of oxygen, so that oxygen transfer is promoted, and boron combustion is improved. The problem that the combustion efficiency of the boron-containing propellant is low due to insufficient boron combustion is solved, and the process performance and the combustion performance of the propellant are improved on the premise that the comprehensive performance of the propellant is not affected.The problem that a ramjet engine needs a high-performance fuel-rich propellant can be solved, and the application prospect is wide.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Preparation method of proton-exchanging membrane fuel-cell catalyst composite carrier

InactiveCN102522571AIncrease the number ofIncreased ability to poisonCell electrodesHeteropoly acidProton

The invention provides a preparation method of a proton-exchanging membrane fuel-cell catalyst composite carrier, which comprises the following steps of: mixing a carrier base material with a heteropoly-acid solution, and filtering after uniformly mixing to obtain the carrier base material dipped with heteropoly acid; and firing the carrier base material dipped with the heteropoly acid in an inert atmosphere to obtain the proton-exchanging membrane fuel-cell catalyst composite carrier. The catalytic efficiency of a catalyst can be improved through the composite carrier prepared by the preparation method provided by the invention. In addition, the preparation method provided by the invention has the advantages of simpleness and easiness in operation, controllable preparation process condition, energy saving and environmental protection.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

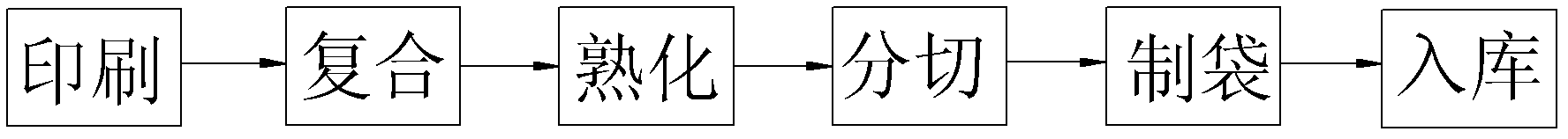

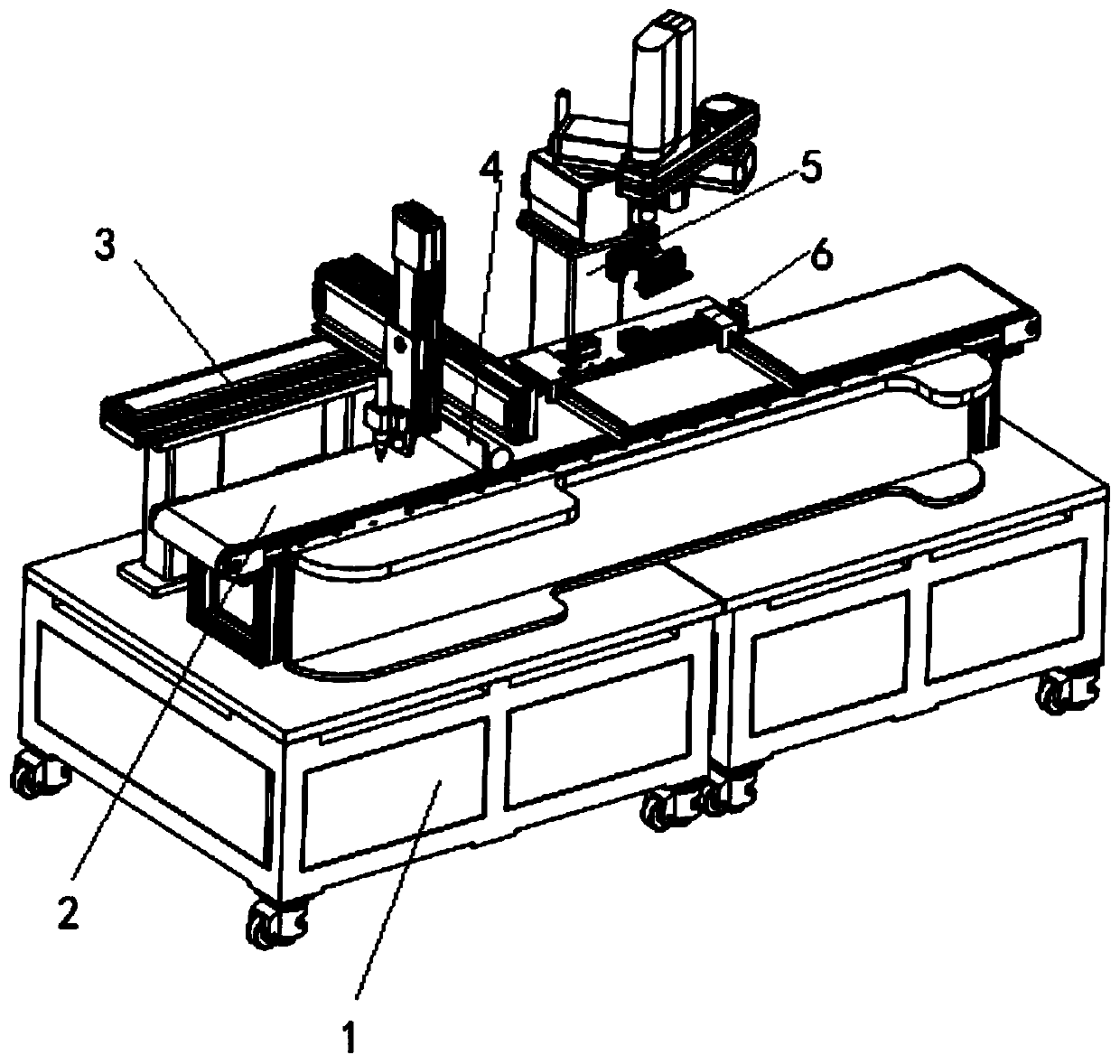

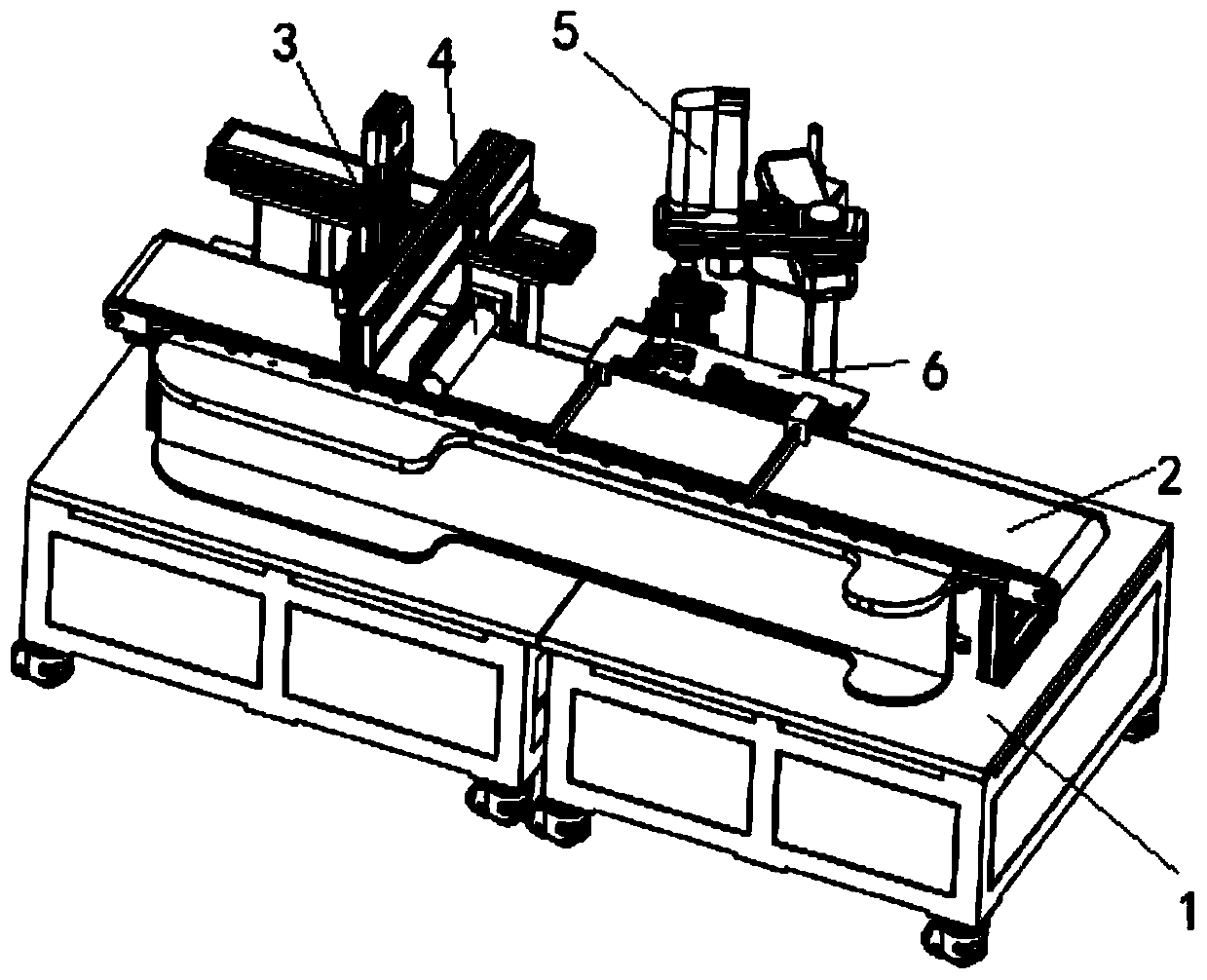

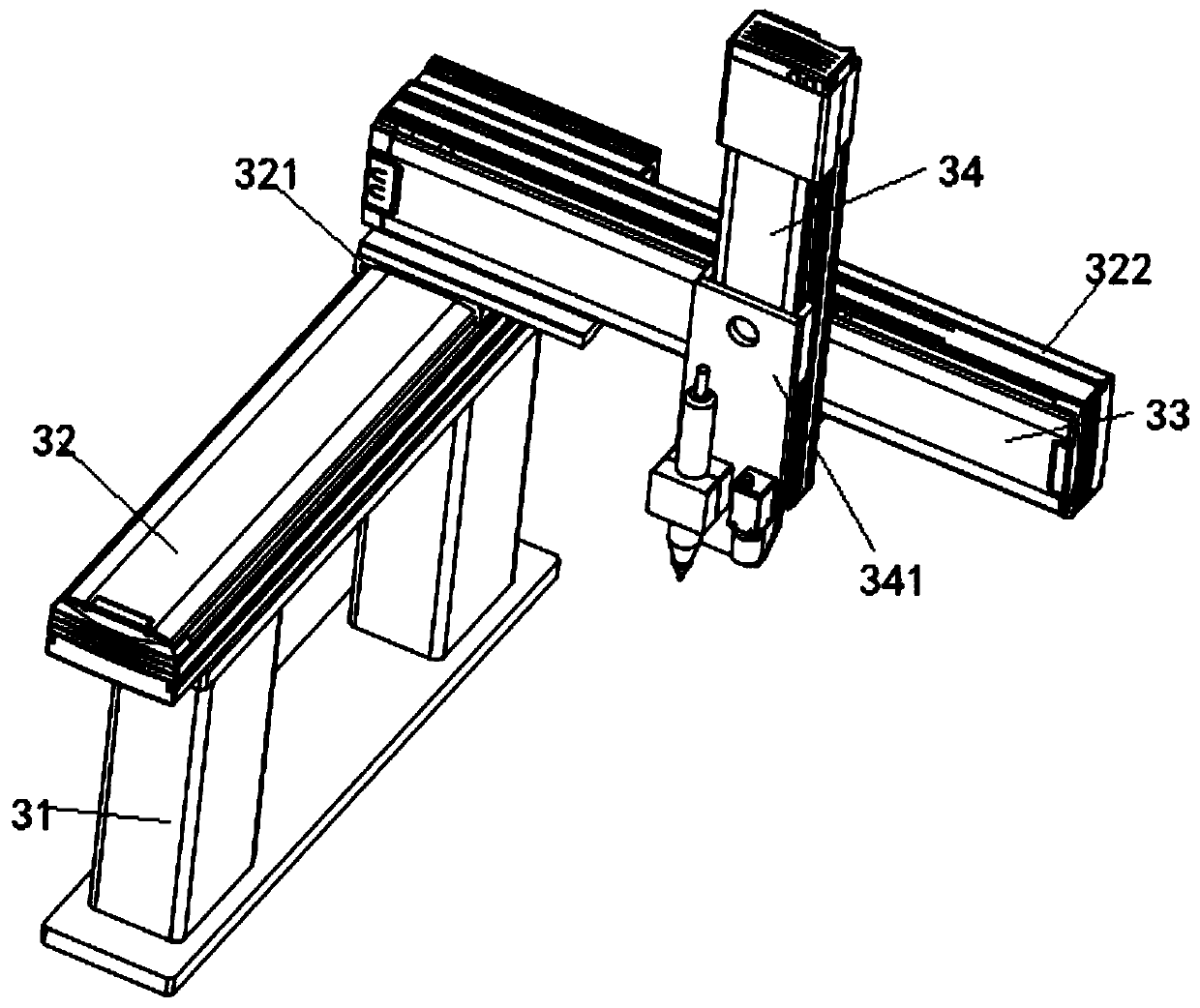

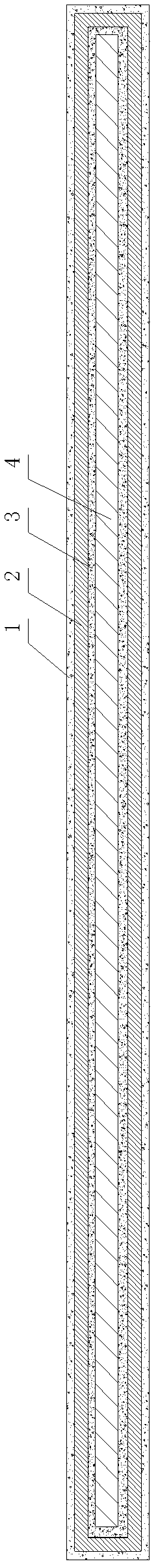

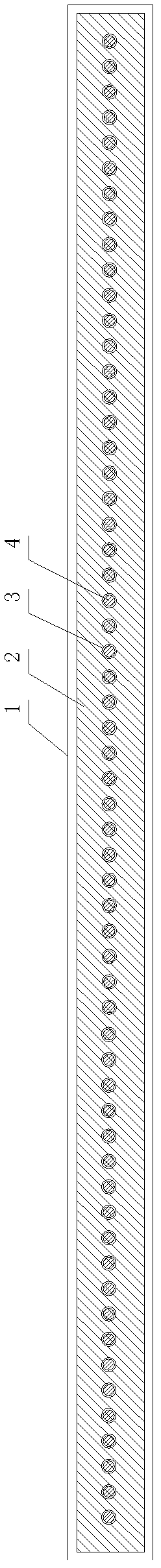

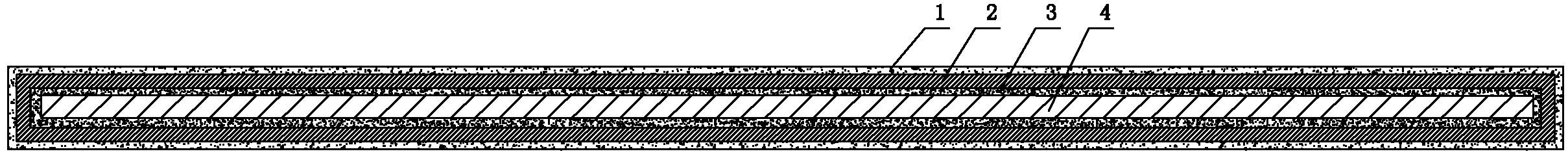

Composite film for medicine packaging, and making method thereof

InactiveCN103171196AResidue reductionComposite tightLamination ancillary operationsSynthetic resin layered productsPressure resistancePolyethylene

The invention relates to a composite film for medicine packaging, and a making method thereof. The composite film for medicine packaging comprises an aluminum foil layer and a modified polyethylene layer from top to bottom, an aqueous binder is coated between the aluminum foil layer and the polyethylene layer, and the aqueous binder is a polyurethane binder. The making method of the composite film for medicine packaging sequentially comprises the operations of printing, compounding, curing, slitting, and bag making. The composite film for medicine packaging has the advantages of distinct gradation, beauty, pressure resistance, close compounding, no bubbles, no fracture, large peeling strength, good heat sealing performance, easy tearing and easy uncovering.

Owner:常州市华健药用包装材料有限公司

Process for preparing seamless composite metal pipe

A method for manufacturing seamless composite metal pipe includes high-temp anealing and natural cooling of internal pipe, washing the internal and external pipes, inserting internal pipe in external pipe, mounting the blank to mandrel of pipe drawer, installing inner mould, drawing, sleeving outer mould on it, pulling-down, straightening and cutting. Its advantages are high strength, easy machining, low cost, high quality and high smooth finish.

Owner:亓登利

Production equipment of waterproof corrugated board

The invention discloses production equipment of a waterproof corrugated board. The production equipment comprises a machining tool, wherein a transmission mechanism is arranged in the middle of a surface of the machining tool, and a gluing mechanism, a glue flattening mechanism, a board suction positioning mechanism and a pressing and shearing mechanism are sequentially arranged on one side of themachining tool from left to right. According to the production equipment, a PVC plastic film is unfolded through the transmission mechanism and is transmitted to the position below the gluing mechanism, then gluing is realized through the forward and backward movement of the gluing mechanism; after gluing, when the plastic film is moved to the position below the glue flattening mechanism, glue iscoated through the glue flattening mechanism, when the coated plastic film is moved to the position below the board suction positioning mechanism, the corrugated board is adsorbed by the board suction positioning mechanism and is placed on a gluing surface of the plastic film, then the glued corrugated board is pressed through the pressing and shearing mechanism, and then the plastic film is sheared, therefore, an integrated generation process is realized, the technological process is simple, and the production efficiency is improved.

Owner:浙江盈翔包装有限公司

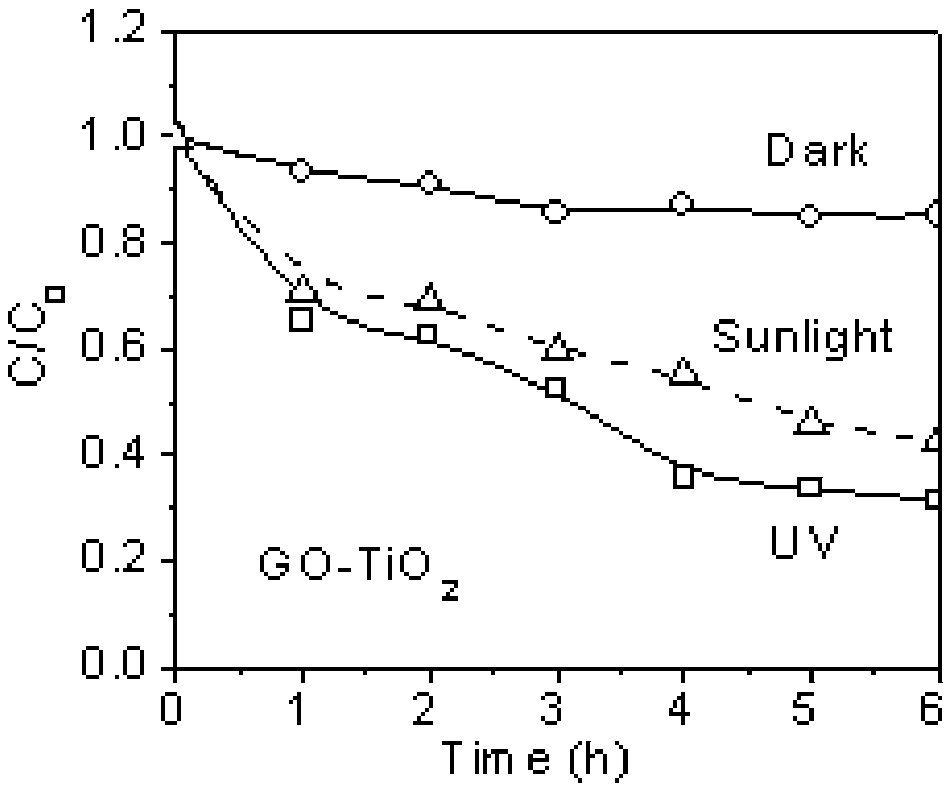

Separation membrane with photocatalytic performance and preparation method of separation membrane

InactiveCN108640214AImprove purification efficiencyEfficient separationPhysical/chemical process catalystsWater/sewage treatment by irradiationUltrafiltrationUltraviolet radiation

The invention discloses a separation membrane with photocatalytic performance and preparation method of the separation membrane by use of layer-by-layer self-assembly. According to the method, the photocatalytic separation membrane is prepared with the ultraviolet-assisted layer-by-layer self-assembly method. Firstly, TiO2 sol and a GO (graphene oxide) aqueous solution are prepared, TiO2 and GO are supported on the surface of an organic ultrafiltration base membrane in the order of TiO2-GO- layer by layer with the layer-by-layer self-assembly method, and then, the supported TiO2 and GO layersare subjected to ultraviolet radiation treatment in an ethanol solution to form a GO-TiO2 assembly.

Owner:JIANGSU UNIV OF TECH

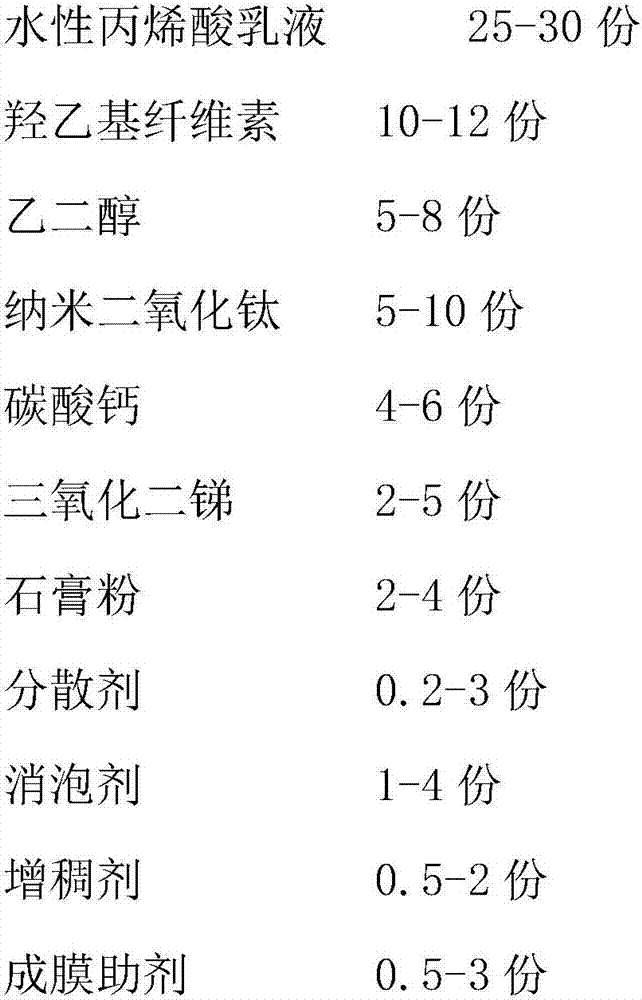

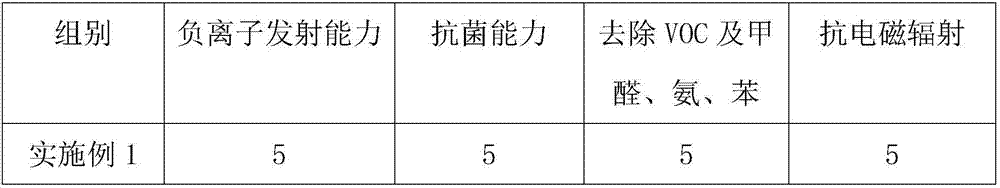

Water-based acrylic acid paint utilizing negative ions to purify air

ActiveCN107201124AImprove dispersion stabilityImprove air qualityCoatingsPigment treatment with organosilicon compoundsActivated carbonSilane coupling

Water-based acrylic acid paint utilizing negative ions to purify air is disclosed. 1-5% by weight of a negative ion paint additive is added into water-based acrylic acid paint. The additive is prepared by modifying negative ion powder and activated carbon powder with a titanate coupling agent. According to the provided water-based acrylic acid paint utilizing the negative ions to purify air, the titanate coupling agent is adopted to modify tourmaline in the negative ion powder and the negative ion powder is composited with the activated carbon powder, and therefore surface hydrophobicity of the tourmaline is improved, the crystal structure of the tourmaline is not destroyed, original physical characteristics of the tourmaline are not influenced, and negative ion release of the tourmaline is improved than negative ion release of tourmaline treated with a traditional silane coupling agent, thus improving air quality.

Owner:湖北佰航建材科技有限公司

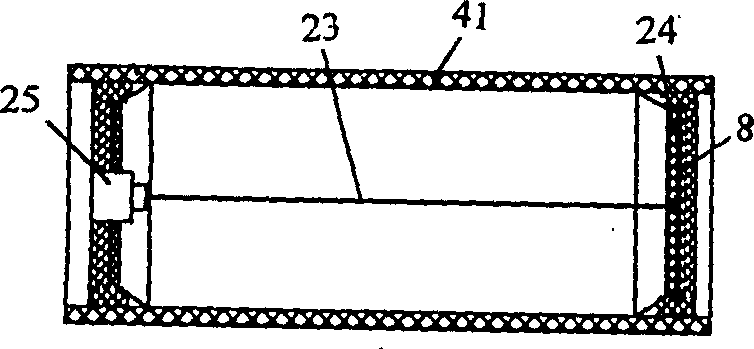

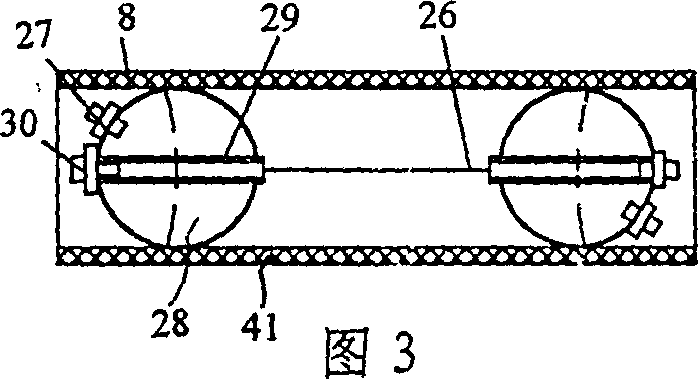

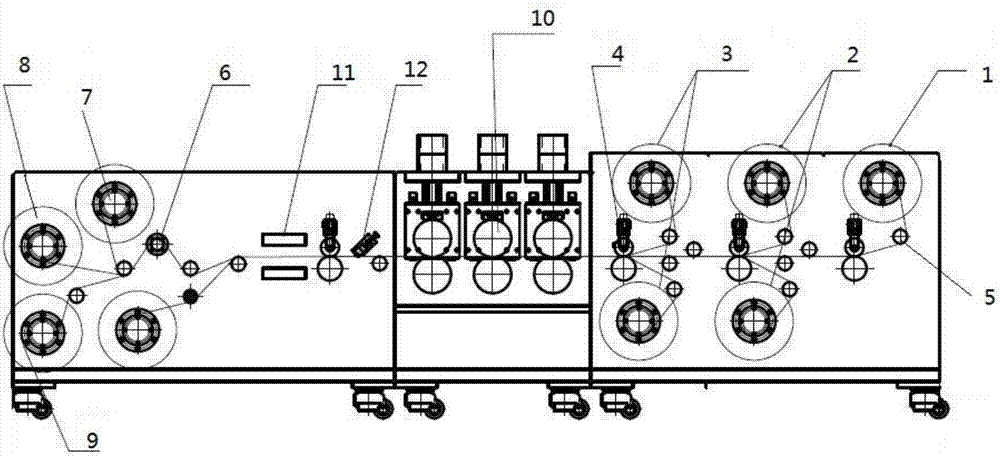

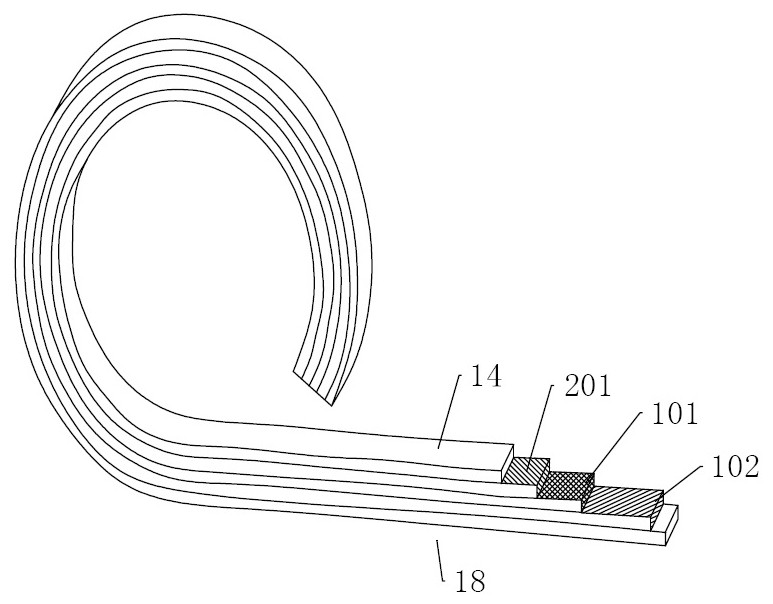

Lithium strip composite calendaring device and method thereof

PendingCN107415406AAchieve compositeSolving and Controlling Sticking ProblemsLaminationLamination apparatusMetallic foilAutomatic control

The invention relates to a lithium strip composite calendaring device and a method. The lithium strip composite calendaring device comprises a feeding device, a rolling calendaring device and a rolling-up device, wherein the feeding device comprises a tinsel unreeling shaft, two lithium strip unreeling shafts and two PE (polyethylene) unreeling shafts, which are sequentially arranged, and the lithium strip unreeling shafts and the PE unreeling shafts are respectively and symmetrically arranged on two sides of tinsel; the feeding device and the rolling-up device further comprise traction devices and a plurality of auxiliary wheels. According to the device and the method, the composite automatic control of a lithium strip and the tinsel is realized, and the quality and production efficiency of products are effectively improved.

Owner:重庆昆瑜锂业有限公司

Thermoplastic composite board and manufacturing method thereof

ActiveCN102555315AEquivalent mechanical strengthQuite rigidLaminationLamination apparatusUltimate tensile strengthThermoplastic composites

The invention discloses a thermoplastic composite board and a manufacturing method thereof. The thermoplastic composite board has set lateral width, longitudinally and continuously extends, and is coiled into a roll or is cut into blocks. The thermoplastic composite board comprises an enhanced skeleton, wherein a thermoplastic material layer is covered out of the enhanced skeleton. The manufacturing method comprises the following steps: (1) leveling the surface bend of the continuously-conveyed enhanced skeleton, and carrying out unoiling and derusting processing; (2) heating the enhanced skeleton, coating conglutinant resin material, and forming a binding layer after the conglutinant resin material is solidified; (3) conveying the enhanced skeleton to a formed mould, extruding the thermoplastic material, and successively coating out of the binding layer to obtain the board; and (4) shaping the board to obtain the thermoplastic composite board. The thermoplastic composite board disclosed by the invention has equivalent strength and rigidity and equivalent buffer performance, and can achieve good safety protection effect. The manufacturing method has the advantages of high production efficiency, simple technology and low production cost.

Owner:华瀚管道系统科技有限公司

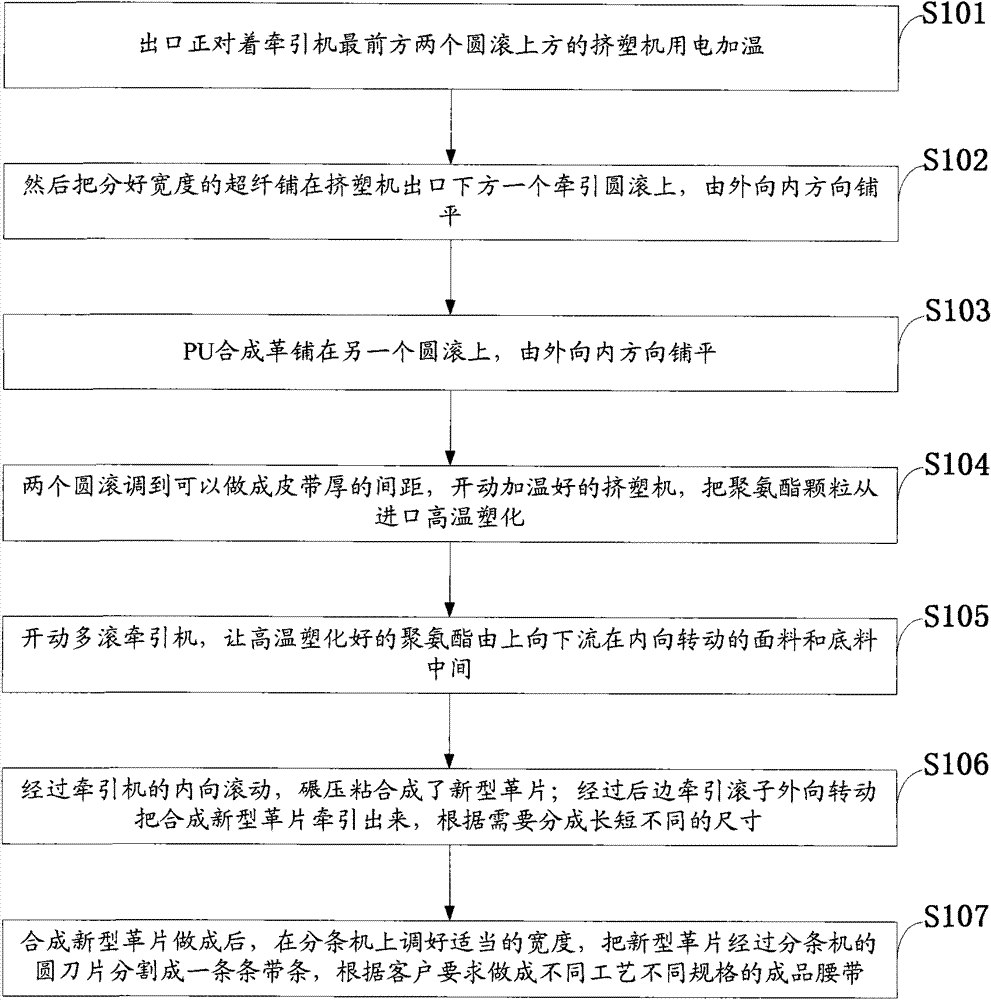

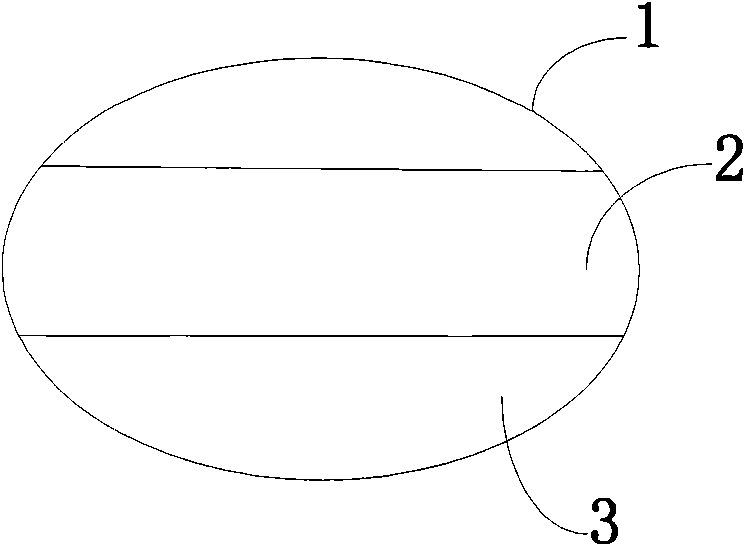

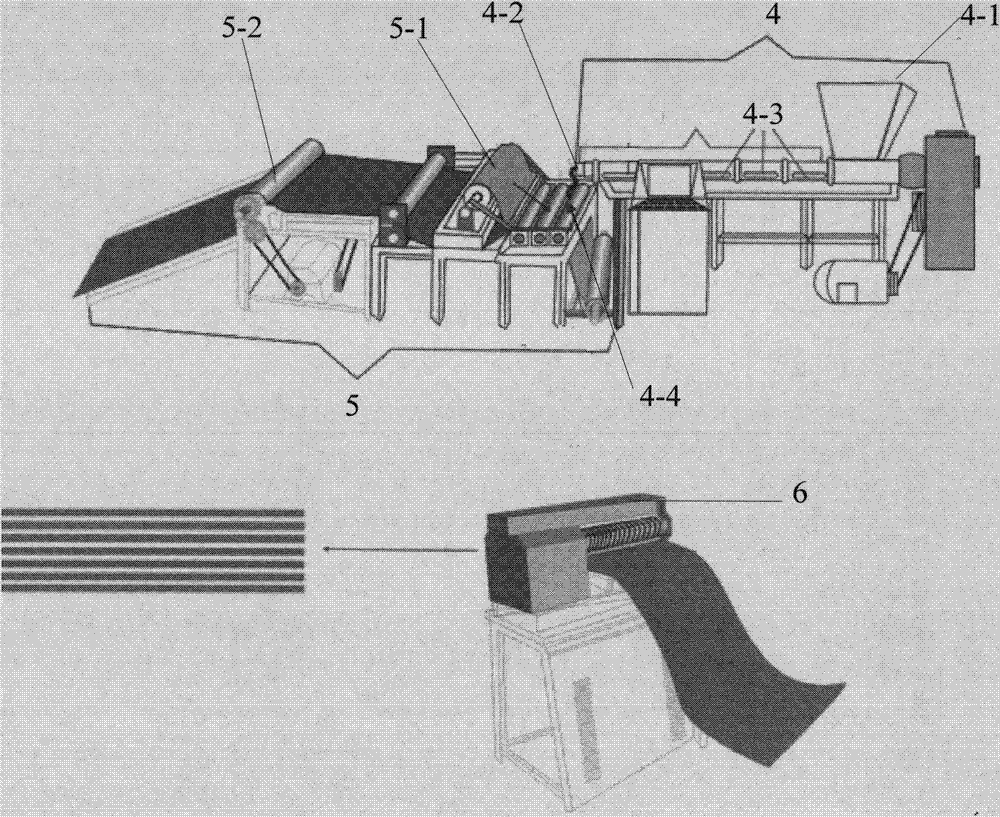

Belt leather piece and production method thereof

ActiveCN103535958AReduce weightExtended service lifeSynthetic resin layered productsLaminationFiberSurface layer

The invention discloses a belt leather piece and a production method thereof. The production method includes that PU (poly urethane) synthetic leather 12% in thickness is taken as a surface layer to be paved on a round roll in the most front of a multi-roll traction forming machine, and micro fiber 7% in thickness is taken as a bottom layer to be paved on the other round roll in the most front of the multi-roll traction forming machine; raw material polyurethane particles in the middle are plasticized through a plastic extruding machine at a high temperature and flow between a surface material and a bottom material, and the front round rolls of the multi-roll traction forming machine are used to roll on the surface layer, the micro-fiber bottom layer and a middle high-temperature polyurethane layer 81% in thickness to obtain a novel leather piece by inward turning roll-off bonding technology. Therefore, a belt is reduced in weight, prolonged in service life, improved in elasticity, and cannot be too soft or too hard due to change of temperature. The micro-fiber bottom layer is compact in composition and less prone to being separated from the middle raw materials, adverse reaction does not occur between the plasticized polyurethane layer and leather edge oil, and the belt with the edge coated by oil is not sticky. In addition, the production method is simple and low in production cost, the belt is improved in quality and prolonged in service life, and adaptive capacity of the belt to an environment is improved.

Owner:李志刚

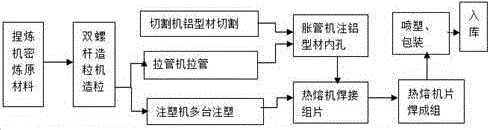

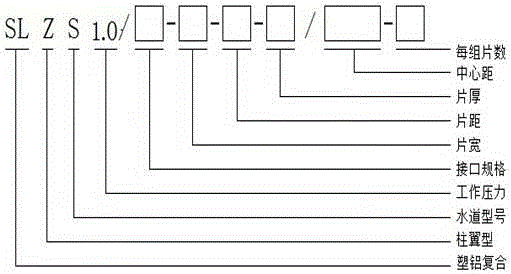

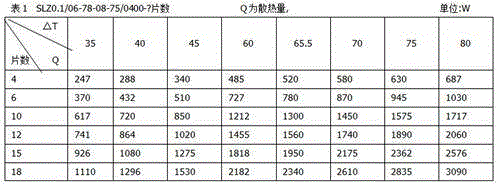

Thermal conductive plastic alloy, radiator based on alloy and preparation method

InactiveCN105175907AGood frost and heat resistanceStable molecular structureHeat exchange apparatusFiberAlloy

The invention discloses a thermal conductive plastic alloy used for a radiator, a radiator and a preparation method. The thermal conductive plastic alloy comprises polybutene or polyisobutene, polyethylene, graphite powder, carbon fiber, thermal conductive carbon black, a thermal conductive reinforcing agent, a titanate coupling agent and stearic acid. The thermal conductive plastic alloy is subjected to granulation, then pipe drawing and injection molding are carried out, an inner water channel pipe and a connecting piece of an radiator are prepared, the inner water channel pipe is expanded into an inner hole of an aluminum wing pipe of the radiator to obtain a radiator column material or sheet material, the column material or the sheet material and the connecting piece are subjected to sweat soldering to prepare a radiator single sheet, and finally the radiator single sheets are subjected to sweat soldering to compose a radiator. The thermal conductive plastic alloy and the radiator are advantaged by good environmental protection and excellent heat radiation performance, are stable and durable, and have protruding characteristics of no fouling, no rusting, no corrosion, no cracking, no pollution, no deformation, no abnormal sound and no aging.

Owner:徐继煌

Preparation method and application of flame-retardant PVC leather compound for traffic interior decoration

ActiveCN111907172AComposite tightRealize heat insulation, oxygen insulation and flame retardantFireproof paintsSynthetic resin layered productsPolymer sciencePolymer chemistry

The invention discloses a flame-retardant PVC leather compound for traffic interior decoration as well as a preparation method and application thereof. The PVC leather compound comprises a PVC leatherlayer, a flame-retardant functional layer and an elastic layer, wherein the flame-retardant functional layer is prepared from 100 parts of PVC paste resin, 50-120 parts of a flame-retardant plasticizer, 5-20 parts of a phosphorus-containing liquid flame retardant, 5-20 parts of a powder flame retardant, 3-10 parts of a flame-retardant synergist, 1-10 parts of zirconium phosphate, 1-5 parts of anantioxidant, 1-5 parts of a heat stabilizer, 1-10 parts of a filler, 0-5 parts of color paste and 1-10 parts of a foaming agent; the elastic layer is polyurethane sponge. The flame-retardant functional layer is combined with the PVC leather layer to form a flame-retardant PVC leather layer, and then the flame-retardant PVC leather layer is tightly combined with the elastic layer through flame compounding, flame-retardant glue compounding or flame-retardant hot melt adhesive compounding. The flame-retardant PVC leather compound has the characteristics of excellent flame retardancy, low smoke, low toxicity, low VOC, low atomization value, no peculiar smell, soft hand feeling, high peel strength, good resilience and the like, and can be widely applied to seats, safety seats, door plates, handrails and the like of cars, passenger cars, trucks, high-speed rails, bullet trains, urban railways, low-speed trains and the like.

Owner:HANGZHOU XIANGJUN TEXTILE FLAME RETARDANT TECH

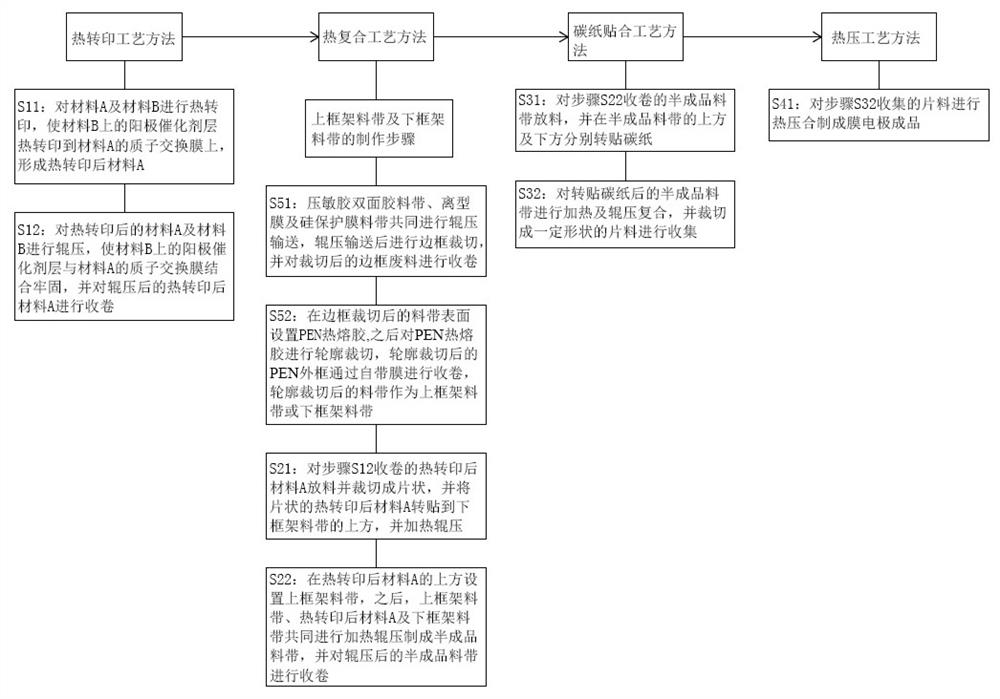

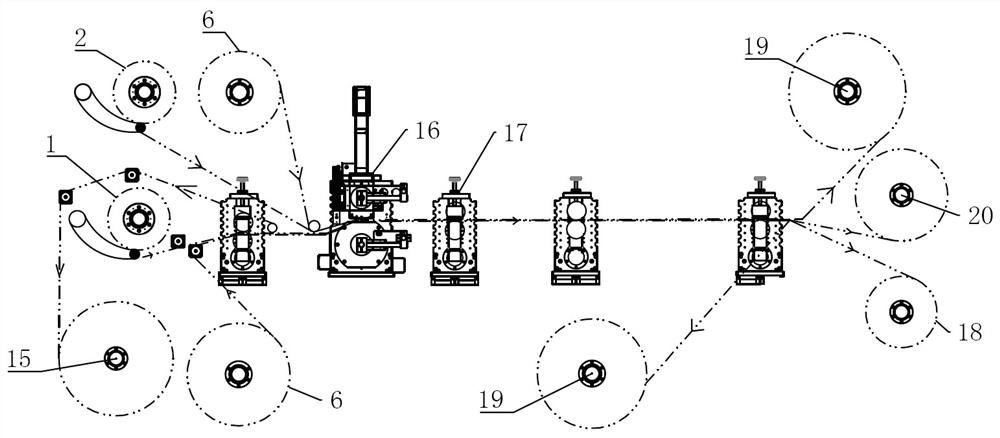

Process method for producing membrane electrode

ActiveCN113517459ASimple processComposite effect is goodFinal product manufactureCell electrodesManufacturing engineeringCarbon paper

The invention relates to the technical field of membrane electrode production processes, and provides a process method for producing a membrane electrode. The process method comprises a thermal transfer printing process method, a thermal compounding process method, a carbon paper laminating process method and a hot pressing process method. The thermal transfer printing process method comprises the following steps that S11, thermal transfer printing is performed on a material A and a material B; and S12, the material A and the material B subjected to heat transfer printing are rolled. The thermal compounding process method comprises the steps that S21, a material A subjected to thermal transfer printing is cut into sheets, and the sheets are transferred and pasted to the position above a lower frame material belt; and S22, an upper frame material belt is arranged above the material A subjected to heat transfer printing, and a semi-finished product material belt is formed through heating and rolling. The carbon paper laminating process method comprises the following steps: S31, respectively transferring and laminating carbon paper above and below a semi-finished product material belt; and S32, heating, rolling and compounding, and cutting into sheets. The hot-pressing process method comprises the following step of S41, carrying out hot pressing on a sheet material. Continuous automatic production of the membrane electrode is realized, and the production efficiency and quality of the membrane electrode are improved.

Owner:SHANDONG HOACO AUTOMATION TECH

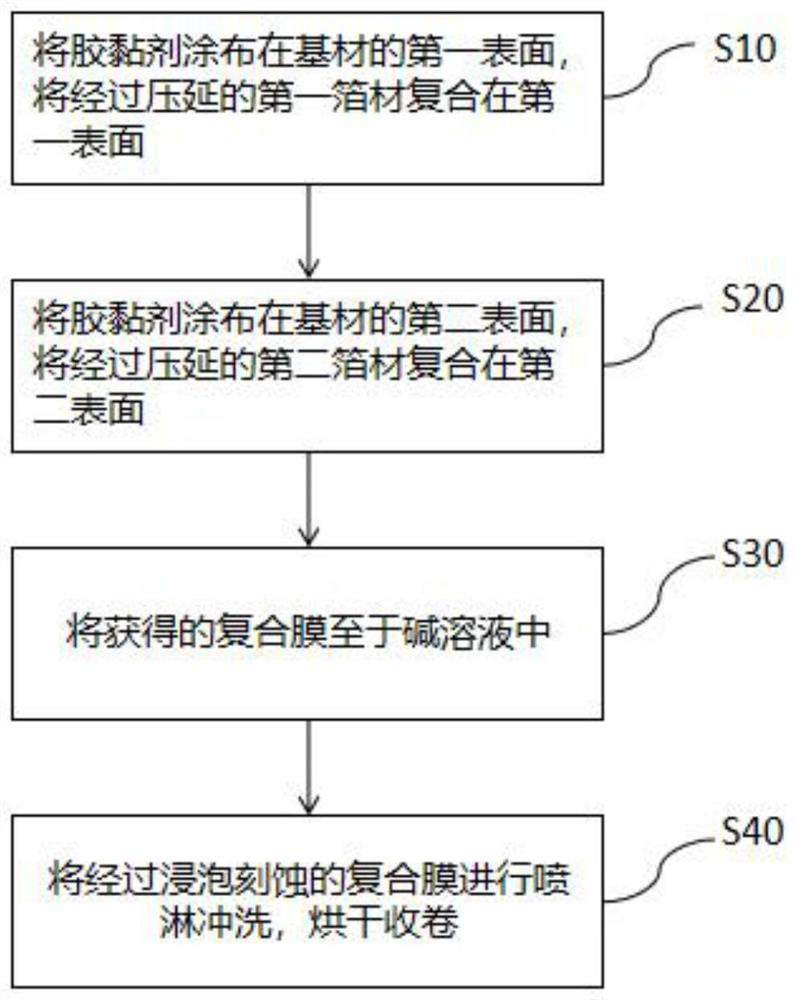

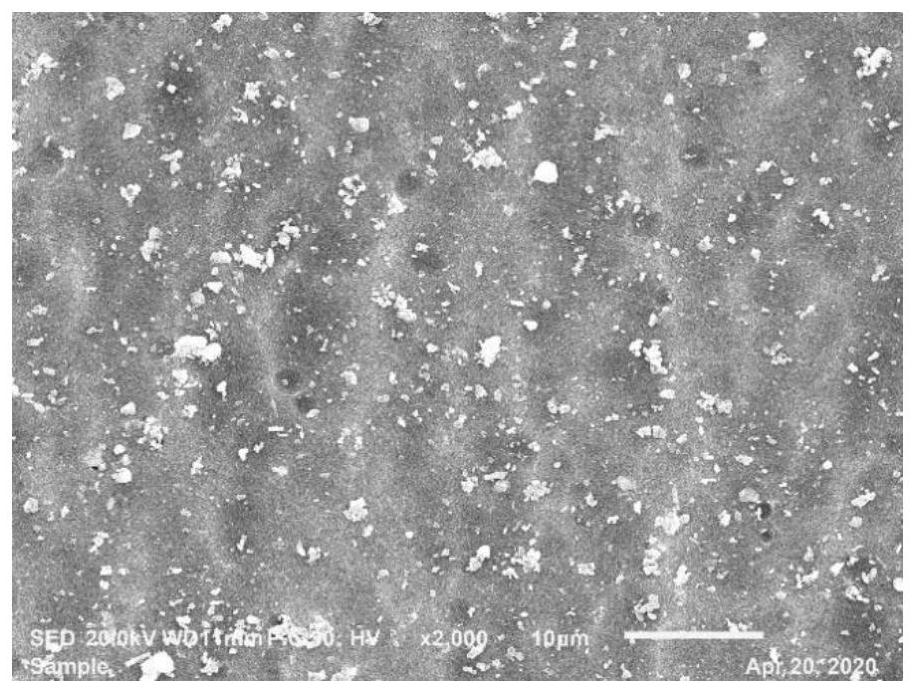

Production method of current collector, current collector and secondary battery

PendingCN112234211AHigh densityComposite tightFinal product manufactureElectrode carriers/collectorsAdhesiveProcess engineering

The invention discloses a production method of a current collector, the current collector and a secondary battery, and relates to the technical field of secondary batteries. A first foil and a secondfoil which are calendered are compounded on the two sides of a base material through an adhesive, and then the first foil and the second foil are thinned to a required thickness through an alkaline solution so that tight compounding between the base material and the foils can be guaranteed, the density of the foils is improved through calendering, and the composite current collector can pass an electrolyte immersion test and has high safety performance. Meanwhile, according to the technical scheme, investment is small, a technological process is similar to that of a cleaning machine, equipmentis low in cost compared with a vacuum coating machine, production can be rapidly expanded depending on domestic equipment manufacturers, and compared with the prior art, stable and continuous production can be achieved more easily.

Owner:JIANGSU ADVANCED MATERIAL TECH CO LTD

Nano polyaniline sulfenyl composite material and application of nano polyaniline sulfenyl composite material

InactiveCN104269537AHigh reactivityComposite tightElectrode manufacturing processesSecondary cellsElectrical batteryCarbon nanofiber

The invention discloses a nano polyaniline sulfenyl composite material and a preparation method and application of the nano polyaniline sulfenyl composite material. The preparation method of the nano polyaniline sulfenyl composite material comprises the following steps: adding sulfur, performing compounding on carbon nanofibers and the sulfur, and then adding aniline and coating by virtue of a micro-emulsion method to obtain the nano polyaniline sulfenyl composite material. Nano polyaniline is utilized for coating the material, so that on one hand, the occurrence of dissolution and shuttling effects of sulfur reduction products can be further restrained, on the other hand, the capacity of an electrode can be complemented by virtue of reversible oxidation reduction characteristics of the polyaniline so as to improve the capacity of a battery. The preparation method of the positive electrode material is simple to operate, easily available in raw materials, safe, environmentally-friendly and high in capacity.

Owner:NANJING ZHONGCHU NEW ENERGY

Unsized composite pipe and manufacture thereof

InactiveCN1614281AComposite tightReduced corrosion resistanceLayered productsRigid pipesFluid transportPolyvinyl chloride

A non-adhesive composite pipe for delivering hot fluid or gas is composed of a metallic pipe, and two surficial layers which are the polyvinyl chloride layer with directional thermal shrinking memory function. Its advantages are high strength, light weight, and long service.

Owner:徐益鑫

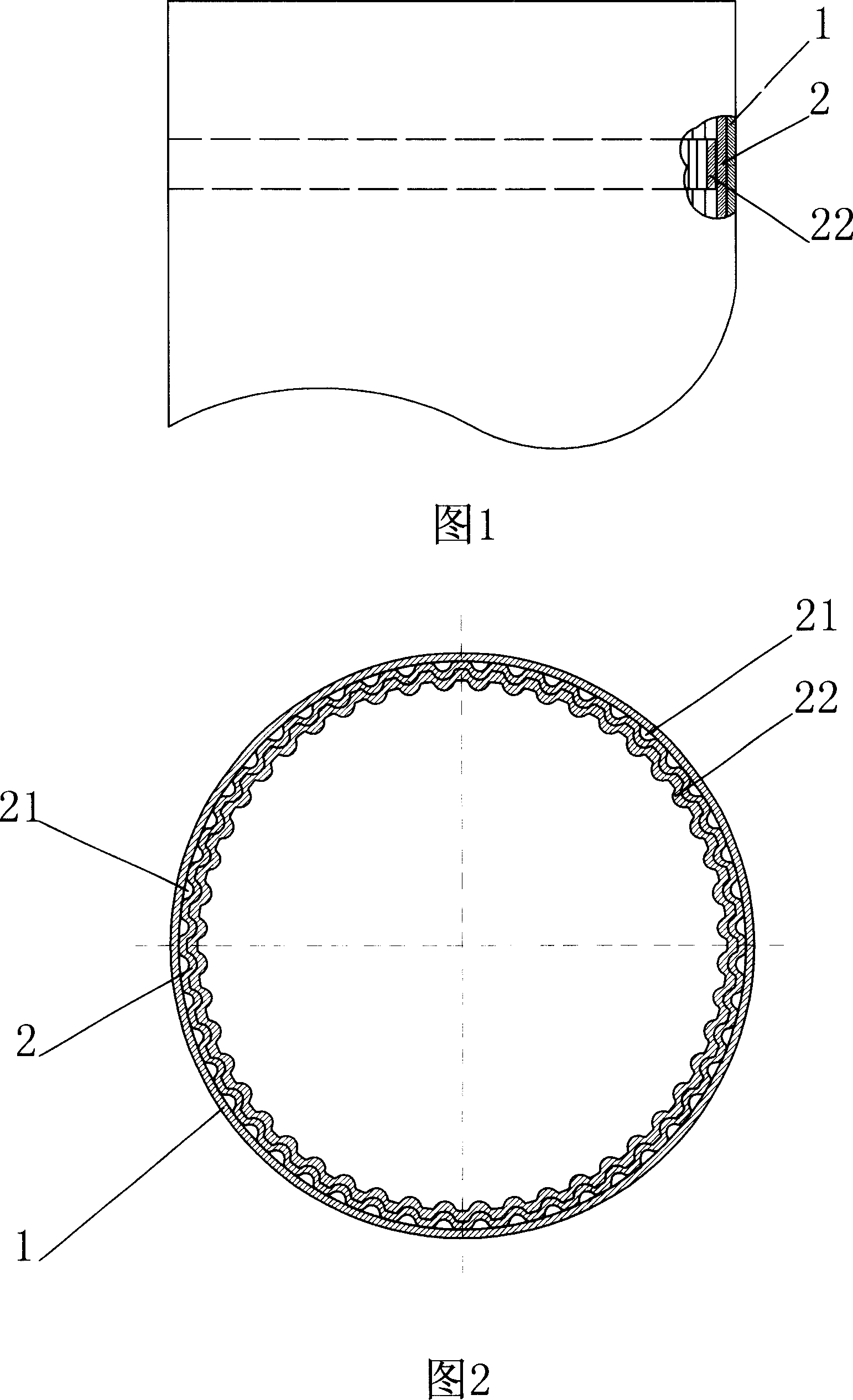

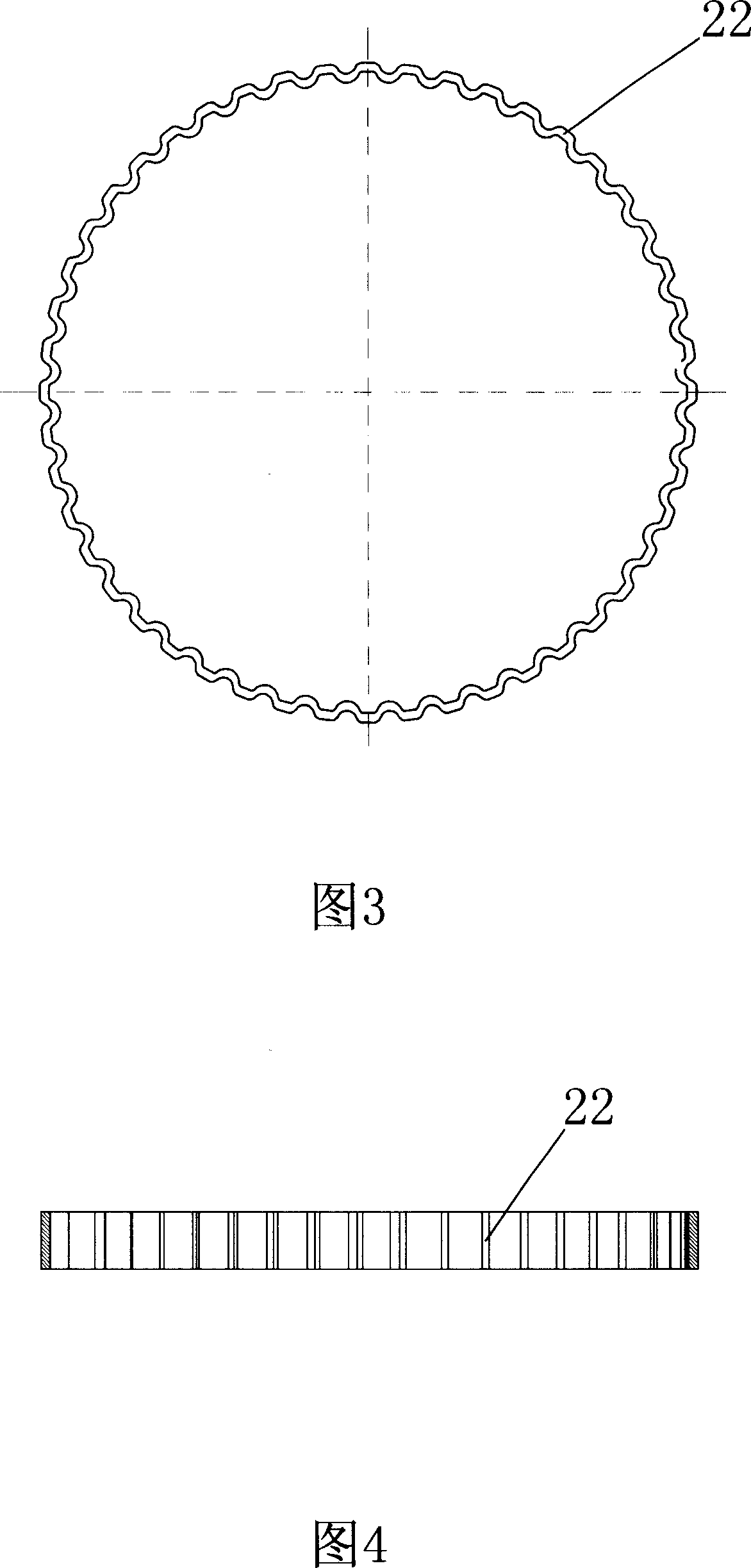

Light high-strength composite pipe and production method thereof

InactiveCN1995796AHigh strengthSave raw materialsElongated constructional elementsSheet steelHigh intensity

The invention relates to a light high-strength composite pipe and the manufacturing method. The pipe is compounded by double-layer steel reel pipe. The outer layer is made of thin stainless steel reel pipe and the inner layer is made of thin carbon steel reel pipe. Reinforced rib tube with several concave-convex alternation shapes. The manufacturing method is that 1, cutting by the dimension; 2, fabricating the cut plate into the plate with several concave-convex alternation shapes by the mould with several concave-convex alternation shapes and retaining the margin for next drawing and shaping procedure; 3, trimming by the unfold size; 4, winding the circular cylinder by mould; 5, clamping the roller tightly for spot welding and welding; 6, shaping the internal roller with concave-convex mould under the drawing force; 7, extruding the roller by mould in cold so as to achieve the dimension demand needed when it is folded with the outer roller and forming the inner roller; 8, fixing the outer roller; 9, folding inner and outer rollers with concave-convex shape; 10, extruding the inner layer of roller with concave-convex shape by mould in cold. The composite pipe is provided with higher intensity, stock saving, light self-weight of roller, improved bending strength of roller and tighter composite.

Owner:陈联社 +1

Novel glass ceramic composite wall and floor tile

InactiveCN103232224AEmission reductionComposite tightCeramic materials productionClaywaresAdhesiveHeat resistance

The invention discloses a novel glass ceramic composite wall and floor tile. The novel glass ceramic composite wall and floor tile is manufactured by adopting a method comprising the following steps of: grinding raw materials into powder, then uniformly mixing, adding water with a temperature of 86-88 DEG C to obtain a mixture, pressing the mixture in a die, then sintering in a high-temperature sintering furnace, and naturally cooling to room temperature after temperature preservation for a peroid of time, wherein the novel glass ceramic composite wall and floor tile comprises the following raw materials in percentage by mass: 48-55 percent of waste ceramic, 18-22 percent of glass cullet, 25-28 percent of clay and 1-5 percent of nucleation agent; and 3-5 percent of adhesive is contained in the water. Due to the manner, the cost can be saved, the waste gas emission is reduced, and glass and the ceramic can be compound more closely; and meanwhile the bending strength, the wear resistance, the heat resistance, the antifreezing property, corrosion resistance and hardness of the glass ceramic composite wall are improved.

Owner:SUZHOU IND PARK FANGYUAN METAL PROD

Synthetic method for high-capacity sulfurized lithium iron phosphate positive electrode material

InactiveCN108199012AComposite tightStable structureCell electrodesSecondary cellsNitrogen gasReducing agent

The invention provides a synthetic method for a high-capacity sulfurized lithium iron phosphate positive electrode material. The synthetic method comprises the following steps: with a water-soluble lithium-source compound, a ferrous-sulfide-source compound and a phosphorus-source compound as main reactants, adding a surface additive and a carbon-source reducing agent, and carrying out grinding anduniform mixing in a water phase; carrying out a low-temperature hydrothermal reaction and then carrying out drying to obtain a precursor of sulfurized lithium iron phosphate; and subjecting the precursor to calcining under the protection of high-temperature nitrogen gas to obtain the sulfurized lithium iron phosphate / carbon-sulfur composite positive electrode material.

Owner:北京锦锂盛元科技有限公司

Hot-rolling process for high-strength anode oxidizing aluminum alloy

InactiveCN110756581AImprove performanceHigh strengthAuxillary arrangementsMetal rolling arrangementsIngotSteel belt

The invention relates to a hot-rolling process for a high-strength anode oxidizing aluminum alloy. The hot-rolling process comprises the following steps: accomplishing manufacturing of a skin materialthrough a cast ingot saw blade production way in a production process of a 5252 alloy skin material; tightening the 5252 alloy skin material with a 7075 alloy core material through a steel belt, thereby accomplishing pre-rolling compounding of the skin material and the core material; rolling a heated composite cast ingot on a hot rough-rolling machine, guaranteeing small rolling reduction and lowspeed 1-6 passes before hot-rolling, not spraying emulsion, thereby accomplishing composite rolling; after composite rolling is ended, rolling composite intermediate blank according to large rollingreduction and high speed, and finally rolling to needed hot-rolling thickness through a 3-rack hot finish-rolling machine, thereby accomplishing production of a hot-rolled composite coiled material. The hot-rolling process solves the problem that an existing 5252 alloy, taken as a high-end oxidizing material housing, is insufficient in strength through hot-rolling compounding of 5252 aluminum alloy skin material and the 7075 alloy core material, so that high-strength aluminum alloy hot-rolled coiled material suitable for anode oxidizing is obtained.

Owner:CHINALCO RUIMIN +1

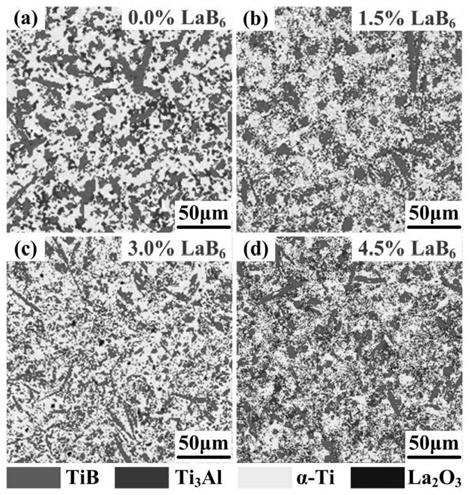

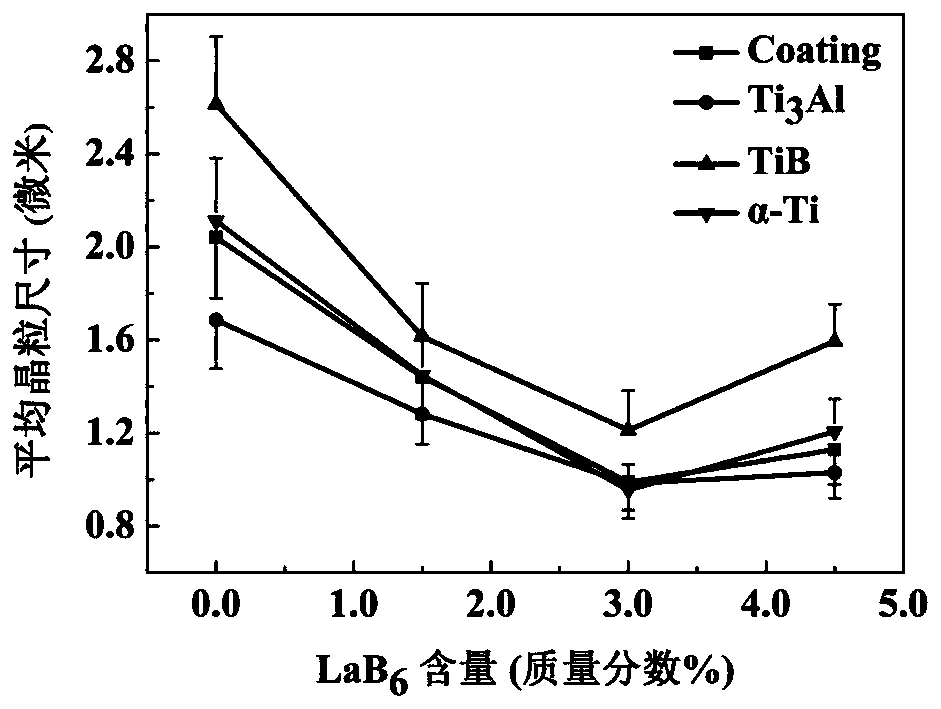

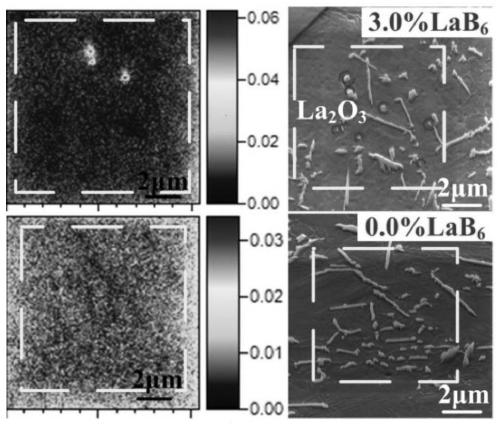

Method for modifying titanium-based laser cladding coating through LaB6

InactiveCN110344054ASmall grain sizeReduce residual stress concentrationMetallic material coating processesTitaniumHardness

The invention discloses a method for modifying a titanium-based laser cladding coating through LaB6. The method comprises the steps that firstly, the LaB6 is added into laser cladding powder in advance to prepare mixed powder; secondly, the surface of a titanium alloy base plate is ground and cleaned; thirdly, the surface of the titanium alloy base plate is coated with the mixed powder in the first step, laser cladding is carried out, and the modified titanium alloy base plate is obtained; and fourthly, the modified titanium alloy base plate in the third step is subjected to friction wear test. Through grain refining, solid O and grain more uniform distribution, the hardness, plasticity and toughness, wear resistance, high temperature oxidation resistance and other properties of the titanium-based laser cladding coating can be improved.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com