Thermoplastic composite board and manufacturing method thereof

A manufacturing method and composite board technology are applied in the fields of composite board and its manufacturing, thermoplastic composite board and its manufacturing field, which can solve the problems of many accessories required for installation, reducing the service life of the guardrail board, and being prone to damage, and achieving convenient transportation. and storage, facilitate the installation of guardrails, and reduce the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

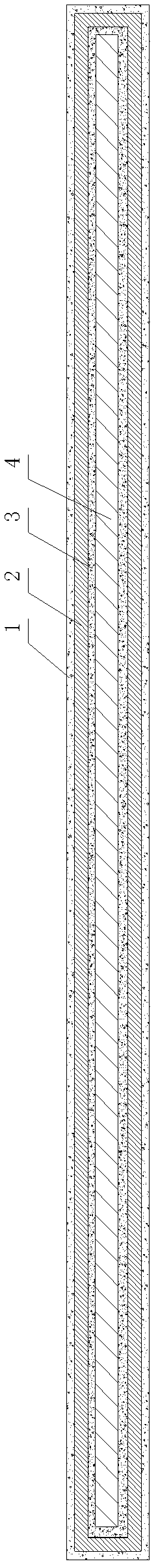

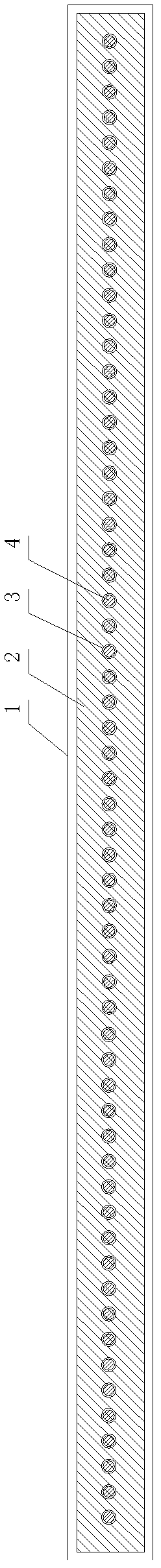

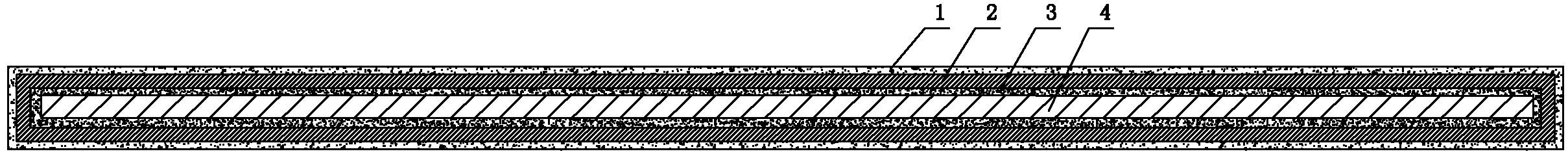

[0045] Embodiment 1, as figure 1 , 2 As shown, a thermoplastic composite board has a set transverse width, a board that extends continuously in the longitudinal direction and can be rolled into a roll by a winding device, that is, the thermoplastic composite board is set according to the requirements of on-site installation. The width of the thermoplastic composite board , through continuous production to obtain ultra-long sheets of unlimited length, for the convenience of transportation and storage, thermoplastic composite sheets can be rolled into rolls, unfolded when laying, and cut on site as needed to obtain a certain length of thermoplastic composite sheets. Thermoplastic composite panels can also be cut to length during production to obtain thermoplastic composite panels one by one.

[0046] The thermoplastic composite board includes a reinforced skeleton 4 covered with a thermoplastic material layer, and the reinforced skeleton 4 and the thermoplastic material layer a...

Embodiment 2

[0057] Embodiment 2, the manufacturing method of thermoplastic composite panel, comprises the following steps:

[0058] (1) Leveling the curved surface of the continuously conveyed reinforced skeleton, and degreasing and rust-removing treatment on the surface of the reinforced skeleton. Firstly, the roll-shaped profiles used as reinforced skeletons are continuously unfolded, and the curved surface of the continuously conveyed reinforced skeleton is leveled. For metal profiles, it is necessary to scrape off the burrs on the edges of the metal profiles; before or after leveling treatment, it is necessary to degrease and derust the surface of the reinforced skeleton, or to degrease the surface of the reinforced skeleton before and after the leveling treatment Rust treatment. Degreasing and derusting treatment is to use friction to remove rust on the surface of the reinforced skeleton and other impurities deposited on the surface of the reinforced skeleton, and remove the debris ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com