Production equipment of waterproof corrugated board

A production equipment and technology of corrugated cardboard, which is applied in the field of production equipment of waterproof corrugated cardboard, can solve problems such as moisture damage to internally loaded items, cumbersome process, and impact on production efficiency, so as to improve production efficiency, simplify the process, and save energy. The effect of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

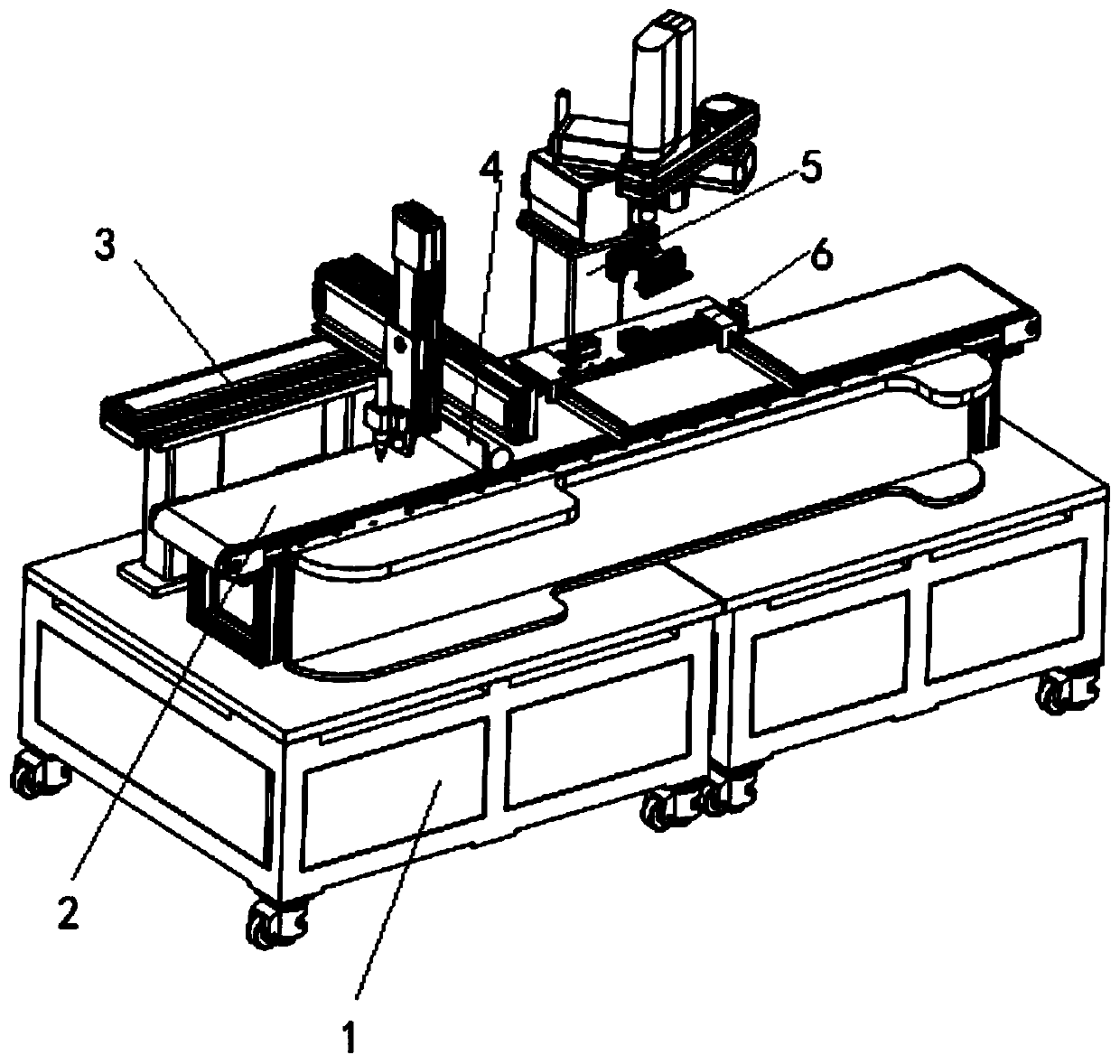

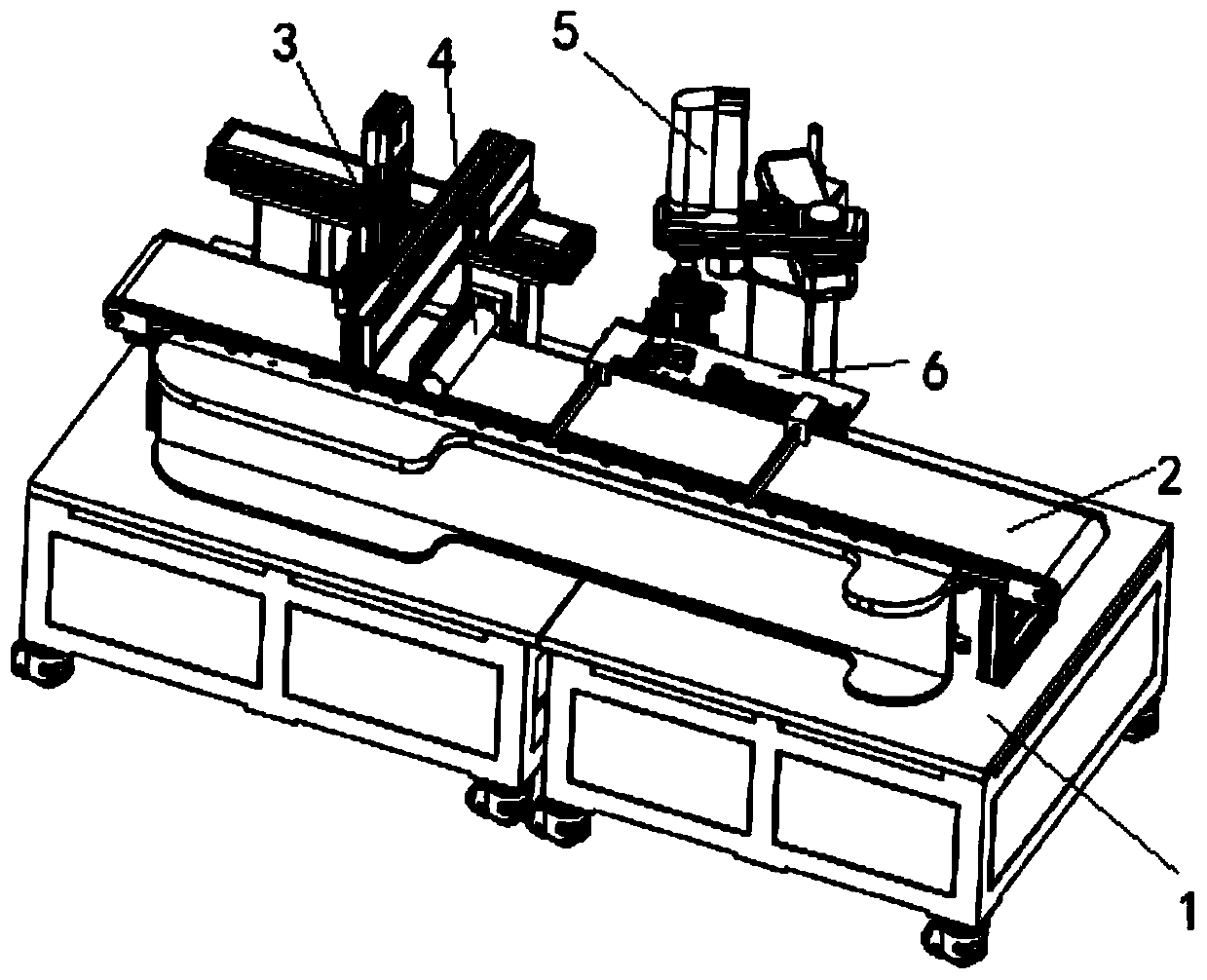

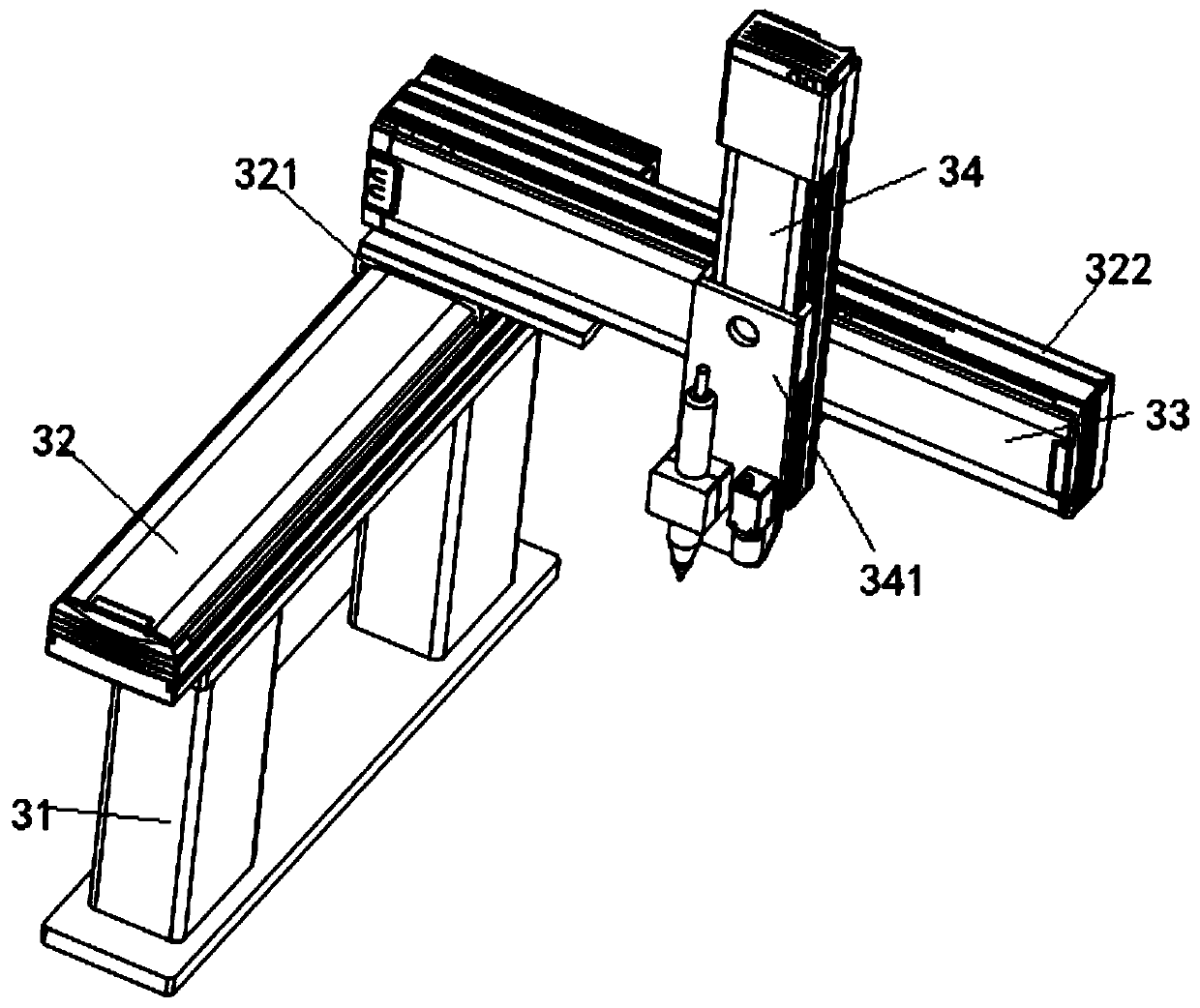

[0029] A production equipment for waterproof corrugated cardboard, such as figure 1 with figure 2 As shown, including a processing machine tool 1, a transmission mechanism 2 is installed in the middle of the surface of the processing machine tool 1, and a side of the processing machine tool 1 is sequentially provided with a glue application mechanism 3, a flat glue mechanism 4, a suction plate positioning mechanism 5 and Pressing and shearing mechanism 6, the PVC plastic film roll is placed on the transmission mechanism 2 after being opened, and is driven forward by the transmission mechanism 2. When it moves to the bottom of the gluing mechanism 3, the gluing mechanism 3 moves back and forth to realize gluing, gluing Finally, when the plastic film moves to the bottom of the flat glue mechanism 4, the glue liquid is spread flat by the flat glue mechanism, and when the coated plastic film moves to the bottom of the suction plate positioning mechanism 5, the corrugated cardboar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com