Patents

Literature

122results about How to "Realize integrated processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

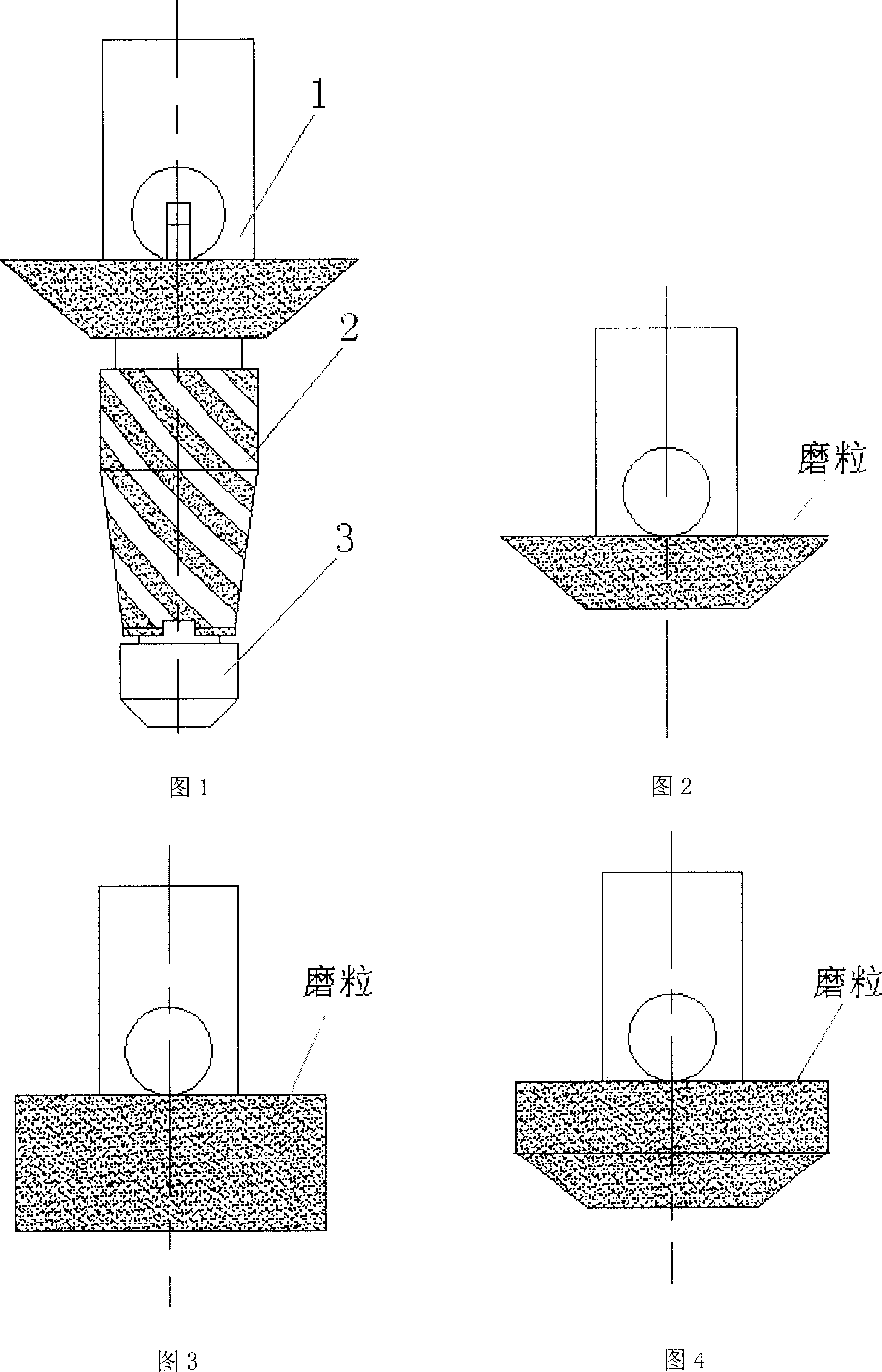

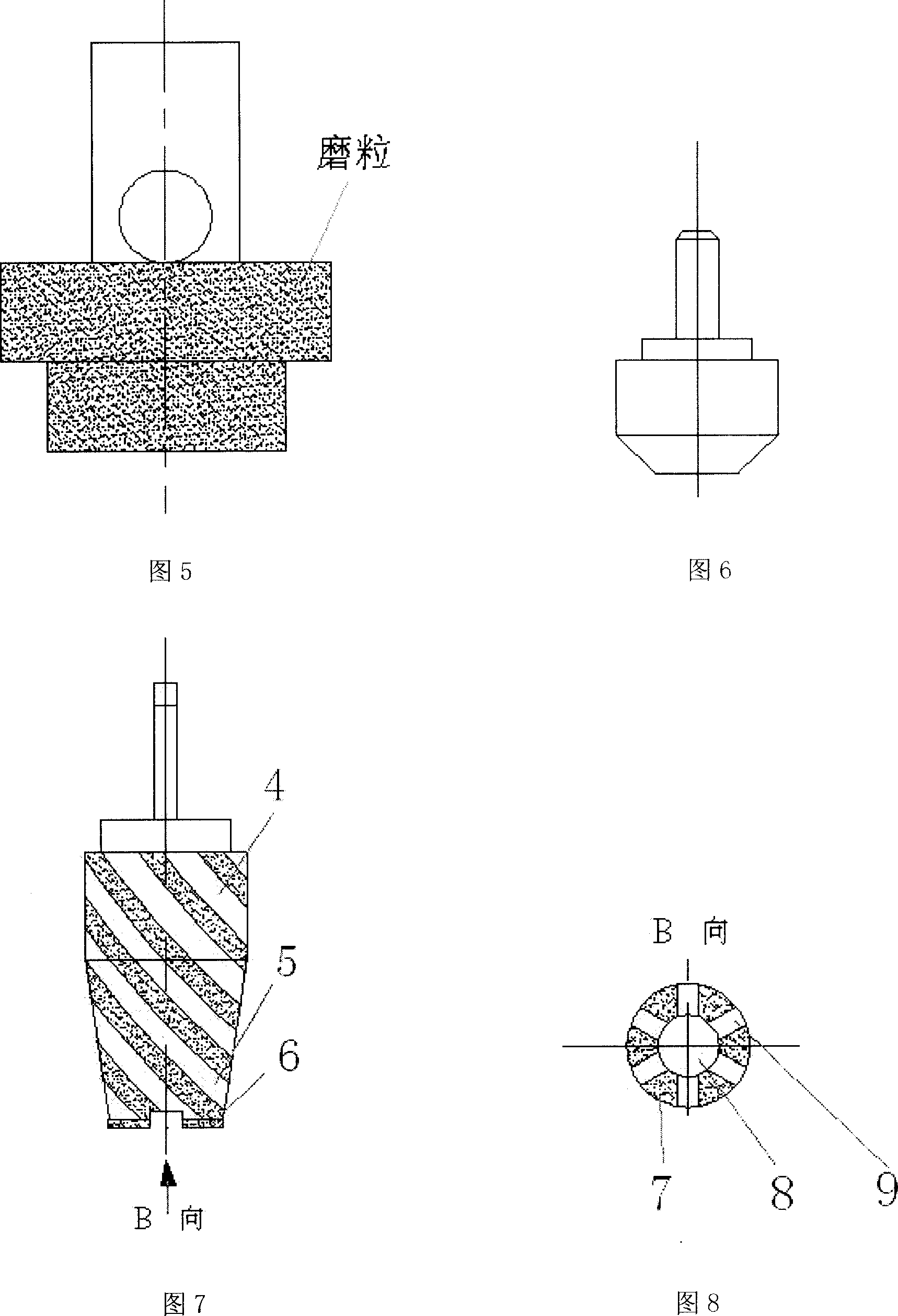

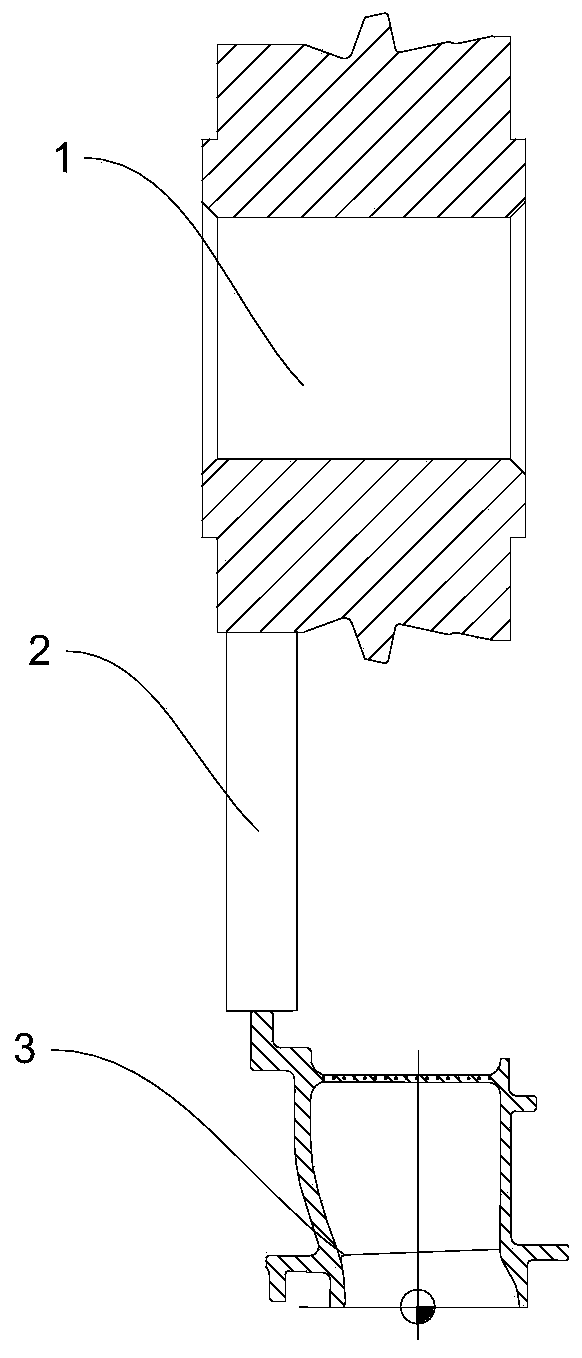

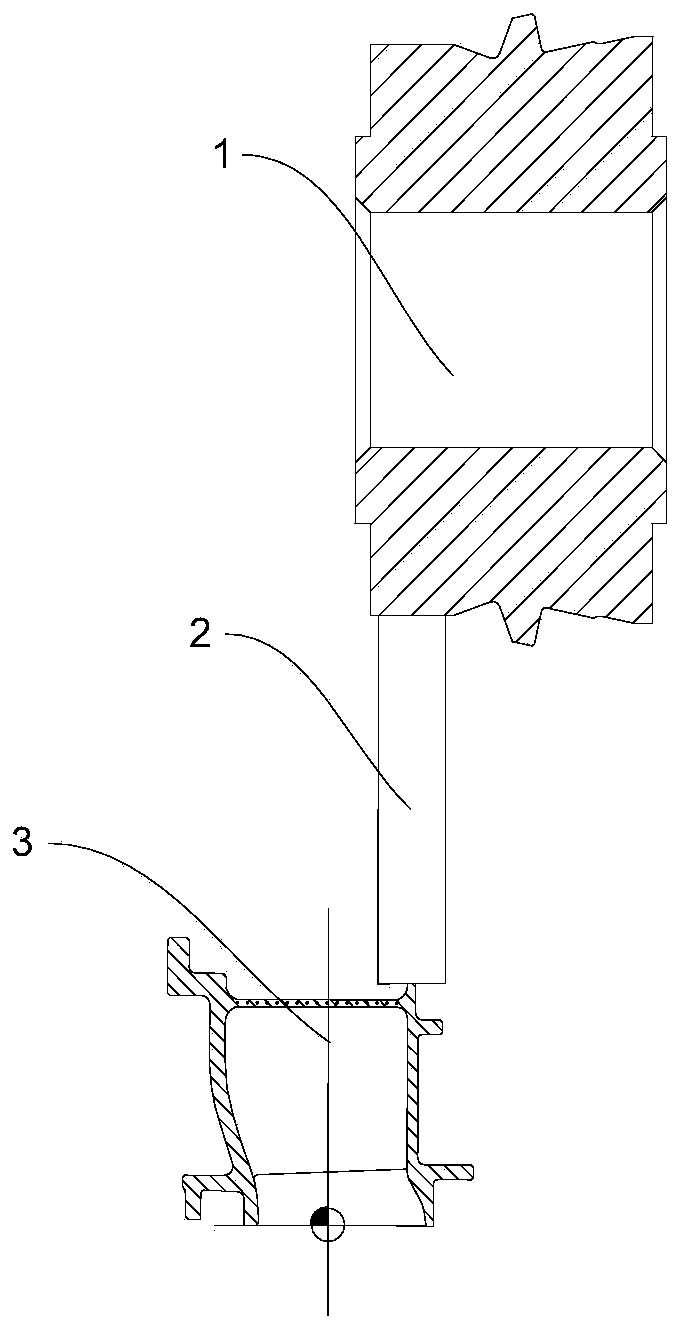

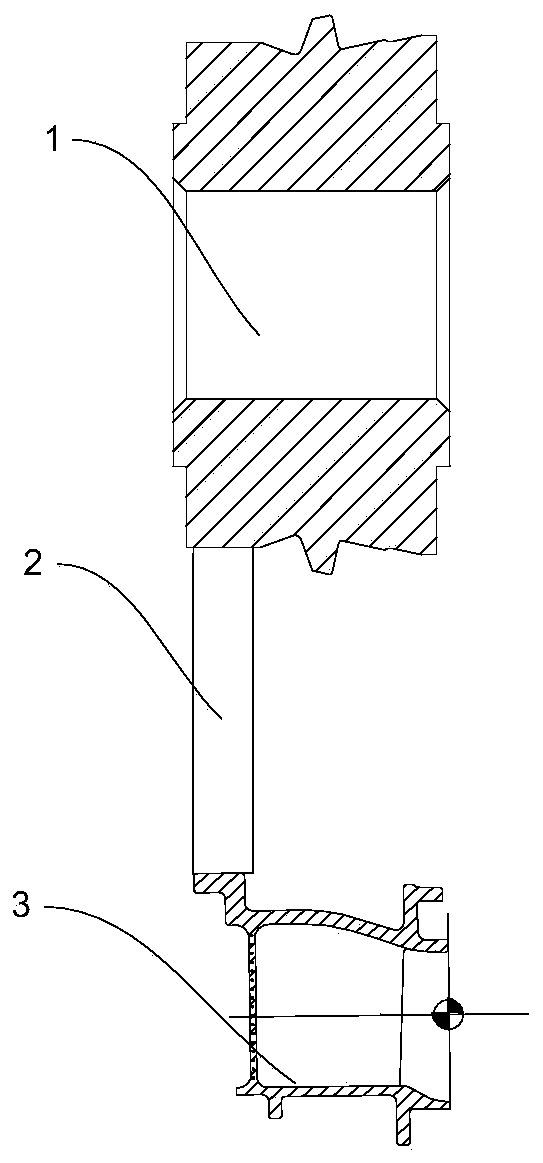

Drilling/grinding integrated combined tool

InactiveCN1935430AImprove processing qualityExtend your lifeTransportation and packagingAbrasion apparatusStructural engineeringConoid

The present invention relates to an integral combined cutting-tool with hole-drilling and hole-grinding functions. Said cutting-tool is formed from three portions of counter-boring hole-grinding and hole-sinking section, hole-expanding and hole-grinding section and guide head. Said invention also provides the concrete structure of the above-mentioned every portion and its production method.

Owner:DALIAN UNIV OF TECH

Algae removal method and movable algae removal platform suitable for river channel type water body

InactiveCN103129713AEnhanced inhibitory effectReduce operating costsWater cleaningWater/sewage treatment by irradiationEutrophicationWater quality

The invention provides an algae removal method and a movable algae removal platform suitable for a river channel type water body. The algae removal method and the movable algae removal platform suitable for the river channel type water body utilize a ship body as a carrier, adopt an ultrasonic algae removal instrument, a microfiltration machine, a self-suction type spiral stirring aeration machine and a rotary type algae salvage machine for matching, achieves ultrasonic removal, mechanical salvage, algae-water separation, and functional combination of water body oxygen enrichment and air floatation to restrain the growth of the algae in water, the irradiation frequency of ultrasonic waves is A which equals to 20-50 kHz, the irradiation distance is B which equals to 0.5m, and the irradiation time is C which equals to 5min. According to the algae removal method and the movable algae removal platform suitable for the river channel type water body, the algae body cell air bags and cell ectocrine are affected to further affect the agglomeration effect of the algae in water so that the removal of the algae is achieved. Compared with a stationary type ultrasonic algae removal method, rapid and accurate function can be carried out on the entire research water area. The movable algae removal platform eliminates the heavy workload of algae salvage for workers when a water bloom occurs, causes smaller economic loss compared with that caused by eutrophication of the water body, is suitable for water quality characteristics of secondary rivers in the Three Gorges Reservoir Region, and has a good demonstration effect.

Owner:CHONGQING UNIV

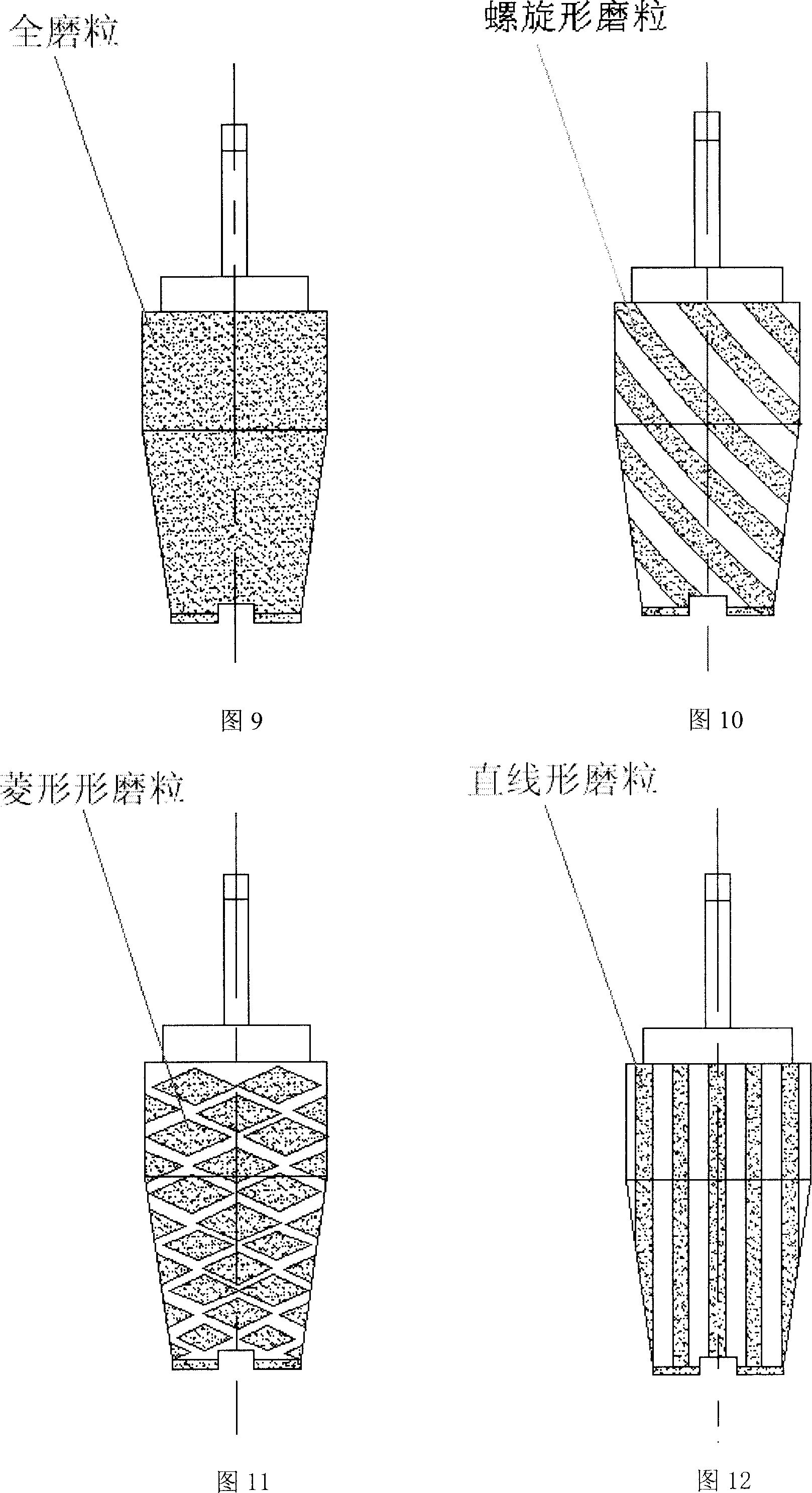

Method for integral micromachining multilayer composite structure

InactiveCN1583543AReduce mistakesSolve the problem of relative position accuracy between layersDecorative surface effectsPhotomechanical apparatusPosition errorPhotoresist

A method for integrally microprocessing copmlex multi-layer structure features that the photoresist SU-8 and quisi-LIGA processing are used, the multiple layers are simultaneously etched to reduce the relative position error between layers, a surface activating technique is used to improve the binding force between electrocast layers, and the seed layer techinque is used for generating big electrocasting pattern.

Owner:SHANGHAI JIAO TONG UNIV

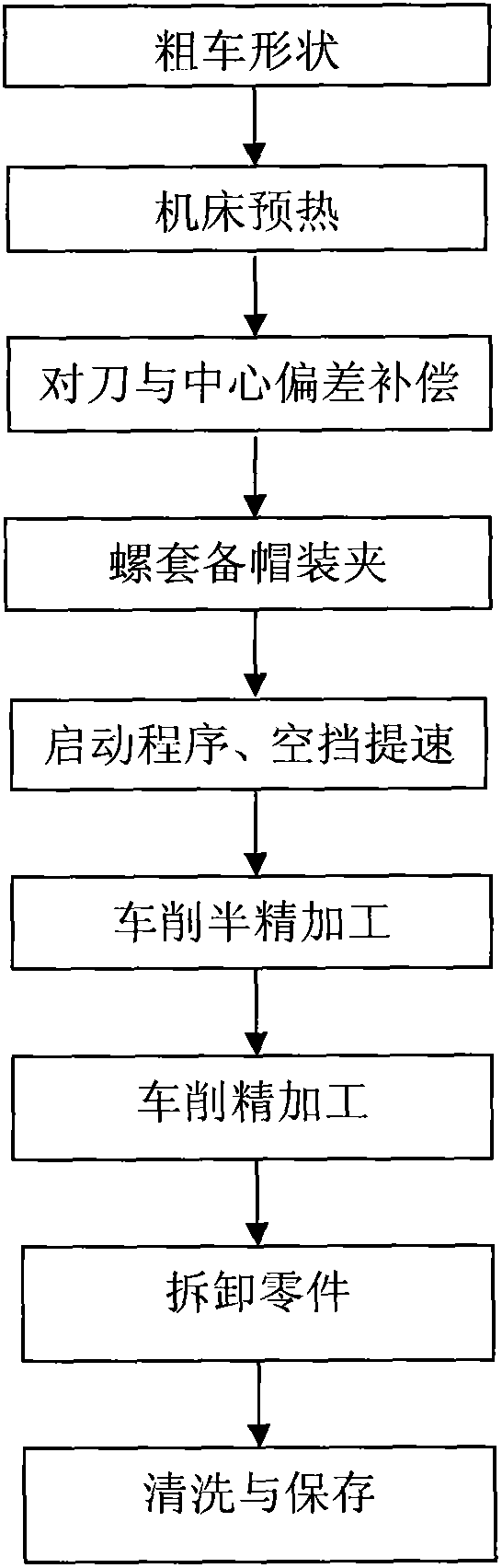

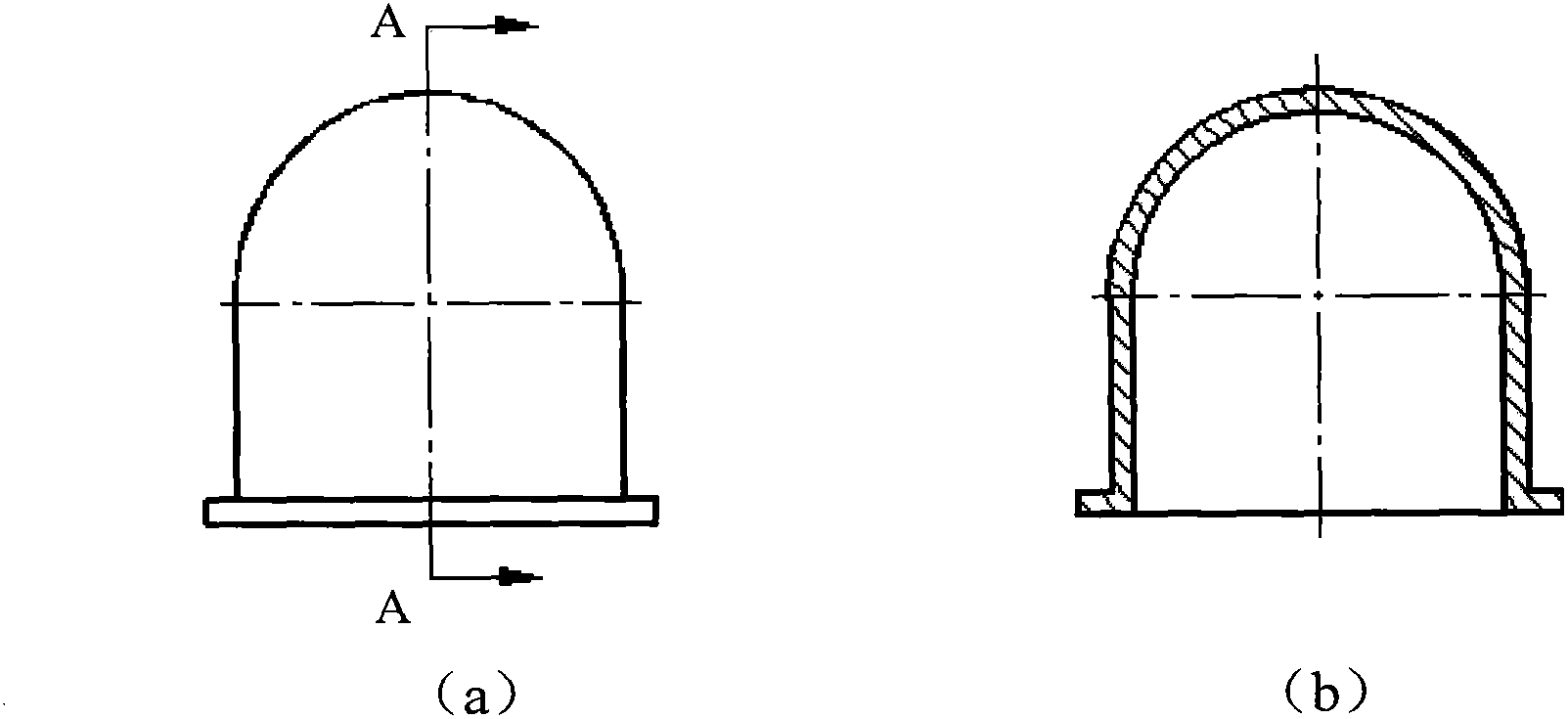

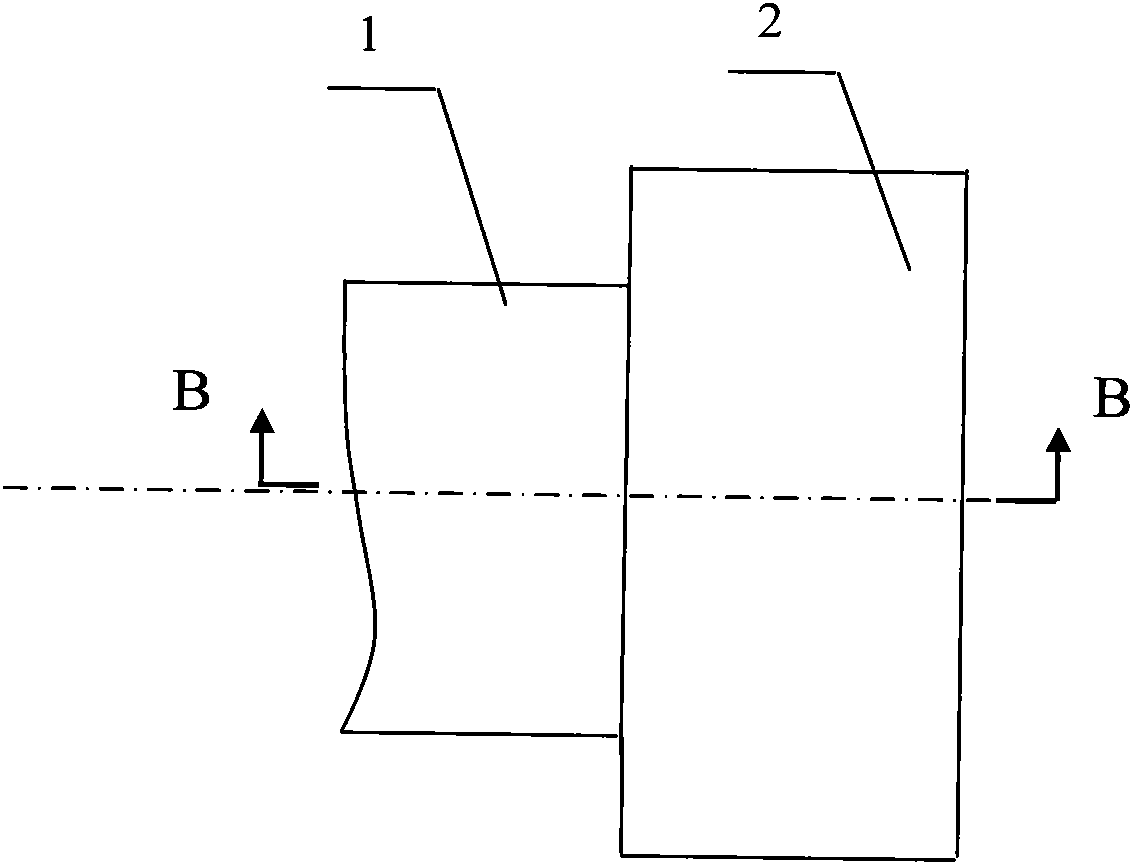

Precision finishing method of inner spherical surface of high-purity aluminum thin-wall part

The invention belongs to the processing technology of a precise component made from special material, and relates to a processing method of a high-purity aluminum precise element. In the invention, the high-purity aluminum thin-wall part is clamped on a spindle of a numerical control machine through a screw sleeve cap and quakeproof improvement so as to achieve the purposes of accurately positioning based on an end surface and simultaneously improving the radial force; reasonable tool structure parameters for cutting the high-purity aluminum material are obtained by early research so as to improve the previous tool; then a reasonable tool setting method is adopted so that the central point of the tool is precisely meshed with the center of a workpiece; and numerically-controlled turning processing is performed. Compared with the previous processing methods, the processing method of the high-purity aluminum precise part provided by the invention can be used for changing the condition that the high quality of surface of a part cannot be obtained before, and overcoming the problems of deformation, vibration, wave, built-up edge and the like in the processing, so that the inner spherical surface of the part reaches the level of a mirror bright surface and the requirements on light reflection are met; and moreover, the processing quality is stable, and the efficiency is high.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

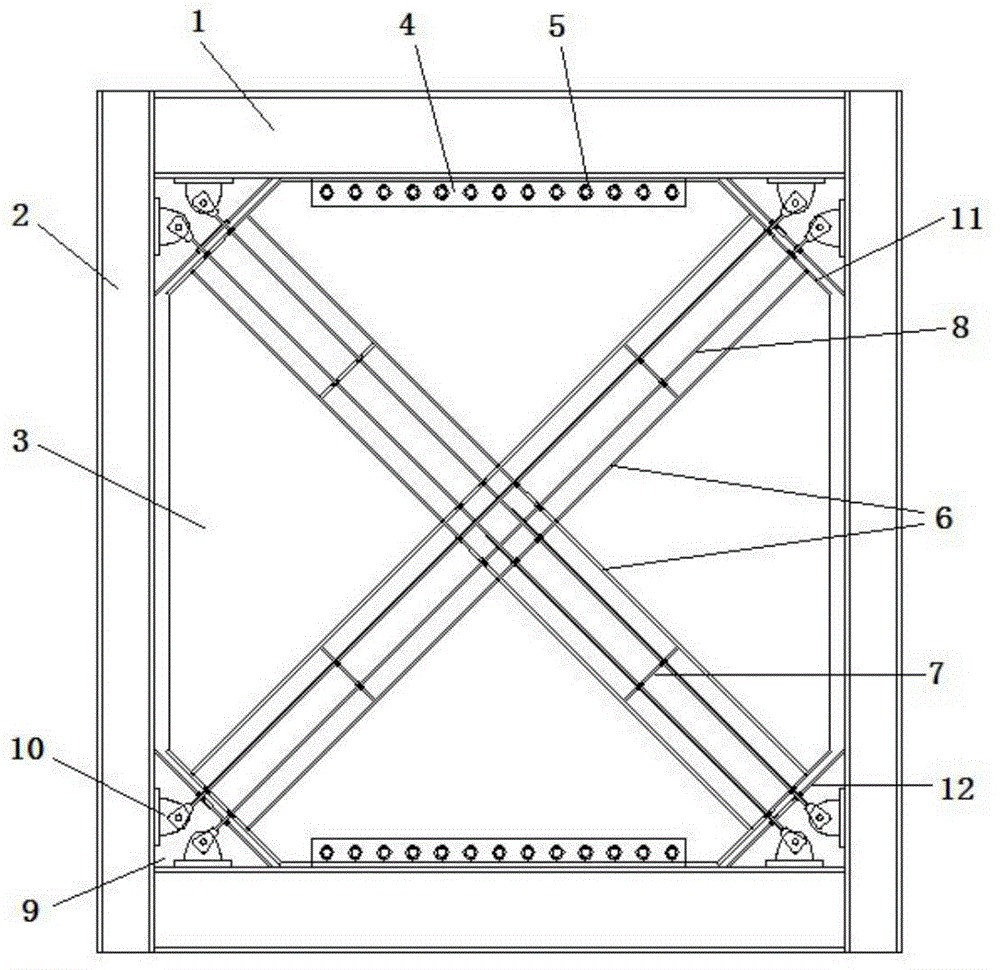

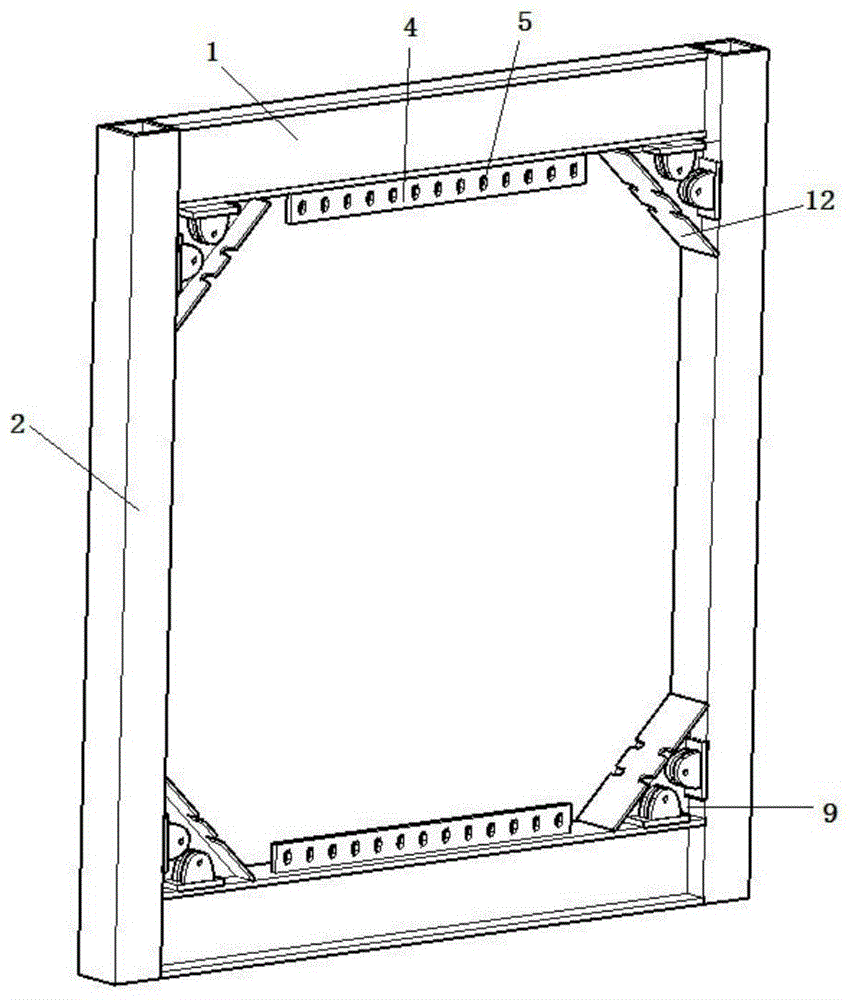

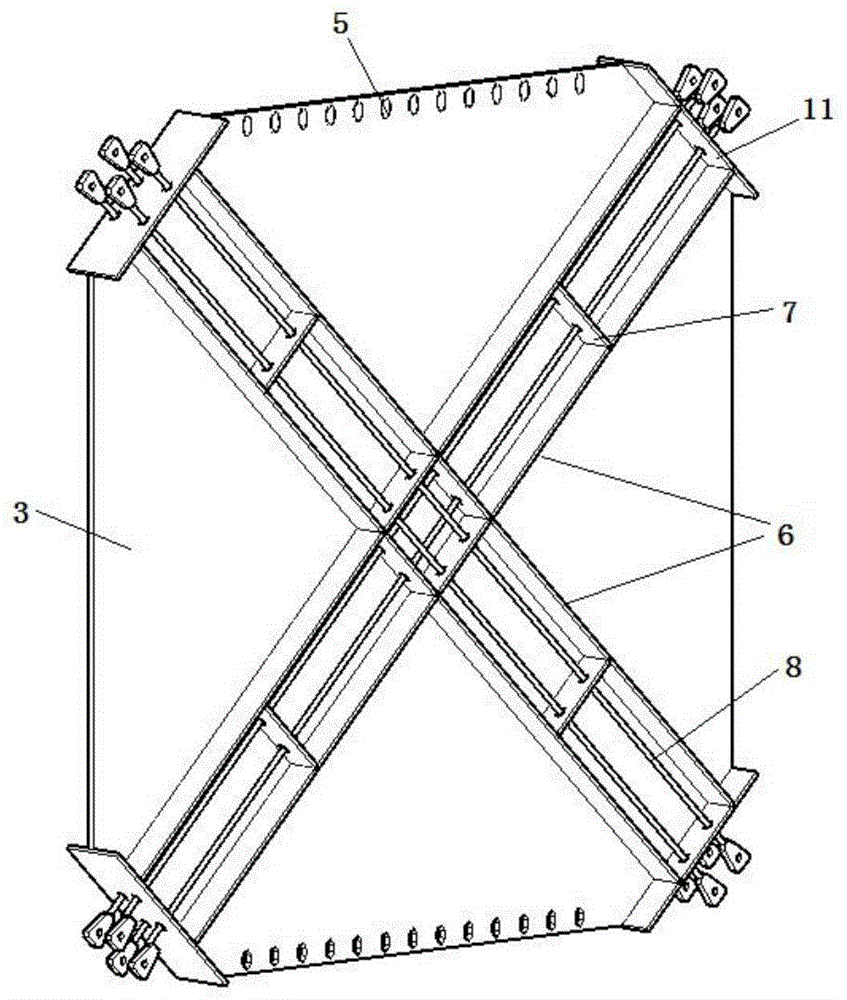

Prestressed steel plate shear wall capable of separating tension field

The invention provides a prestressed steel plate shear wall capable of separating a tension field, and relates to the field of civil engineering. The prestressed steel plate shear wall capable of separating the tension field is a novel energy-consuming and buckling-restrained shear wall component. The technical problems that a diagonal tension field is formed after the traditional steel plate shear wall is stressed, steel plates are buckled, and components are damaged are solved. The prestressed steel plate shear wall capable of separating the tension field mainly comprises a steel plate wall, a prestressed cable, a perforated diagonal bracing, a perforated rib plate, a corner connector and a horizontal edge connector. The prestressed cable is separated from the steel plate wall, so that the prestressed cable bears all diagonal tension, the problem that the traditional steel plate wall is damaged due to the tension field is solved, after the cable is tensioned, buckling of the steel plate wall out of a plane can be limited, and the steel plate wall is protected well, and only needs to bear diagonal pressure and horizontal shear. By the method for separating the diagonal tension of the steel plate wall through the prestressed cable, the steel plate wall has features of good anti-seismic property and high ductility, and is a high-performance lateral force resistant component for a high-rise building structure or other structures.

Owner:ARUP INT CONSULTANTS (SHANGHAI) CO LTD BEIJING BRANCH

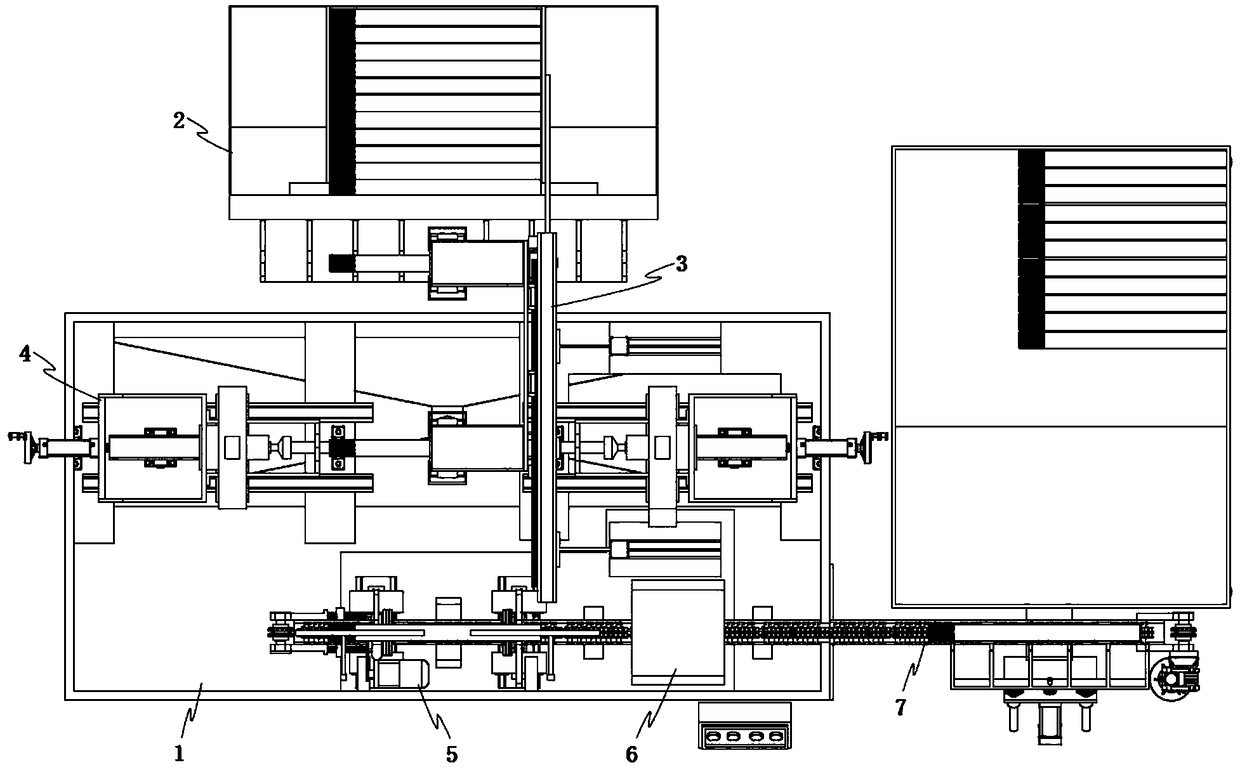

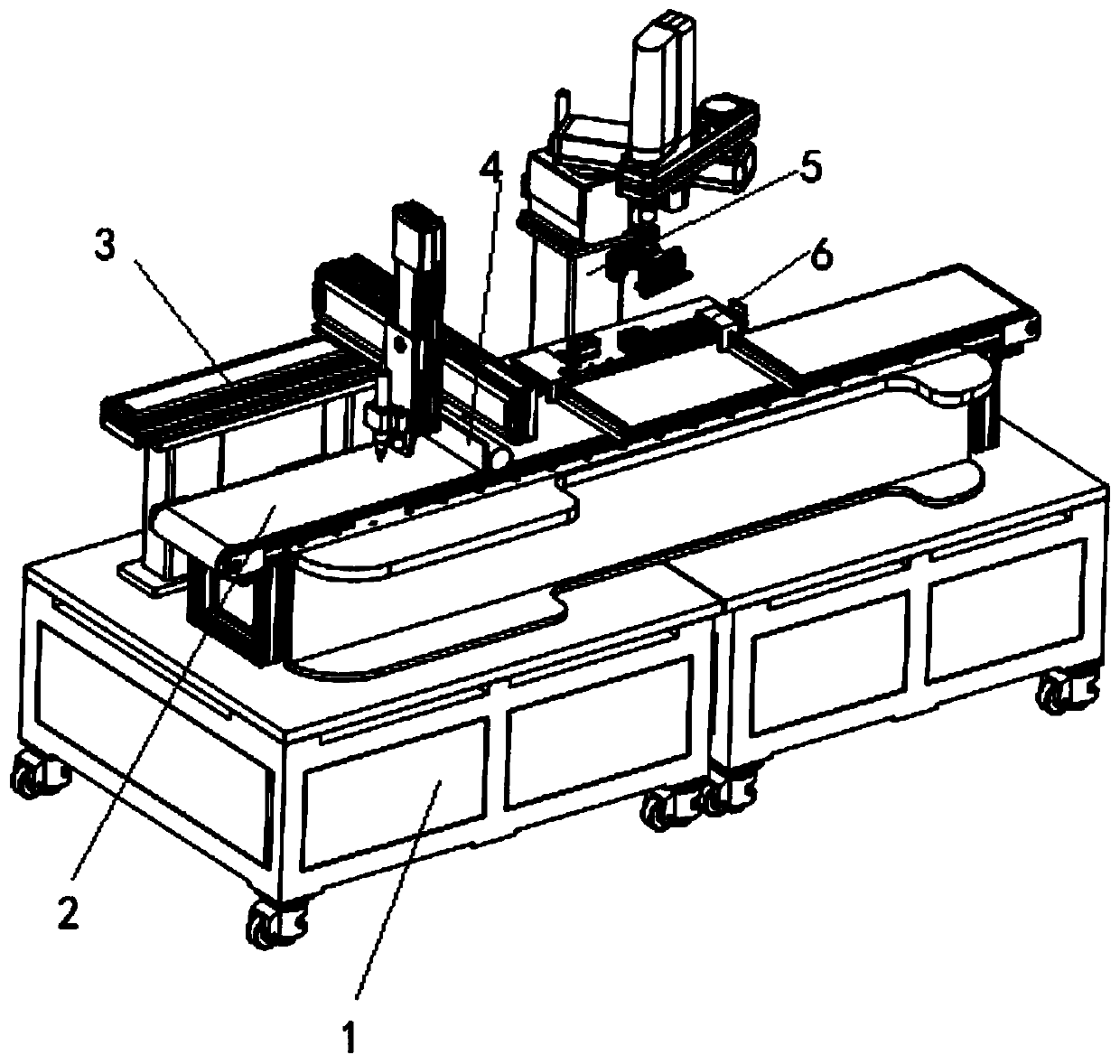

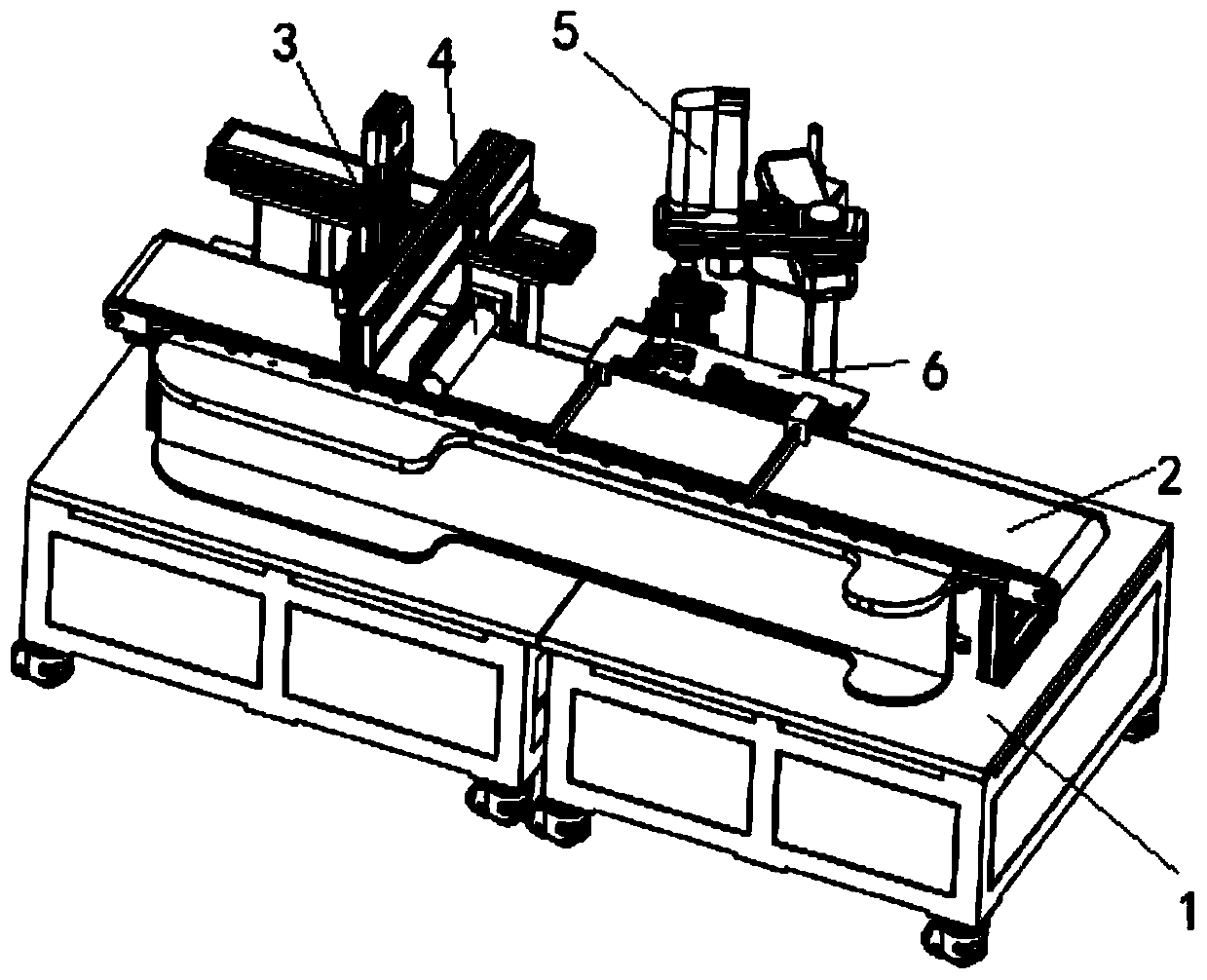

Double-linkage bending machine allowing molds to be rapidly replaced and used for large panels

ActiveCN106862326AShorten the processing cycleRealize integrated processingShaping toolsPress brakeArchitectural engineering

The invention discloses a double-linkage bending machine allowing molds to be rapidly replaced and used for large panels. The double-linkage bending machine comprises a worktable, a PLC control device, a mold base, a left bending device and a right bending device. The worktable comprises a front beam, a rear beam and at least two guide columns. The at least two guide columns are fixed between the front beam and the rear beam in parallel. A mold base rail is further fixed to the middle positions of the multiple guide columns. Molds of different shapes and structures are sequentially connected to the mold base rail. The left mold and the right mold of the mold base rail of the bending machine are directly connected to the mold base rail through sliding trolleys correspondingly, and meanwhile the sliding trolleys are fixed to the left bending device and the right bending device through connection rods correspondingly. The bending machine is compact in structure, suitable for bending multiple structures of the large panels and capable of rapidly unloading and unloading bent parts, and the bending machine can also conduct two-side same-time bending for large-width bending machines.

Owner:JIANGSU JIANGHAI MACHINE TOOLS GROUP

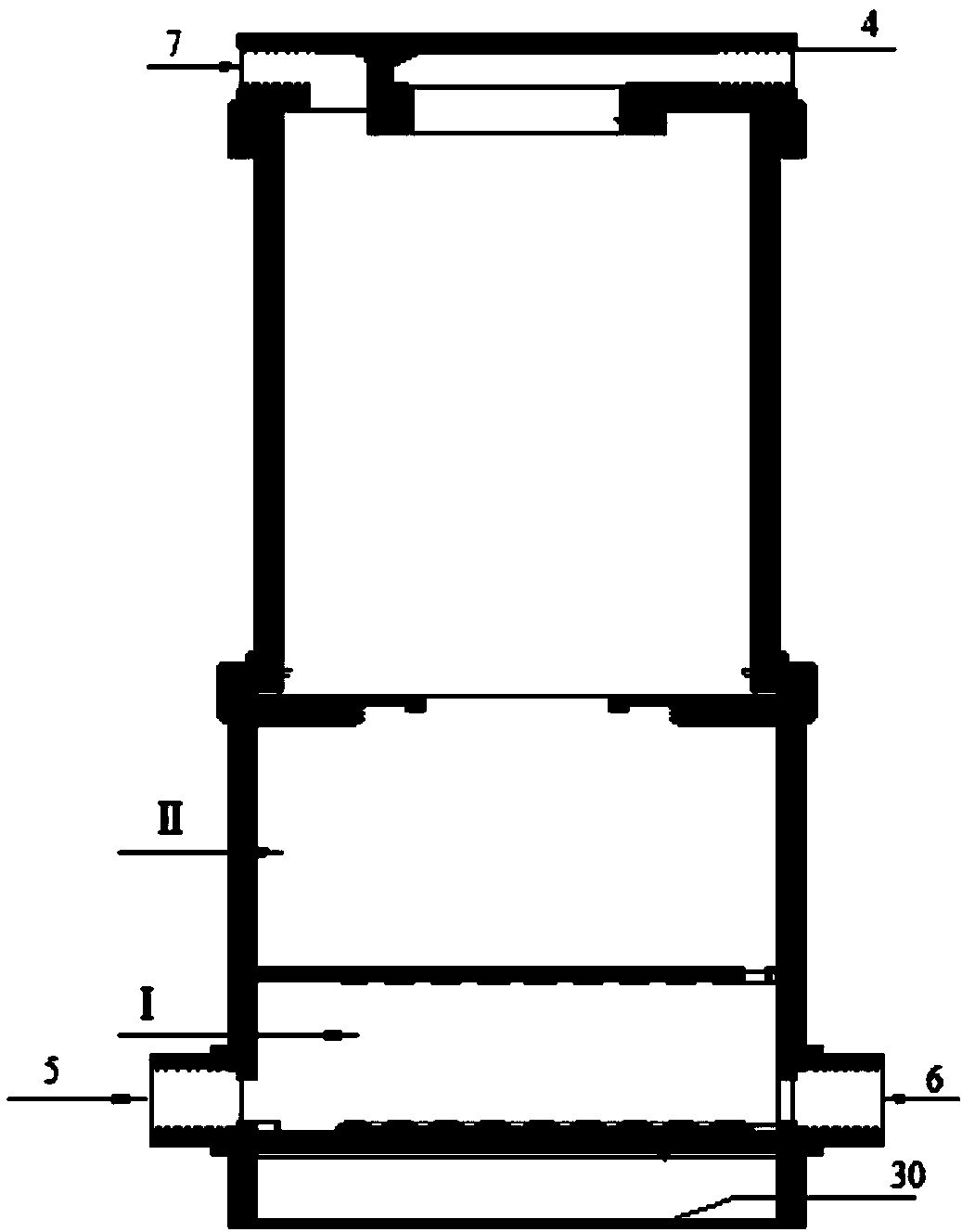

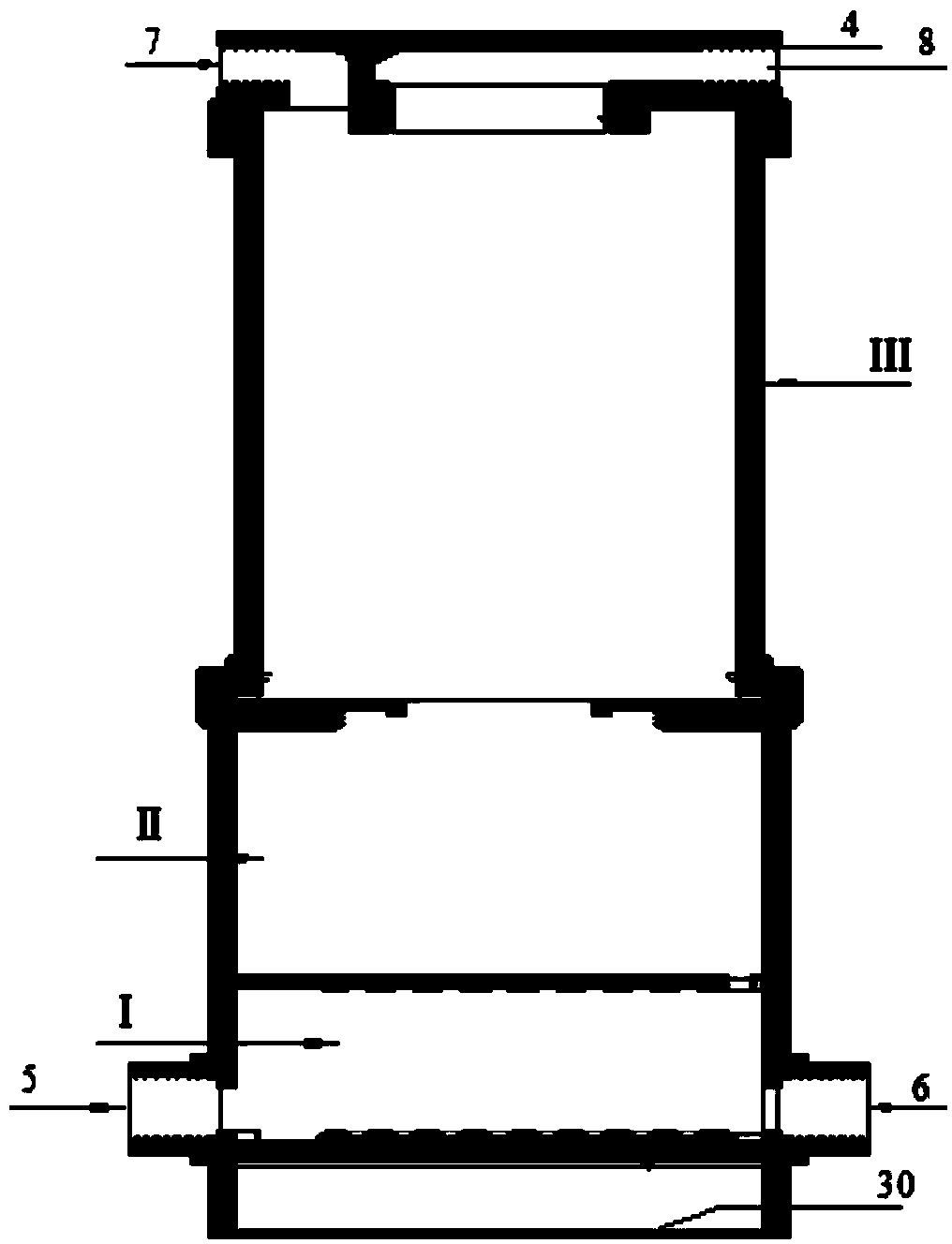

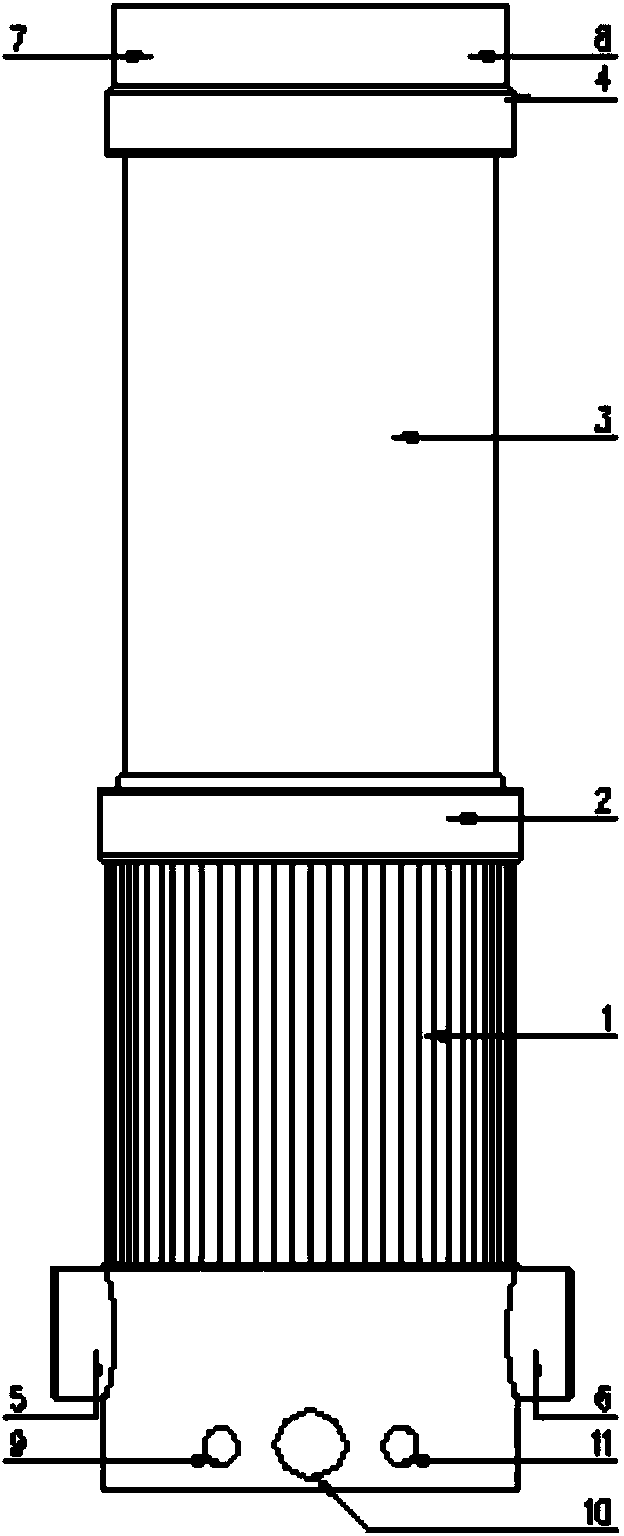

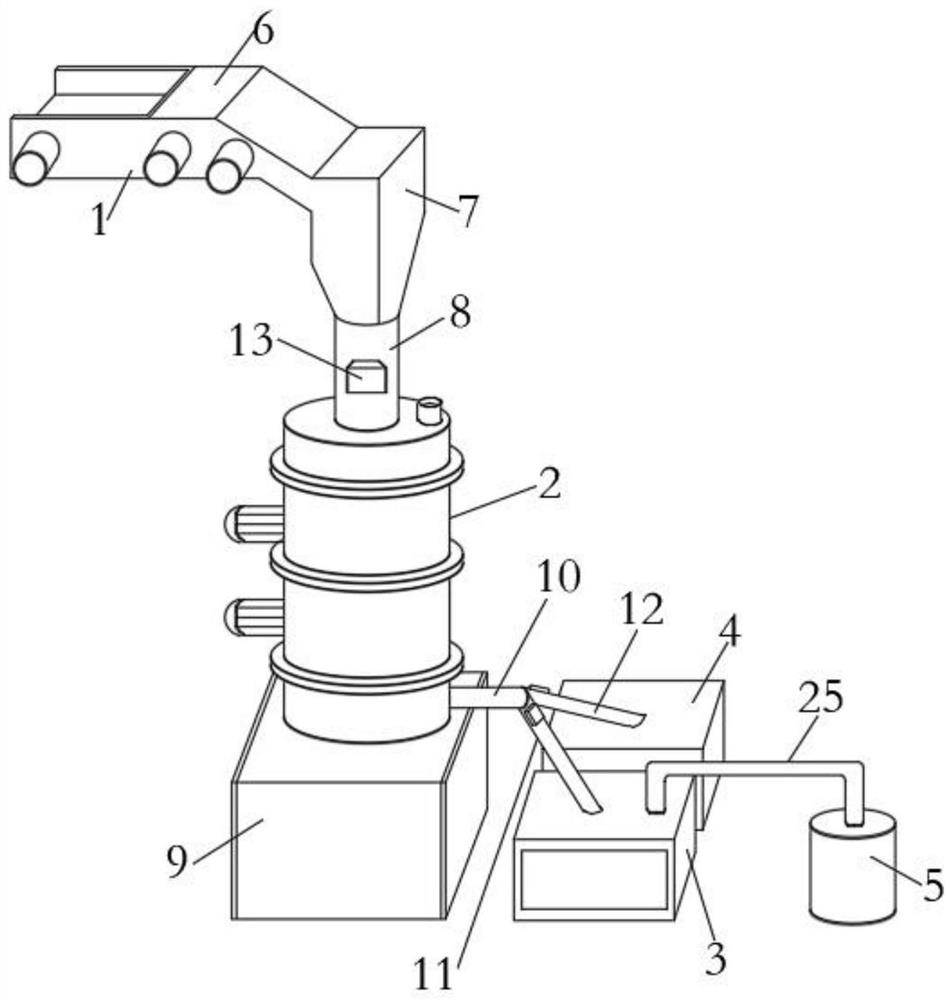

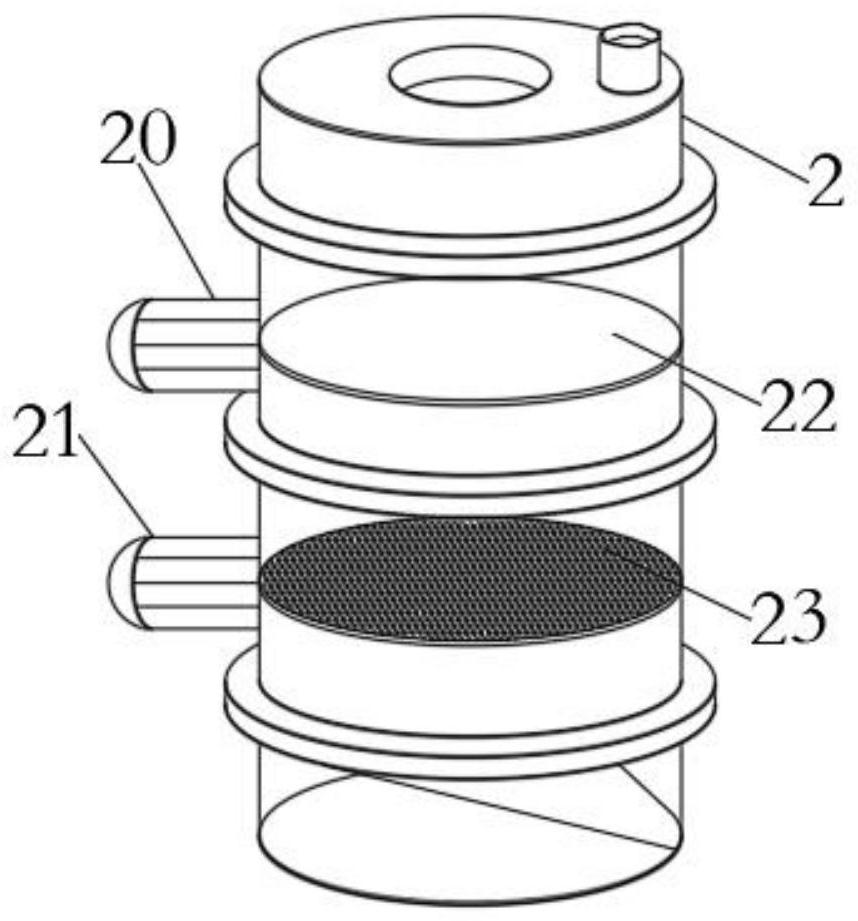

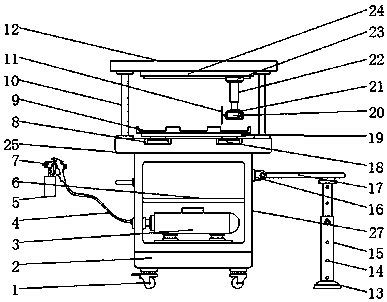

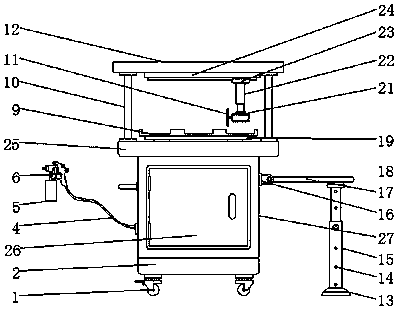

Water-purifying process and water-purifying equipment thereof

InactiveCN104098218ARealize integrated processingRealize water conservation and environmental protectionMultistage water/sewage treatmentWater savingTap water

The invention relates to a water-purifying process and water-purifying equipment thereof. Tap water is treated into flushing water, clean water and direct drinking water in a grading and classifying manner as required through a first-stage purification treatment device, a second-stage purification treatment device and a third-stage purification treatment device which are connected in sequence from bottom to top. By adopting the water-purifying process and the water-purifying equipment, water resources are utilized more optionally and reasonably, the problems of secondary pollution and the like since heavy metal pollutants in tap water cannot be removed in an efficient and environment-friendly way in the prior art are solved effectively, heavy metal ions, residual chlorine and other harmful particles in tap water are removed efficiently, bacteria are killed, the water quality is improved, sewage is disposed automatically, and the water yield and the utilization ratio of water are increased greatly; the health of a user is ensured; tap water is classified and treated effectively and is utilized in a shunting way according to the water quality, water amount and water pressure requirements of household water, and water is saved; energy is saved efficiently, space is saved, and remarkable energy-saving and environmental protection effects are achieved. The water-purifying process and the water-purifying equipment are suitable to be popularized and applied in relevant tap water treatment field.

Owner:合肥一言科技发展有限公司

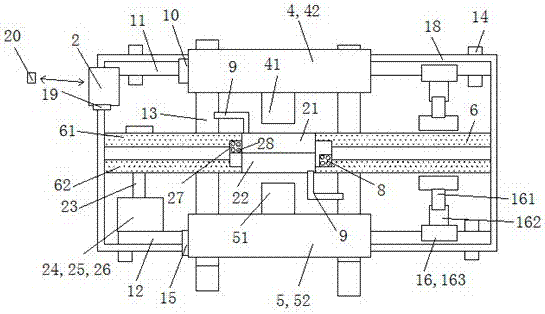

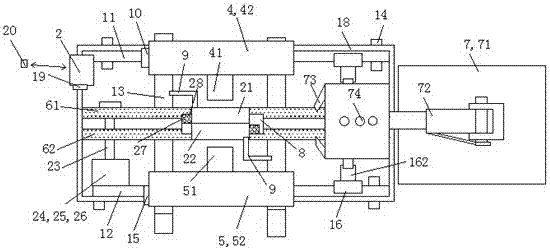

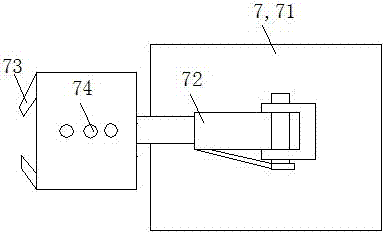

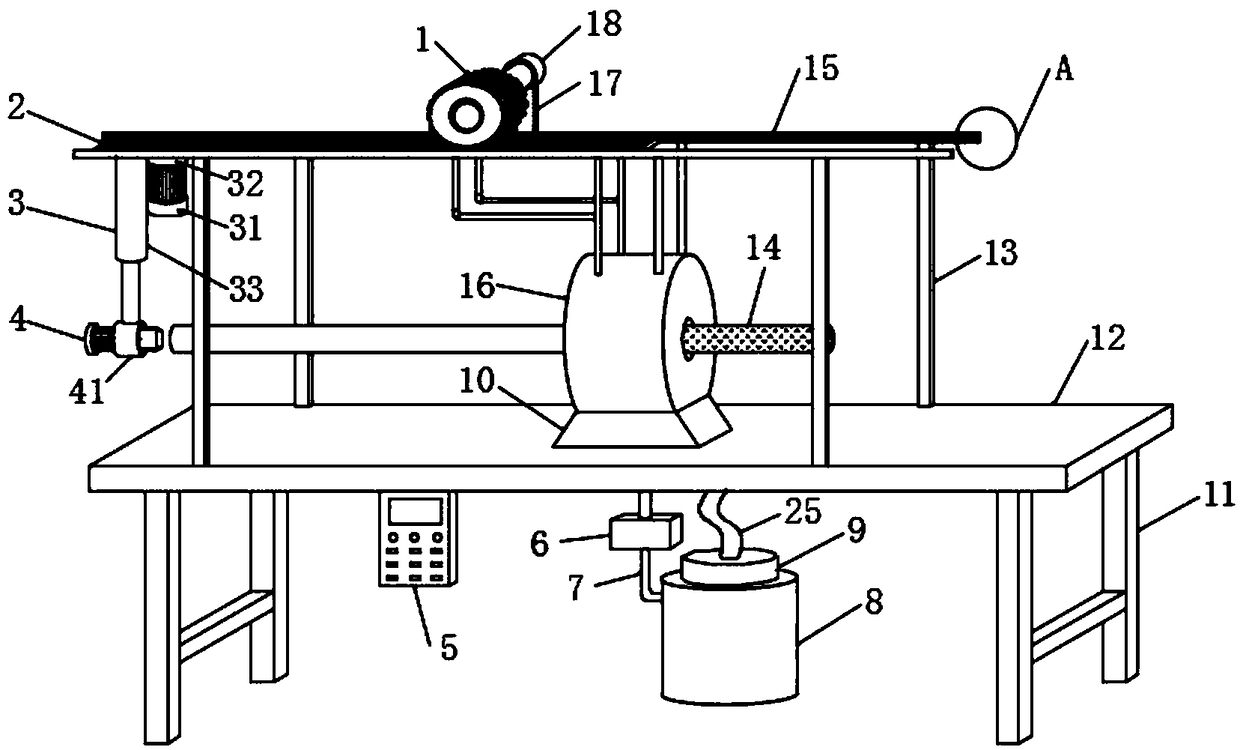

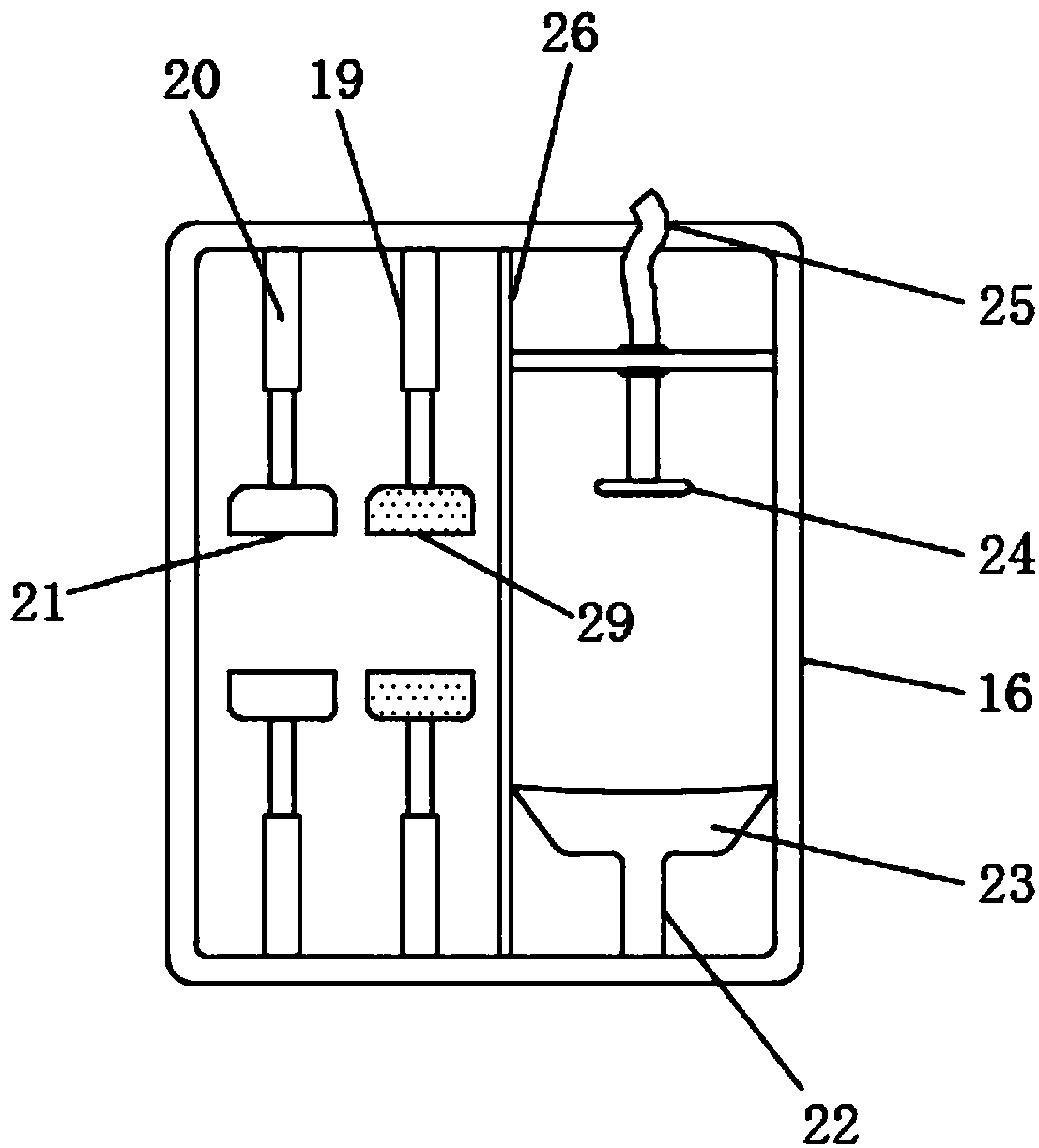

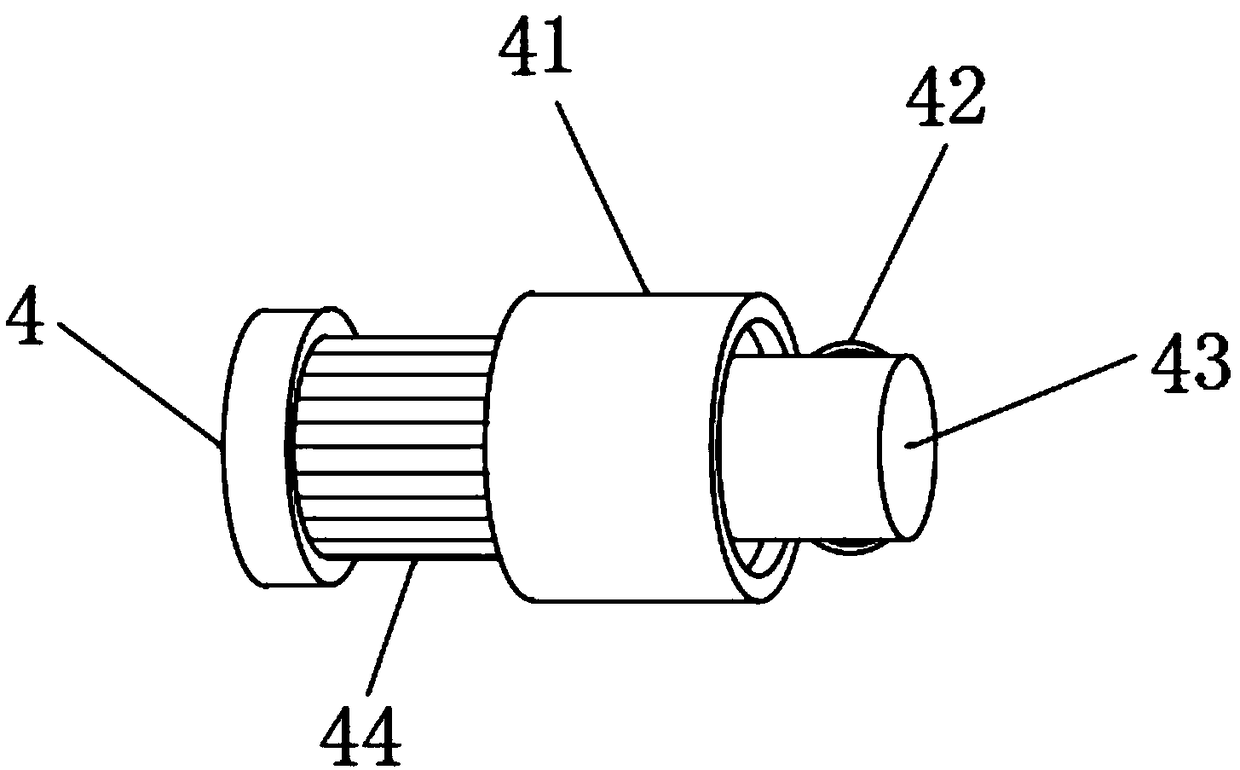

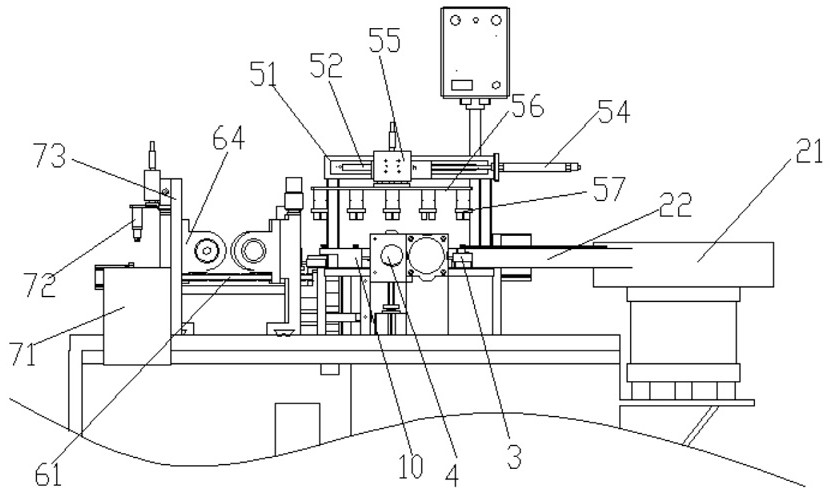

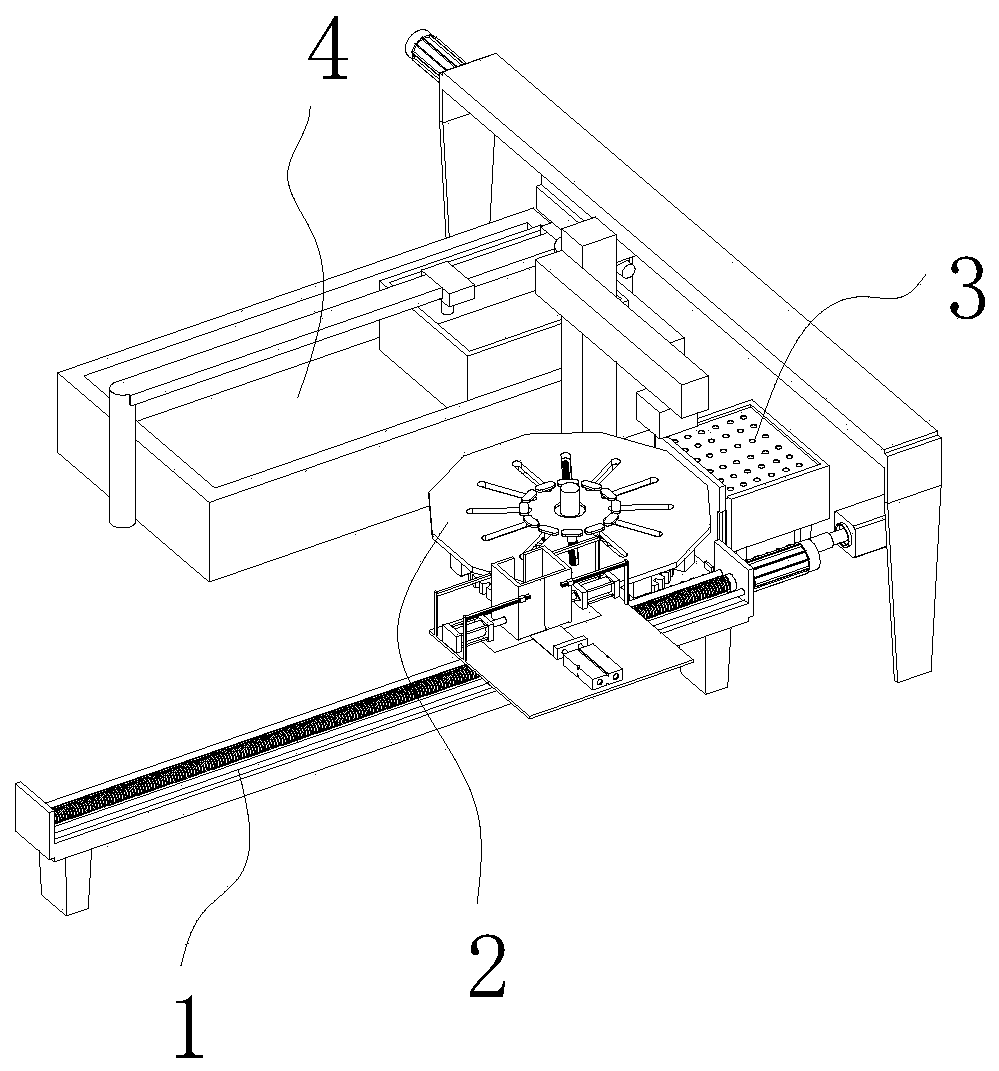

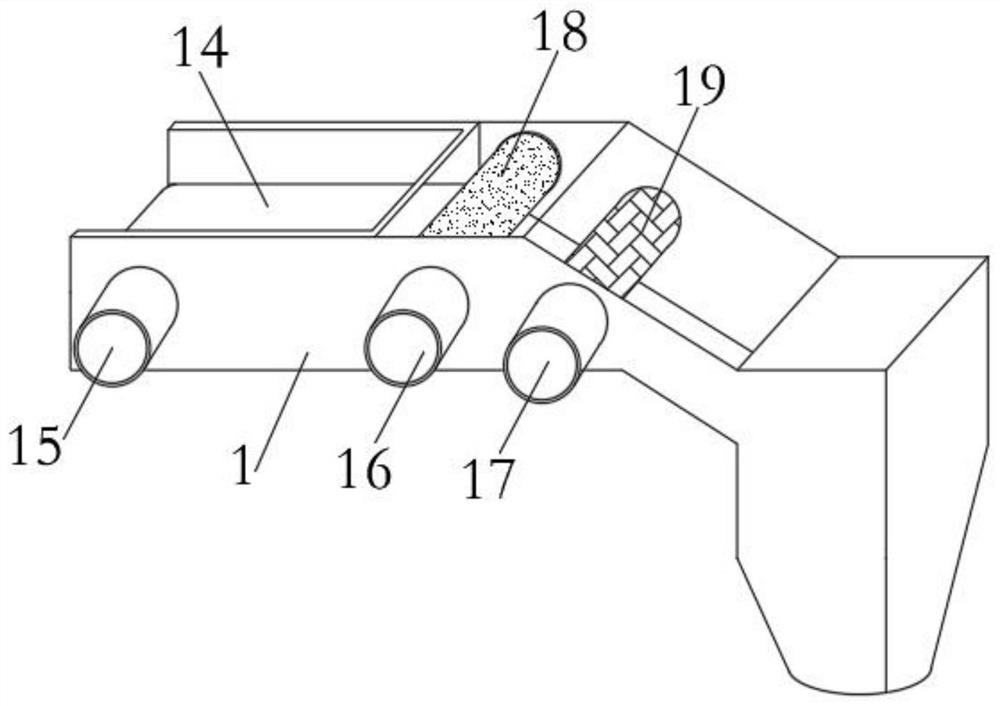

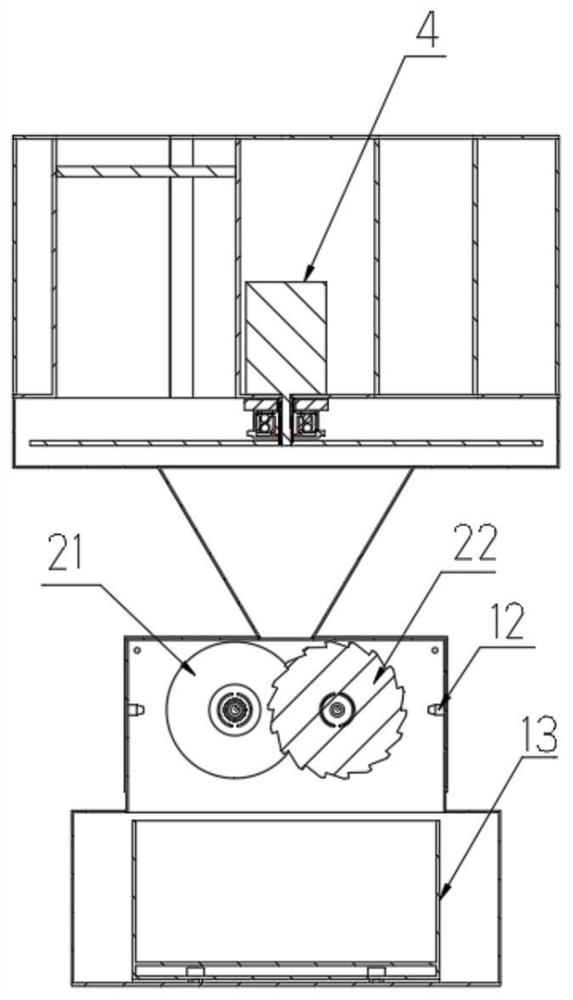

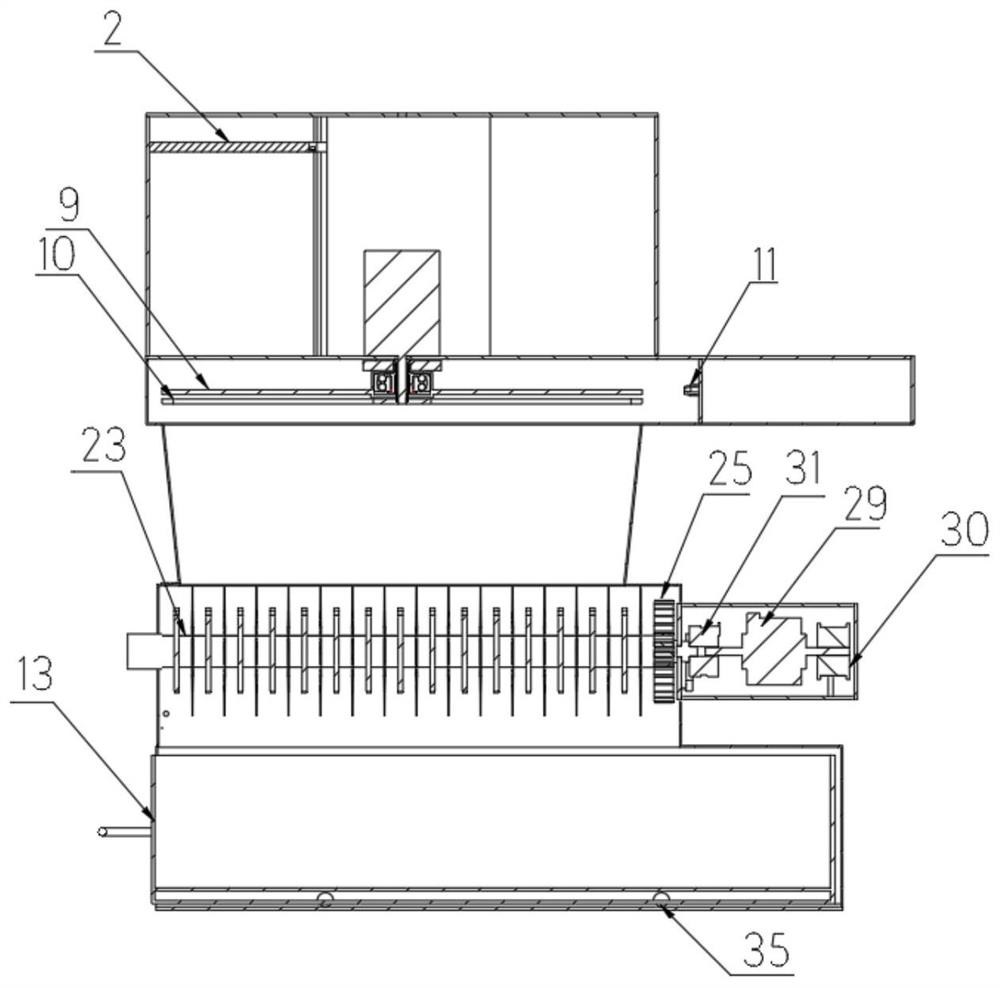

Drilling, grinding and spraying all-in-one machine for transmission shaft machining

InactiveCN108972007AImprove processing efficiencyEnsure processing consistencyOther manufacturing equipments/toolsDrive shaftEngineering

The invention relates to a drilling, grinding and spraying all-in-one machine for transmission shaft machining. The drilling, grinding and spraying all-in-one machine for transmission shaft machiningcomprises a mounting table body, wherein a transmission shaft carrying mechanism, a grinding and drilling mechanism, a spraying mechanism and a baking chamber are arranged on the mounting table body;a transmission shaft input mechanism is arranged on the side, close to the transmission shaft carrying mechanism, of the mounting table body; and a transmission shaft output mechanism is arranged onthe side, close to the spraying mechanism, of the mounting table body. Integrated machining of end face grinding, side wall surface drilling and surface rustproof paint spraying of a transmission shaft is realized, the machining method of grinding and drilling the transmission shaft by operating equipment manually in the past is replaced, not only is the machining efficiency of the transmission shaft improved, but also the machining consistency of the transmission shaft is guaranteed, the accuracy is ensured, meanwhile, rustproof paint is also sprayed on the surface of the transmission shaft,the corrosion protection effect of the transmission shaft is improved, and the service life of the transmission shaft is long.

Owner:杭州佰牛科技有限公司

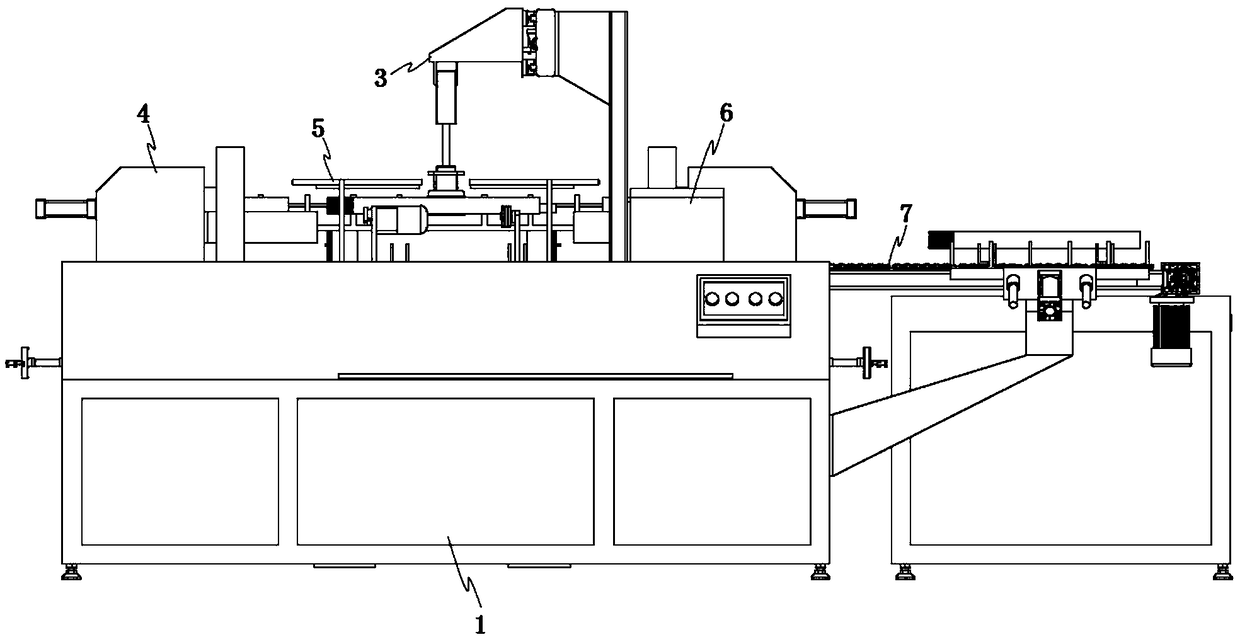

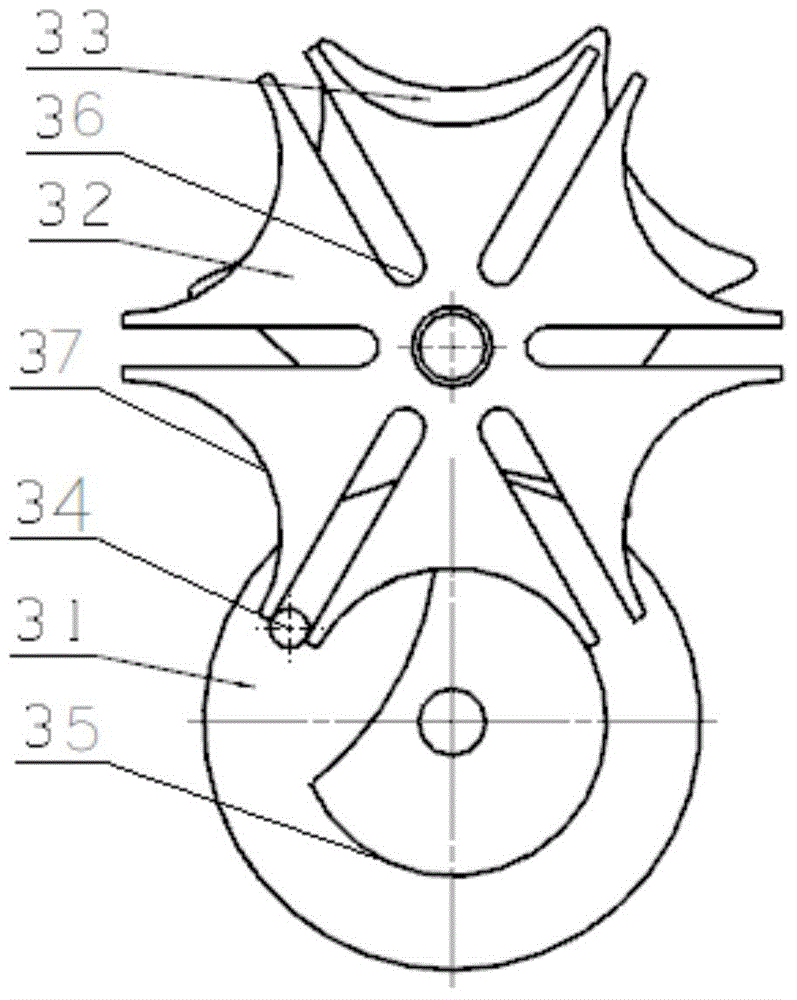

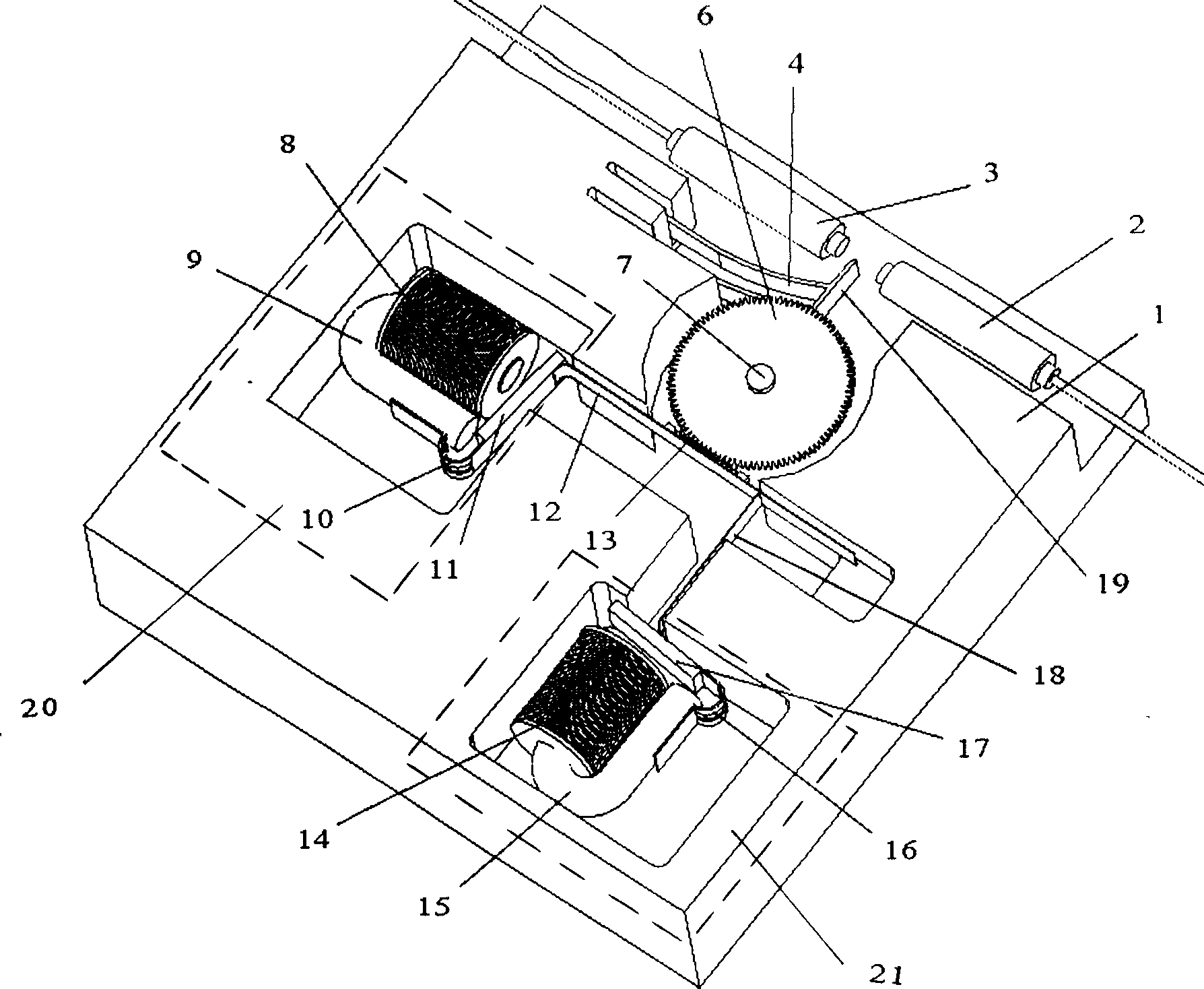

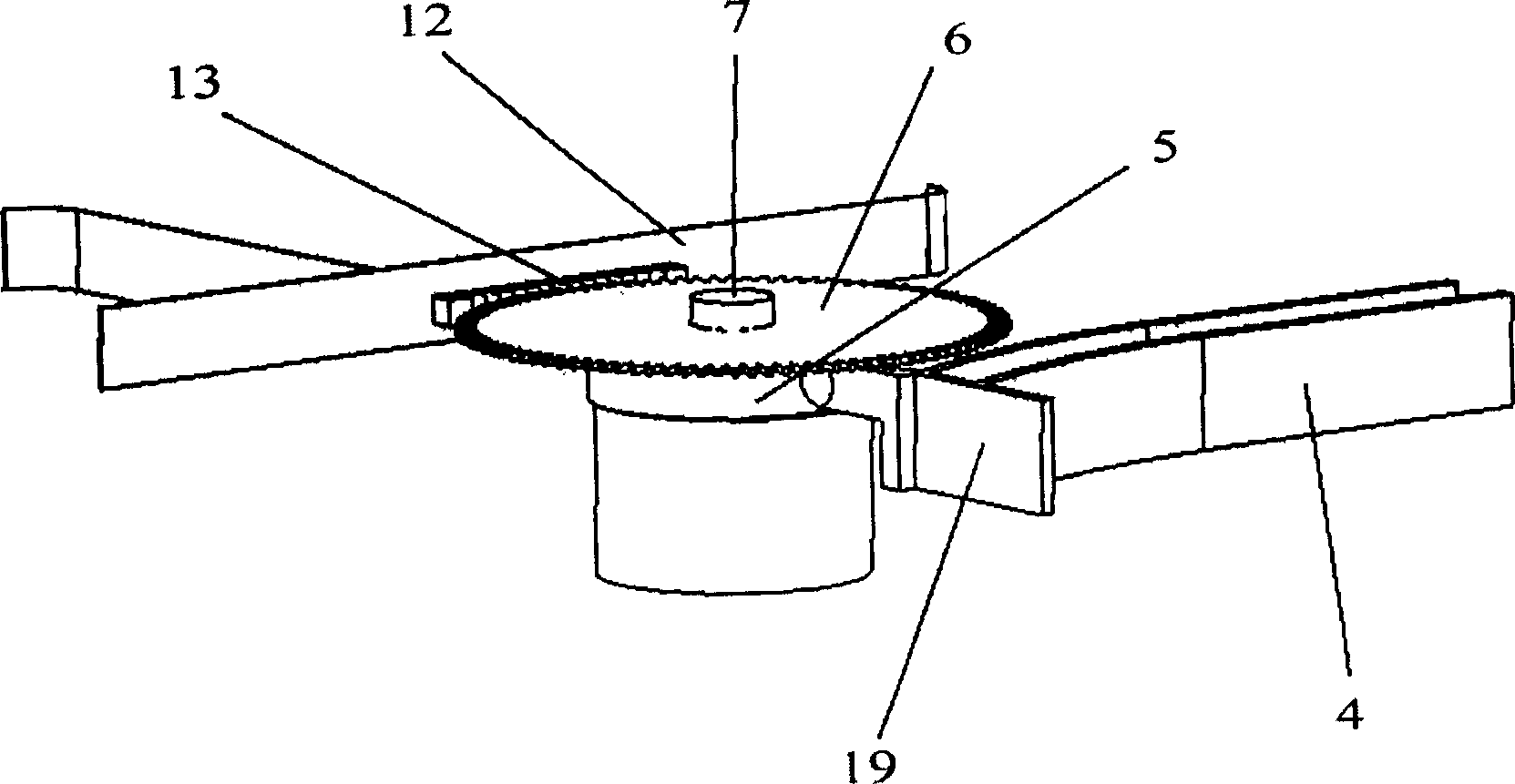

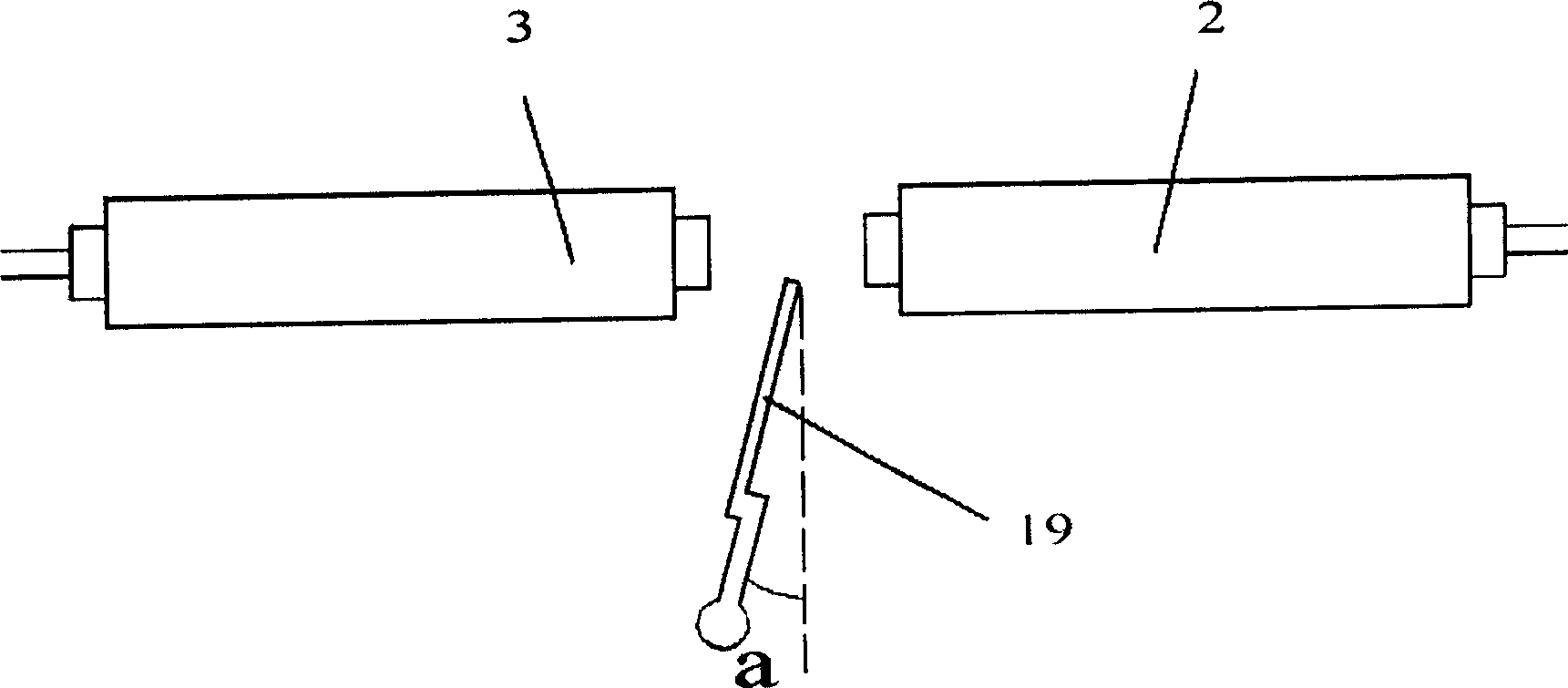

Automatic centering core-taking fresh lotus seed processing all-in-one machine

InactiveCN104824792ARealize integrated processingImprove integrityFruit stoningHuskingEngineeringAgricultural machinery

The invention belongs to the field of agricultural machinery, and relates to an automatic centering core-taking fresh lotus seed processing all-in-one machine which comprises a conveying mechanism, a shell removing mechanism, a centering core-taking mechanism and a membrane removing mechanism. The centering core-taking mechanism is a six-blade rotating shaft automatic centering core-taking mechanism which comprises an oblique sliding box, a geneva wheel device arranged below the oblique sliding box, a second sliding block, a core-taking needle installed on the second sliding block and a transmission device connected with the second sliding block; the geneva wheel device comprises a driving plate, a driven geneva wheel and a six-blade positioning wheel located on the same axis with the core-taking needle, the driving plate is provided with a round pin and an outward flange, the driven geneva wheel is provided with radial slots and inward flanges, when the round pin of the driving plate does not enter the radial slots of the driven geneva wheel, the corresponding inward flange of the driven geneva wheel is stuck by the outward flange of the driving plate, and therefore the driven geneva wheel is locked; when the round pin of the driving plate enters the radial slots of the driven geneva wheel, the corresponding inward flange of the driven geneva wheel is loosened from the outward flange of the driving plate, and therefore the driven geneva wheel is unlocked.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Production equipment of waterproof corrugated board

The invention discloses production equipment of a waterproof corrugated board. The production equipment comprises a machining tool, wherein a transmission mechanism is arranged in the middle of a surface of the machining tool, and a gluing mechanism, a glue flattening mechanism, a board suction positioning mechanism and a pressing and shearing mechanism are sequentially arranged on one side of themachining tool from left to right. According to the production equipment, a PVC plastic film is unfolded through the transmission mechanism and is transmitted to the position below the gluing mechanism, then gluing is realized through the forward and backward movement of the gluing mechanism; after gluing, when the plastic film is moved to the position below the glue flattening mechanism, glue iscoated through the glue flattening mechanism, when the coated plastic film is moved to the position below the board suction positioning mechanism, the corrugated board is adsorbed by the board suction positioning mechanism and is placed on a gluing surface of the plastic film, then the glued corrugated board is pressed through the pressing and shearing mechanism, and then the plastic film is sheared, therefore, an integrated generation process is realized, the technological process is simple, and the production efficiency is improved.

Owner:浙江盈翔包装有限公司

Adjustable digital electromagnetic driven light-barrier attenuator

InactiveCN1472584ANon-linear relationship correctionRealize digital controlWavelength-division multiplex systemsElectromagnetic transmissionEngineeringOptical attenuator

A attenuator comprises two input / output optical fibre collimators aligned through couple light path to be set on base with light blocking sheet between as its tail end contacted with ecentric in point-contact, light blocking sheet rotated at its level in coaxial with rotary shaft, rack bar engaged with gear to be set on leteral elastic sheet which is connected with longitudinal elastic sheet, the two connected to displacement driver separately. In the present invention, the gear and rack bar engaging mechanism is driven by the displacement driver to bring the ecentric so the light attenuation volume can be adjusted by moving the light blocking sheet.

Owner:ZHEJIANG UNIV

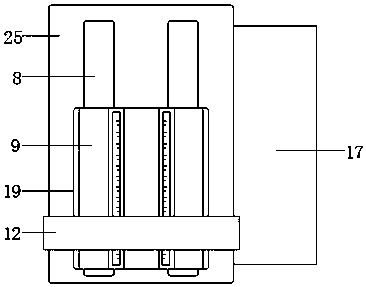

Integrated intelligent processing device

InactiveCN108580096AScientific and reasonable structureEasy to useSpraying apparatusMotor driveEngineering

The invention discloses an integrated intelligent processing device which comprises a working table. Four support legs distributed in a rectangular shape are fixedly connected under the working table;a support seat is fixedly connected to the middle of the upper surface of the working table; a spray paint cleaning tank is fixedly connected above the support seat; an infusion hose is arranged in the middle of the working table in a penetrating way; a conveying pump is connected to the bottom end of the infusion hose in a cut-through way; a paint bucket is arranged under the conveying pump; a liquid inlet pipe is arranged on the outer surface of the paint bucket in a penetrating way; and a filter box is fixedly connected to the top end of the liquid inlet pipe. The integrated intelligent processing device provided by the invention is scientific and reasonable in structure, safe and convenient to use, and capable of cleaning the outer surface of a steel pipe and spraying paint on the outer surface of the cleaned steel pipe at the same time so as to realize integrated processing. A rotary motor drives the steel pipe to rotate, so that the processing efficiency can be improved, the labor intensity is reduced, and integrated processing is realized.

Owner:叶秋云

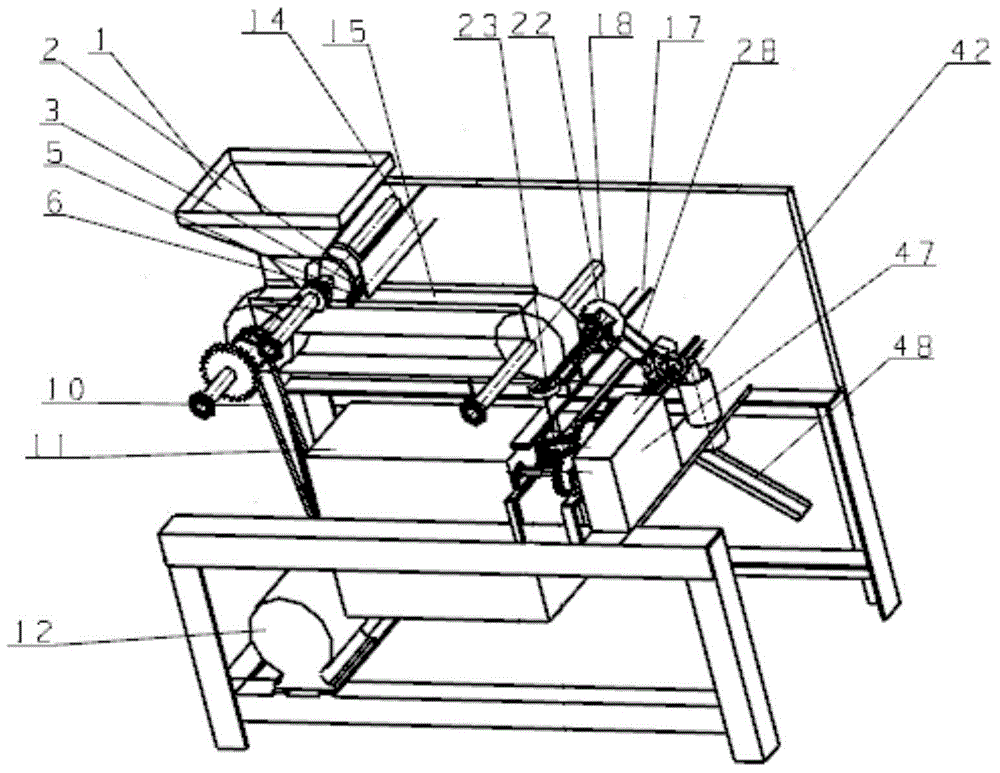

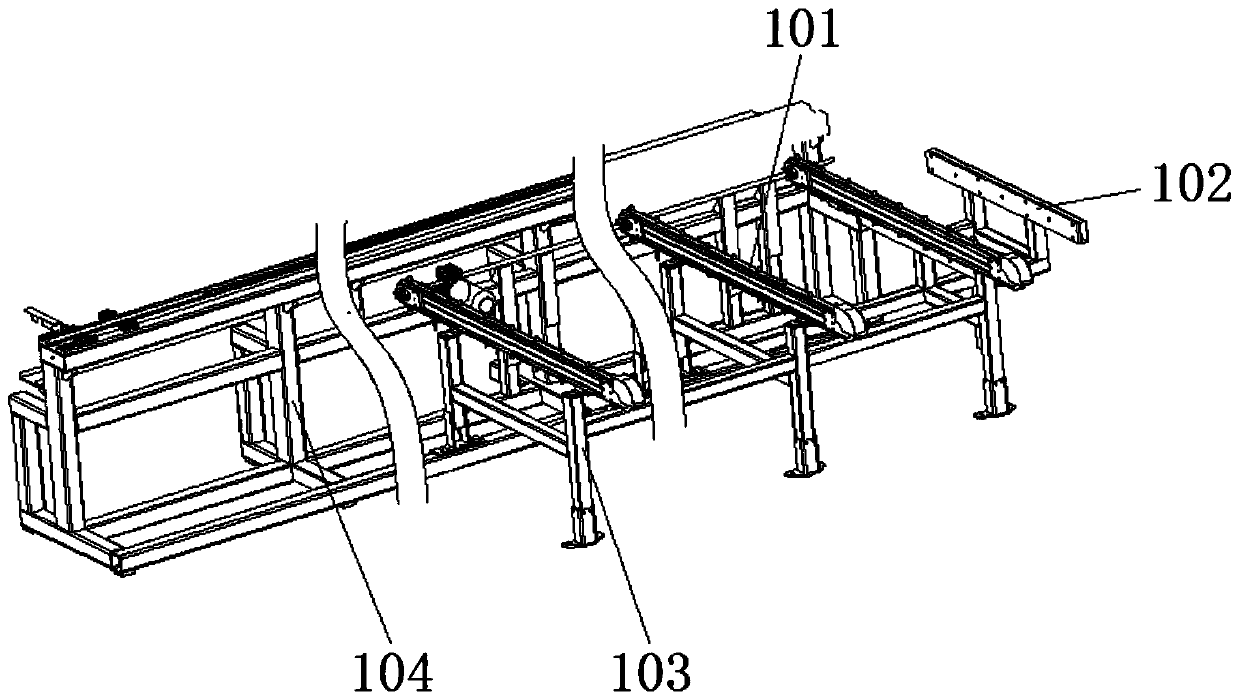

Automatic sawing and end milling equipment

PendingCN111015225ARealize automatic feedingRealize dischargeOther manufacturing equipments/toolsStructural engineeringMechanical engineering

The invention relates to the technical field of hydraulic die equipment, and discloses automatic sawing and end milling equipment. The automatic sawing and end milling equipment comprises a feeding area, a processing area and a discharging area, wherein the feeding area comprises a feeding table, profile clamping devices, a feeding manipulator and a positioning device, the feeding table comprisessynchronous belt turntables A, a profile baffle, a feeding base and a feeding frame, the feeding base is formed by assembling aluminum profiles and connecting parts, the side of the feeding base is welded to the profile baffle, and the other side of the feeding base is fixedly welded to the feeding frame through anchors A1. According to the automatic sawing and end milling equipment, the feeding area and the discharging area are arranged, a plurality of raw materials are simultaneously loaded through the feeding table in the feeding area, and the raw materials are fixed through clamping rollers, material supporting rollers and adjusting rollers, and a conveying mechanism, a material pulling mechanism and a discharging table are arranged in the discharging area to take out the processed profiles, so that automatic feeding and discharging are achieved, and the machining efficiency is improved.

Owner:济南凯之岳机器有限公司

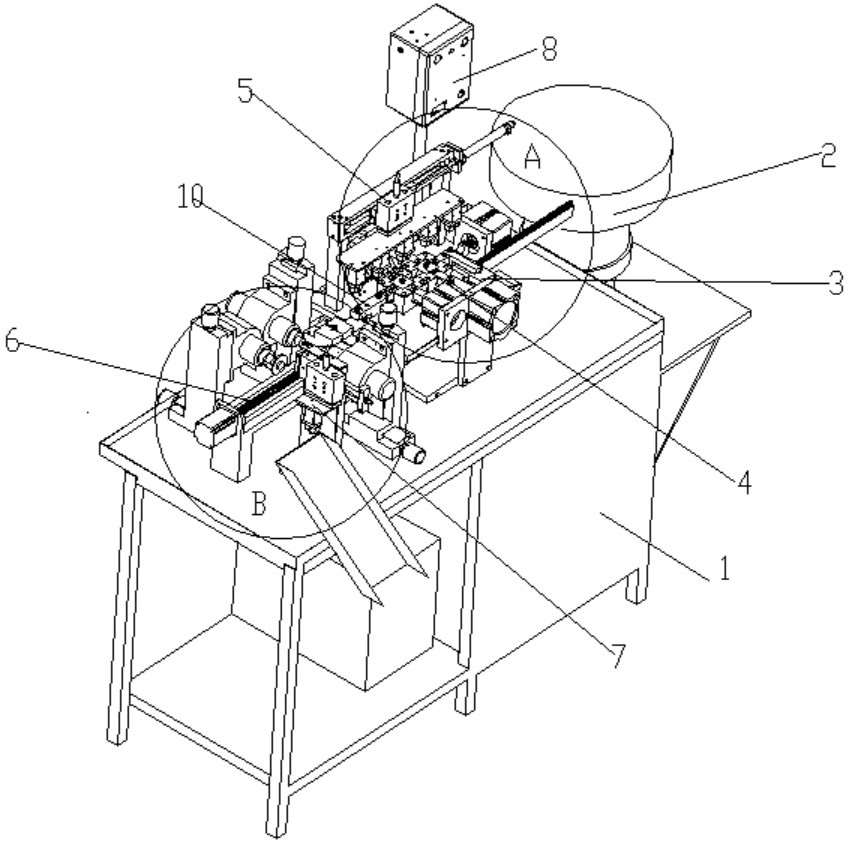

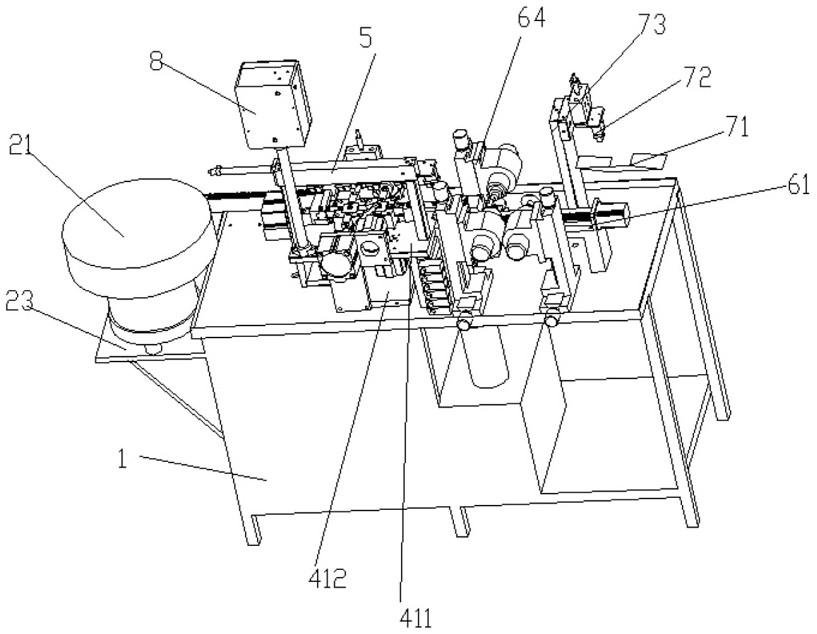

Punching and milling all-in-one machine

PendingCN114210852AIncrease flexibilityRealize processingPerforating toolsMetal-working feeding devicesPunchingMachine

The invention discloses a punching and milling machining all-in-one machine which comprises a machine cabinet, a vibration feeding mechanism, a movable material receiving mechanism, a multi-directional punching mechanism, a movable material clamping mechanism, a multi-station milling mechanism, a discharging mechanism and an electric control box, and the vibration feeding mechanism, the movable material receiving mechanism, the multi-directional punching mechanism, the movable material clamping mechanism, the multi-station milling mechanism, the discharging mechanism and the electric control box are installed on the machine cabinet. A to-be-machined accessory is conveyed to the movable material receiving mechanism through the feeding channel, the movable material receiving mechanism conveys the to-be-machined accessory to the clamping and feeding position, the movable material clamping mechanism clamps and conveys the to-be-machined accessory to the multi-directional punching mechanism for punching machining, and then the movable material clamping mechanism conveys the punched accessory to the multi-station milling mechanism. And the machined accessories are subjected to automatic discharging operation through the discharging mechanism. Punching and groove milling synchronous machining of accessories is achieved, the machining efficiency is improved, and the machining cost is reduced.

Owner:深圳市正良制品有限公司

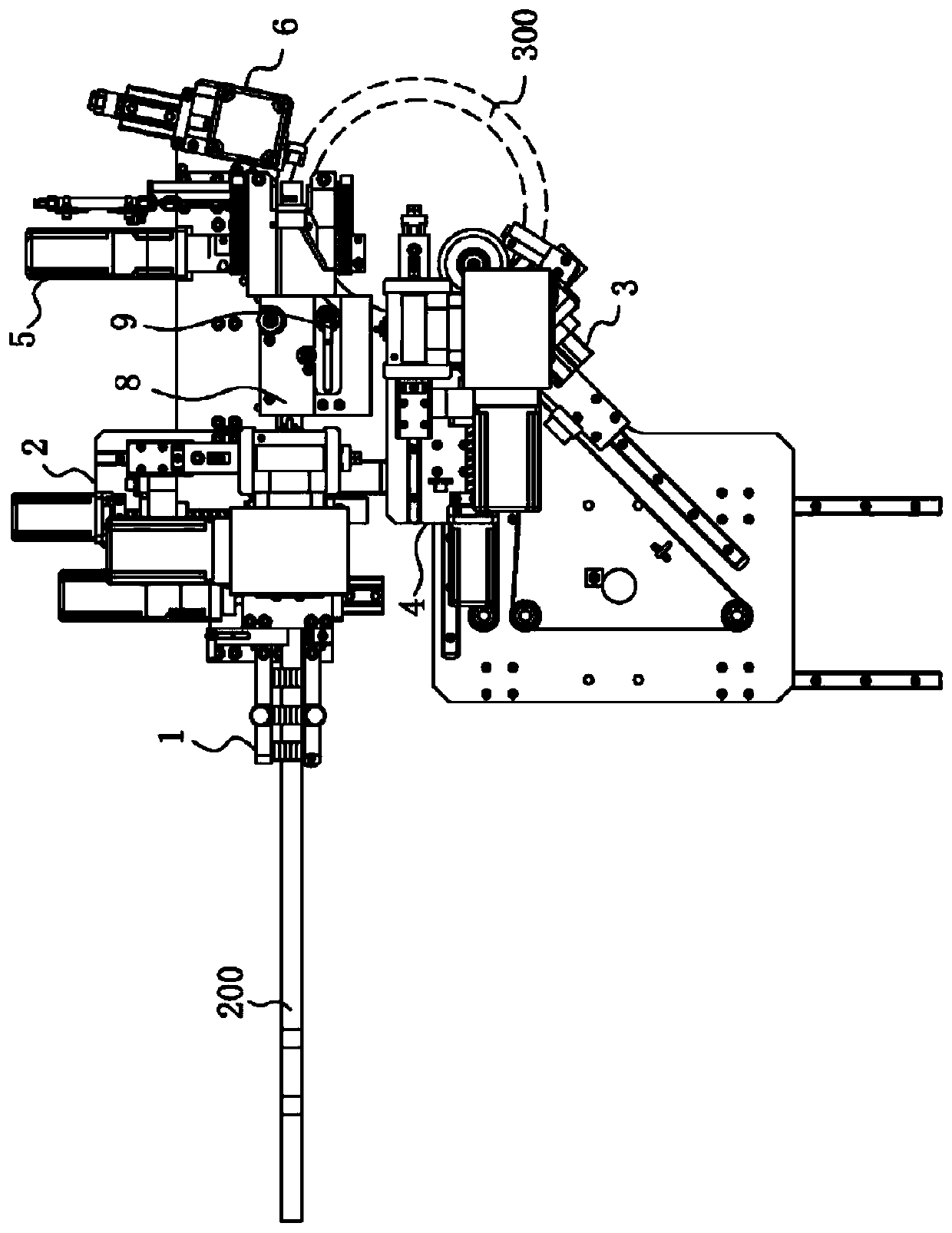

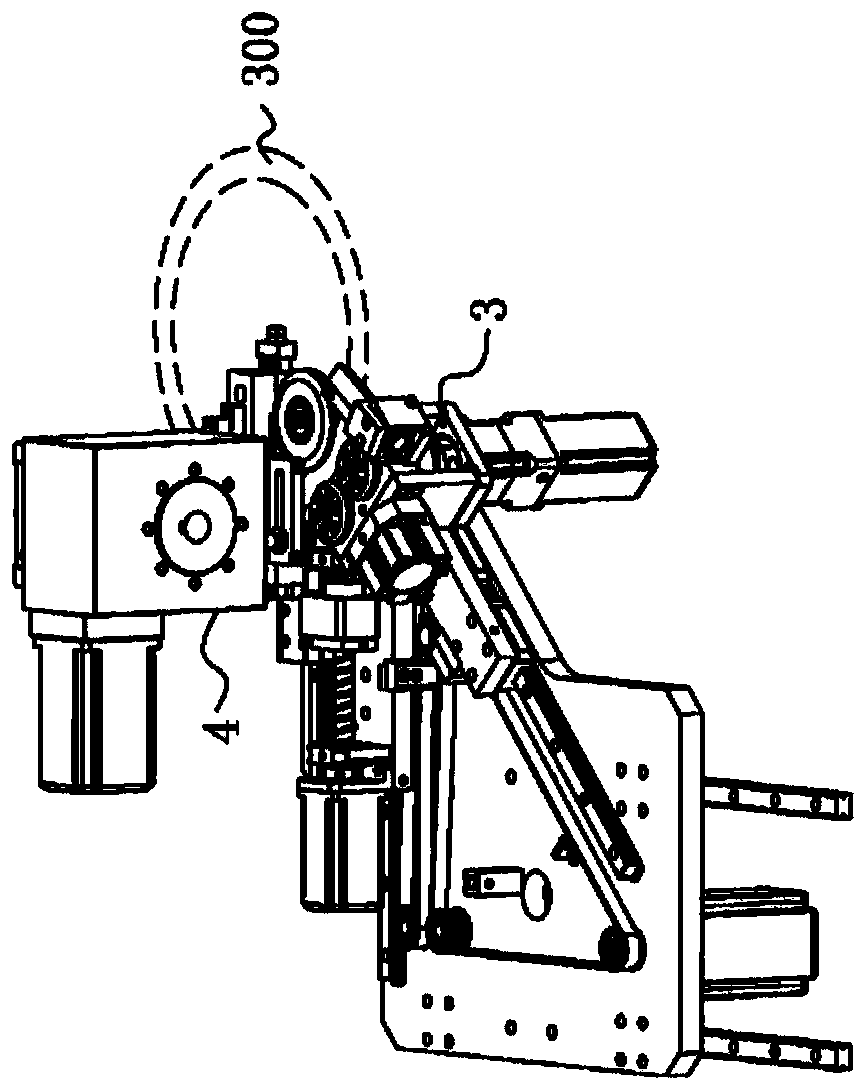

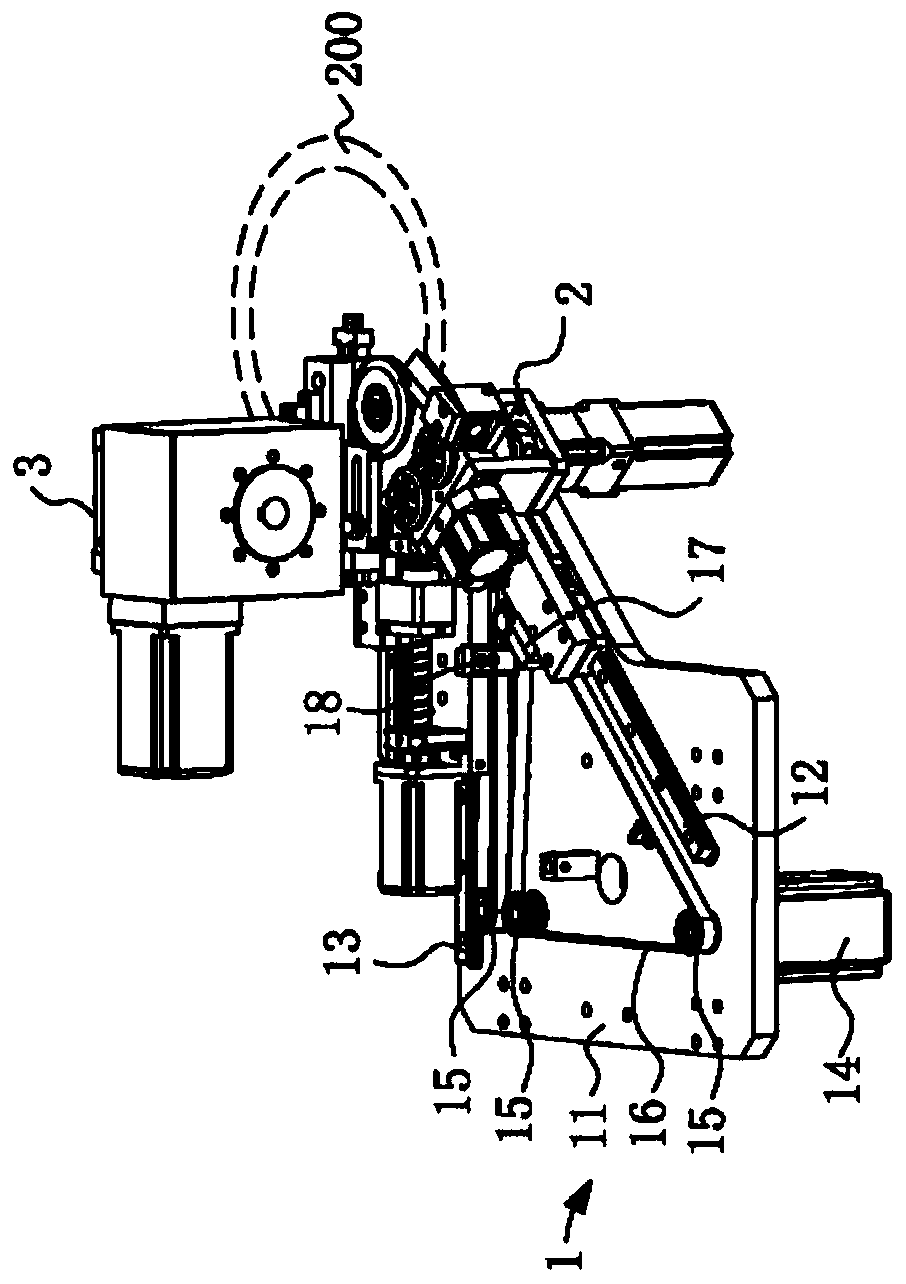

Cutter bending machine of roller cutter die

ActiveCN109926480ARealize integrated processingEasy to processMetal-working feeding devicesPositioning devicesPunchingMachining

The invention provides a cutter bending machine of a roller cutter die. The cutter bending machine is suitable for integral machining of a straight blade and an arc blade and comprises a straight blade front end machining structure, an arc blade front end machining structure and a rear end machining structure. The straight blade front end machining structure comprises a straight blade feeding device and a straight blade punching device so as to feed and punch the straight blade. The arc blade front end machining structure comprises an arc blade feeding device and an arc blade punching device so as to feed and punch the arc blade. The discharging end of the straight blade front end machining structure and the discharging end of the arc blade front end machining structure are connected withthe feeding end of the rear end machining structure. The rear end machining structure comprises a bending device and a shearing device, and then the punched straight blade and arc blade can share thebending device and the shearing device. Under the condition without adjusting, the straight blade or the arc blade is selectively machined. The cutter bending machine of the roller cutter die achievesintegral machining of the straight blade and the arc blade, and the effects of convenient machining and high efficiency are brought.

Owner:深圳市骏昊自动化科技有限公司

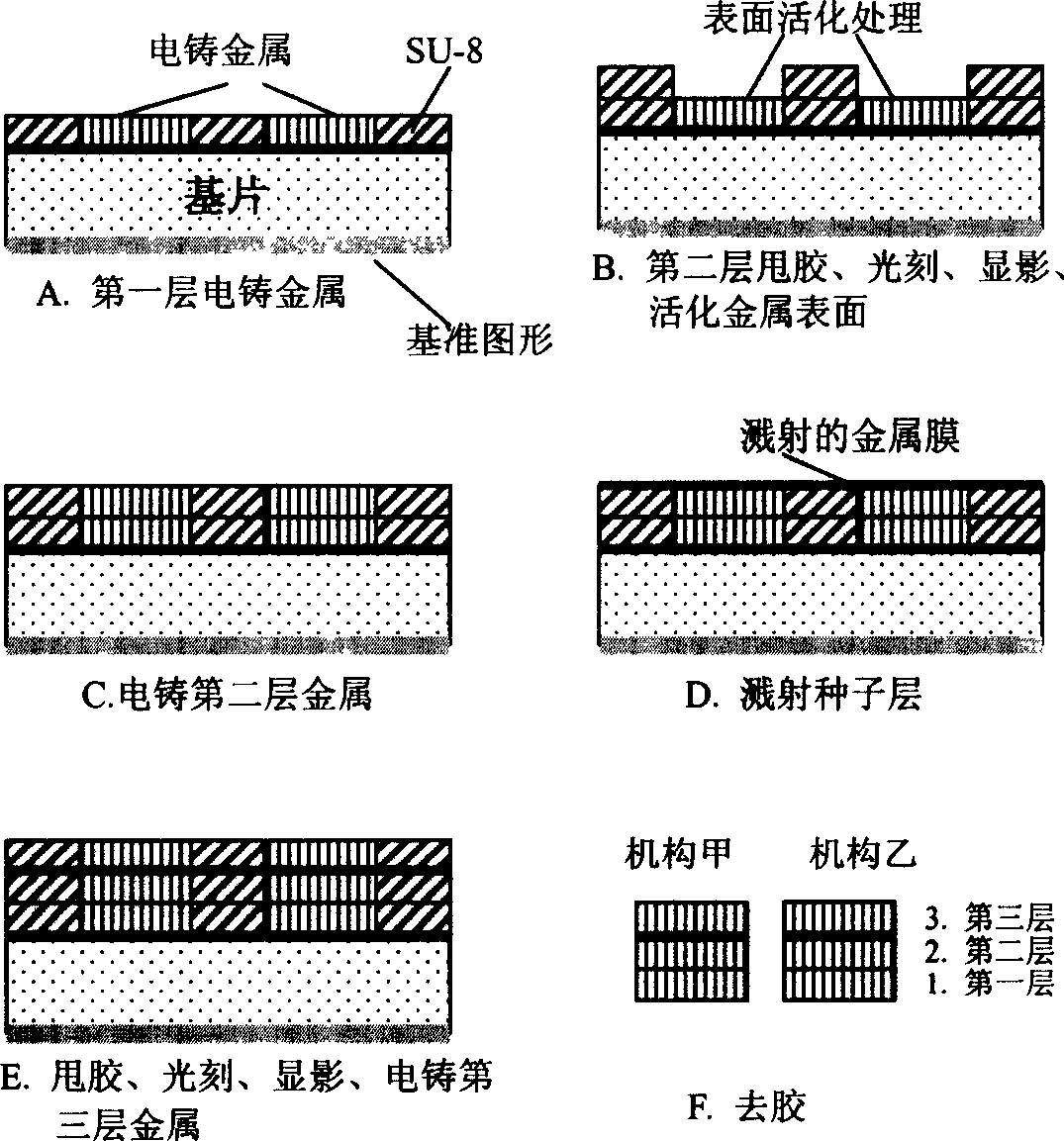

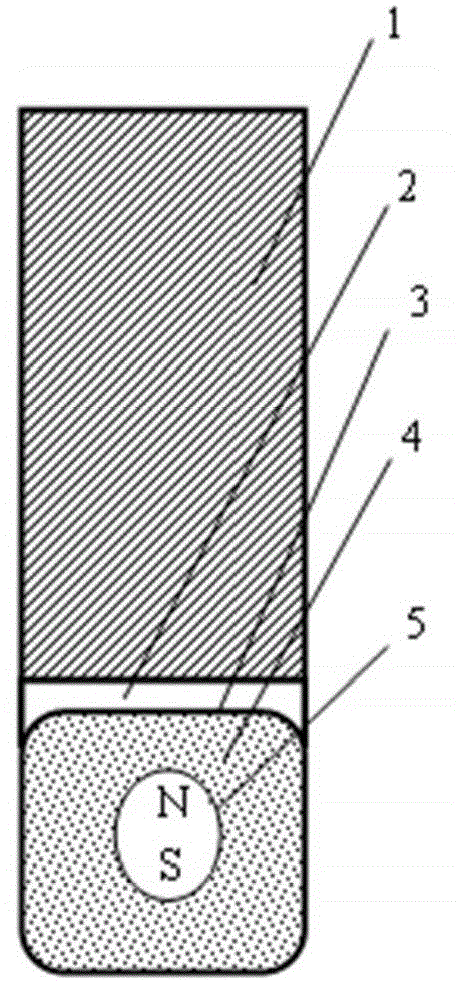

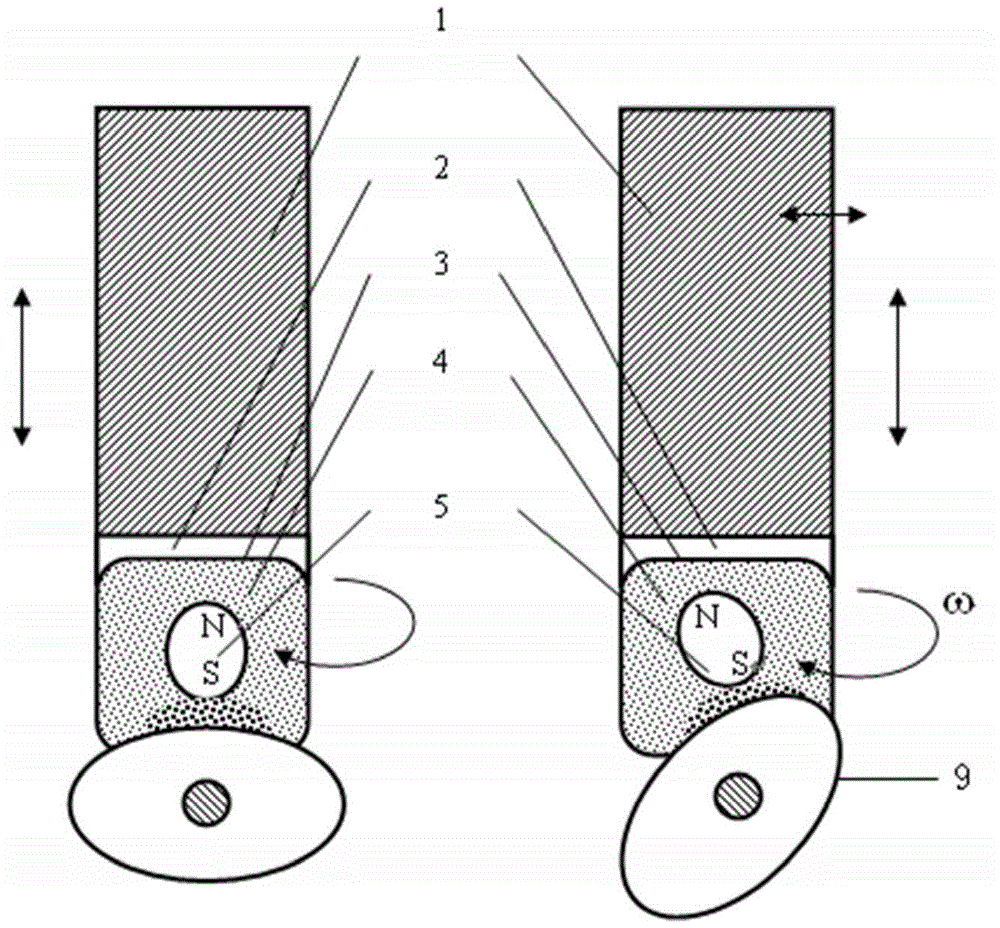

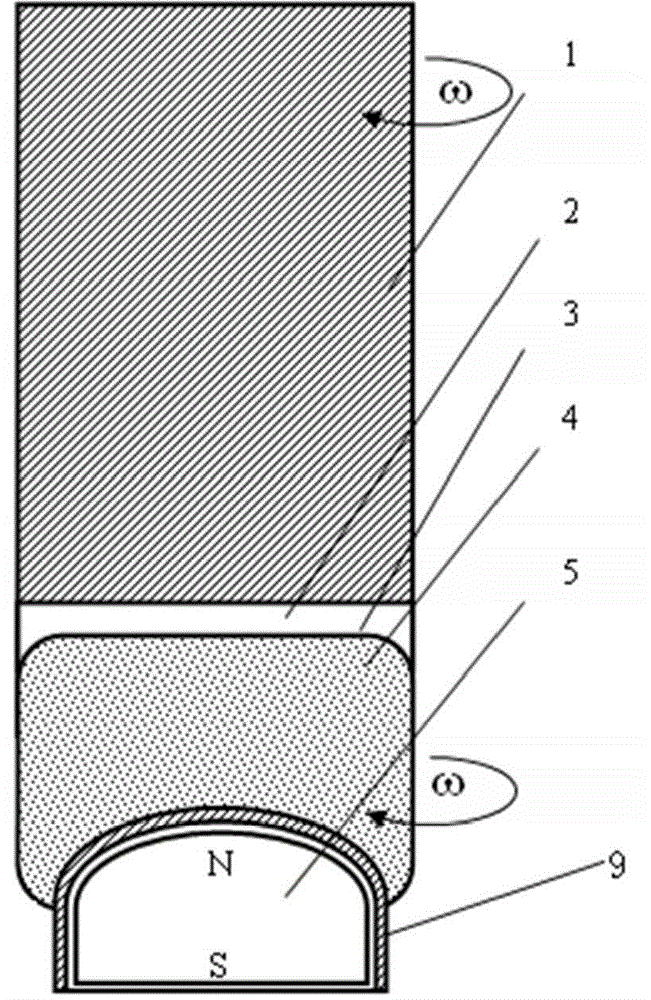

Controllable deformable soft cutter

ActiveCN103600276ARealize integrated processingImprove grinding performanceOptical surface grinding machinesGrinding headsEngineeringContact friction

The invention discloses a controllable deformable soft cutter which comprises a cutter handle, a function accessory and a deformable cutter bit. The deformable cutter bit is connected with the cutter handle through the function accessory. The deformable cutter bit comprises a sealing deformable soft casing, a deformable medium filled in the sealing deformable soft casing and a deformable medium excitatory mechanism acting with the deformable medium in a mutual mode to enable the sealing deformable soft casing to generate machining force. The sealing deformable soft casing is in contact with a workpiece, the controllable deformable soft cutter can move along with a machine tool, namely translation and rotation with strokes relative to the workpiece, contact friction movement matched with a face type is conducted on a workpiece with a complex face type, and efficient and smooth machining on the surface of the complex workpiece is achieved.

Owner:杨斌堂

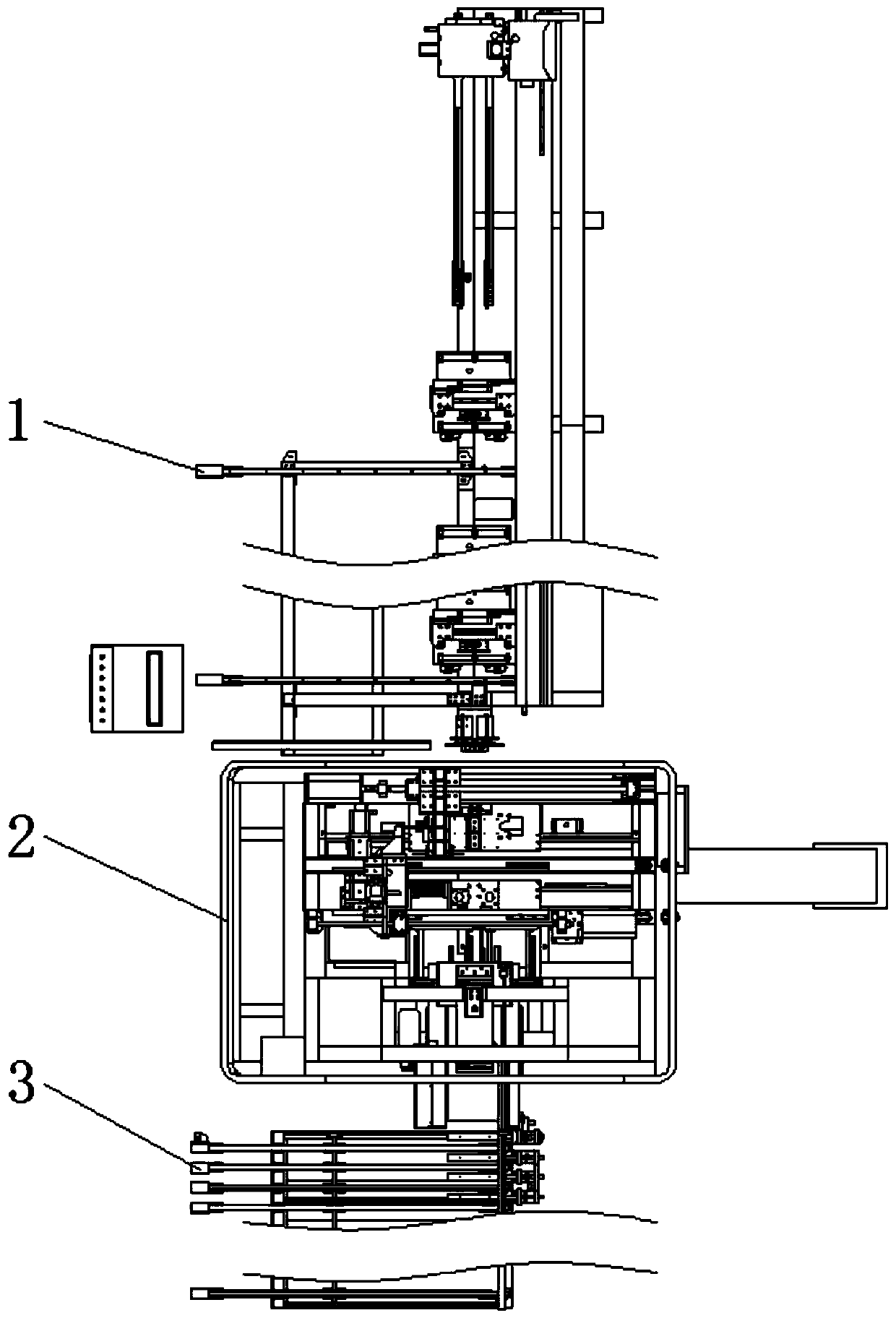

Drilling and copper deposition all-in-one equipment for processing via holes of circuit boards

ActiveCN111299867ARealize integrated processingAchieve clamping positioningPrinted circuit manufactureWelding/soldering/cutting articlesTransfer mechanismProcess engineering

The invention relates to the field of processing for circuit boards, in particular to drilling and copper deposition all-in-one equipment for processing via holes of circuit boards. The equipment comprises a feeding and discharging mechanism, a drilling mechanism, a transfer mechanism and a copper deposition mechanism. An output end of the feeding and discharging mechanism is connected with an input end of the drilling mechanism, an output end of the drilling mechanism is connected with an input end of the transfer mechanism, and an output end of the transfer mechanism is connected with an input end of the copper deposition mechanism. According to the drilling and copper deposition all-in-one equipment, the multiple circuit boards which are laminated in sequence are quickly and effectivelyfed and discharged through the feeding and discharging mechanism, and the equipment can be matched with the circuit boards different in size through the drilling mechanism so as to complete clampingpositioning and continuous drilling operation on the circuit boards. The circuit boards after being drilled are conveyed to the transfer mechanism, the transfer mechanism transfers the circuit boardsto the copper deposition mechanism to perform chemical copper deposition, and integrated processing of drilling and copper deposition for the via holes of the circuit boards is achieved.

Owner:赣州中盛隆电子有限公司

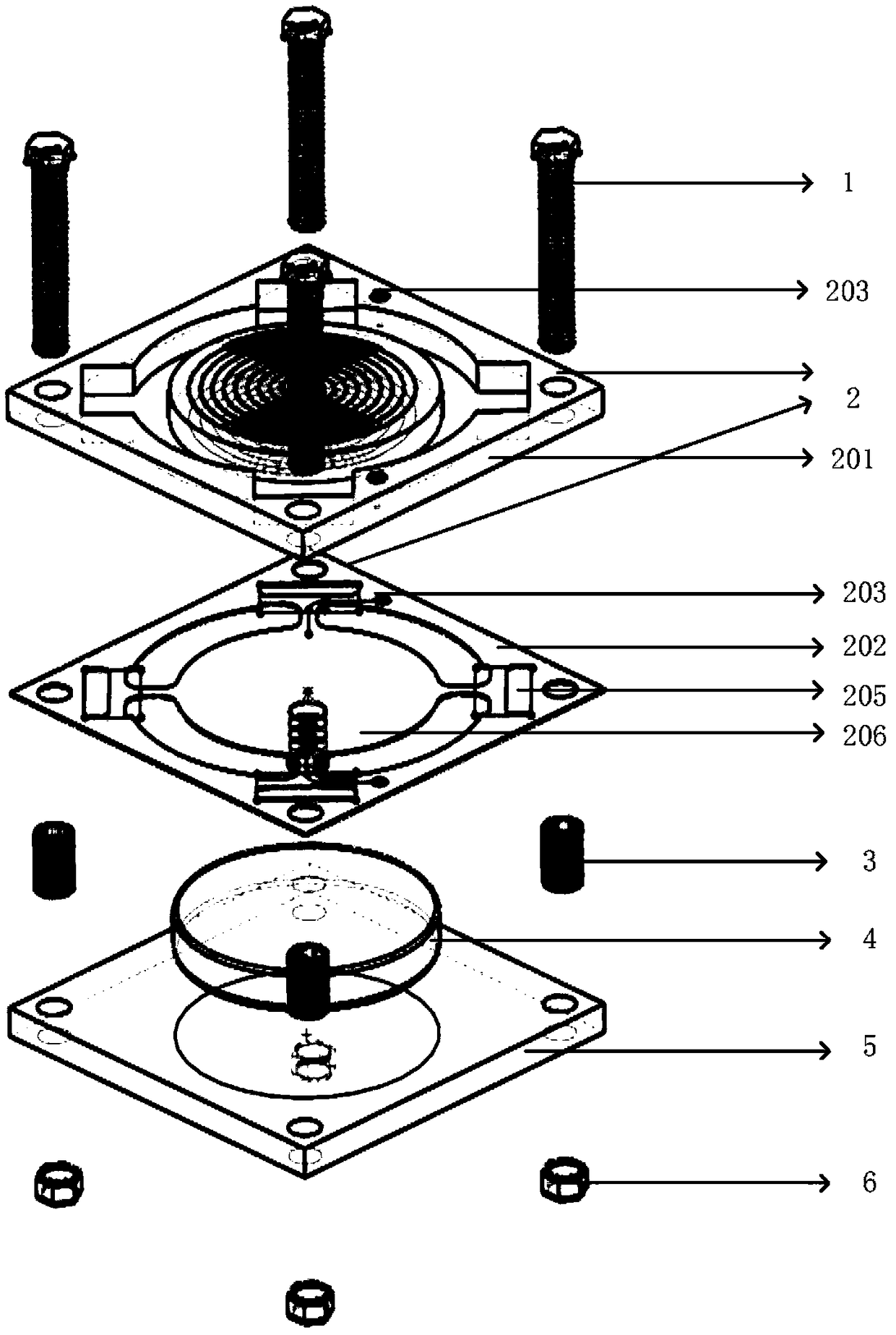

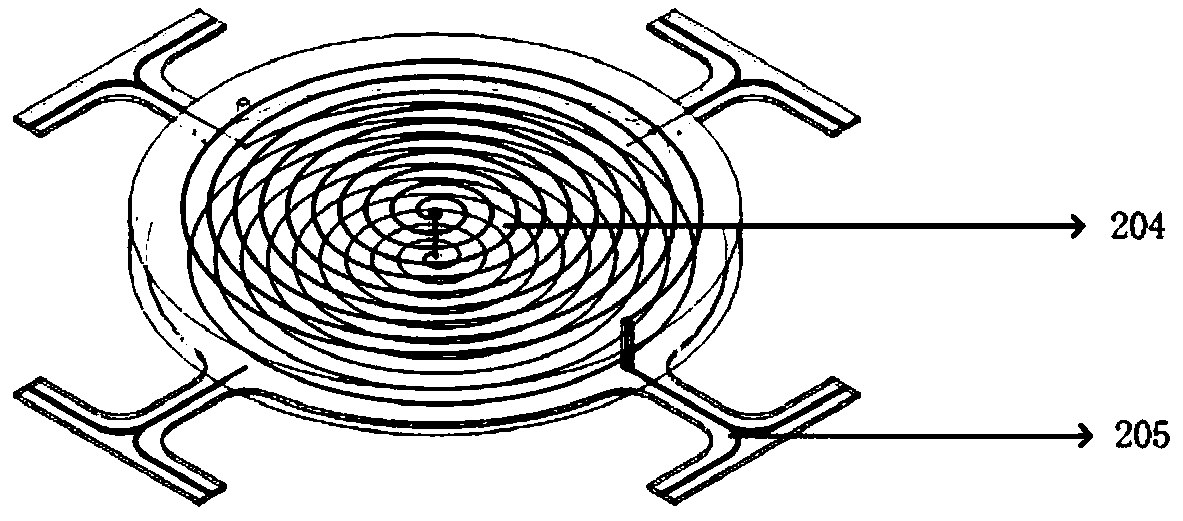

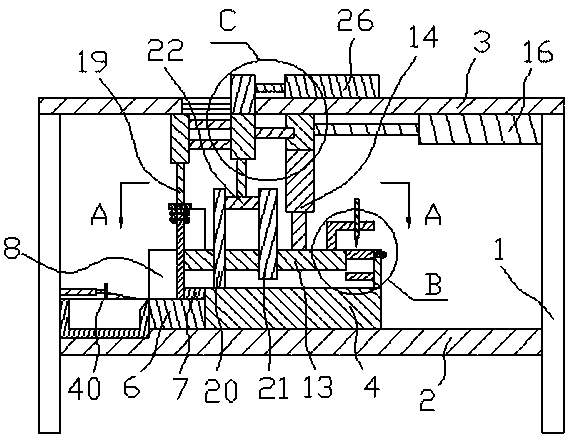

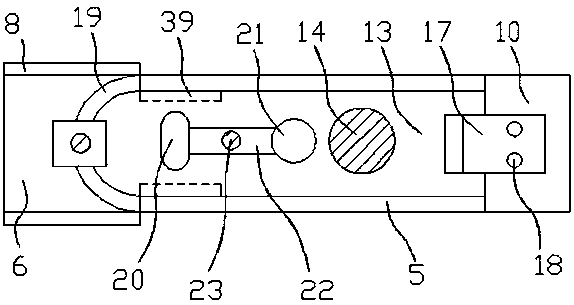

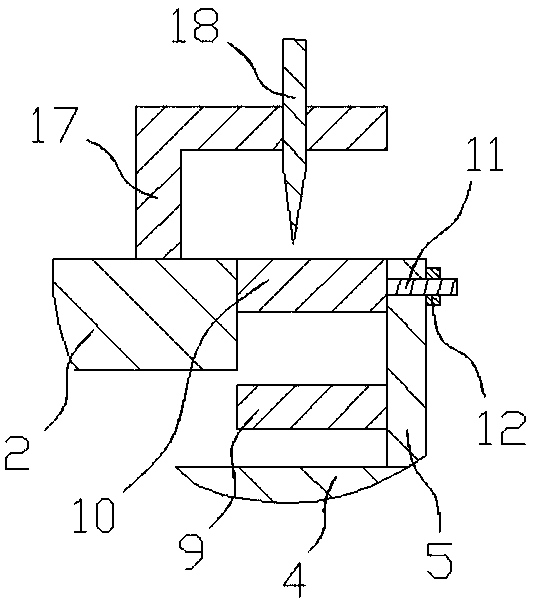

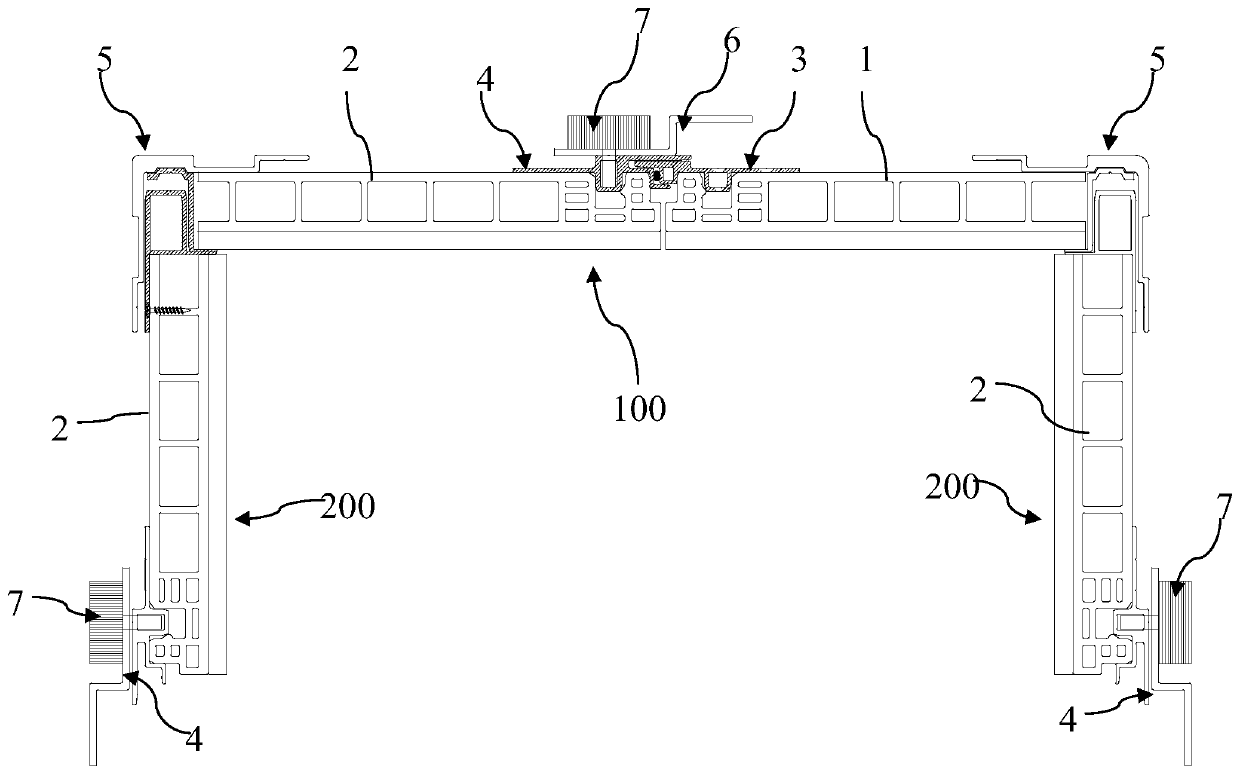

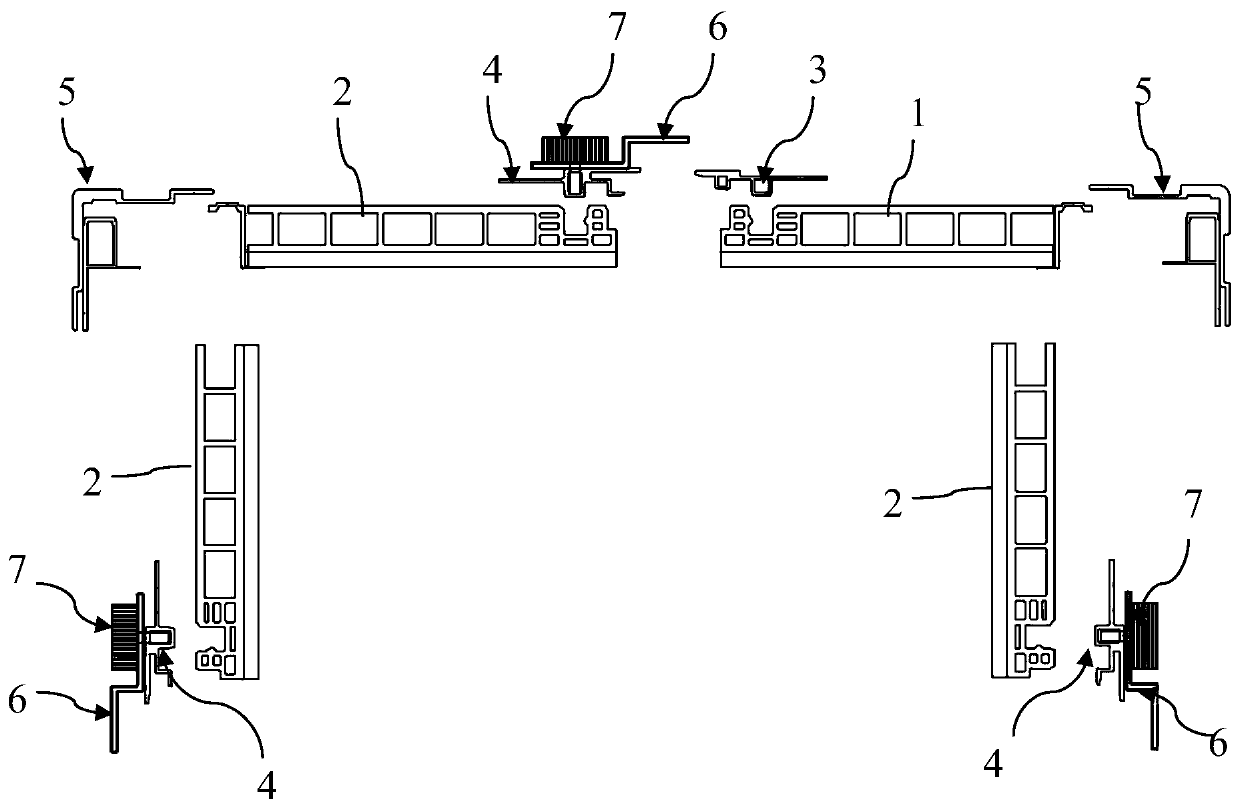

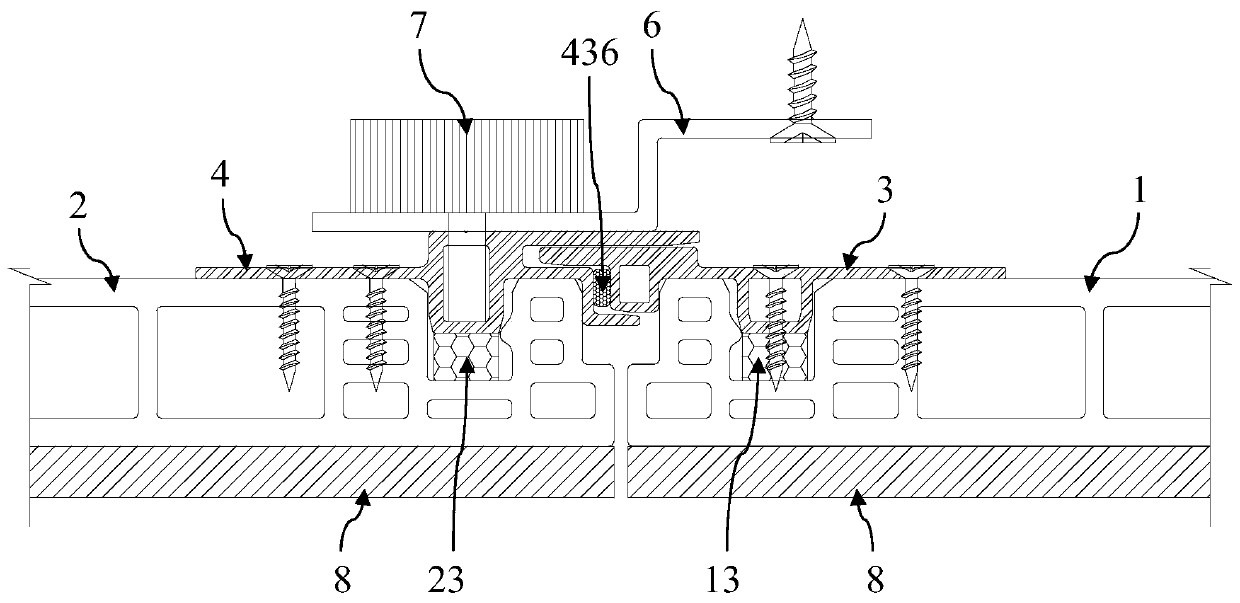

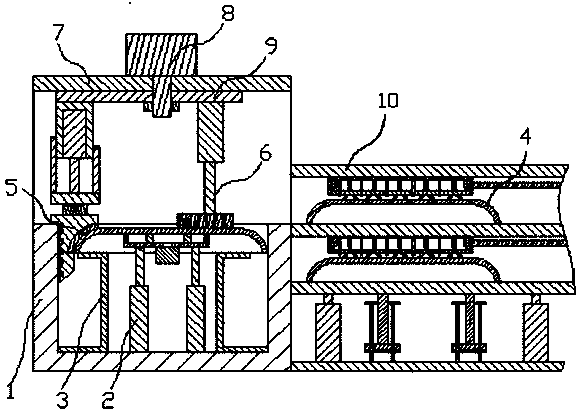

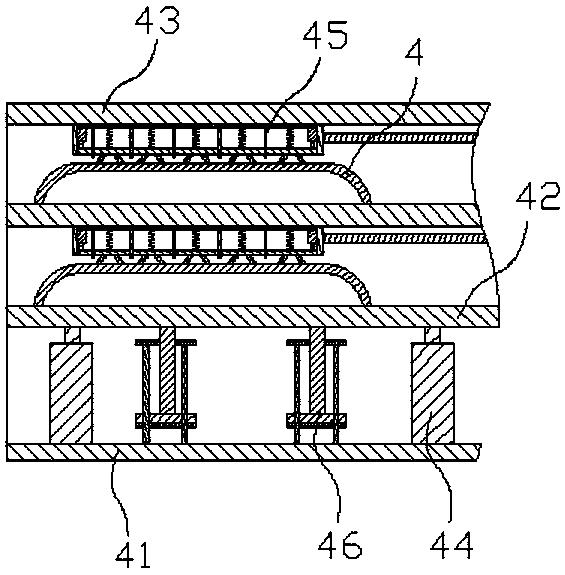

Electromagnetic T-shaped beam vibration energy harvester on basis of rigid and flexible combined structure

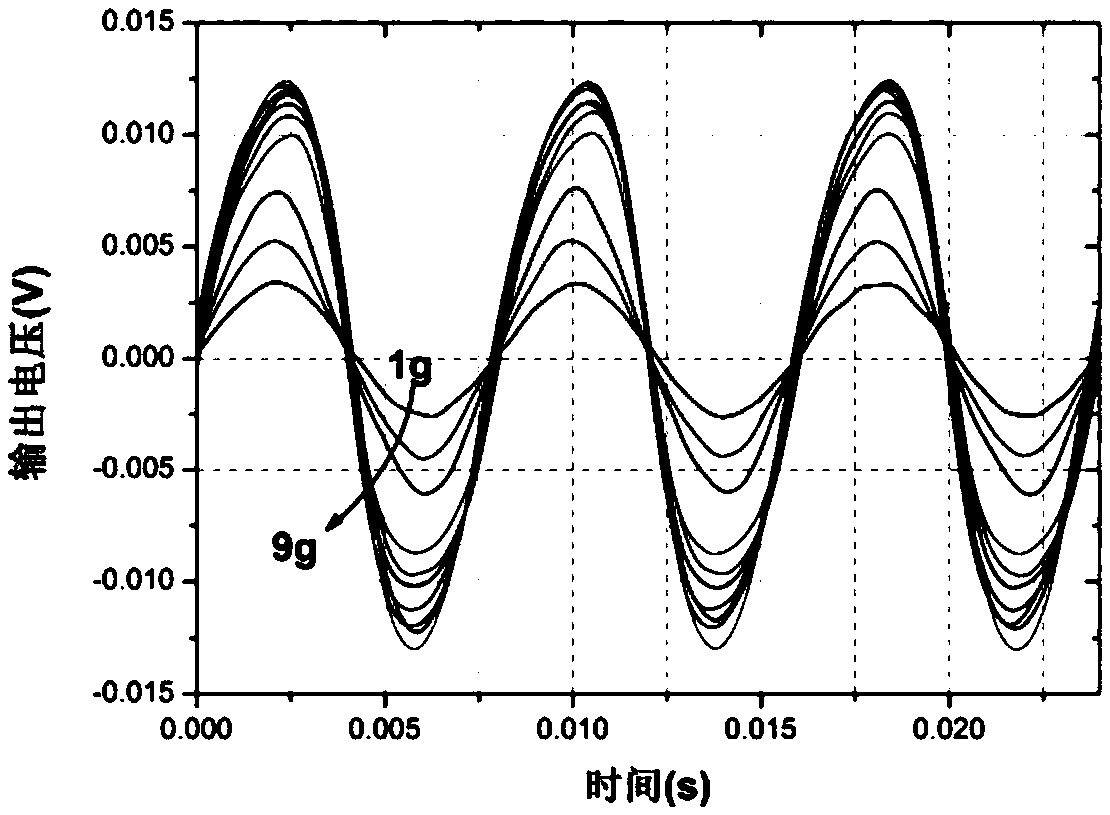

ActiveCN108809039AExtended Beam Effective LengthRealize wireless power supplyDynamo-electric machinesEnergy harvesterEffective length

The invention discloses an electromagnetic T-shaped beam vibration energy harvester on the basis of a rigid and flexible combined structure. The electromagnetic T-shaped beam vibration energy harvester comprises a rigid support plate (5), a magnet (4) and a rigid and flexible combined plate (2). The rigid support plate (5), the magnet (4) and the rigid and flexible combined plate (2) are sequentially arranged from bottom to top; the magnet (4) closely clings to the rigid support plate (5), and a plurality of copper cylinders (3) are uniformly arranged between the rigid support plate (5) and the rigid and flexible combined plate (2), so that gaps can be reserved between the magnet (4) and the rigid and flexible combined plate (2). The electromagnetic T-shaped beam vibration energy harvesterhas the advantages that the electromagnetic T-shaped beam vibration energy harvester is of a movable coil structure; a coil is positioned on a rigid plate portion of the rigid and flexible combined plate, a vibration pickup beam is in a polyimide T-shaped beam design, the effective length of the vibration pickup beam can be prolonged by the design, and the resonance frequencies of the electromagnetic T-shaped beam vibration energy harvester further can be lowered; printed circuit rigid and flexible combination technologies are introduced into the electromagnetic T-shaped beam vibration energyharvester for the first time as compared with other vibration energy harvesters, the electromagnetic T-shaped beam vibration energy harvester has low frequencies as compared with rigid beam harvesters, the requirements on energy harvesting at different mounting angles can be met by the T-shaped beam design, and accordingly the electromagnetic T-shaped beam vibration energy harvester is high in harvesting efficiency.

Owner:XI AN JIAOTONG UNIV

Die-casting machine for plug-and-socket fasteners

The invention relates to a die-casting machine for plug-and-socket fasteners. The die-casting machine comprises a machine frame; a lower working plate and an upper working plate are arranged on the machine frame; the lower working plate is provided with a lower module, and side plates are arranged on the front side, the rear side and the right side of the lower module; a clamping opening forming block and a clamping opening forming cover plate are arranged on the inner side of the right side plate of the lower module; a pressing block lifting cylinder is arranged below the upper working plate;the lower portion of the pressing block lifting cylinder is connected with an upper mold pressing block matched with the lower module; the left end of the upper mold pressing block is arc, and buckleplate forming openings are formed in the lower portions of the front side and the rear side of the left end; a socket opening forming column is arranged on the upper mold pressing plate and located between the two buckle plate forming openings in a penetrating and inserting fit mode; the upper end of the socket opening forming column is connected with a socket opening forming lifting block; the upper portion of the socket opening forming lifting block is connected with a socket opening forming lifting cylinder which is matched with a mold unloading movable device on the upper working plate; and the upper working plate is further provided with a side mold device in arc fit with the left end of the upper mold pressing block. By means of the die-casting machine, lateral mold-loading can be achieved, and the fastener machining efficiency is improved significantly.

Owner:DONGGUAN UNIV OF TECH

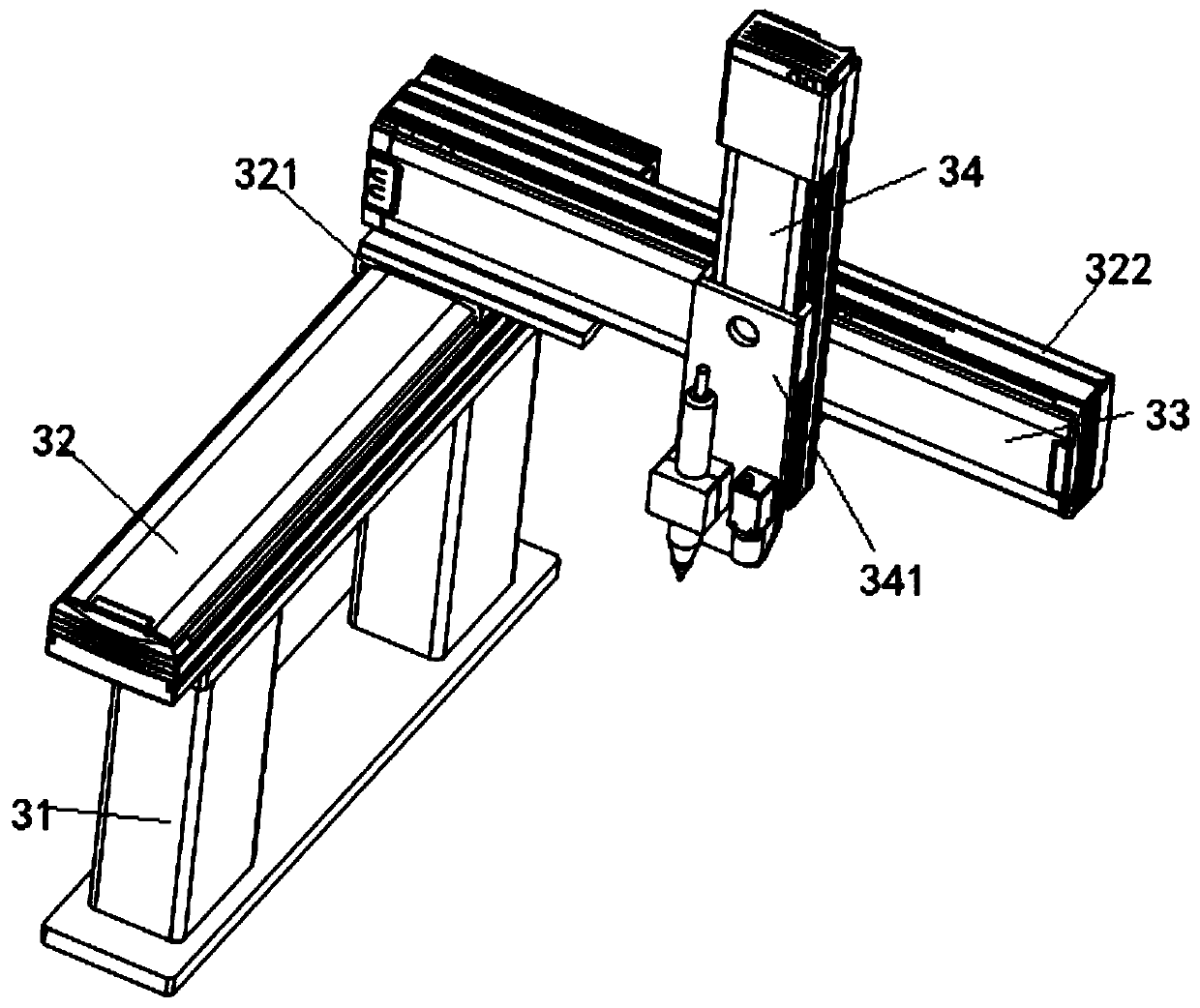

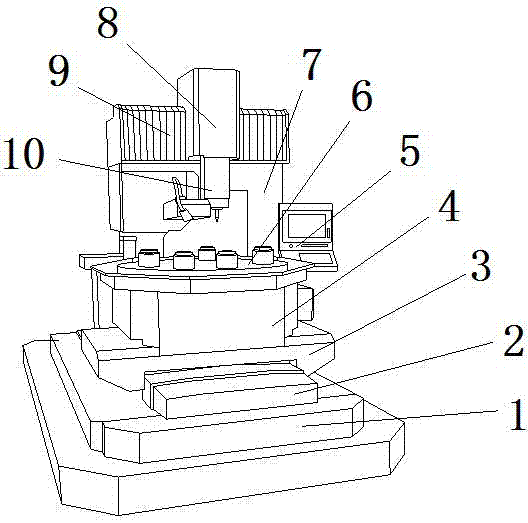

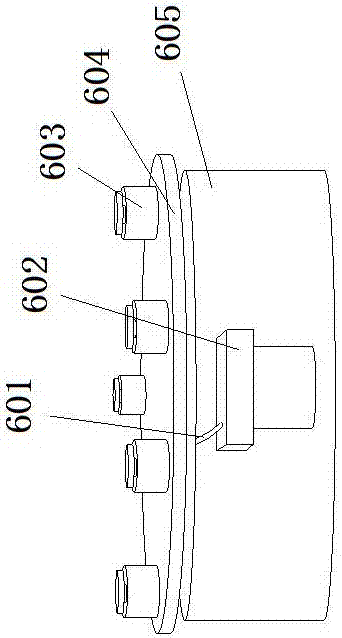

Gantry type dual-turntable CNC milling machine

InactiveCN107297530AExtended service lifeRealize integrated processingMilling machinesLarge fixed membersControl lineEngineering

The invention discloses a gantry-type double turntable numerical control milling machine, the structure of which comprises a machine base, an X-axis guide rail, a transmission plate, a protective plate, a controller, a double turntable device, a gantry frame, a main shaft protective cover, a Y-axis guide rail, a main shaft, a control Line, turntable controller, clamping turntable, direction changing turntable, main engine, the double turntable device is a hexagonal structure and has more than two protective plates on the side, the top and rear end of the double turntable device are connected with the bottom of the gantry frame, and the gantry is U-shaped structure with a controller installed on the right side and electrically connected. The beneficial effects of the present invention are: the double turntable device provided by the utility model can place multiple processed products at the same time through a plurality of clamping turntables, and then switch the clamping turntables through the control of the host computer to change the direction of the turntable, realizing the double turntable with multiple workpieces The integrated processing greatly improves work efficiency and avoids wasting time.

Owner:郑少华

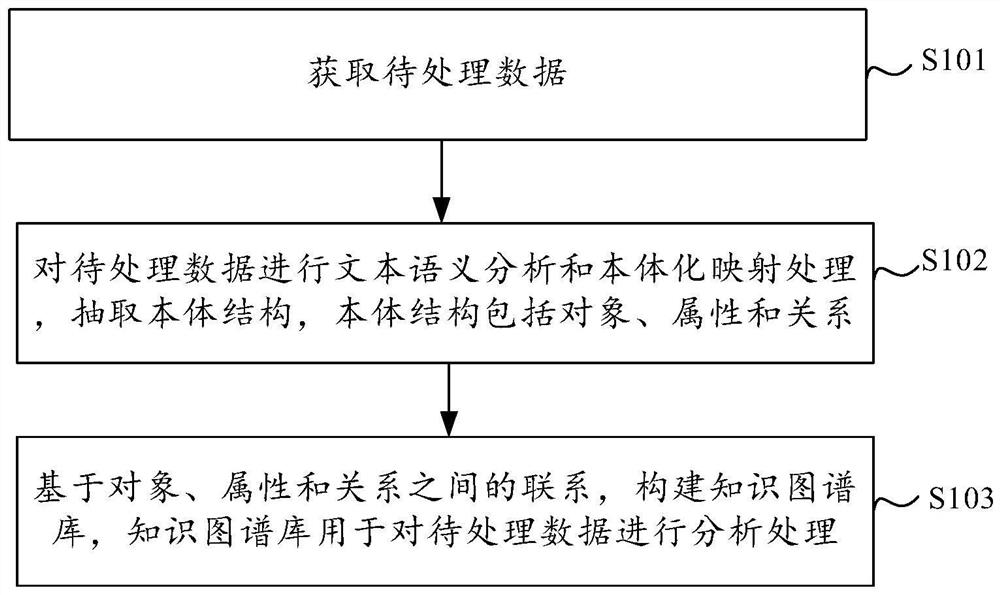

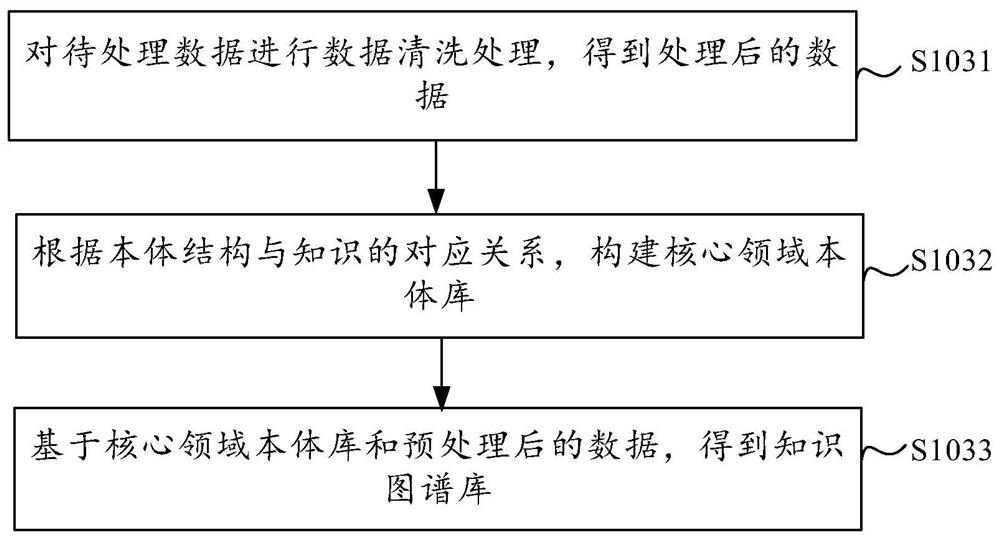

Semantic and knowledge graph analysis method, platform and device based on dynamic ontology

PendingCN113326381AFast Association MiningImprove use valueSemantic analysisText database queryingKnowledge modellingTheoretical computer science

The invention discloses a semantic and knowledge graph analysis method, platform and device based on a dynamic ontology. The method comprises the following steps of acquiring the to-be-processed data; performing text semantic analysis and ontology mapping processing on the to-be-processed data, and extracting an ontology structure which comprises an object, an attribute and a relationship; and on the basis of the relation among the object, the attribute and the relationship, constructing a knowledge graph library so as to analyze and process the to-be-processed data. According to the technical scheme, multiple technologies such as dynamic ontology knowledge modeling, a knowledge graph technology and a big data technology are fused, the integrated processing of multi-source heterogeneous data is achieved, the ontology structure can be automatically extracted through a text semantic analysis and ontology mapping processing method, then the knowledge graph library is constructed, the rapid association mining of massive multi-source heterogeneous data is realized, comprehensive analysis of the multi-source heterogeneous data can be realized, and the use value of the data is improved.

Owner:BEIJING TOPWALK INFORMATION TECH

Integrated wall surface device and assembling method thereof

PendingCN110805219AImprove construction efficiencyKeep cleanCovering/liningsWall plateIndustrial engineering

The invention discloses an integrated wall surface device and an assembling method thereof. The integrated wall surface device comprise a first wallboard and two second wallboards; the two second wallboards are connected to the two ends of the first wallboard through female corner connecting components correspondingly; the first wallboard comprises a first board body and a second board body; the end part, close to the second board body, of the first board body is provided with a flush joint sub part, and the end part, close to the first board body, of the second board body is provided with a flush joint main part; the flat joint sub part is connected with the flat joint main part in an inserted mode; one second wallboard is connected with the first board body through one internal corner connecting component, and the other second wallboard is connected with the second board body through one internal corner connecting component. The integrated wall surface device and the assembling method thereof realize the integrated treatment of wall boards, improve the construction efficiency, and are beneficial to keeping the sanitation of the construction site.

Owner:ZHEJIANG YASHA DECORATION

Almond and almond protein brittle vibration screening equipment

PendingCN113499823ARealize integrated processingIncrease productivitySievingScreeningElectric machineryAgricultural engineering

The invention discloses almond and almond protein brittle vibration screening equipment. The equipment comprises a transmission device, a screening barrel, a first collecting box, a second collecting box and a distillation barrel, the transmission device is composed of a transmission seat and a material guiding cover, the transmission seat and the material guiding cover are of an integrated structure, a transmission opening is formed in the transmission seat, a transmission belt is arranged in the transmission opening, a first grinding roller and a second grinding roller are arranged in the transmission seat, a first motor, a second motor and a third motor are arranged at the side end of the transmission seat, the first motor is connected with the transmission belt, the second motor is connected with the first grinding roller, the third motor is connected with the second grinding roller, a connecting pipe is connected to the material guiding cover, and the connecting pipe is communicated with the interior of the screening barrel. By means of the design of the vibration screening equipment of an integrated structure, the processing efficiency of almonds is effectively improved, the processing time is saved, and meanwhile shells and kernels of the almonds can be independently collected in a water injection type vibrating screening manner.

Owner:ANHUI NONG ANKANG FOODS LTD CO

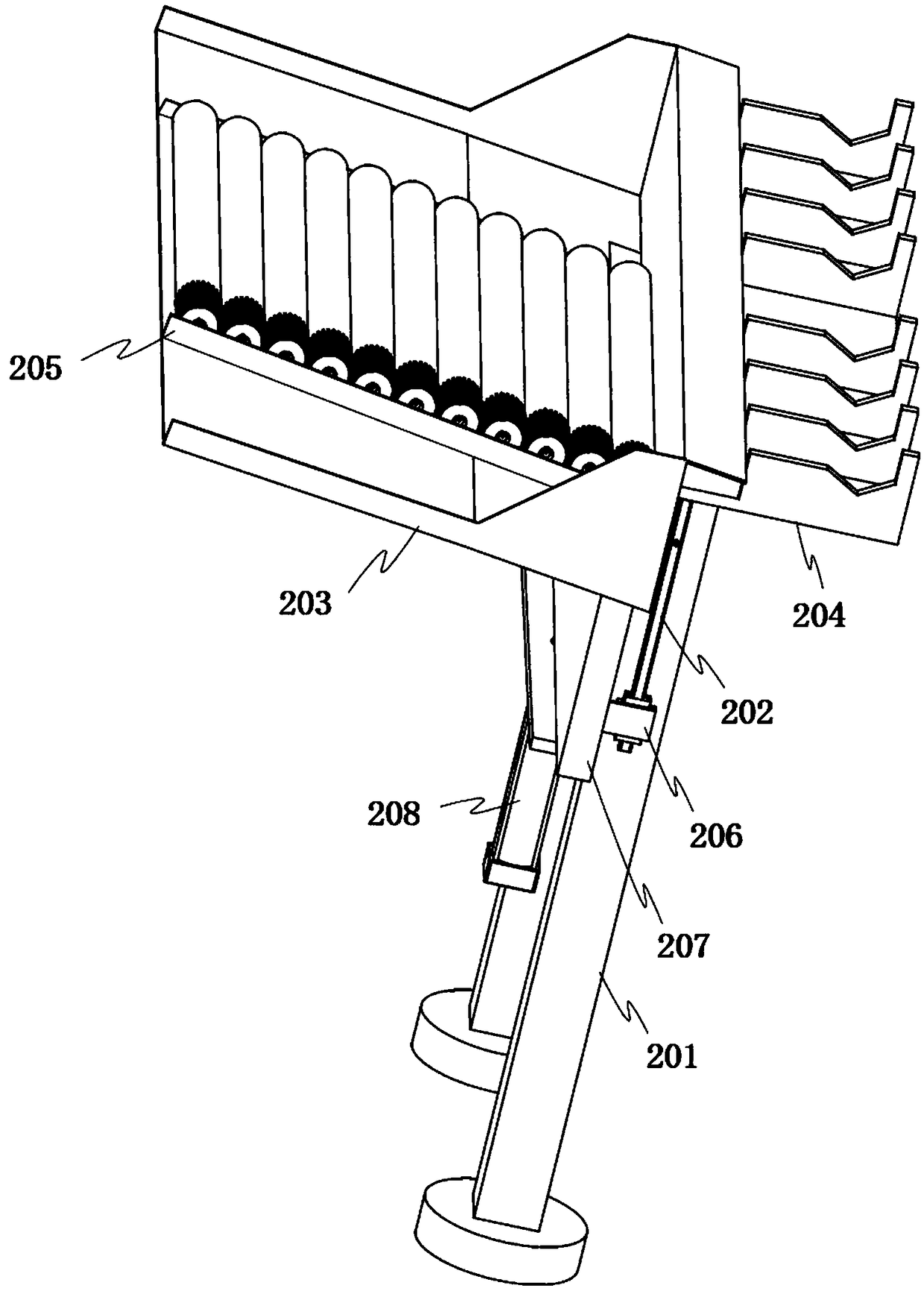

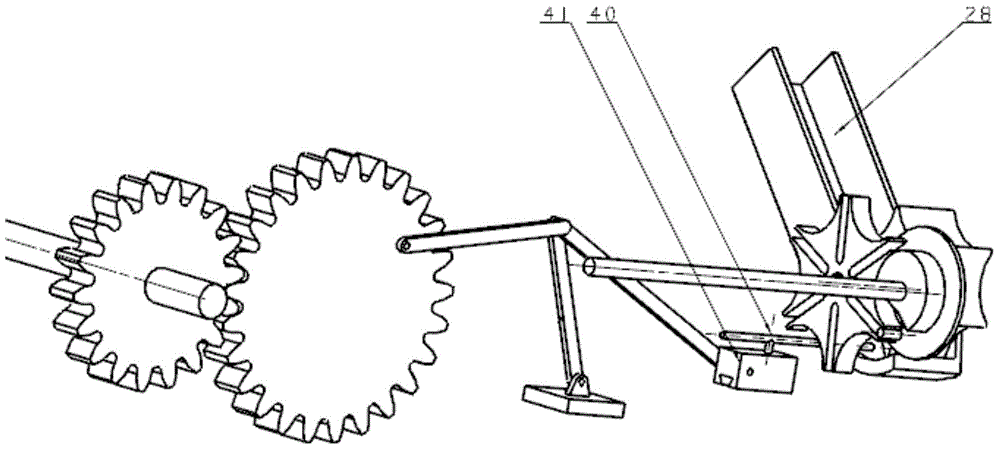

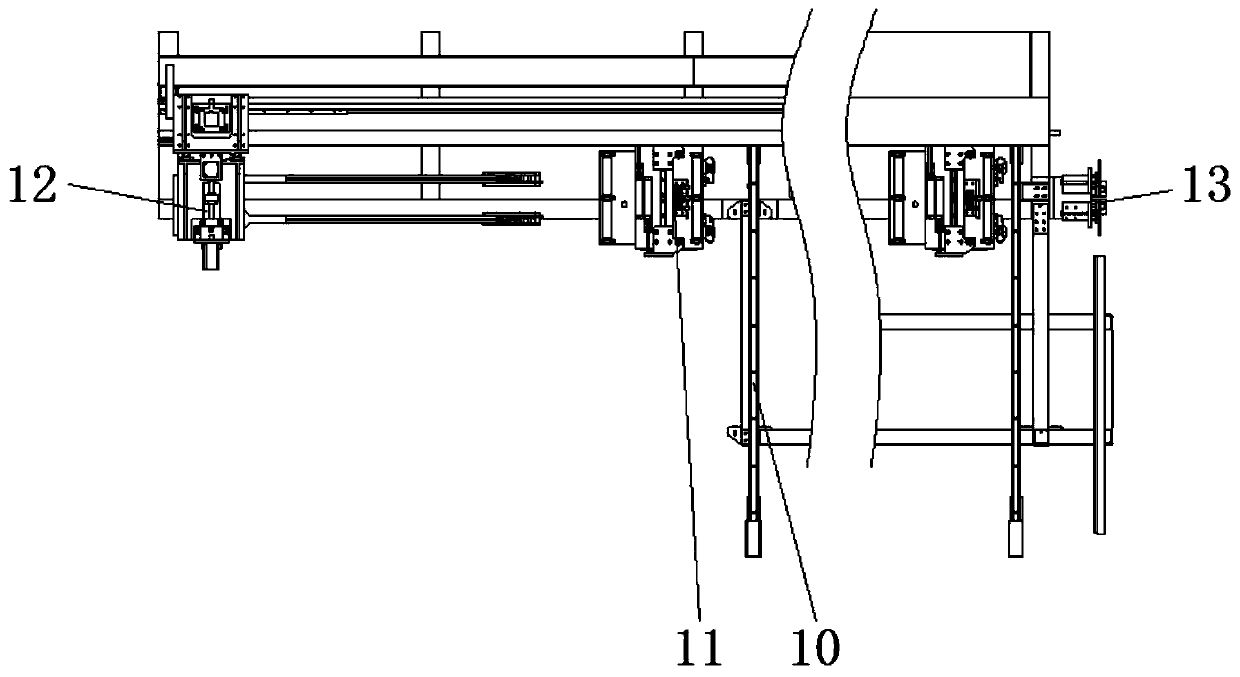

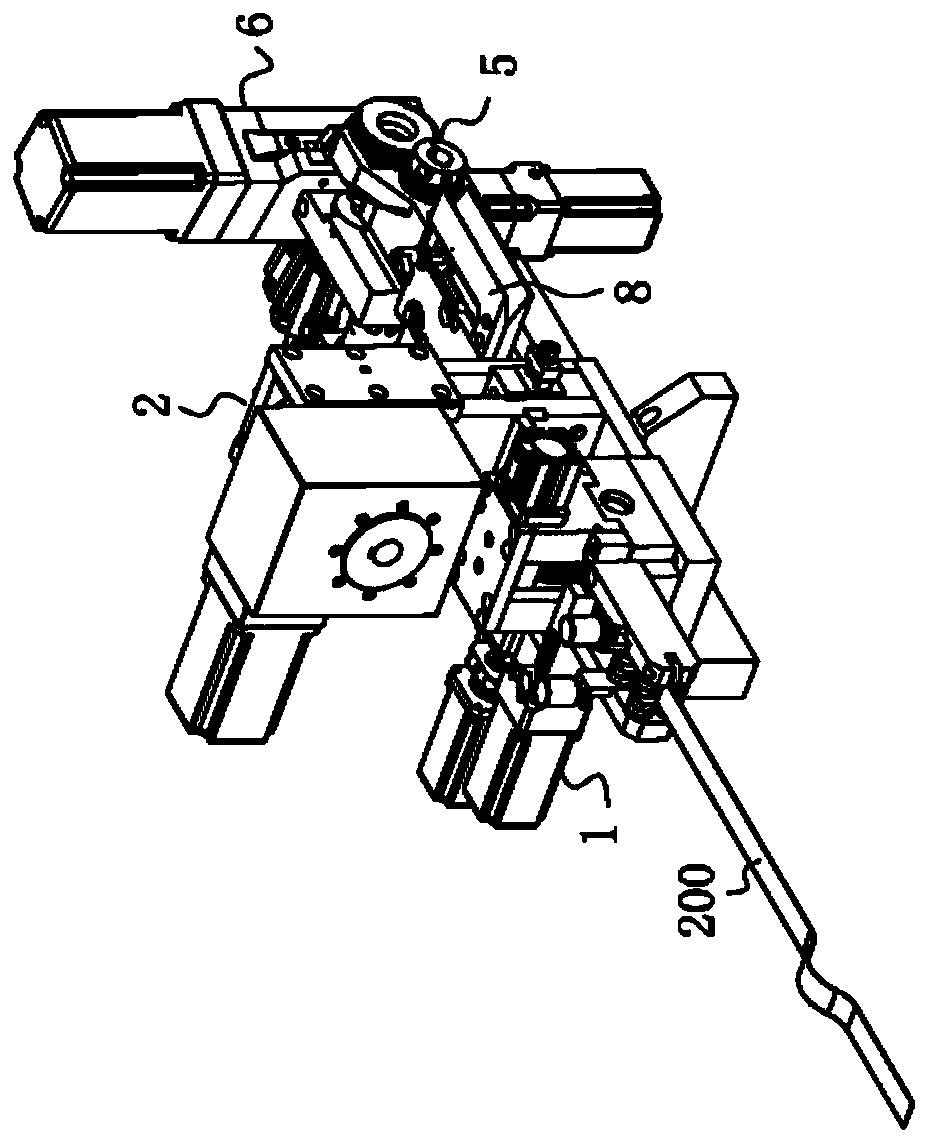

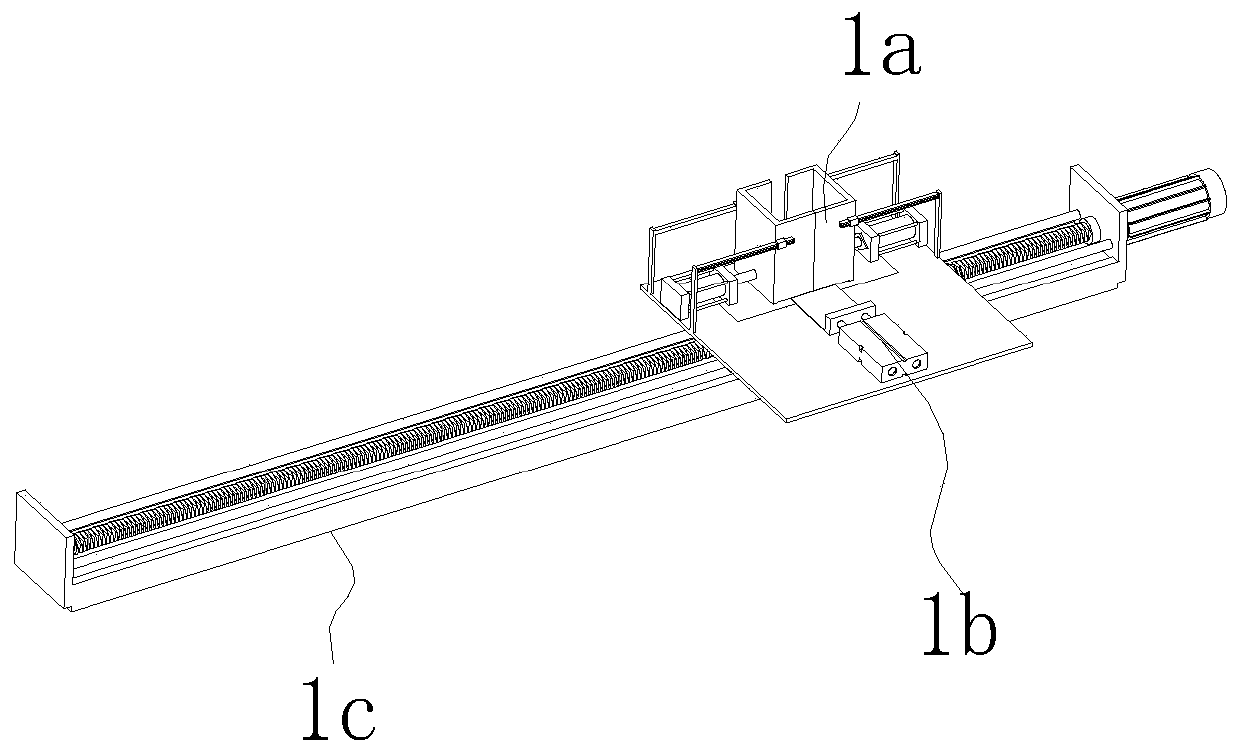

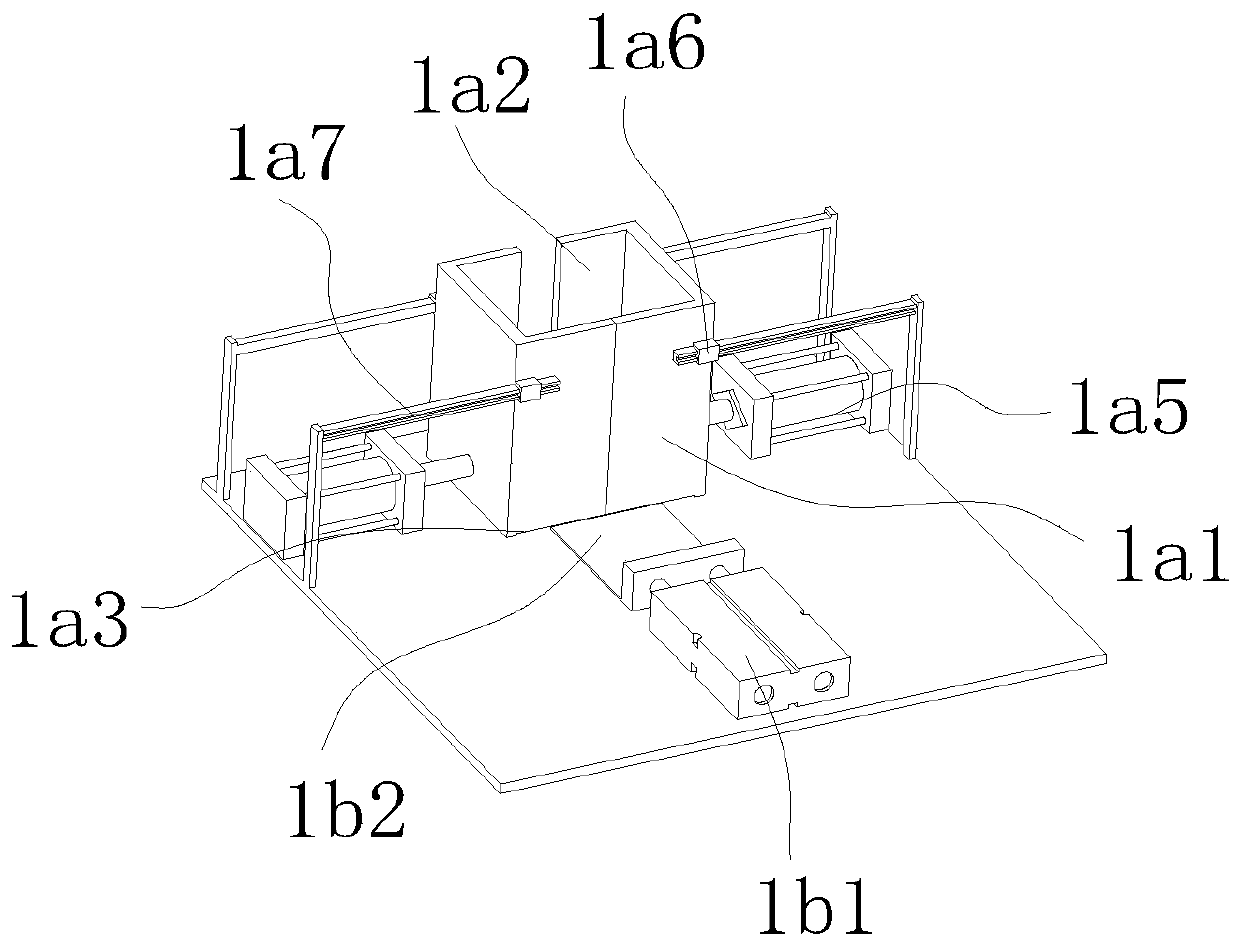

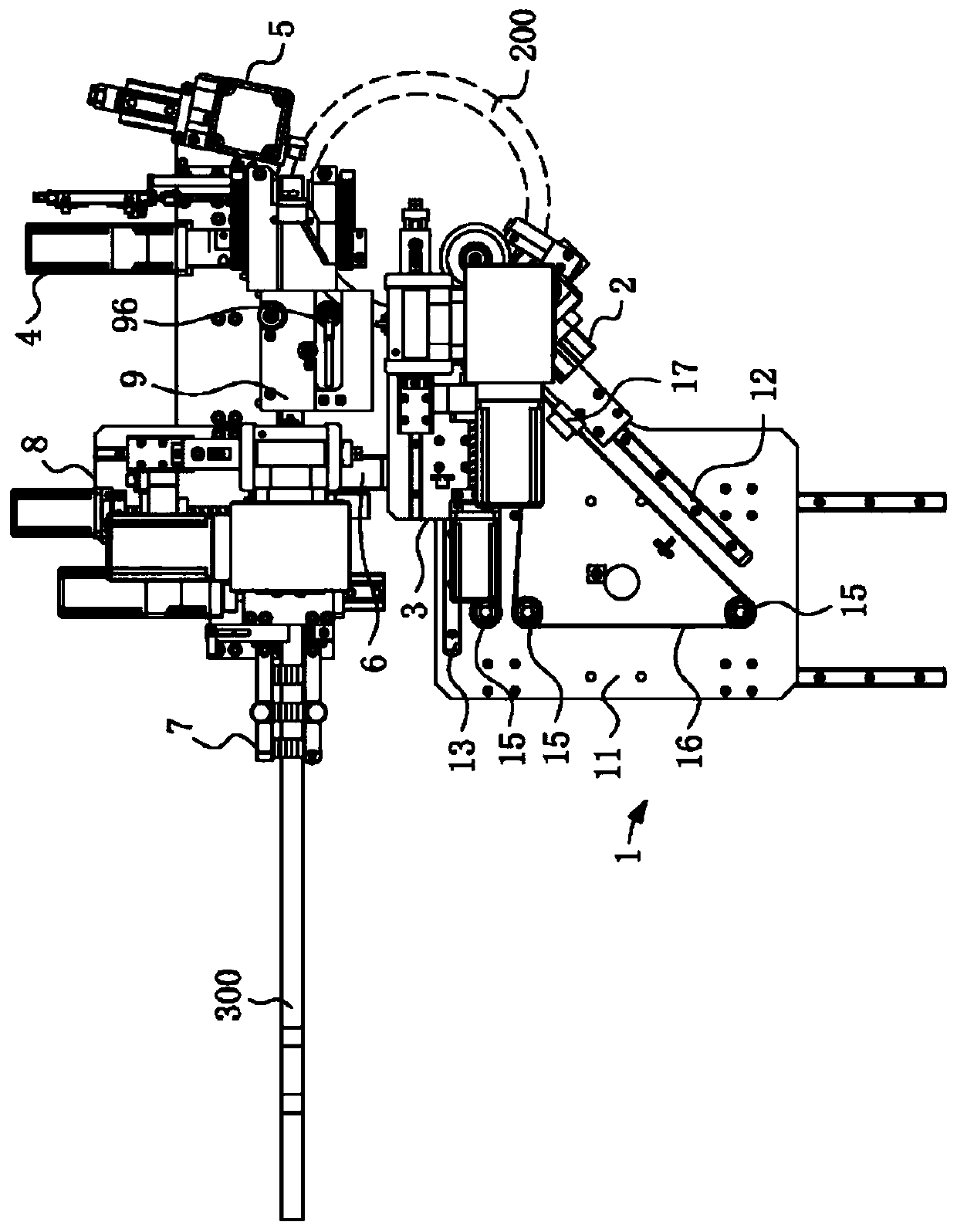

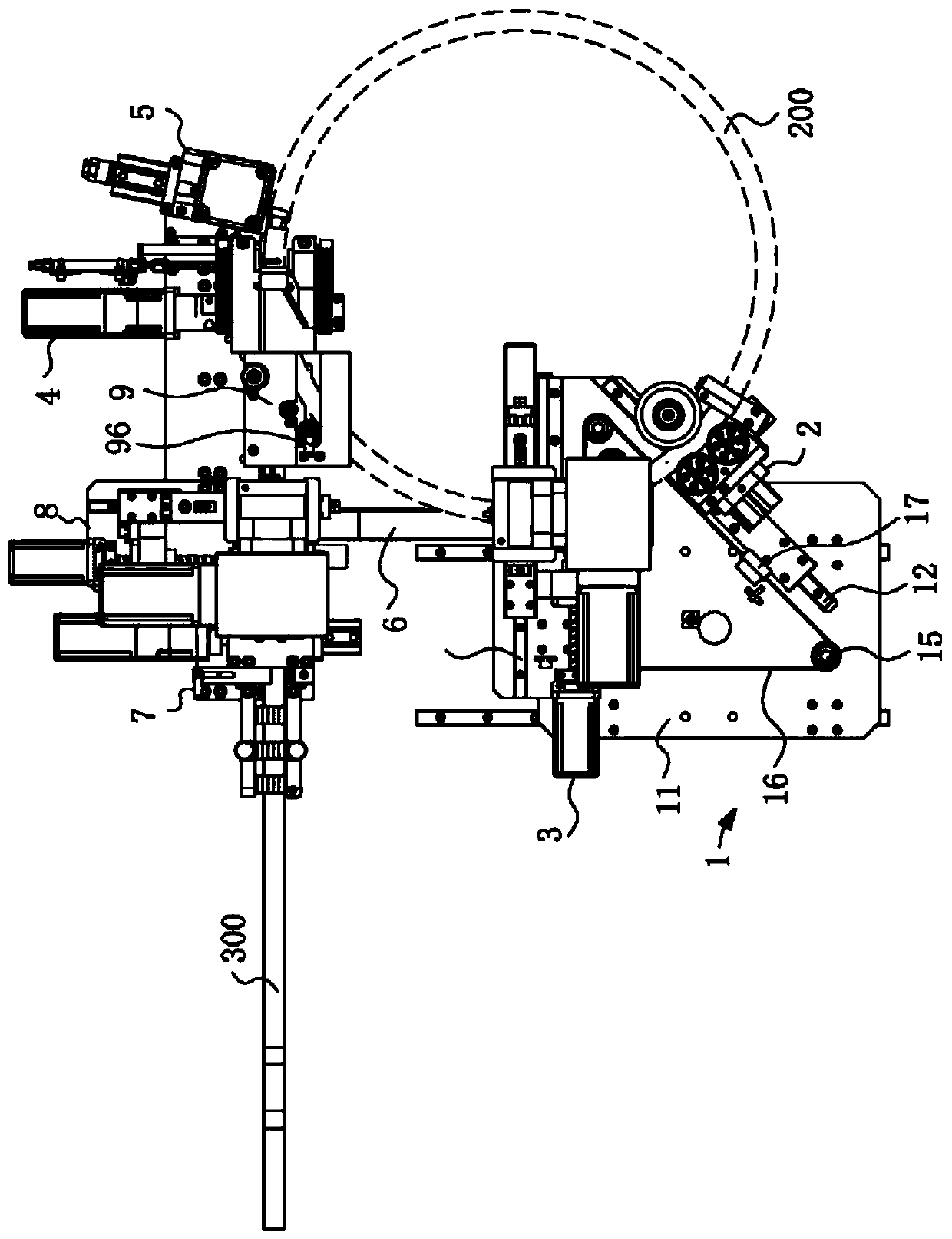

Automatic cutter bending machine and moving device of automatic cutter bending machine

ActiveCN109985962AImprove processing efficiencyHigh degree of processing automationMetal-working feeding devicesOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention provides an automatic cutter bending machine and a moving device of the automatic cutter bending machine. The automatic cutter bending machine is suitable for machining a roller cutter mold, the moving device comprises an installing base and a driving device, wherein the installing base is installed on a rack of the automatic cutter bending machine, a feeding sliding rail and a stamping and cutting sliding rail which are respectively used for providing an arc-shaped blade feeding device and an arc-shaped blade stamping and cutting device to be installed are fixedly arranged on the installing base, and the driving device is installed on the installing base. The driving device drives the arc-shaped blade feeding device and the arc-shaped blade stamping and cutting device to move on the feeding sliding rail and the stamping and cutting sliding rail respectively, so that the positions of the arc-shaped blade feeding device and the arc-shaped blade stamping and cutting deviceon the installing base are changed, and the moving device is suitable for machining arc blades with different diameters; and then when the arc-shaped blades with different specifications and diametersare machined, the arc-shaped blade feeding device and the arc-shaped blade stamping and cutting device only need to be driven by the driving device to move on the sliding rails, and then the moving device is further suitable for the machining of the arc-shaped blades with the various specifications and diameters.

Owner:深圳市骏昊自动化科技有限公司

Cutting and spraying integrated device of decoration plates

PendingCN108372530AEasy to cut and sprayQuick cutSpraying apparatusMetal working apparatusEngineeringIntegrated processing

The invention discloses a cutting and spraying integrated device of decoration plates. The device comprises a base, a first installation plate, a spraying plate, a second installation plate, and a shell, wherein traveling wheels are installed at the bottom of the base, the shell is installed at the top of the base, a booster pump is installed at the bottom in the shell through an installation piece, a paint gun extending out from the shell is installed at the output end of the shell through a guide tube, a matched paint tank is installed at the bottom of the paint gun, and a support plate is installed in the shell above the booster pump. The cutting and spraying integrated device of decoration plates comprises a series of components including the base, the first installation plate, the spraying plate, the second installation plate and the shell, the spraying plate realizes the spraying function of the device effectively, a telescopic rod can support or shrink the spraying plate according to actual operation requirements, a cutting plate enables workers to cut off plates rapidly through a cutting groove, so that the device realizes integrated processing, is highly practical, and isworth of promoting and using.

Owner:湖州泰信环保科技有限公司

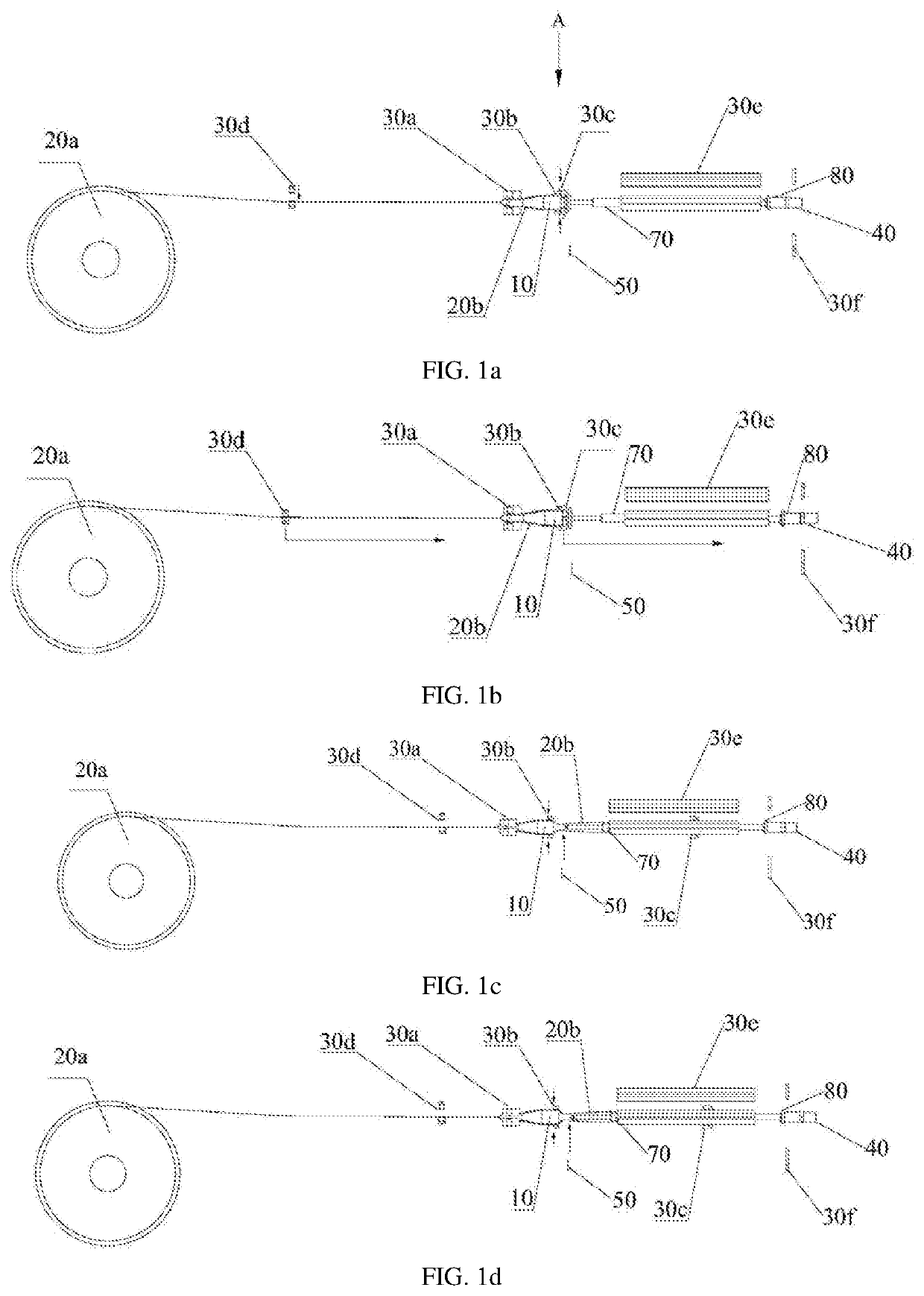

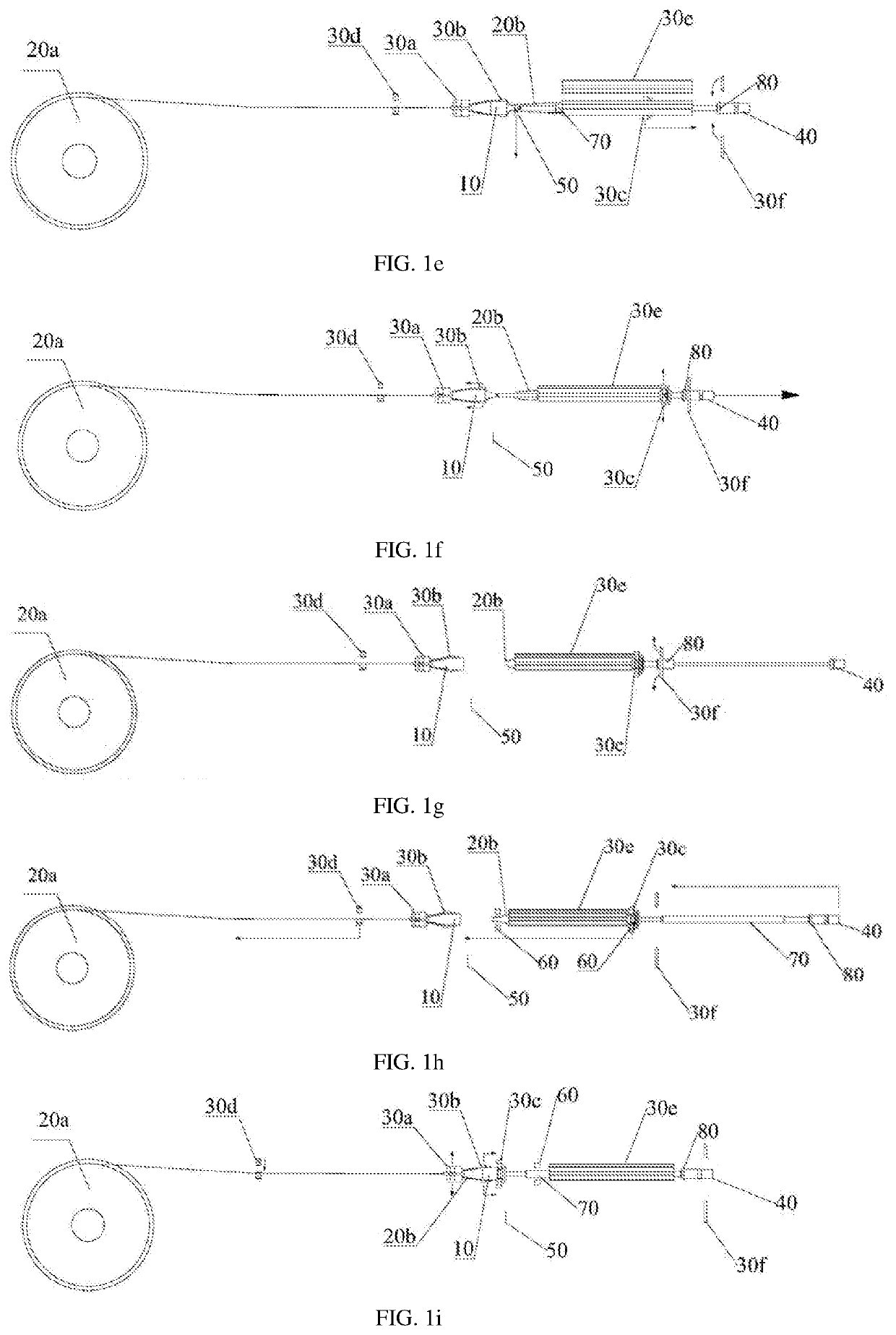

Packaging Equipment for Continuous Automatic Net Sleeving of Casing, Shirring Machine and Packaging Method

PendingUS20200288728A1Improve efficiencyRealize integrated processingSkinless sausage makingSausage casing manufactureReciprocating motionPinch grip

The present disclosure relates to packaging equipment for continuous automatic net sleeving of a casing, a shirring machine and a packaging method. The packaging equipment is provided with a shuttle; a first gripper, capable of being opened or closed to release or clamp and fix the shuttle; a second gripper, capable of driving an open end of the net bag to make reciprocating motion between a first position and a second position on the shuttle when being closed, and capable of allowing the net bag to move freely in a net bag conveying direction when being opened; a third gripper, configured to clamp the open end of the net bag and pull the net bag to sleeve a whole shirred casing in a penetrating mode; and a fourth gripper, configured to pull the net bag, and designed to be capable of moving with the third gripper.

Owner:FOSHAN VEHICIAN LNTELLIGENT EQUIP CO LTD

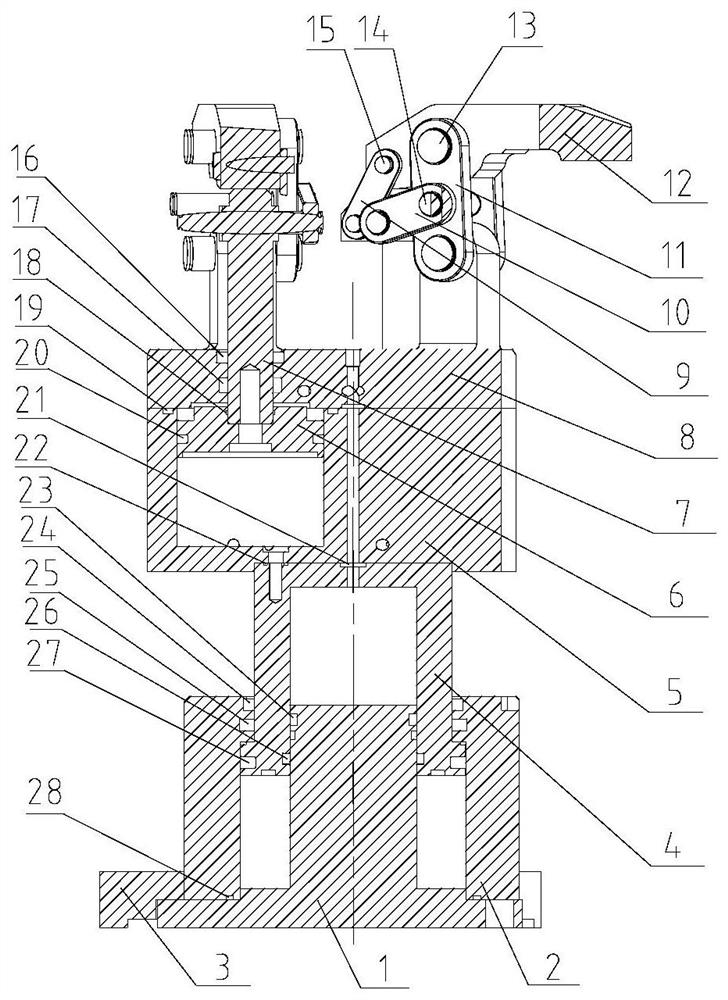

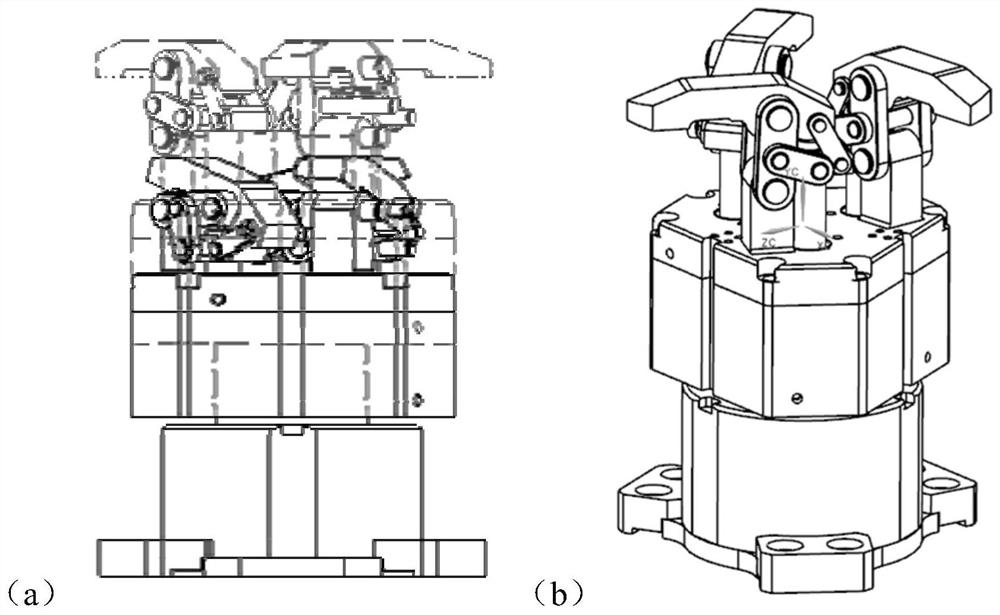

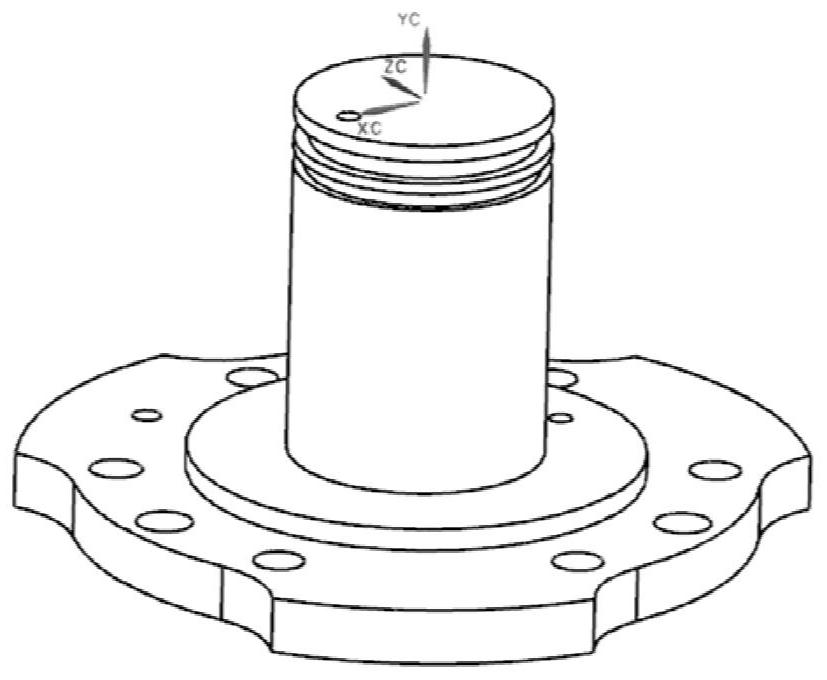

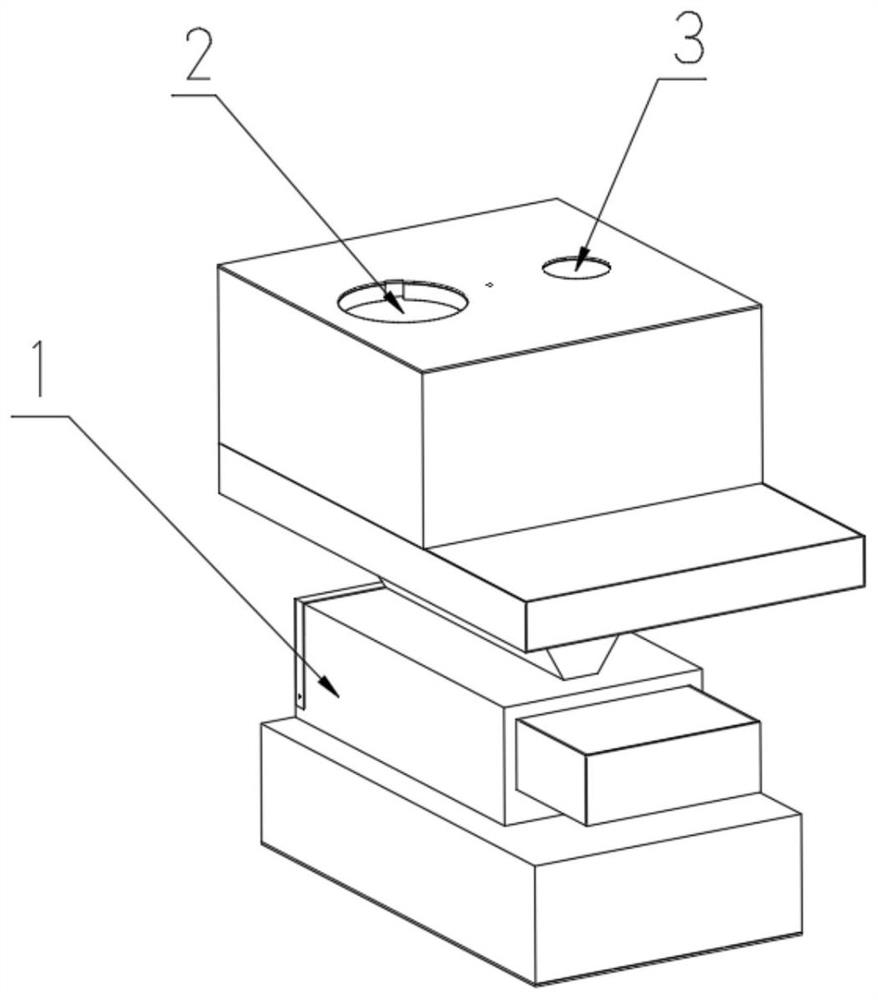

Indexable lifting type hydraulic clamping device

PendingCN113414618AAvoid interferenceLess interferencePositioning apparatusMetal-working holdersControl engineeringStructural engineering

The invention discloses an indexable lifting type hydraulic clamping device, and belongs to the technical field of automatic tools and equipment. The indexable lifting type hydraulic clamping device comprises a lifting mechanism and a clamping mechanism which are arranged from bottom to top. The lifting mechanism comprises a lower end cover, a lower cylinder body is arranged outside the lower end cover, and an annular piston is arranged between the lower end cover and the lower cylinder body. The clamping mechanism comprises an upper cylinder body and a double-connecting-rod clamping device, a piston is arranged in the upper cylinder body, an upper end cover is arranged on the upper end face of the upper cylinder body, and a hole penetrating through the double-connecting-rod clamping device is formed in the upper end cover. According to the indexable lifting type hydraulic clamping device, when automatic integrated machining of multiple parts of a part is completed through one-time clamping and the appearance of the part is machined, the end face of the part can be rapidly clamped by lifting the whole mechanism from an inner hole of the part and rotating a pressing arm; and when the end face of the part is machined, the whole mechanism descends and is hidden in the clamp through transposition of the pressing arm, and interference generated during machining is avoided.

Owner:AECC AVIATION POWER CO LTD

Household intelligent all-category vegetable and meat processing machine

PendingCN111716427AWell formedNot easy to accumulateCleaning using liquidsMetal working apparatusAgricultural scienceAgricultural engineering

The invention provides a household intelligent all-category vegetable and meat processing machine. Two feeding ports are located on the top part of the machine, an adjustable knife plate part used toprocess vegetable and meat into slices as a first processing step is arranged directly below the feeding ports, a knife tackle part used to cut the sliced vegetable and meat into strips, chunks or dices as a second processing step is arranged directly below the knife plate part, a finished box is arranged directly below the knife tackle part, the finished box is also the bottom of the whole machine, and a housing supporting the whole machine is arranged outside the finished box. The invention provides the household intelligent all-category vegetable and meat processing machine, and the problemof difficulty in adjusting the thickness of the slices and the thickness of shreds in the vegetable cutting process is solved, so that the liberation of hands is achieved, the efficiency of cutting vegetables is improved, and the purpose of improving living standards is achieved.

Owner:ZHEJIANG UNIV OF TECH

Method for machining arc and end surface of turbine guide blade of small gas turbine

ActiveCN110497250AImprove processing efficiencyRealize integrated processingGrinding machinesEngineeringGrinding wheel

The invention relates to the field of grinding machining, in particular to a method for machining an arc and an end surface of a turbine guide blade of a small gas turbine. According to the method, agrinding wheel in grinding is finished by adopting a mode that a rolling wheel and the grinding wheel are matched, so that the precise grinding machining problems of an inner circle, an outer circle and the end surface of the turbine guide blade of the small gas turbine are solved, the integrated machining of the arc and the end surface of the turbine guide blade of the small gas turbine is realized, a measuring tool and a clamp for arc machining are improved, the machining efficiency of the inner circle, the outer circle and the end surface is improved, and a reasonable method and reasonableexperience are provided for precise grinding integrated machining of the inner circle, the outer circle and the end surface of other similar blades in the future.

Owner:成都和鸿科技股份有限公司

3C product shell integrated processing equipment

ActiveCN110370127ARealize integrated processingImprove processing efficiencyGrinding drivesGrinding machinesEngineeringIntegrated processing

The invention relates to 3C product shell integrated processing equipment. The equipment comprises a material carrying frame and an upper frame, a material receiving device capable of adsorbing the inner bottom surface of a shell is arranged in the material carrying frame, the width of the material carrying frame is larger than the width of the shell, a grinding device is arranged below the upperframe, the grinding device comprises a grinding movable device which is arranged below the upper frame and can be lifted and move forwards and backwards, the grinding movable device is connected witha grinding installation block, the outer side of the grinding installation block is provided with a grinding lifting ball which is in tangent fit with the inner wall of one side of the material carrying frame, the inner side of the upper part of the grinding installation block is embedded with a grinding arc block which is consistent with the arc of a standard shell, a material pressing device incooperation with the shell is further arranged on the upper frame, a feeding and discharging device is arranged on the outer side of the material carrying frame, the loading and unloading device comprises a lower frame, a feeding and discharging lifting air cylinder is arranged on the lower frame, a discharging barrel and a feeding barrel are arranged above the feeding and discharging lifting aircylinder in a stacking mode, the discharging barrel and the feeding barrel are internally provided with a feeding and discharging taking and placing device, and the processing efficiency is improved.

Owner:DONGGUAN KEHENG HAND MODEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com