Almond and almond protein brittle vibration screening equipment

A vibratory screening and equipment technology, which is applied in the fields of filtration, wet separation, solid separation, etc., can solve the problems of long processing time, cumbersome procedures, and low efficiency, and achieve the effect of avoiding cumbersome processing procedures and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

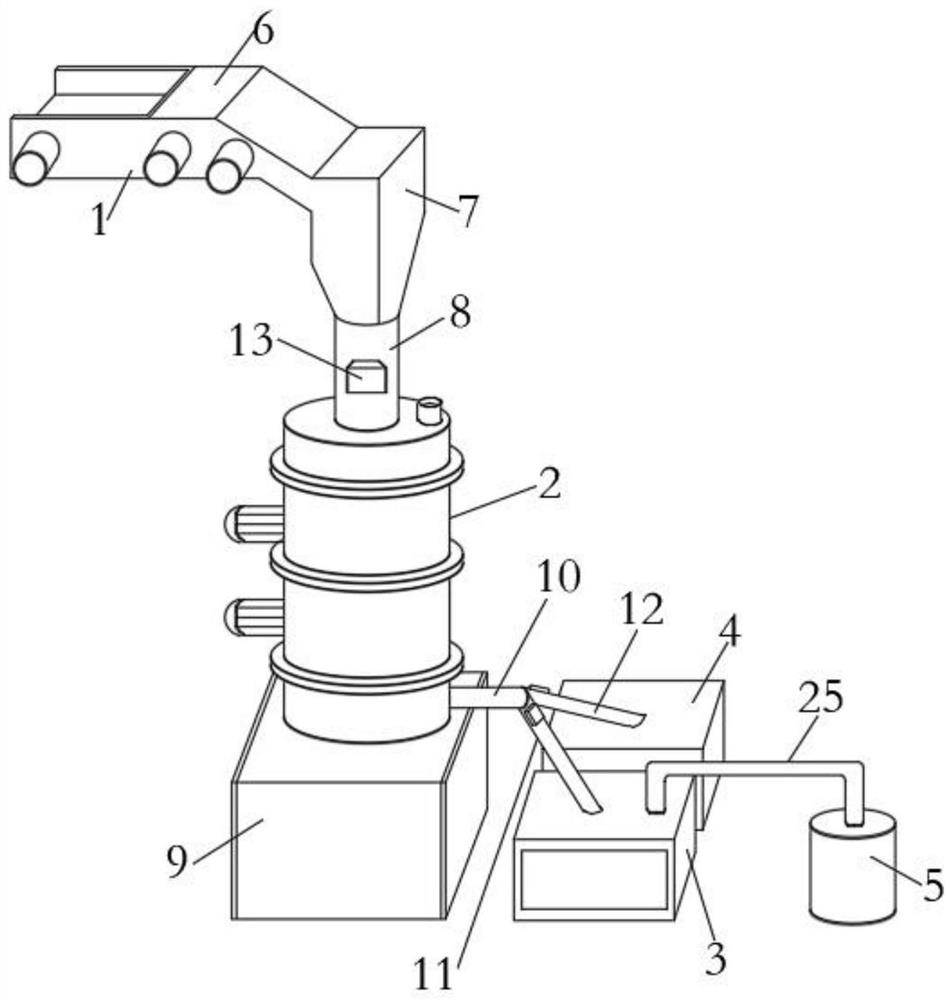

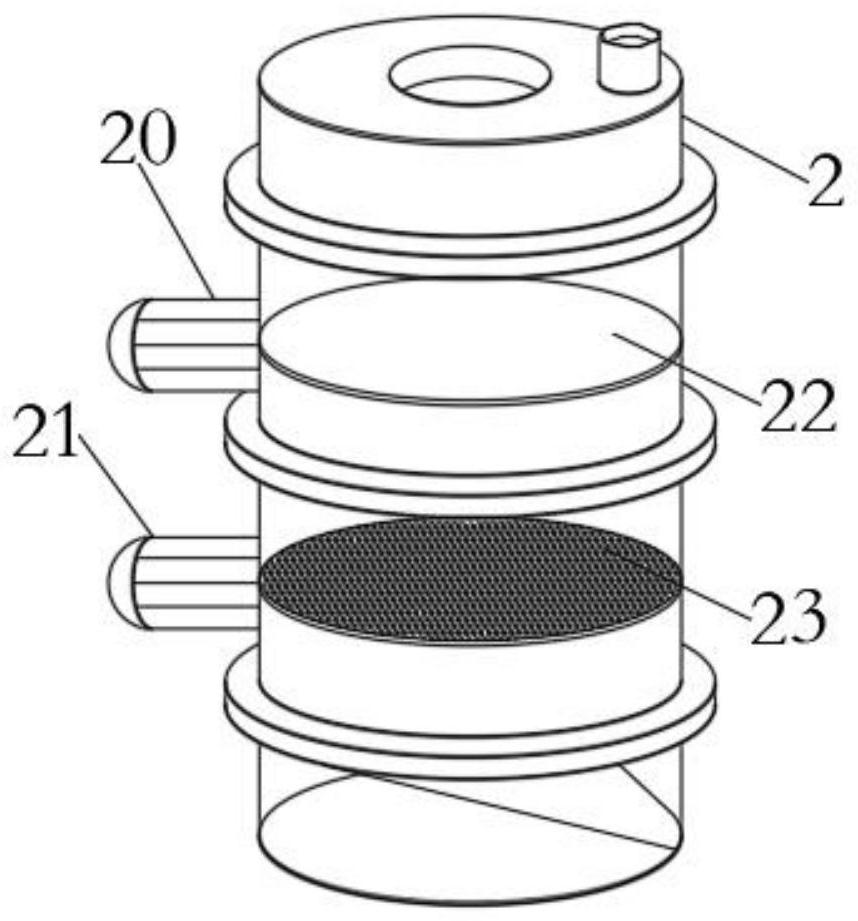

[0026]As a preferred embodiment of the present invention, the connecting pipe 8, the first branch pipe 11 and the second branch pipe 12 are provided with control valves 13, the control valves 13 are electronic valves, and the two ends of the connecting pipe 8 are respectively Sealed on the material guide cover 7 and the sieve bucket 2, the connecting pipe 8, the first branch pipe 11, the second branch pipe 12 and the main discharge pipe 10 are all made of carbon steel, and the control valve 13 is connected to the connecting pipe 8 and the first branch pipe respectively. 11 and the circulation of the second branch pipe 12 are controlled, and the pipe body made of carbon steel is corrosion-resistant and not easy to be damaged. The model of the control valve 13 is F9A74807.

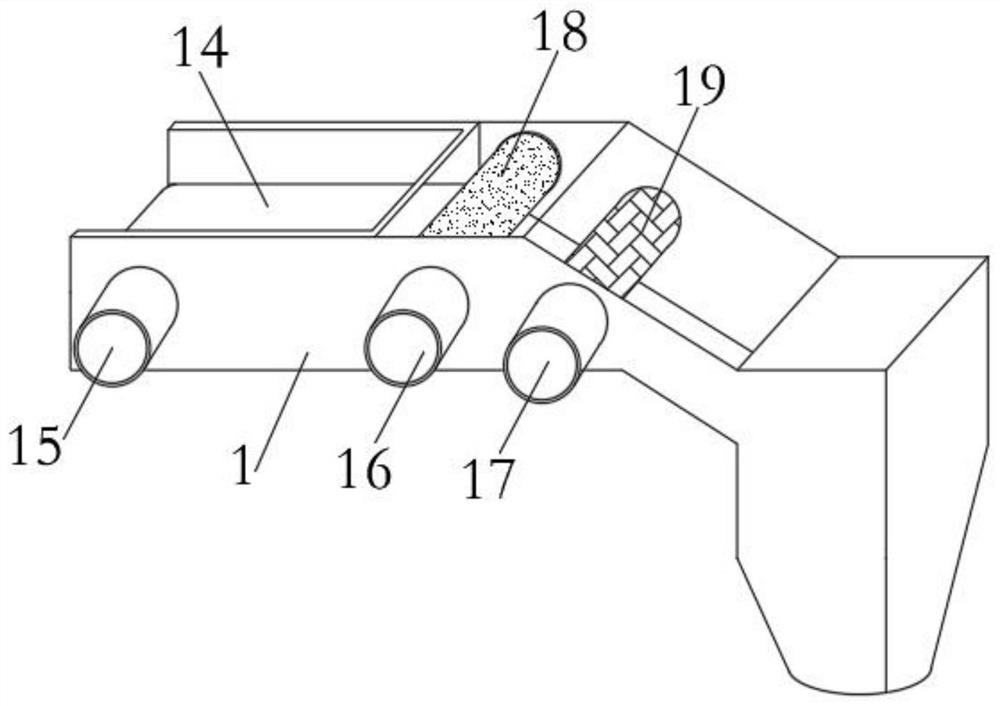

[0027] As a preferred embodiment of the present invention, the first lamination roller 18 and the second lamination roller 19 are all made of stainless steel, and the first lamination roller 18 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com