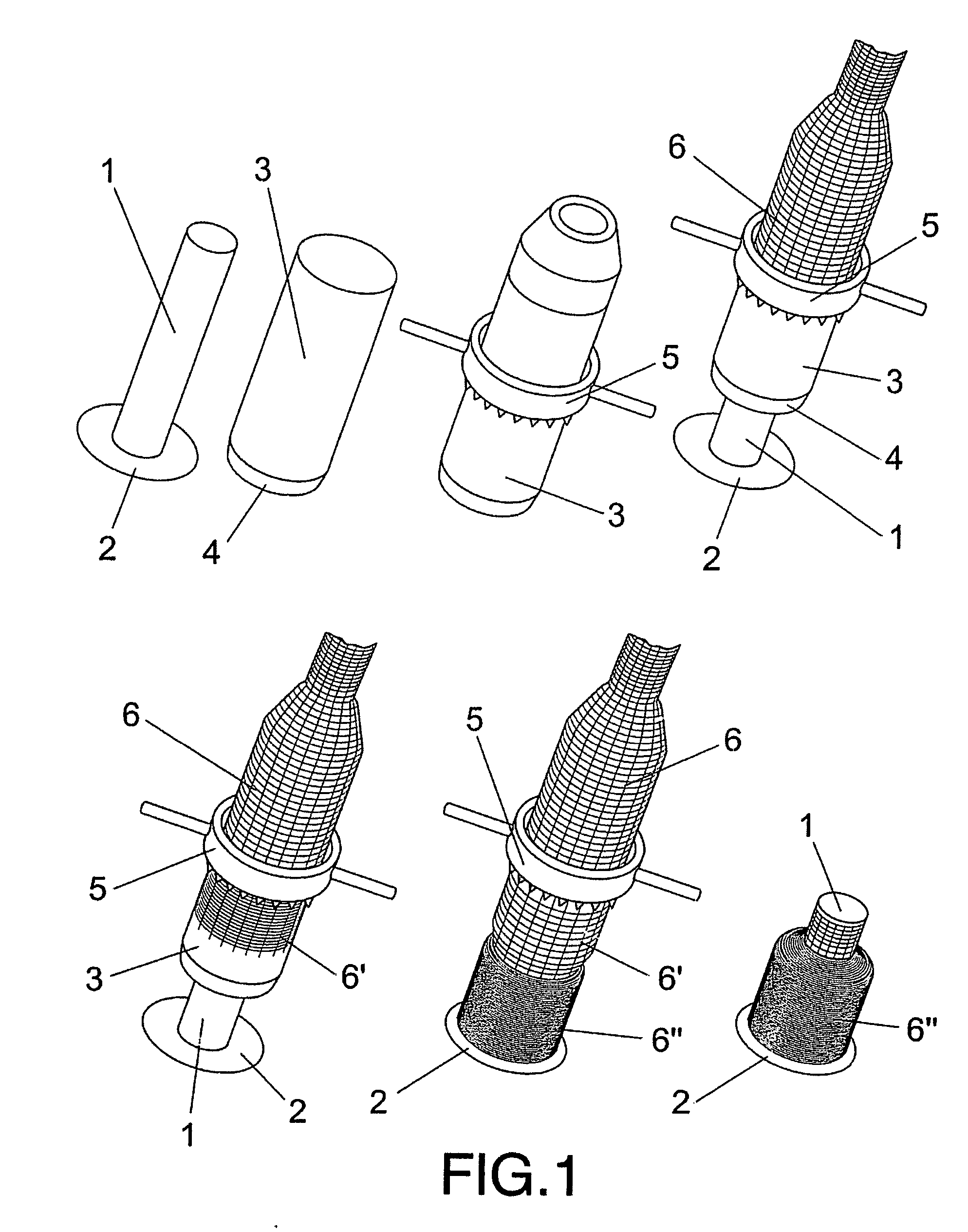

Patents

Literature

120results about "Sausage casing manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

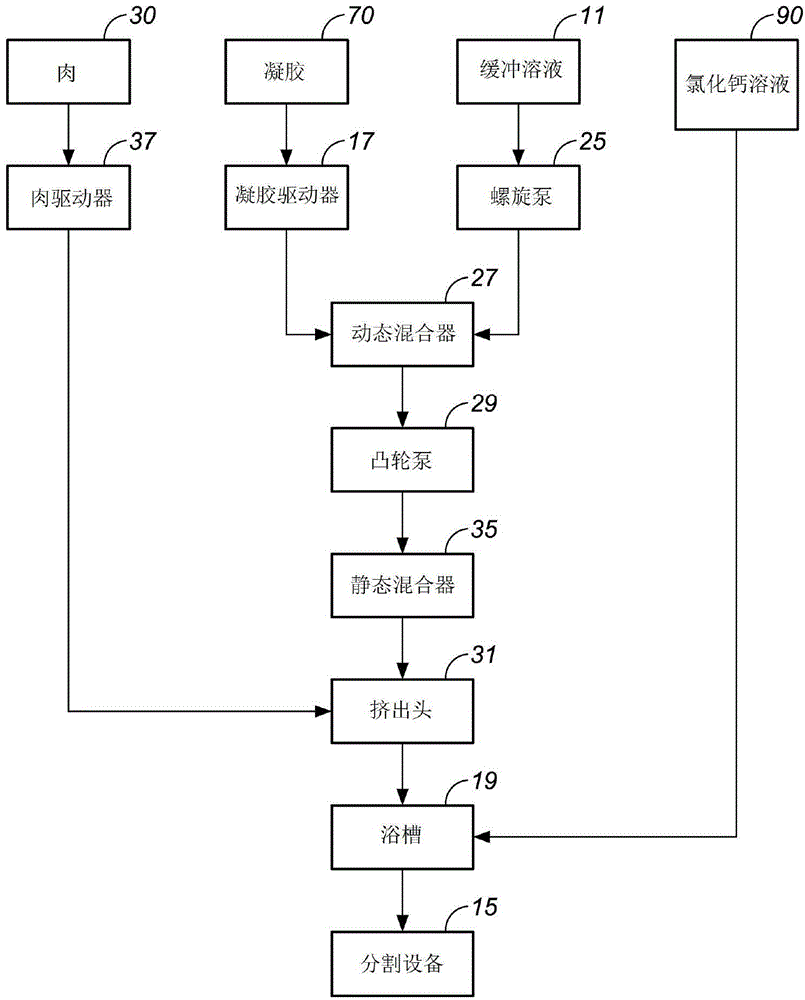

Food Product Having a Casing

ActiveUS20090317522A1Less prone to weakening over timeTimely controlMilk preparationAlcoholic beverage preparationCo extrusionFood products

The present invention is directed to a process for preparing a food product having a casing, the process comprising the step of applying a casing paste comprising alginate and a sparingly soluble calcium salt by co-extrusion to the exterior of a material to be cased to form a co-extruded product, and contacting the co-extruded product with a solution comprising calcium ions, thereby causing the alginate to gel.

Owner:DUPONT NUTRITION USA INC

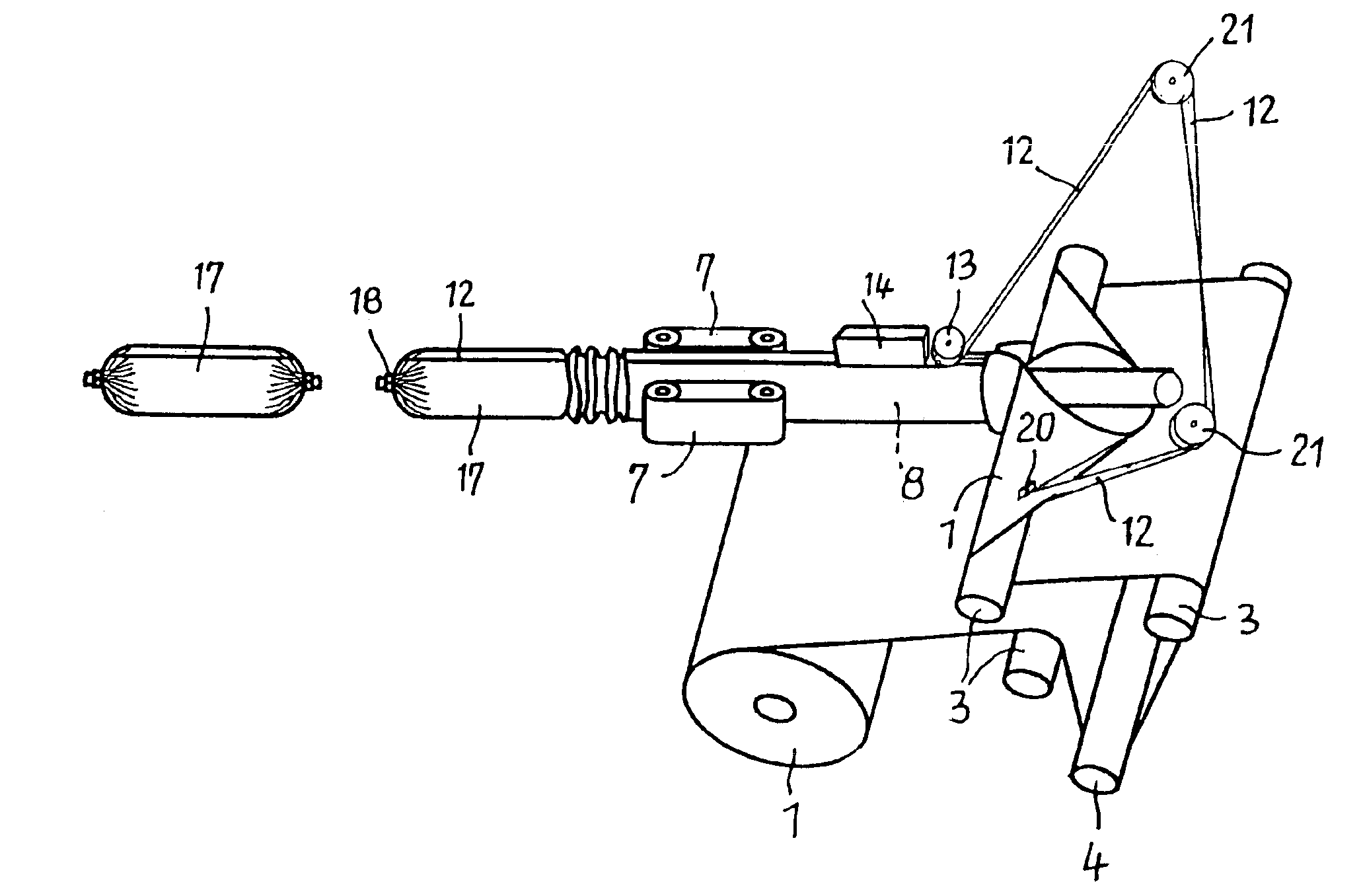

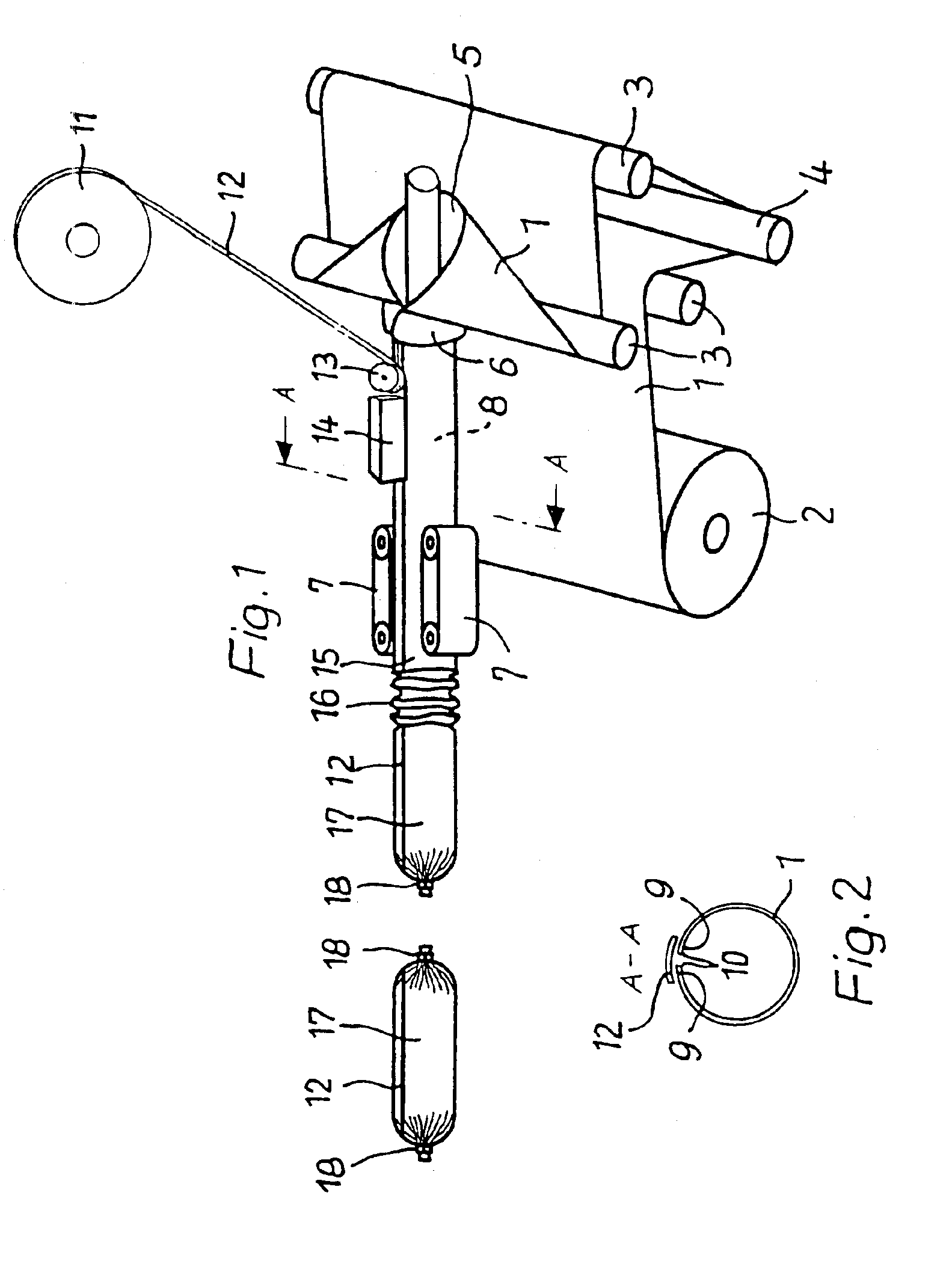

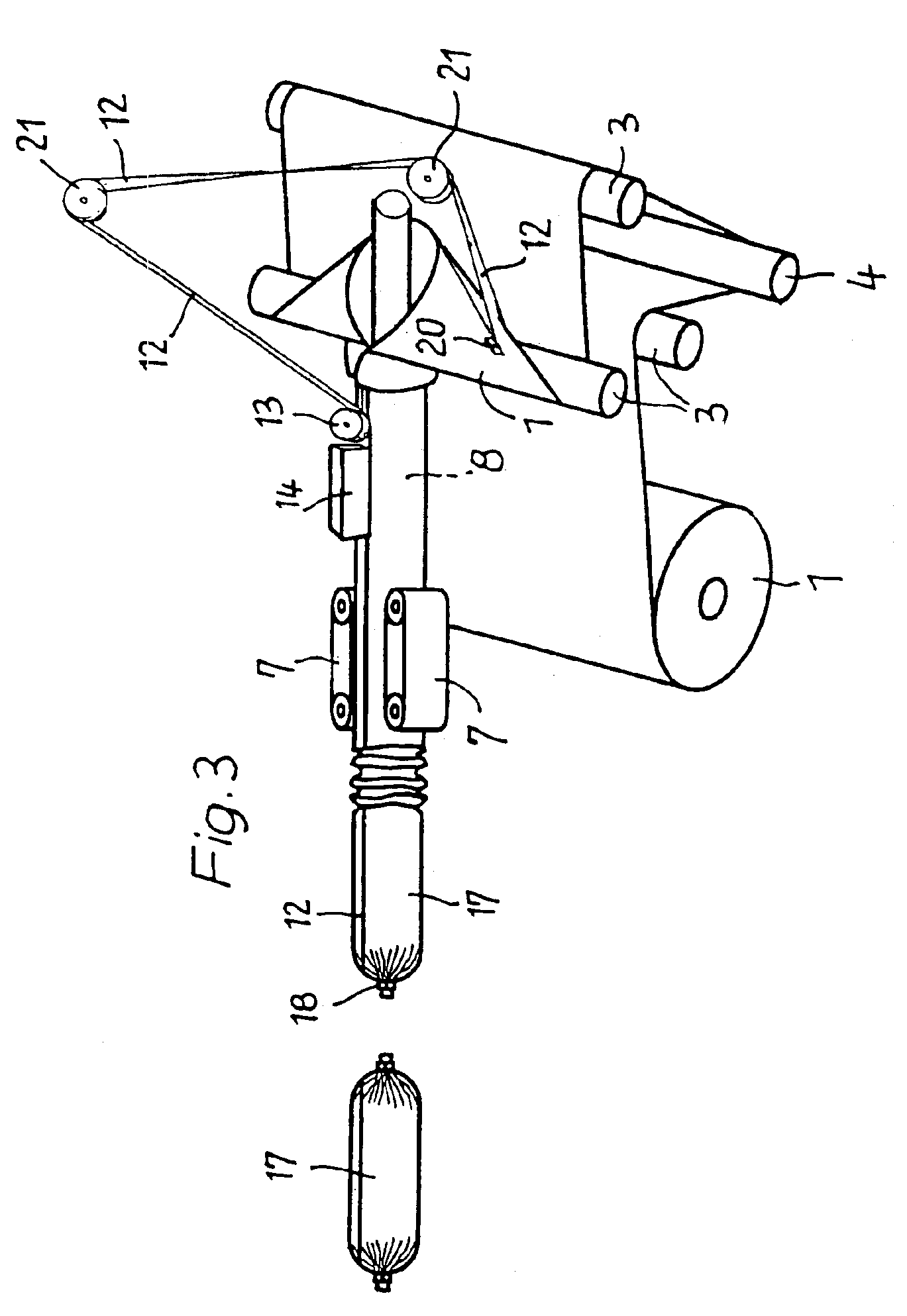

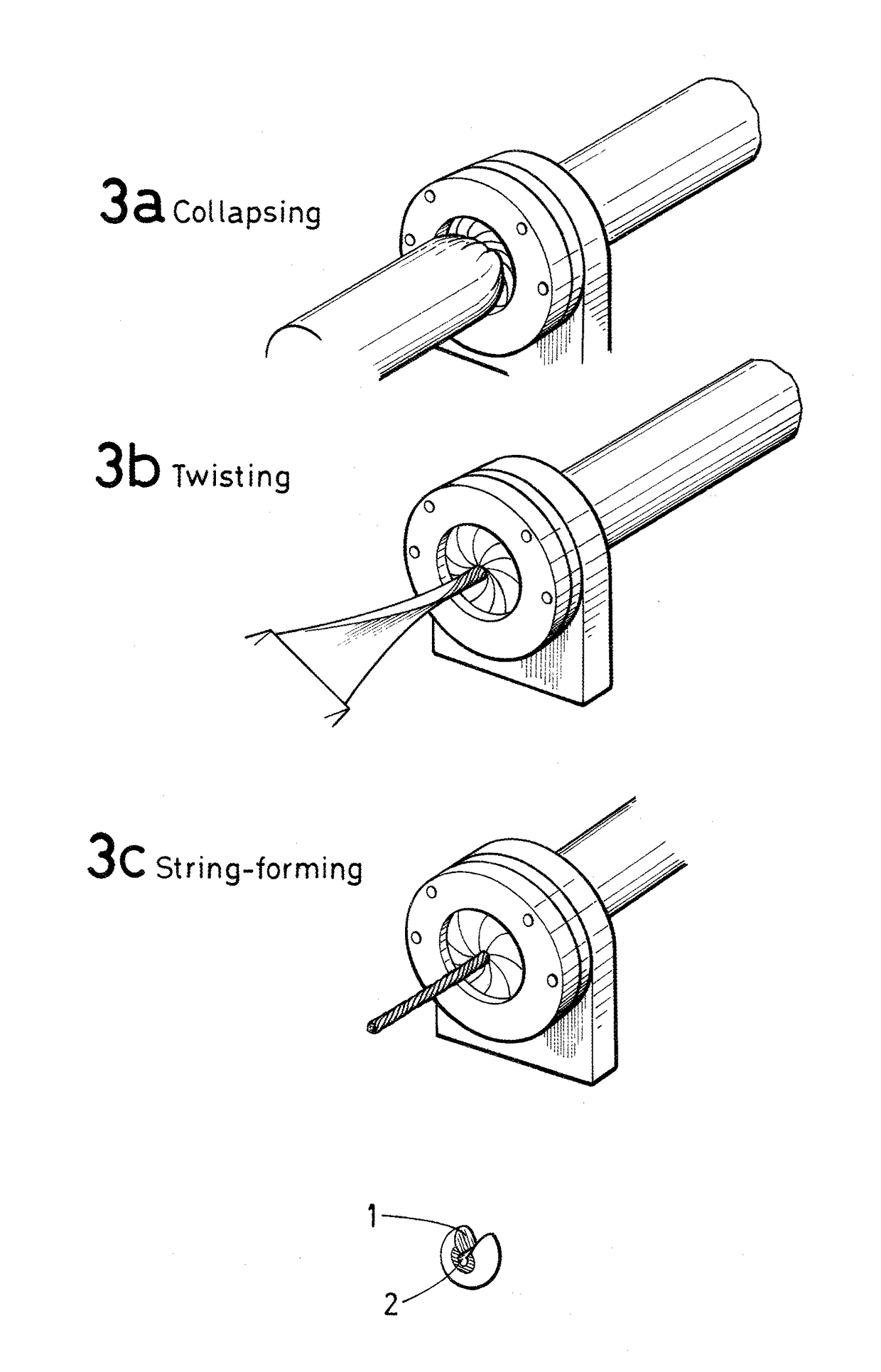

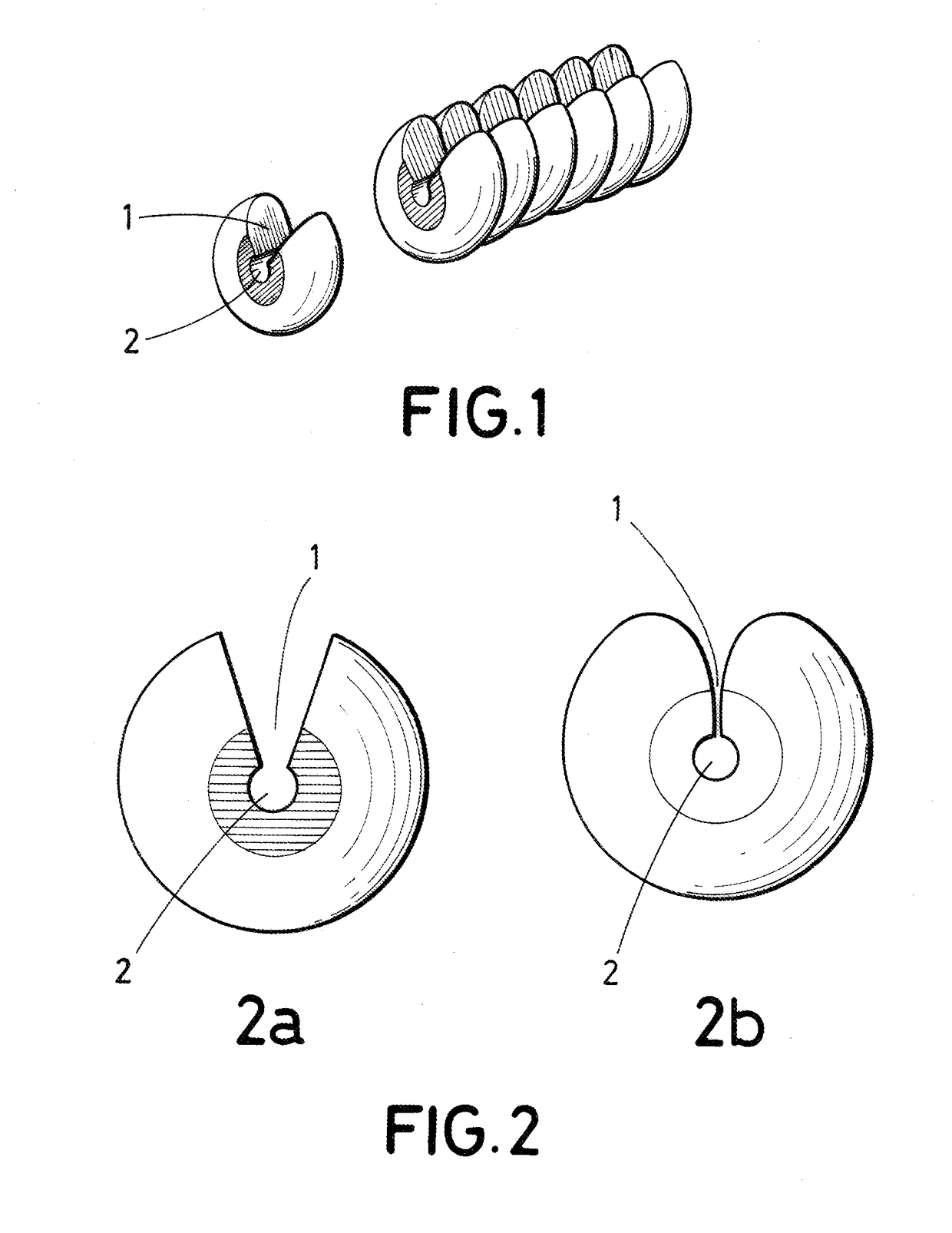

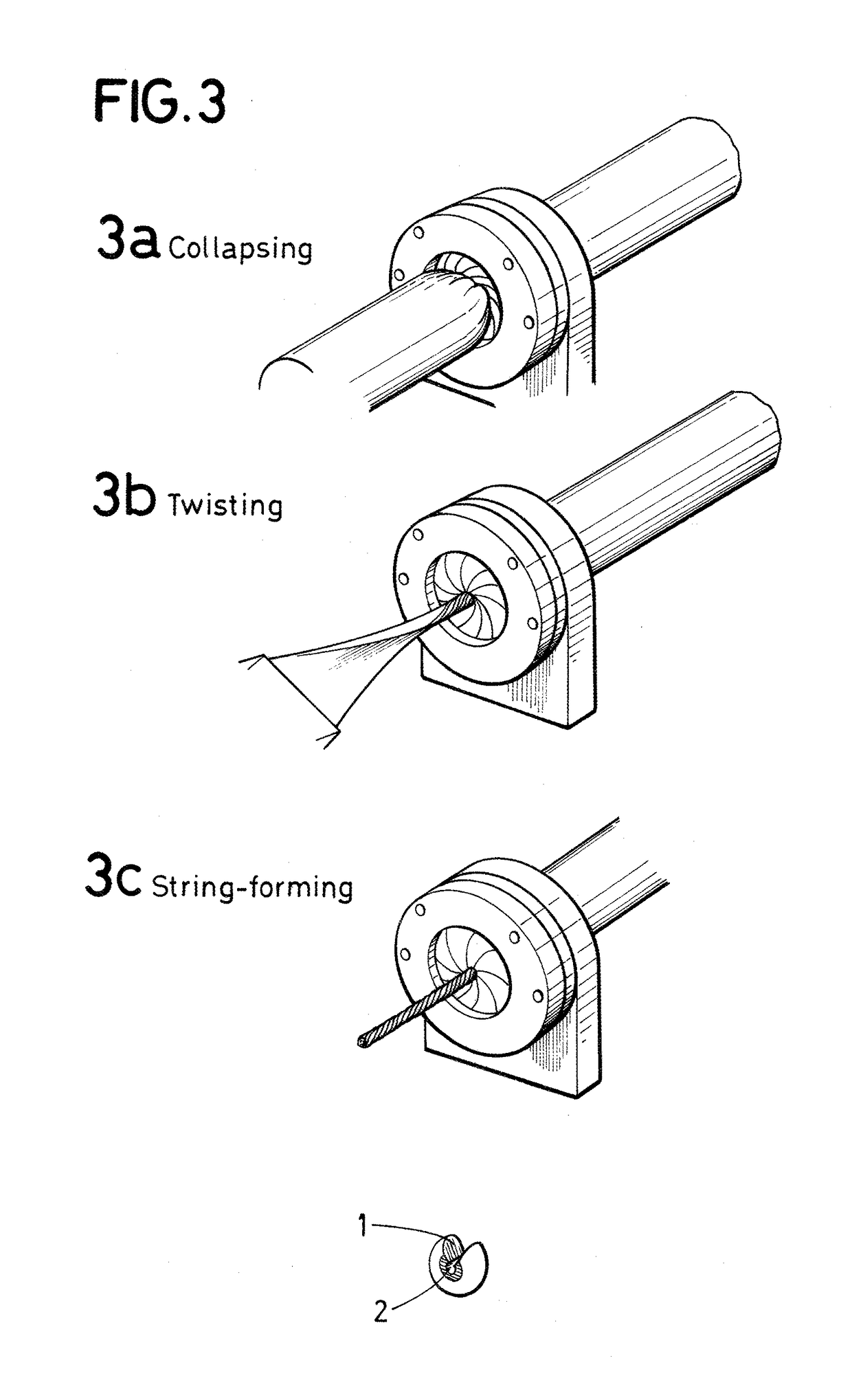

Method for producing a casing

InactiveUS7059102B2Small sizeCan be without delayWrapper twisting/gatheringSausage makingBand shapeEngineering

Owner:POLY CLIP SYST

Edible casing membrane with blend of collagen fibers and starch

ActiveCN104585289AImprove bindingSatisfied with high temperature boilingSausage casing manufactureFiberCarboxymethyl cellulose

The invention discloses an edible casing membrane with a blend of collagen fibers and starch. The edible casing membrane comprises the following components in percentage by weight: 35-50% of collagen fibers, 23-30% of starch, 2-5% of chitosan, 2-5% of sodium carboxymethyl cellulose (CMC), 16-22% of water, 2-5% of glycerol and 0.002% of glyoxal. According to the edible casing membrane with a blend of collagen fibers and starch, the casings produced by modified starch have better combination with meat stuffing, can meet the requirements of boiling at high temperature for long time and frying at high temperature above 180 DEG C of sausages, and are more suitable for breakfast sausages; compared with the previous invention, the casings have a significant improvement in resistance to boiling and frying at high temperature.

Owner:山东冠华蛋白肠衣有限公司

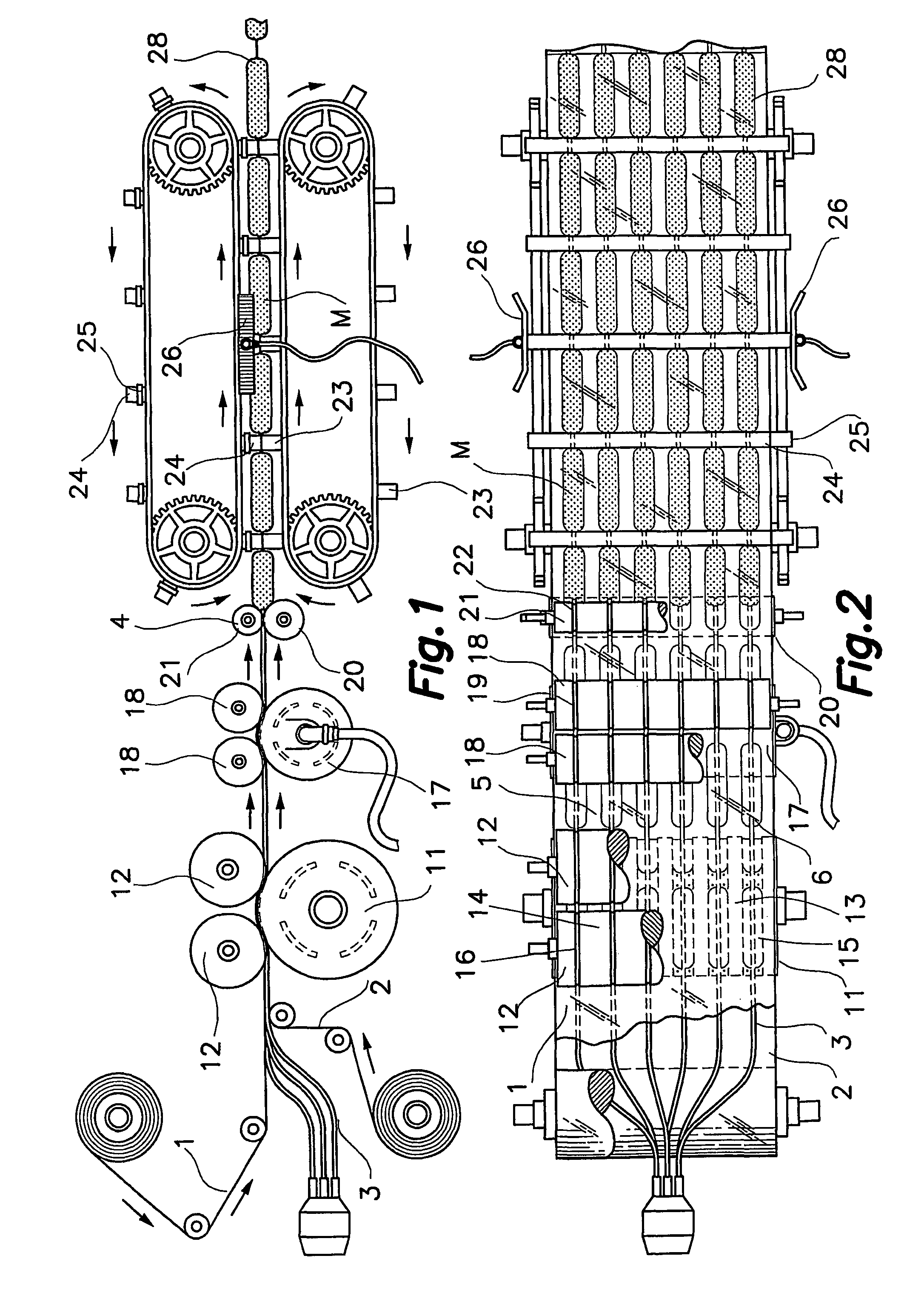

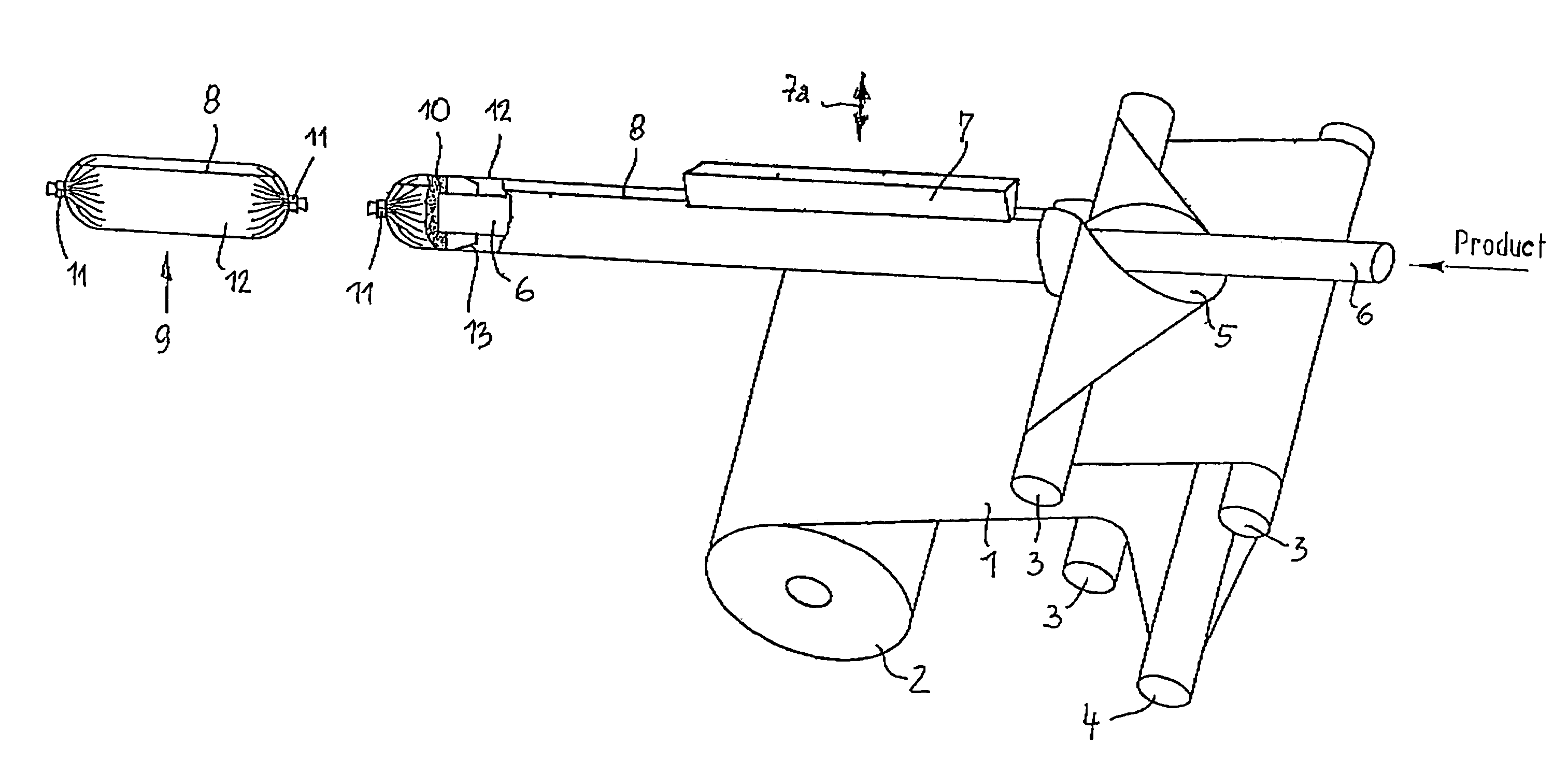

Process and machine for packing pasty, liquid or semiliquid products

InactiveUS7254929B1Accurate acquisitionSkinless sausage makingSausage casing manufactureLiquid productEngineering

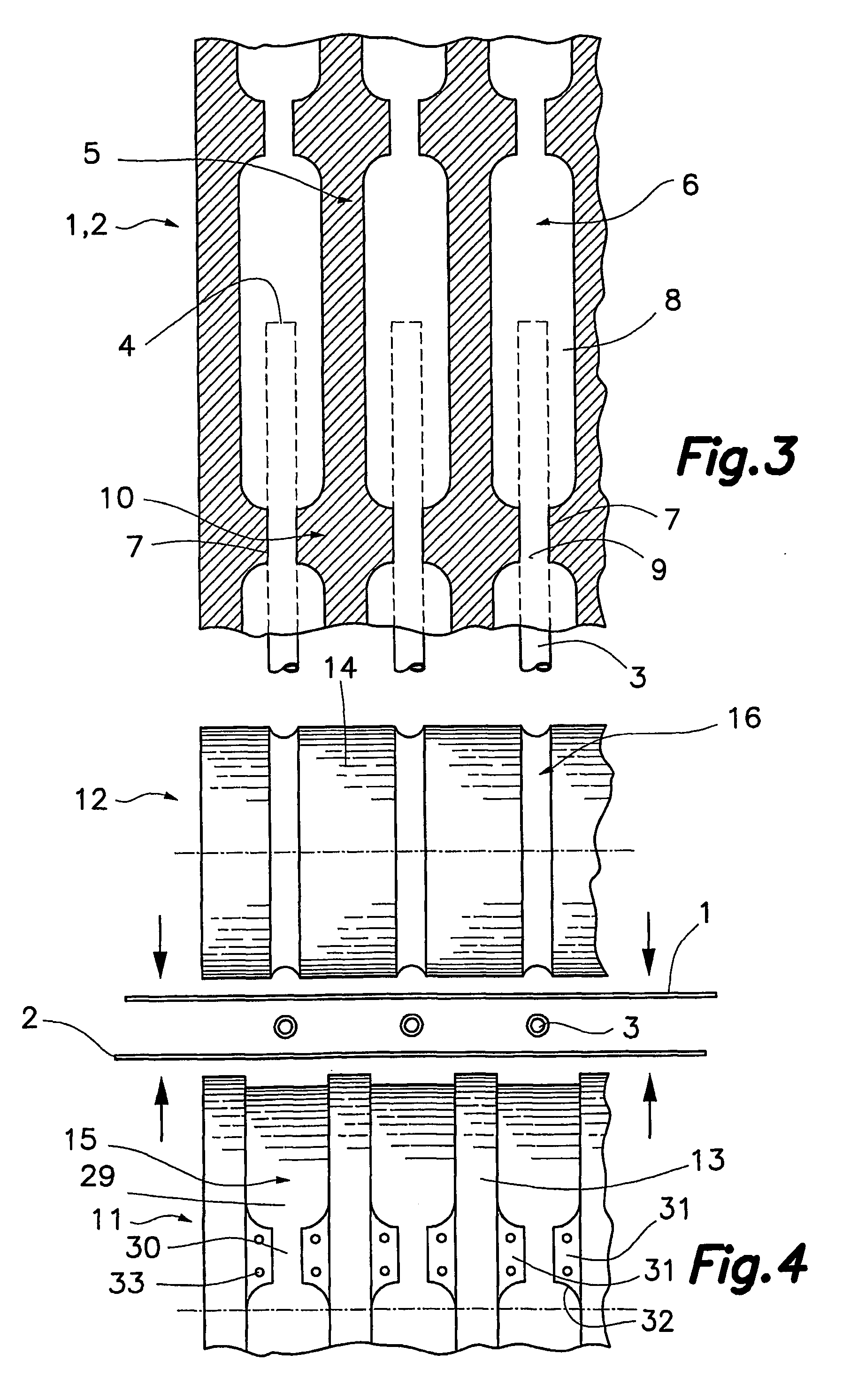

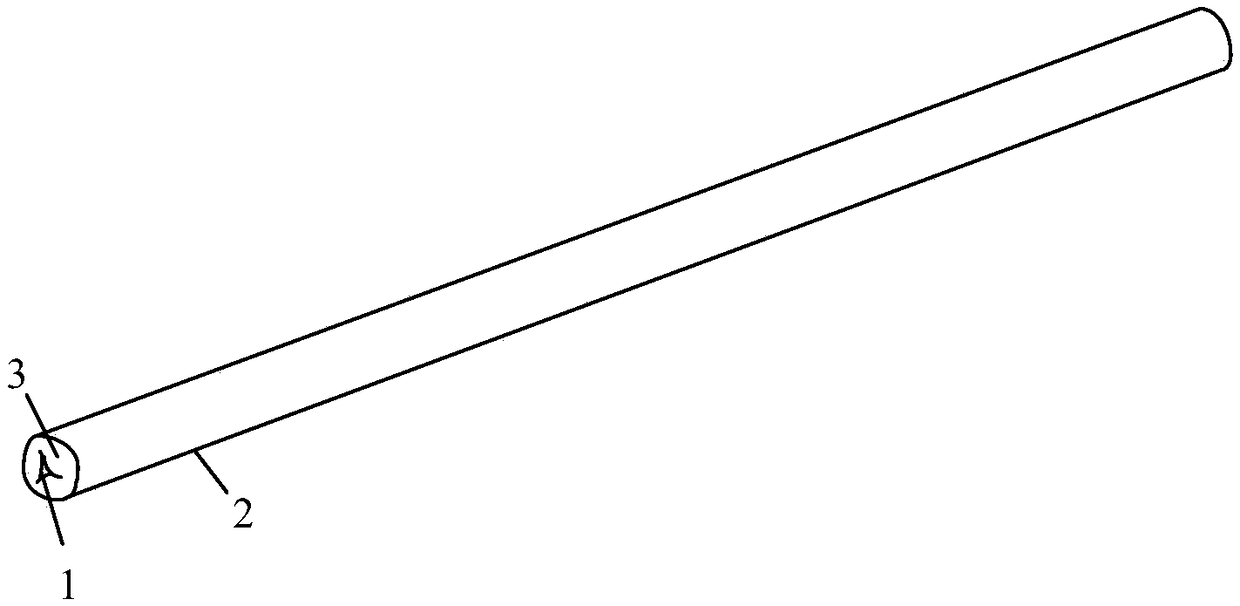

Process and machine for packing pasty, liquid or semiliquid products comprising: nonstop feeding two sheets (1, 2) sandwiching ducts (3) ending in nozzles (4) feeding pasty, liquid or semiliquid products to be packed (M); nonstop longitudinally sealing the said sheets (1, 2) through longitudinal continuous beads (5) adjacent to the said continuous sleeves (6); forming through the said longitudinal sealing narrowings arranged at intervals longitudinally regular in the said sleeves (6) making possible the passage of the said ducts (3) and defining in the sleeves (6) long, wide lengths (8) and short narrow lengths (9); nonstop injecting with nozzles (4) material (M) within the said sleeves (6) which are inflated forming units (28) of material (M) with prior pressure closing of a narrow length (9) each sleeve advanced to each nozzle (4) while the sheets (1, 2) are moving forwards, and pressure closing and transversally sealing at regular intervals the said sleeves (6) filled with material (M).

Owner:SCHUTZ ALEJANDRO JAVIER +1

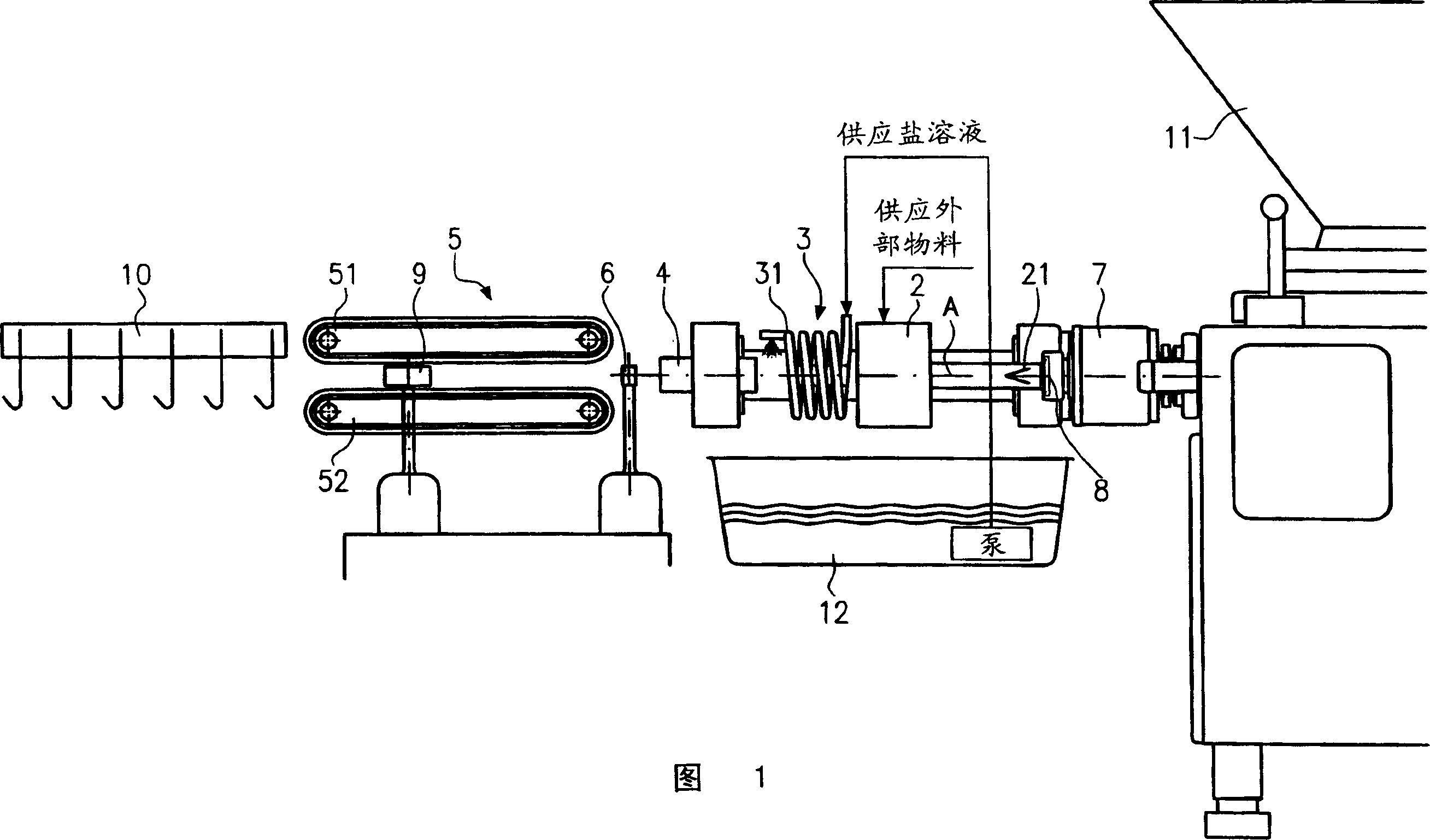

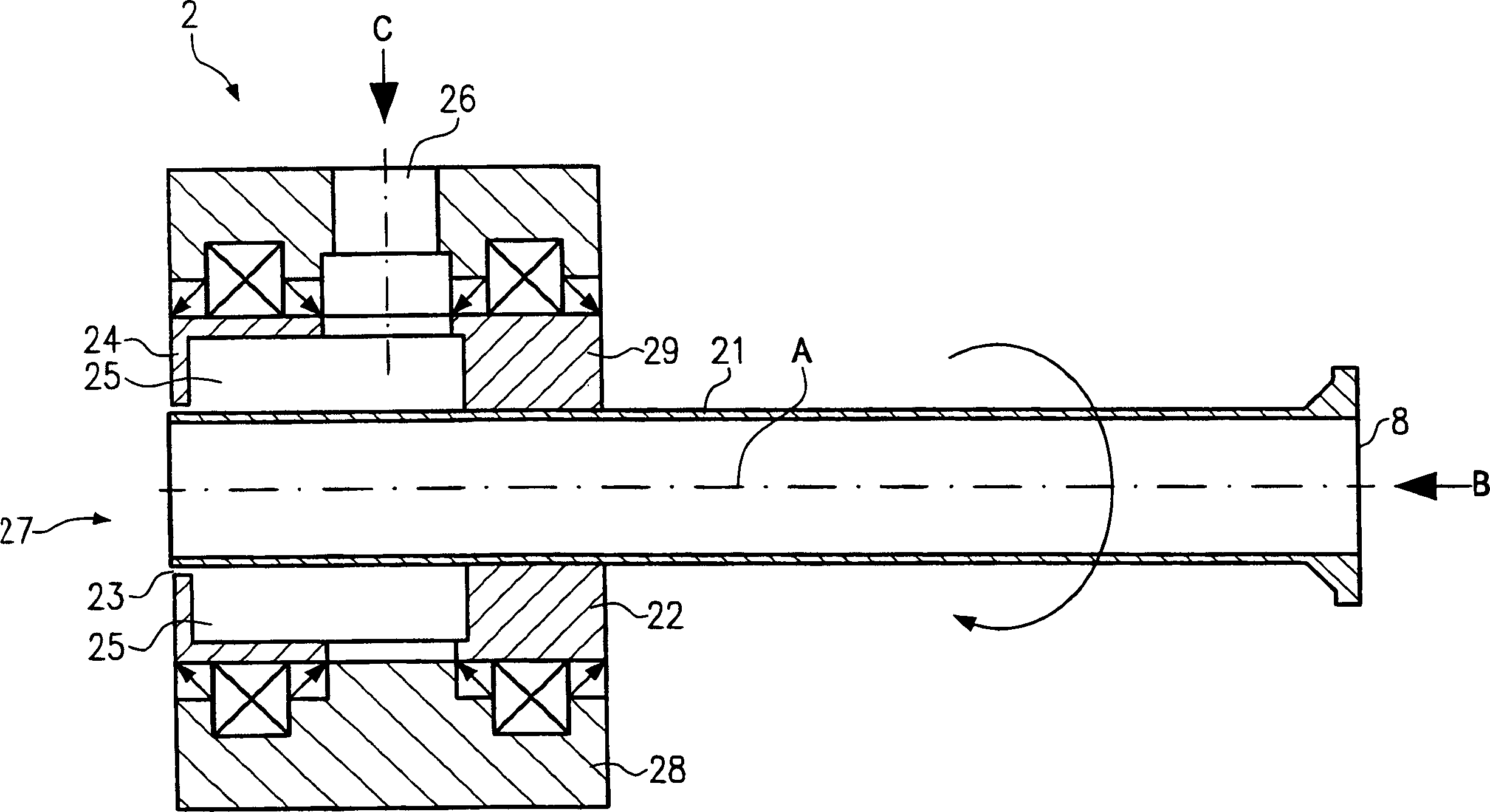

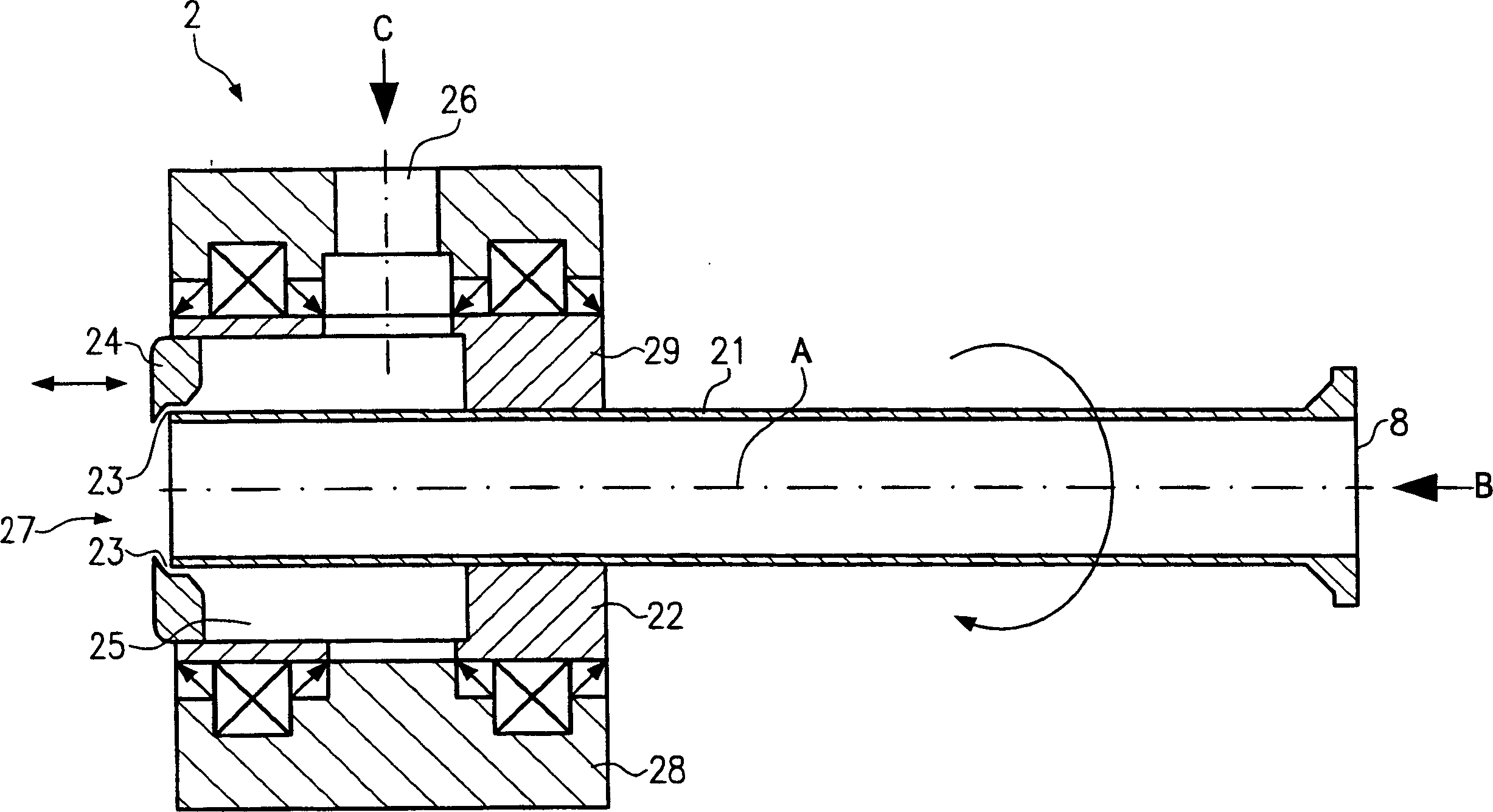

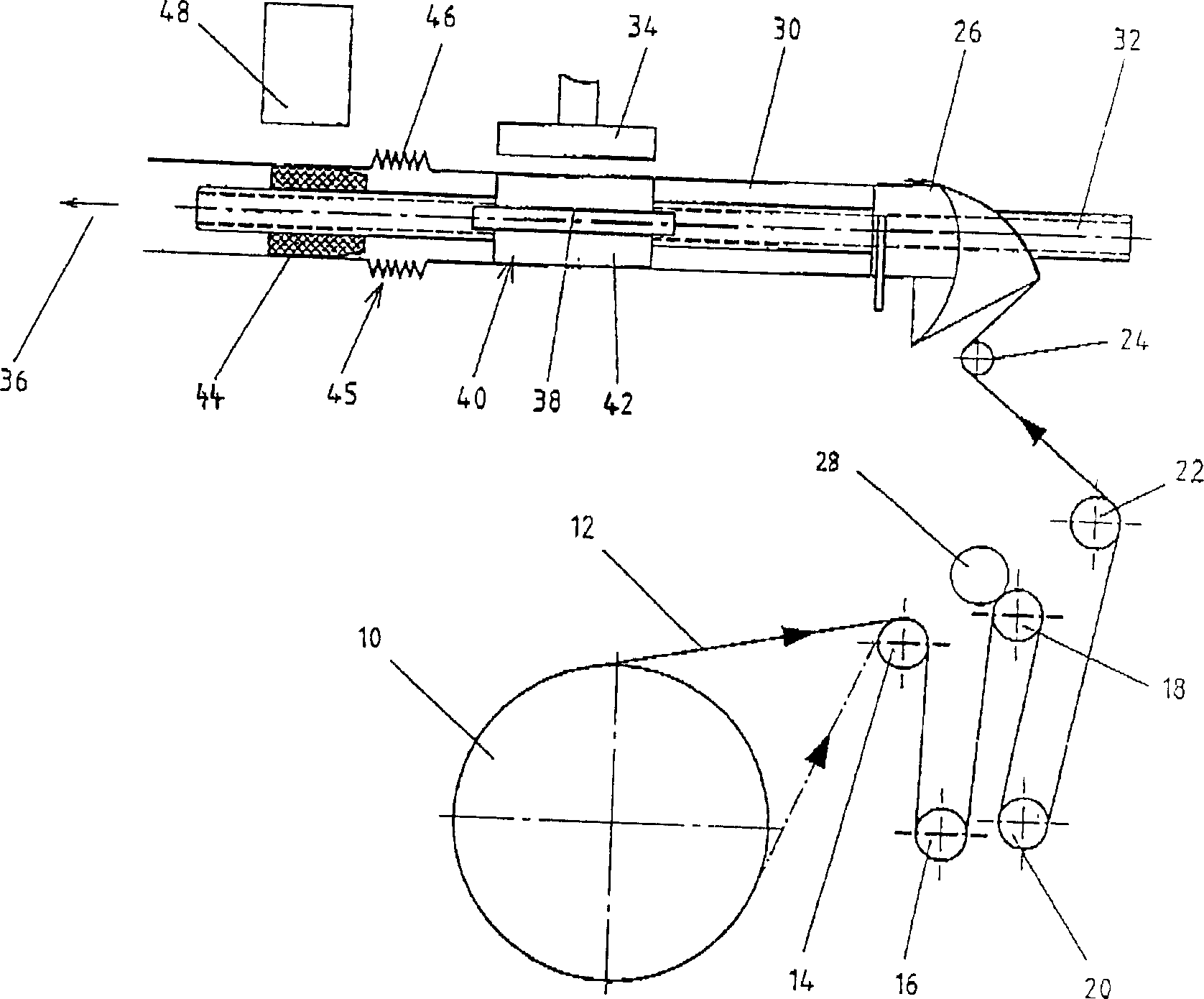

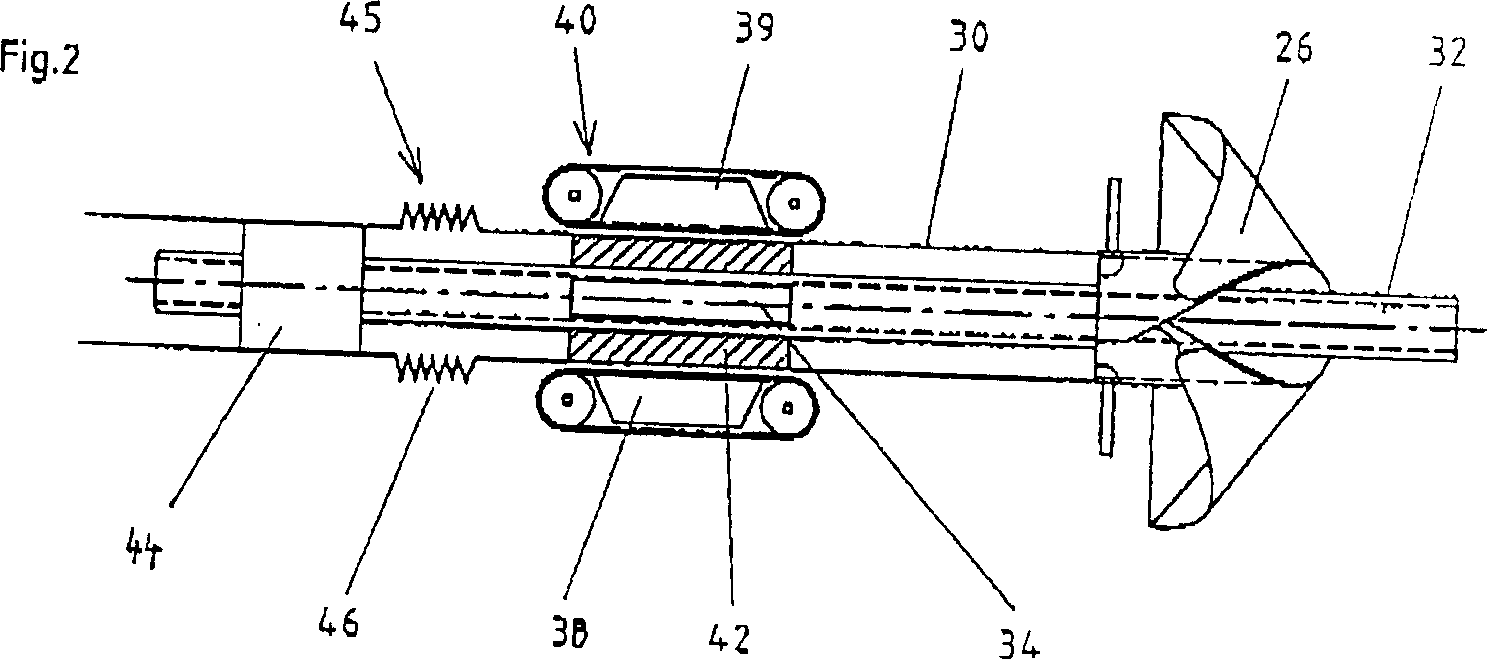

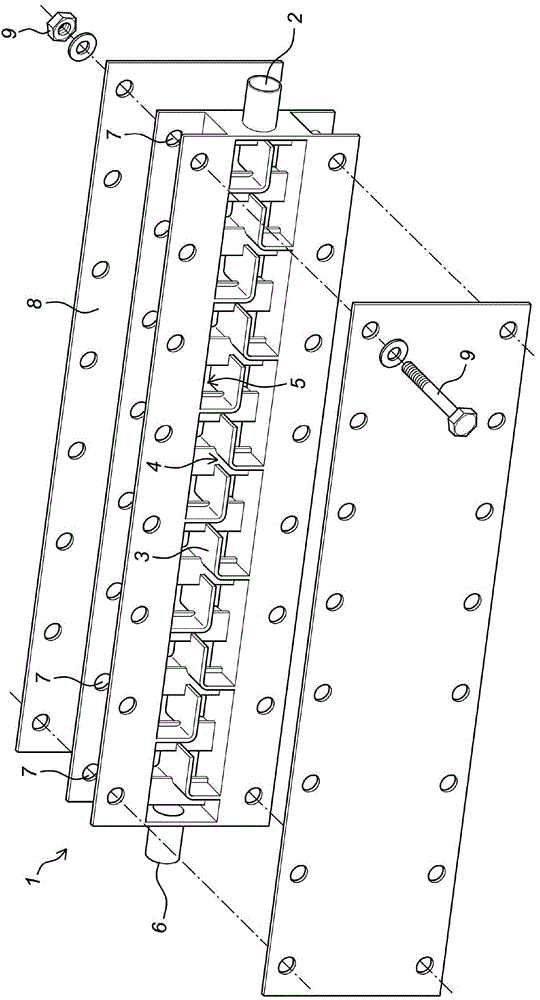

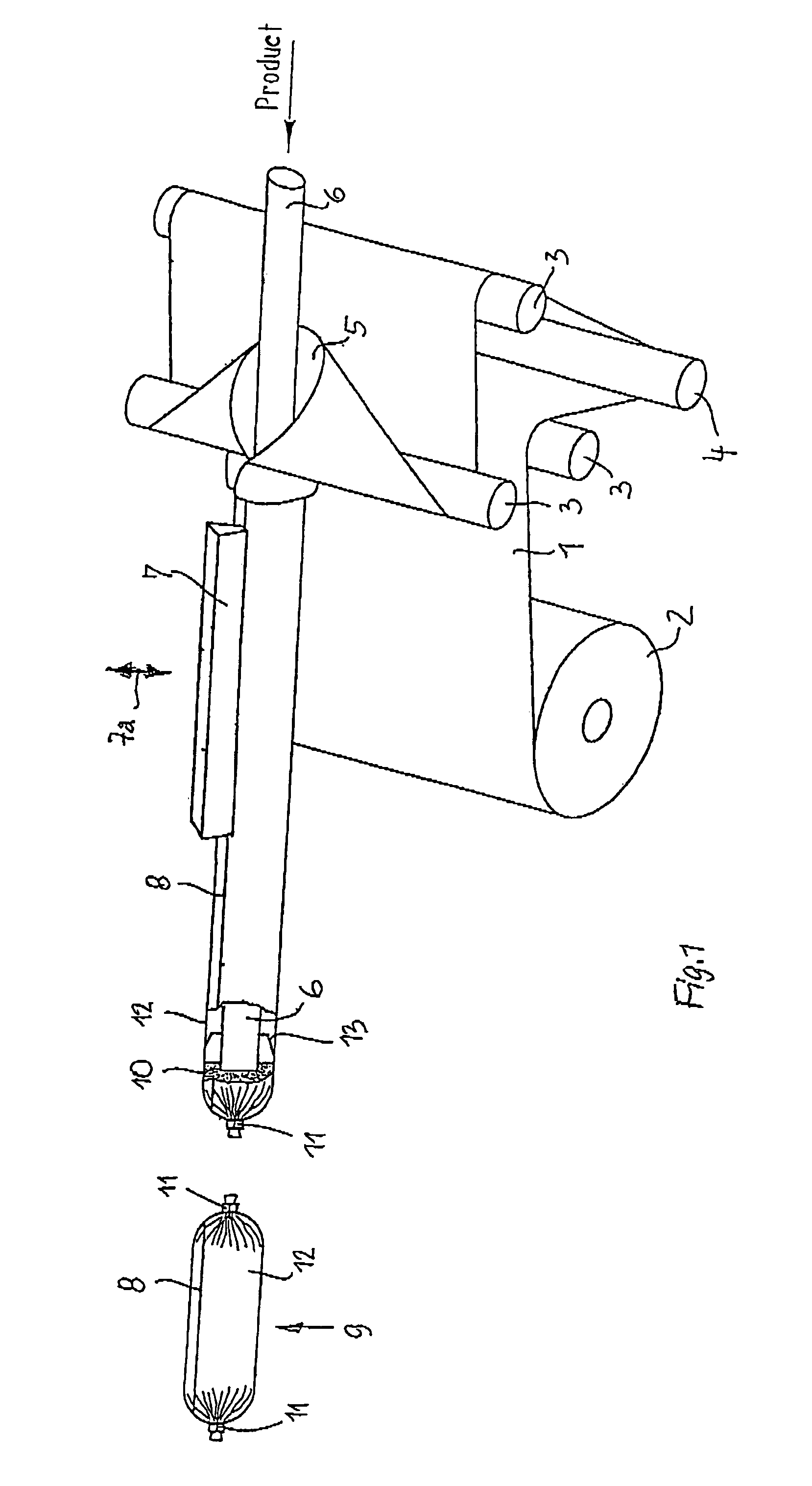

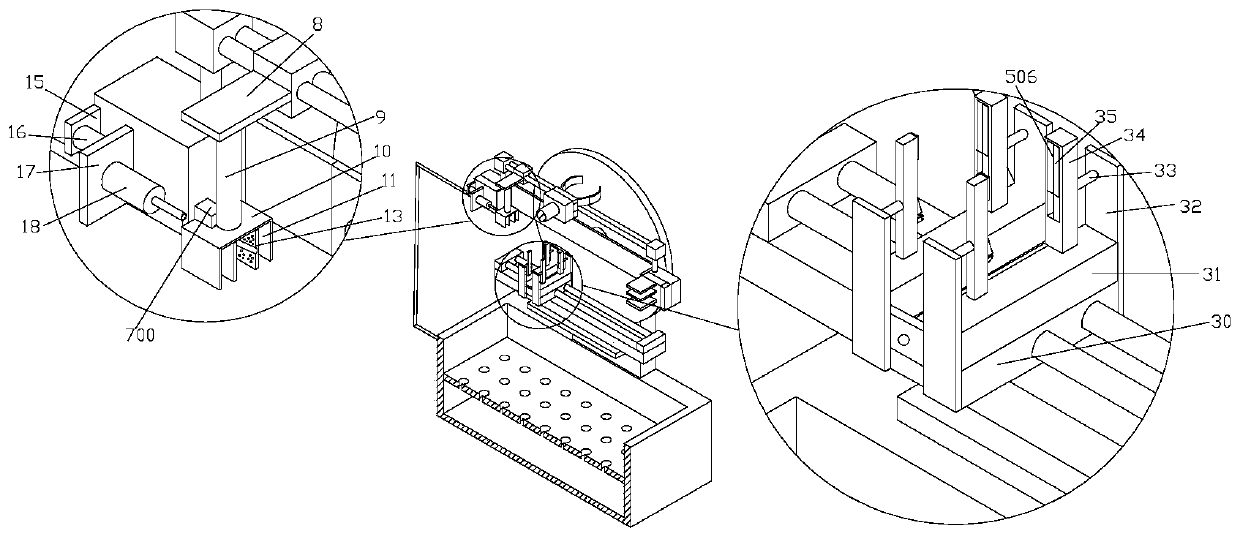

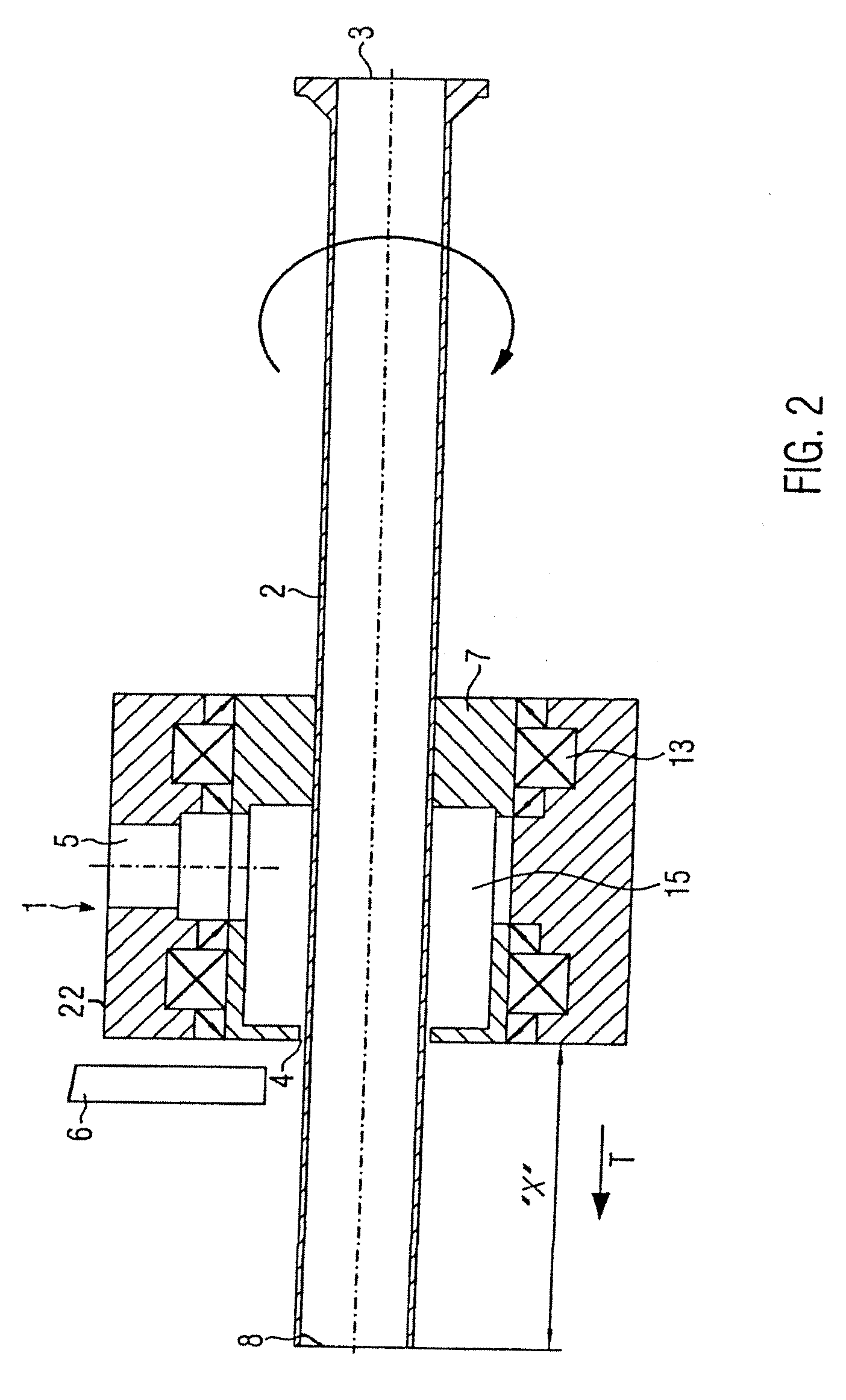

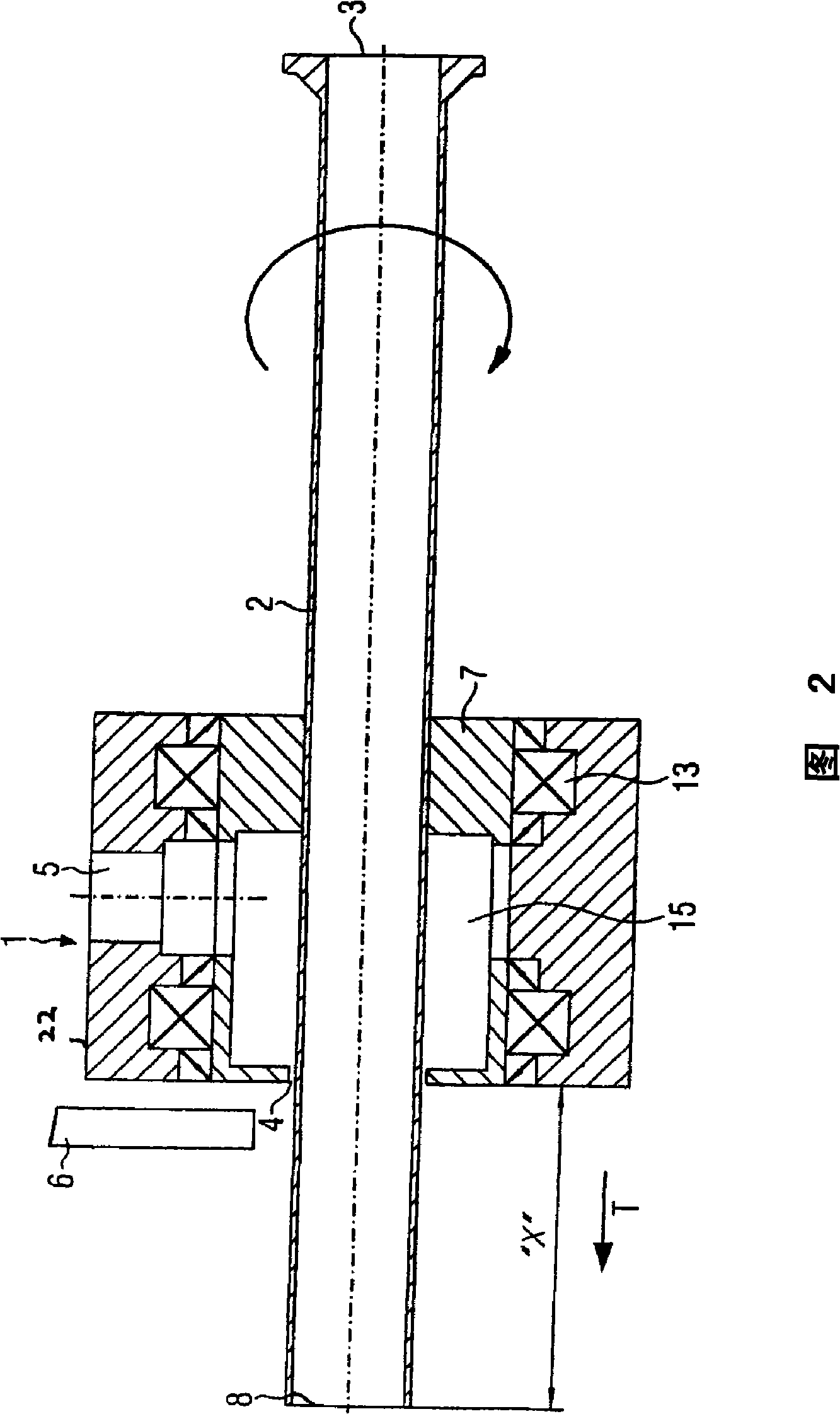

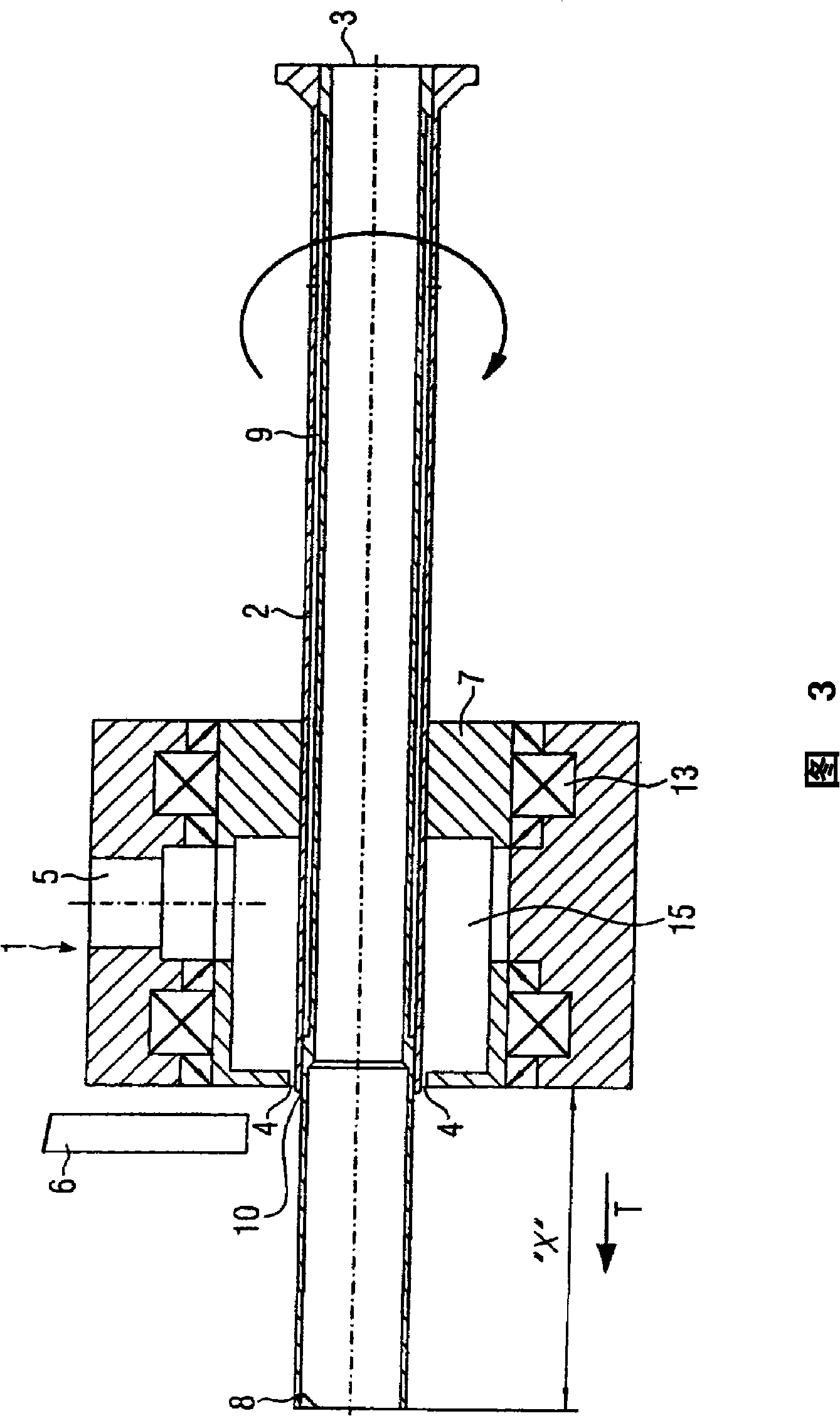

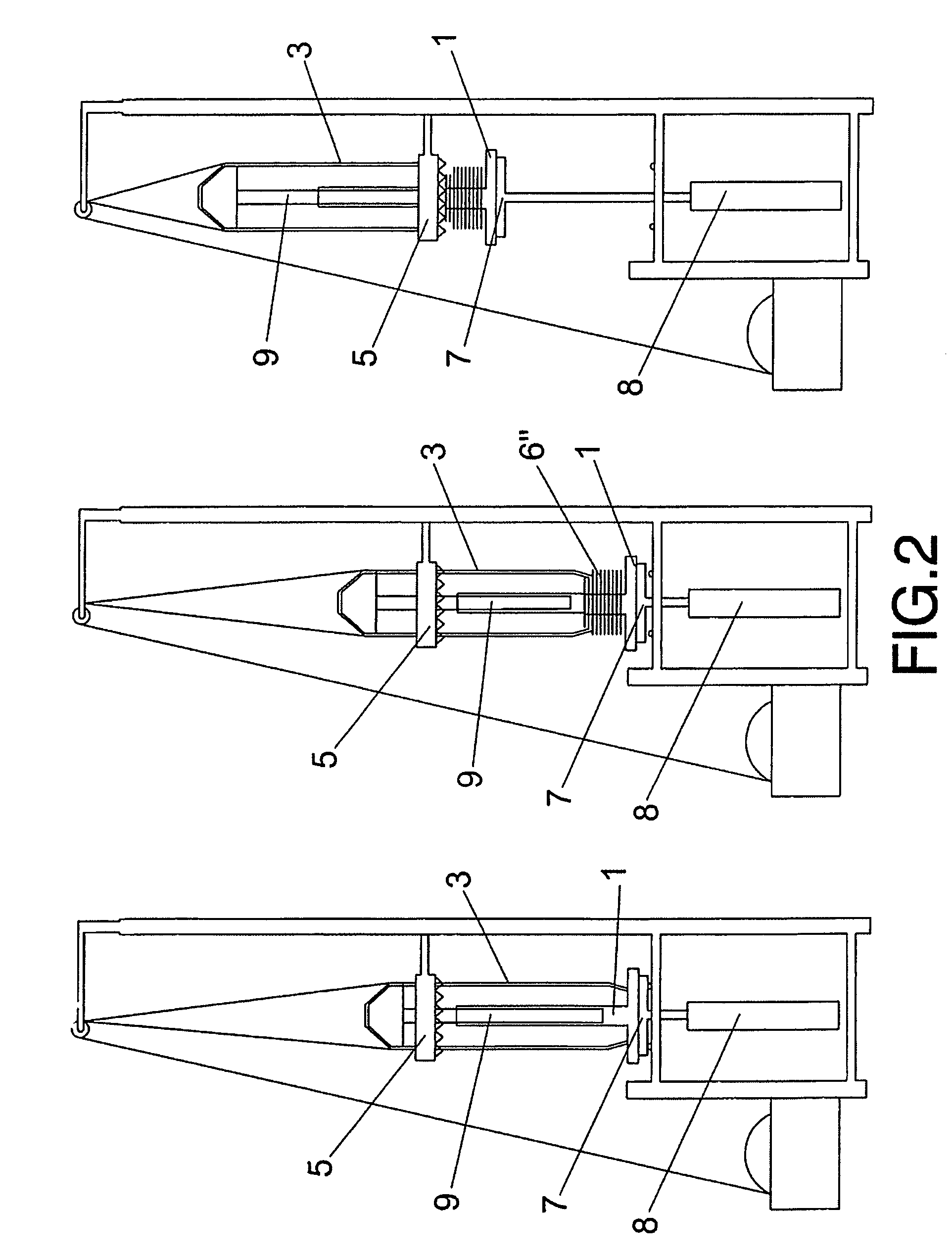

Device and method for the manufacture of a strand of a pasty mass and extrusion head for such a device and method, respectively

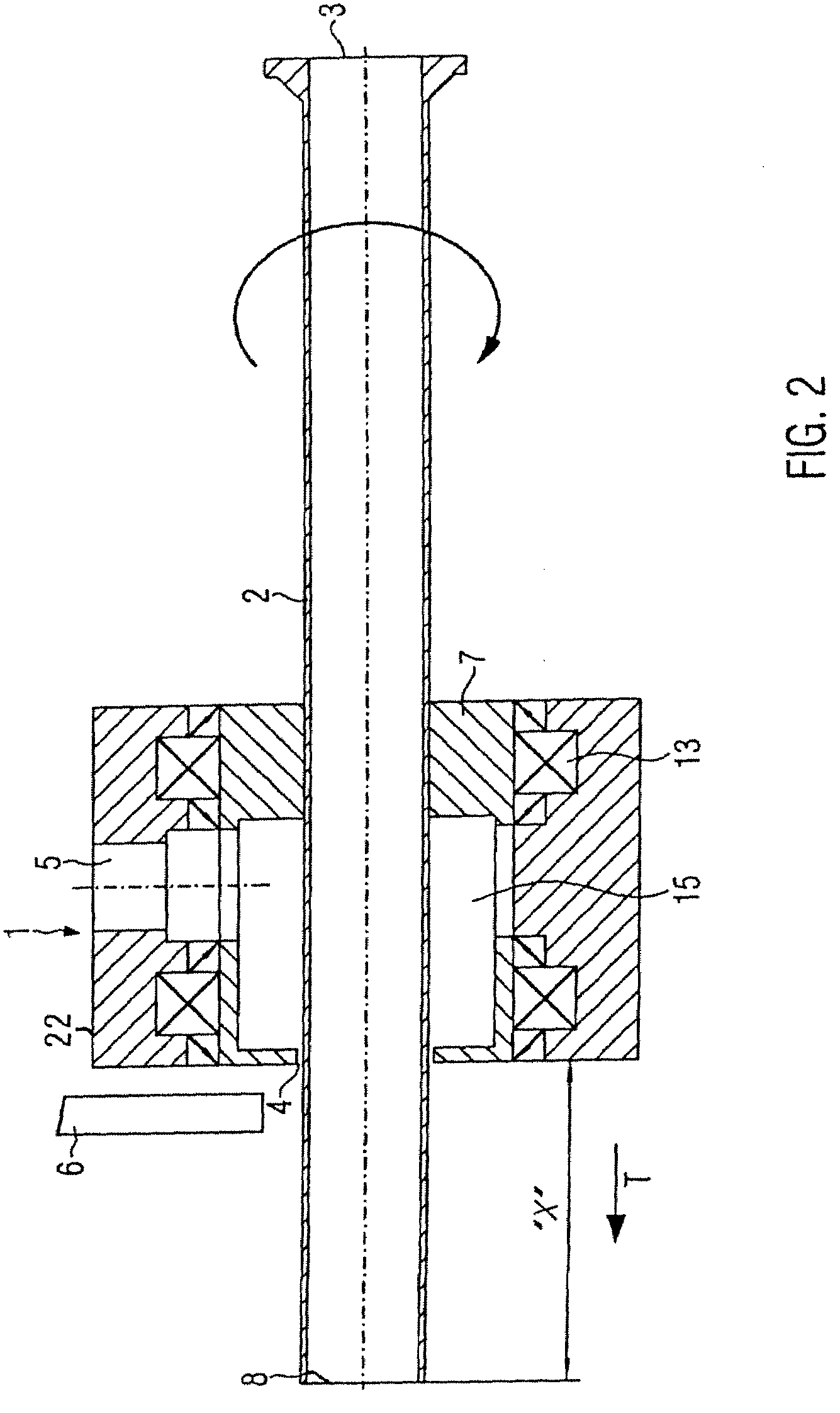

ActiveUS6988943B2Increase productivityCompact structureSausage casing manufactureSausage filling/stuffing machinesBiomedical engineeringExtrusion

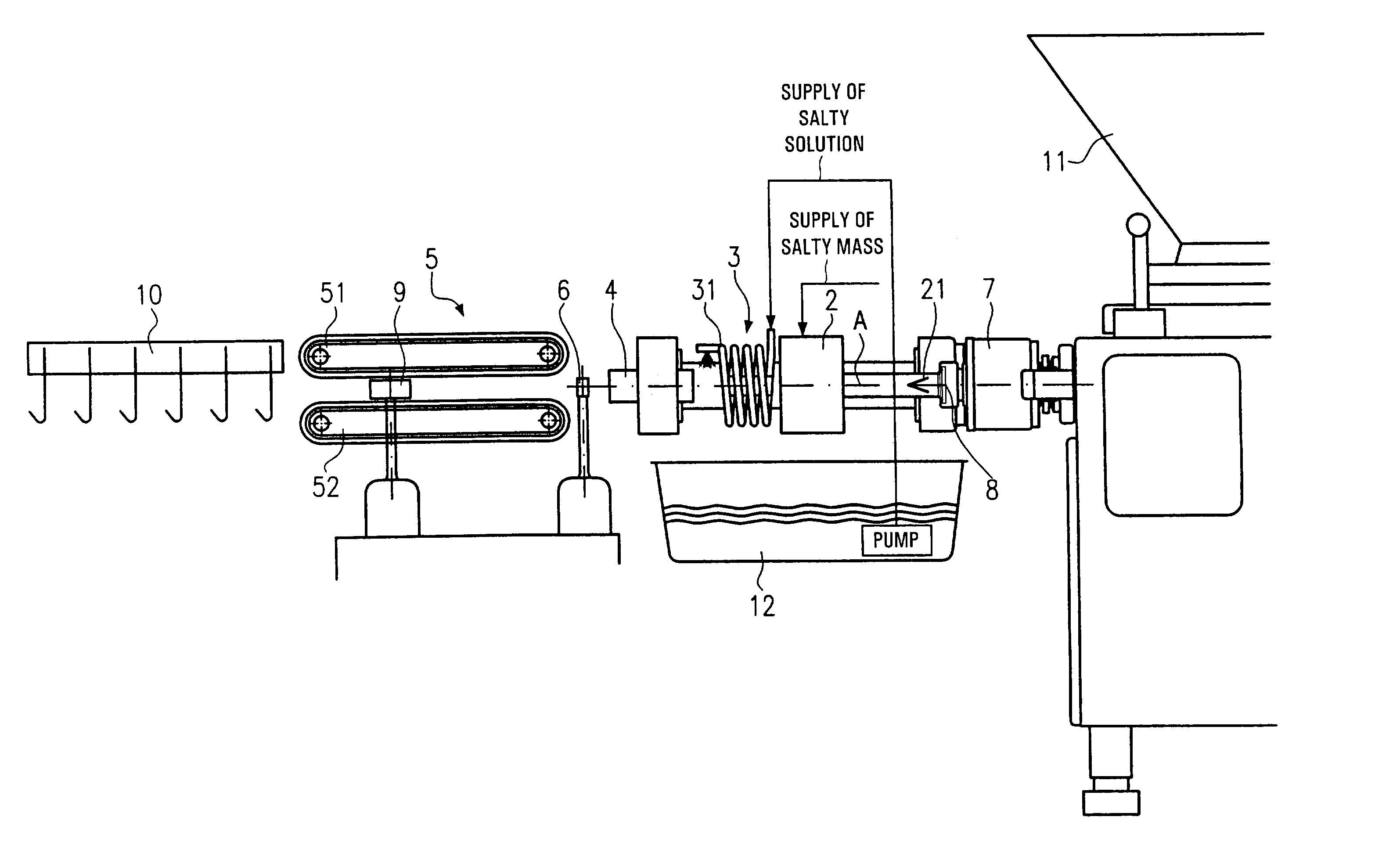

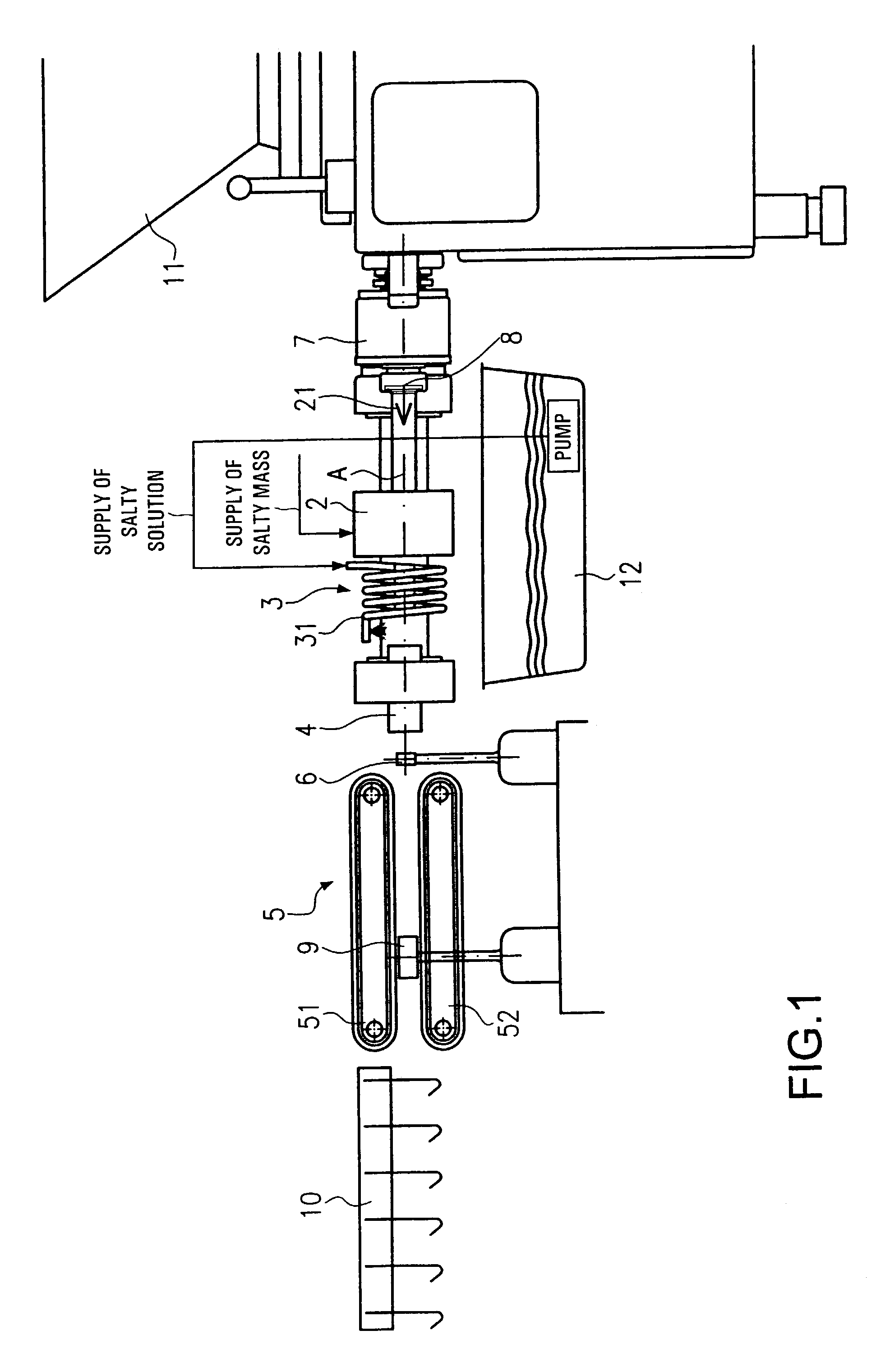

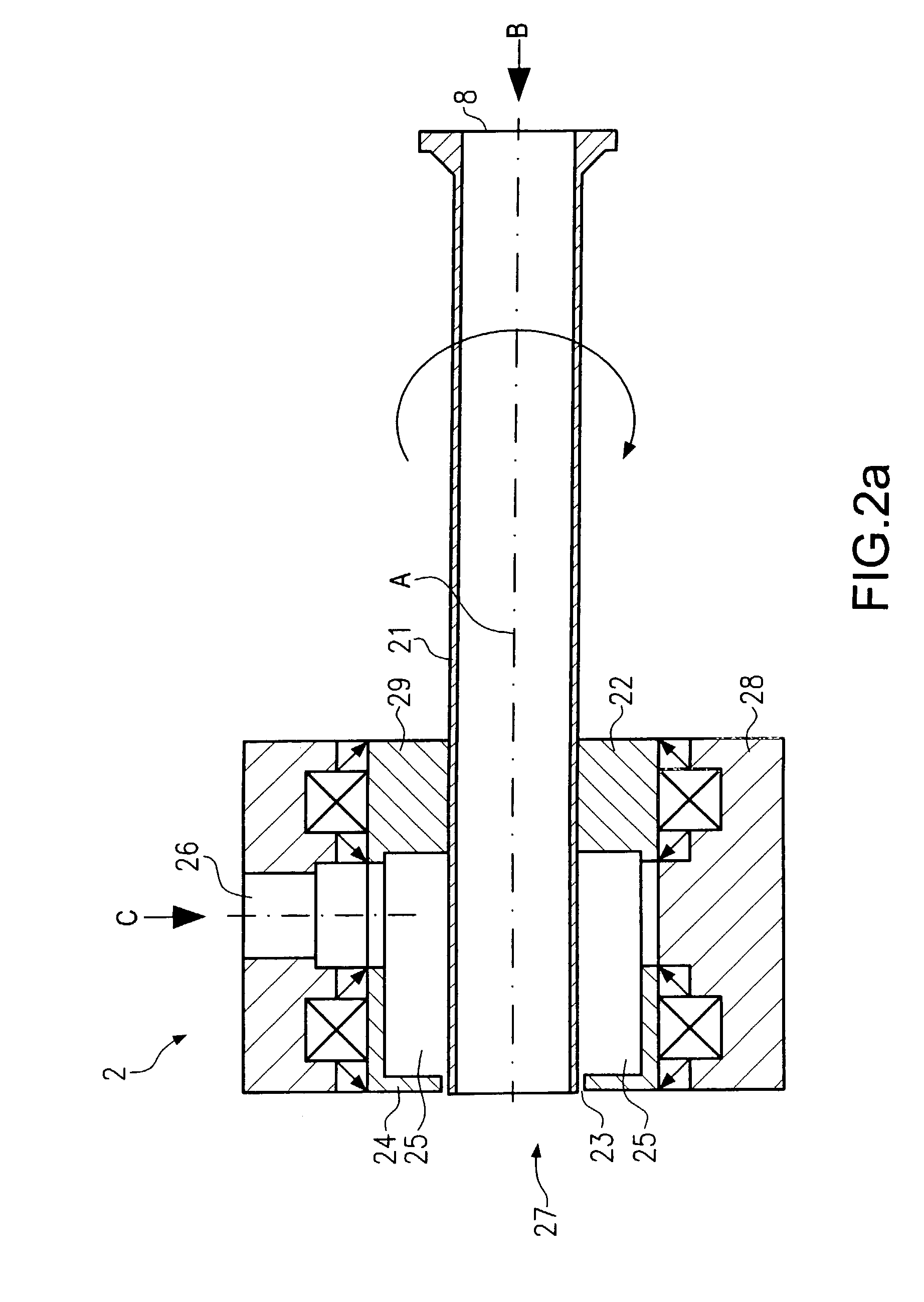

The invention relates to a device for the manufacture of a strand of a pasty mass, in particular sausage meat, with an extrusion head 2, comprising a device 27 for coextruding the pasty mass and a casing surrounding the pasty mass, a solidification device 3 for solidifying the casing, and a wring-off device 4. The invention is characterized in that a conveyor device 5 is arranged downstream of the wring-off device 4, the coextrusion device 27 and a strand guide 41 of the wring-off device 4 on the one hand and the conveyor device 5 on the other hand can be rotated relatively to one another.

Owner:ALBERT HANDTMANN MASCHFABRICK

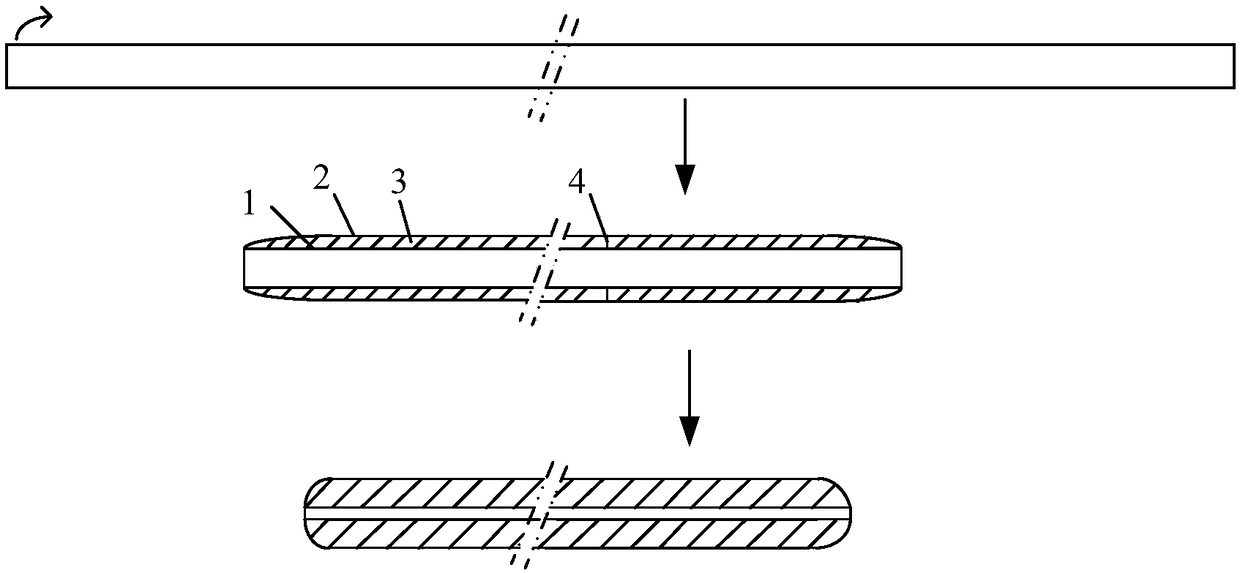

End closure for an edible collagen casing and a method for obtaining thereof

InactiveUS20180084792A1Facilitate expulsionIncrease the number ofSausage skin tying apparatusSausage casing manufactureMoisturePolymer chemistry

The invention relates to an edible tubular collagen film which has a closure at either of their ends. The closure is formed by an edible solid ring-like element which tightens the end portion of casing and seals the outlet of the same, in order to stop the filling mass upon beginning of a sausage stuffing process, whereby in such a process one can rescue the initial filled sausage for its further processing, whereafter the ring disappears. This edible closing element is characterized by being of an edible, and thermoplastic composition, which is preferably based on collagen or gelatine. The solid composition has a low melting temperature and becomes adhesive at fluid state onto the surface of a collagen film which contains a certain level of moisture. The strong cohesiveness of the material of said composition in the fluid state as well as the so narrow difference between its melting temperature and the temperature of solidification, makes that a welding of said material to be set very quickly. The closure can be made before or after the shirring of the collagen casing and the present invention provides also a process to perform such a closure by heat welding the closing element on the casing material.

Owner:VISCOFAN TECH SUZHOU

Apparaus and method for producing paste material and extrusion head separately used for the apparatus and method

InactiveCN1468540AHigh normal sclerosisIncrease distanceSausage skin tying apparatusSausage casing manufactureMechanical engineeringExtrusion

Owner:ALBERT HANDTMANN MASCHFABRICK

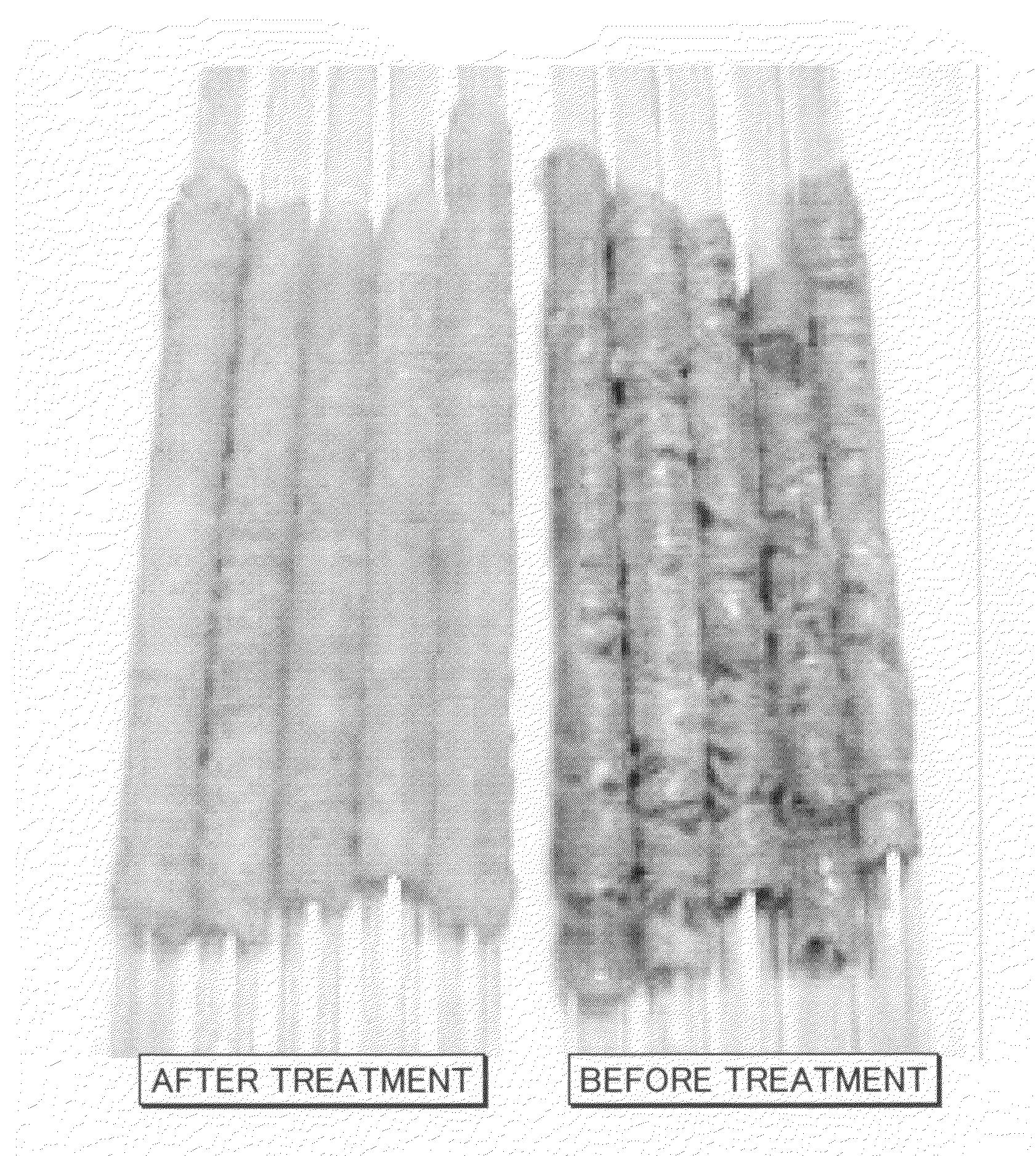

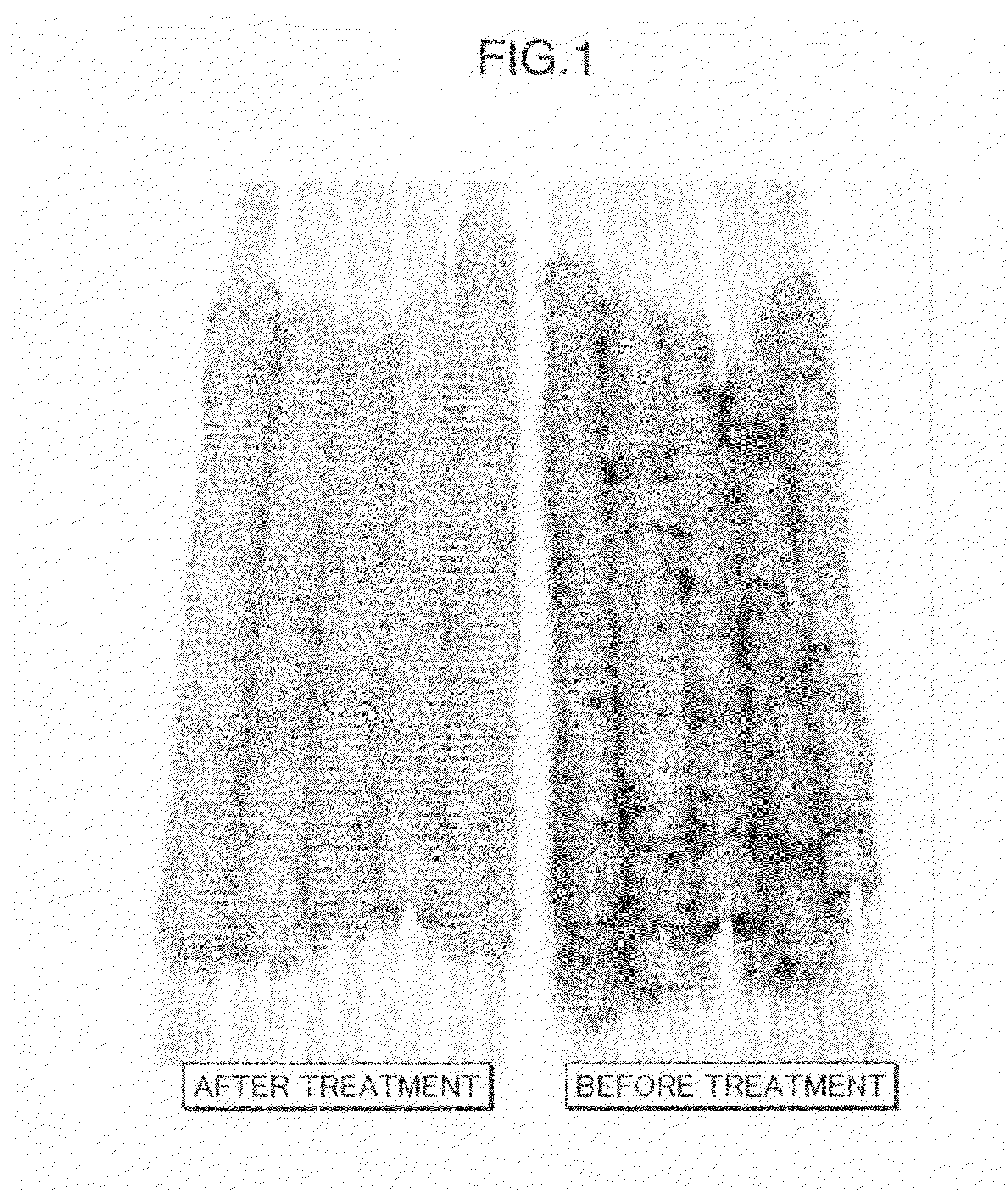

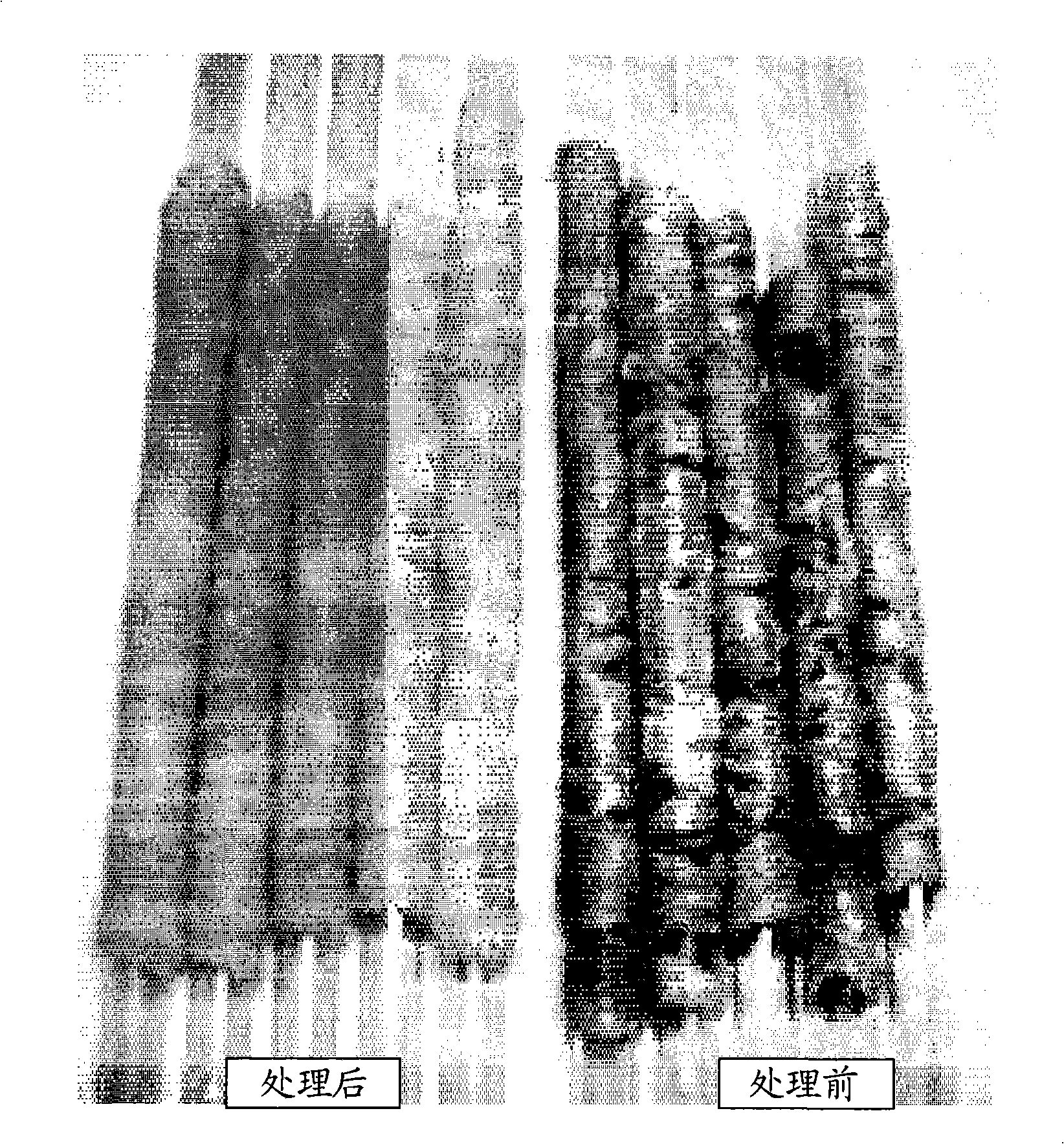

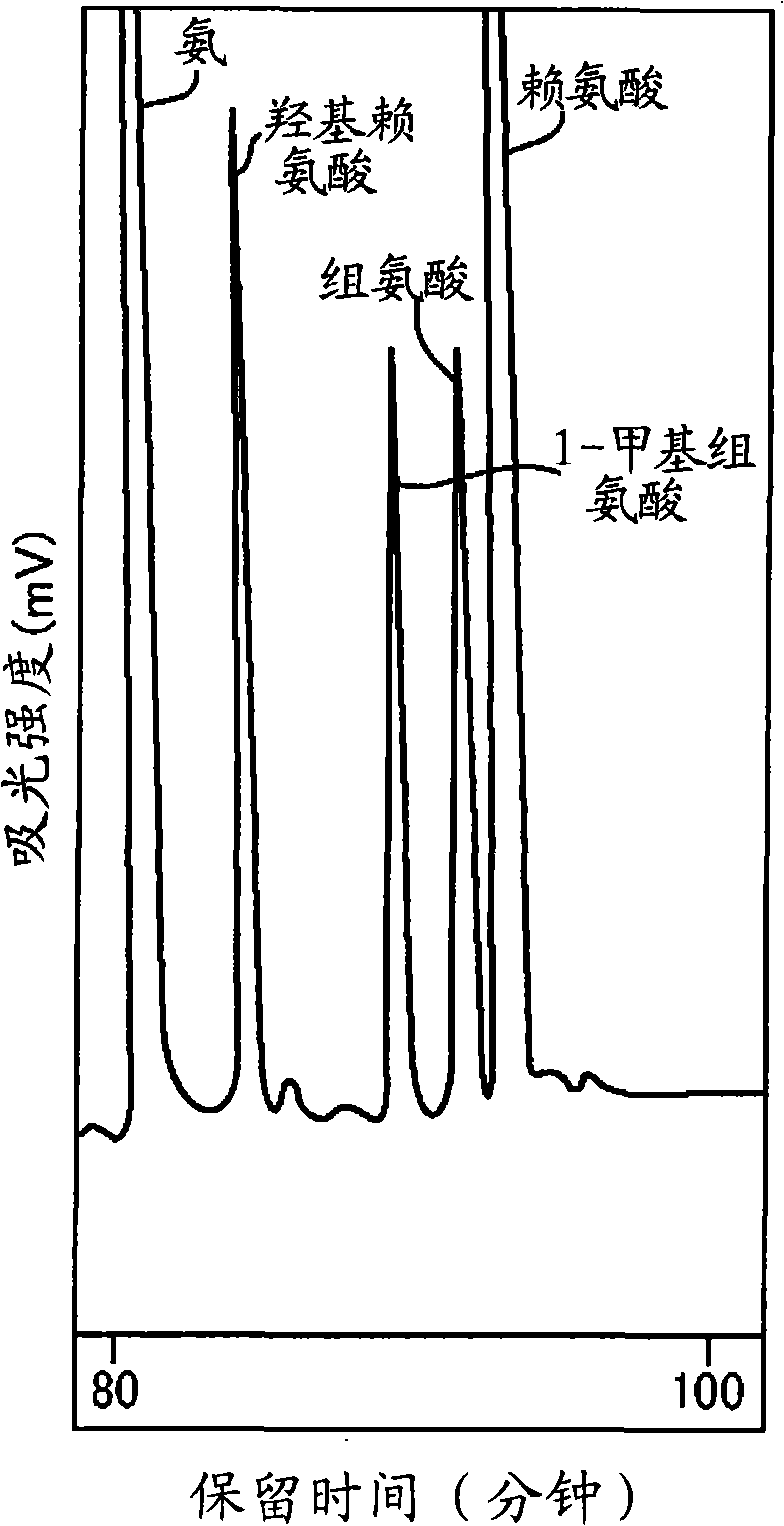

Method for Producing Soft Natural Intestine Casing, Soft Natural Intestine Casing, and Processed Meat Product

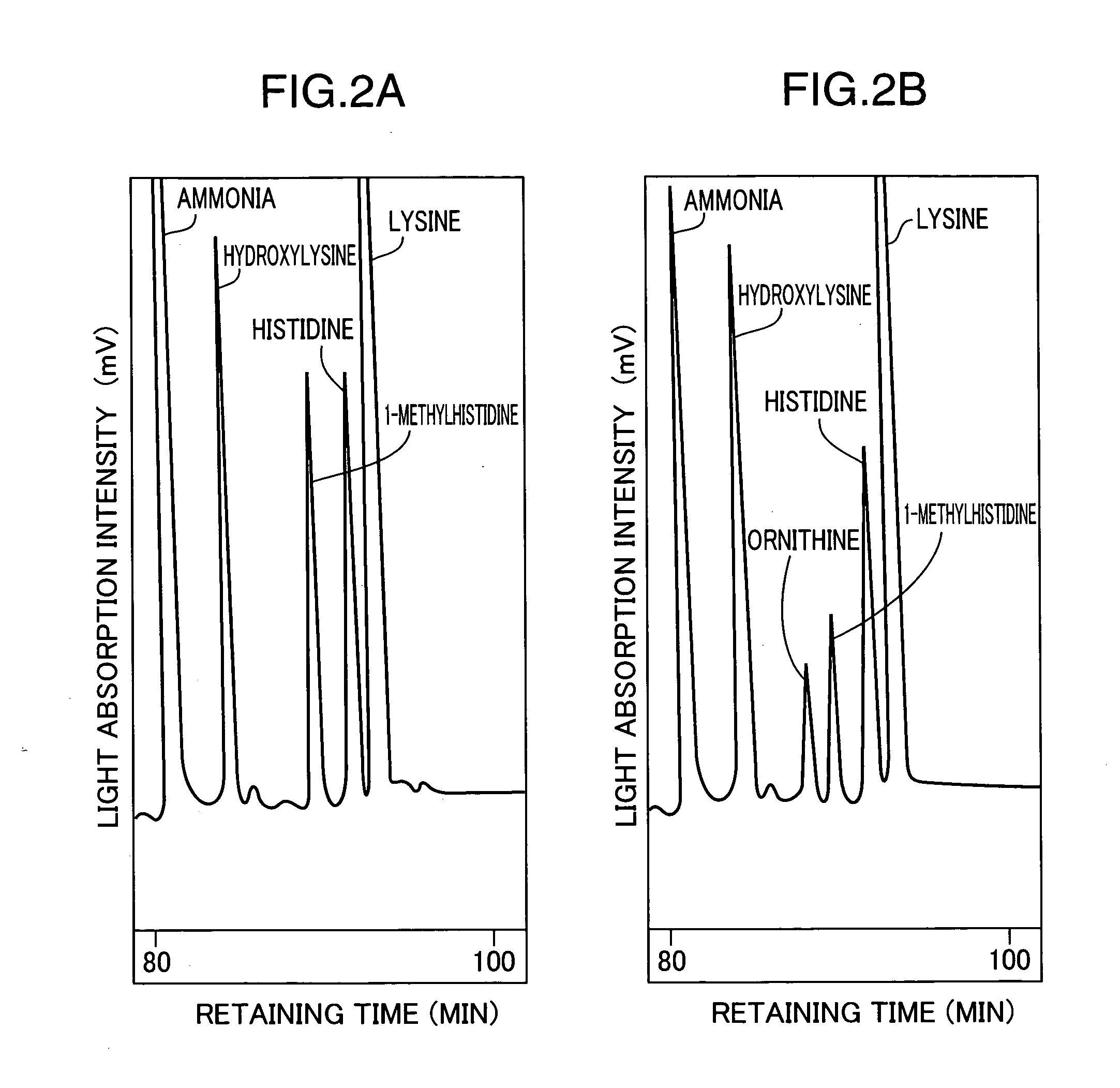

InactiveUS20090269449A1Soften a hard natural intestine casingImprove textureContainers for flexible articlesMilk preservationFlavorAqueous solution

In a method for a producing soft natural intestine casing, a natural intestine casing is treated in an alkaline aqueous solution at a temperature from 3 to 40° C. and pH from 11 to 13. By the method for producing a soft natural intestine casing, a soft natural intestine casing with a superior texture can be easily obtained. The natural intestine casing does not adversely affect the savor or flavor of sausages themselves.

Owner:TAGUCHI YASUKI +2

Equipment for producing filmed pipe by filmed strip

The invention concerns an apparatus for producing film tube which can be filled with liquid, viscous or granular filling material, from a film strip. The apparatus comprises a filling tube which can be connected to a filling machine, a transformation device surrounding the filling tube for transforming the film strip into a film tube, a sealing device arranged downstream of the transformation device in the filling expulsion direction for sealing longitudinal edges of the film strip, and a measuring device for determining a supply amount of film tube delivered by the sealing device. The measuring device includes a first sensor which detects the length of the film tube delivered by the sealing device to the film tube supply and a second sensor which detects the length of the film tube drawn off the film tube supply.

Owner:POLY CLIP SYST

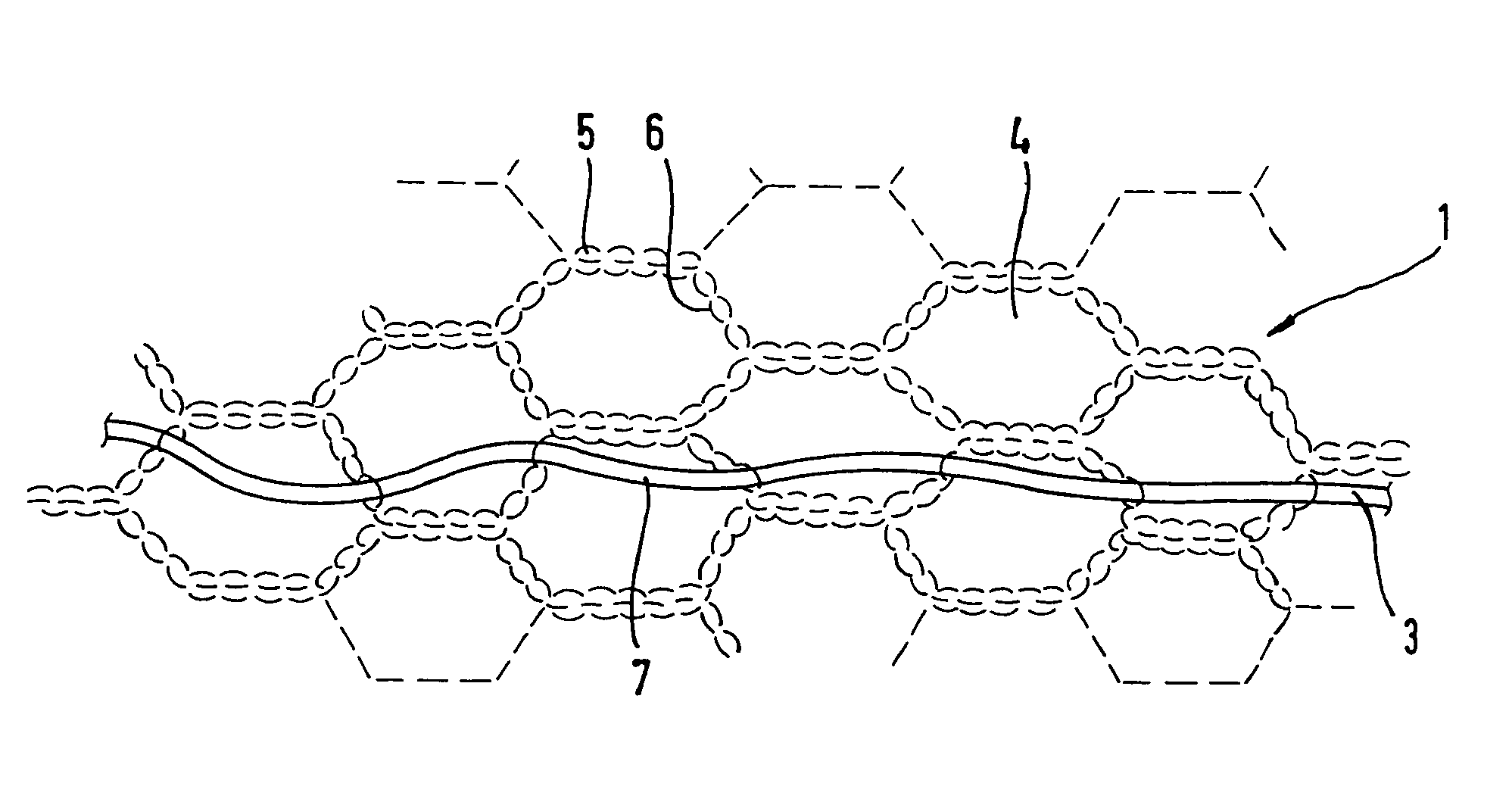

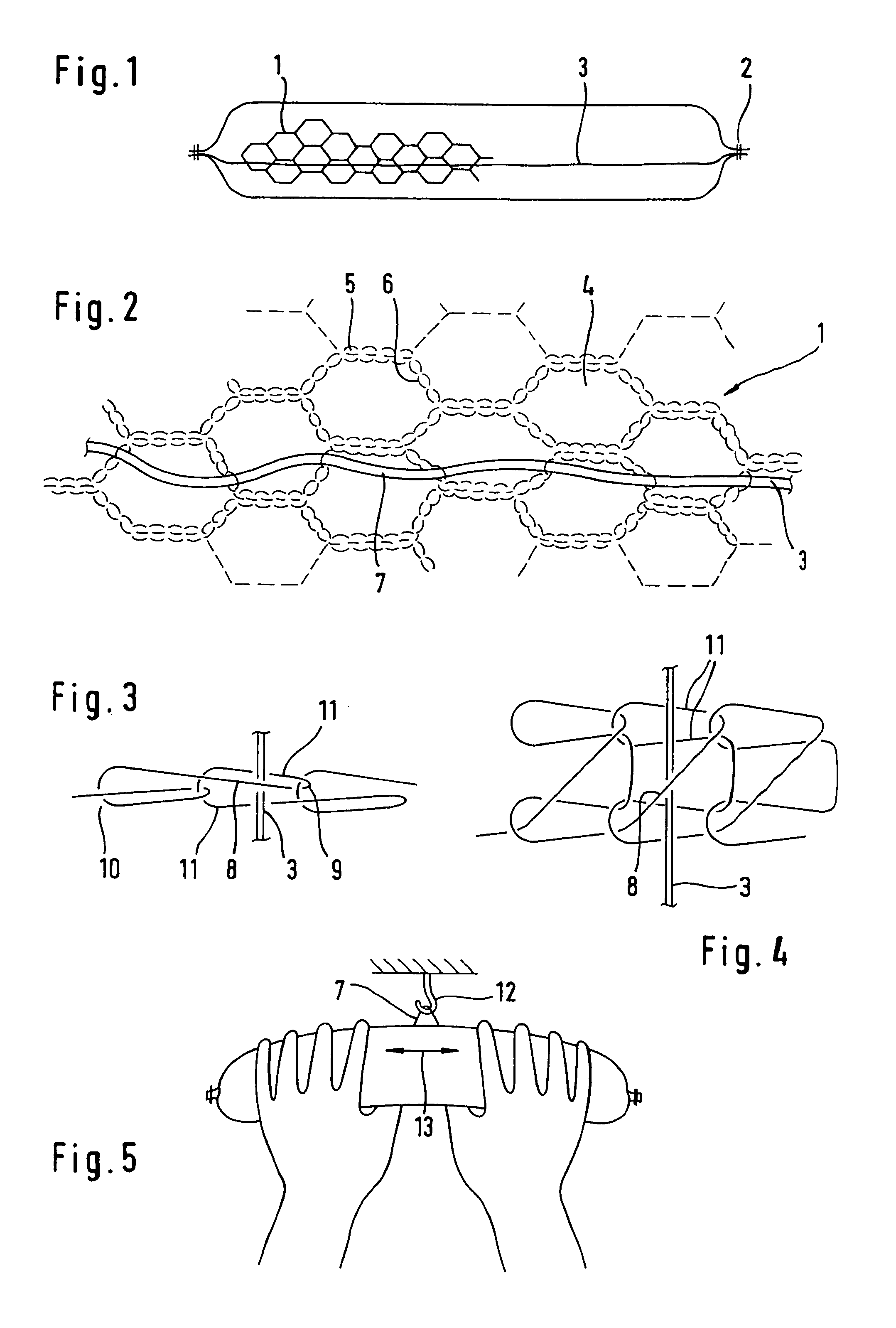

Wrapping net for sausages and method for production thereof

Owner:HUCKFELDT & THORLICHEN

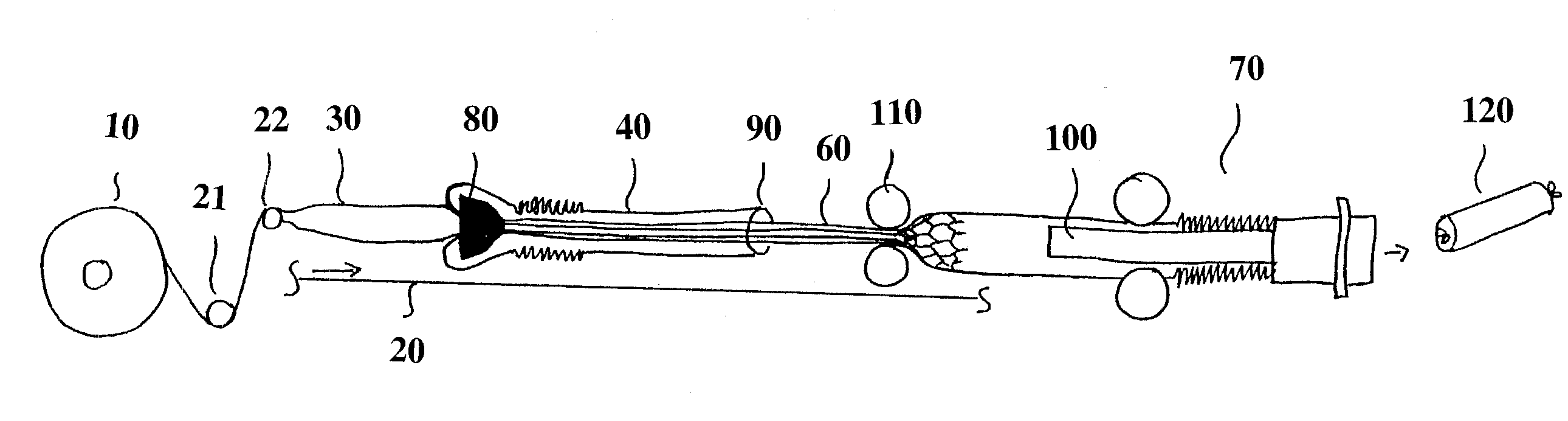

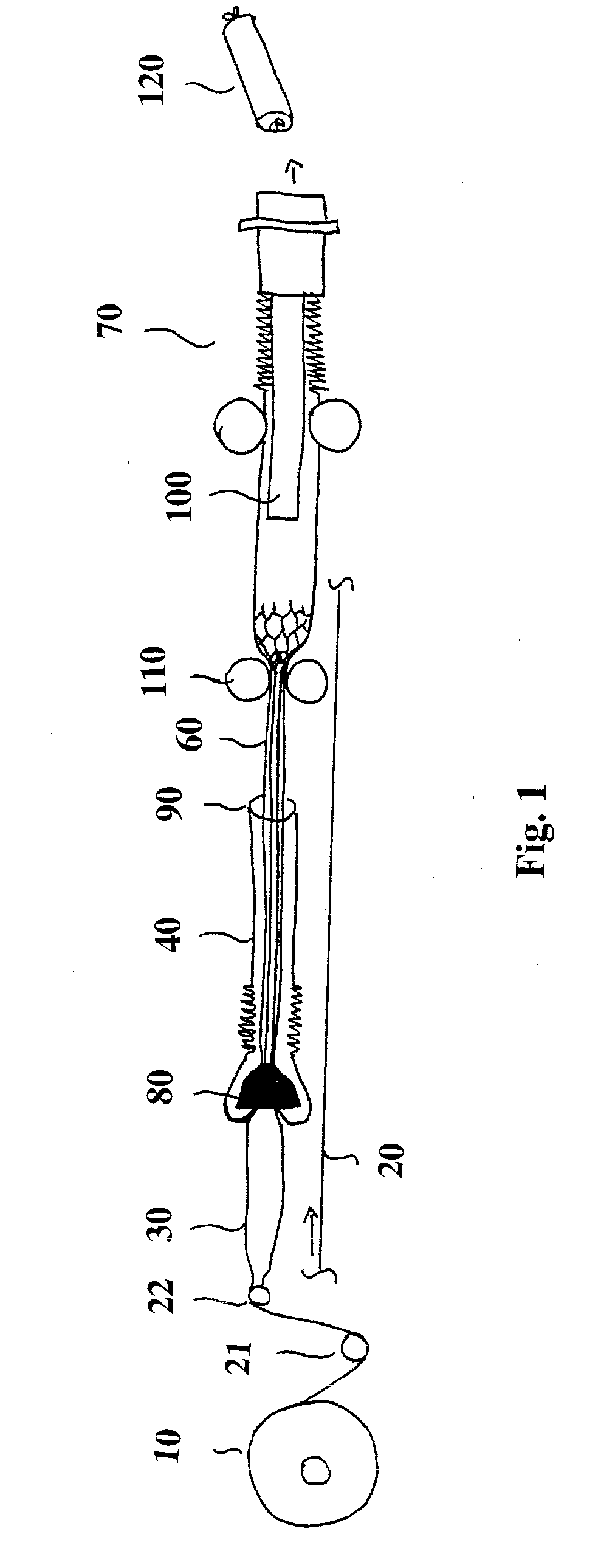

Method for Producing a Netted Casing

InactiveUS20090075575A1Avoid bendingShorten the lengthSausage casing manufactureSausage casing shirringEngineeringMechanical engineering

The invention relates to a method for producing a shirred food casing covered by a net, and a method for combining a net with a surface of a carrier casing, said method comprising steps wherein air or an inert gas is blown into the carrier casing, the carrier casing inflated / pressurized to be round is pulled in the direction of the tubular net towards a pleating head attached to one end of the tubular net, said net being attached at the open end thereof to a clamp centralized with a shirring mandrel, the carrier casing being thus folded into the tubular net while pulling the net inside out over itself, followed by pulling the carrier casing through the pleating head to the shirring machine where the pressure of air or an inert gas blown from inside of the shirring mandrel forces the areas of the carrier casing between the meshes of the net to form bulges, and finally the net / carrier casing combination is shirred by the shirring machine. The invention is further directed to a shirred product produced with the method.

Owner:VISKOTEEPAK BELGIUM NV

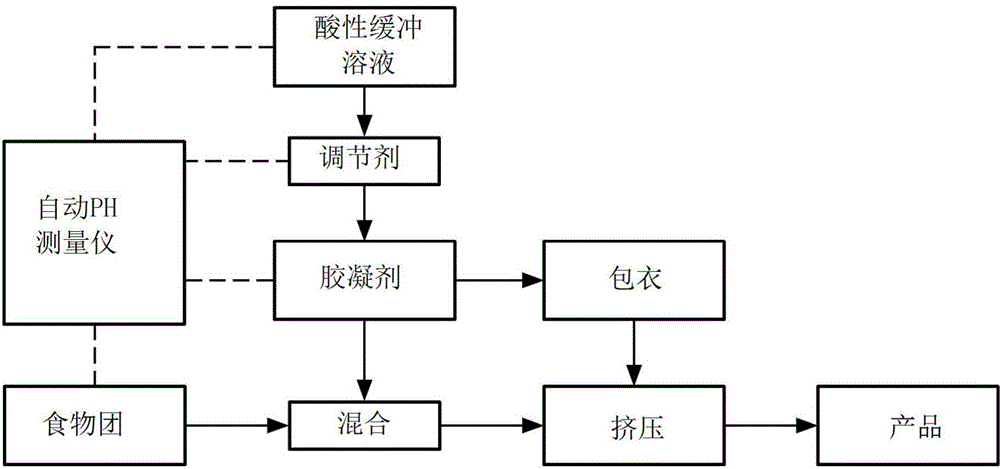

Stabilized meat products

The present invention relates to a method for preparing food products by means of processing food particles with a gelling agent, comprising the processing steps of: a) providing a food particles; b) providing a viscous gelling agent; c) treating the viscous gelling agent with an acidic buffer solution; and d) bringing at least a part of the food particles in contact with the viscous gelling agent. The present invention further relates to a device for performing this method, to the obtained food product and the use of an acidic buffer solution for stabilizing food products.

Owner:MAREL TOWNSEND FURTHER PROCESSING +1

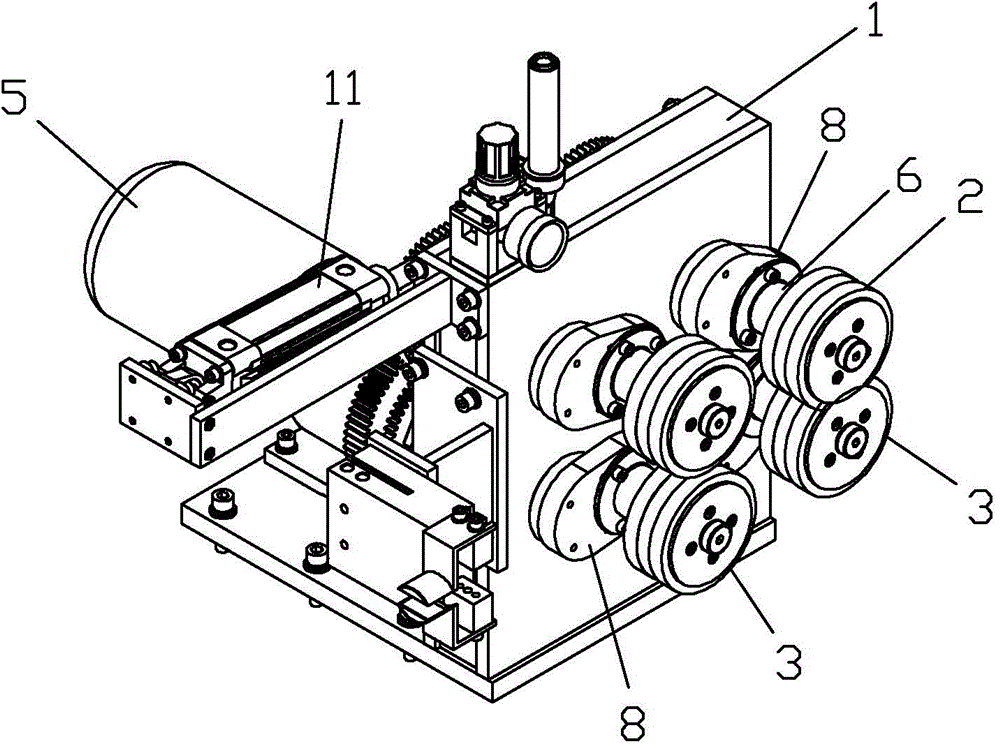

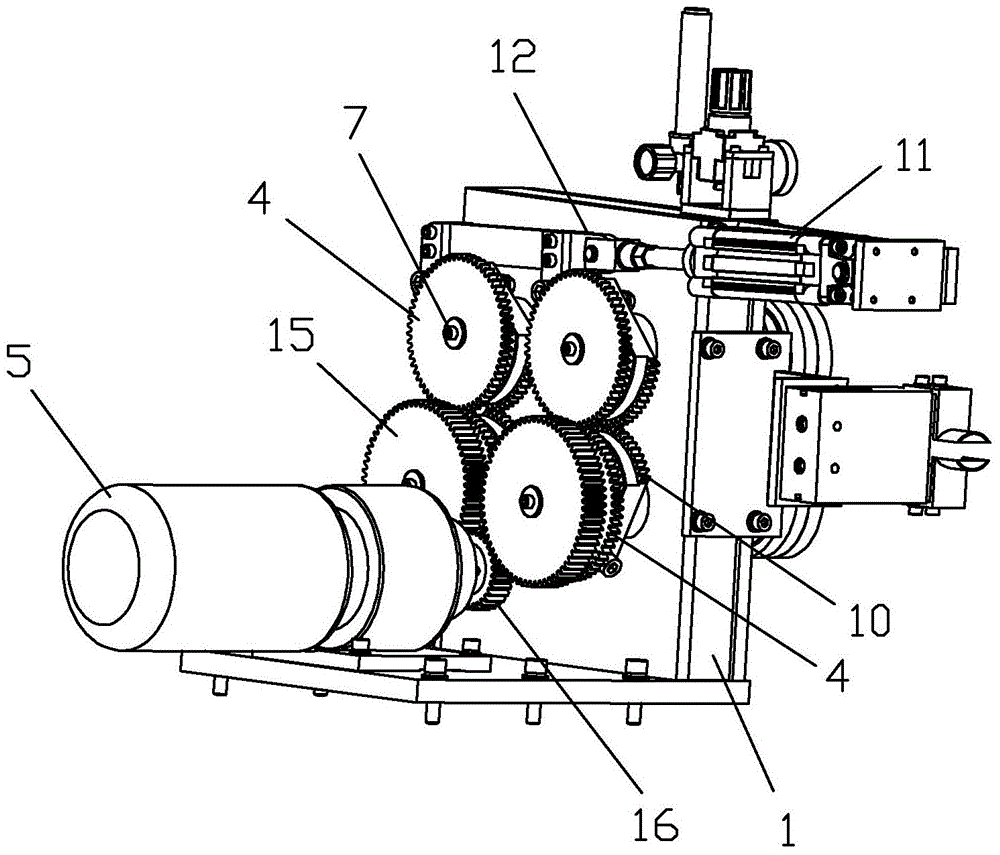

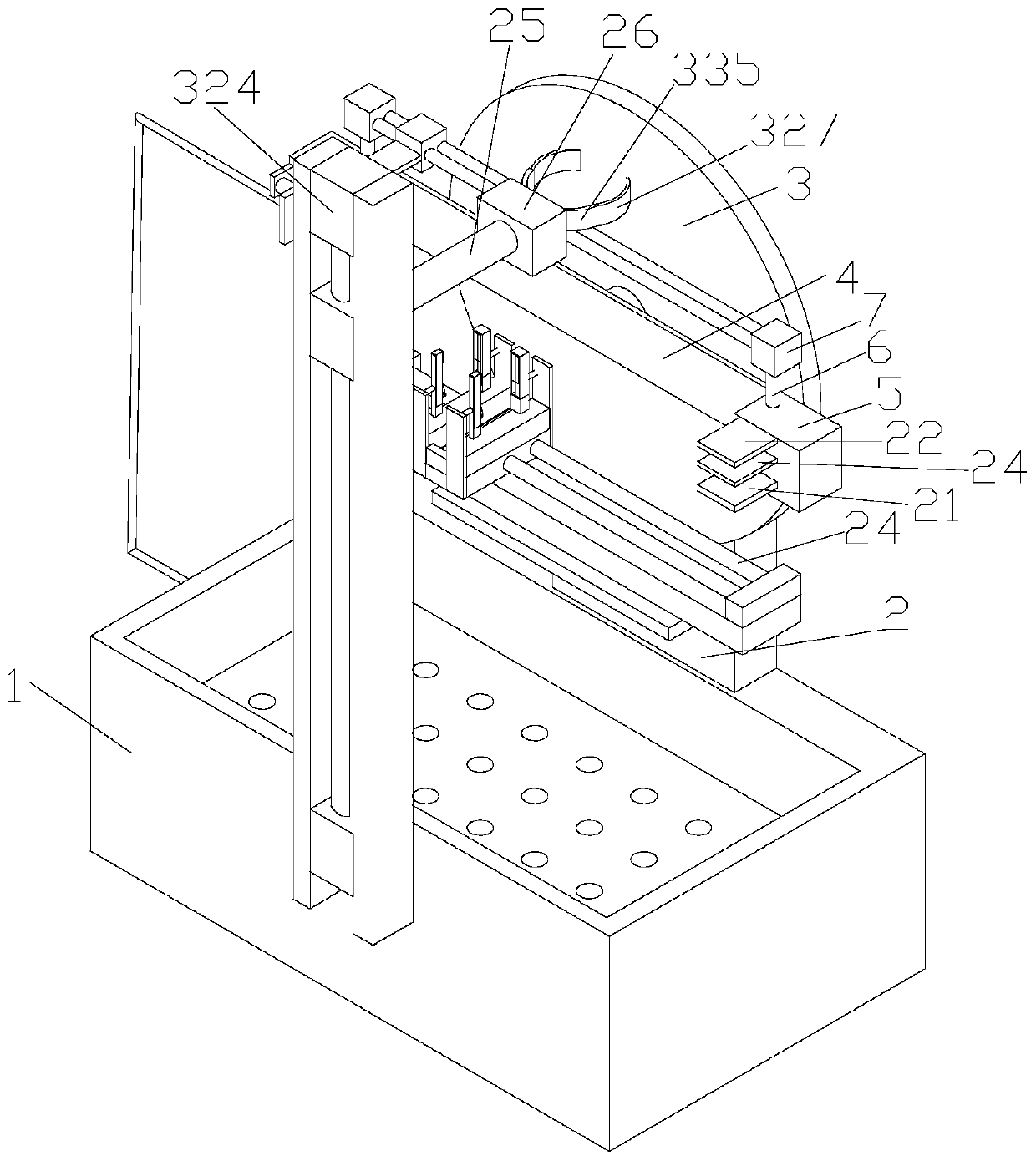

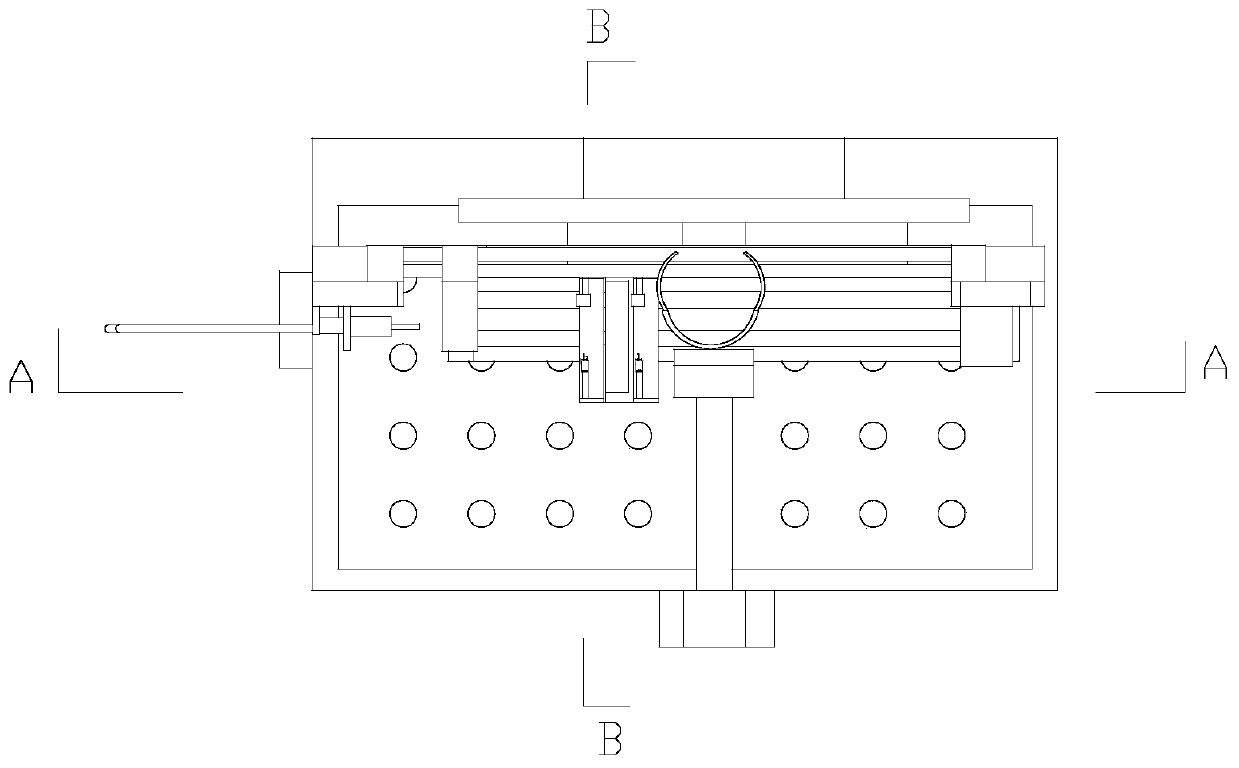

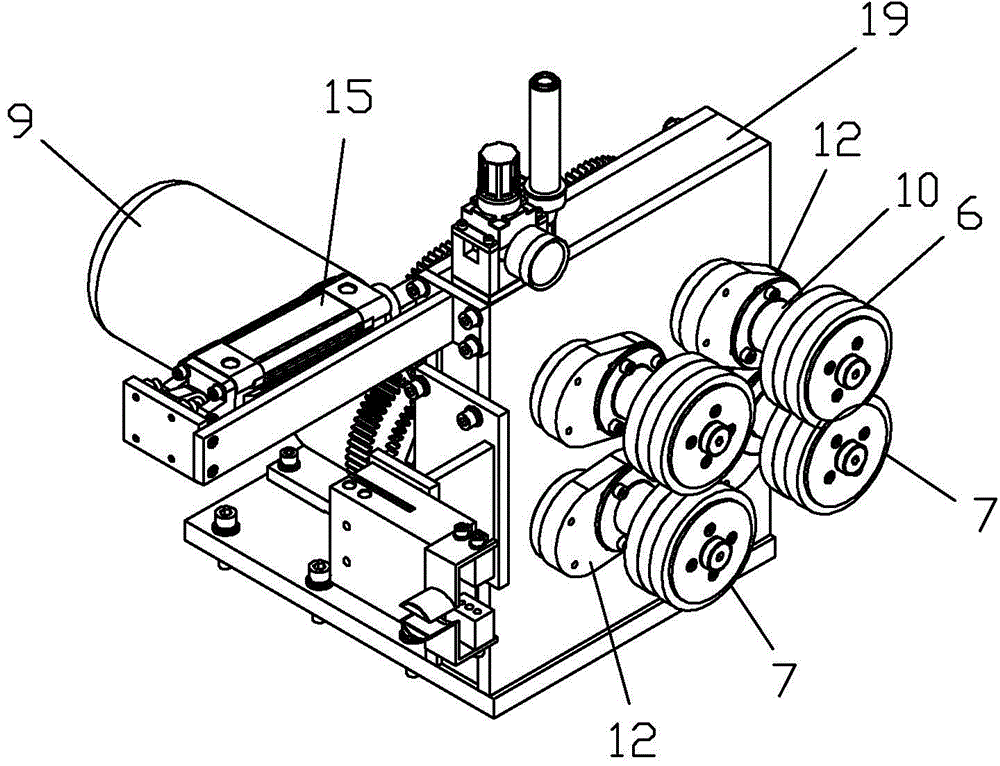

Double sausage casing dial wheels for casing shrinking machine

ActiveCN104872262AImprove driving effectEasy to adjustSausage casing manufactureDrive shaftGear wheel

The invention relates to double sausage casing dial wheels for a casing shrinking machine. The double sausage casing dial wheels comprise a rack, wherein at least two pairs of sausage casing dial wheels are arranged on the rack; each pair of sausage casing dial wheels comprises an upper sausage casing dial wheel and a lower sausage casing dial wheel; the upper sausage casing dial wheels and the lower sausage casing dial wheels are connected with transmission shafts; the transmission shafts penetrate through the rack and are connected with external gears; the external gears are driven by a motor, and further drive the upper sausage casing dial wheels or the lower sausage casing dial wheels to rotate. According to the double sausage casing dial wheels for the casing shrinking machine, the driving effect on sausage casings is good, and the gaps between the upper sausage casing dial wheels and the lower sausage casing dial wheels can be regulated, so that the double sausage casing dial wheels can be suitable for sausage casings with different sizes and different thicknesses.

Owner:广东德福隆生物科技有限公司

Method for production of soft natural casing, soft natural casing, and processed meat product

Owner:NIPPON HAM

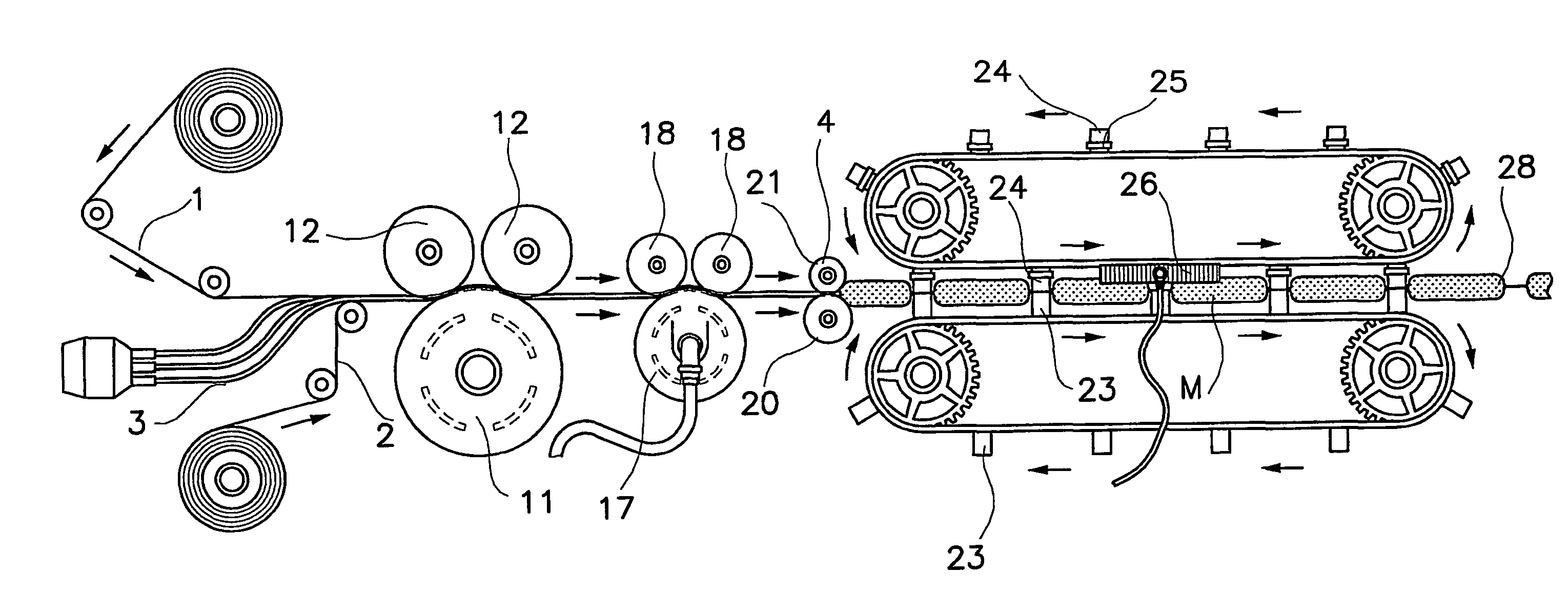

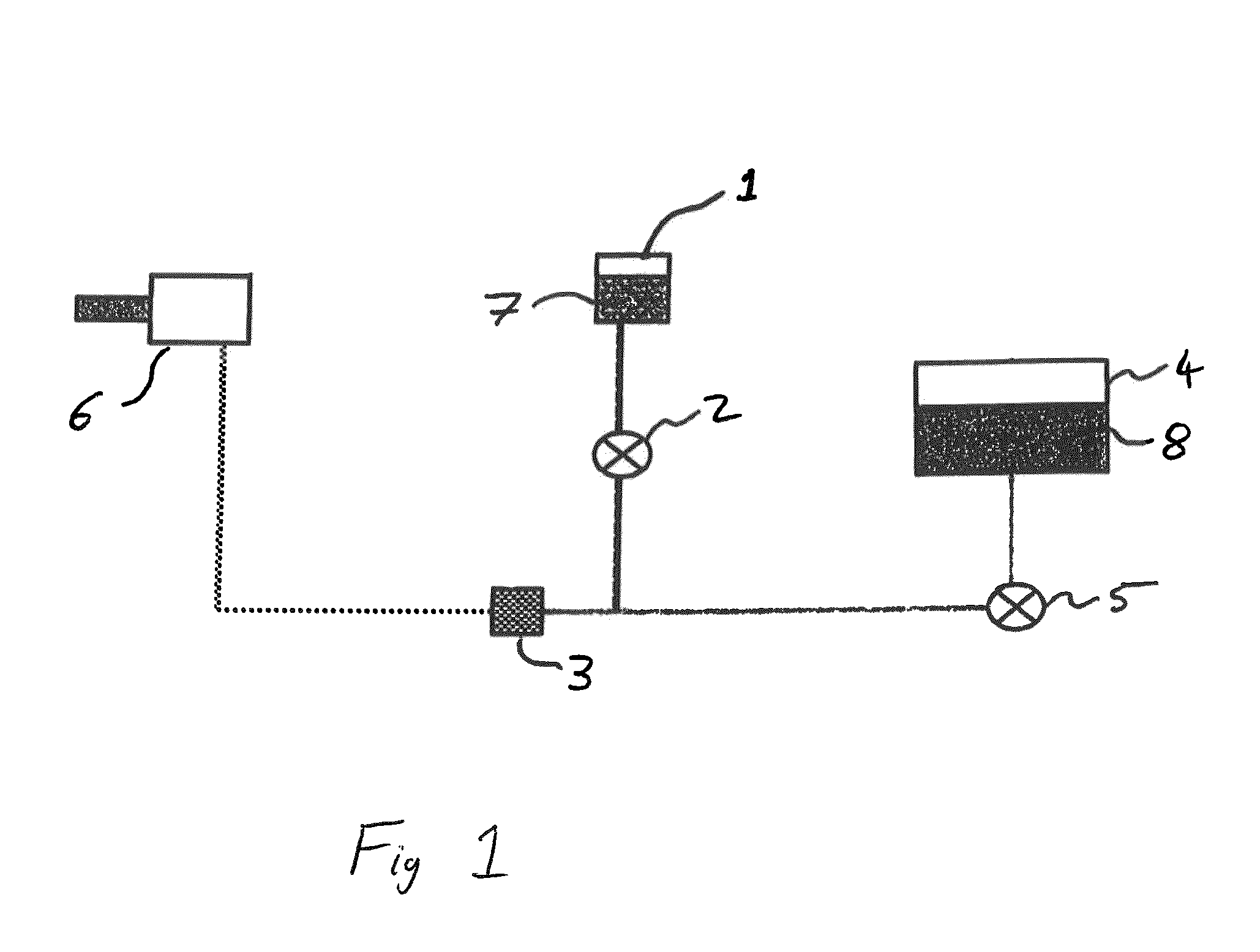

Process for the production of portion packs in a tubular film

In a process for the production of portion packs of viscous to pasty filling material such as sausage meat, grease, putty or cement and the like in a tubular film (12) which is formed prior to introduction of the filling material (10) by welding or sealing of the longitudinal edges of a film strip (1) drawn off a supply and bent into a tubular form, and into which filling material portions are discontinuously introduced under pressure, whereupon the tubular film (12) is closed with braid formation, the tubular film (12) is drawn out of the welding or sealing station towards the filling station directly by the filling pressure and film strip (1) is subsequently drawn along from the supply into the welding or sealing station.

Owner:POLY CLIP SYST

Production process of dried sausage casing

ActiveCN104814110AReach neutral pHGood flexibilitySausage casing manufactureRoom temperatureSodium hydroxide

The invention discloses a production process of a dried sausage casing. The production process comprises the following steps of: (1) placing a salted sausage casing into clear water to clean salt; (2) placing the cleaned sausage casing into a hydrochloric acid solution, and rinsing for 1-2 hours; (3) taking out, and cleaning by using the clear water till a pH value is 5-6; (4) placing the cleaned sausage casing into a sodium hydroxide solution, and rinsing for 1-2 hours; (5) taking out, and cleaning by using the clear water till the pH value is 7-8; (6) sleeving the cleaned sausage casing on a drying mould, and drying at the temperature of 40-60 DEG C for 2-3 hours; (7) then increasing the temperature to 70-80 DEG C, and drying for 3-4 hours; (8) drying, then regulating humidity within a range of 45%-50%, and after the temperature of the sausage casing is reduced to room temperature, demoulding to obtain the dried sausage casing. The dried sausage casing produced through the production process disclosed by the invention is white, uniform and beautiful in color. By neutralizing alkali by using acid, the production process disclosed by the invention can be used for enhancing the flexibility of a product, enabling the color to be white, uniform and beautiful, reducing the used water and fast enabling the sausage casing to achieve pH neutrality to conveniently carry out next-step production.

Owner:HEILONGJIANG YUANGUANG CASING

Preparation method of edible animal collagen casing

ActiveCN110547318AEasy to implementImprove work efficiencyDetection of fluid at leakage pointSausage casing manufactureCelluloseFiltration

The invention discloses a preparation method of an edible animal collagen casing. The preparation method comprises the following steps: a, material preparation: cleaning and splitting animal skin; b,material treatment: performing alkali treatment on the split animal skin, adding water according to a weight ratio of the animal skin to the water of 1:1, performing enzyme treatment with protease, cleaning the animal skin, and then, performing acid treatment; c, preparation of fiber pulp: cooling the animal skin after acid treatment to be lower than 10 DEG C, cutting up the animal skin by means of dicing, tabletting, chopping and grinding or a combination mode thereof, rolling the cut animal skin into sheets, and extracting silk fiber by means of high pressure filtration; d, preparation of collagen pulp: adding edible cellulose or edible cellulose derivates and grease emulsion while stirring, controlling pH value and water content, and performing uniform mixing and stirring to form a collagen group; e, preparation of casing: freezing the collagen group, performing extrusion to spray a tubular substance, drying the tubular substance, and adding a curing agent and a plasticizing agent for treatment; f: curing and forming: curing and shaping the casing for 6 hours at 82 DEG C; and g: defect detection: detecting whether the casing is broken or not by using a casing detection device.

Owner:PUJIANG CAREX BIOTECH

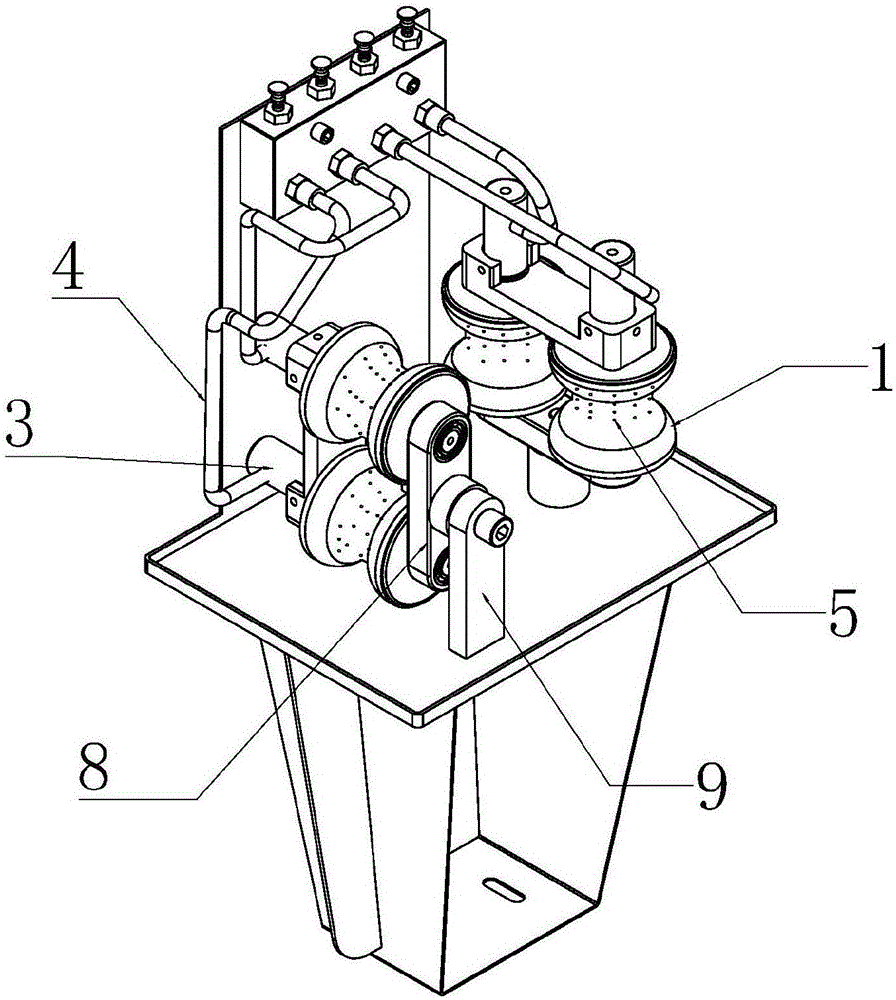

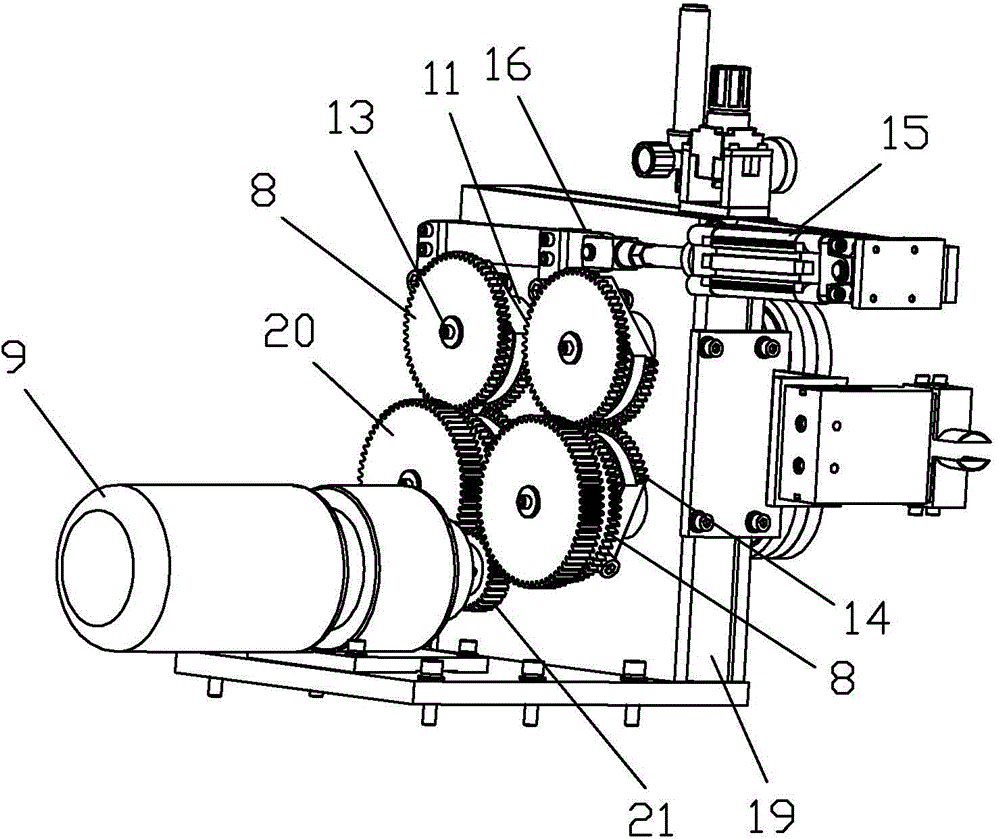

Oiling device

ActiveCN106417546AReduce frictional resistanceReduce resistanceSausage casing manufactureEngineeringMechanical engineering

The invention relates to an oiling device used for oiling outer walls of inflated casings. The oiling device comprises a plurality of oiling rollers, oiling material layers and a roller retaining device. Each oiling roller is in a waist drum shape with a thin middle and two thick ends and is capable of freely rotating around a center rotation axis, each oiling roller is provided with a hollow oil injection hole on the center rotation axis, one end of each oil injection hole is closed while the other end of each oil injection hole is communicated with an oil inlet pipe through a rotary connector, and a plurality of micropores are uniformly and peripherally distributed on the outer wall of each oiling roller and communicated with the corresponding oil injection hole. Each oiling material layer is made of an oil adsorbing and spreading material and coats the outer wall of the corresponding oiling roller. The roller retaining device is designed to be suitable for pressing the oiling rollers against outer walls of the inflated casings. By design of quantity and outer wall profiles of the oiling rollers, each casing corresponds to at least one oiling roller in any arc on the periphery of an outer wall cross section.

Owner:FOSHAN VEHICIAN LNTELLIGENT EQUIP CO LTD

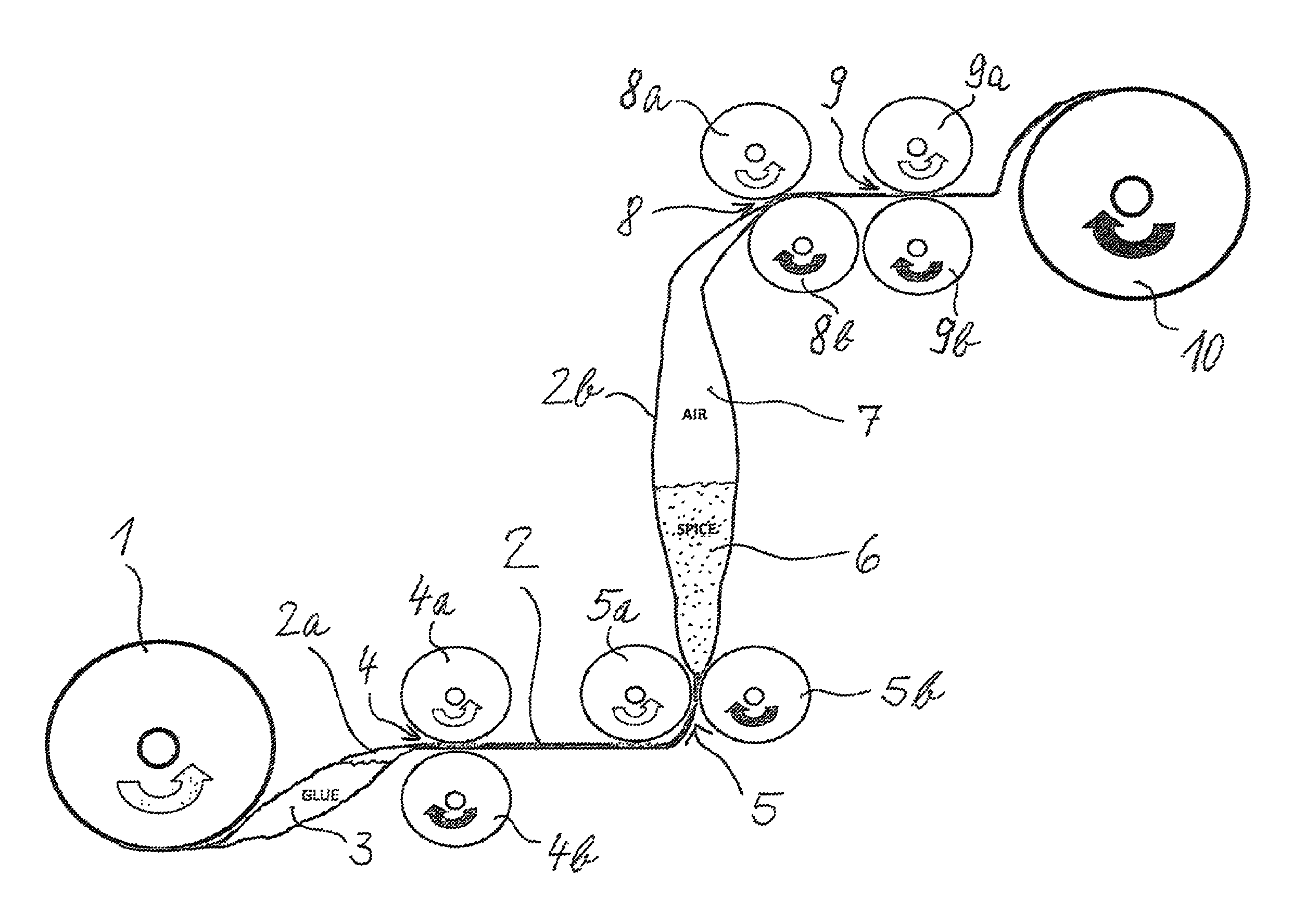

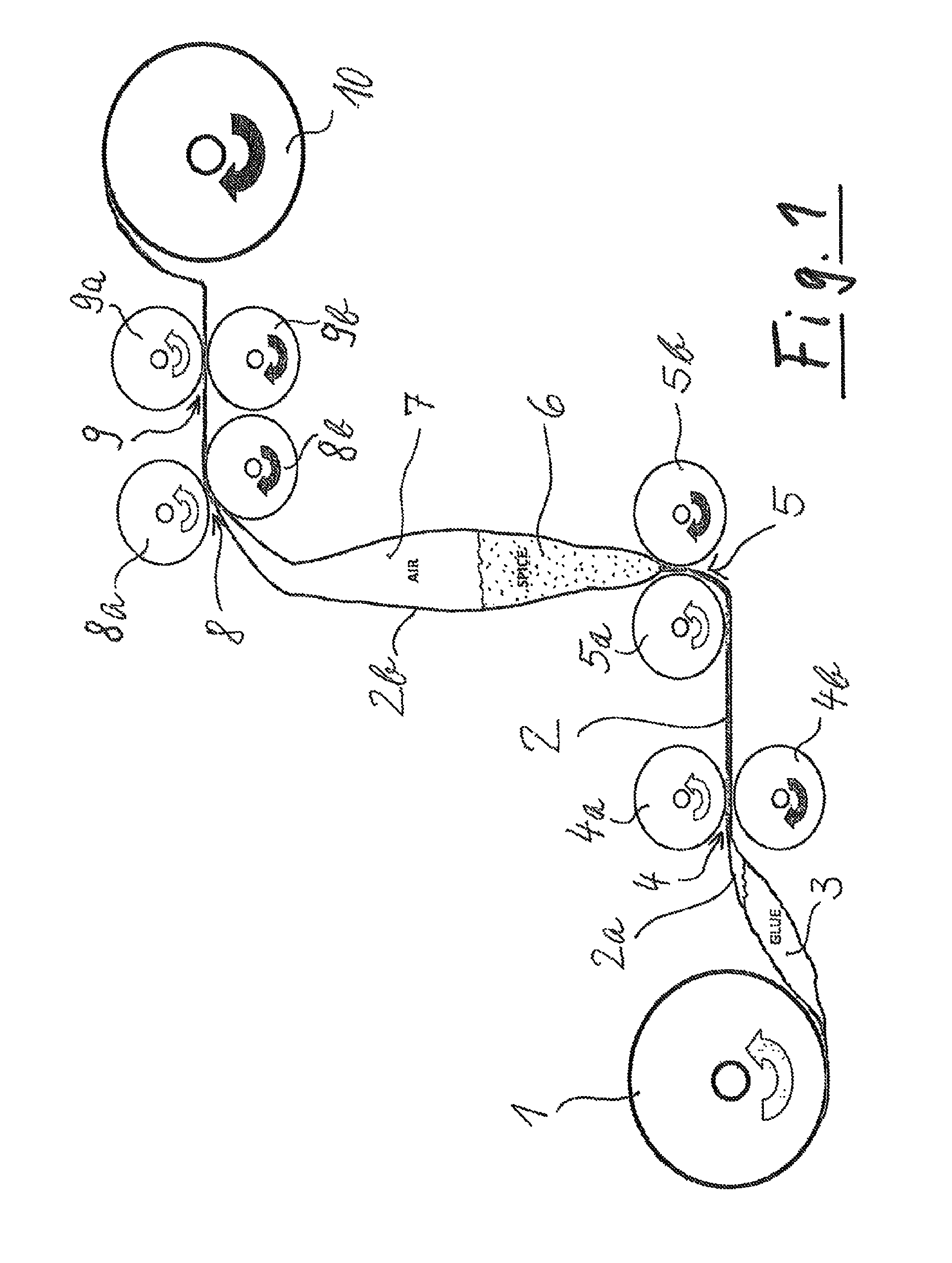

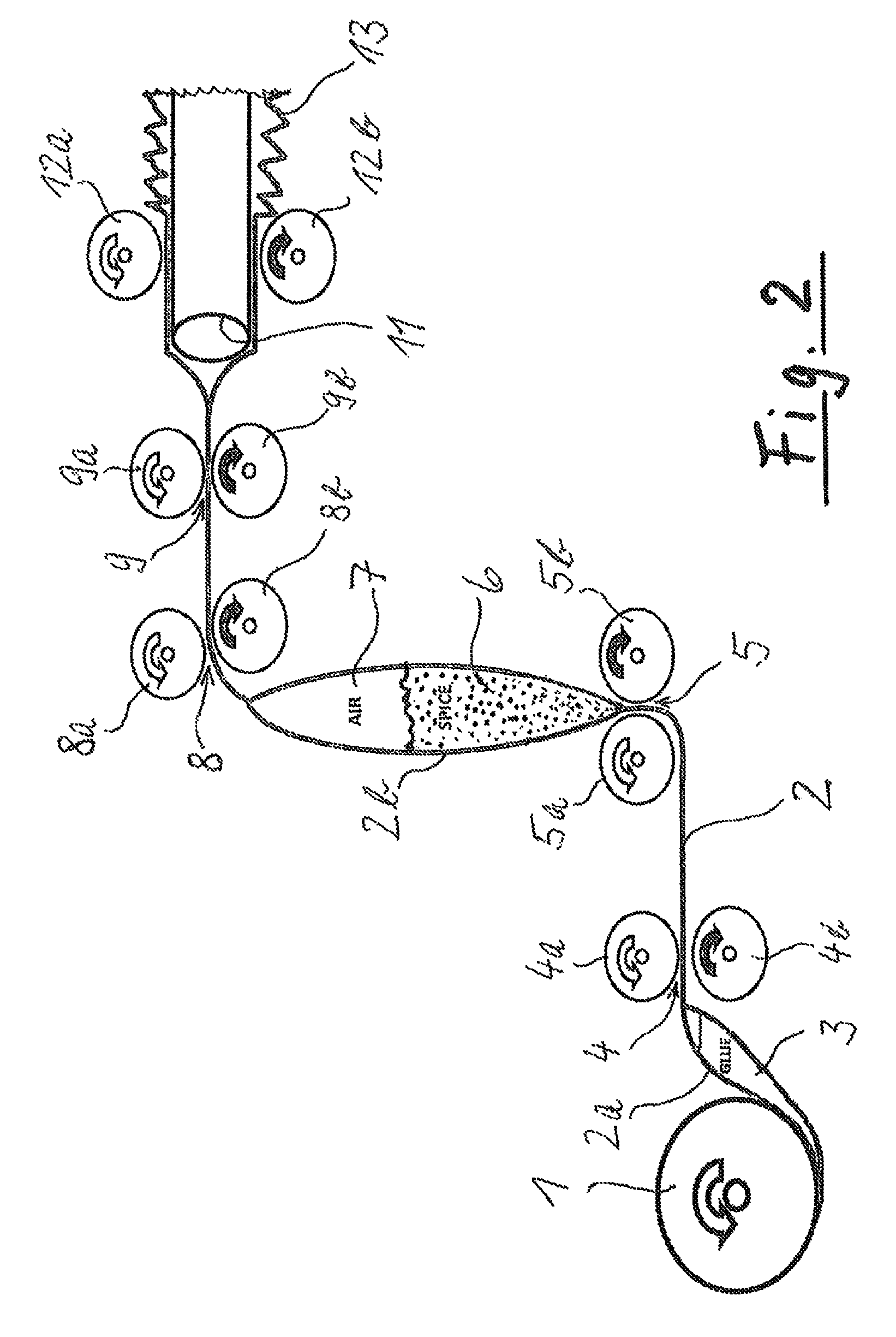

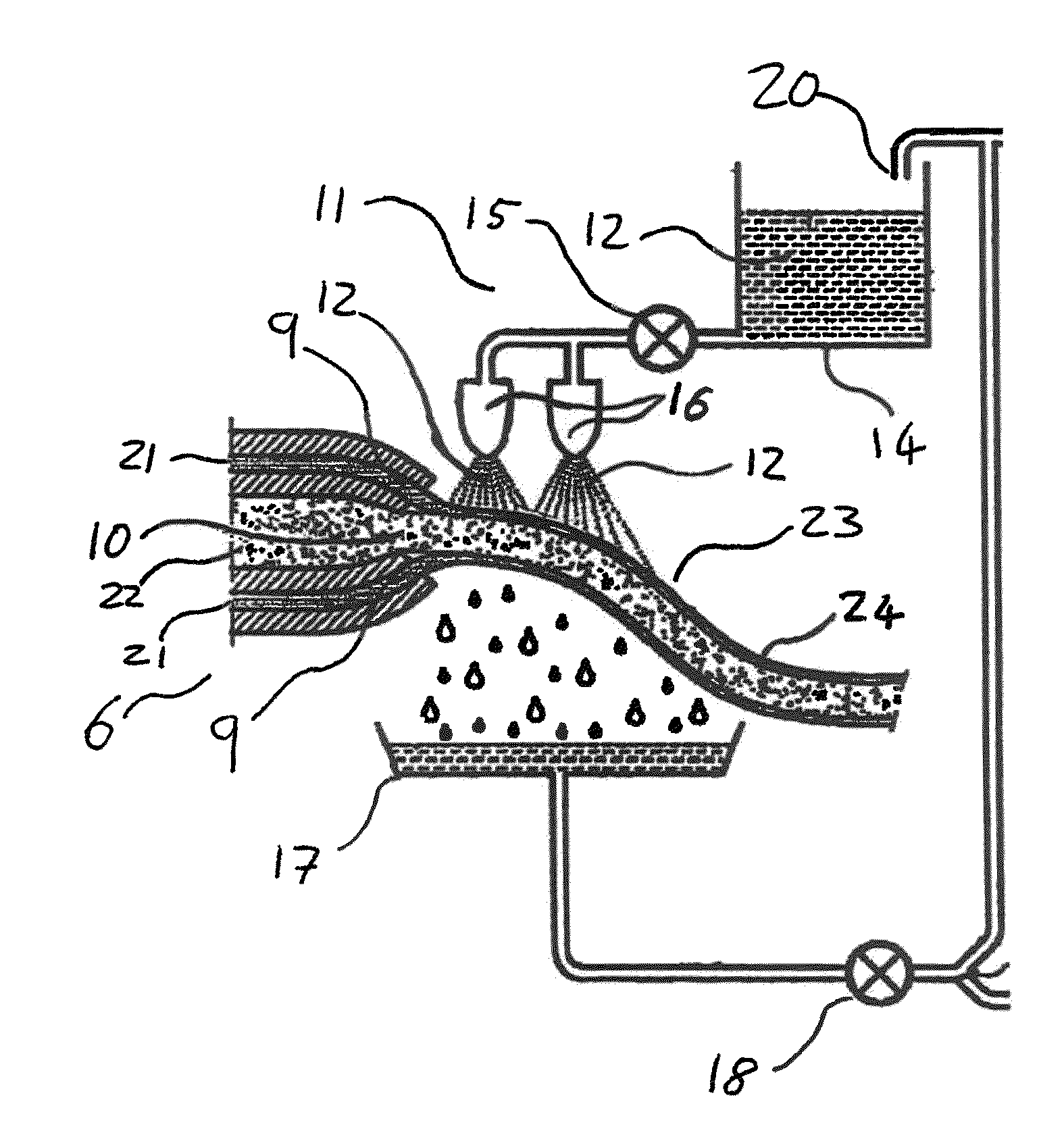

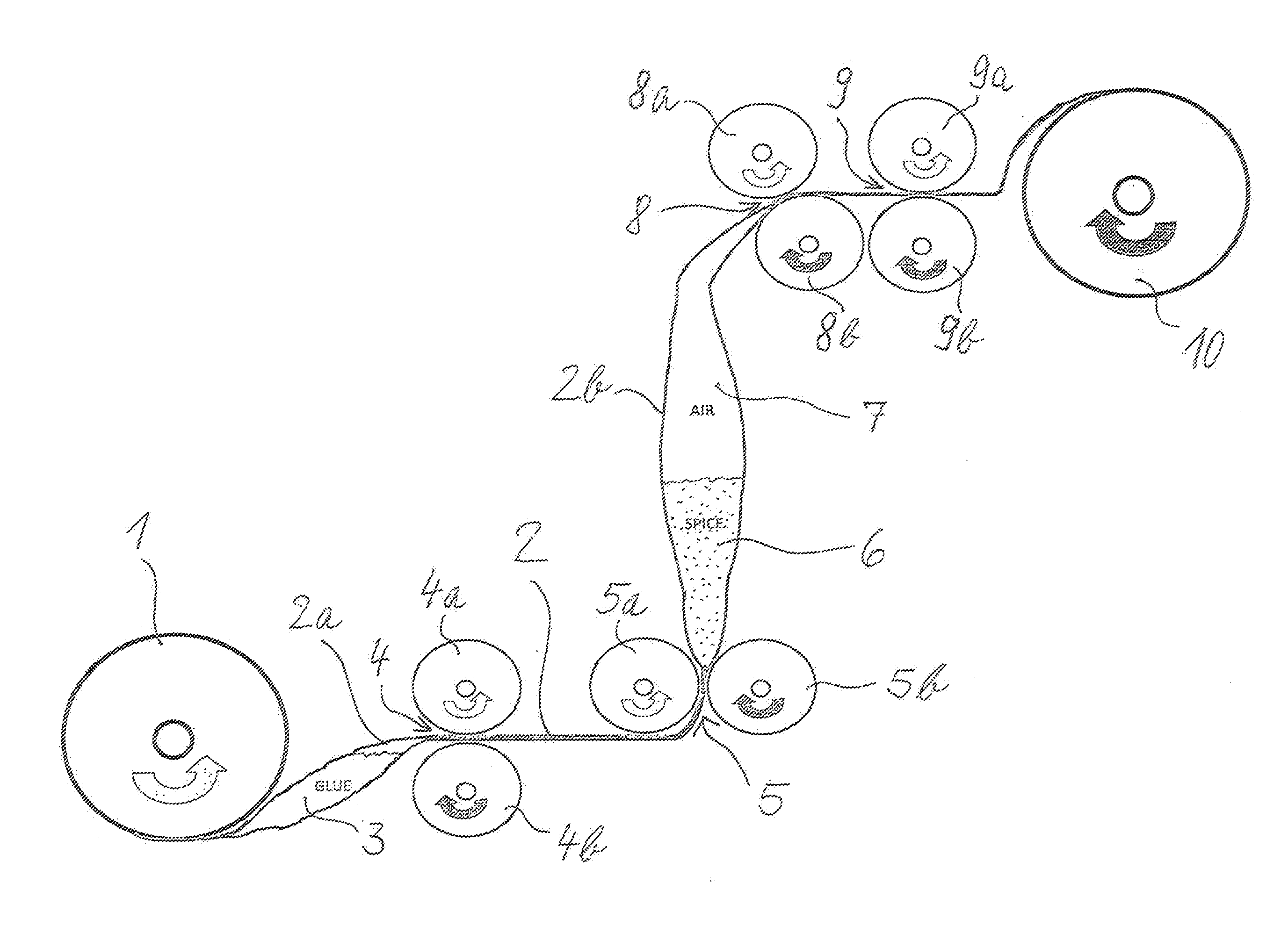

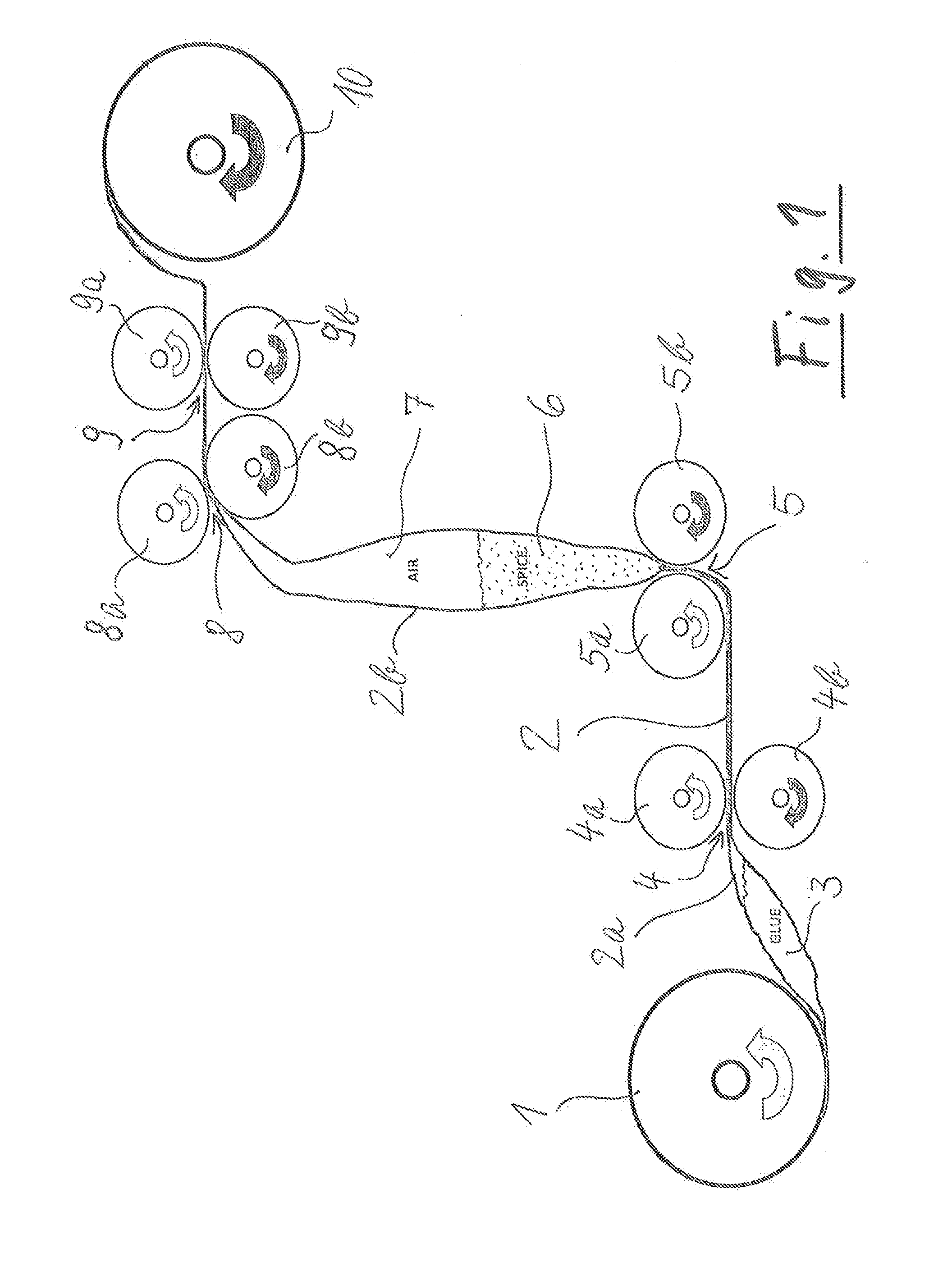

Casing for foodstuff

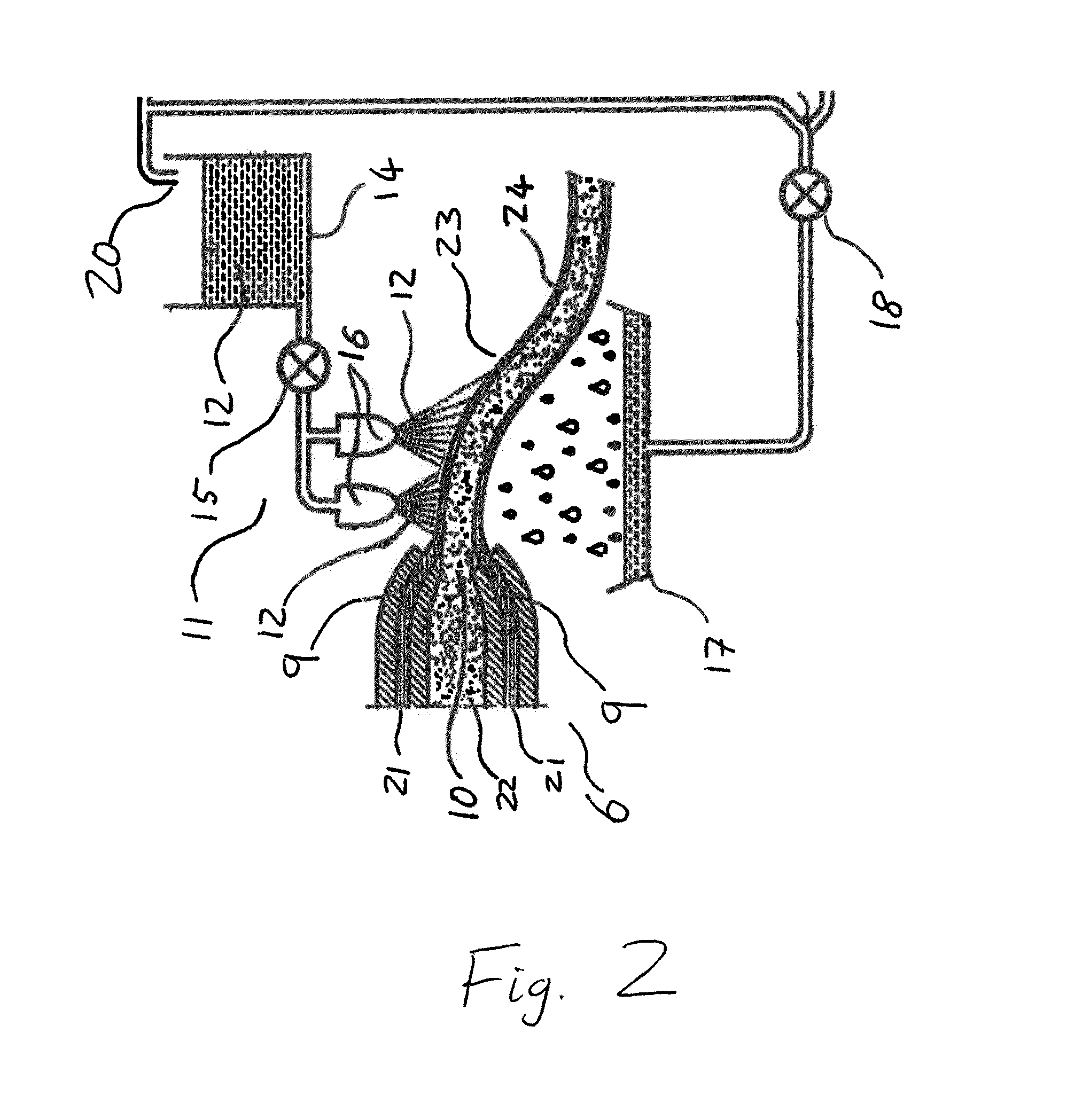

A method for coating tubular food-casings (2), particularly skins with flavoring substances in particle form, includes wetting the casing (2) on the inside with adhesive, and then applying desired flavoring substances (6) onto the formed adhesive layer. The tubular casing (2), coated on the inside with adhesive, is guided through a first squeezing zone (5) and a second squeezing zone (8) in the travel direction, where the respective interior cross-sections of the tubular casing are temporarily closed. The second squeezing zone (8) is positioned higher than the first squeezing zone (5). The tubular casing is brought into the form of an inflated sack (2b) in between the two squeezing zones (5, 8) by a supply of particulate flavoring substances (6) and an air pocket (7) inserted into the interior of the tubular casing. During travel, the casing entrains the flavoring substances (6) from the supply.

Owner:WORLD PAC INT

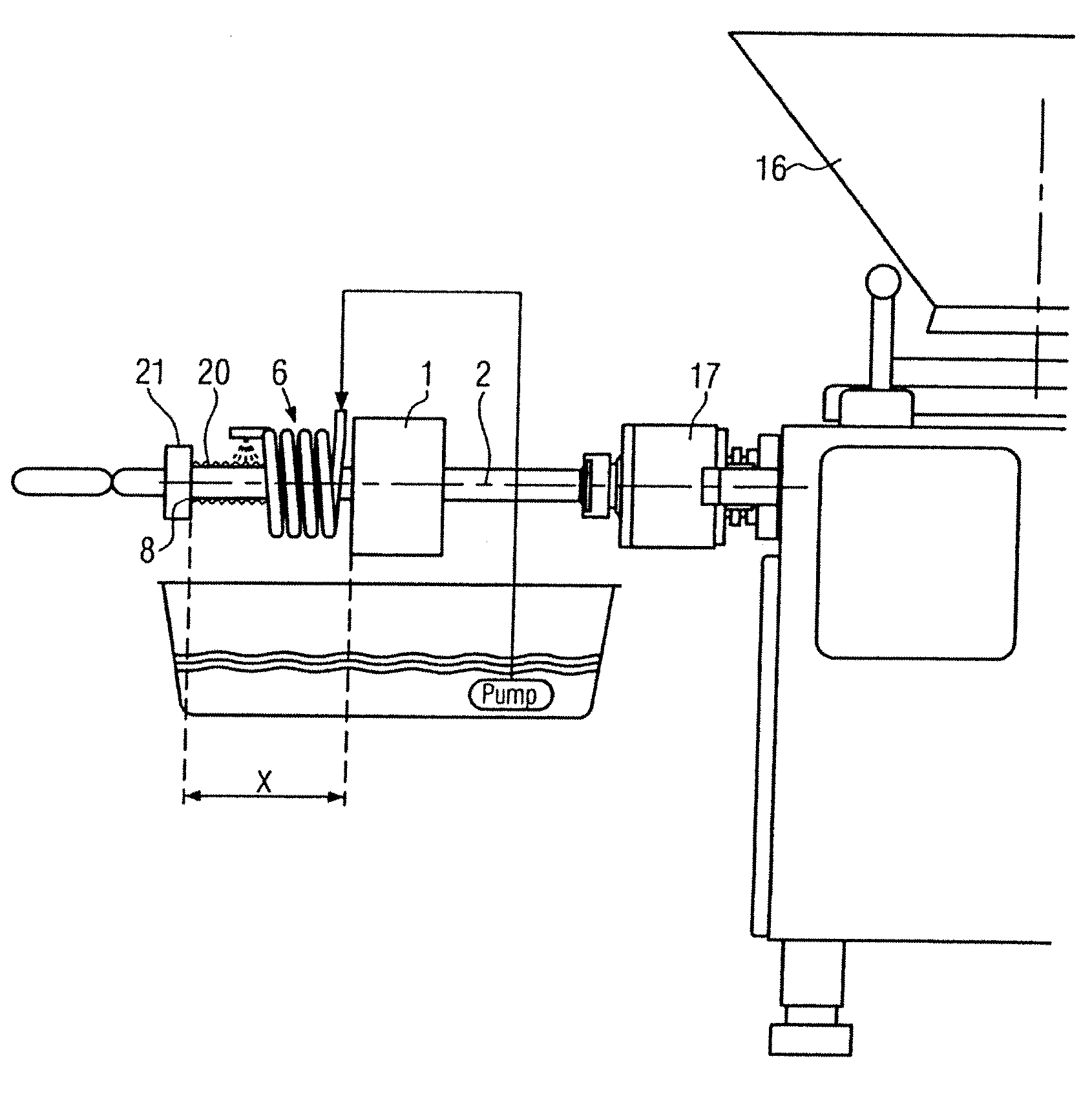

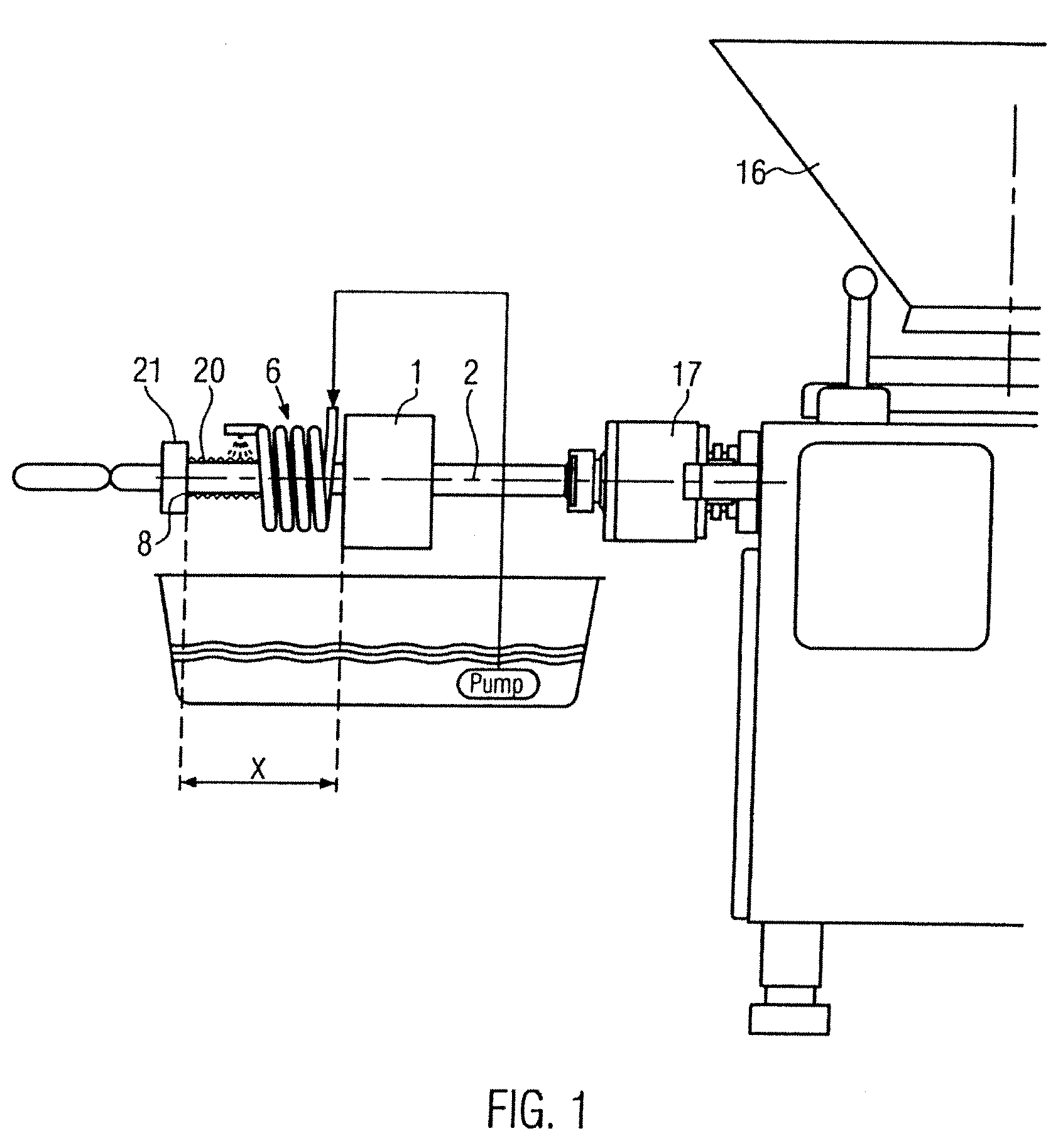

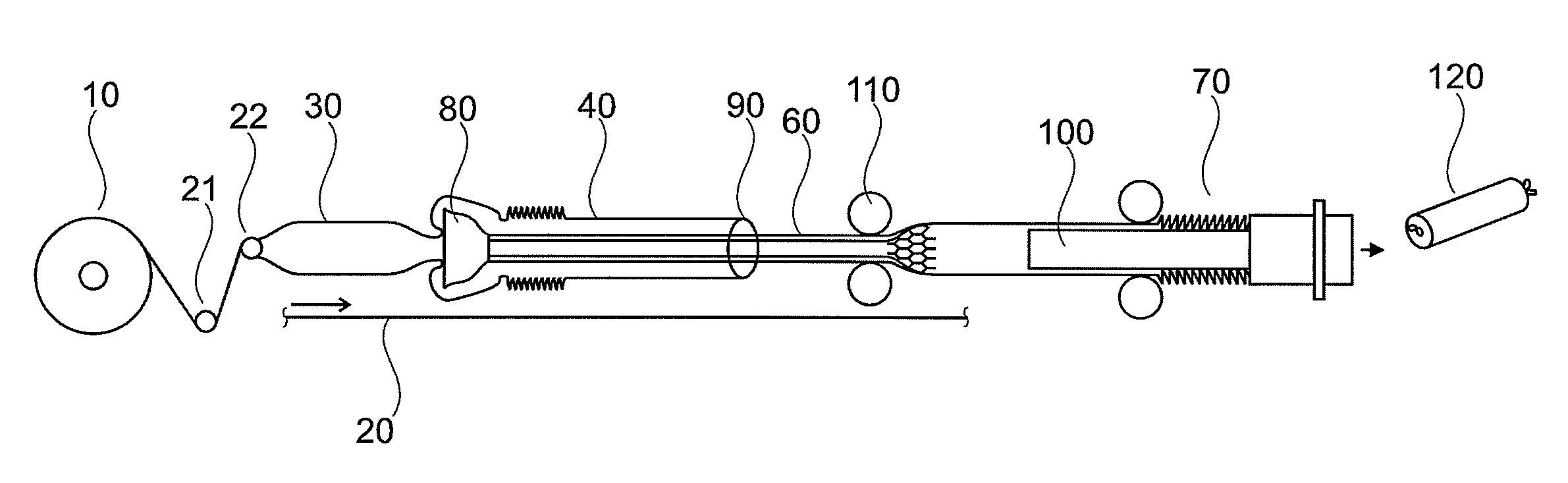

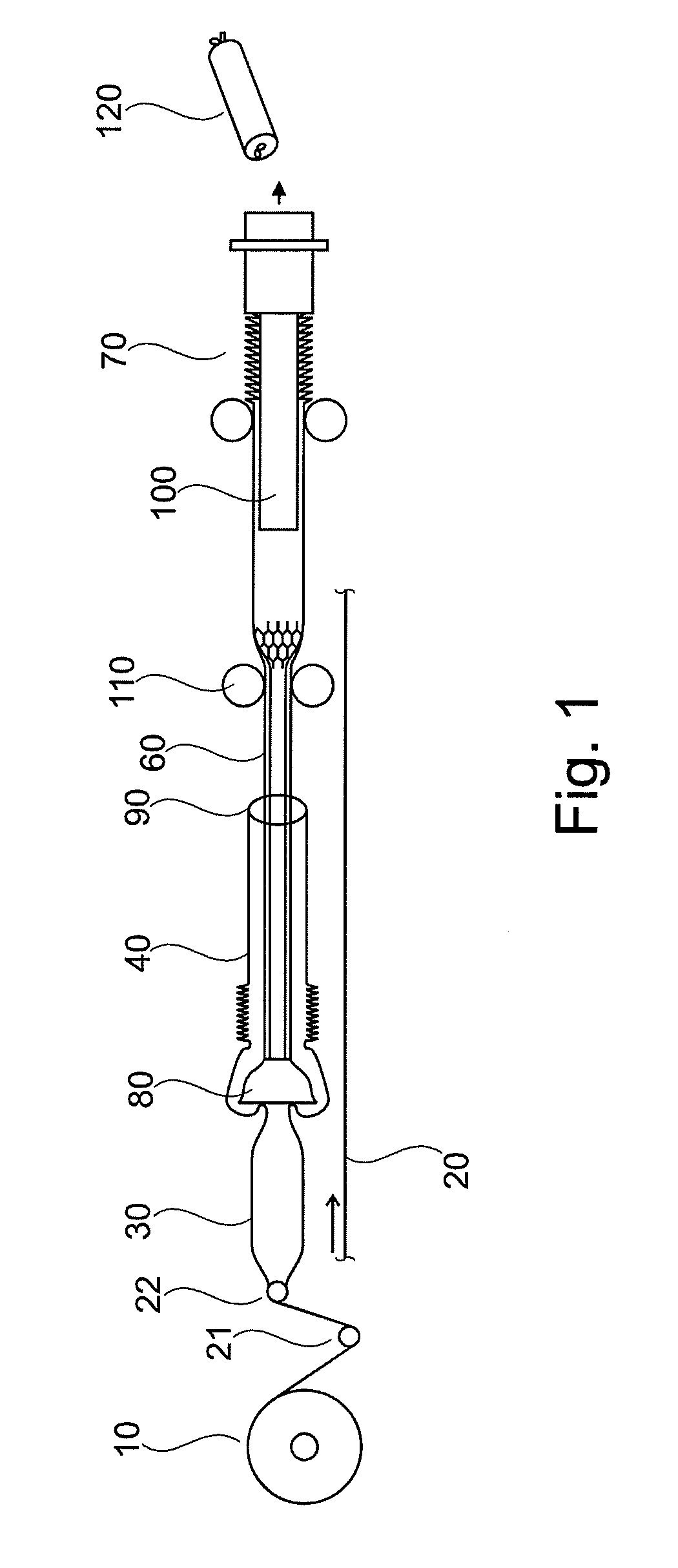

Device and method for manufacturing sausages

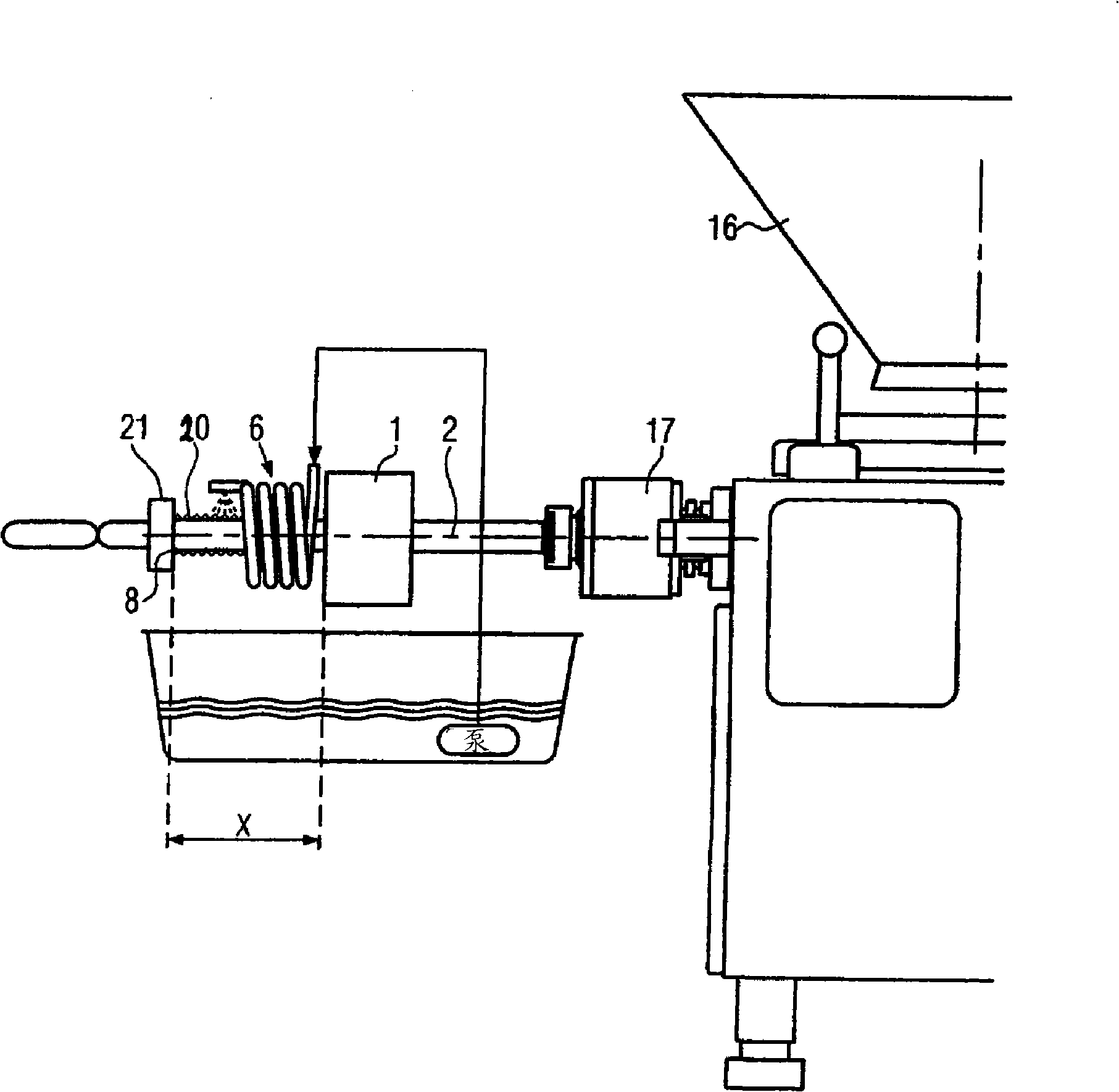

ActiveUS20090023373A1Easy to manufactureIncrease pressureSausage casing manufactureSausage filling/stuffing machinesEngineeringMechanical engineering

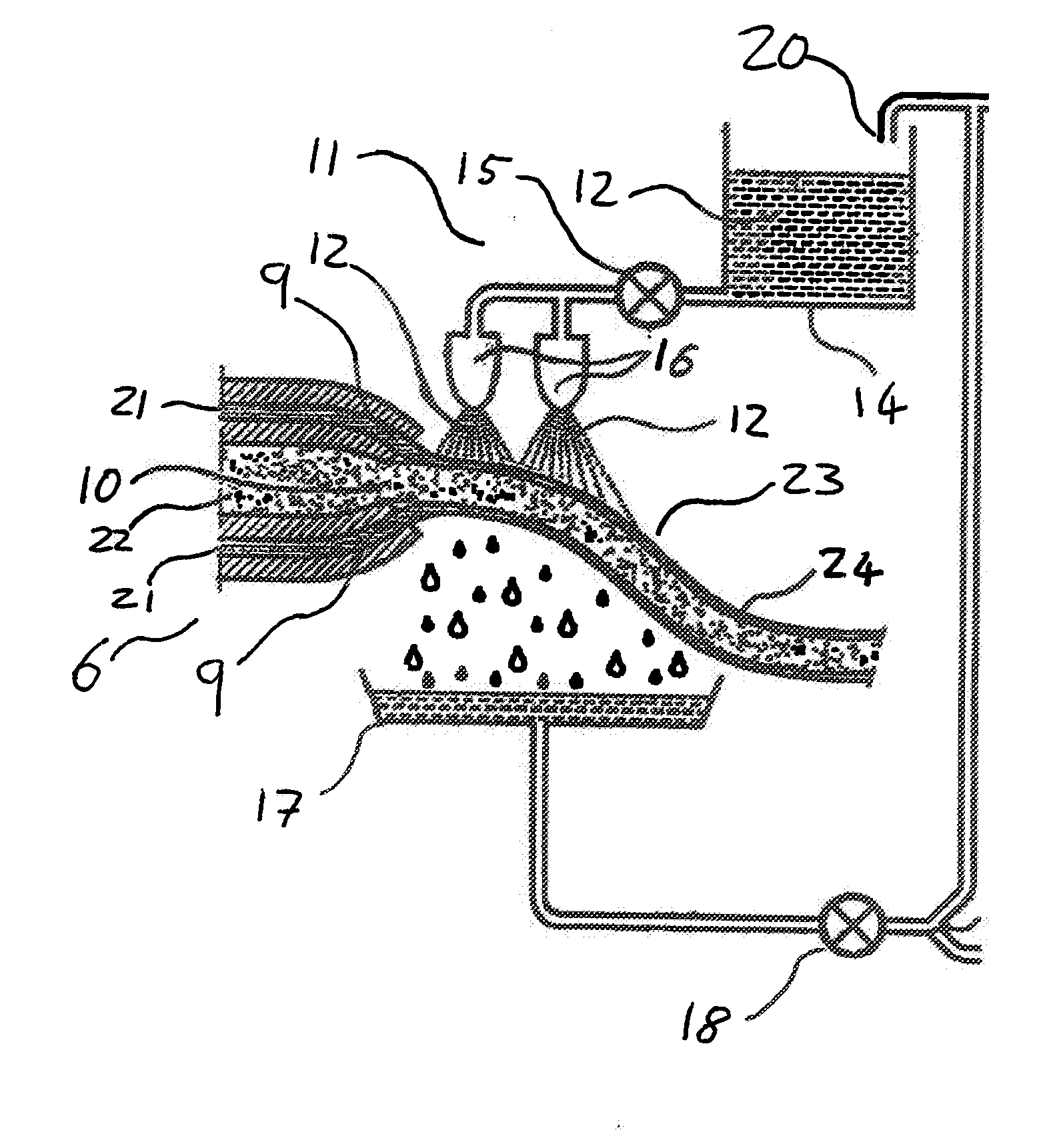

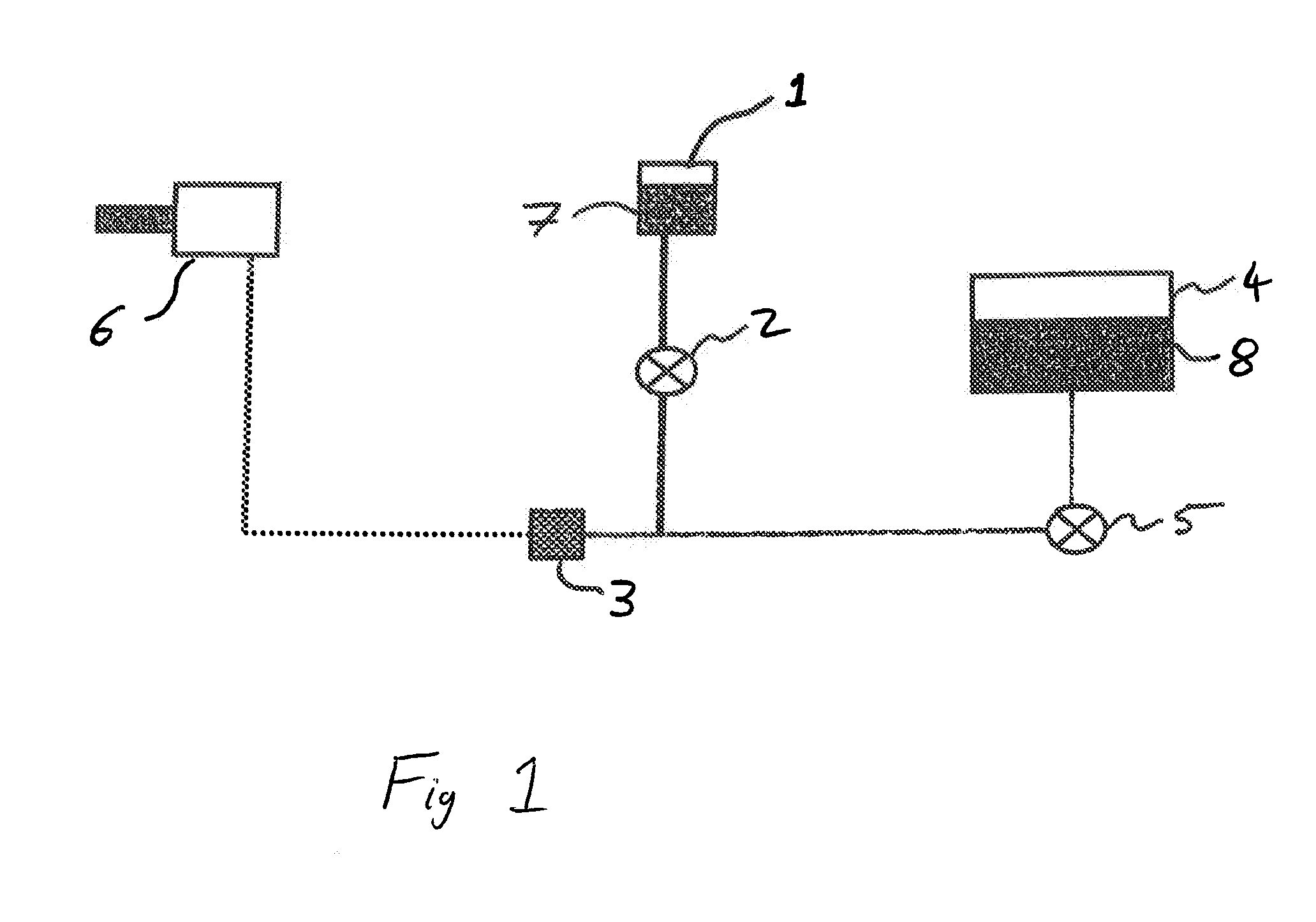

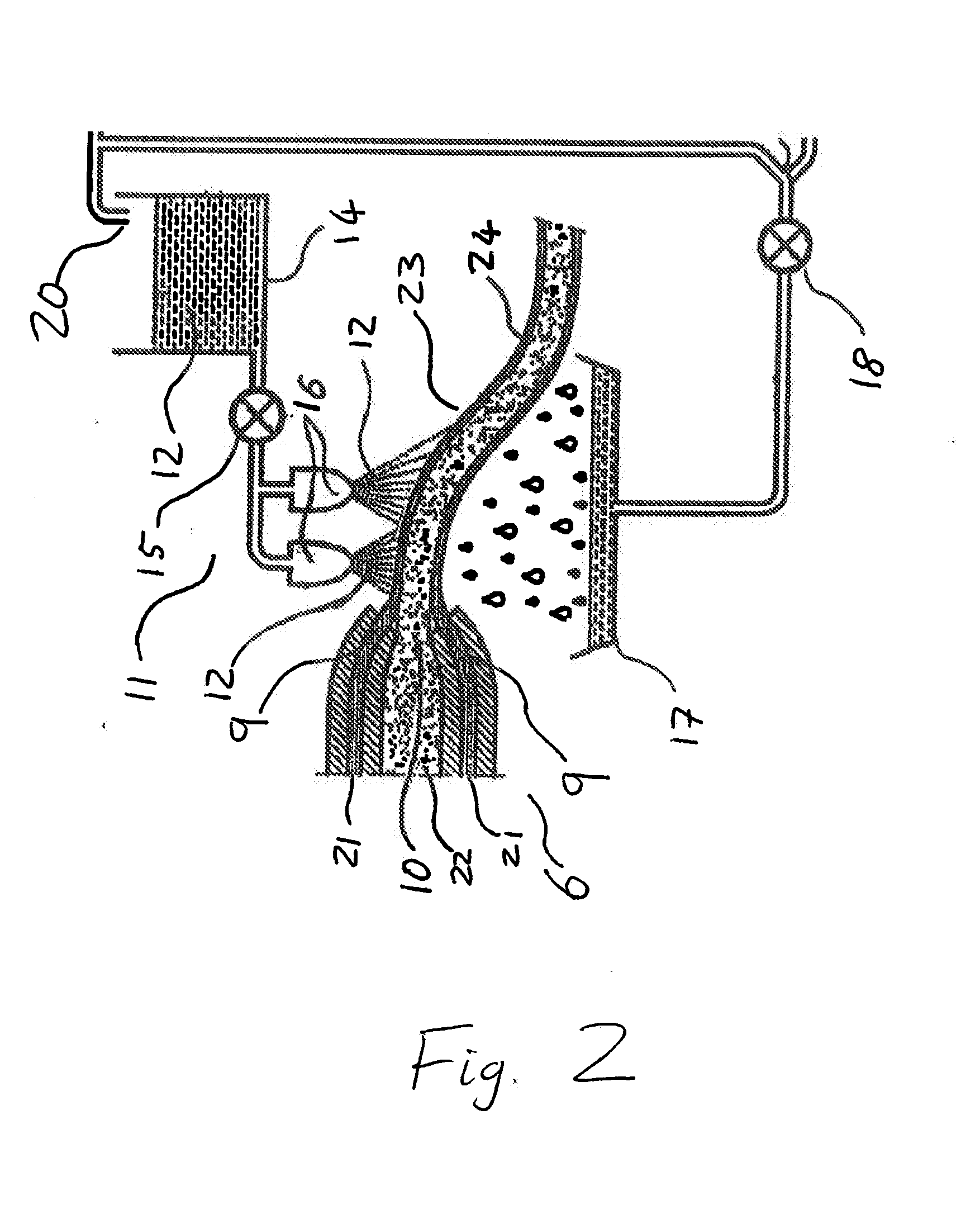

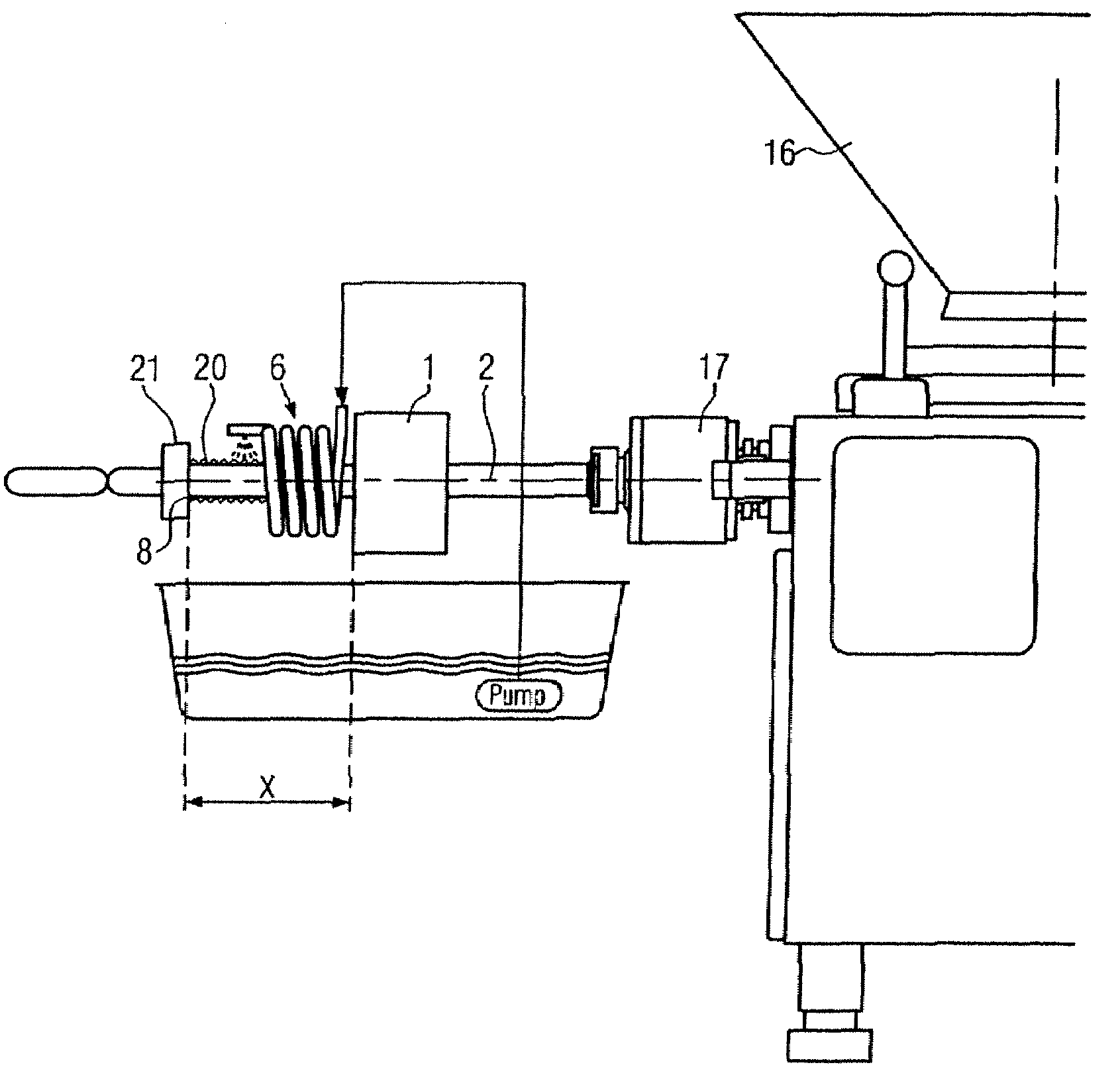

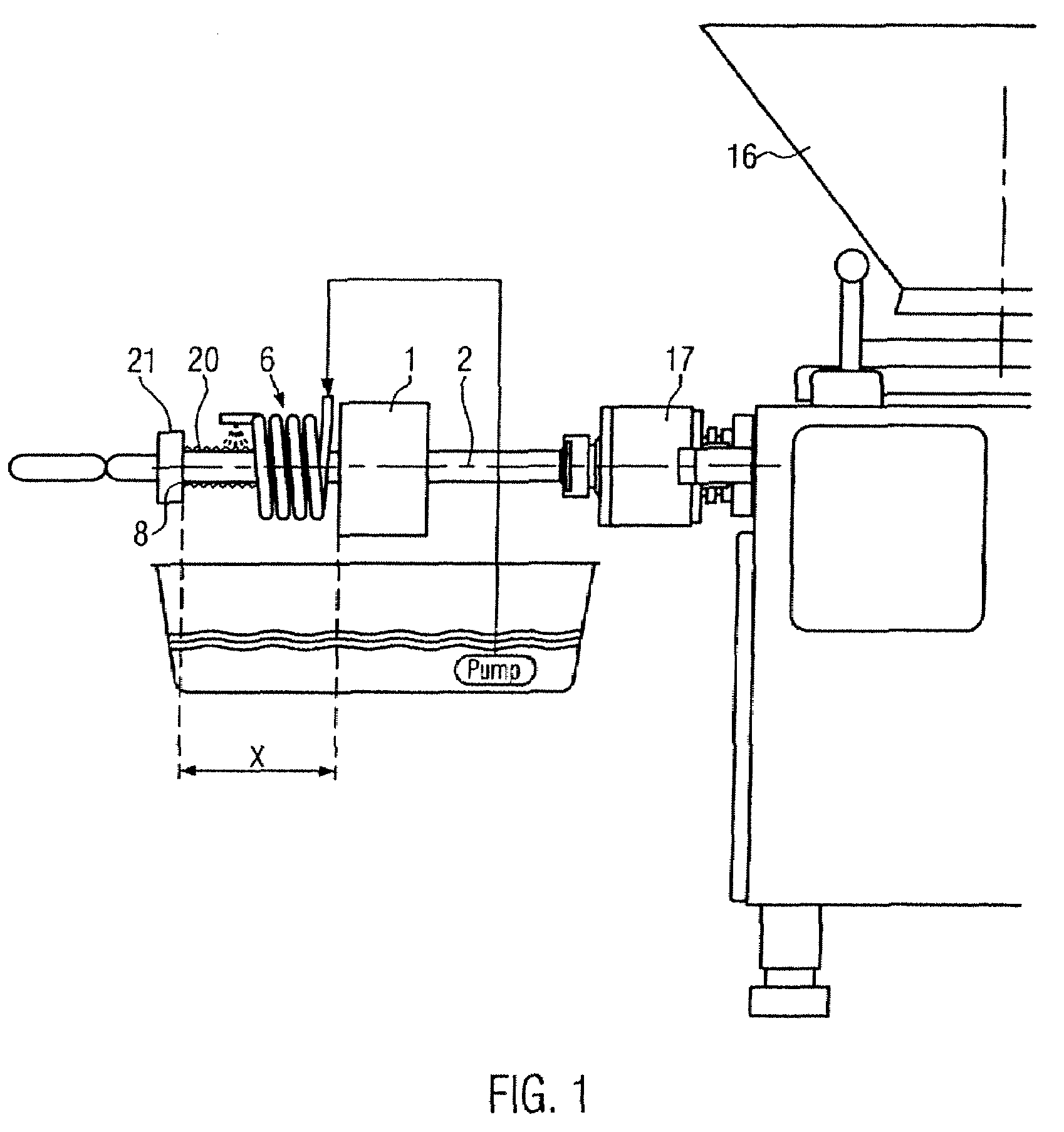

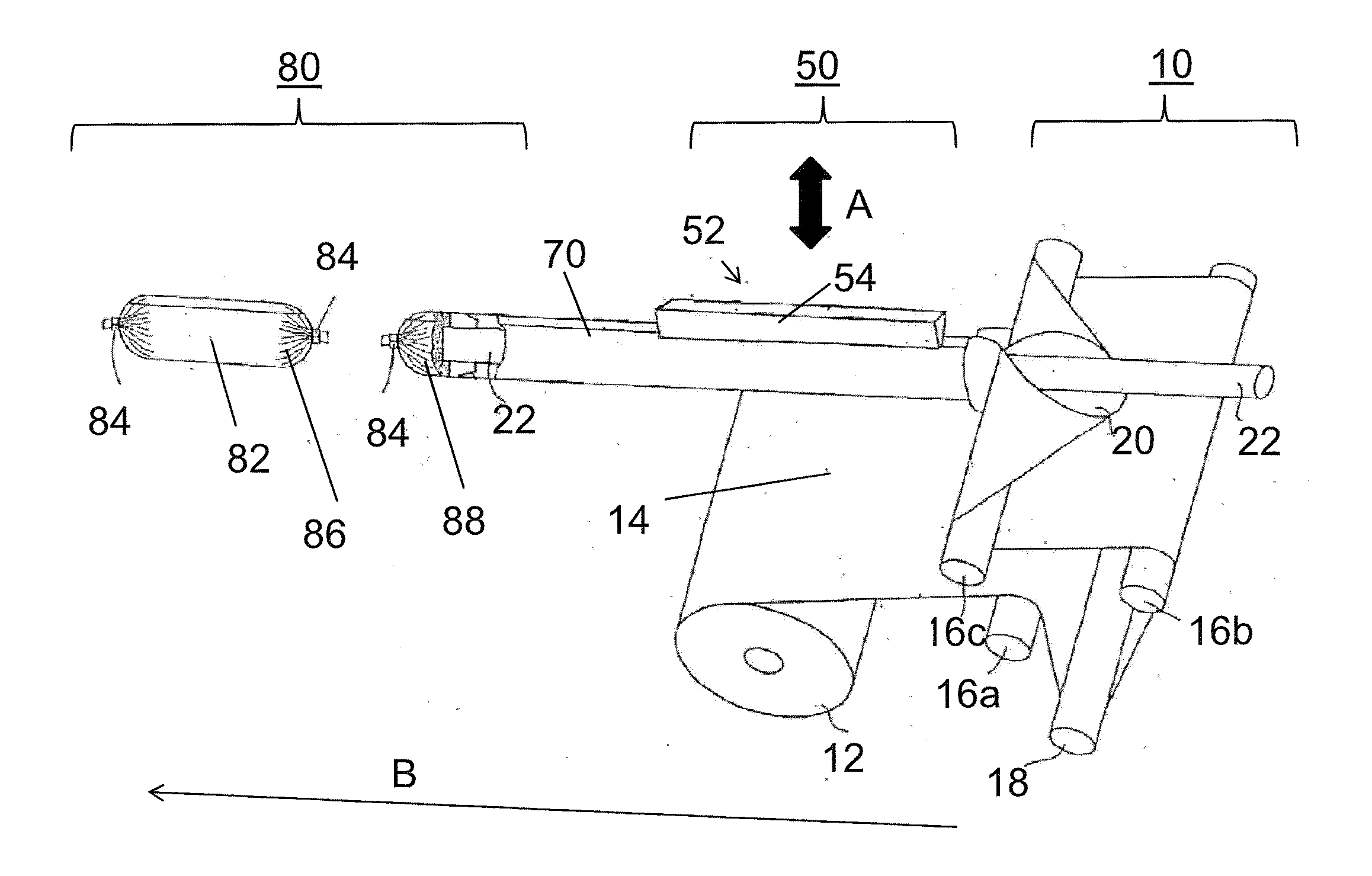

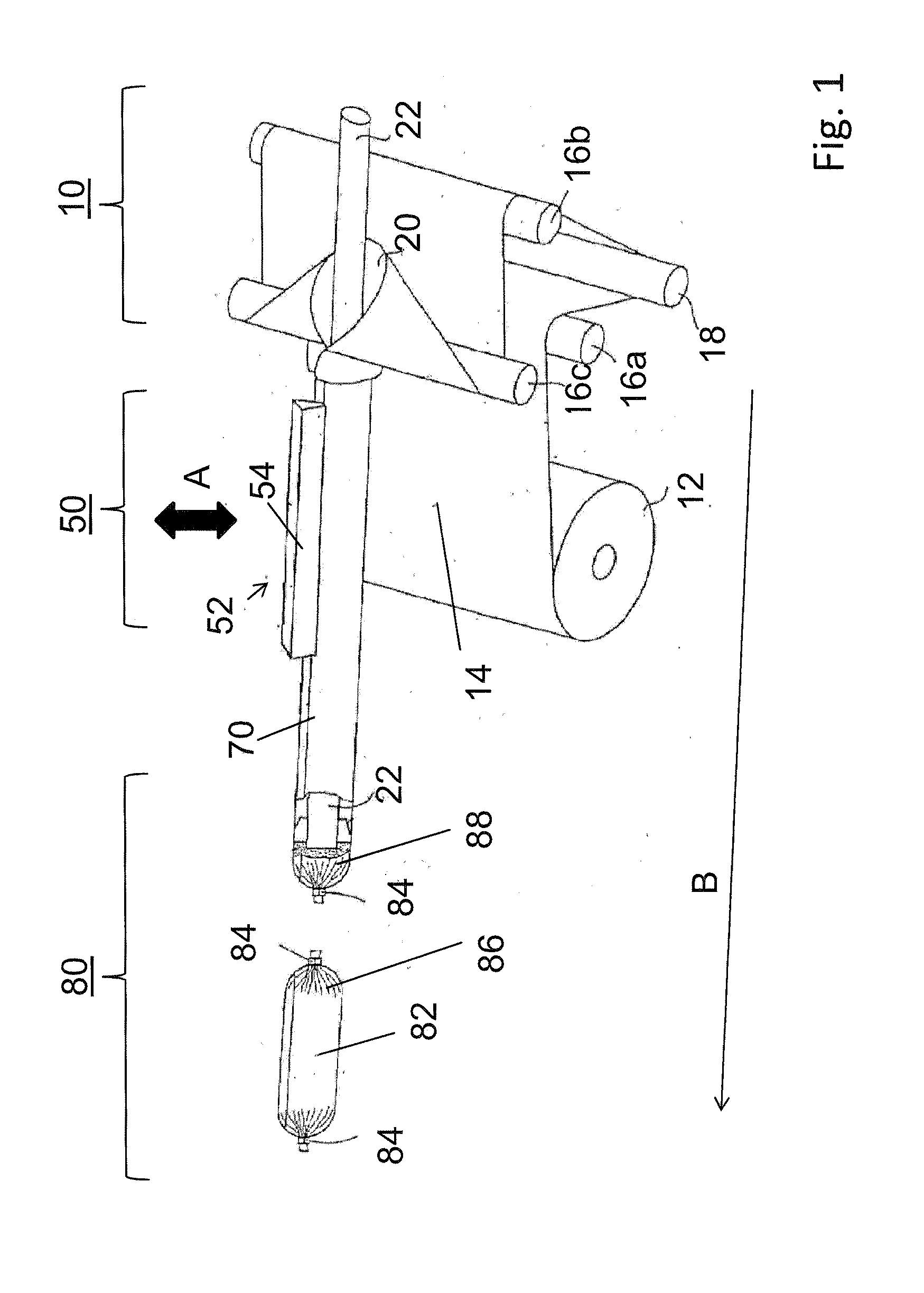

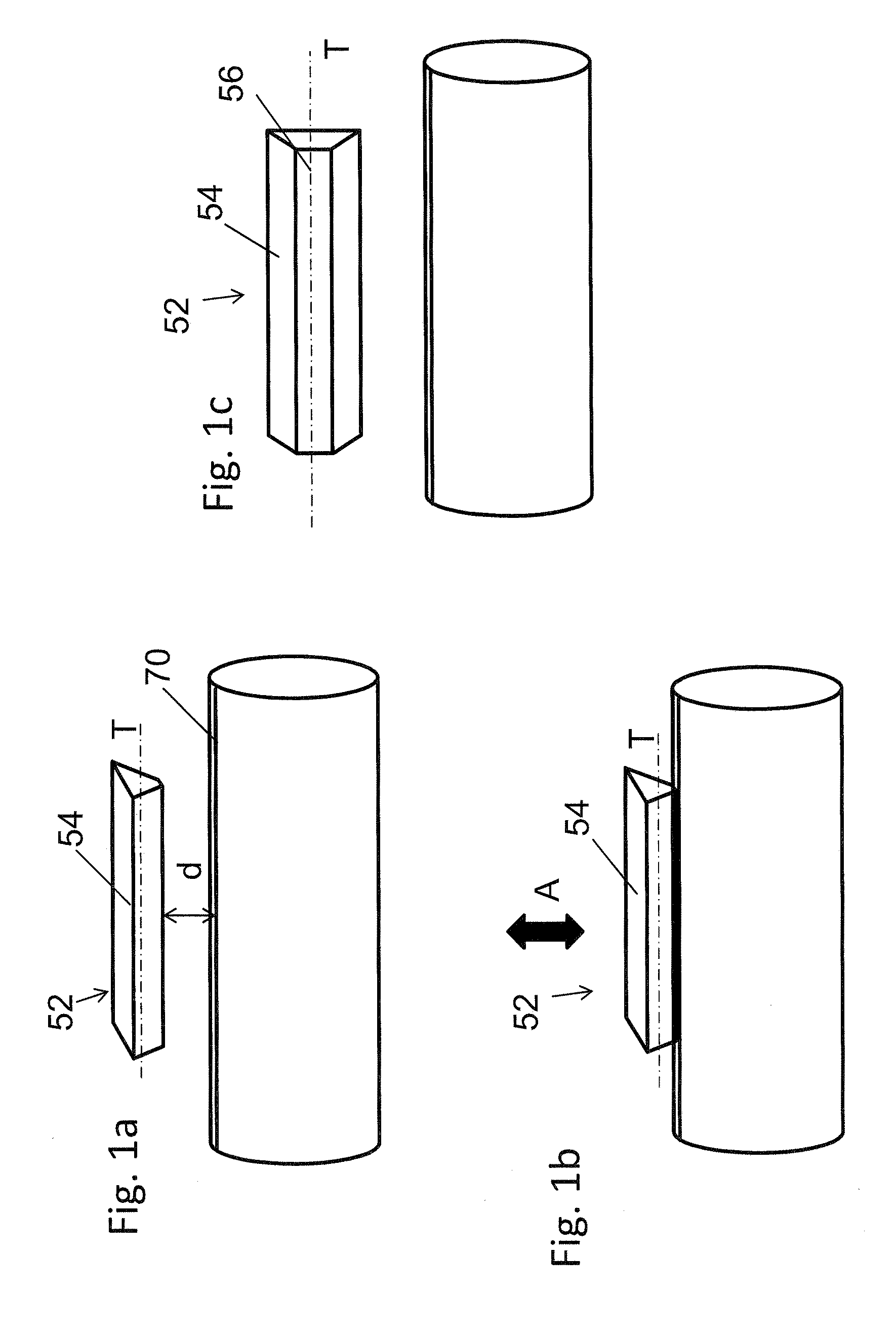

A device and a method for the manufacture of sausages from paste mass, in particular sausage meat, with a coextrusion head for coextruding the paste mass and a sausage casing, wherein the coextrusion head comprises a filling tube for the ejection of the paste mass as well as an extrusion die assigned to the filling tube with an extrusion gap for ejecting the casing material. In order to produce strong sausage casings, the filling tube protrudes by a distance X beyond the annular gap so that the casing material is extruded through the annular gap onto the filling tube and solidifies along the filling tube.

Owner:ALBERT HANDTMANN MASCHFABRICK

Device and method for manufacturing sausages

A device and a method for the manufacture of sausages from paste mass, in particular sausage meat, with a coextrusion head for coextruding the paste mass and a sausage casing, wherein the coextrusion head comprises a filling tube for the ejection of the paste mass as well as an extrusion die assigned to the filling tube with an extrusion gap for ejecting the casing material. In order to produce strong sausage casings, the filling tube protrudes by a distance X beyond the annular gap so that the casing material is extruded through the annular gap onto the filling tube and solidifies along the filling tube.

Owner:ALBERT HANDTMANN MASCHFABRICK

Method for producing a netted casing

InactiveUS7883399B2Sausage casing manufactureSausage casing shirringEngineeringStructural engineering

Owner:VISKOTEEPAK BELGIUM NV

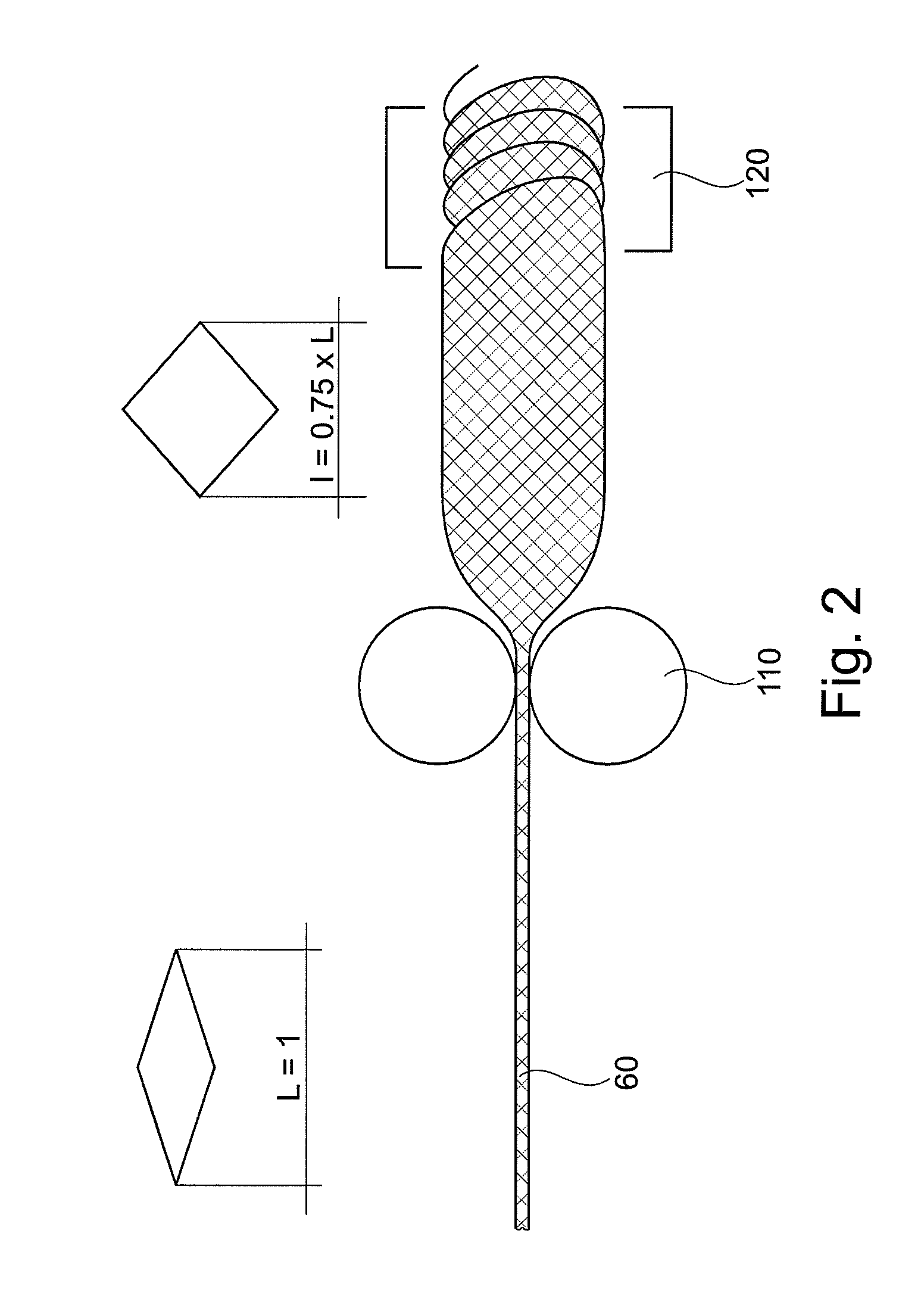

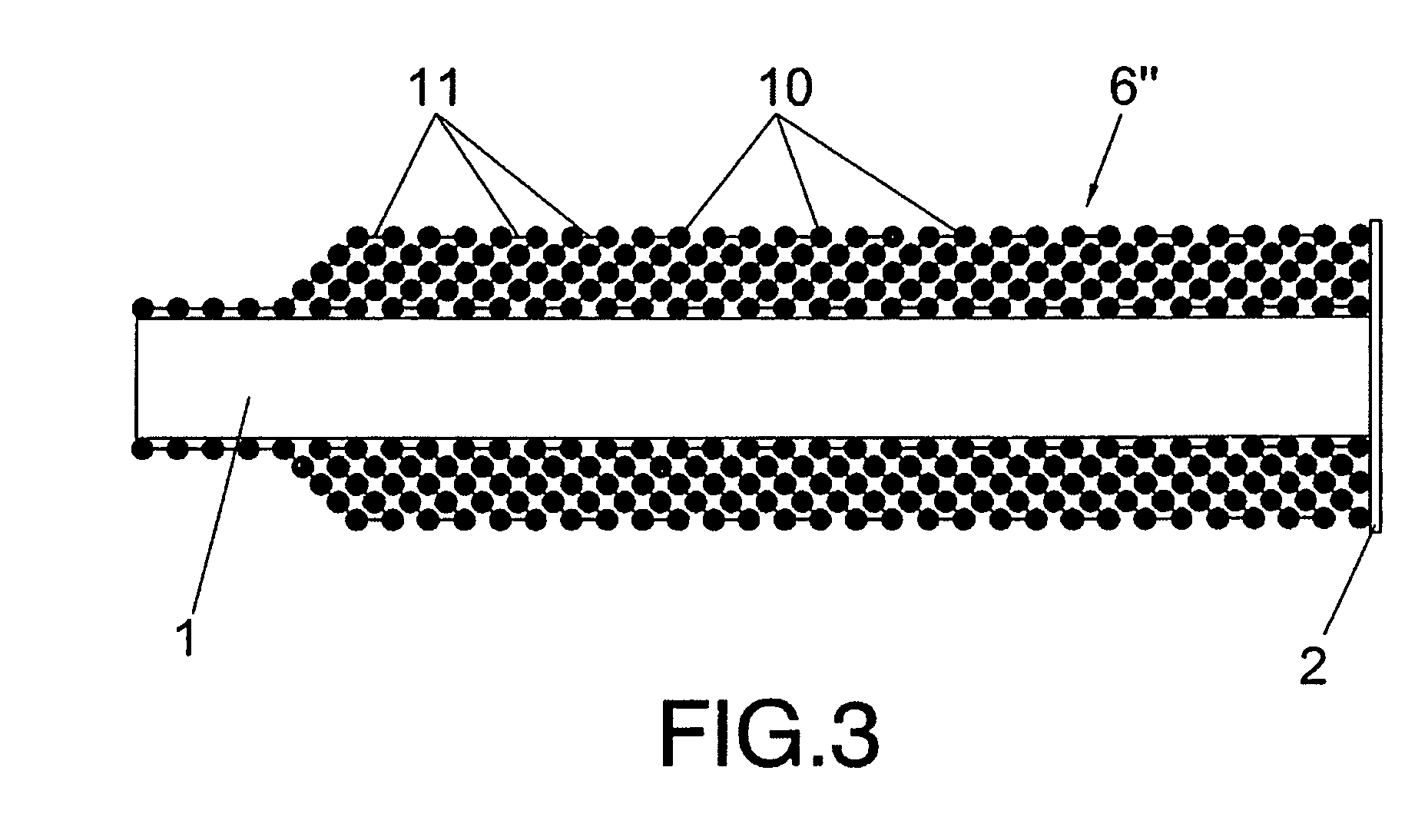

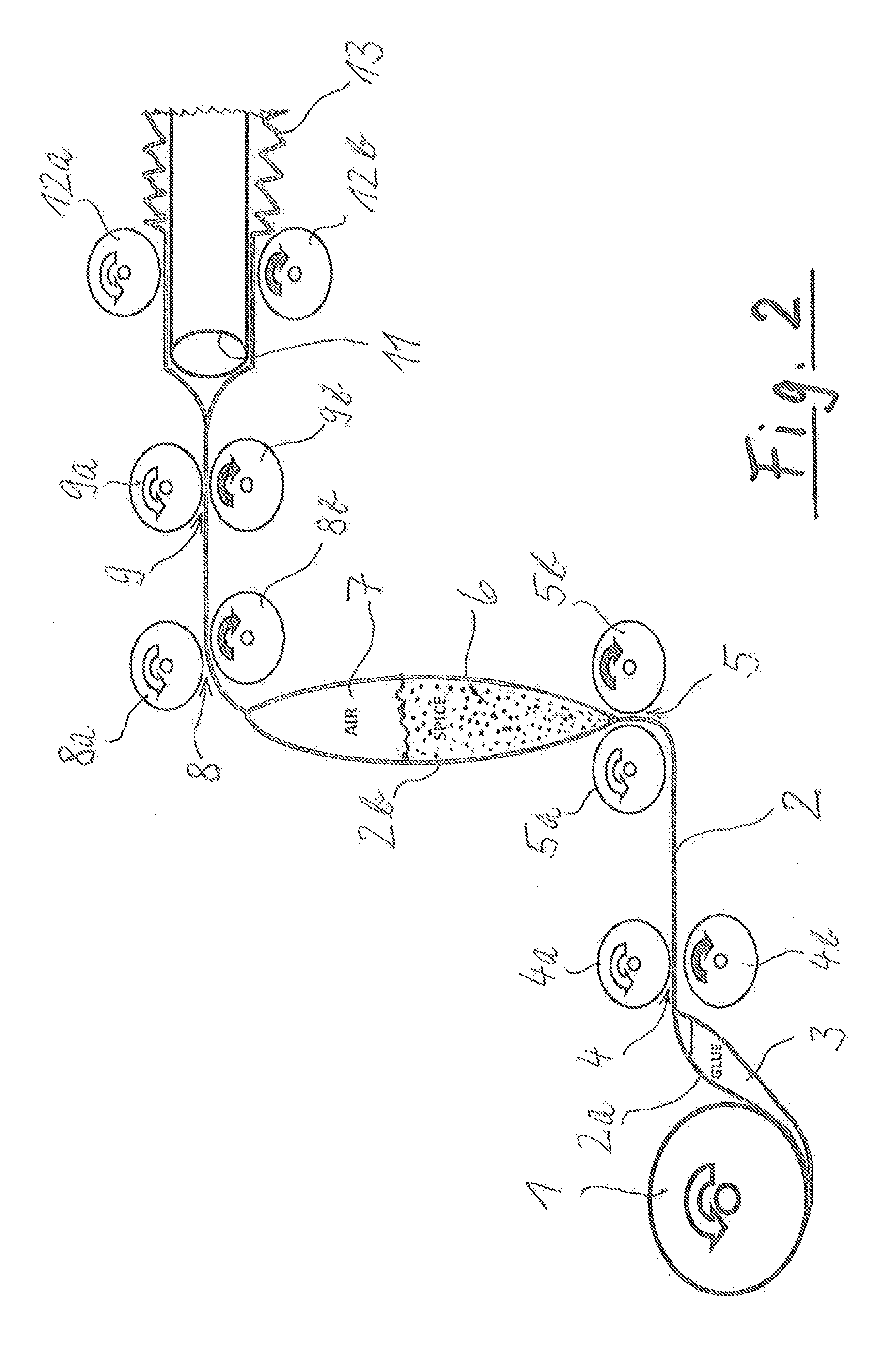

Multi-layer arrangement of a tubular net on a support tube, and device and method for obtaining same

ActiveUS20050281924A1Smoothly unfoldSmooth unloadingContainers for flexible articlesReady-for-oven doughsMaximum diameterEngineering

The invention relates to a method and means which are used to obtain a multi-layer arrangement of a tubular net (6) which is first positioned on a transfer tube (3). According to the invention, a toothed loader (5) is used to slide the net (6) along the outside of the transfer tube (3) to the end thereof, said end comprising a slightly conical end zone (4). When the net (6′) reaches said end zone (4), it falls on to the support tube (1) in an arrangement of concentric layers (6′). In this way, the outer layers of the loaded net (6″) have a maximum diameter equal to that of the transfer tube (3) while the inner diameter of the loaded net (6″), which corresponds to the outer diameter of the support tube (1) is less than the maximum diameter of the stretched net.

Owner:VISCOFAN

Food product having a casing

ActiveUS8980349B2Less prone to weakening over timeTimely controlMilk preparationAlcoholic beverage preparationCo extrusionFood products

The present invention is directed to a process for preparing a food product having a casing, the process comprising the step of applying a casing paste comprising alginate and a sparingly soluble calcium salt by co-extrusion to the exterior of a material to be cased to form a co-extruded product, and contacting the co-extruded product with a solution comprising calcium ions, thereby causing the alginate to gel.

Owner:DUPONT NUTRITION USA INC

Device and method for manufacturing sausages

ActiveUS7591717B2Easy to manufactureIncrease pressureSausage makingSausage casing manufactureMechanical engineeringExtrusion

A device and a method for the manufacture of sausages from paste mass, in particular sausage meat, with a coextrusion head for coextruding the paste mass and a sausage casing, wherein the coextrusion head comprises a filling tube for the ejection of the paste mass as well as an extrusion die assigned to the filling tube with an extrusion gap for ejecting the easing material. In order to produce strong sausage casings, the filling tube protrudes by a distance X beyond the annular gap so that the casing material is extruded through the annular gap onto the filling tube and solidifies along the filling tube.

Owner:ALBERT HANDTMANN MASCHFABRICK

Bonding station for two different bonding processes

ActiveUS20140206515A1Easy to disassembleLow costMechanical working/deformationPaper/cardboard wound articlesBonding processMechanical engineering

The invention concerns a method and an apparatus for producing a tubular packaging casing, wherein a film web is fed in a feeding direction to forming means for forming a tubular casing having edge areas which extend in the feeding direction and which are arranged adjacent to each other, and wherein the edge areas are bonded together in a bonding station having one bonding tool. Moreover, the bonding tool can be moved in a first and a second working position for carrying out two alternative processes of firmly bonding in one of each of the working positions for bonding the edge areas of the tubular casing together.

Owner:POLY CLIP SYST

Natural sausage casing sleeve drying mould and technology

PendingCN108576166AGuaranteed StrengthWon't swellSausage casing manufactureOperation modeEngineering

The invention relates to a natural sausage casing sleeve drying mould and technology. The natural sausage casing sleeve drying mould comprises a flexible pipe made from elastic material, the flexiblepipe comprises an inner layer and an outer layer, the inner layer is hollow, a sealed cavity is formed between the outer layer and the inner layer, and liquid is encapsulated in the cavity. The technology of a natural sausage casing sleeve comprises the steps that the two ends of the mould are tightened to form a straight rod; the mould is covered by one or more layers of natural sausage casing pipes or natural sausage casing pieces until the mould is completely covered; a sausage casing on the mould is dried; the moulded dried natural sausage casing is pulled off from the mould directly to obtain the dried natural sausage casing sleeve. Compared with the prior art, the natural sausage casing sleeve drying mould and technology have the advantages that the length of the mould can reach 10 meters or above, through the annular sealed cavity structure of the mould, the radial strength of the mould is guaranteed, by adopting the sausage casing drying technology, the steps of inflation and deflation of the mould are not needed, a complex operation mode of taking out moulds such as rice chaff is also not needed, and the dried natural sausage casing sleeve can be pulled off from the moulddirectly, so that the working efficiency is greatly improved.

Owner:王孝磊

Casing for Foodstuff

ActiveUS20120082768A1Easy to storeEasy to transportLiquid surface applicatorsWrappersParticulatesAdhesive

A method for coating tubular food-casings (2), particularly skins with flavoring substances in particle form, includes wetting the casing (2) on the inside with adhesive, and then applying desired flavoring substances (6) onto the formed adhesive layer. The tubular casing (2), coated on the inside with adhesive, is guided through a first squeezing zone (5) and a second squeezing zone (8) in the travel direction, where the respective interior cross-sections of the tubular casing are temporarily closed. The second squeezing zone (8) is positioned higher than the first squeezing zone (5). The tubular casing is brought into the form of an inflated sack (2b) in between the two squeezing zones (5, 8) by a supply of particulate flavoring substances (6) and an air pocket (7) inserted into the interior of the tubular casing. During travel, the casing entrains the flavoring substances (6) from the supply.

Owner:WORLD PAC INT

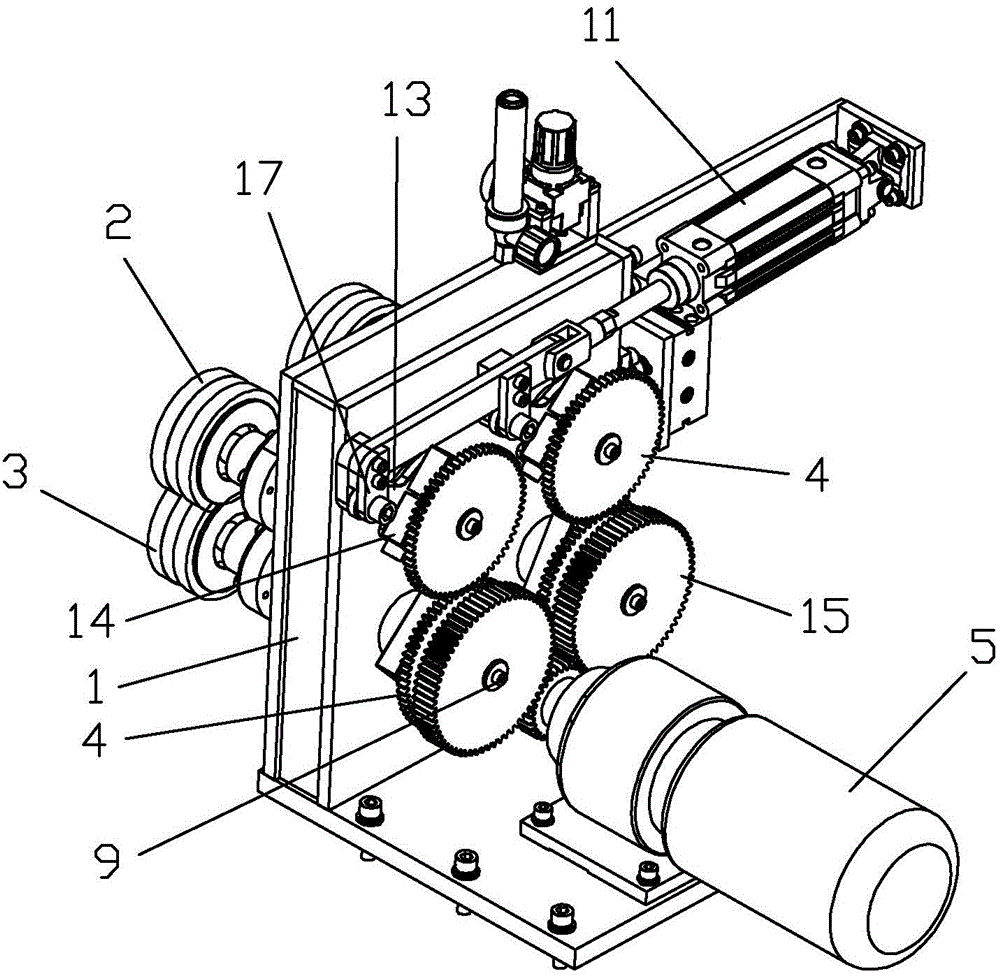

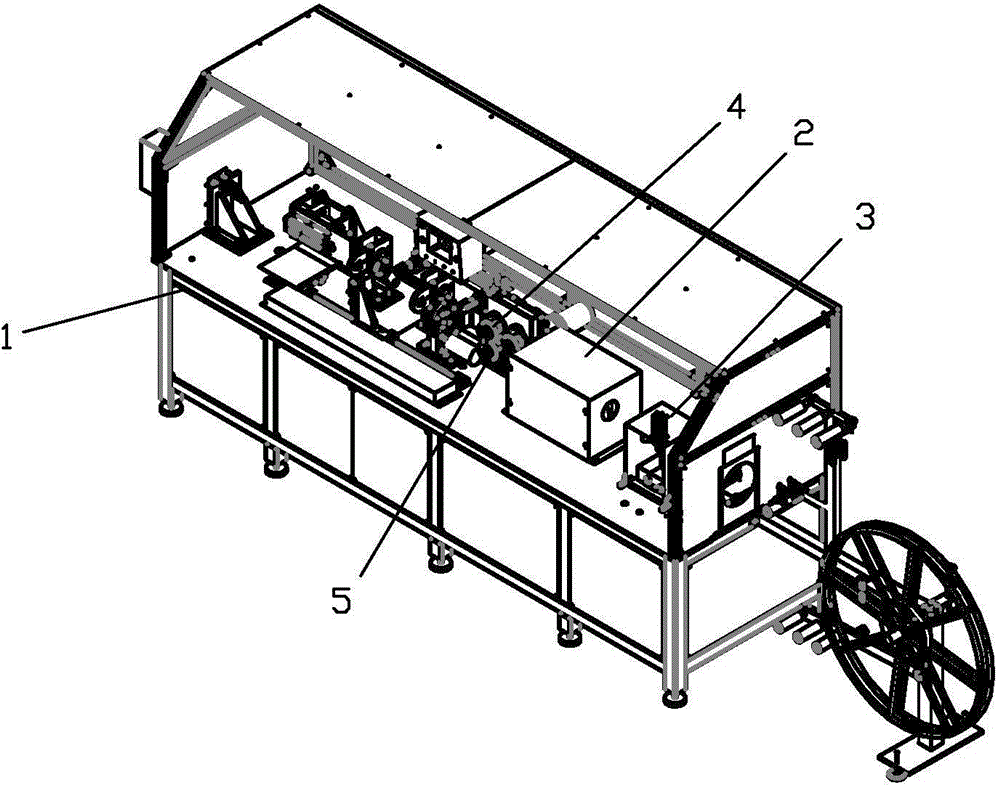

Improved sleeving and shrinking machine

ActiveCN104872263AHigh clothes removal efficiencyIncrease delivery speedSausage casing manufactureSausage casing shirringProduction lineDrive shaft

The invention provides an improved sleeving and shrinking machine which includes a machine frame, wherein the machine frame includes a sleeving and shrinking machine body, oil coating clamps and a casing stripping device; the casing stripping device includes at least two pairs of casing stripping wheels, and each pair of casing stripping wheels includes an upper casing stripping wheel and a lower casing stripping wheel; the upper casing stripping wheels and the lower casing stripping wheels are connected with transmission shafts; the transmission shafts penetrate through a machine panel and are connected with external gears; the external gears are driven by a motor, so as to drive the upper casing stripping wheels or the lower casing stripping wheels to rotate. According to the improved sleeving and shrinking machine provided by the invention, the casing stripping efficiency of the casing stripping wheels is high, the casing conveying speed is increased, and the oil coating clamps can be used for on-line oil coating without affecting the conveying of casings, therefore, the production efficiency of the entire production line is greatly improved.

Owner:广东德福隆生物科技有限公司

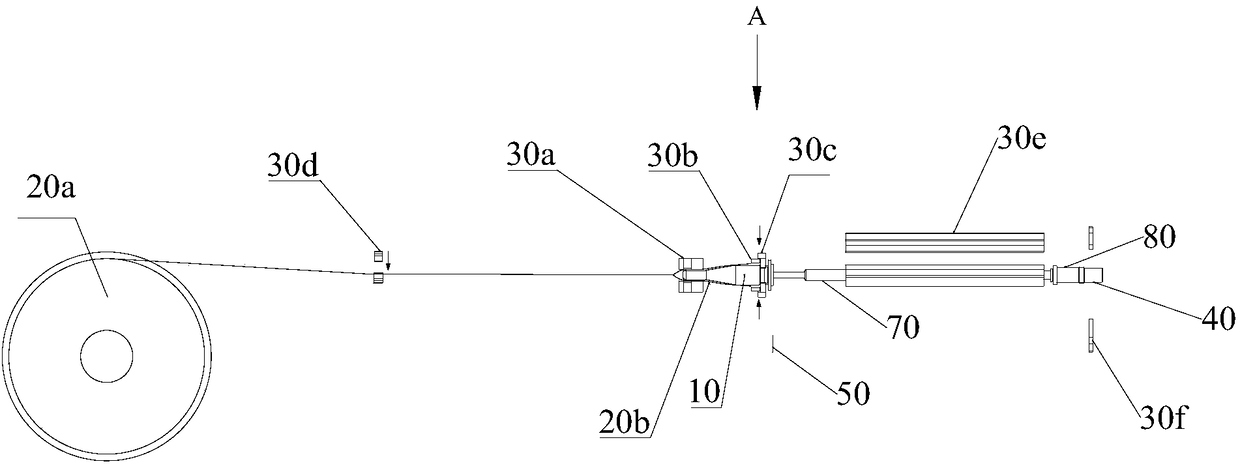

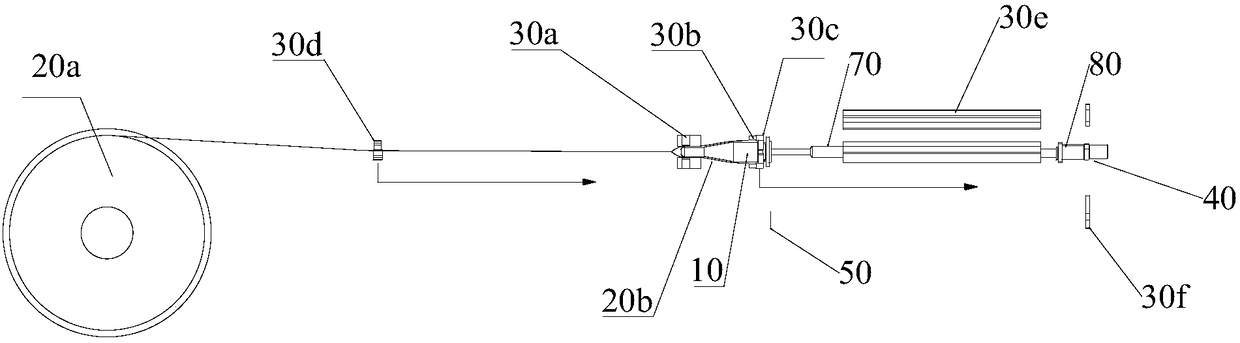

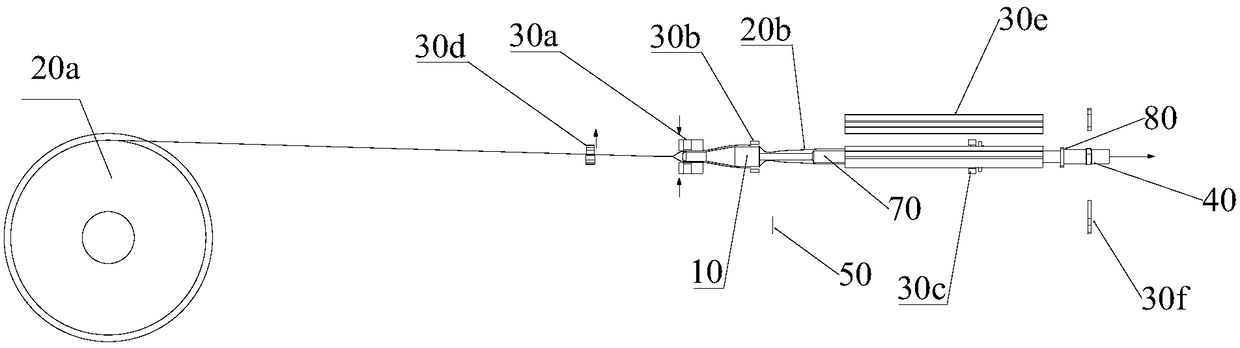

Packaging equipment, sleeving and shrinking machine and packaging method for performing continuous and automatic mesh sleeving of sausage casings

ActiveCN108477273ARealize fully automatic packagingSkinless sausage makingSausage casing manufactureReciprocating motionBiomedical engineering

The invention relates to packaging equipment, a sleeving and shrinking machine and a packaging method for performing continuous and automatic mesh sleeving of sausage casings. The packaging equipmentcomprises a shuttle (10), a first clamp hand (30a), a second clamp hand (30b), a third clamp hand (30c) and a fourth clamp hand (30d), wherein the shuttle (10) is used for sleeving mesh bags (20b); the first clamp hand (30a) can be opened or closed to release or fixedly clamp the shuttle (10); when closed, the second clamp hand (30b) can drive an open end of the mesh bag (20b) to perform reciprocating motion between a first position and a second position on the shuttle (10), and when opened, the second clamp hand (30b) can allow the mesh bag (20b) to move freely along a conveying direction ofthe mesh bag; the third clamp hand (30c) is used for clamping the open end of the mesh bag (20b) and dragging the mesh bag to sleeve a whole sleeved and shrunk sausage casing (70); and the fourth clamp hand (30d) is used for dragging the mesh bag (20b) to unwind the mesh bag (20b) from a mesh bag roll (20a), and the fourth clamp hand (30d) is designed in a form of capable of moving together with the third clamp hand (30c).

Owner:FOSHAN VEHICIAN LNTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com