Method for production of soft natural casing, soft natural casing, and processed meat product

A manufacturing method and natural technology, which can be used in the chemical treatment of natural sausage, processed meat, sausage casings, etc., and can solve problems such as unusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

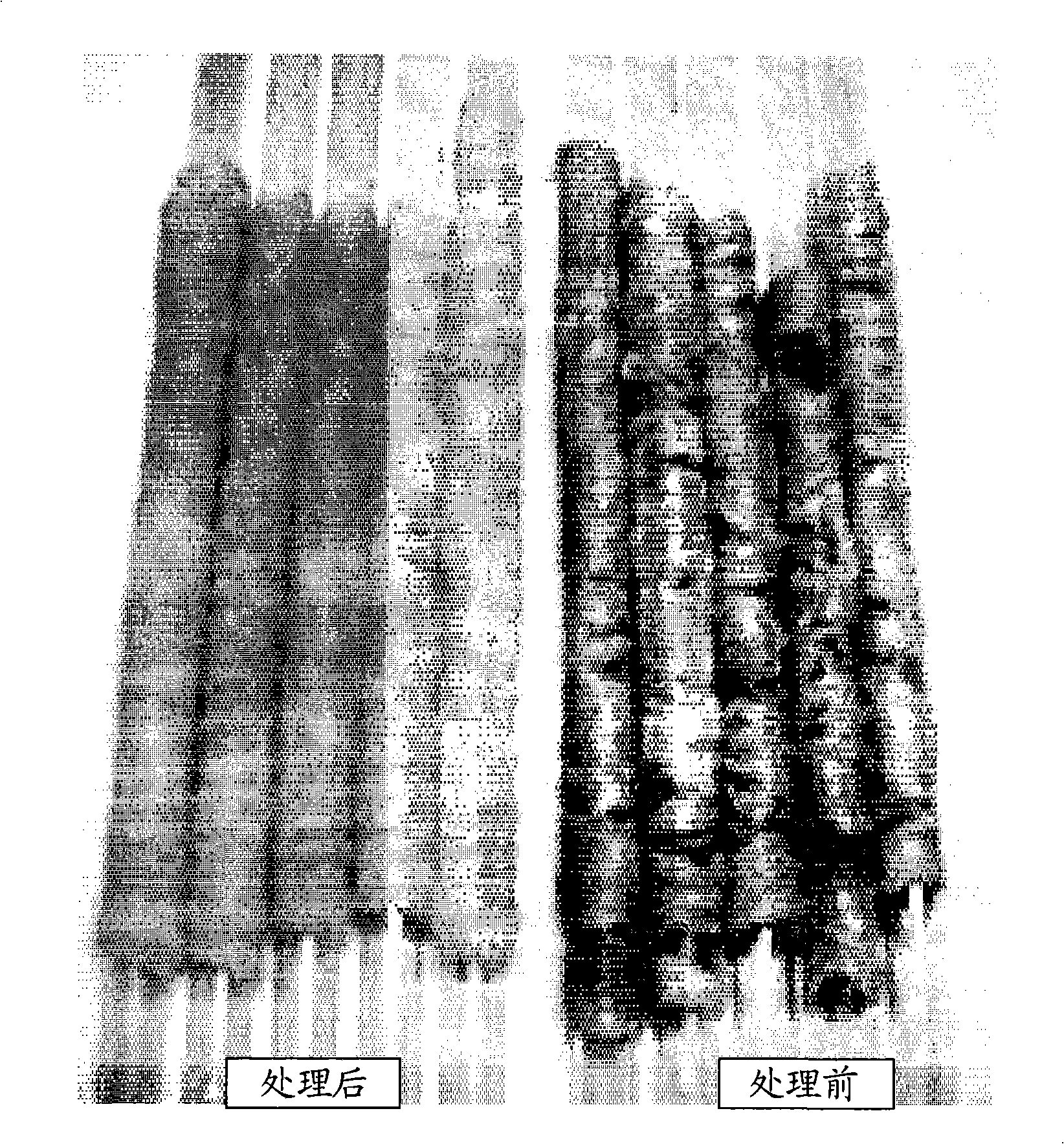

[0051] 1% by mass of calcium hydroxide was mixed and dissolved in water at a water temperature of 25°C to prepare a calcium hydroxide aqueous solution with a pH of 12 to 13. Then, in the above-mentioned calcium hydroxide aqueous solution, natural casings from Chinese pig intestines mounted on a tubular support were immersed for 12 days. In addition, the immersion liquid was stirred once a day.

[0052] Next, the natural casings 12 days after immersion were taken out, washed with running water, immersed in a 0.1% by mass ammonium sulfate aqueous solution for 30 minutes to neutralize, and washed with running water to obtain soft natural casings.

[0053] As a result of measuring the breaking strength of the natural casing, the breaking strength before the softening treatment was 7.2N, the breaking strength after 7 days of immersion treatment was 6.2N, and the breaking strength after 12 days of immersion treatment was 4.8N.

[0054] In addition, each natural casing is cut into a film...

Embodiment 2

[0076] Except for setting the water temperature of the calcium hydroxide aqueous solution to 10°C and immersing for 18 days, the natural casings derived from Chinese pig intestines were softened and evaluated in the same manner as in Example 1.

[0077] As a result of measuring the breaking strength of the obtained natural casing, the breaking strength before the softening treatment was 7.2N, the breaking strength after 7 days of immersion treatment was 6.6N, and the breaking strength after 18 days of immersion treatment was 5.0N.

[0078] Then, in the same manner as in Example 1, the food texture of the sausage using the soft natural casing that had been immersed for 18 days was evaluated. The results are shown in Table 1.

Embodiment 3

[0080] Except for setting the water temperature of the calcium hydroxide aqueous solution to 30°C and immersing for 9 days, the natural casings derived from Chinese pig intestines were softened and evaluated in the same manner as in Example 1.

[0081] As a result of measuring the breaking strength of the natural casing, the breaking strength before the softening treatment was 7.2N, the breaking strength after 7 days of immersion treatment was 5.9N, and the breaking strength after 9 days of immersion treatment was 4.6N.

[0082] Then, in the same manner as in Example 1, the food texture of the sausage using the soft natural casing that had been immersed for 9 days was evaluated. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com