Patents

Literature

60results about "Natrual gut chemical treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high meat viscosity collagen sausage casings and the high meat viscosity collagen sausage casings

PendingCN107439656AImprove shrinkageHigh meat viscosityNatrual gut chemical treatmentMacromolecular SubstancesSlurry

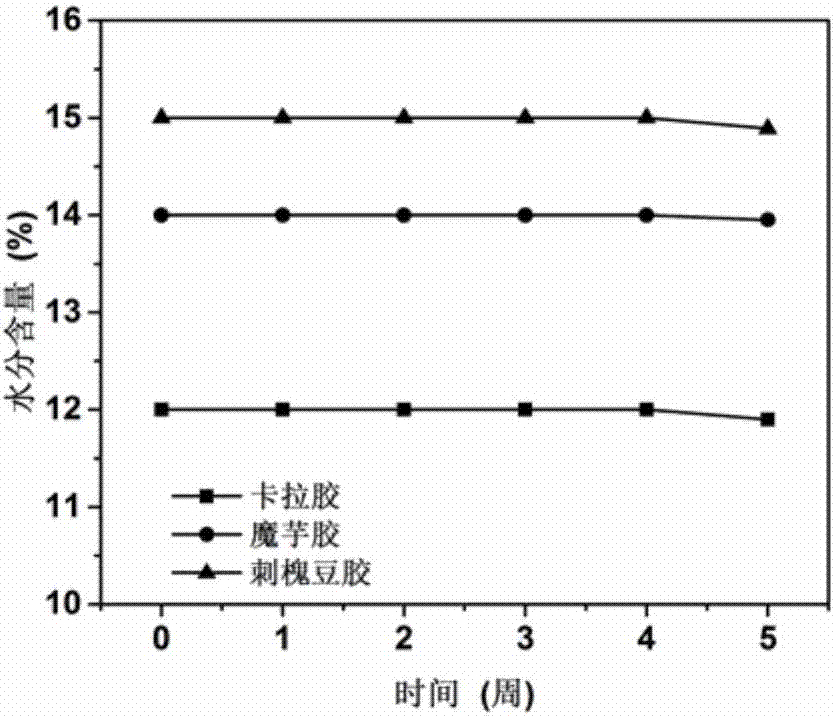

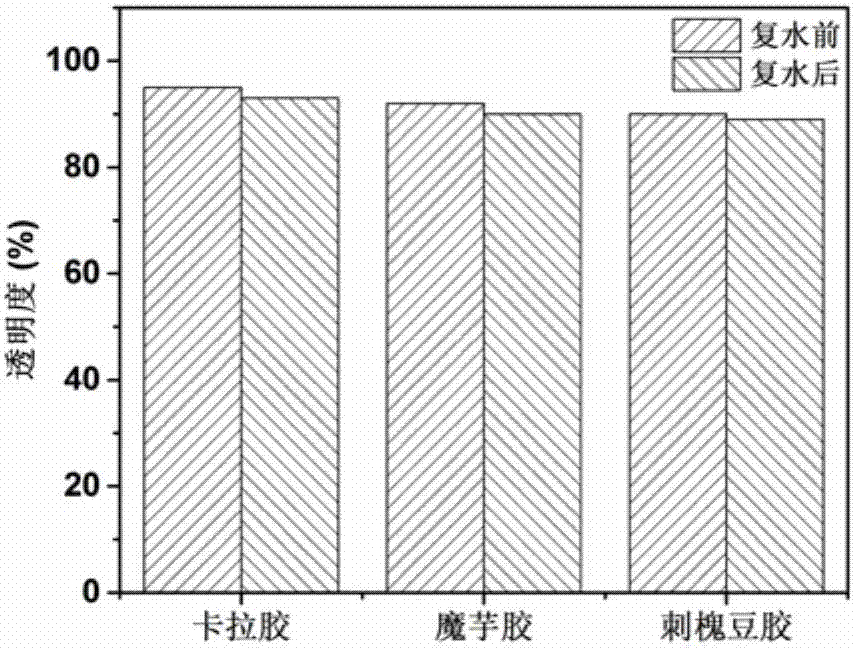

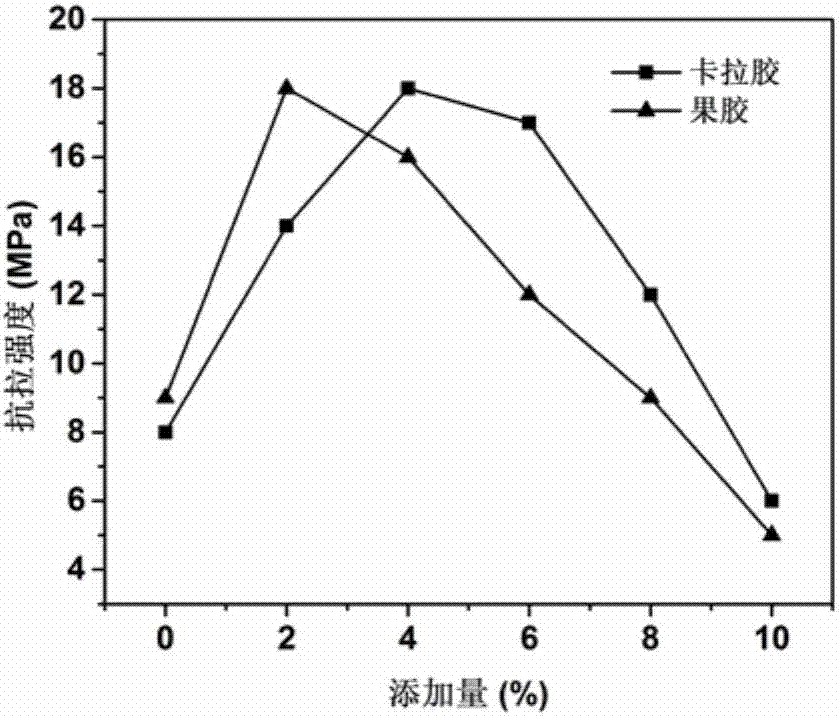

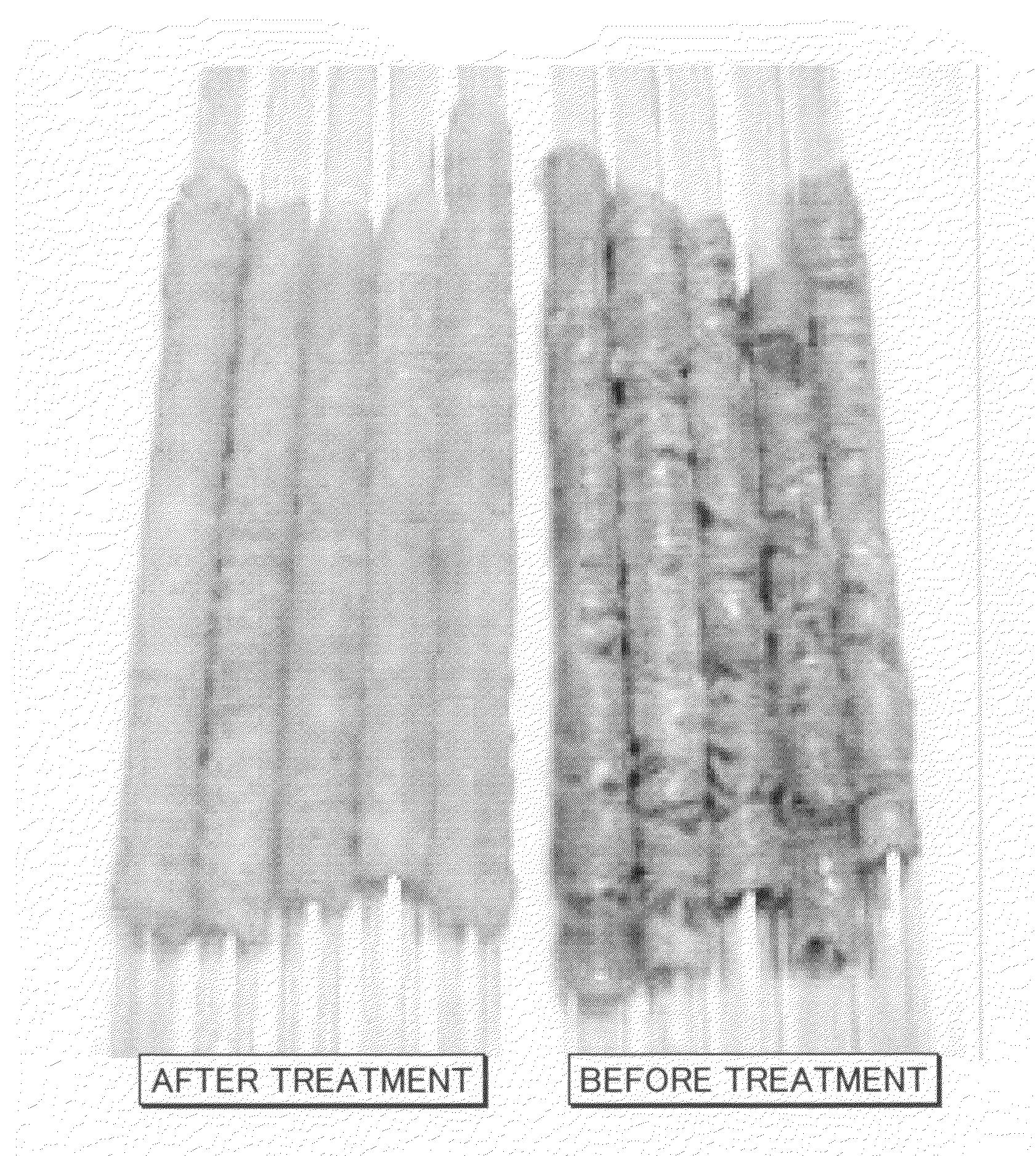

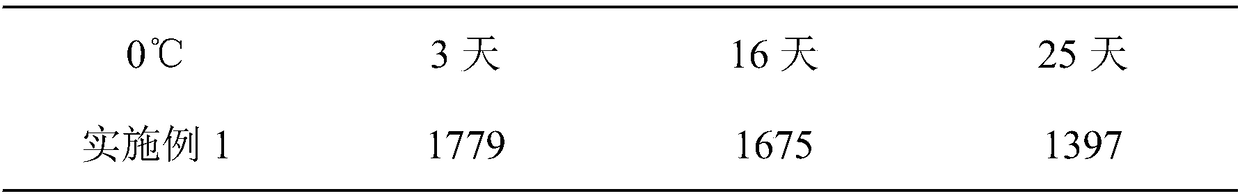

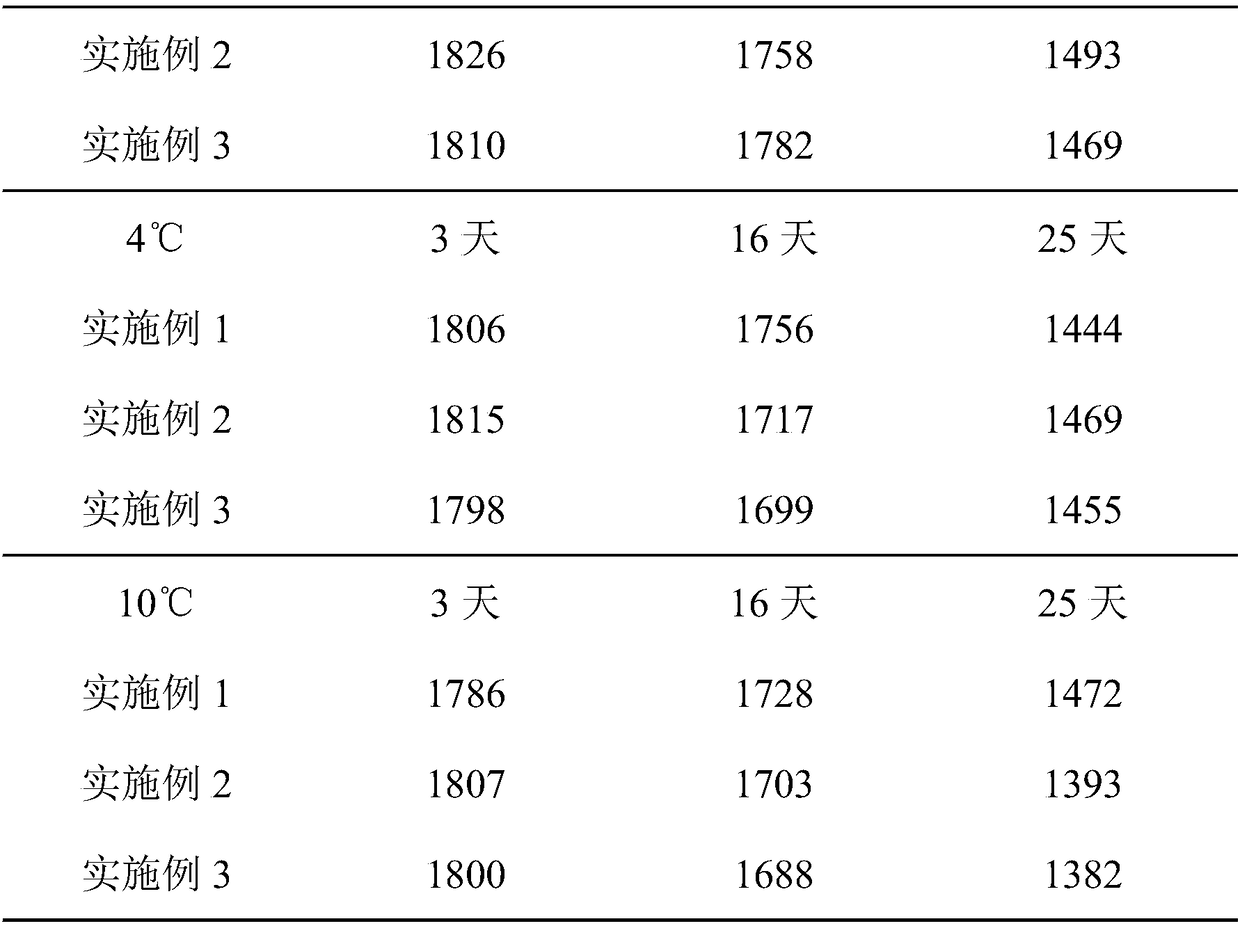

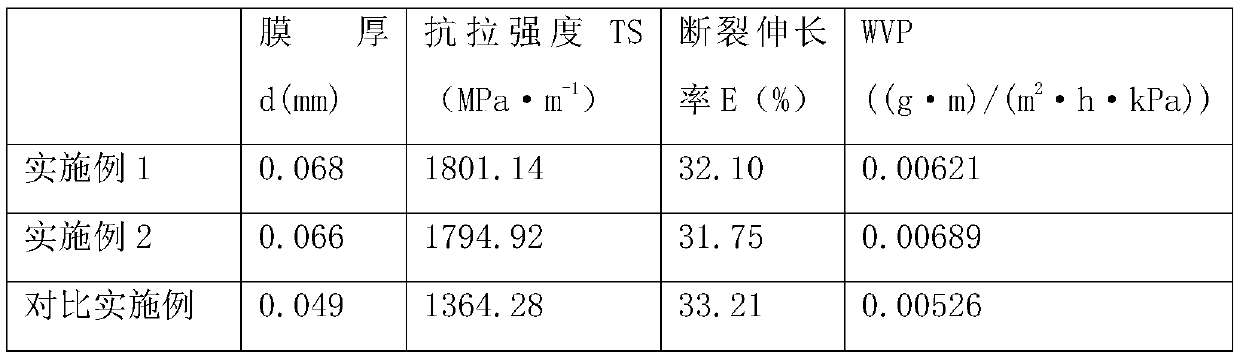

The present invention discloses a preparation method of high meat viscosity collagen sausage casings and the high meat viscosity collagen sausage casings. The method comprises the following steps: an edible macromolecular substance and a hydrochloric acid solution are mixed to obtain a macromolecular acid dispersion liquid; the macromolecular acid dispersion liquid and a cattle hide slurry are mixed, glycerin is added, the materials are mixed to prepare collagen balls, and the collagen balls are put still; the collagen balls are homogenized, the homogenized materials are filtered, the filtered materials are squeezed, air and ammonia gas are ventilated to conduct a solidification, and washing, continuous drying with hot air and rewetting are conducted to obtain the high meat viscosity collagen sausage casings. The specific edible macromolecular substance in the prepared collagen sausage casings exists in granular states in the sausage casings, can be slowly dissolved during processing of cooking, frying and baking, and is not limited by meat stuffings of the sausages, so that the sausage casings are excellent in contractility and high in meat viscosity. The prepared collagen sausage casings are strong in water-holding capacity, high in transparency before and after rehydration, uniform in thickness, delicate and even in taste, and also extremely excellent in strength, toughness and barrier properties.

Owner:BEIJING QIUSHI AGRI DEV

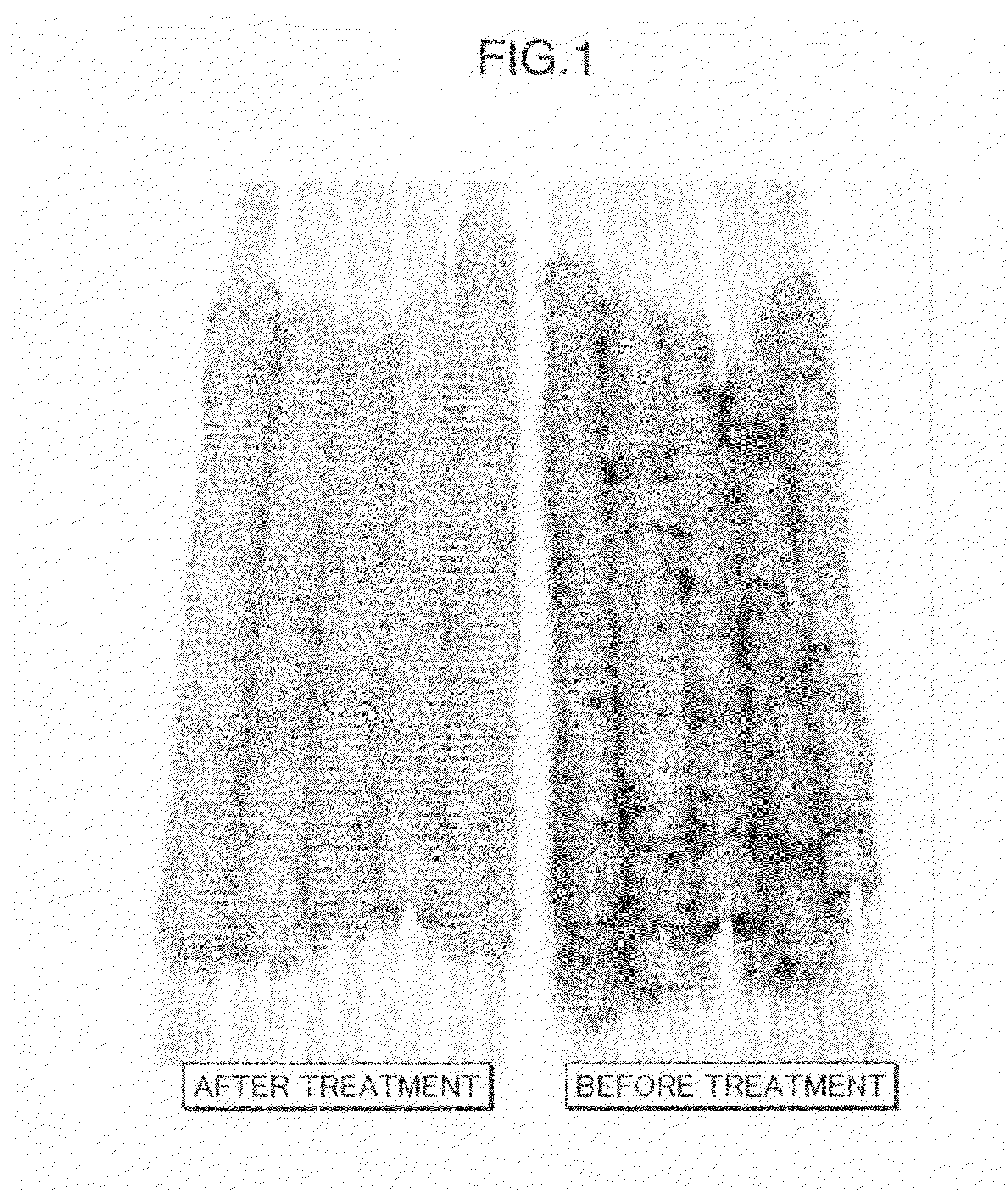

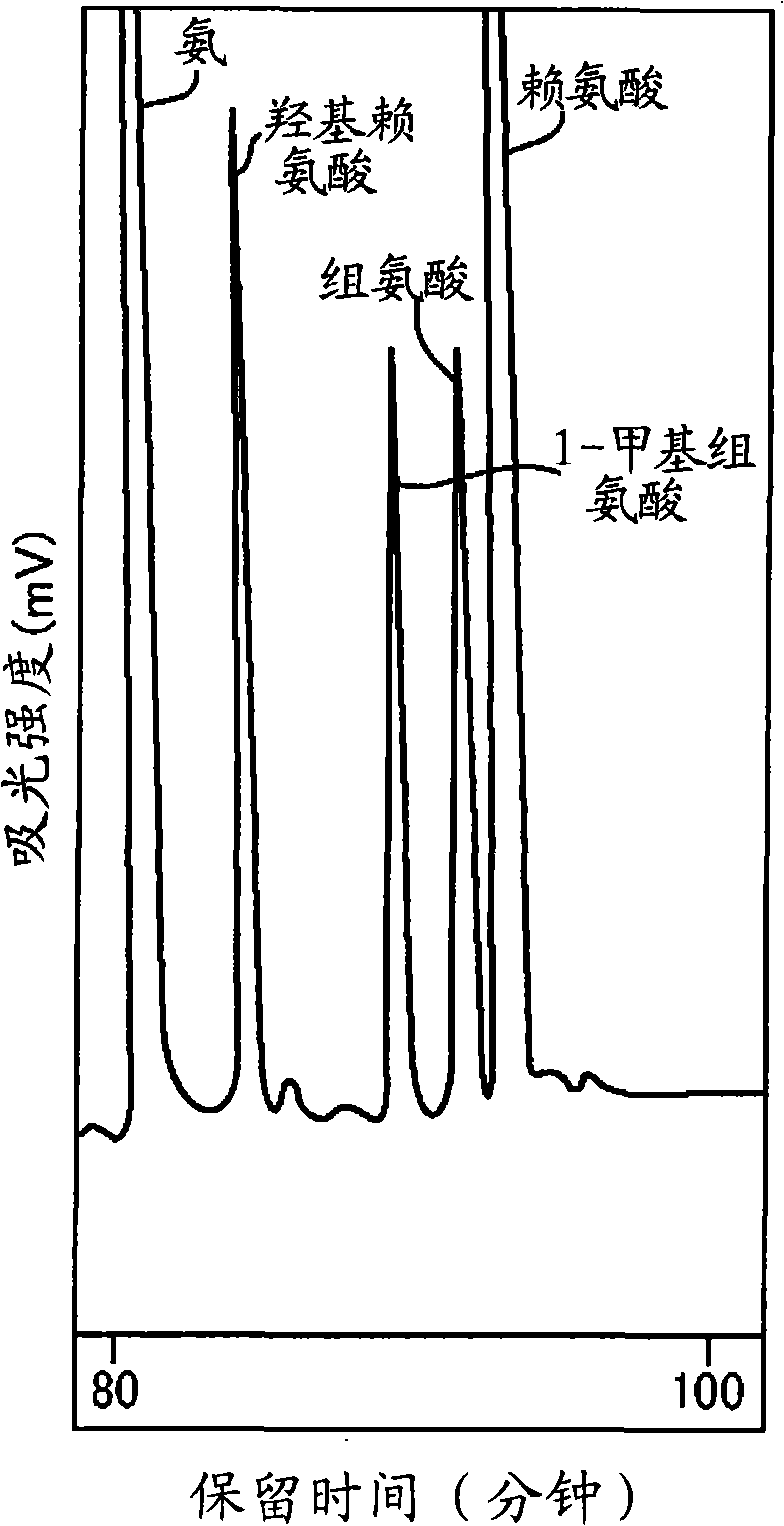

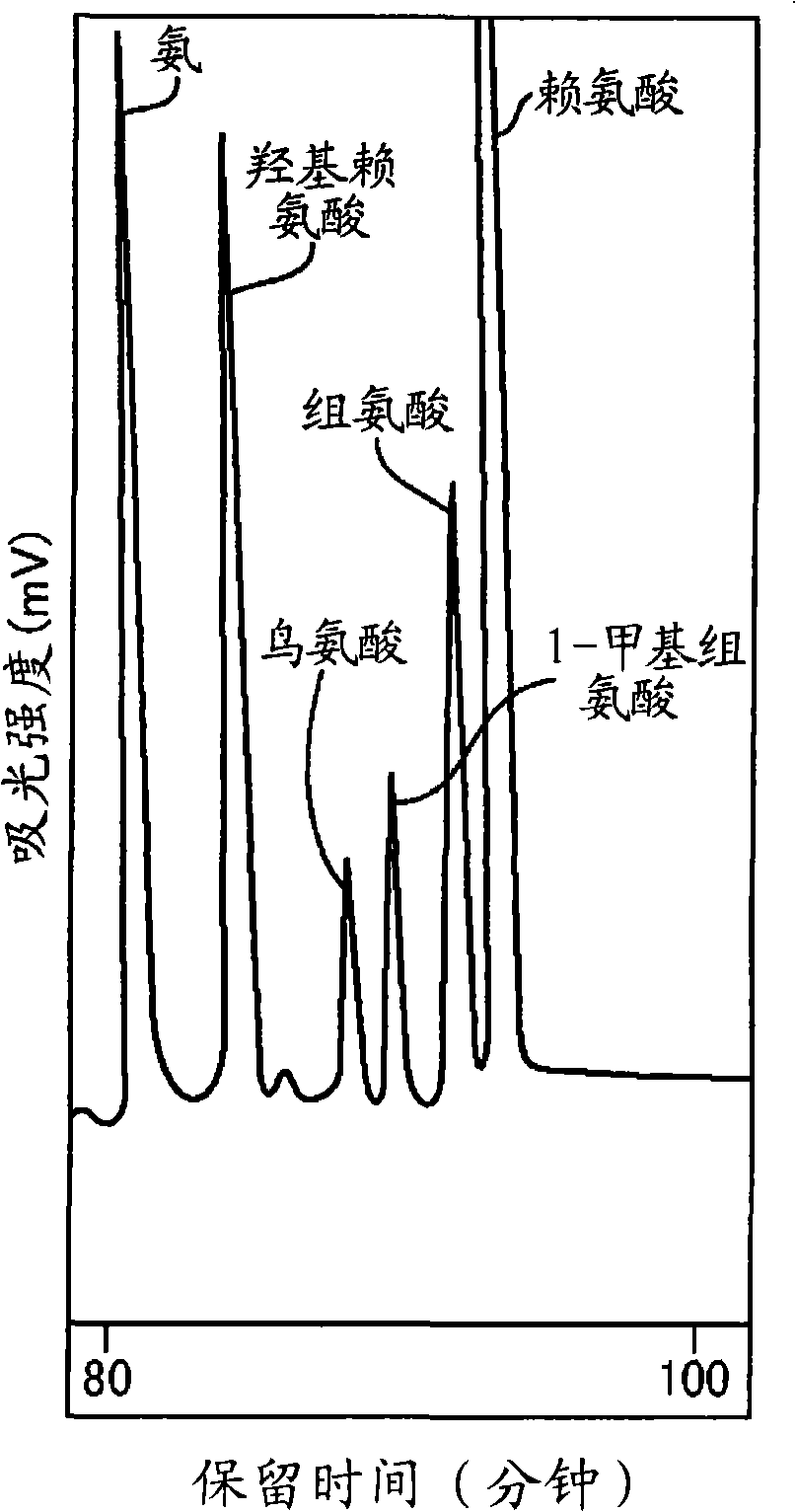

Method for Producing Soft Natural Intestine Casing, Soft Natural Intestine Casing, and Processed Meat Product

InactiveUS20090269449A1Soften a hard natural intestine casingImprove textureContainers for flexible articlesMilk preservationFlavorAqueous solution

In a method for a producing soft natural intestine casing, a natural intestine casing is treated in an alkaline aqueous solution at a temperature from 3 to 40° C. and pH from 11 to 13. By the method for producing a soft natural intestine casing, a soft natural intestine casing with a superior texture can be easily obtained. The natural intestine casing does not adversely affect the savor or flavor of sausages themselves.

Owner:TAGUCHI YASUKI +2

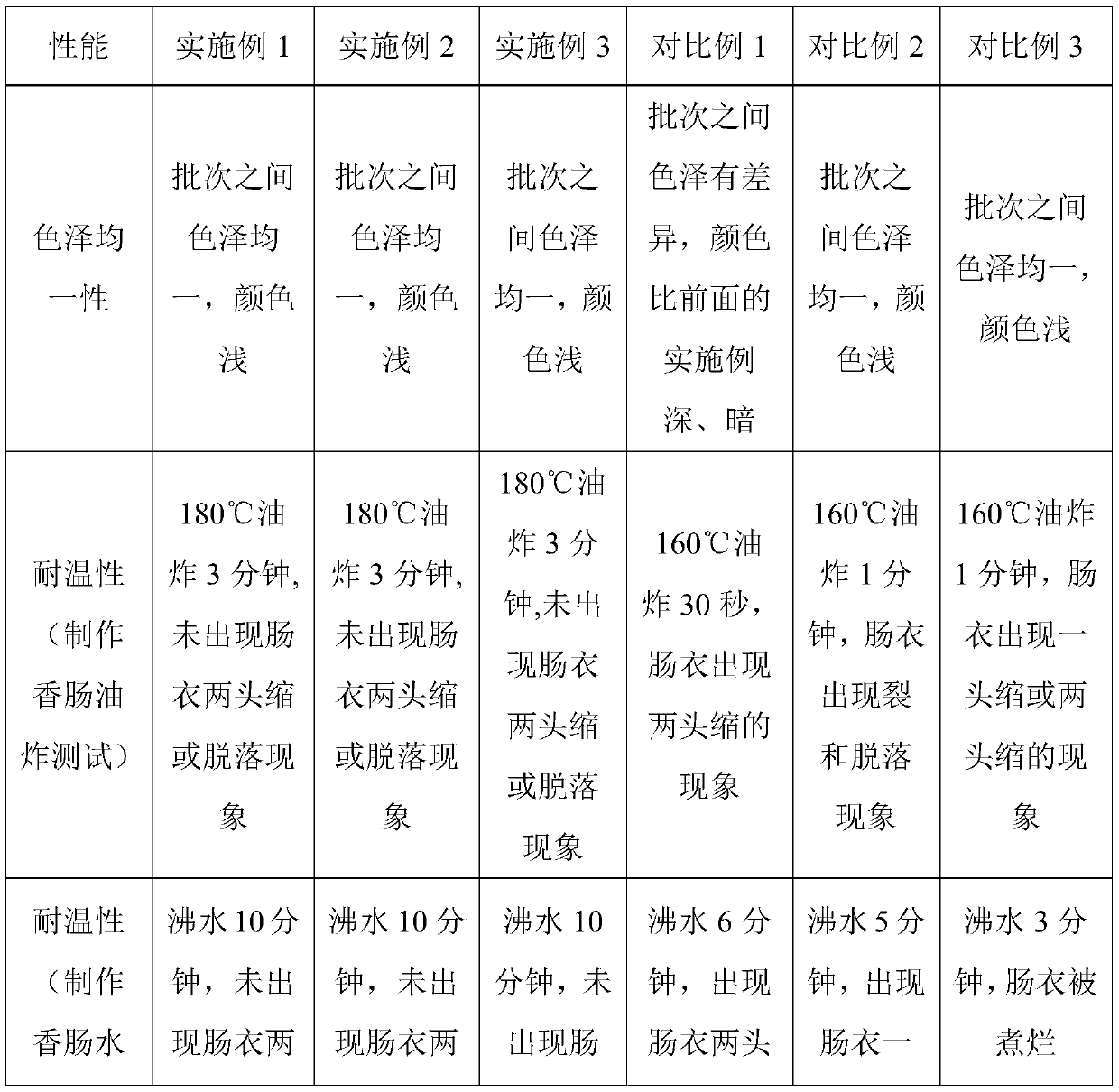

Production process of boiled/fried collagen casing

ActiveCN110140747AIncrease the degree of cross-linkingWeave evenlyTextile casingsCellulosic sausage casingsFiberPolyol

The invention relates to the technical field of casing production, in particular to a production process of a boiled / fried collagen casing. In the process of extracting collagen fibers, small molecular polyols, a strong oxidant and ferric ions are added into a semi-finished product after ash washing to carry out pretreatment, and then acidification is carried out. The method performs pretreatmenton the semi-finished product after ash washing, increases the crosslinking degree in the collagen casing; a collagen group is obtained by adding proper auxiliary materials and collagen fibers; the casing blowing process is improved by optimizing the process parameters and adjusting the process steps; and the crosslinking further occurs among collagen molecules and in the molecules by optimizing the technological parameters of a sleeve shrinkage curing process. The process is simple and feasible; the prepared casing has good temperature resistance, pressure resistance and mechanical properties;and the casing is uniform and beautiful in color, stable in quality and beneficial to industrial production.

Owner:山东海奥斯生物科技股份有限公司

Process for preparing dried casing with controllable aperture

ActiveCN104413132AEfficient removalStay hydratedNatrual gut chemical treatmentCream preparationAcetic acidRoom temperature

The invention discloses a process for preparing dried casing with a controllable aperture. The process comprises the following steps: firstly, soaking salted casing in clear water, regulating the pH value to 2-3 by using glacial acetic acid, clearing the soaked salted casing, soaking the casing in clear water again, regulating the pH value to 11-13 by using sodium hydroxide, clearing the casing with clear water again, adding glycerinum, and stirring uniformly to obtain primary casing; sleeving a tubular mould by he primary casing, and drying the primary casing at 40-60 DEG C; cooling the primary casing to the room temperature, and dehumidifying to demould; manually necking or necking the demoulded casing on a thin plastic pipe with a target outside diameter by a necking machine, and standing and ageing the casing necked on the thin plastic pipe at the temperature of 65-85 DEG C for 2-6 hours; and finally performing moisture preservation package or vacuum package. The casing prepared by the process is good in toughness and cannot be easily damaged during necking, and dried casing with various apertures can be customized without depending on the aperture of the raw material salted casing.

Owner:顺平县志一肠衣技术开发有限公司

Method for production of soft natural casing, soft natural casing, and processed meat product

Owner:NIPPON HAM

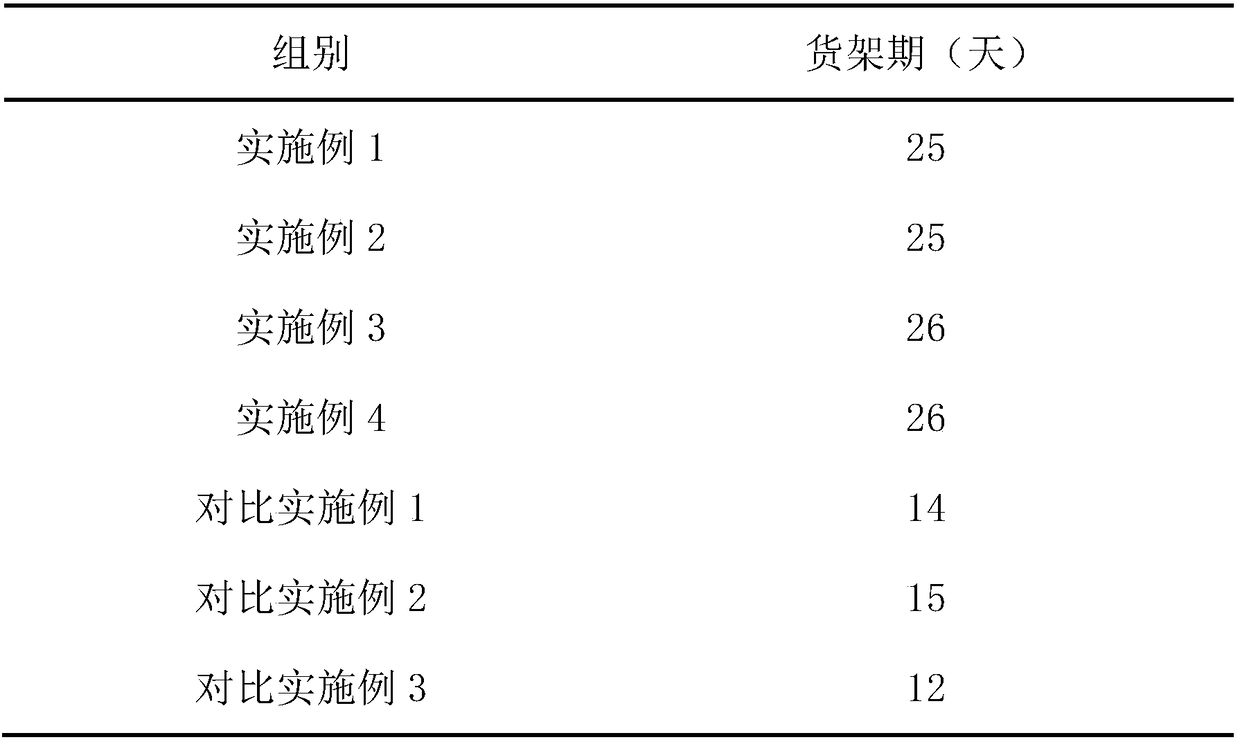

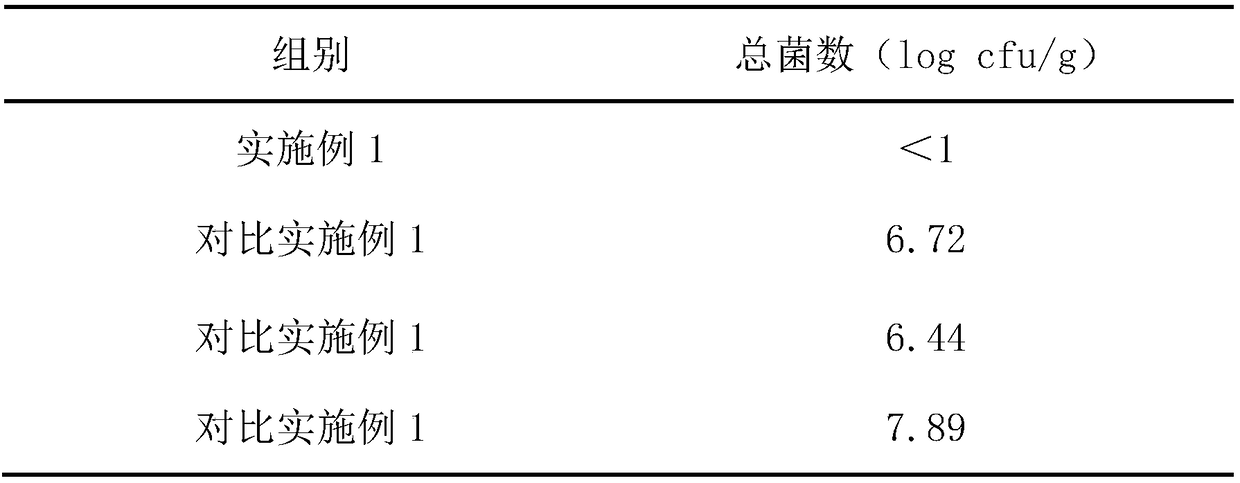

Composite film capable of prolonging shelf life of sausage with modified casing and preparation method of composite film

The invention provides a preparation method of a composite film capable of prolonging the shelf life of a sausage with a modified casing. The method comprises the following steps: 1) 0.8-1.2 parts by weight of chitosan and 0.3 parts by weight of glycerin are added to an aqueous acetic acid solution in the volume fraction of 0.2% for dissolution processing, 0.4-0.6 parts of tea polyphenol is added after complete dissolution, and the mixture is heated, stirred, homogenized and subjected to degassing under 0.10 MPa vacuum; 2) the material obtained in the step 1) is cast on a polyvinylidene chloride film with the coating quantity of 6 ml / cm<2>, the film is stripped after drying, and the composite film is obtained. The invention further provides the composite film prepared with the method.

Owner:VISCOFAN TECH SUZHOU

Process for preparing dried casing with ultra large aperture

ActiveCN104413134AGood expansion performanceExpansion fully tappedAnimal intestines working-upNatrual gut chemical treatmentPhysical chemistryEngineering

The invention discloses a process for preparing dried casing with an ultra large aperture. The process comprises the following steps: firstly, washing salted casing with clear water, sleeving a tapered increaser by the salted casing to expand the aperture, and lubricating the expanded salted casing by using an acetic acid solution with a pH value of 2-3; then soaking the expanded casing in a sodium hydroxide solution with a pH value of 11-13, and washing the expanded casing with clear water; sleeving a sleeve by the washed casing, sleeving the washed casing from the head end of a bar-shaped mould and pulling out the washed casing from the tail end of the bar-shaped mould, then rotating the sleeve for 180 degrees, knotting the casing and reversely arranging the casing on the head end of the bar-shaped mould in a sleeving manner through the sleeve, cutting off the casing to obtain upper mould casing; finally air drying or drying the upper mould casing, and then demoulding to obtain the dried casing with an ultra large aperture. According to the process, dried casing with an aperture of 55-60mm can be efficiently and quickly prepared, the yield is high, and the dried casing is suitable for mass production.

Owner:顺平县志一肠衣技术开发有限公司

Production technology of dried casing for sausages

InactiveCN107114451AReach neutral pHGood flexibilityNatrual gut chemical treatmentNeutral phRoom temperature

The invention discloses a production technology of dried casing for sausages. The production technology of the dried casing for sausages comprises the following steps of soaking salted casing for sausages in clean water so as to wash off salt; rinsing the soak-washed casing for sausages in a hydrochloric acid solution for 2 hours; fishing the soaked casing for sausages out from the hydrochloric acid solution, and carrying out washing by using clean water until the pH value is 6; rinsing the washed casing for sausages in a sodium hydroxide solution for 2 hours; taking the rinsed casing for sausages out from the sodium hydroxide solution, and carrying out washing by using clean water until the pH value is 8; coating the washed casing for sausages onto drying moulds, and carrying out drying at 40-60 DEG C for 3 hours; carrying out heating until the temperature reaches 85 DEG C, and carrying out drying for 5 hours; and then, regulating the humidity within the range of 55% after completion of the drying process, and carrying out demoulding when the temperature of the casing for sausages is lowered to room temperature so as to obtain the dried casing for sausages. The casing for sausages produced by the production technology is pale, uniform and beautiful in color. Alkali is neutralized by acid so as to increase flexibility of the dried casing for sausages, as well as make the color pale, uniform and beautiful; moreover, water consumption is reduced, and neutral pH value of the casing for sausages can be rapidly achieved so as to facilitate next-step production.

Owner:南通天龙畜产品有限公司

Novel casing processing salt and preparation method and application thereof

ActiveCN105580877AEnsure safetyIncrease elasticityNatrual gut chemical treatmentFood additiveDisodium phosphate

The invention belongs to the field of light industries and particularly relates to novel casing processing salt and a preparation method and application thereof. According to the novel casing processing salt, sodium chloride serves as a main raw material, a specific phosphate combination is added, the mass ratio of trisodium phosphate Na3PO4 to disodium phosphate Na2HPO4 is 1:1 to 1:4, and ball-milling mixing is adopted. The novel casing processing salt is used for casing salting and storage and transportation stages, casing raw materials, semi-finished products and finished products are salted or soaked in casing processing salt bittern with the pH value of 7.0 to 10 by adding the novel casing processing salt with the mass accounting for 10% to 50% that of casings, the antimicrobial problem of traditional casing processing salt is solved, the mechanical properties of the natural casings are obviously improved, the elasticity and toughness of the casings are improved, and a good color protecting effect is achieved. Phosphate adopted in the salt is low in cost and is used as a food additive in natural casing products, and food safety is guaranteed.

Owner:CHINASALT JINTAN

Process for joining of pieces of natural casing

Owner:DAT SCHAUB

Low-bacteria-degree edible animal collagen casing and preparation method thereof

InactiveCN109122795AReasonable designSimple stepsAnimal intestines working-upNatrual gut chemical treatmentCellulosePolyvinyl alcohol

The invention discloses a low-bacteria-degree edible animal collagen casing and a preparation method thereof. The low-bacteria-degree edible animal collagen casing comprises the following raw materials in parts by weight: 60-75% of protein, 1.5-2.5% of edible celluloses (CMC), 1.5-7.5% of polyvinyl alcohol, 2.5-4.5% of glycerinum and 12-18% of water. In a production process of the casing, the casing is in a humid and gentle environment before drying, bacterium breeding on the casing is easily caused, and thus, lots of bacterial colonies are on the casing. Compared with the prior art, the low-bacteria-degree edible animal collage casing has the advantages that the design is reasonable, steps are simple, after being cut according to the required length, the casing is filled with air, is hoisted and is vertically conveyed to a drying chamber, then the casing is dried at a time, meanwhile, sterilization is carried out by an ultraviolet radiator, in a drying step, sterilizing is carried outwith the aid of ultraviolet rays, bacterial colonies on the surface and in the casing can be removed by modes of heating and ultraviolet irradiation degeneration, and thus, the casing has a low-bacteria-degree effect, and is popularized favorably.

Owner:PUJIANG CAREX BIOTECH

Production technology of casing

InactiveCN105394148APure lusterFeel smoothNatrual gut chemical treatmentReduction treatmentPull force

The invention discloses a production technology of a casing. The technology comprises the following steps: cleaning, carrying out primary oxidation treatment, carrying out reduction treatment, and carrying out secondary oxidation treatment to complete production of the casing. The casing produced through the production technology has a milky white color, and has the advantages of pure luster, glossiness and transparency, smooth hand feeling, fresh smell, good elasticity, large pulling force, great improvement of the utilization rate of a raw material; and the new technological casing obtained in the invention can be kept at normal temperature for 3 years or more, and traditional technological casings can only be kept at 0-5DEG C for 1 year, so the fresh keeping life of the casing is greatly prolonged.

Owner:NANTONG RENSHOU FOOD CO LTD

Cumin roasted sausage and making method thereof

InactiveCN105341742AGreat tasteDelicious and saltyNatrual gut chemical treatmentFood ingredient as mouthfeel improving agentCooking & bakingPork meat

The invention relates to a cumin roasted sausage and a making method thereof. The cumin roasted sausage comprises the following raw materials of pork, beef, mutton, carrots, garlic, butter, red wine, pepper fruits, cumin, salt, vinegar and sausage casings according to a certain proportion, and is made through the following steps of mincing, pickling, baking, packaging and the like. According to the sausage made by the method disclosed by the invention, the pork, the beef and the mutton are added, and the carrots are also added, so that the mouth feel is improved, and the nutrient components are increased; the method of firstly pickling and then baking is adopted, so that the minced meat is tasteful, and good in mouth feel; the garlic and the cumin are added, so that the sausage is fresh, fragrant, salty and delicious in mouth feel; the sausage casings are processed, so that impurities on the sausage casings can be effectively eliminated, and the fishy taste of the sausage casings can be effectively eliminated.

Owner:ANHUI XIANGZEYUAN FOOD

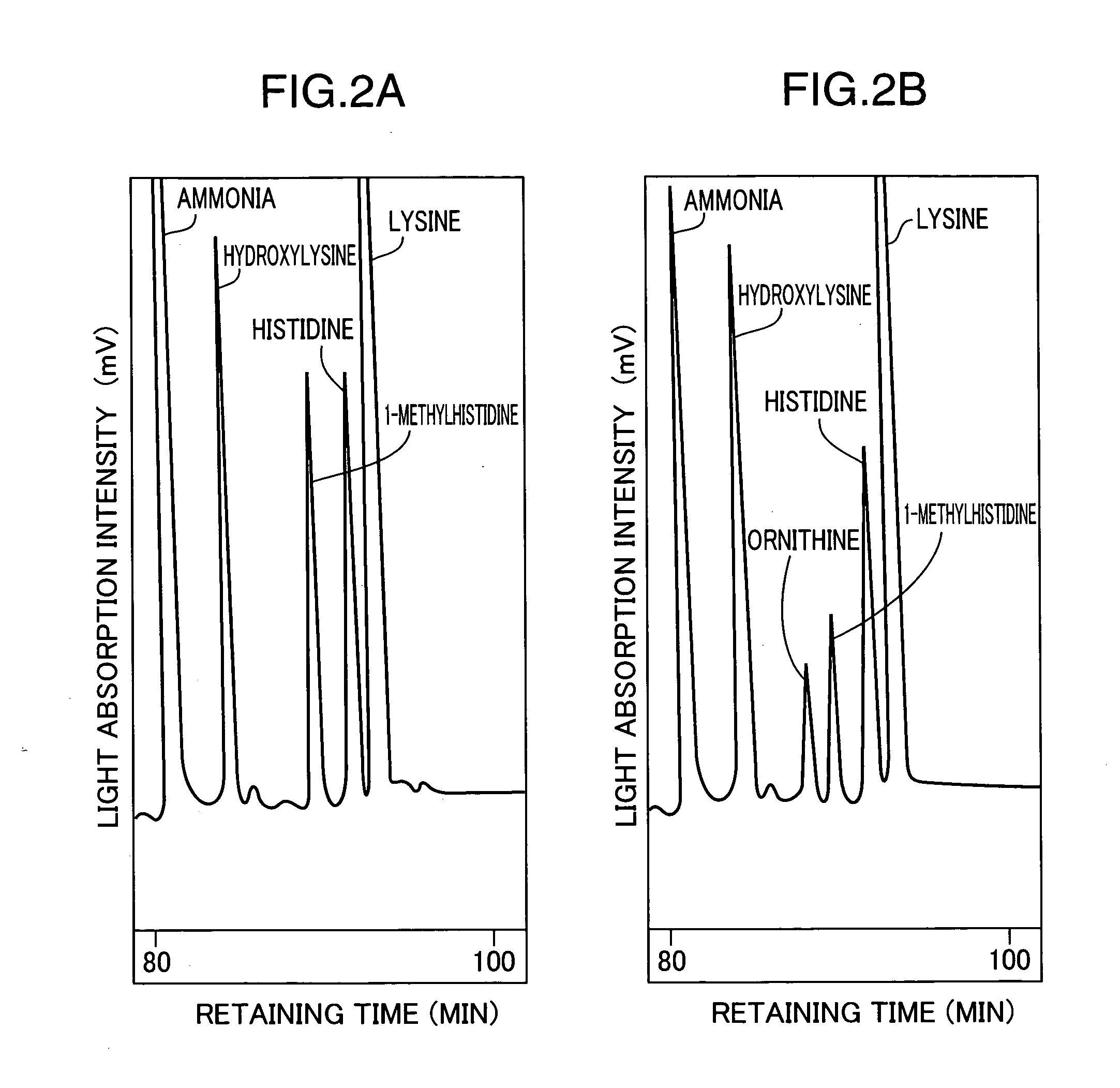

Method for producing modified natural intestines

The present invention is to provide a method for producing an animal natural intestine having improved texture and hardness by treatment with a solution containing a food emulsifier.

Owner:RIKEN VITAMIN COMPANY

Ultrahigh-pressure production technology of natural sausage casings

InactiveCN106561784AEnsure safetyAchieve sterilization effectAnimal intestine cleaningNatrual gut chemical treatmentWork in processChemistry

Owner:YANGZHOU UNIV

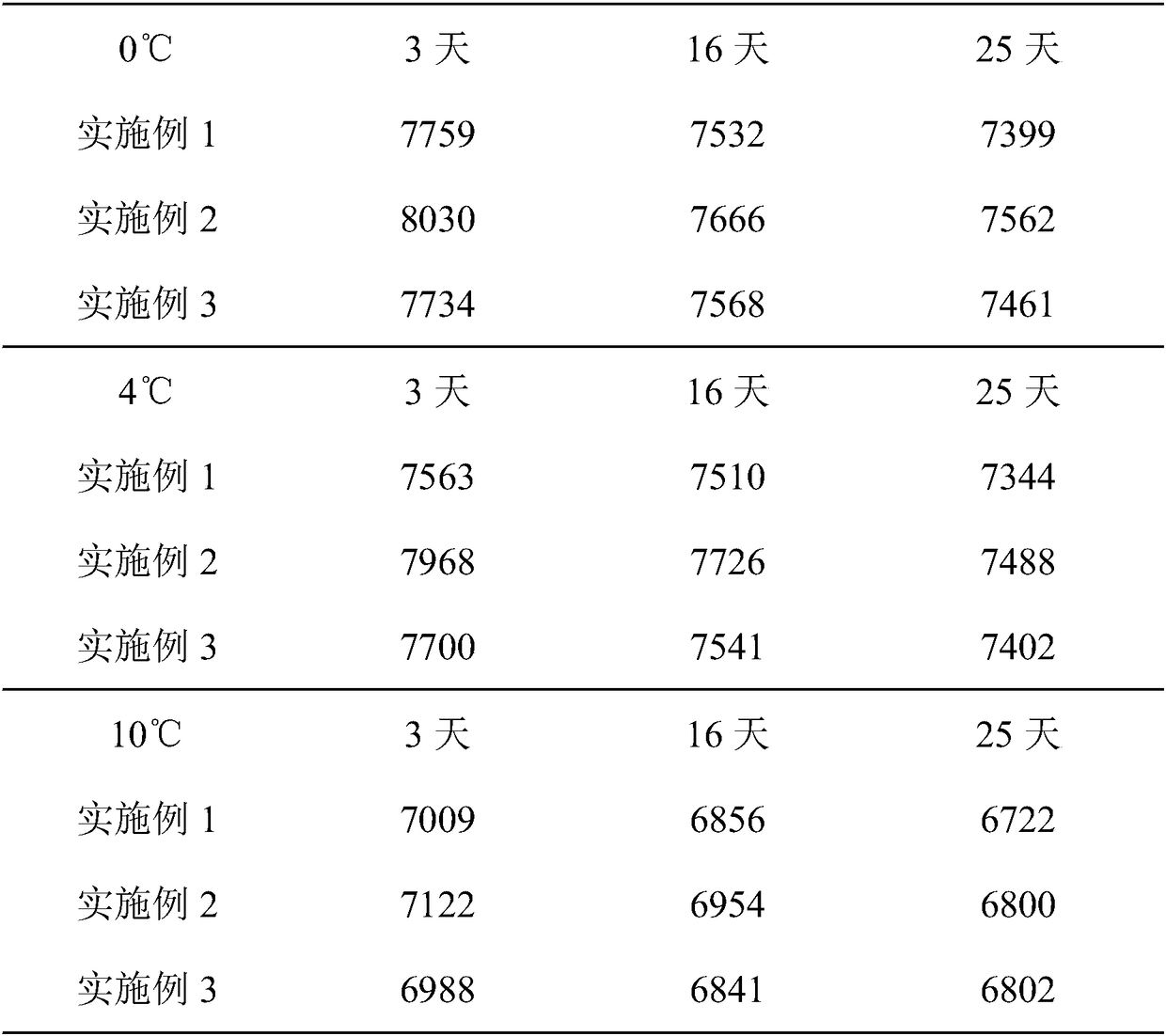

Casing for maintaining toughness and tenderness of sausage for a long time, preparation method thereof, and prepared sausage

The invention provides a preparation method of a casing for maintaining the toughness and tenderness of a sausage for a long time. The method comprises the following steps: (1) washing natural pig casing and then performing desalting treatment; (2) treating the treated casing obtained in the step (1) in a mixed solution of soybean lecithin and soybean oil for 70 to 100 minutes; (3) treating the product obtained in the step (2) with a treatment agent A for 30 to 45 minutes; (4) treating the product of the step (3) with a treatment agent B for 70 to 100 minutes; and (5) drying the product obtained in the step (4), immersing the dried product in a ferulic acid solution with a concentration of 1.2-1.5 wt% for 2 to 5 minutes, taking out the product, and then air-drying the product.

Owner:CHENGDU UNIV +1

Orange-flavor sausage and processing method thereof

ActiveCN110946244AImprove securityGreat tasteMultilayer sausage casingsClimate change adaptationBiotechnologySodium ascorbate

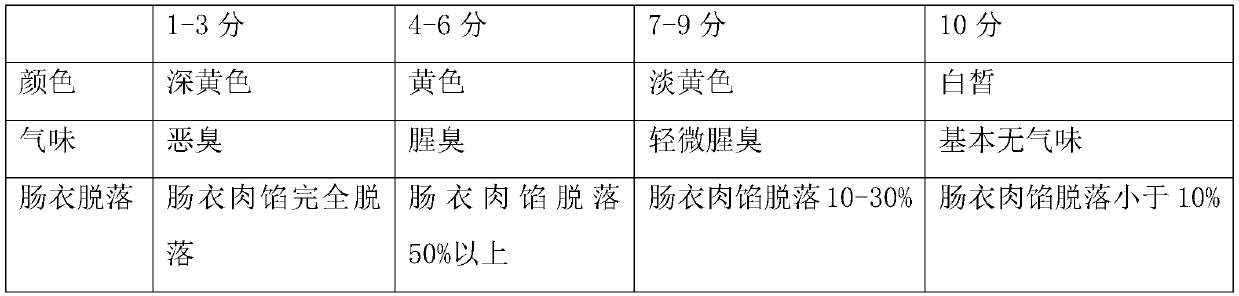

The invention discloses an orange-flavor sausage and a processing method thereof, and belongs to the technical field of food processing. The orange-flavor sausage comprises the following raw materials: modified hog casings, meat, salt, sugar, baijiu, sodium nitrite, monascus color, sodium erythorbate, fresh orange peel, orange-flavor edible essence and starch, wherein the modified hog casings areobtained after crosslinking modification of hog casings and a pigskin gelatin solution prepared from pigskin. According to the sausage, the tensile strength and taste of the sausage are improved whilethe fishy smell of a sausage casing and extra oil are removed, the sausage casing does not separate from meat filling after heating, and meanwhile, the orange flavor of the sausage can be highlighted.

Owner:重庆汇光饲料有限公司 +2

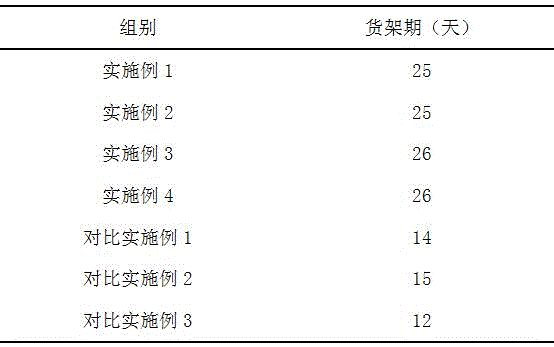

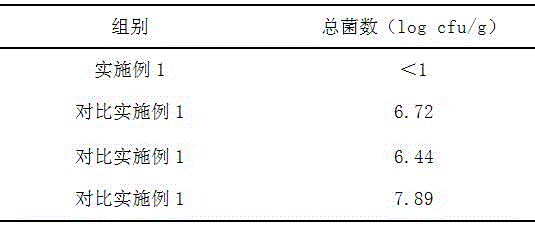

Method for Improving the Shelf Life of Modified Casing Sausage

The invention provides a preparation method of a composite film capable of prolonging the shelf life of a sausage with a modified casing. The method comprises the following steps: 1) 0.8-1.2 parts by weight of chitosan and 0.3 parts by weight of glycerin are added to an aqueous acetic acid solution in the volume fraction of 0.2% for dissolution processing, 0.4-0.6 parts of tea polyphenol is added after complete dissolution, and the mixture is heated, stirred, homogenized and subjected to degassing under 0.10 MPa vacuum; 2) the material obtained in the step 1) is cast on a polyvinylidene chloride film with the coating quantity of 6 ml / cm<2>, the film is stripped after drying, and the composite film is obtained. The invention further provides the composite film prepared with the method.

Owner:VISCOFAN TECH SUZHOU

Preparation method of dried tubed casing

ActiveCN109077095AGuaranteed Strong AlkalineGood adhesionMultilayer sausage casingsAnimal intestines working-upChemistryDrying tube

The invention discloses a preparation method of dried tubed casing. The preparation method includes the steps of soaking the casing with acid liquor; soaking the casing once again with alkali liquor;washing the casing, and drying or draining broken pieces till the Ph value is 8-12; knocking and beating the casing till collagen extrudes into a colloidal mass; applying a mold to the colloidal massand drying the same at the temperature of 50-60DEG C to demold, and then performing aging treatment on the demolded casing for more than 9 hours in shading environment of 80-90DEG C. The casing prepared with the method has good adhesion between layers, and situations of delaminating, peeling, cracking, falling and the like are avoided in subsequent use.

Owner:顺平县志一肠衣技术开发有限公司

Treatment method of fresh duck intestines

InactiveCN106172677AAchieve water retentionReduce water lossAnimal intestines working-upPoultry eviscerating devicesLoss rateFood grade

The present invention discloses a treatment method of fresh duck intestines. The method comprises the following steps: S1: fresh duck intestines are washed clean and the washed duck intestines are drained for standby application; S2, food-grade sodium hydrogen carbonate powder with the weight being 2-8% the total weight of the fresh duck intestines is sprayed on the surfaces of the fresh duck intestines; S3, the fresh duck intestines are put into a rolling and rubbing machine to be rolled and rubbed for 5-20 minutes at a temperature of 5-15 DEG C, the rolled and rubbed duck intestines stand for 10-50 minutes at room temperature, the sodium hydrogen carbonate is permeated into the fresh duck intestines, then the fresh duck intestines are washed clean with clear water, and the washed duck intestines are filtered; and S4, the processed fresh duck intestines in the step S3 is cut, the cut duck intestines are sub-packaged in a plastic bag, compound phosphate solution is poured into the bag, the cut duck intestines are soaked for 10-40 minutes at a normal temperature, and then the soaked duck intestines are washed with clear water, the washed duck intestines are drained, and the drained duck intestines can be eaten instantly; and the compound phosphate solution is at least one of sodium tripolyphosphate solution, sodium hexametaphosphate solution and sodium pyrophosphate solution at a mass percentage of 0.1-0.5%. The prepared fresh duck intestines by the treatment method has the advantages of being relatively low in water loss rate during storage, relatively strong in water-retaining ability after rinsing and boiling, not tough after the duck intestines are put into a pot to be rinsed and boiled, and good and crisp in tastes.

Owner:河南禾胜合食品有限公司

Production method of casing

InactiveCN108236006APure lusterFeel smoothMeat/fish preservation by freezing/coolingAnimal intestine cleaningSodium bicarbonateNutrient

The invention discloses a production method of a casing. The production method comprises the following steps: sequentially carrying out citric acid water solution soaking, dilute brine soaking, ultrasonic treatment, mixed solution soaking and sodium hydrogen carbonate water solution soaking on a fresh casing; cleaning with clean water until the casing is neutral; and finally, carrying out step type refrigeration. Compared with the prior art, the production method has the advantages that the casing is treated by virtue of a citric acid water solution, dilute brine, ultrasonic waves and the like, the prepared casing is pure and glossy in luster, transparent, smooth in hand feel and fresh in odor; and by carrying out step type refrigeration, the loss of nutrients of the casing is little, thecasing has good flavor quality and a long guarantee period, and the preservation time limit of the casing is greatly prolonged.

Owner:李峰

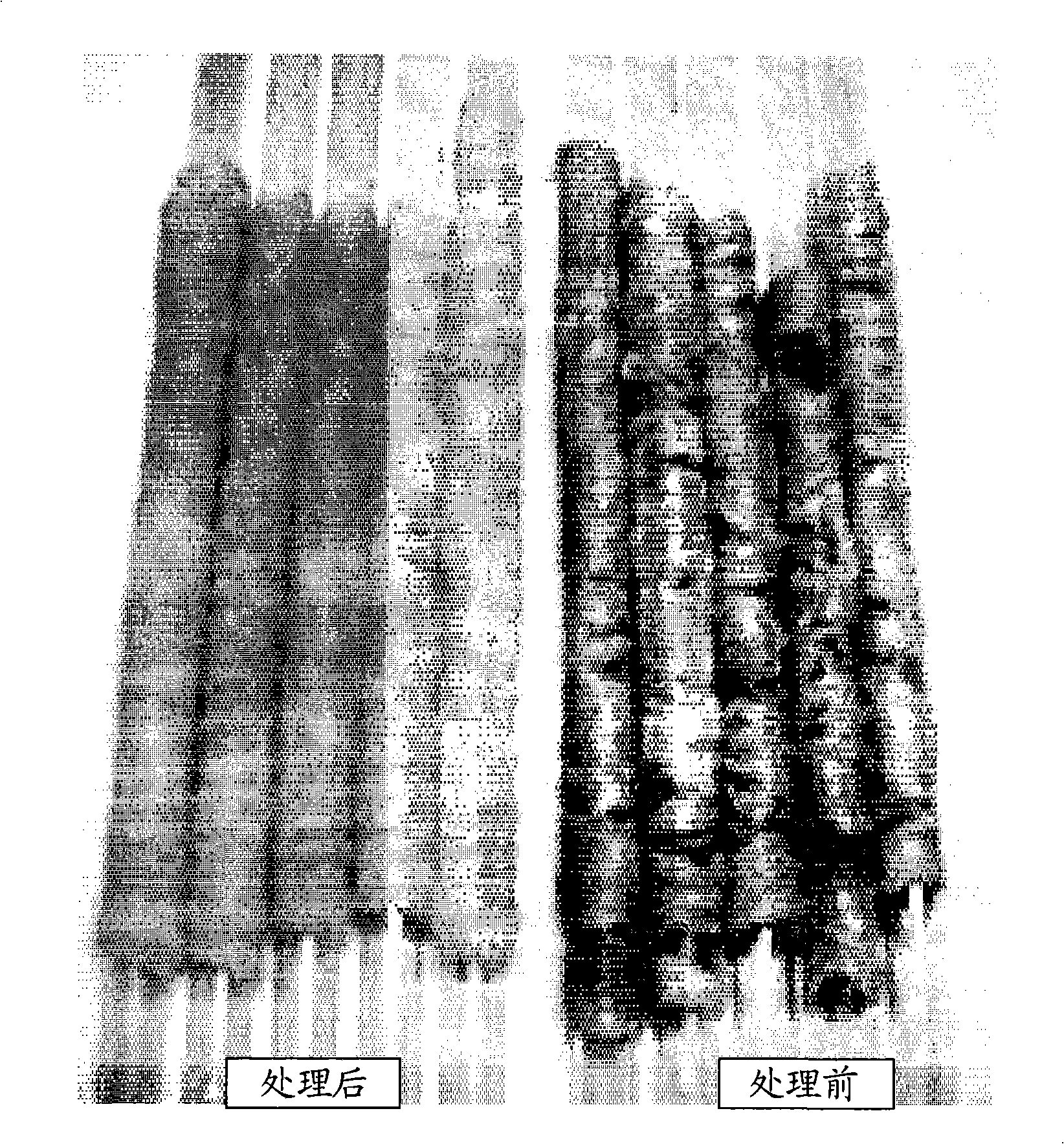

Technology of microbial hydrolysis of natural casing byproducts

InactiveCN107183135AQuality is not affectedImprove qualityNatrual gut chemical treatmentMicroorganismPull force

The invention belongs to the field of casing production methods, and particularly relates to a technology of microbial hydrolysis of natural casing byproducts. The technology of the microbial hydrolysis of the natural casing byproducts aims at making casing products in China have significant improvement in quality and reach international standards, and the economic value of exported casing products is improved. To achieved the technical scheme, the technology specifically comprises the steps that 1, firstly, semi-finished casings are cleaned with clear water; 2, treatment is conducted with oxidation liquid at room temperature; 3, oxidized casings are put into reducing liquid and pulled out when colors are consistent, and the oxidized casings are washed to be neutral with clear water; 4, reduced casings are put into the oxidation liquid again to be treated and pulled out after being slightly stirred for 15 minutes, and the casings are washed to be neutral with clear water to obtain the finished products. The technology of the microbial hydrolysis of the natural casing byproducts has the advantages that the casings produced by adopting the production method are milky white, pure in luster, glossy, transparent, smooth in hand feeling, fresh in smell, good in elasticity and high in pulling force, the utilization rate of raw materials is greatly increased, and the economic value of the casings in exported foreign exchange earnings is greatly improved.

Owner:NANTONG RENSHOU FOOD CO LTD

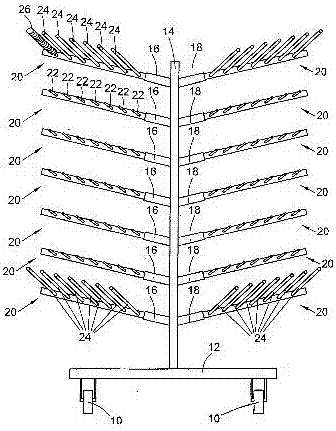

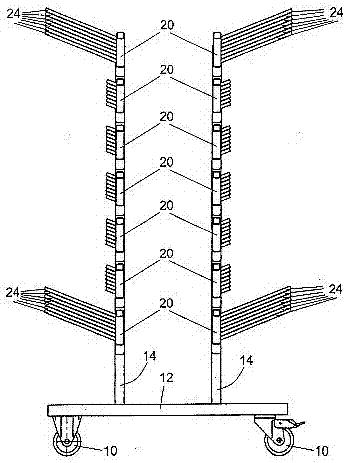

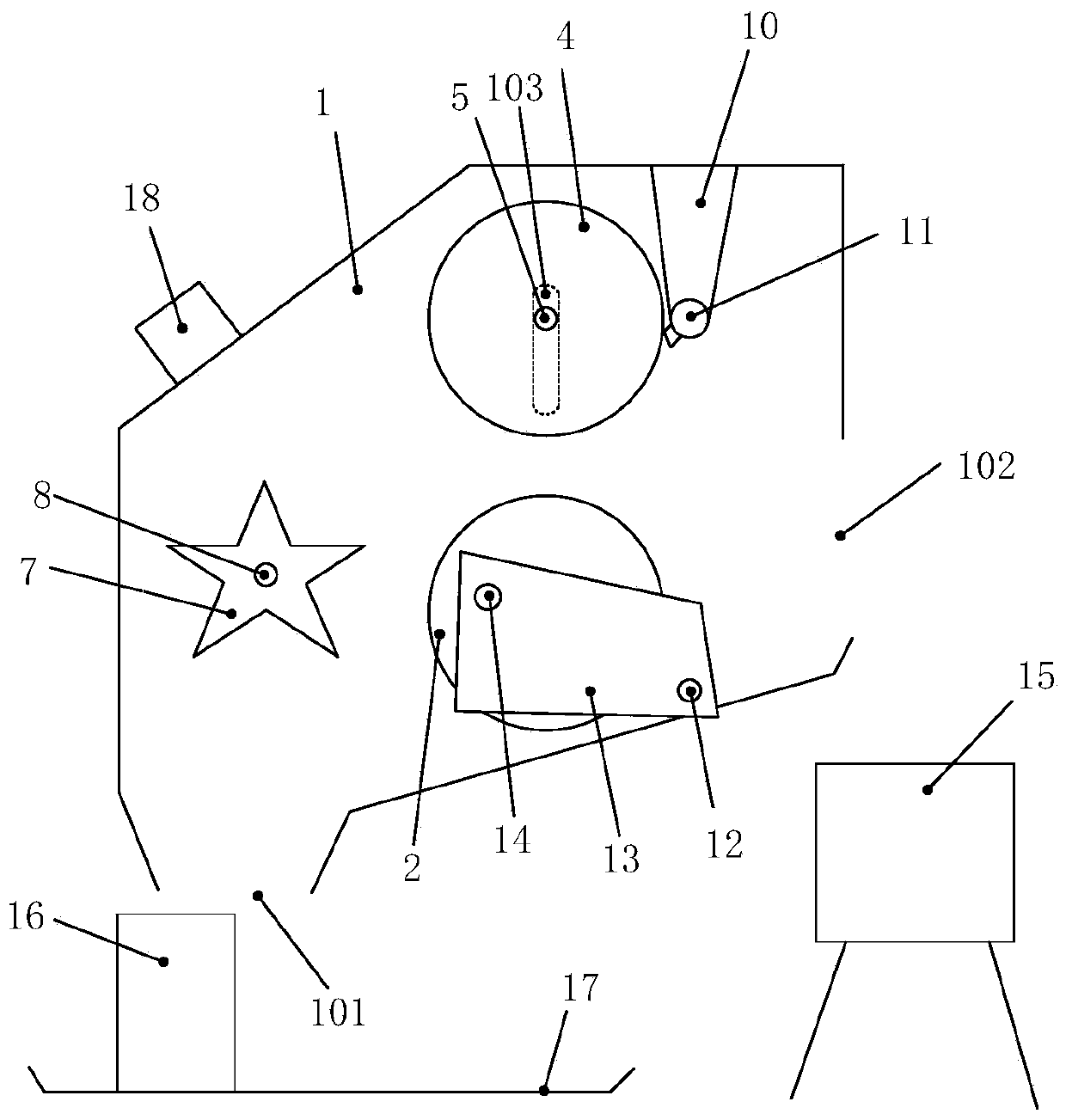

Natural sausage casing storage method

InactiveCN107148992AAvoid mutual contactAvoid damageMeat/sausage hanging-upNatrual gut chemical treatmentEngineeringDeep freezing

The invention belongs to a natural sausage casing storage method. According to the method, natural sausage casings are deeply frozen after being processed. A natural sausage casing fixing device allows placement of sausage casings on rod-like supporting devices and comprises two supporting rods (14) and a plurality of insertion parts (16 and 18) connected with the supporting rods, and receiving devices (20) are inserted into the insertion parts. Each receiving device comprises a plurality of fixing parts (22), gathered natural sausage casings are put on the rod-like supporting devices (24) which are arranged on the fixing parts (22), and finally, a frame with natural sausage casings (26) can be transported into equipment for deep freezing.

Owner:南通天龙畜产品有限公司

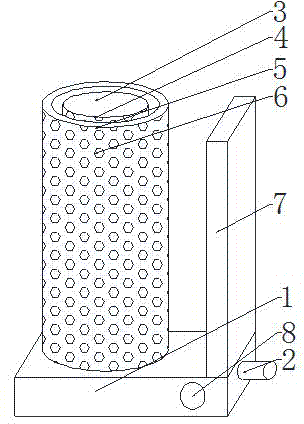

Disinfecting device for casing production

The invention relates to a disinfecting device for casing production. The device comprises a base; an air feeding tube fixedly connected with a high-temperature steam discharging tube is fixedly connected to the sidewall of the base; a rod body communicated with the air feeding tube is fixedly connected to the upper surface of the base; a plurality of first air outlets for discharging steam are formed in the sidewall of the rod body; a slow flowing sleeve, which is in match with the rod and used for preventing a casing from being damaged by high temperature steam, sleeves the periphery of the rod body; a plurality of second air outlets for discharging steam is formed in the slow flowing sleeve; the bottom surface of the slow flowing sleeve is movably connected with the upper surface of the base; an UV lamp for disinfecting the casing through UV rays is fixedly connected to the upper surface of the base, positioned to the right side of the slow flowing sleeve; a power supply device for supplying power to the UV lamp is arranged in the base. According to the device, a steam and UV disinfecting device is arranged, so that the health and sanitation in the casing production can be ensured.

Owner:艾和美

Casing preservation process

InactiveCN111280223ASolve the Salt Red ProblemProtect colorNatrual gut chemical treatmentPreservativeHalobacterium salinarium

The invention discloses a casing preservation process. According to the invention, salting preservation is adopted, a preservative solution is added into a special salt for casings, and then salting is conducted on the casings, wherein the mass of the preservative solution is 3-8% of the mass of the casings. The casing preservation process disclosed by the invention has the advantages that a casing preservative effectively inhibits the propagation of halophilic bacteria of the casings by utilizing the synergistic effect between lysozyme and an antioxidant, so the phenomenon of salty red of thecasings is prevented, the problem of salty red of the casings is fundamentally solved, the colors of the casings are protected, and the quality of the casings is better guaranteed.

Owner:肖爱兵

Efficient sausage casing cleaning technology

InactiveCN108308251AReduce economic costsImprove cleaning efficiencyAnimal intestine cleaningNatrual gut chemical treatmentEngineeringCleansing Agents

The invention provides an efficient sausage casing cleaning technology. The efficient sausage casing cleaning technology comprises the steps of performing cold storage for taking fat, rinsing originalintestines, reversing the rinsed intestines for rough cleaning, and reversing the roughly-cleaned intestines for fine cleaning, wherein the cold storage temperature is 2-8 DEG C, after the cold storage time being 1-2 hours, taking out the intestines after cold storage, and then removing massive fat which can be seen; the steps of rinsing the original intestines, reversing the rinsed intestines for rough cleaning, and reversing the roughly-cleaned intestines for fine cleaning are all performed in a roller cleaning machine; in the step of reversing the rinsed intestines for rough cleaning, a mixture of large-grain salt, sweet potato flour or flour, and white vinegar is added for rough cleaning, or a mixture of the large-grain salt, edible oil, the white vinegar and cooking wine is added forrough cleaning; and in the step of reversing the roughly-cleaned intestines for fine cleaning, a sausage casing cleaning agent is added for cleaning. According to the cleaning technology disclosed bythe invention, the operations of reversing the intestines and cleaning the intestines are mainly completed through machinery, and a large number of human resources are liberated, so that the cleaningefficiency is improved, the work of human resources is saved, economic costs are saved for enterprises, and besides, the efficient sausage casing cleaning technology further has the advantages of being good in cleaning effects and low in damage ratio and is suitable for large-scale cleaning operations of the food processing trade.

Owner:GUANGYUAN HAITIAN IND

Dry casing production technology

InactiveCN106889159AReach neutral pHGood flexibilityNatrual gut chemical treatmentNeutral phAgricultural engineering

The invention discloses a production process of dry casings, which is characterized in that: the production process of dry casings is completed through the steps of soaking, rinsing, secondary rinsing and drying; It can not only increase the flexibility of the product, make the color whitish uniform and beautiful, get rid of the original smell of the casing, but also reduce water consumption and quickly make the casing reach neutral pH.

Owner:南通天龙畜产品有限公司

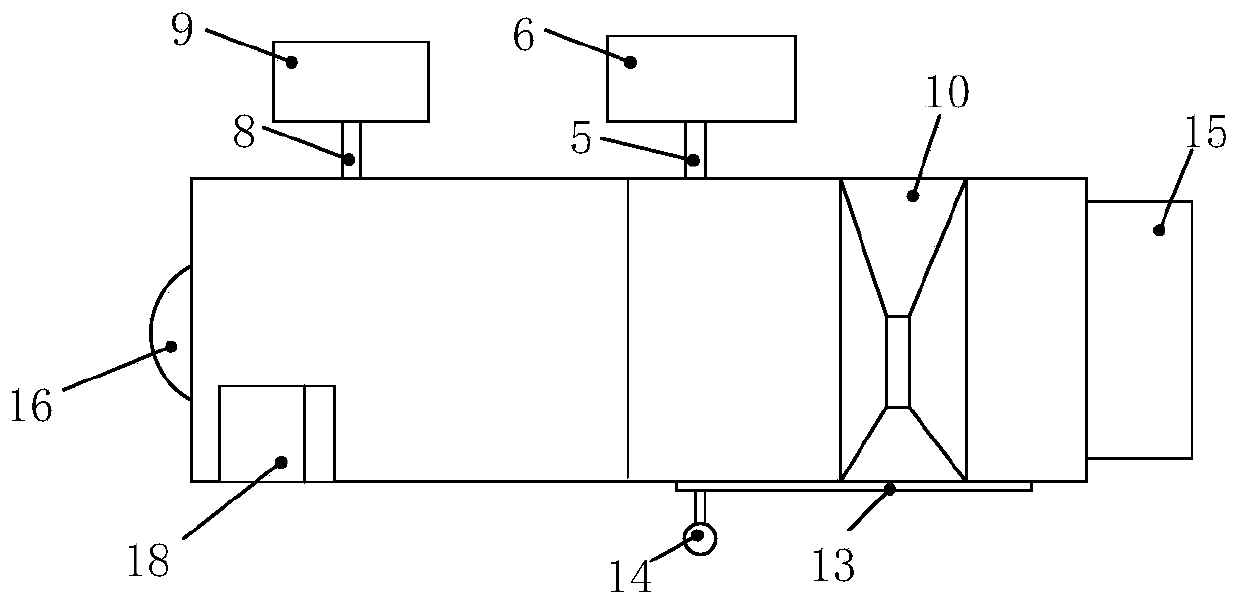

Sausage casing salting apparatus

PendingCN110037086AIncrease the speed of adding saltIncrease productivitySausage casings with flavour impregnationNatrual gut chemical treatmentDrive shaftEngineering

The invention relates to a sausage casing salting apparatus. The sausage casing salting apparatus comprises a protective shell, a first rotating gear, a first transmission shaft, a second rotating gear, a second transmission shaft, a lifting motor, and a gear motor; the protective shell has an opening on the front, as well as a material outlet and a material inlet arranged on the two sides; the first rotating gear is mounted between the material outlet and the material inlet; the gear motor is connected with the first rotating gear via the first transmission shaft; the second rotating gear ismounted above the first rotating gear; a long-hole slide way is arranged on the protective shell; the second transmission shaft penetrates through the long-hole slide way; one end of the second transmission shaft is connected with the lifting motor; and the other end of the second transmission shaft is connected with the second rotating gear. Compared with the prior art, the sausage casing saltingapparatus is good in salting quality, high in production efficiency, and high in practicability.

Owner:上海重安塑料制品有限公司

Processing technology of natural casings for sausages

InactiveCN111280228AGood colorEfficient crushingAnimal intestine cleaningNatrual gut chemical treatmentBiotechnologyEnzyme digestion

The invention discloses a processing technology of natural casings for sausages. The processing technology comprises the following steps of: cleaning of raw intestines, soaking, removal of mucous membrane layers and muscle layers in the intestines, high-pressure irrigation and flushing, irrigation inspection, measuring, pickling and storing in a barrel. The process for removing the mucous membranelayers and the muscle layers in the intestines is implemented by combining a physical method, namely repeated freezing and thawing and a chemical method, namely a biological enzyme digestion method.The processing technology is simple; by adopting the physical repeated freezing and thawing, wet cell membranes can be effectively broken, cell contents are released, and the subsequent chemical biological enzyme digestion is facilitated; in virtue of the biological enzyme digestion, cell membranes and organelle structures in tissues are destroyed, and the cells and the matrix are separated to generate a decellularization effect; and then the tissues in the intestines are flushed out by using high-pressure irrigation and flushing. With the processing technology, the tissues outside casings canbe easily and rapidly removed so as to obtain the casings with characteristics of lightness, thinness, transparency and good color; and modern large-scale production can be achieved, production efficiency can be improved, and industry development can be promoted.

Owner:周光明

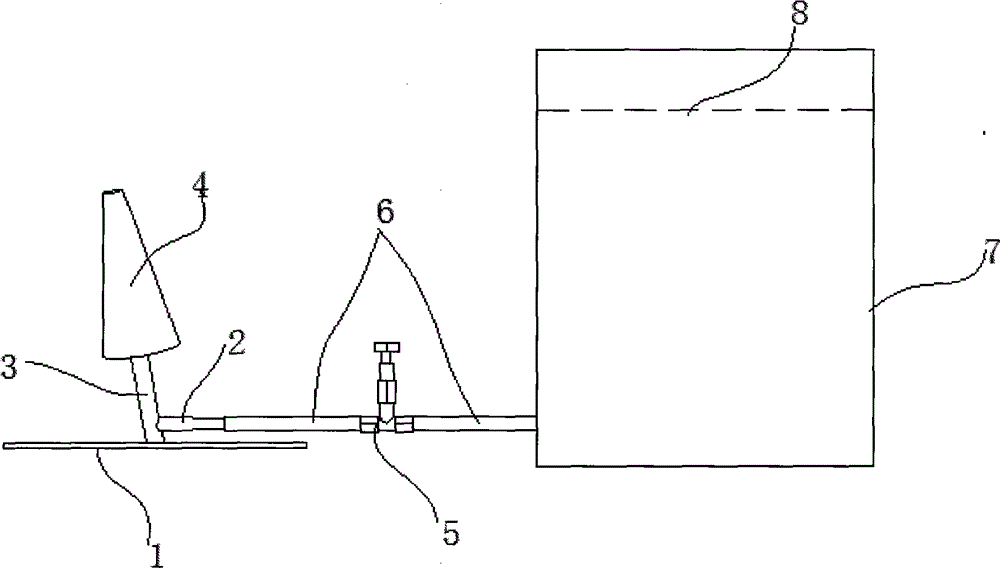

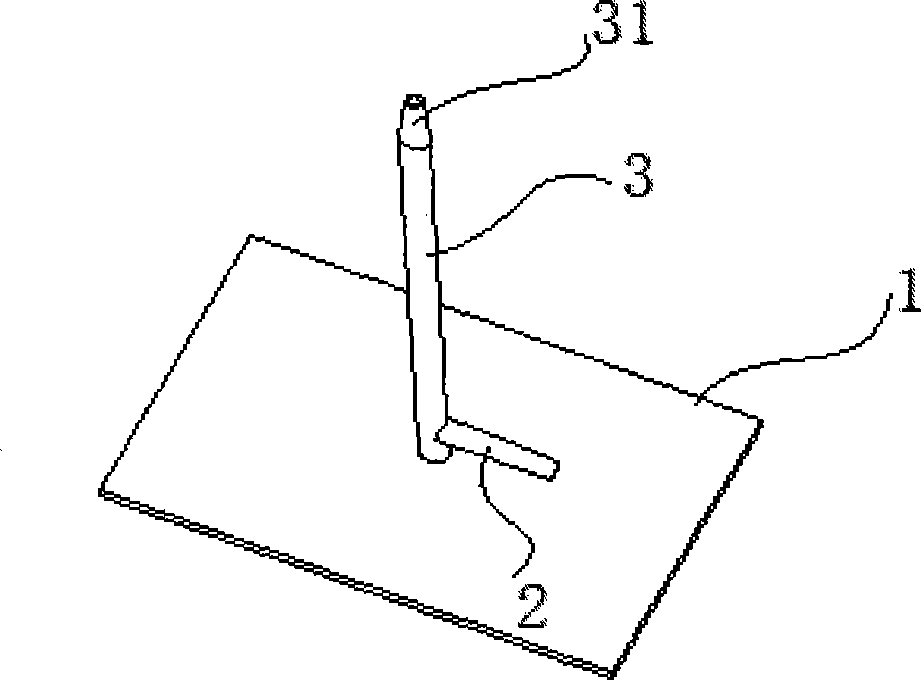

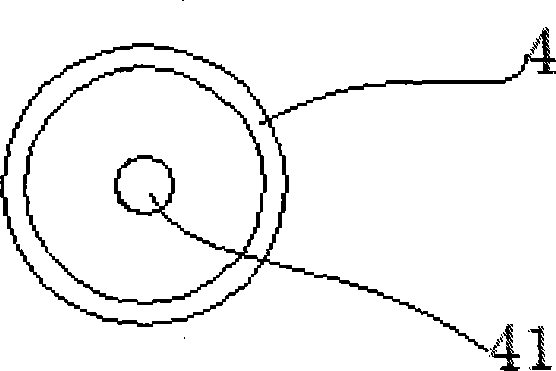

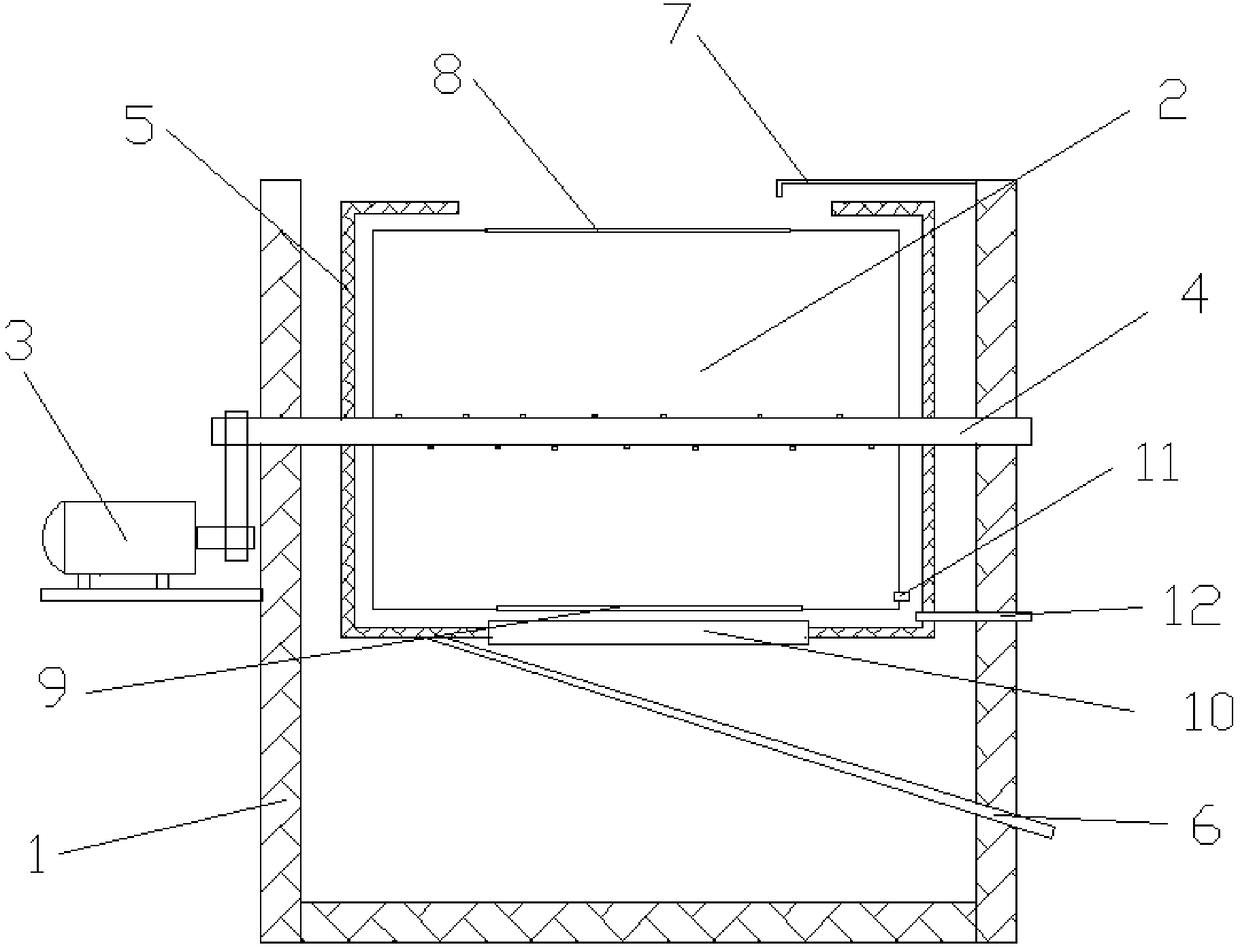

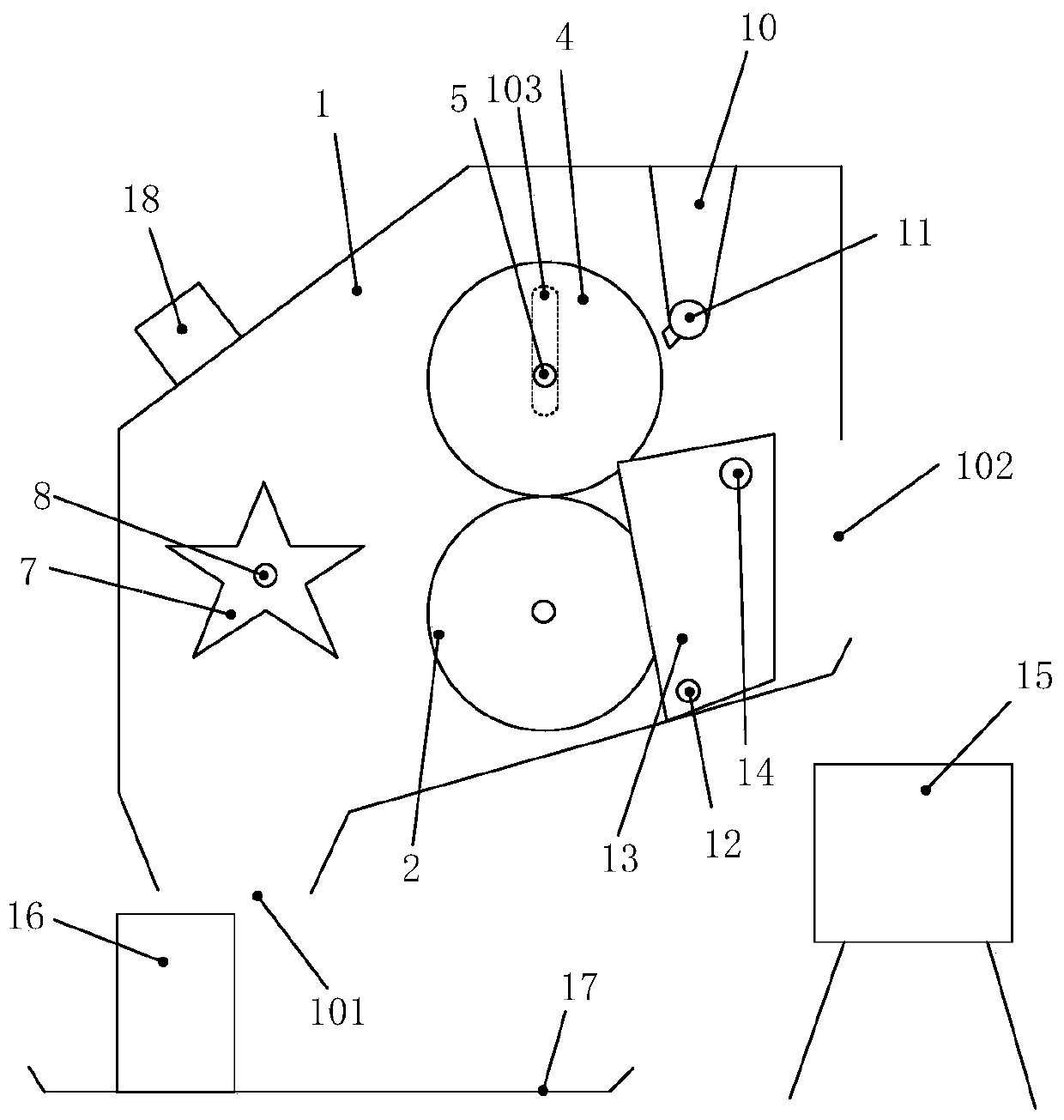

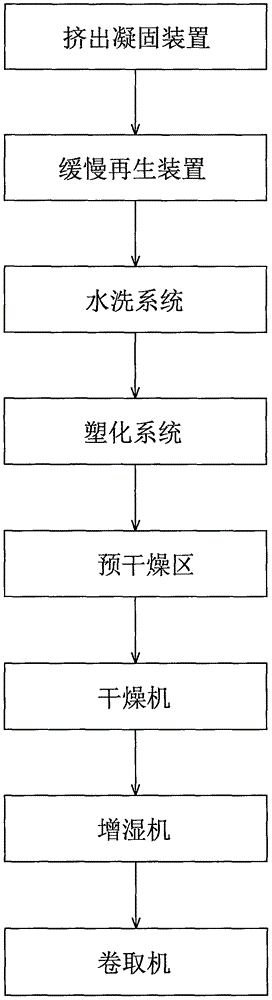

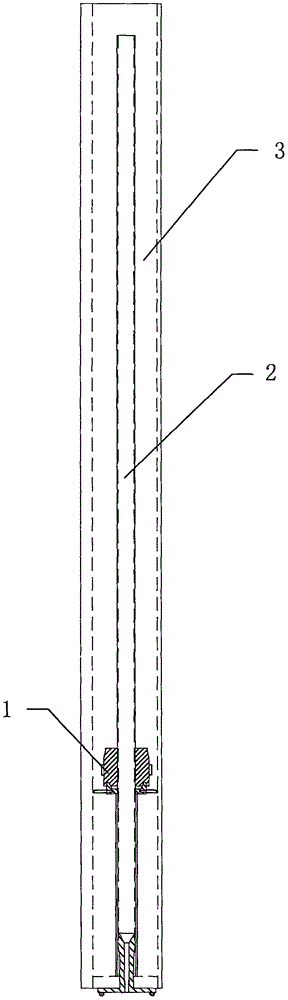

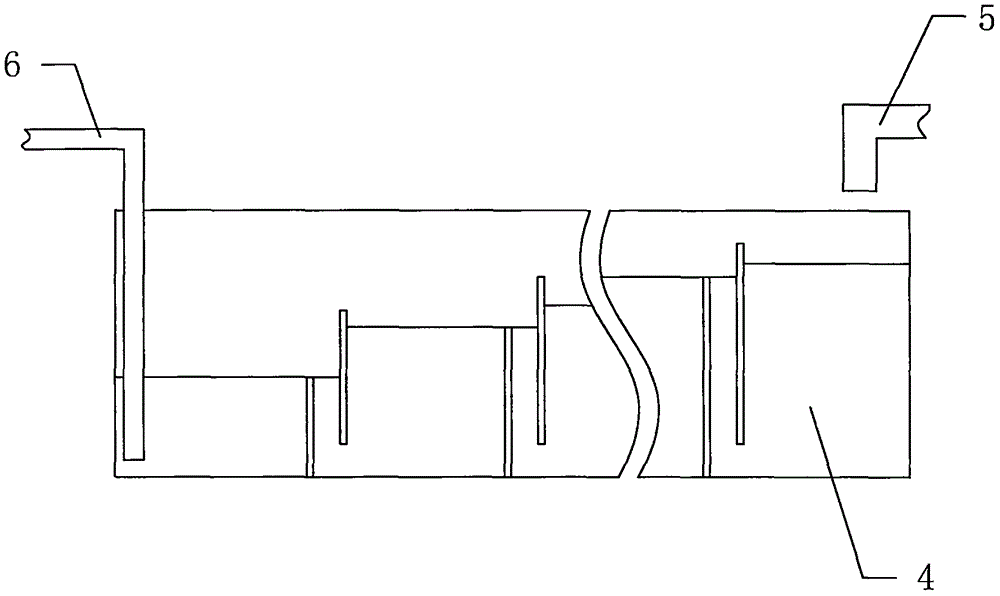

Production line for cellulose sausage casing and production process for cellulose sausage casing

ActiveCN106720142ASuitable for shared useIncrease productivitySausage casing manufactureCellulosic sausage casingsProduction lineCellulose

The invention discloses a production line for a cellulose sausage casing and a production process for the cellulose sausage casing. The production line for the cellulose sausage casing comprises an extruding solidification device, a slow regenerating device, a water washing system, a plastifying system and a drying system. The production process for the cellulose sausage casing comprises the following steps: A) extruding and solidifying, namely extruding a sticky glue from a jet, carrying out solidifying reaction with an acid bath in an acid bath tank and generating a sleeve type film; B) slowly regenerating, namely jetting the acid bath to the sleeve type film and controlling the degree of the sausage casing regenerating reaction; C) washing with water, namely reducing the temperature, ending the slowly regenerating reaction in the step B, washing, desulfurizing and removing impurities and sulfide; and D) plastifying, namely fixing water in the product of the step C; E) drying. According to the technical scheme, the production line is high in production efficiency and is suitable for multiple jets, the product quality is stable and the diameter and the thickness are high in consistency.

Owner:WEIFANG WEISEN FIBER NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com