Efficient sausage casing cleaning technology

A casing and high-efficiency technology, which is applied to sausage casings, processed meat, and cleaning intestines, etc. It can solve the problems of affecting the health of cleaning personnel, affecting the use of casings, and time-consuming manual cleaning, so as to achieve long-term food quality preservation, save economic costs, and save manpower effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of high-efficiency casing cleaning process comprises the following steps:

[0027] (1) Refrigeration: Put the original sausage into the refrigerator, control the refrigeration temperature to 2-8°C, take it out after refrigeration for 1-2 hours, and then remove large pieces of visible fat;

[0028] (2) Original intestine rinsing: put the original intestine after removing large pieces of visible grease in step (1) into a drum washing machine, rinse with warm water at 42-50°C, and remove the dust on the outer surface of the original intestine;

[0029] (3) Intestinal turning and rough cleaning: the original intestine after rinsing in step (2) is turned over through the intestine turning mechanism and put into the drum cleaning machine, and 20-50 grams of large-grained salt, sweet potato Powder or flour 10-20 grams and white vinegar 50-100 ml scrub for 20-30 minutes, rinse in warm water at 30-40°C for 2-3 times, 3-5 minutes each time; or add to the original intestine...

Embodiment 2

[0032] The casing cleaning agent described in step (4) in Example 1 consists of 10-20 parts of sweet potato powder, 5-15 parts of aloe extract, 10-20 parts of calendula extract, 5-10 parts of Asparagus extract 3-5 parts of ginger-mint extract, 10-15 parts of edible alkali, 10-15 parts of okra oil, 50-80 parts of white wine, and 500-700 parts of water. The preparation method comprises the following steps:

[0033] (1) Ginger and mint are crushed, then soaked in white wine for 24 hours and then filtered to obtain a mixed extract of ginger and mint;

[0034] (2) fresh aloe is pulverized to obtain aloe pulp, in the aloe pulp, add 3 times the water of fresh aloe quality, centrifugal filtration obtains aloe extract;

[0035] (3) Pulverize Calendula chrysanthemum, add 95% ethanol solution to mix according to the ratio of solid to liquid 1:10~20, then carry out microwave extraction, the extraction temperature is 52~58°C, the extraction time is 15~20 minutes, filter After obtaining th...

Embodiment 3

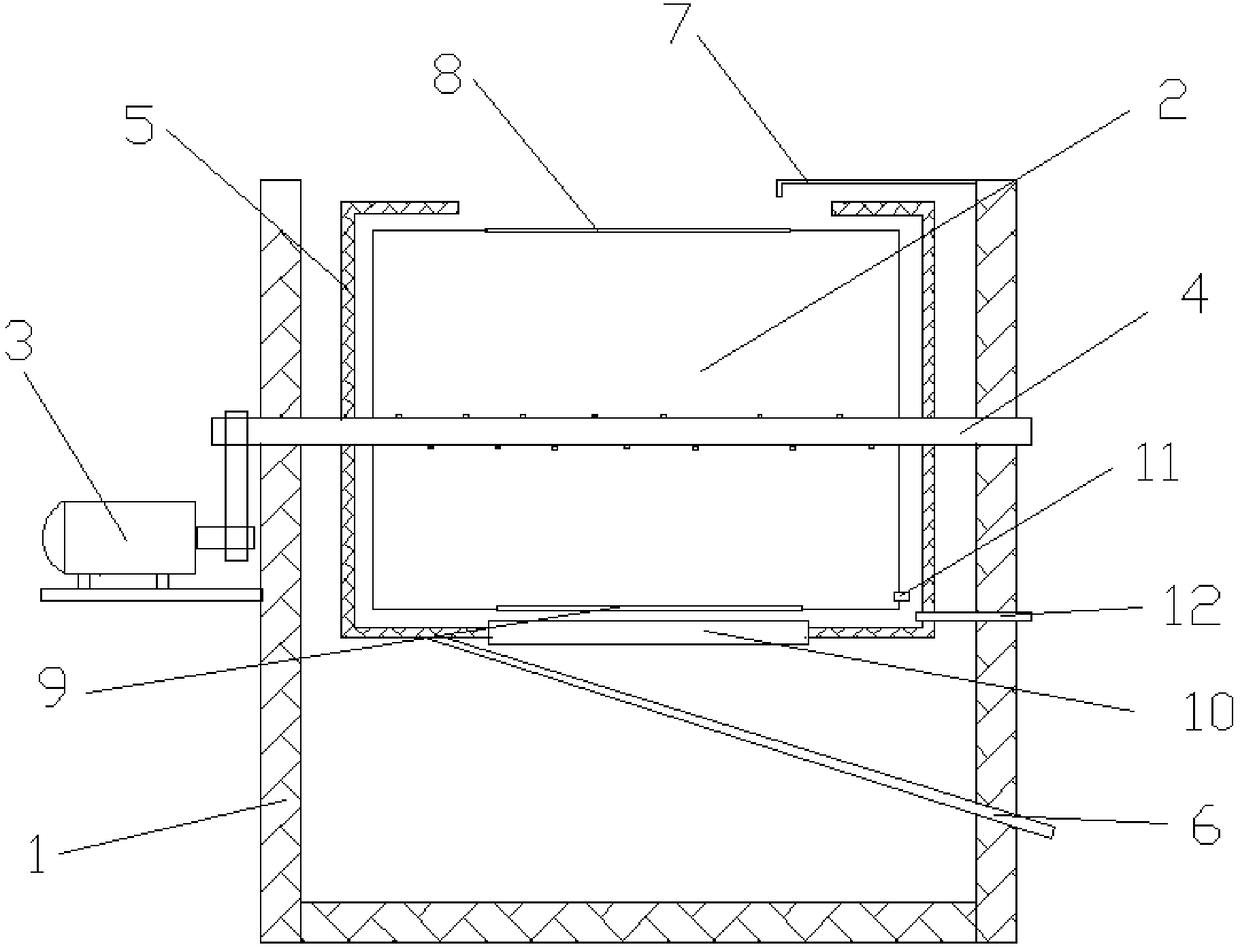

[0040] Such as figure 1 , is the drum cleaning machine described in Embodiment 1, comprising a metal shell 1, a rotating shaft motor 3, a faucet 7 connected to a water heater is provided at the upper end of the metal shell 1, and a faucet 7 is arranged below the faucet 7 There is a drum 2, the upper position of the drum 2 is provided with a feed inlet door 8, the bottom position of the drum is provided with a discharge outlet door 9, and one side of the discharge outlet door 9 is provided with a water outlet 11. The central position inside the drum 2 is provided with a rotating shaft 4 along the radial direction of the drum 2 .

[0041] The outside of the drum 2 is provided with a drum shell 5, the drum shell 5 is fixed on the metal shell 1 by a fastening device, and the bottom of the drum shell 5 is provided with a shell door 10, and the shell door 10 It is arranged directly below the machine door 9 of the discharge port, and the length and width of the shell machine door 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com