Patents

Literature

38results about How to "Improve throughput per hour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

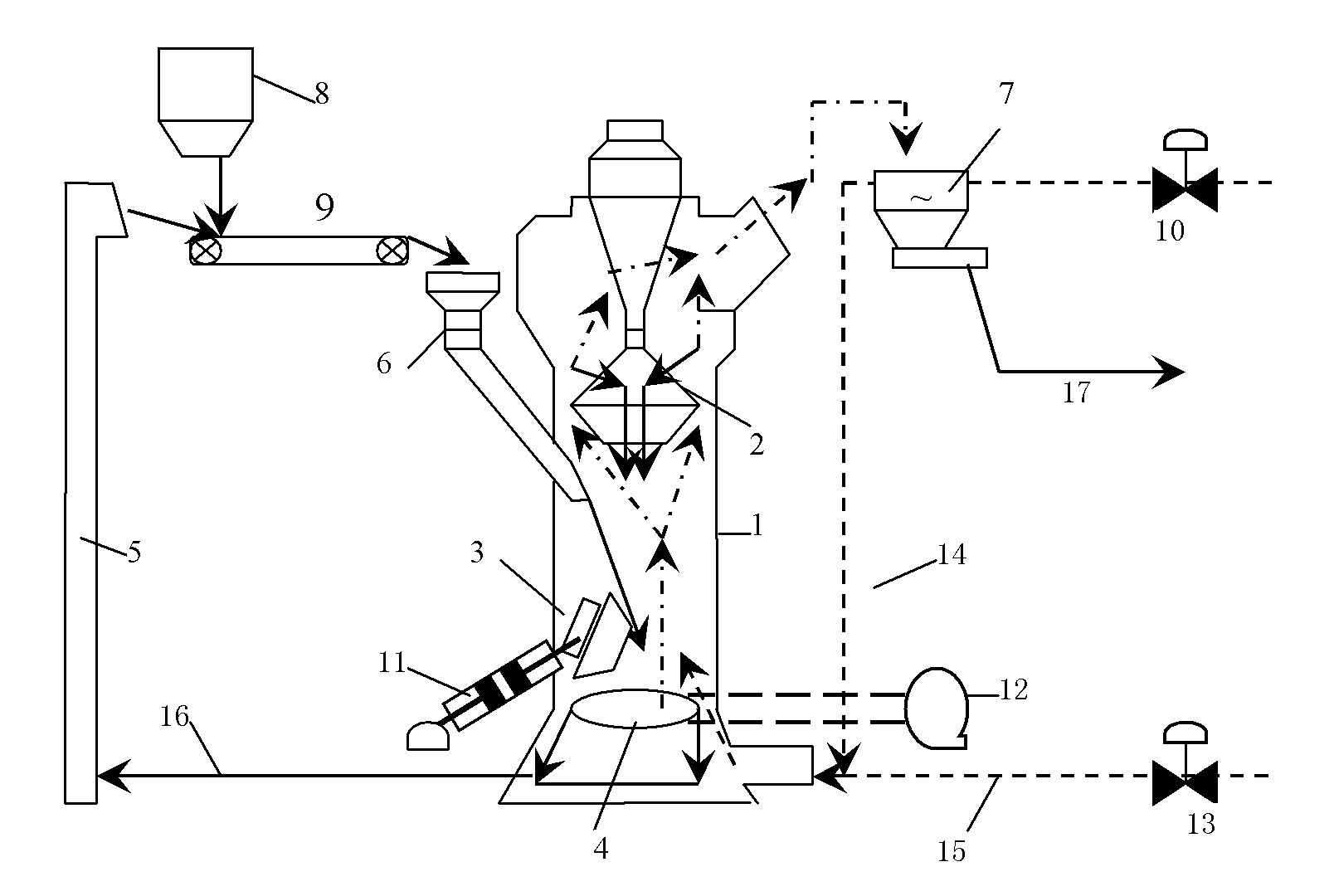

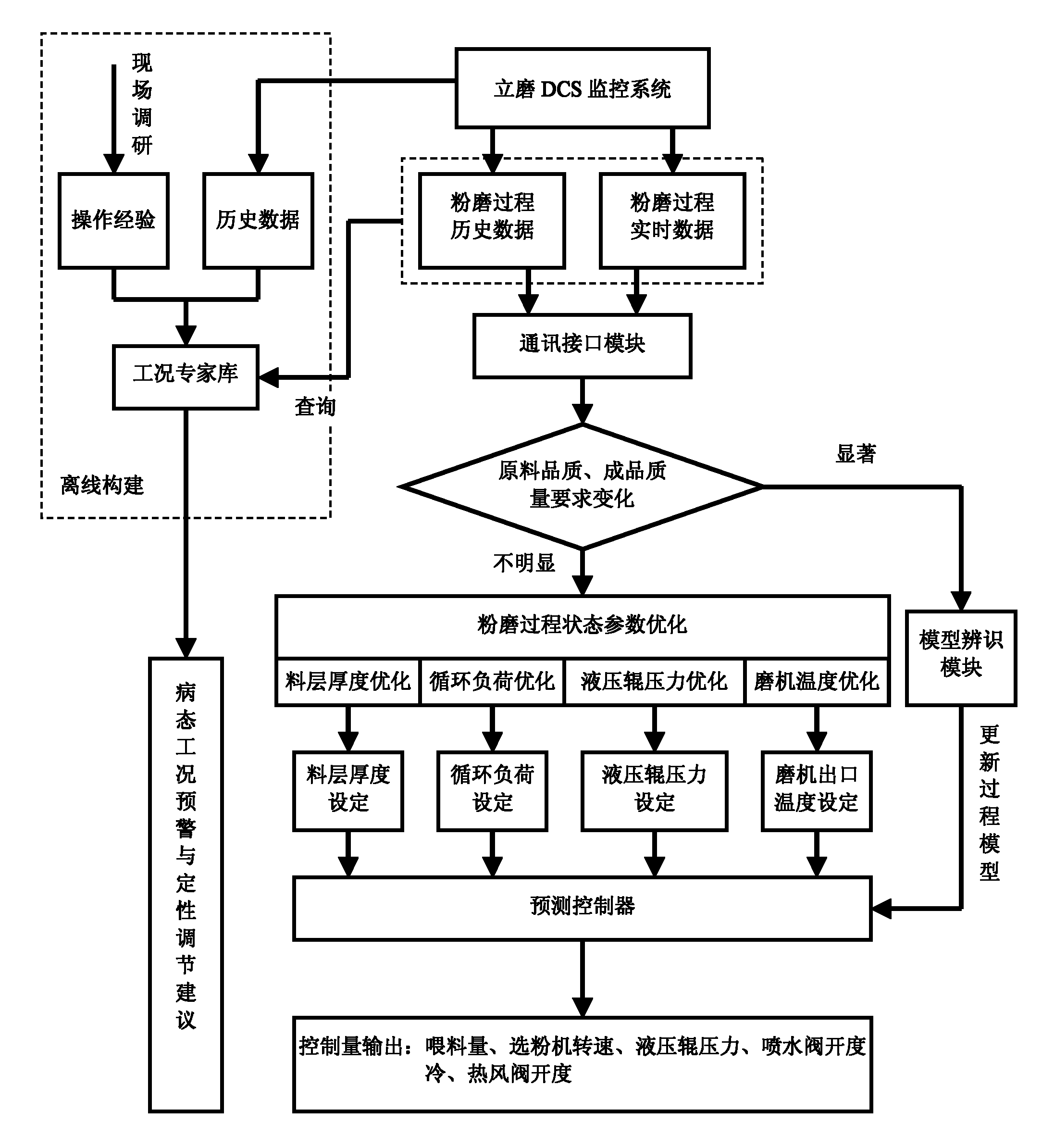

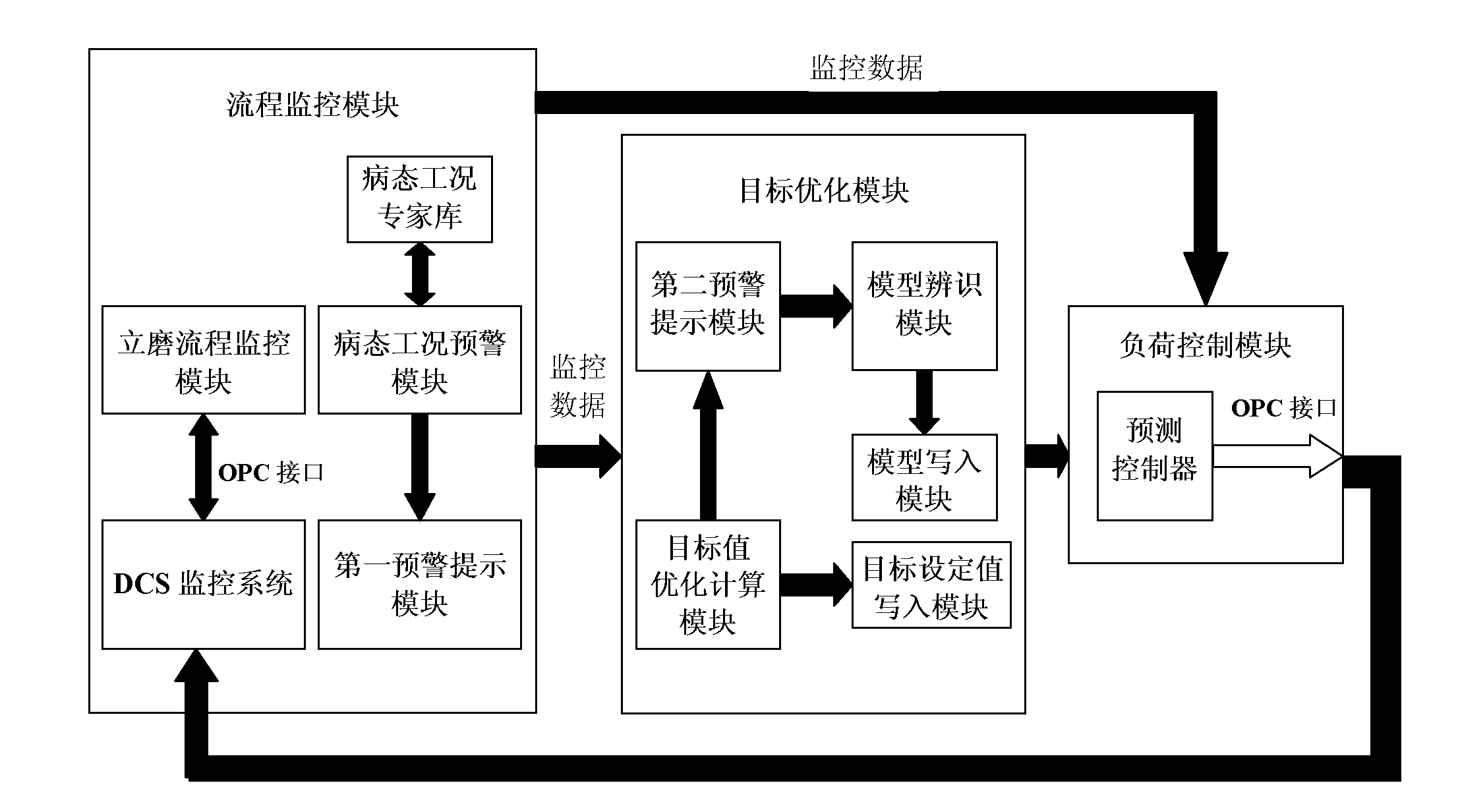

Advanced control method and system for vertical mill based on model identification and predictive control

InactiveCN102151605AIncrease the level of automationQuality improvementCement grindingCement productionMathematical modelOptimal control

The invention relates to raw material grinding in the field of cement process industries, and aims to provide an advanced control method and system for a vertical mill based on model identification and predictive control. The method comprises the following steps of: acquiring real-time data from a distributed control system (DCS) monitoring system; analyzing a variation trend of the operation and technology parameters, and then invoking a pathological working condition expert database for performing trend matching; if a pathological working condition appears, issuing early warning display and giving qualitative adjustment suggestion remind; giving an optimal target set value according to the basic operation condition of the vertical mill and the variation situation of the product quality requirement, and writing into a predictive controller; setting an optimal controlled quantity output according to the optimal target set value, and outputting to the DCS monitoring system to control a field actuator to take action. By adopting the invention, the qualitative adjustment suggestion can be precisely given; a mathematical model of the grinding process of the vertical mill is established and updated in real time; the steady-state error of the control system is reduced; and the grinding process of the vertical mill is instructed, so that the mill can operate stably for long term at a maximum efficiency point, and stable margin is maintained.

Owner:ZHEJIANG UNIV

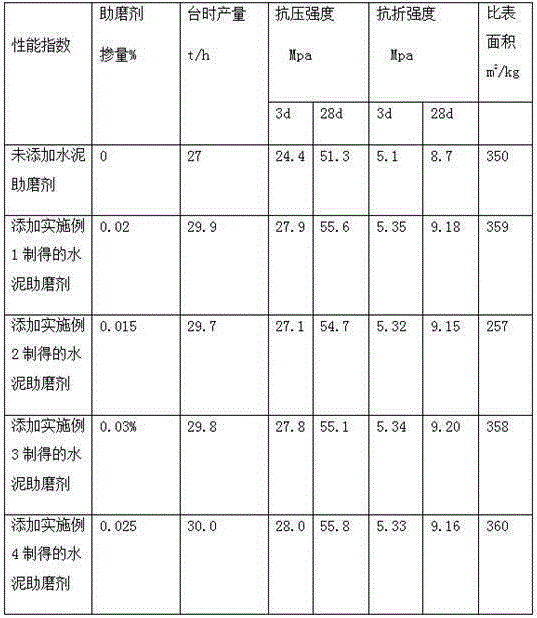

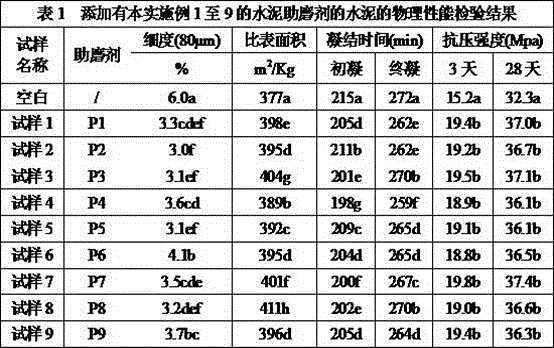

Cement grinding aid and preparation method thereof

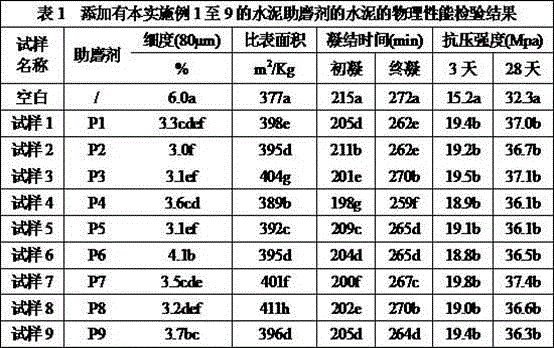

The invention relates to a cement grinding aid, in particular to a cement grinding aid and a preparation method thereof. The cement grinding aid is prepared from, by weight, 13-18 parts of polymeric polylol, 8-12 parts of tri-isopropanolamine, 12-15 parts of polyol ether, 15-20 parts of ethanediol, 25-30 parts of triethanolamine, 15-18 parts of molasses, 13-15 parts of lignin, 0.03-0.06 part of sodium chloride, 0.5-1 part of silane coupling agents and 40-45 parts of water. By means of the obtained cement grinding aid, in the cement production process, the phenomena of clinker fine particle aggregation and ball pasting can be effectively improved, mobility of clinker particles is enhanced, thereby the pulverization effect of grinding media in a grinding machine for materials is enhanced, grinding efficiency can be improved by 15-20%, the cement machine-hour yield is increased, electricity consumption is greatly lowered, production cost is lowered, in addition, strength of cement at different ages can be remarkably improved, and flowability of the cement is improved.

Owner:内蒙古同佳技术发展有限公司

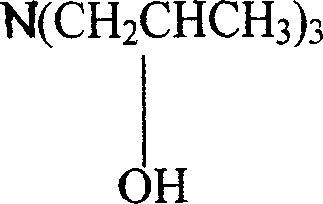

Use of tri-isopropanolamine in cement grinding aid

InactiveCN1749195AImprove liquidityImprove throughput per hourCement productionLignosulfonatesCarboxylic acid

The present invention relates to the application of triisopropanolamine in cement grinding aid. The cement grinding aid contains triisopropanolamine 40-100 wt%, triethanolamine 0-15 wt%, assistant 0-25wt%, and water 0-30wt%. The assistant is one or several kinds of carboxylic acid, lignosulfonate and alkay sulfonate. The cement grinding aid with triisopropanolamine has high grinding aiding effect, can raise the later stage strength of cement obviously, and has low cost and wide application foreground.

Owner:BAOJIA CHEM NANJING

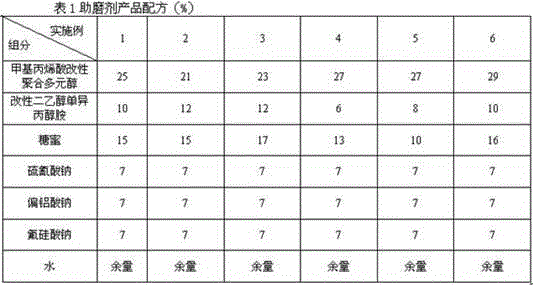

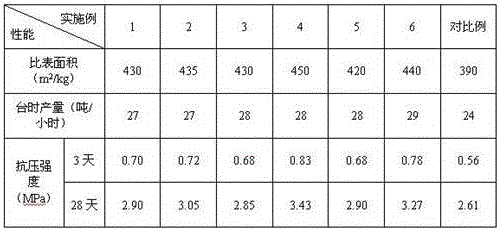

Grinding aid for preparing cementing material for filling and dry stacking of mines

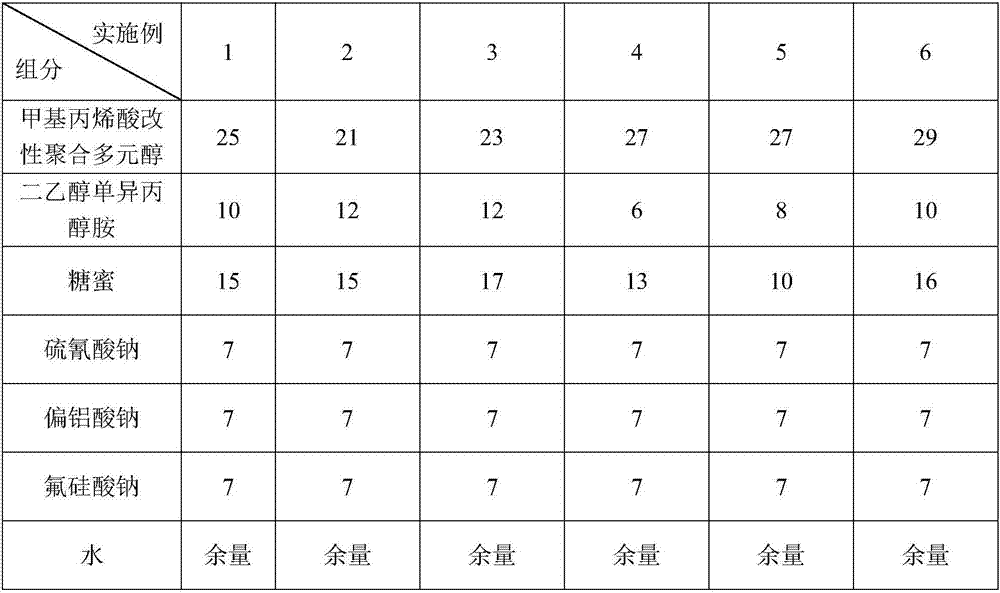

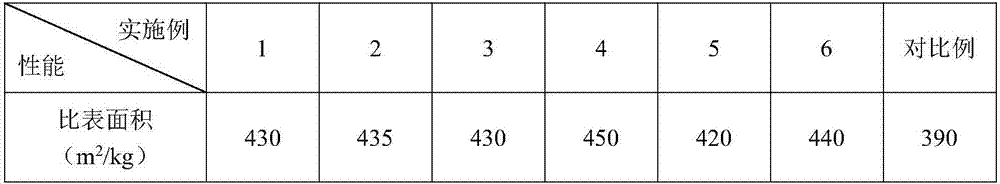

The invention discloses a grinding aid for preparing a cementing material for filling and dry stacking of mines. The grinding aid comprises the following raw material components in percentage by mass: 20%-30% of modified polymeric glycol, 5%-15% of diethanolisopropanolamine, 10%-20% of molasses, 5%-10% of sodium sulfocyanate, 5%-10% of sodium metaaluminate, 5%-10% of sodium fluosilicate and the balance of water. According to the grinding aid provided by the invention, the problems that a mixed material of water granulated slag, quick lime, water glass and the like is liable to cause ball pasting and is difficult to be finely ground in a grinding process are solved, the fluidity of the cementing material can be remarkably improved, the grinding efficiency of a ball mill can be improved, the machine-hour yield of the ball mill can be increased, the early strength of the cementing material can be remarkably improved, and the long-term strength of the cementing material can be properly improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Retarding-type cement grinding aid

InactiveCN106082761AImprove early and late strengthSpeed up the flowPolyaspartic acidCement grinding

The invention relates to the technical field of cement additives, particularly a retarding-type cement grinding aid. The retarding-type cement grinding aid is prepared from the following raw materials in parts by weight: 18-28 parts of triethanolamine, 12-24 parts of diethanolisopropanolamine, 2-8 parts of sodium tartrate, 5-17 parts of coco fatty acid diethanol amide, 8-16 parts of sodium gluconate, 6-14 parts of polyaspartic acid and 50-70 parts of water. The retarding-type cement grinding aid has favorable retarding effect, can enhance the early strength and later strength of cement, and is beneficial to enhancing the impermeability and freeze-thaw resistance of hardened concrete.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Slag grinding aid

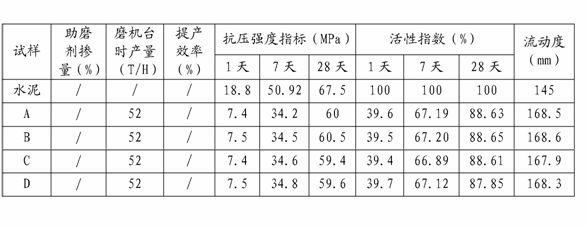

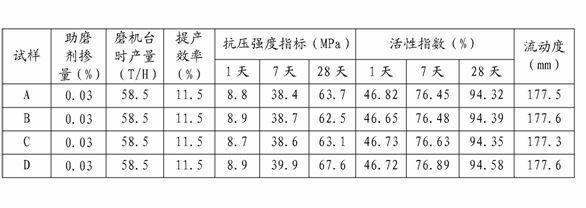

InactiveCN102618011AEliminate static electricityImprove grinding efficiencyOther chemical processesPolyolSlag

The invention discloses a slag grinding aid, which comprises the following components in percentage by weight: 40-60 percent of polymeric polylol, 5-15 percent of molasses, 2-8 percent of calcium lignosulphonate, 4-6 percent of glycerol and the balance of water. Due to the adoption of the slag grinding aid, the grinding efficiency of slag and the machine-hour yield of a grinder are increased, and the effect of improving mineral powder activity index can be enhanced. The slag containing a large quantity of vitreous bodies is ground separately, and the slag grinding aid is doped, so that the grinding efficiency can be increased by 10-15 percent, the energy consumption is lowered by 10-15percent, the 7-day activity index of slag fine powder obtained by grinding is increased by 4-6 percent, and the 28-day activity index is increased by 2-4 percent; and after slag mineral powder is added into cement, the cement mortar flowing degree is increased by 5-10 percent.

Owner:柳州宝能建材科技有限公司

Preparation method of modified molasses waste liquid and cement grinding aid

ActiveCN104609765AGive full play to auxiliary grindingGive full play to the effect of hydrationLiquid wasteMonoisopropanolamine

The invention provides a preparation method of a modified molasses waste liquid. The preparation method comprises the following steps: A, regulating the PH of the molasses waste liquid to the range of 9-11 by use of a sodium hydroxide solution, and filtering under a normal pressure to obtain a molasses filtrate A; B, adding an acetic acid solution to the molasses filtrate A until the PH is within the range of 2-3, thereby obtaining a molasses waste liquid B; C, thoroughly oxidizing the molasses waste liquid B by using 35% hydrogen peroxide, potassium permanganate or ozone, thereby obtaining a molasses waste liquid C; D, regulating the PH of the molasses waste liquid C to the range of 9-11 by use of the sodium hydroxide solution, thereby obtaining the modified molasses waste liquid. The invention also provides a cement grinding aid which is prepared by mixing the following raw materials in parts by weight with water: 2-5 parts of triethanolamine, 18-25 parts of diethanol monoisopropanolamine, 3-5 parts of industrial salt and 20-30 parts of modified molasses waste liquid. The modified molasses waste liquid has the characteristics of low production cost, and good grinding assisting and hydration assisting effects on the cement.

Owner:华润水泥技术研发(广西)有限公司

Powdery compound cement grinding aid and preparation method thereof

InactiveCN101708971AQuality assuranceReduce clinkerSolid waste managementSodium acetateSodium nitrite

The invention relates to a cement admixture, in particular to a powdery compound cement grinding aid and a preparation method thereof. The invention solves the problems of bottleneck effect in the reactions among various cement components in the prior cement grinding aid, poor effect of enhancing cement properties in various aspects, and the like. The powdery compound cement grinding aid is prepared from a liquid part and a powder part, wherein the liquid part is prepared from triethanolamine, cocoanut oil diethan olamide, potassium dichromate, sodium nitrite, sodium hexametaphosphate, an SM naphthalene water-reducing agent and the like; and the powder part is prepared from alunite powder, sodium acetate, iron vitriol, sodium thiosulfate, limestone powder and the like. The powdery compound cement grinding aid can provide an intermediate platform for the reactions among various cement components, so that the components in the cement produce mutual compound cooperation and superimposition effects, thereby effectively exciting the lateral reactivities of the components, enabling the components to perform the respective grind aiding functions in the powder grinding process, effectively eliminating the phenomena of ball paste and heavy grinding, increasing the specific area of the cement and the production output per hour of the cement grinder and greatly enhancing the rupture strength and the compression strength of the cement.

Owner:YANGCHENG JIXIN BUILDING MATERIAL

Liquid composite cement grinding aid and preparation method thereof

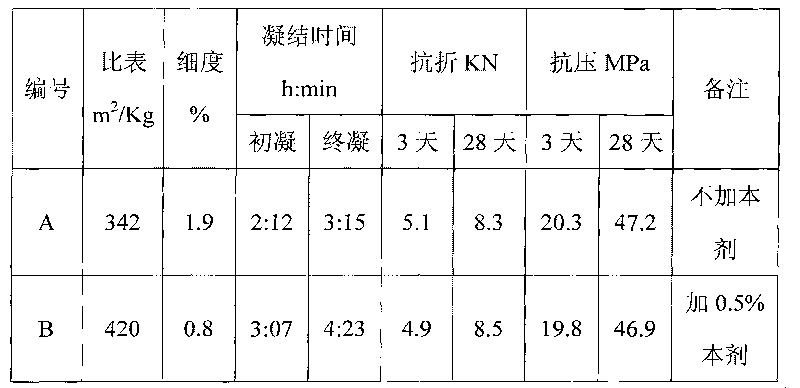

The invention relates to a cement additive, in particular to liquid composite cement grinding aid and a preparation method thereof, which solve the problems of bottleneck effect occurring in reactions among various components in cement caused by conventional cement grinding aid, poor effect in improving performance of each aspect of the cement and the like. The grinding aid is prepared from coconut oil diethan olamide, water, acetic acid, melamine, sodium nitrite, sodium acetate, sodium thiosulfate, molasses, sodium hexametaphosphate, calcium lignosulfonate and soap, can provide an intermediate platform for reactions among the components in the cement to ensure that the components in the cement can generate compound synergy and additive effects with one another, and more effectively excites potential activity of raw material components, thereby receiving sufficient reactions to play respective grinding aid effect in a powder grinding process, effectively eliminating ball stick and over grinding phenomena, improving the specific surface area of the cement, and simultaneously improving the machine-hour output of a cement mill; and the product which is added with 0.1 weight percent of cement can improve the 3-day strength of the cement by 4 to 7MPa, and improve the 28-day strength of the cement by 3 to 6MPa.

Owner:YANGCHENG JIXIN BUILDING MATERIAL

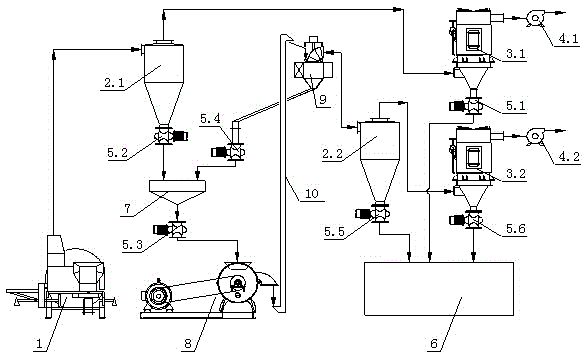

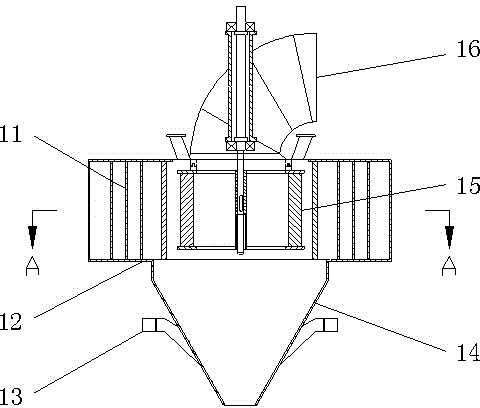

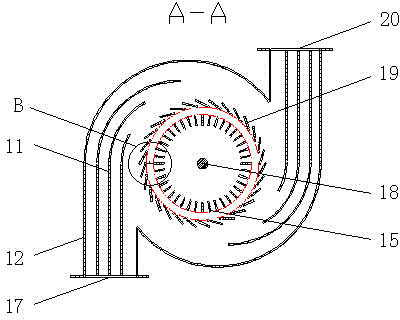

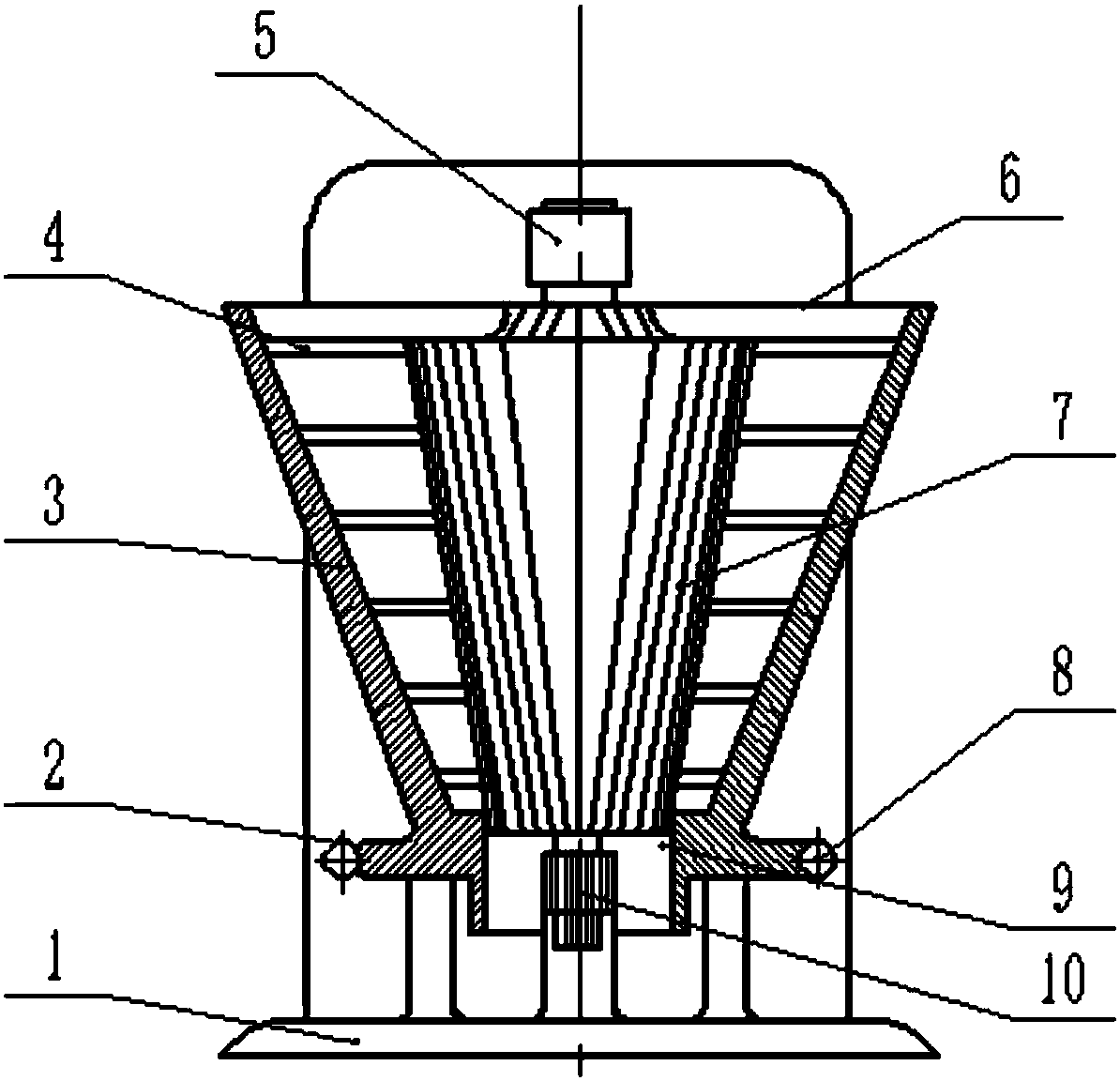

System for preparing straw micro powder

ActiveCN104826721AControl granularityQuality assuranceGas current separationGrain treatmentsEngineeringAir classifier

The invention discloses a system for preparing straw micro powder, and relates to a micro powder grinding facility. A turbo air classifying technology is used to optimize the system, and the system is composed of a pre-grinding subsystem and a grinding and classifying subsystem. The system comprises a straw pre-grinding machine, a cyclone separator, a pulse-jet bag dust collector, a blower fan, an air-lock feeder, a finished product chamber, a semi-finished product collecting chamber, a straw grinding machine, an elevating machine, and a turbo air classifier. The system can grind, classify and collect crop straws, is capable of effectively controlling the particle size of the straw micro powder, and thus guarantees the quality of finished products. The finished product fineness (D98) is adjustable in a range of 80 to 200 um. The system is a closed circulation system, can work continuously, saves the time, and shortens the production period. At the same time, the whole production process is carried out under a negative pressure, so no ash is generated, and the system is clean and environment-friendly.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Granular neutral cement grinding aid and its prepn process

The present invention discloses one kind of granular neutral cement grinding aid and its preparation process. The grinding aid is produced with anhydrous sodium sulfate 40-50 wt%, gypsum dehydrate 10-20 wt%, elite calx 25-45 wt% and triehtanolamine 1-5 wt%. The grinding aid can activate the effective components in cement to raise the strength of cement, save cement clinker and reduce pollutant gas exhaust. The granular grinding aid has less stickness to bin.

Owner:魏文龙

Novel cement grinding aid and cement employing same

The invention discloses a novel cement grinding aid and cement employing the same and belongs to the field of cement manufacture. The novel cement grinding aid comprises the following raw materials in parts by weight: 1-5 parts of sodium dodecyl benzene sulfonate, 2-6 parts of sodium tripolyphosphate, 1-5 parts of calcium formate, 3-9 parts of polyethyleneglycol, 2-6 parts of unsaturated polyester resin, 1-9 parts of diglycolamine, 1-5 parts of silica ash, 2-6 parts of ethoxyl diethylene triamine and 2-6 parts of sodium thiosulfate. Meanwhile, the invention further discloses the cement containing the novel cement grinding aid. The novel cement grinding aid is low in mixing amount and good in enhancement effect, can improve the cement performance and the output per machine hour and reduces the cement production cost, and the cement is low in clinker proportion, can reduce environmental pollution and saves mineral resources.

Owner:广西路佳道桥勘察设计有限公司

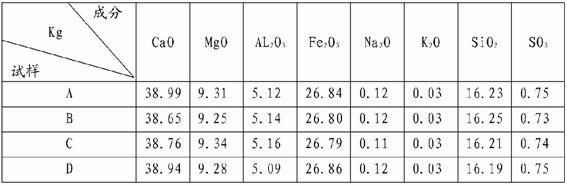

Portland cement clinker

InactiveCN1161300CSolve the problem of storage and occupation of landReduce contentCement productionSlagPortland cement

A portland cement clinker is prepared from lime stone (73-86 wt.%), iron ore tailings (5-18), flyash (2-12), and cinder (1-8) through compounding. Its advantages are low energy consumption and low pollution.

Owner:唐山协兴水泥有限公司

Slag grinding aid

InactiveCN102618011BEliminate static electricityImprove grinding efficiencyOther chemical processesPolyolSlag

Owner:柳州宝能建材科技有限公司

TK-JH mineral interface active material, and preparation method and application method thereof

ActiveCN104496255AOvercoming high heat of hydrationSpeed up the construction periodCircular economyConstruction industry

The invention discloses a TK-JH mineral interface active material, and a preparation method and application method thereof. The TK-JH mineral interface active material is composed of the following components in percentage by weight: 30-60% of sulfate, 20-30% of silicate, 20-30% of plasticizing and water reducing agent, 3-6% of phosphate and 1-3% of alkylol amine salt. The TK-JH mineral interface active material can perform green revolution on the cementing material and foundation work, can make great contribution to energy saving and environmental protection, protection of mine resources, utilization of waste resources, sustainable development of circular economy and great exploits of centuries, and can become historical transitions in sunrise industry of cementing material and application of construction industry new materials in construction industry.

Owner:苏笮斌

Mineralized material used in cement grinding process

The invention is suitable for the technical field of cement grinding aids, and provides a mineralized material used in a cement grinding process, the mineralized material is composed of the following substances by mass: 2-5% of sodium sulfate, 4-7% of sodium thiosulfate, 0-3% of sodium sulfite, 1-3% of maleic anhydride dimer acid triethanolamine ester, 1-3% of ethylene glycol, and 79-92% of fly ash. By determining proper substances and content, promoting early hydration of cement and greatly improving the early hydration rate of cement particles, the early strength is improved, the hydration durability is considered, the later hydration of the cement is promoted through sodium thiosulfate, maleic anhydride dimer acid triethanolamine ester and ethylene glycol, the strength of cement paste is improved, and the cement paste can also wrap the surface of cement particles to form a protective film to eliminate bonding and adsorption agglomeration, the maleic anhydride dimer acid triethanolamine ester can form an oxidation protection film on the metal surface to retard the corrosion of steel bars so that the machine-hour yield of a mill is increased, the comprehensive performance of the product is improved, the power consumption of cement grinding is reduced, and the damage to the cement concrete caused by excessive chloride ions is avoided.

Owner:山西天润恒德新材料有限公司

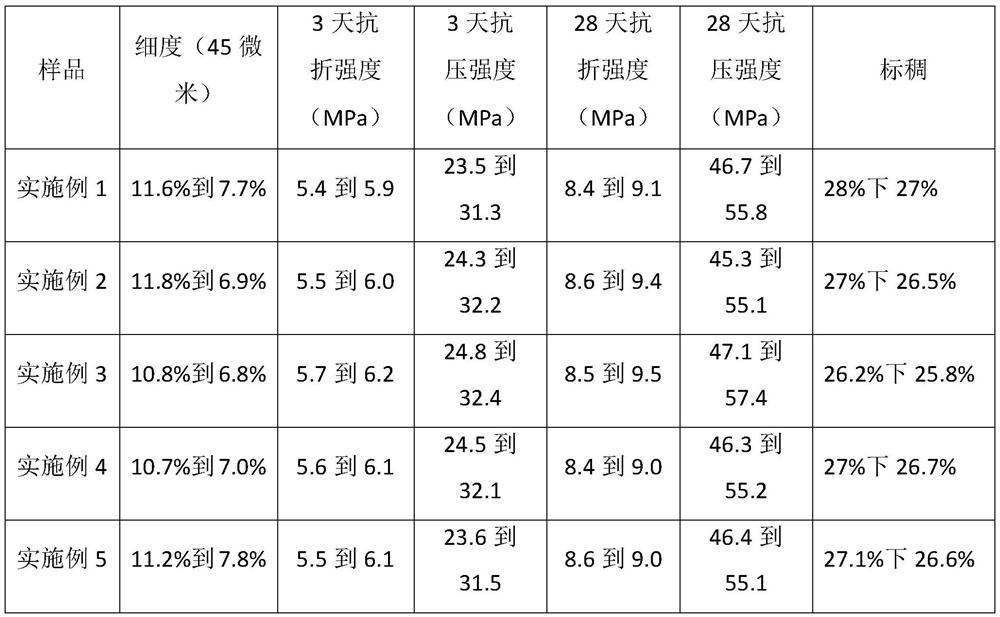

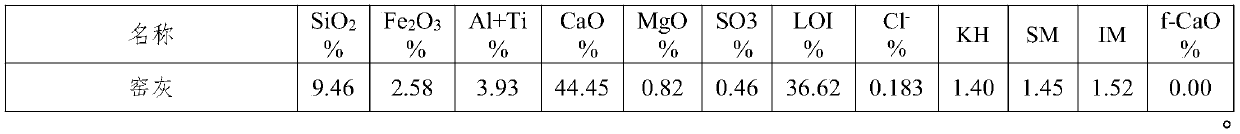

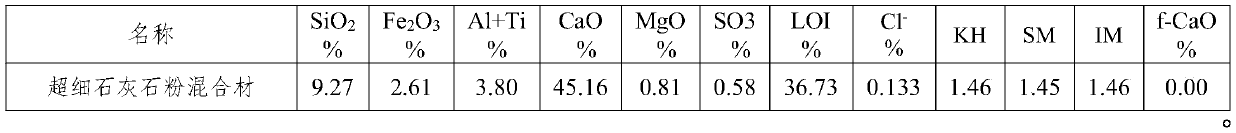

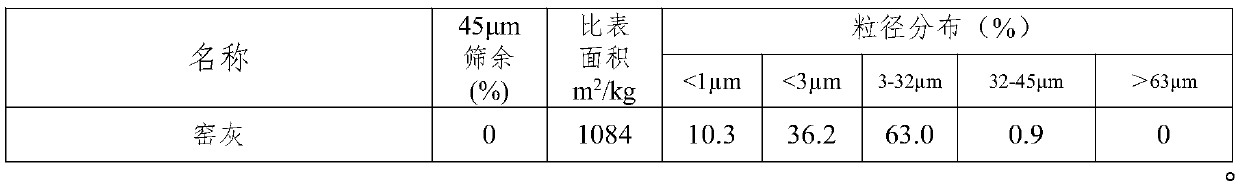

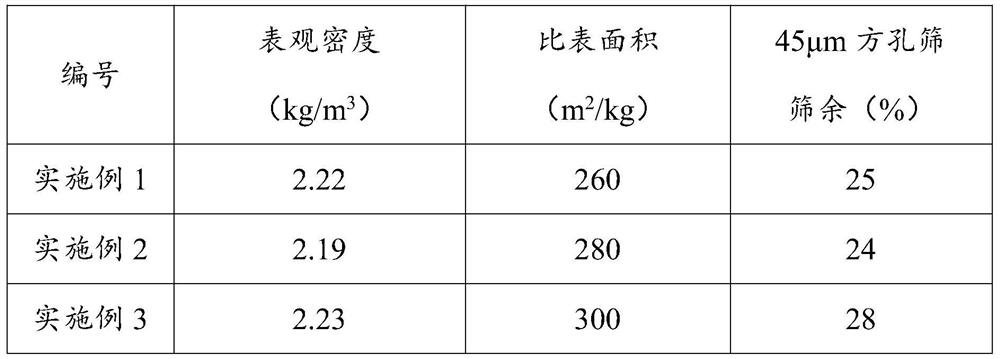

Cement preparation method

InactiveCN110922072AHigh strengthImprove throughput per hourCement productionMixed materialsClinker (cement)

The invention discloses a cement preparation method. Superfine limestone powder in a raw material vertical mill system and kiln dust in the production process is taken as a mixed material to be applied to a cement mill to produce cement. When the superfine powder is applied to the cement mill to replace limestone to serve as the mixed material, the characteristics of the superfine powder can be fully utilized, the stacking density of cement particles is increased, the distribution of the cement particles is closer to the particle size distribution requirement of a Fuller curve and the cement strength is improved. When the superfine powder is used as the mixed material to be added into the cement mill, the superfine powder can be directly used as a finished product to be selected by a powder selecting machine without being ground again so that the machine-hour yield of the cement mill is increased, the 3-day and 28-day strength of cement is also increased, the effect of reducing the clinker consumption ratio in the cement can be achieved and the production cost is saved.

Owner:SICHUAN YADONG CEMENT CO LTD

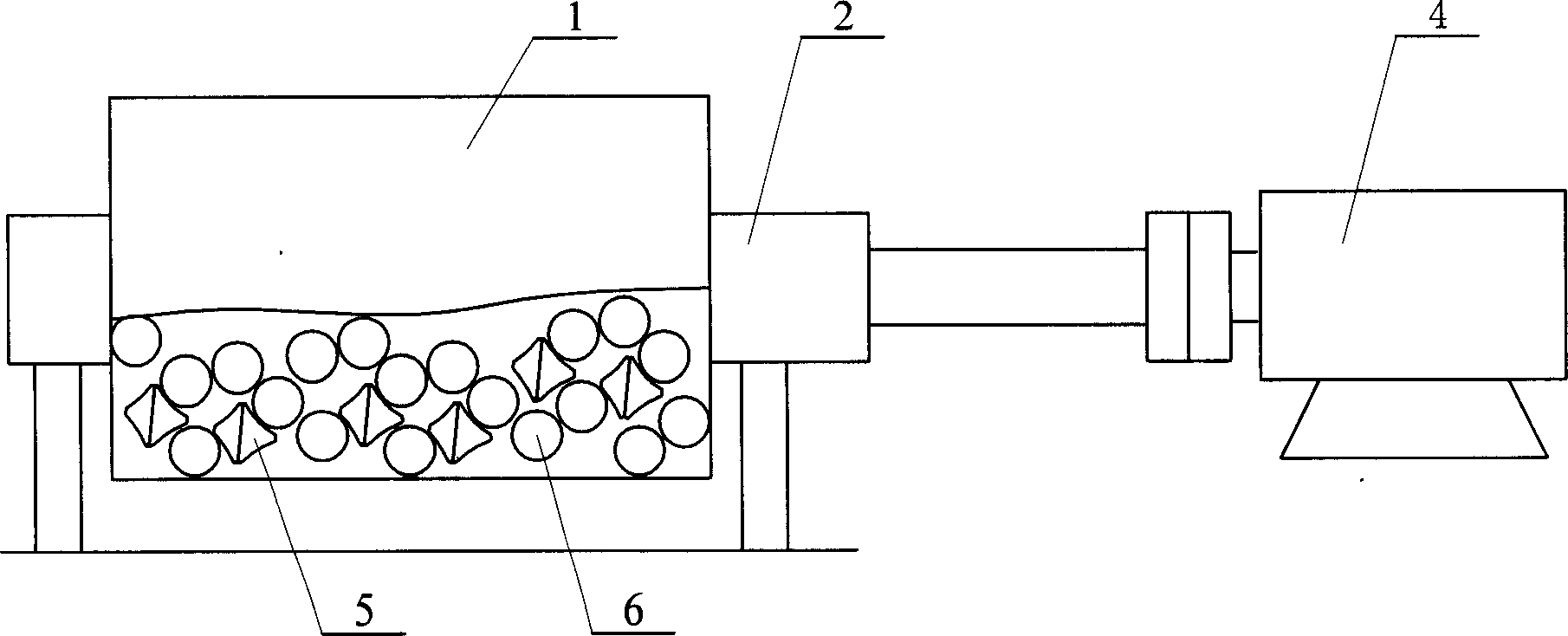

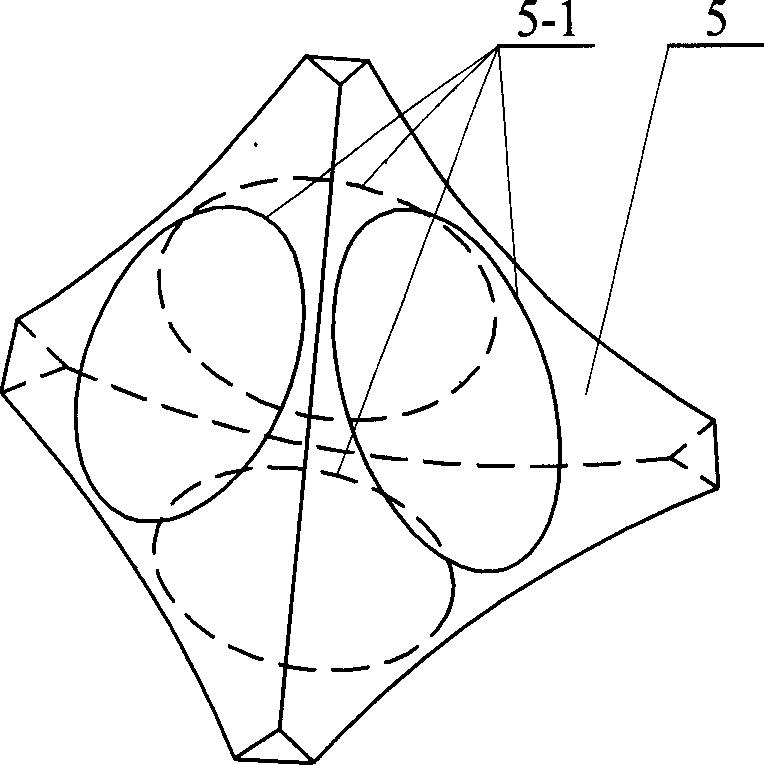

Ball mill with four-face pyramid grinding body

InactiveCN1644240AImprove grinding efficiencyImprove throughput per hourGrain treatmentsSteel ballBall mill

A ball grinder using the conic tetrahedals as grinding body is composed of cylinder, axle, motor, and the conic tetrahedals and circular balls in the ratio of (1-2):(1-10). Its advantages are high productivity, low loss of steel balls, and high specific surface area of powder body.

Owner:宋延秋

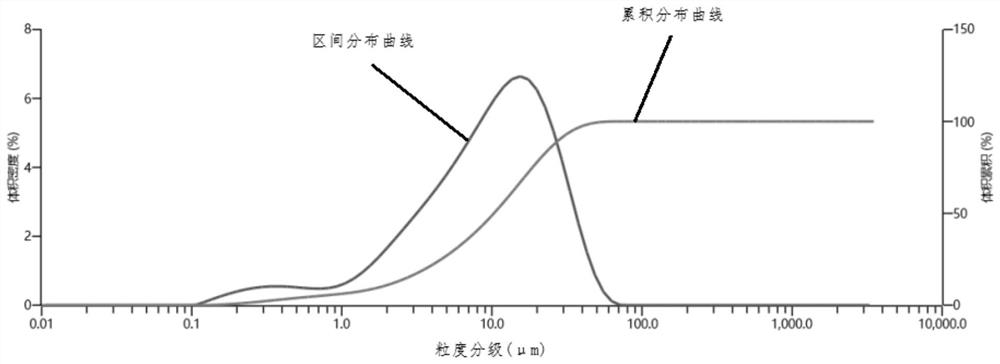

Powder modified excitant for finely grinding fly ash and preparation method thereof

PendingCN112679131AHigh activityImprove early strengthCement productionLignosulfonatesSodium phosphates

The invention belongs to the field of excitants and preparation thereof, and discloses a powder modified excitant for finely grinding fly ash and a preparation method of the powder modified excitant, the powder modified excitant comprises the following preparation raw materials: a modifier, a sacrificial agent, a reinforced excitant and anhydrite, wherein the modifier comprises lignosulfonate, sodium hexametaphosphate and sodium tripolyphosphate; the powder modified excitant can give full play to the potential of the pozzolanic effect of the pulverized coal ash, so that the strength and comprehensive performance of the prepared pulverized coal ash are greatly improved, the water demand of the pulverized coal ash is reduced, the filling effect of the pulverized coal ash is enhanced, and the application range and field of the pulverized coal ash are expanded; the machine-hour yield of production and preparation of the levigated fly ash is increased, and the power consumption of preparation and production of the levigated fly ash is reduced; the preparation method is simple and easy to operate and implement.

Owner:内蒙古宏尔高新材料科技有限公司

Biomass fodder compressing device

InactiveCN107553963ASolve the problem of uneven compression density and low compression qualitySmooth feedingFeeding-stuffShaping pressConvex sideEngineering

The invention discloses a biomass feed compression device, which comprises a device body, a worm, a chuck, a spiral convex groove, a motor, a feed port, a tapered pressing roller, a worm wheel, a discharge port and a fixed end. The device body A worm is arranged on the upper side, a chuck is arranged on the upper side of the worm, a spiral convex groove is arranged on the inner side of the chuck, a feed inlet is arranged on the upper side of the spiral convex groove, a motor is arranged on the upper side of the feed inlet, and a motor is arranged on the lower side of the motor. A conical nip roller is set, a discharge opening is set on the lower side of the conical nip roller, a worm wheel is set on the right side of the discharge opening, and a fixed end is set on the lower side of the worm wheel. The biomass feed compression device realizes the The function of uniform compression of material feed solves the problem of uneven compression density and low compression quality of traditional compression devices. The invention has the characteristics of uniform feeding, high output per machine hour, easy maintenance, energy saving, and stable working conditions.

Owner:成都汇鲤科技有限公司

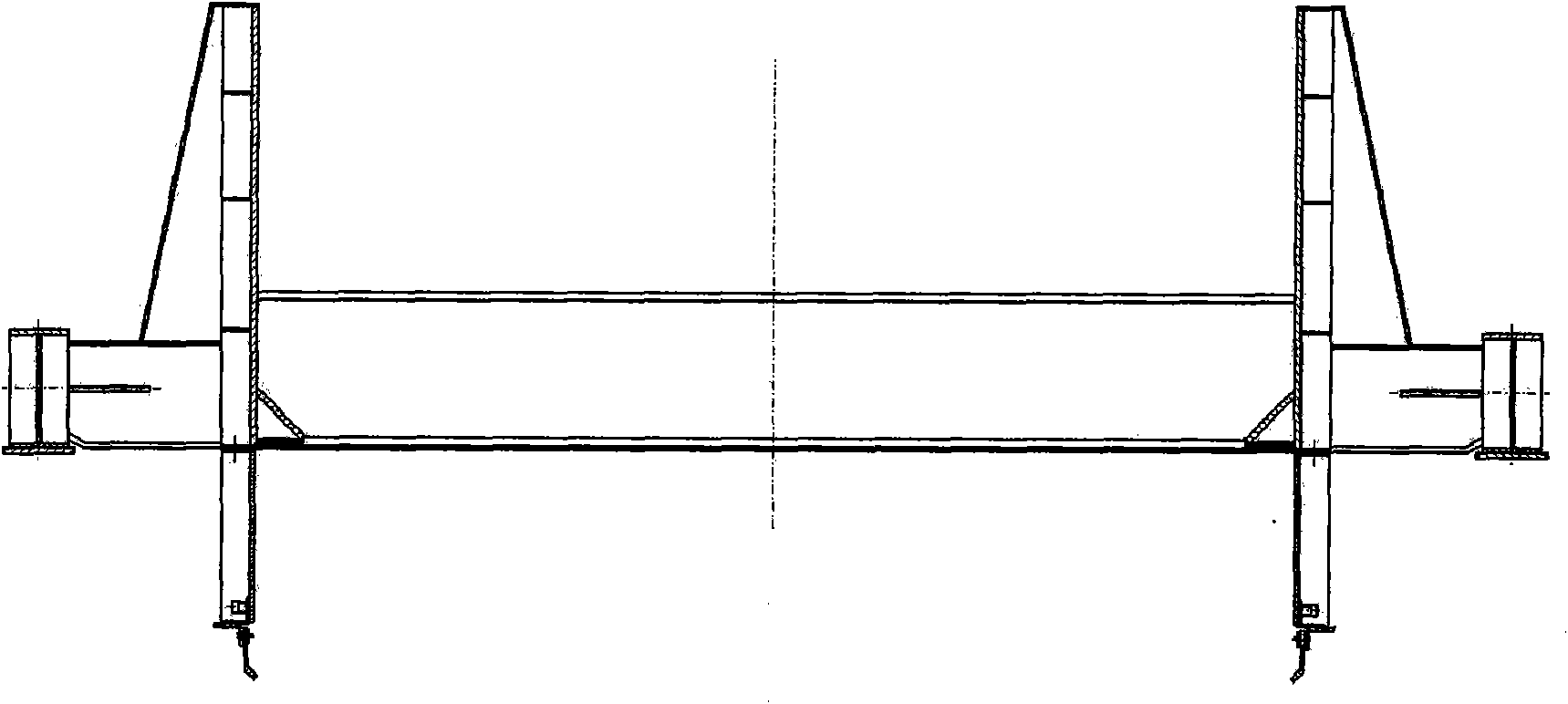

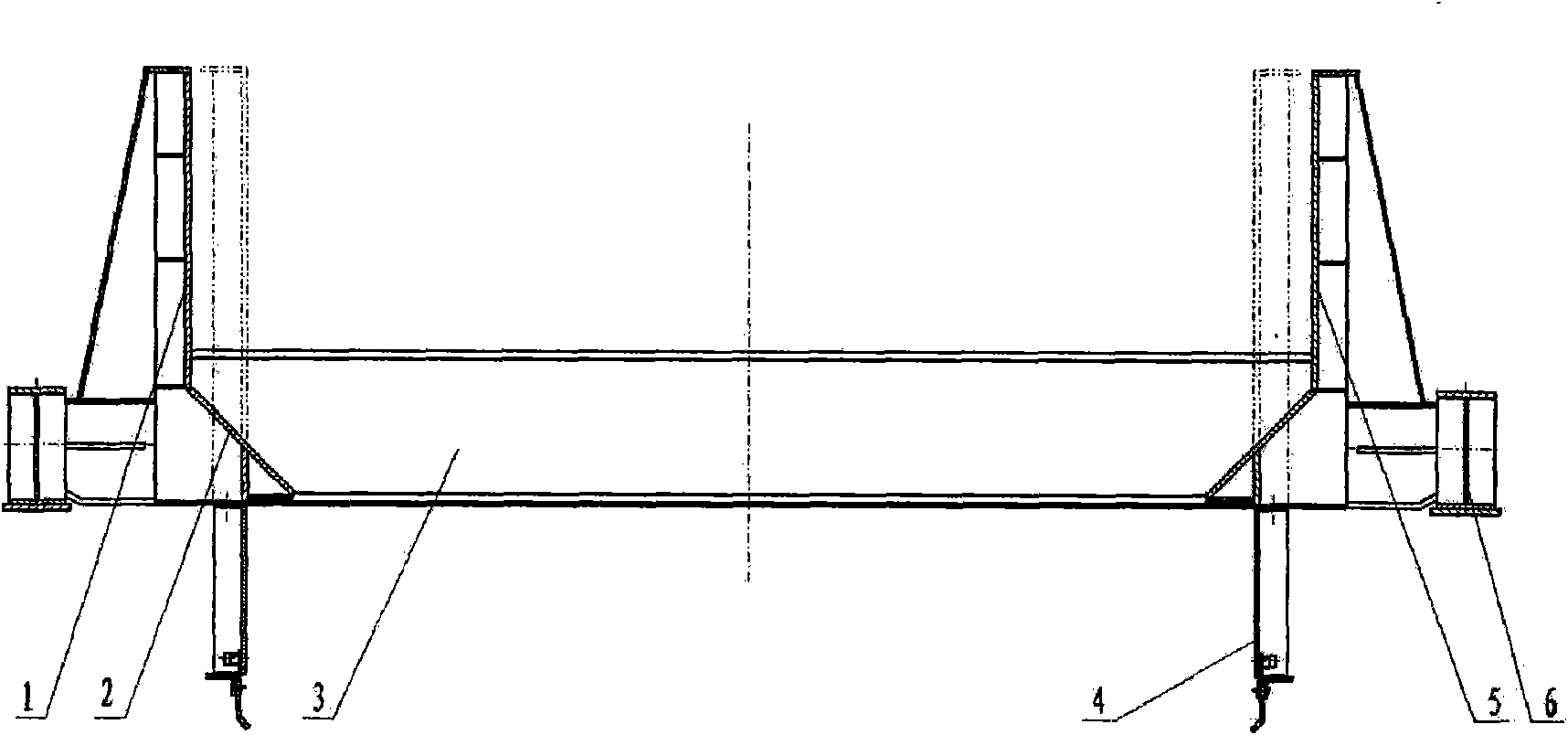

A method for widening trolley sideboard of sintering ring cooler

ActiveCN101551196AThe overall structure is simple and reliableNo increase in manufacturing difficultyFurnace typesButt jointEngineering

The invention is a method for widening trolley sideboard of sintering ring cooling machine belonging to the field of sintering equipment technology. It needs to keep the wind box, rack, rotating frame and trolley main body of the ring cooler constant. It first uses the trolley triangular beam as the base, adds the outward trolley sloping plate at an angle of 30 DEG-60 DEG to the horizontal plane at the intersection of the triangular beam and the wind box below the trolley, and then moves the trolley sideboard outward according to the ultimately set width of the trolley sideboard. When widening the trolley sideboard, it needs to adjust and process the sideboard, namely make the smooth butt-joint of the trolleys outside sideboard, trolley inside sideboard and trolley sloping plate. It can improve the loading and operating efficiency of the ring cold machine, reduce the material leakage at the edge when conducting cooling ventilation and finally effectively improve the machine-hour output of the ring cooler. It has simple structure and is easy for designing and manufacturing.

Owner:BEIJING SHOUGANG INT ENG TECH

A kind of powder grinding aid, its preparation method and application

ActiveCN109467957BGood dispersionImprove grinding efficiencyPigment physical treatmentSODIUM METAPHOSPHATESodium phosphates

The invention discloses a novel environmentally-friendly powder grinding aid as well as a preparation method and application thereof, and belongs to the technical field of powder grinding. The grinding aid comprises the following raw materials in parts by weight: 40-50 parts of diethanol monoisopropanolamine, 30-40 parts of hexadecanol ester, 10-15 parts of calcium lignosulfonate, 5-10 parts of ethylene glycol, 4-8 parts of hydroxyethyl methylcellulose, 8-12 parts of sodium hexametaphosphate and 2-5 parts of sodium polyacrylate. The calcium lignosulfonate has good dispersibility, so that the grinding efficiency can be improved, the machine-hour output is increased, the electricity consumption is lowered, a synergistic effect of raw material components can be also promoted, and the adaptability of the grinding aid to calcium carbonate is improved. The hexadecanol ester is applied to fusion of polyol and a lignin derivative, and high-adsorption strength dispersing agents, namely the sodium hexametaphosphate and the sodium polyacrylate, are contained, so that a phenomenon of powder agglomeration can be obviously solved, gradation of calcium carbonate particles is improved and the content of micropowder particles is increased.

Owner:濮阳圣恺环保新材料科技股份有限公司

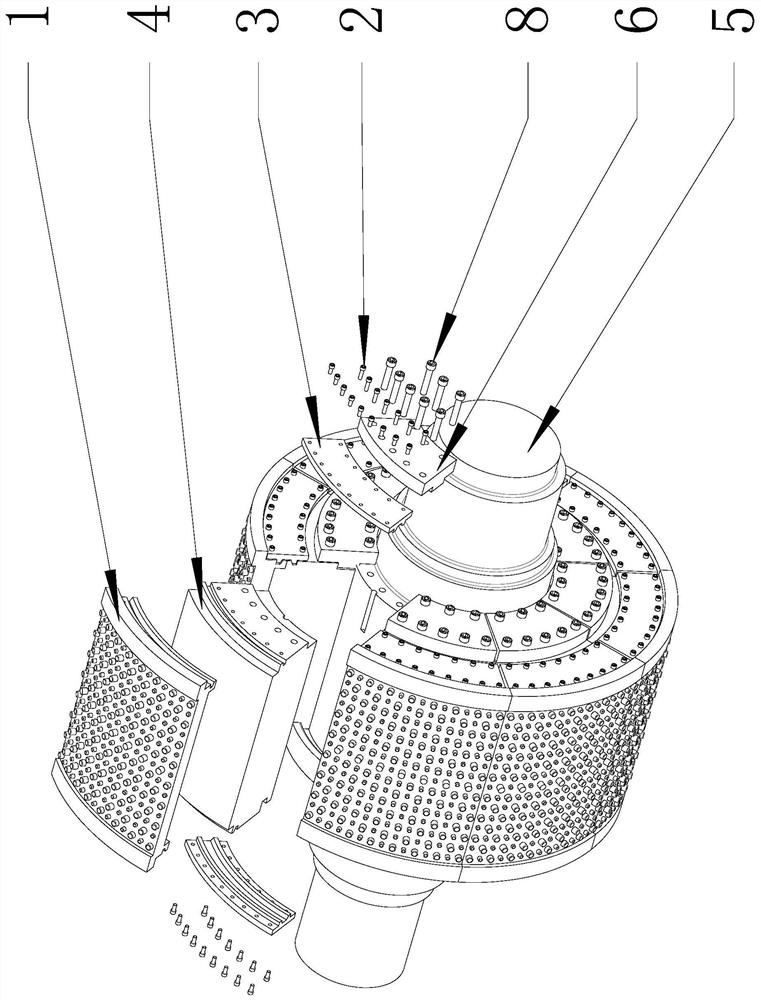

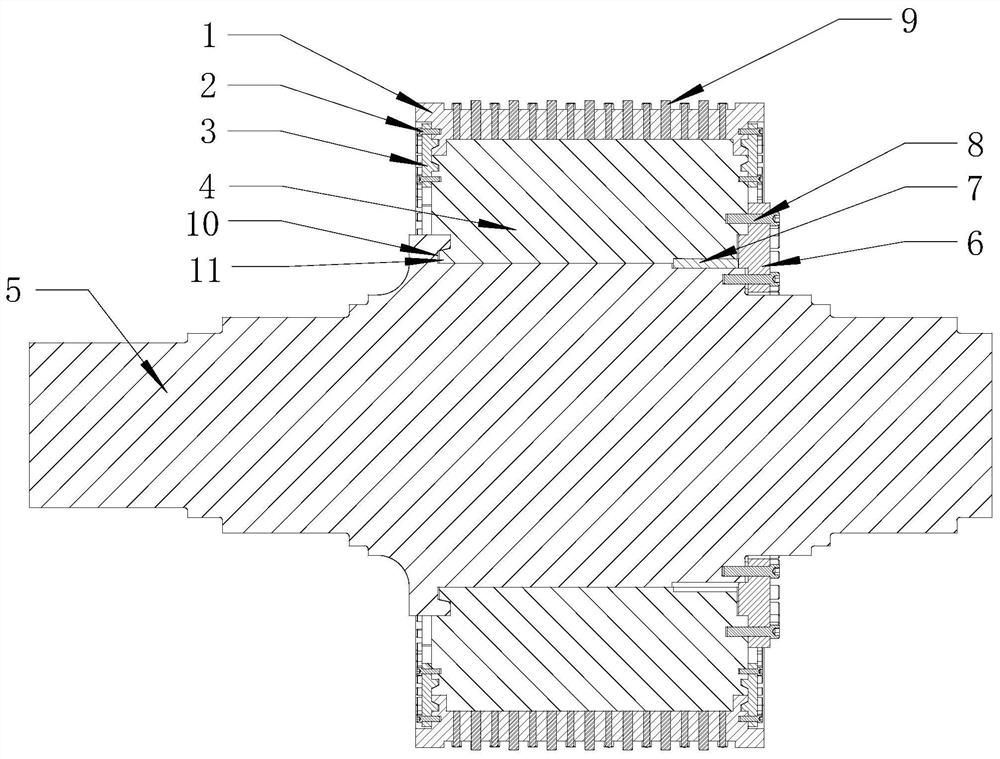

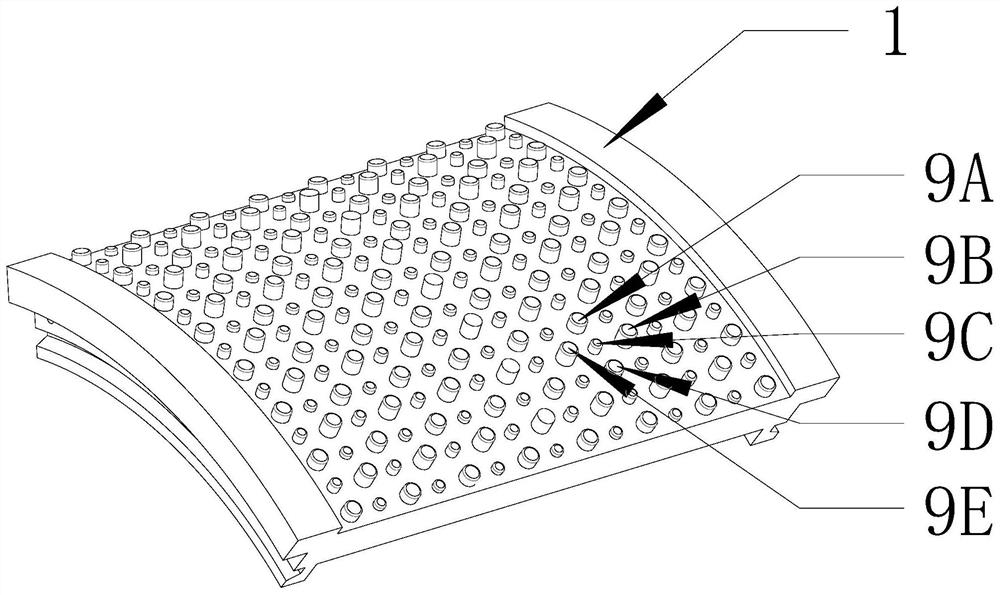

Roller structure of a roller press embedded with cemented carbide studs

ActiveCN111570013BReduce replacement timeReduce maintenance costsGrain treatmentsStructural engineeringAlloy

The invention discloses a roller structure of a rolling machine inlaid with cemented carbide studs, which comprises a main shaft, a roller cover structure and a roll surface structure. structure, which includes a number of roller cover base modules uniformly arranged along the circumference of the main shaft; A plurality of roller surface modules, each of which is evenly inlaid with a plurality of cemented carbide studs. The invention improves the efficiency of on-site maintenance and replacement of worn parts of the roller press, avoids labor, time and economic losses, and reduces the user's use cost. At the same time, the arrangement of the hard alloy studs on the roller surface structure can improve the occlusal effect of materials , reduce the sliding displacement of the material during the roller surface extrusion process, and improve the efficiency of high-pressure crushing. In addition, the invention can also conveniently recycle and separate the base material of the roller sleeve and the cemented carbide stud to reduce pollution.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

A kind of preparation method of modified molasses waste liquid and cement grinding aid

ActiveCN104609765BHighlight substantive featuresSignificant progressLiquid wasteMonoisopropanolamine

The invention provides a preparation method of a modified molasses waste liquid. The preparation method comprises the following steps: A, regulating the PH of the molasses waste liquid to the range of 9-11 by use of a sodium hydroxide solution, and filtering under a normal pressure to obtain a molasses filtrate A; B, adding an acetic acid solution to the molasses filtrate A until the PH is within the range of 2-3, thereby obtaining a molasses waste liquid B; C, thoroughly oxidizing the molasses waste liquid B by using 35% hydrogen peroxide, potassium permanganate or ozone, thereby obtaining a molasses waste liquid C; D, regulating the PH of the molasses waste liquid C to the range of 9-11 by use of the sodium hydroxide solution, thereby obtaining the modified molasses waste liquid. The invention also provides a cement grinding aid which is prepared by mixing the following raw materials in parts by weight with water: 2-5 parts of triethanolamine, 18-25 parts of diethanol monoisopropanolamine, 3-5 parts of industrial salt and 20-30 parts of modified molasses waste liquid. The modified molasses waste liquid has the characteristics of low production cost, and good grinding assisting and hydration assisting effects on the cement.

Owner:华润水泥技术研发(广西)有限公司

Granular neutral cement grinding aid and its prepn process

The present invention discloses one kind of granular neutral cement grinding aid and its preparation process. The grinding aid is produced with anhydrous sodium sulfate 40-50 wt%, gypsum dehydrate 10-20 wt%, elite calx 25-45 wt% and triehtanolamine 1-5 wt%. The grinding aid can activate the effective components in cement to raise the strength of cement, save cement clinker and reduce pollutant gas exhaust. The granular grinding aid has less stickness to bin.

Owner:魏文龙

Magnetized cement grinding aid mother liquor for building

The invention relates to the field of building processing aids, and discloses magnetized cement grinding aid mother liquor for building. The mother liquor comprises polyol, calcium lignosulfonate, anacidic solvent, alkaline lignin, hydroxyethyl methyl group cellulose ether, hydroxyethyl acrylate, magnetized water and auxiliary materials, the polyol, the calcium lignosulfonate and the acidic solvent are fixed in a reaction kettle, the alkaline lignin is added to the reaction kettle to adjust the pH of the mixture, the hydroxyethyl methyl cellulose ether and hydroxyethyl acrylate are added to the reaction kettle, standing is conducted, finally, a mixture after standing is introduced into a stirring tank from the reaction kettle, the magnetized water and the auxiliary materials are added forstirring, and the liquor is obtained after stirring is completed. The liquor solves the problems that the stability of a final product is poor in the preparation of existing cement grinding aids, andthe cement setting time and the compressive strength in the introduced cement are not ideal.

Owner:CHENGDU RONGDE CONSTR LABOR

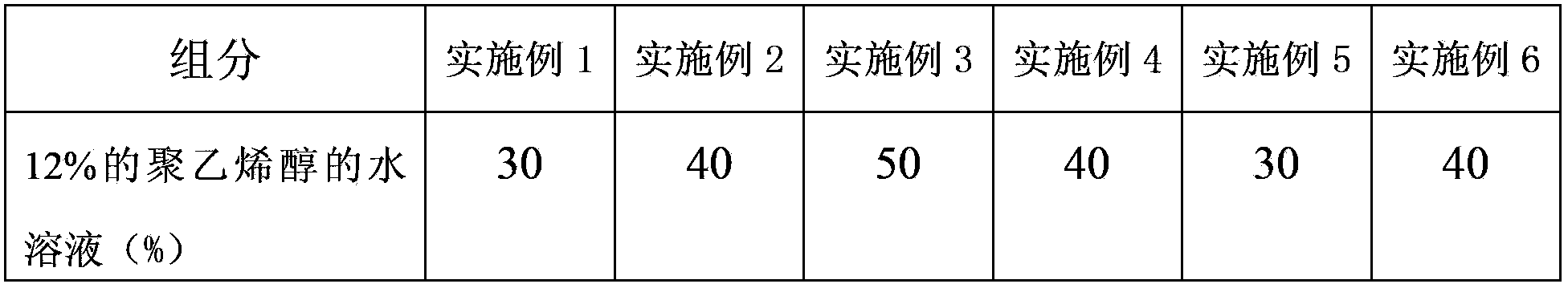

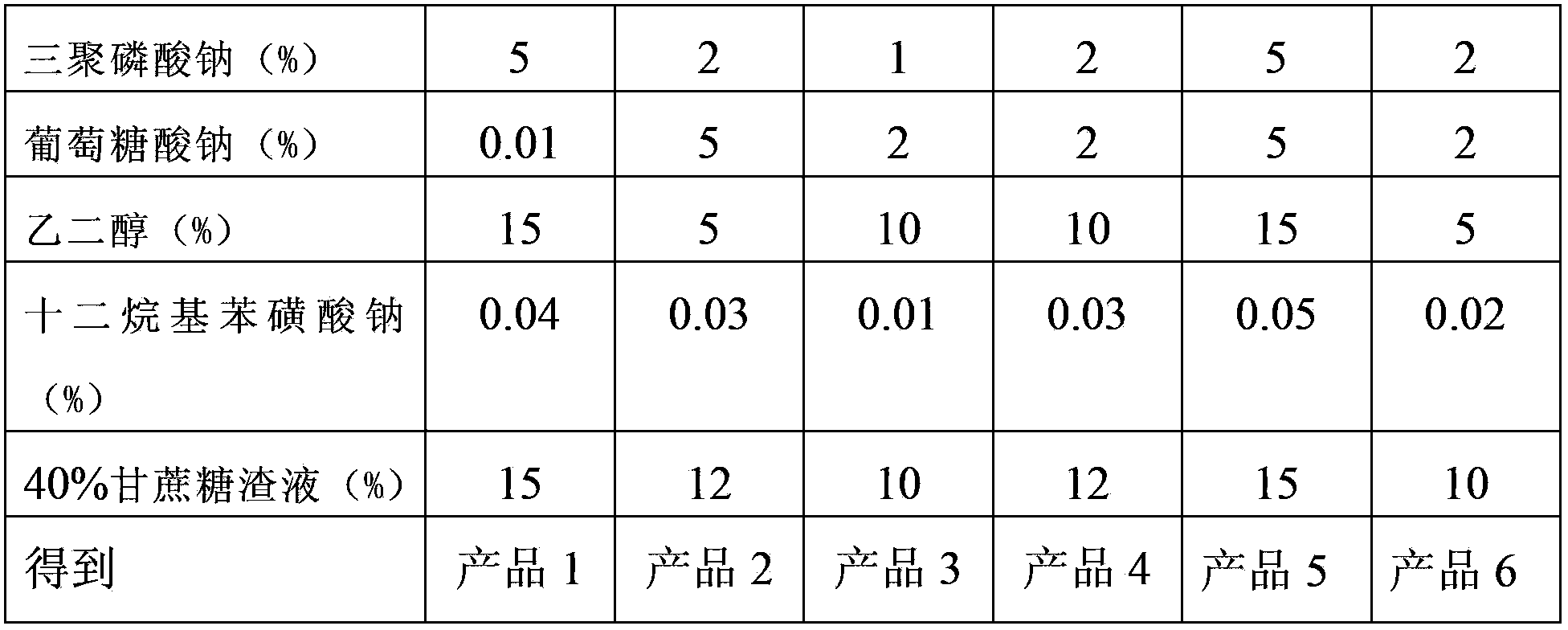

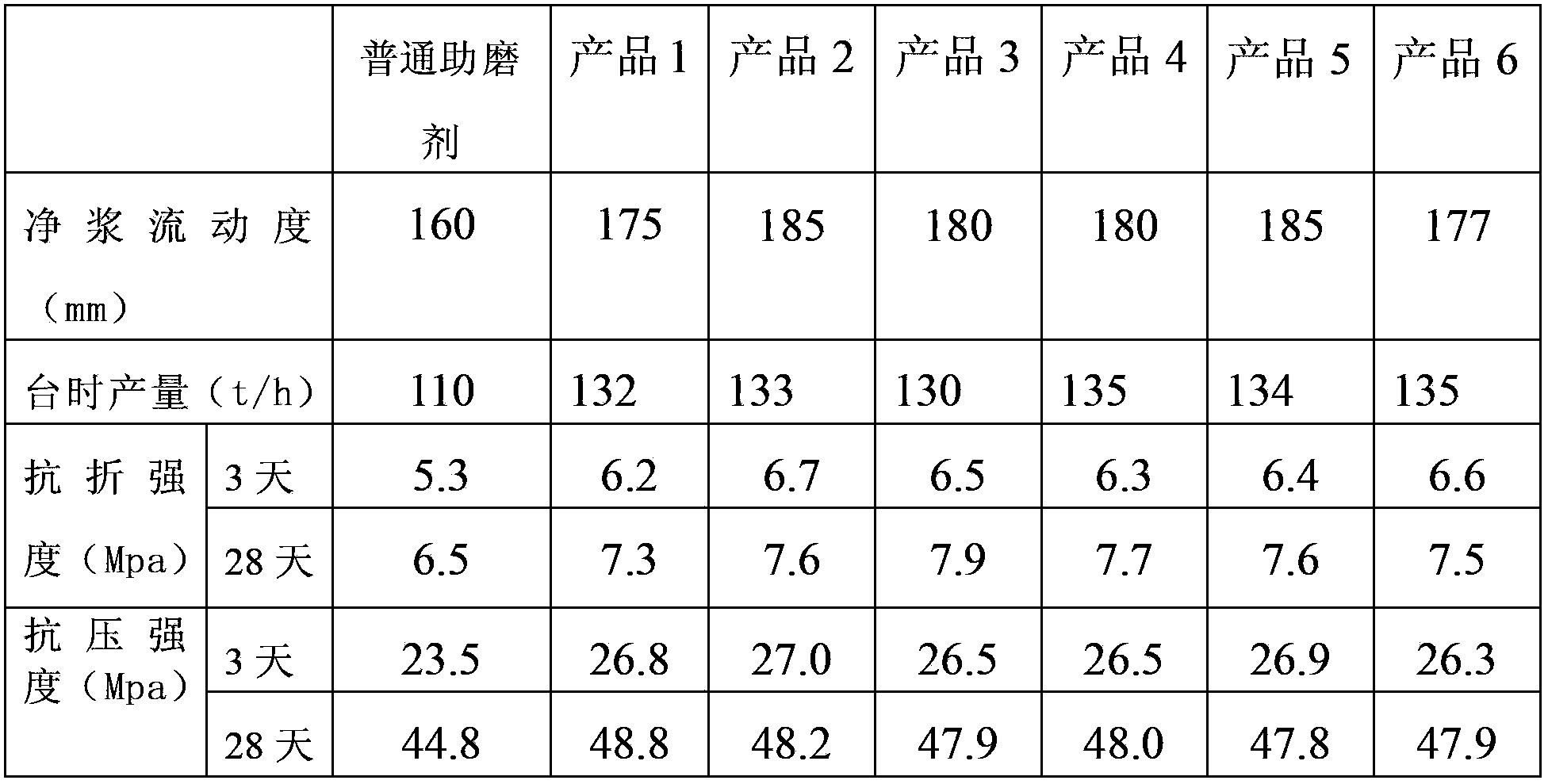

High grinding temperature compound liquid grinding aid and preparation method thereof

ActiveCN102863176BAddress usability issuesAddressing Adaptive IssuesPolyvinyl alcoholCement grinding

Owner:NANJING YONGNENG MATERIALS

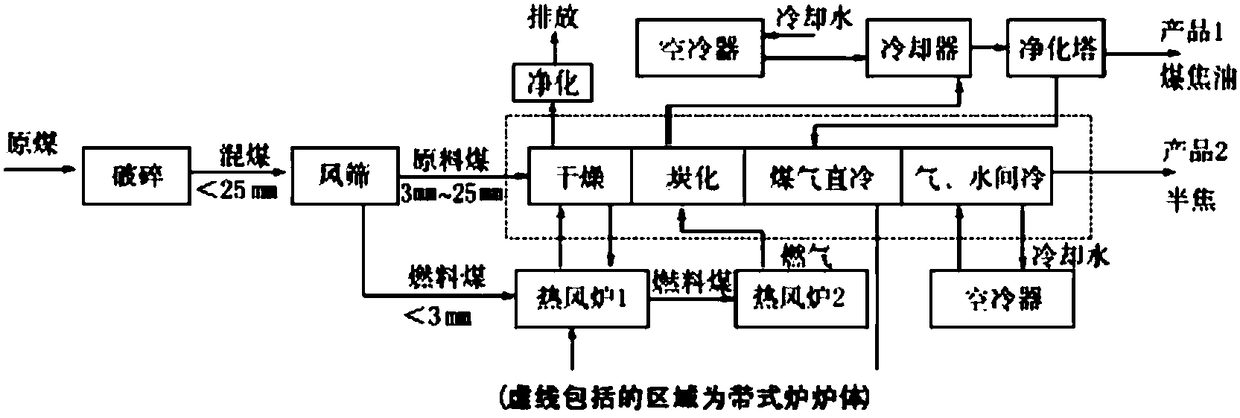

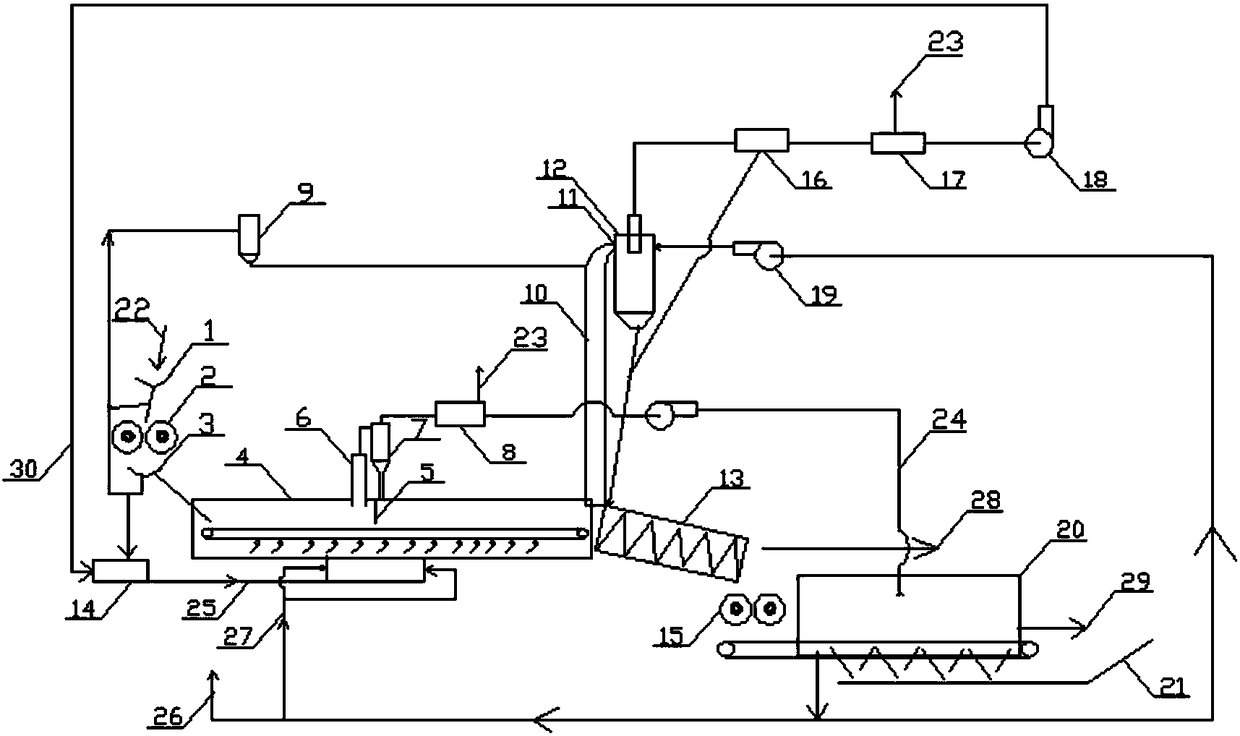

A method for cascade upgrading of lignite

InactiveCN106016971BImprove resource utilizationImprove throughput per hourDrying solid materials with heatGranular material dryingCombustionResource utilization

The invention relates to a gradient upgrading method for lignite. The gradient upgrading method for the lignite comprises the following steps that (1) the lignite is crushed; (2) equipment improvement is carried out, specifically, upgrading equipment is divided into a drying area and an upgrading area through a partition plate, the deformed material section is reshaped to be rectangular as before through the partition plate, and the flue gas heating efficiency is improved; (3) vapor condensation is carried out, specifically, vapor generated in the drying process is collected and condensed independently, the condensation amount is controlled, and 70% (by volume) of vapor in air is made to be standby; and (4) lignite upgrading is carried out, specifically, pyrolysis gas generated in the upgrading area enters a lifting flue of a cyclone barrel, fine powder of a fine coal bin is leaked from the upper end of the flue, the flowing speed of flue gas in the lifting flue is controlled to be 0.5-1.3 Nm<3> / s, and through downward flowing of the fine powder, heat in the flue gas is recycled and coal tar is adsorbed; the fine powder is dried, and the temperature of the fine powder is increased to 150-250 DEG C; upgraded lignite semicoke is obtained by upgrading the lignite in the upgrading area; and the pyrolysis gas is delivered back to a hot blast heater to support combustion. According to the method, the gradient utilization of the lignite is achieved, and the lignite resource utilization rate is high; and a cooling area is reduced, the drying area and the upgrading area are expanded, and the hour output of the equipment is improved.

Owner:INNER MONGOLIA UNIV OF TECH

Grinding aid for preparing cementitious materials for mine filling and dry heaping

The invention discloses a grinding aid for preparing a cementing material for filling and dry stacking of mines. The grinding aid comprises the following raw material components in percentage by mass: 20%-30% of modified polymeric glycol, 5%-15% of diethanolisopropanolamine, 10%-20% of molasses, 5%-10% of sodium sulfocyanate, 5%-10% of sodium metaaluminate, 5%-10% of sodium fluosilicate and the balance of water. According to the grinding aid provided by the invention, the problems that a mixed material of water granulated slag, quick lime, water glass and the like is liable to cause ball pasting and is difficult to be finely ground in a grinding process are solved, the fluidity of the cementing material can be remarkably improved, the grinding efficiency of a ball mill can be improved, the machine-hour yield of the ball mill can be increased, the early strength of the cementing material can be remarkably improved, and the long-term strength of the cementing material can be properly improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

A kind of cement grinding aid and preparation method thereof

The invention relates to a cement grinding aid, in particular to a cement grinding aid and a preparation method thereof, which is made of the following raw materials in parts by weight: 13-18 parts of polymerized polyol; 8-12 parts of triisopropanolamine 12-15 parts of polyol ether; 15-20 parts of ethylene glycol; 25-30 parts of triethanolamine; 15-18 parts of molasses; 13-15 parts of lignin; 0.03-0.06 parts of sodium chloride; ‑1 part; 40-45 parts of water. The cement grinding aid prepared by the present invention can effectively improve the clinker fine particle agglomeration and paste ball phenomenon in cement production, enhance the fluidity of clinker particles, so that the grinding medium in the mill can crush the material Strengthening, improving grinding efficiency, using the cement grinding aid of the present invention can improve the grinding efficiency of 15-20%, improve the output of cement table, greatly reduce power consumption, reduce production costs, and can significantly improve the age of cement. period strength and improve its liquidity.

Owner:内蒙古同佳技术发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com