High grinding temperature compound liquid grinding aid and preparation method thereof

A compound type and grinding aid technology is applied in the field of high grinding temperature compound type liquid grinding aid and its preparation. The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0010] Example 1: A high grinding temperature composite liquid grinding aid, the composition is as follows:

[0011] 30-50% aqueous solution of 12% polyvinyl alcohol

[0012] Sodium tripolyphosphate 1-5%

[0013] Sodium gluconate 0.01-5%

[0014] Ethylene glycol 5-15%

[0015] Sodium dodecylbenzenesulfonate 0.01-0.05%

[0016] 40% sugarcane sugar residue liquid 10-15%

[0017] The preparation method of the high grinding temperature composite liquid grinding aid, the steps are: inject water at about 20°C into the reaction kettle, slowly add polyvinyl alcohol into it while stirring, fully swell and disperse; then raise the temperature of the water Accelerate to about 95°C until completely dissolved to obtain a 12% aqueous solution of polyvinyl alcohol, add sodium tripolyphosphate and sodium gluconate and stir for 15 minutes, then add ethylene glycol, sodium dodecylbenzenesulfonate, 40% The sugarcane dregs liquid was stirred for 10 minutes, and then filtered through 150-mesh...

Embodiment 2 to Embodiment 6

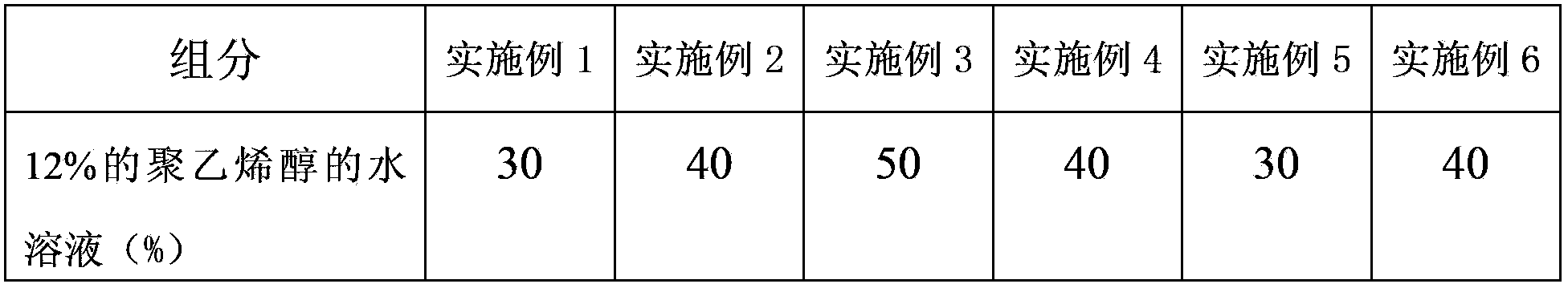

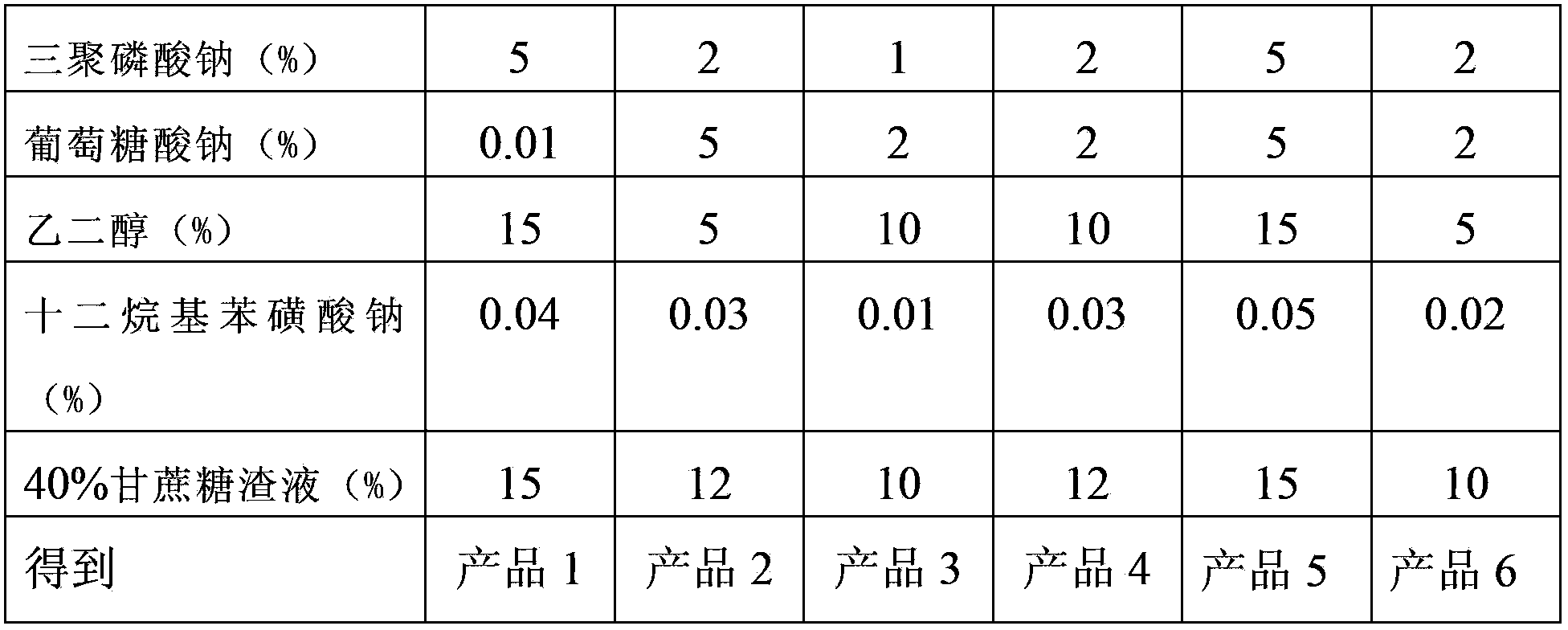

[0019] Repeat the method of Experimental Example 1 according to the content of each component specified in the following table 1, and obtain the high grinding temperature composite liquid grinding aid product of different component content respectively:

[0020] Table 1

[0021]

[0022]

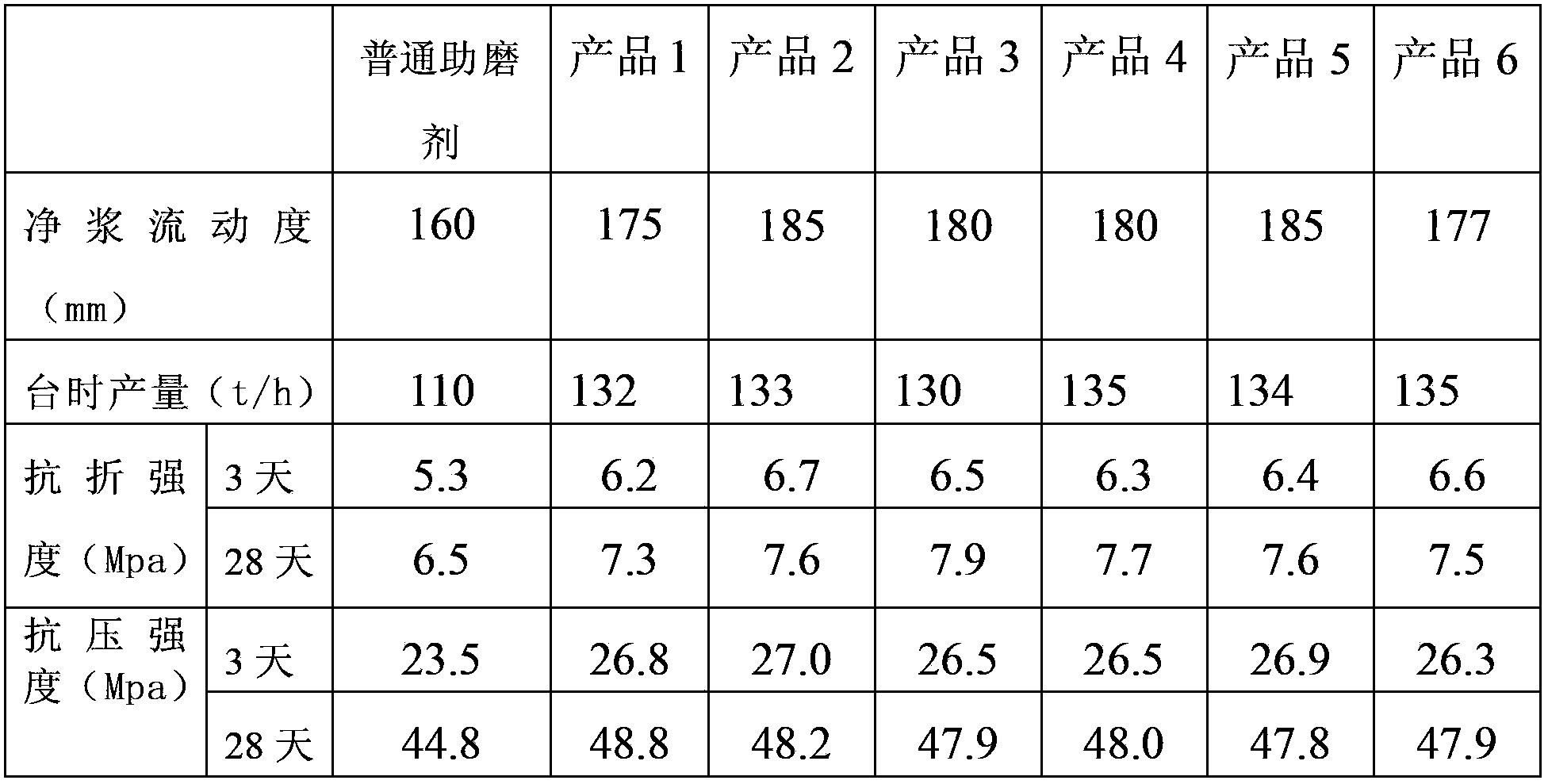

[0023] The high-grinding temperature composite liquid grinding aid products obtained in Examples 1 to 6 were subjected to high-grinding under the condition that the admixture amount was 0.03% of the cement mass, and the average temperature of the cement mill was 140°C. The comparison experiment of warm compound liquid grinding aid and common grinding aid, the experimental results are shown in Table 2:

[0024] Table 2

[0025]

[0026] It can be seen that the high grinding temperature composite liquid grinding aid provided and prepared by the present invention will not cause ball sticking compared with ordinary grinding aids at a high temperature of 140°C, and improves the grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com