Forecasting method of inner and outer wall temperature difference of 9% Cr martensitic steel thick wall pipeline in heat treatment

A martensitic steel and prediction method technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control and other directions, can solve the problems of lack of general applicability, increased cost, waste of time and energy in the temperature difference between inner and outer walls, etc., to ensure the quality of heat treatment. , Solve the waste of time, optimize the effect of heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

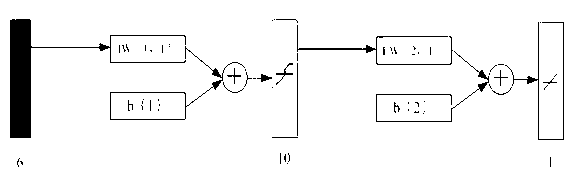

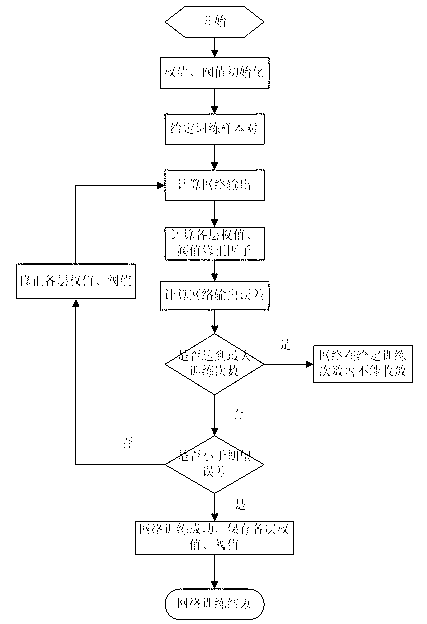

Method used

Image

Examples

Embodiment

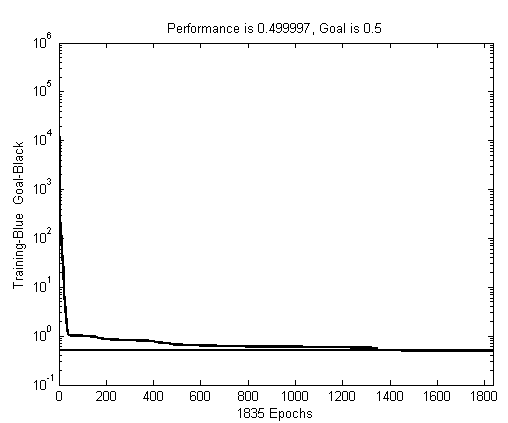

[0070] The BP neural network prediction method involved in the present invention is compared with the measured temperature difference data of the inner and outer walls of the pipeline.

[0071] Analyze and record the dimensions (inner diameter and wall thickness) of 9%Cr martensitic heat-resistant steel pipes of three specifications shown in Table 1, the width of the heating zone, the width of the insulation zone, the ambient temperature and the temperature control temperature, and the influence factors of each The value is input into the prediction model for calculation, and the temperature difference between the inner and outer walls of the 9%Cr martensitic heat-resistant steel pipe after welding heat treatment under this condition can be quickly calculated. In addition, the temperature difference between the inner and outer walls of the pipeline post-weld heat treatment is measured through experiments to verify the accuracy of the prediction model. In this example, the pred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com