Workpiece temperature field determination method and heat treatment parameter determination method

A determination method and technology of temperature field, applied in the field of determination of workpiece temperature field, can solve problems such as energy consumption, waste of process time, long holding time, poor performance of workpiece, etc., to ensure heat treatment quality, reduce energy consumption, and improve process efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

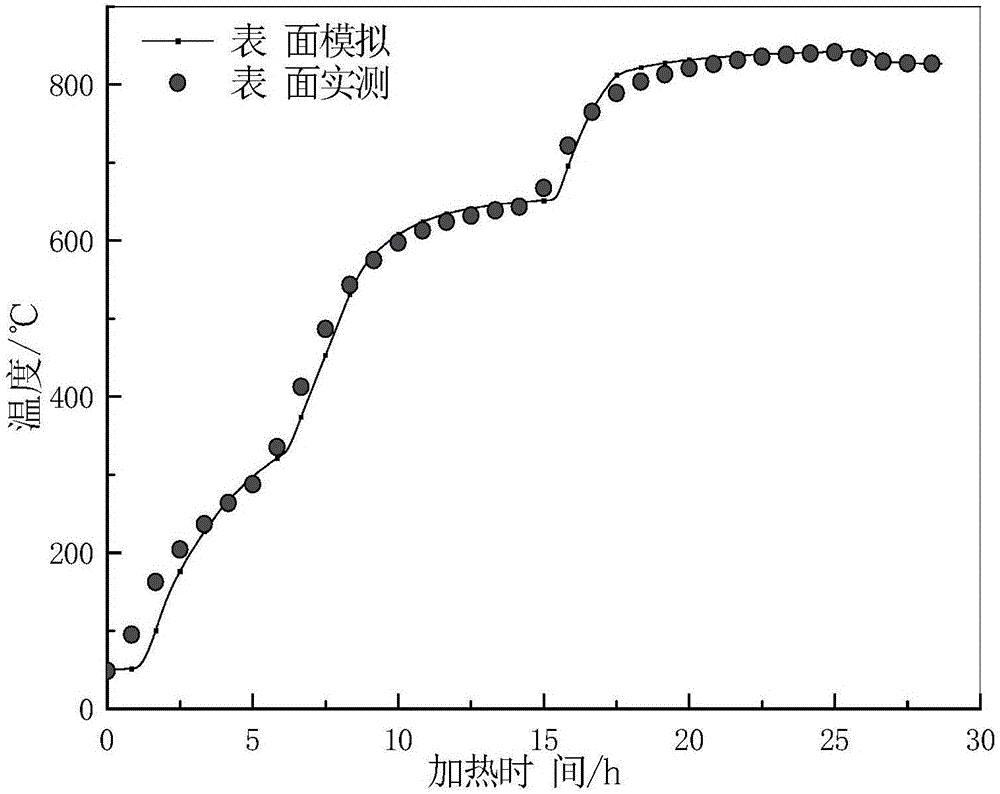

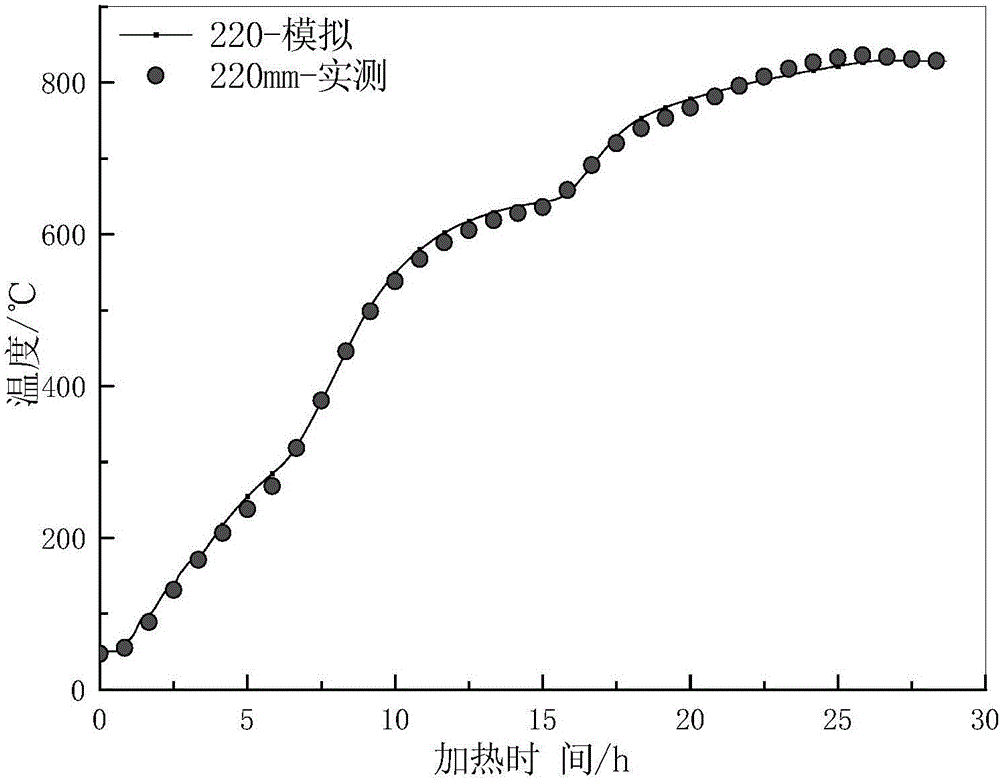

[0025] The method for determining the temperature field of a workpiece comprises the steps of: establishing a three-dimensional model of the workpiece in computer software; importing the model into a finite element analysis simulation software, setting parameters for temperature simulation calculation for the model; and further comprising the following steps in sequence:

[0026] A. The heating temperature curve of the workpiece is T w , the workpiece surface heat transfer coefficient is H;

[0027] According to the fitting formula of air-cooled surface heat transfer coefficient:

[0028] H=2.2×(T w -T c ) 0.25 +4.6×10 -8 ×(T w 2 +T c 2 )×(T w +T c ) formula one;

[0029] In order:

[0030] The first iteration computes:

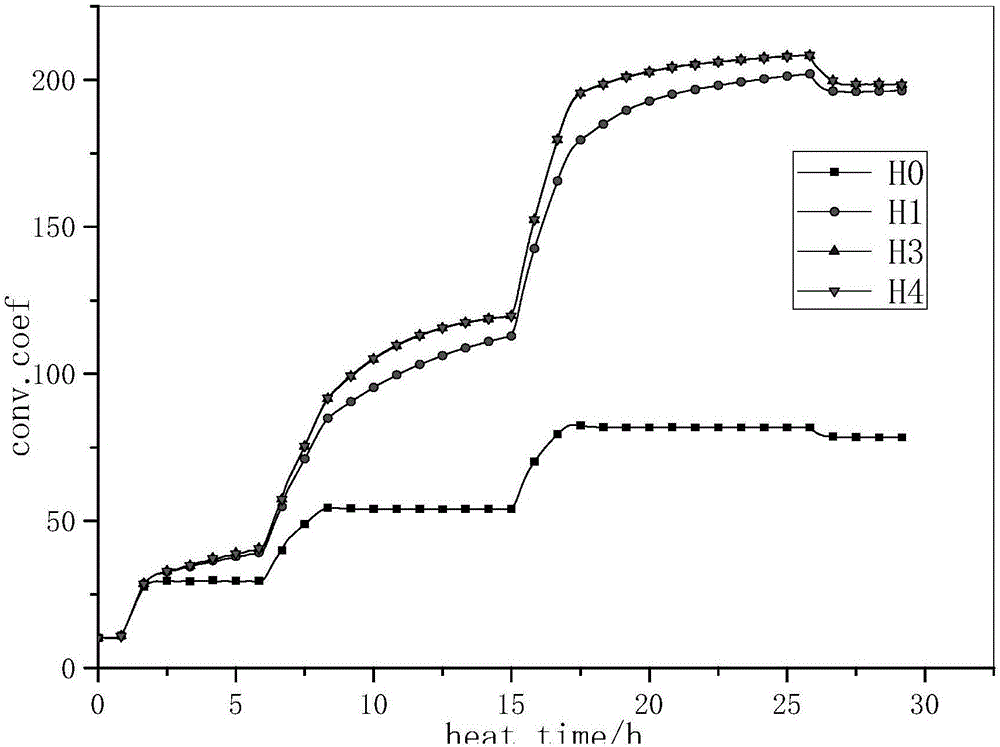

[0031] Let T w =f(t), T c = current room temperature, substituted into formula 1 to calculate the first set of heat transfer coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com